Page 1

MultiLoad II & RCU II

DIVISION 2 (DIV2)

Installation Guide

(Part # 6074)

Page 2

DECEMBER 2018 TOPTECH SYSTEMS

Disclaimer

Toptech Systems assumes no responsibility for damages resulting from installation or use of its products. Toptech Systems will not be liable for any

claims of damage, lost data, or lost time as a result of using its products.

MultiLoad II & RCUII – Division 2 (DIV2)

Installation Guide

1124 Florida Central Parkway

Longwood, FL 32750

USA

Phone +1 (407).332.1774

Copyright Notice

Copyright © 2006 - 2018 Toptech Systems, Inc. All Rights Reserved.

The information contained in this document is proprietary and confidential. No part of this document may be copied, reproduced, or

transmitted in any medium without the express written permission of Toptech Systems, Inc.

MultiLoad II/ RCU II DIV-2 Installation Guide: 20181218 - Part # 6074

Page 3

EU Declaration of Conformity

Notified Body(ies)

NMi Certin B.V., Number 0122

Hugo de Grootplein 1

3314 EG Dordrecht

The Netherlands

The signatory, representing the manufacturer, declares that the products listed below are in conformity with the essential requirements of the

following EC Directive(s) when installed in accordance with the product installation instructions:

2014/32/EU The Measuring Instruments Directive (and its amending directives)

2014/30/EU The Electromagnetic Compatibility Directive (and its amending directives)

2014/34/EU The Potentially Explosive Atmospheres Directive (and its amending directives)

Product: Operator Interface/Process Control Equipment intended for use in potentially explosive atmospheres

Model name/number: MultiLoad II DIV2 (MID, YES), RCU II DIV2 (MID, NO)

Protective Systems: Nonincendive ‘ec ic’

Conformity has been demonstrated with reference to the following documentation:

(ATEX) EC test report for Project 06NK12831, Dated 2007-01-31

(MID) EC type-examination certificate TC7311

Compliance with the Essential Health and Safety Requirements has been assessed by reference to the following standards:

WELMEC guide 8.8 General and Administrative Aspects of the Voluntary System of Modular Evaluation of Measuring

Instruments under MID

OIML R117-1:2007(E) Dynamic measuring systems for liquids other than water

EN 61000-6-4: 2007 Generic emissions for industrial operating environments

EN 61000-6-2: 2005 Generic immunity for industrial operating environments

EN 60079-0: 2012 Explosive atmospheres Part 0: Equipment—General requirements

EN60079-7:2015 Explosive atmospheres – Part 7: Equipment protection by increased safety «e»

EN-60079-11: 2012 Explosive atmospheres Part 11: Equipment protection by intrinsic safety "i"

Year of CE Marking: 2007

Name: William J. Porthouse Position: Director of Engineering & Production Date: 20-December-2018

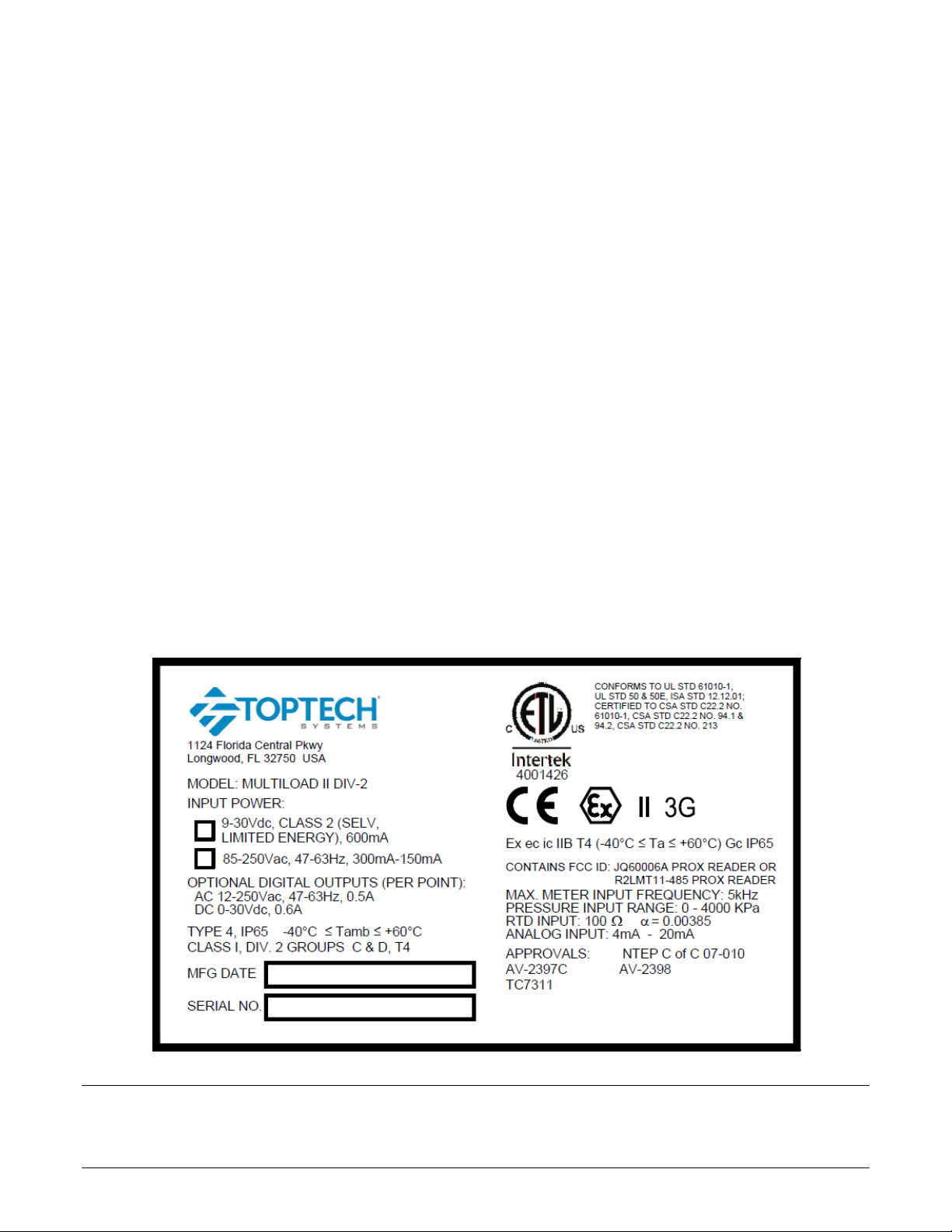

Name Plate

Page 4

Table of Contents

Overview ........................................................................................................................... 1

Chapter 1 General information & Warnings ............................................................ 3

Receiving and/or Returning Equipment ............................................................. 3 1.1

Safety Warnings ................................................................................................ 4 1.2

Electrostatic Discharge (ESD) Protection ................................ ........................... 5 1.3

FCC Note .......................................................................................................... 6 1.4

Chapter 2 Operating conditions and components ................................................... 7

Product Outline and dimensions ........................................................................ 7 2.1

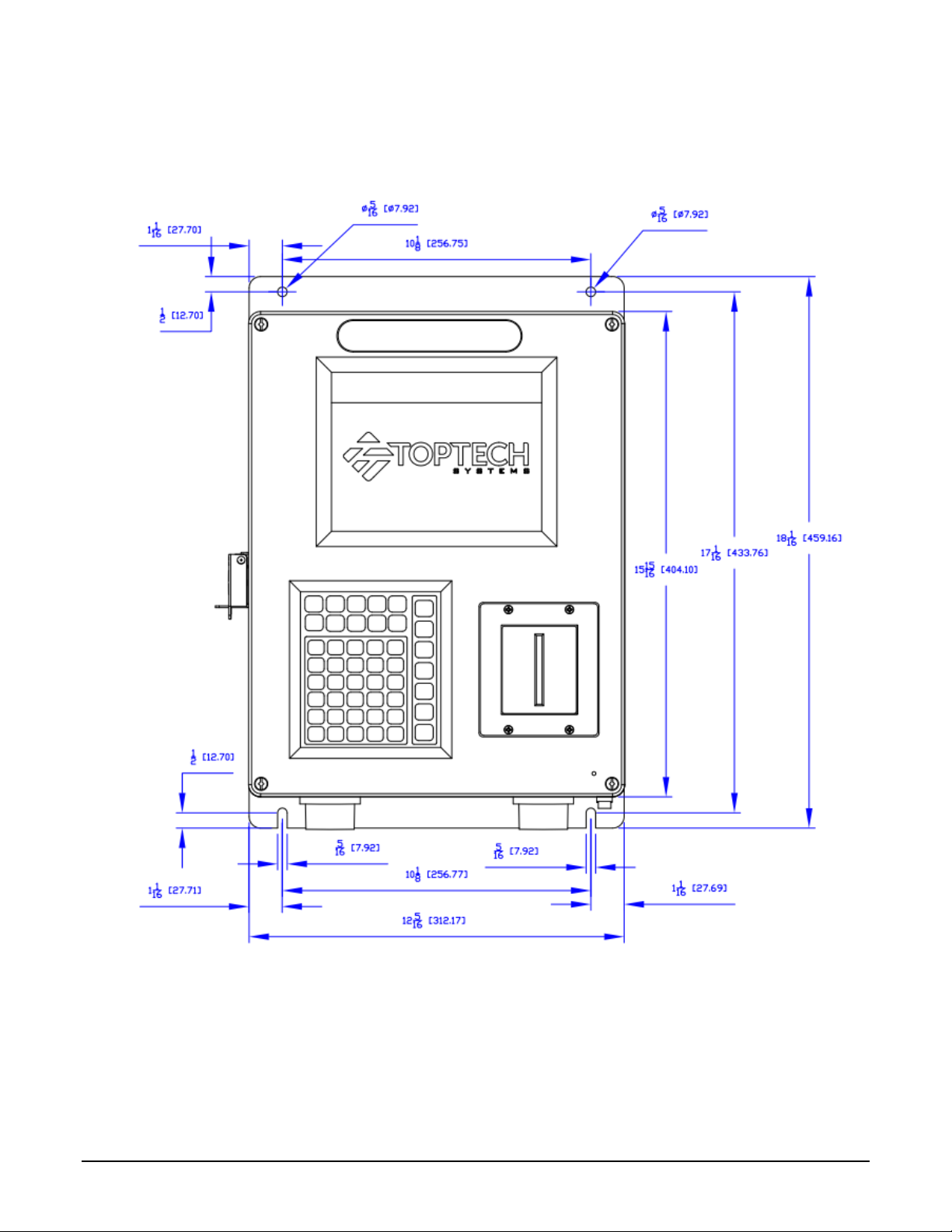

MultiLoadII/ RCUII – DIV2 model - Picture .................................................. 7 2.1.1

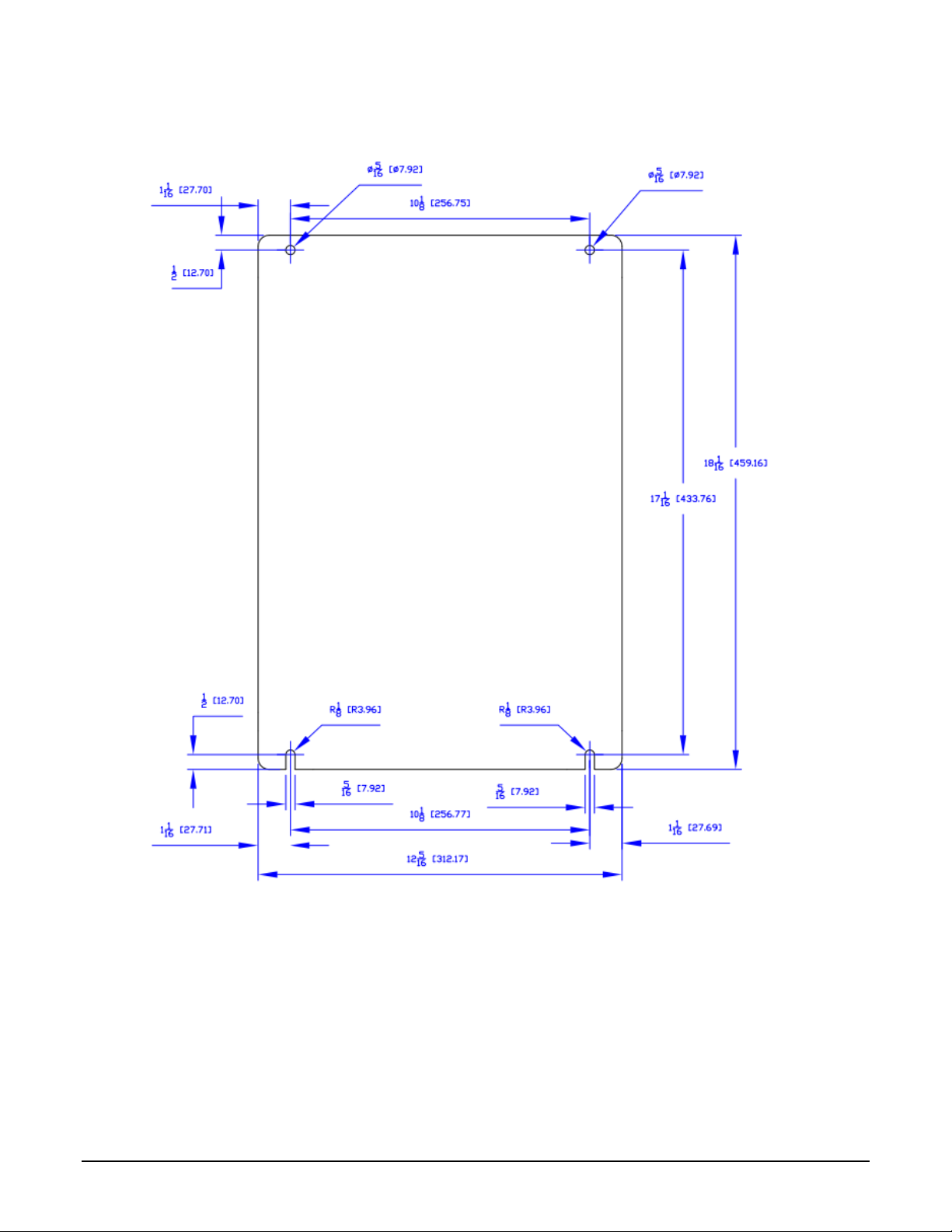

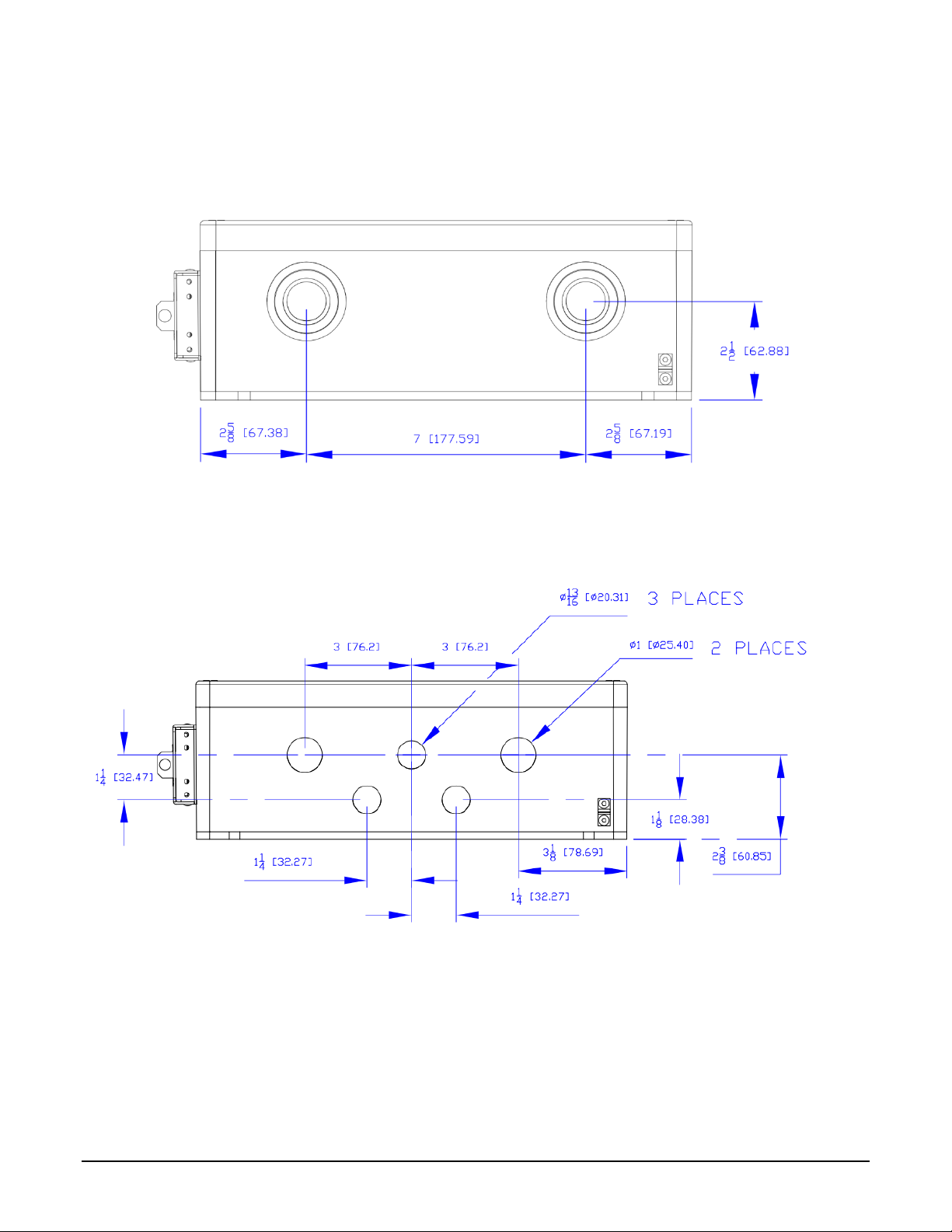

MultiLoadII/ RCUII – DIV2 model – Dimensions .......................................... 8 2.1.2

2.1.2.1 Front View ................................................................................................ 8

2.1.2.2 Back View ................................................................................................ 9

2.1.2.3 Bottom View ........................................................................................... 10

2.1.2.4 Side View ............................................................................................... 11

Operating Characteristics: ............................................................................... 12 2.2

Chapter 3 Installing the MultiLoad II/RCUII DIV2 .................................................. 14

Tools Required ................................................................................................ 14 3.1

Installation ................................................................................................ 14 3.1.1

Servicing and Repair................................................................................. 14 3.1.2

Cover Closure and Bolt Replacement .............................................................. 14 3.2

Cable Entries .................................................................................................. 14 3.3

Mounting the MultiLoad II/ RCU II DIV-2 Enclosure: ........................................ 14 3.4

Drywall ...................................................................................................... 15 3.4.1

Wood ........................................................................................................ 15 3.4.2

Concrete or Cinder Block Walls ................................................................ 15 3.4.3

Mounting Height Considerations ............................................................... 15 3.4.4

Recommended Wire Sizes And Torque For All Terminal Blocks ...................... 17 3.5

Electrical Supply Connections ......................................................................... 17 3.6

AC Powered Models ................................................................................. 18 3.6.1

DC Powered Models ................................................................................. 18 3.6.2

Equipment Grounding ............................................................................... 19 3.6.3

Page 5

Chapter 4 Data Communications Interface ........................................................... 20

Available Communications Protocol Selection and Wire spec .......................... 21 4.1

RS-422/485 .............................................................................................. 21 4.1.1

RS-232 ..................................................................................................... 21 4.1.2

Ethernet .................................................................................................... 22 4.1.3

Communication Connection Wiring .................................................................. 22 4.2

FCM I / FCM II Communications ( MultiLoad II Product Only) - COM 0 –4.2.1

Port – RS485 ....................................................................................................... 22

Host/TMS Communications ...................................................................... 23 4.2.2

4.2.2.1 COM 1 - RS-485 4-wire - Host/TMS Communications ............................ 23

4.2.2.2 COM 1 - RS-485 2-wire : Host/TMS Communications ............................ 24

4.2.2.3 COM 1 - RS-232 - Host/TMS Communications ...................................... 25

4.2.2.4 Ethernet – Host/TMS Communications .................................................. 26

Host Ticket Printer/Data Logger ................................................................ 27 4.2.3

4.2.3.1 COM2 – RS232 - Host Ticket Printer/Data Logger ................................. 27

Chapter 5 Connecting Field devices to the I/O Board .......................................... 30

Where to find the internal I/O board ................................................................. 30 5.1

Available I/O points per board .......................................................................... 31 5.2

Terminal arrangements per board .................................................................... 33 5.3

Digital Analog I/O board (IO_DA) ............................................................. 33 5.3.1

2 Meter I/O board ( IO-2M)........................................................................ 34 5.3.2

How to connect and wire field devices to the I/O boards .................................. 35 5.4

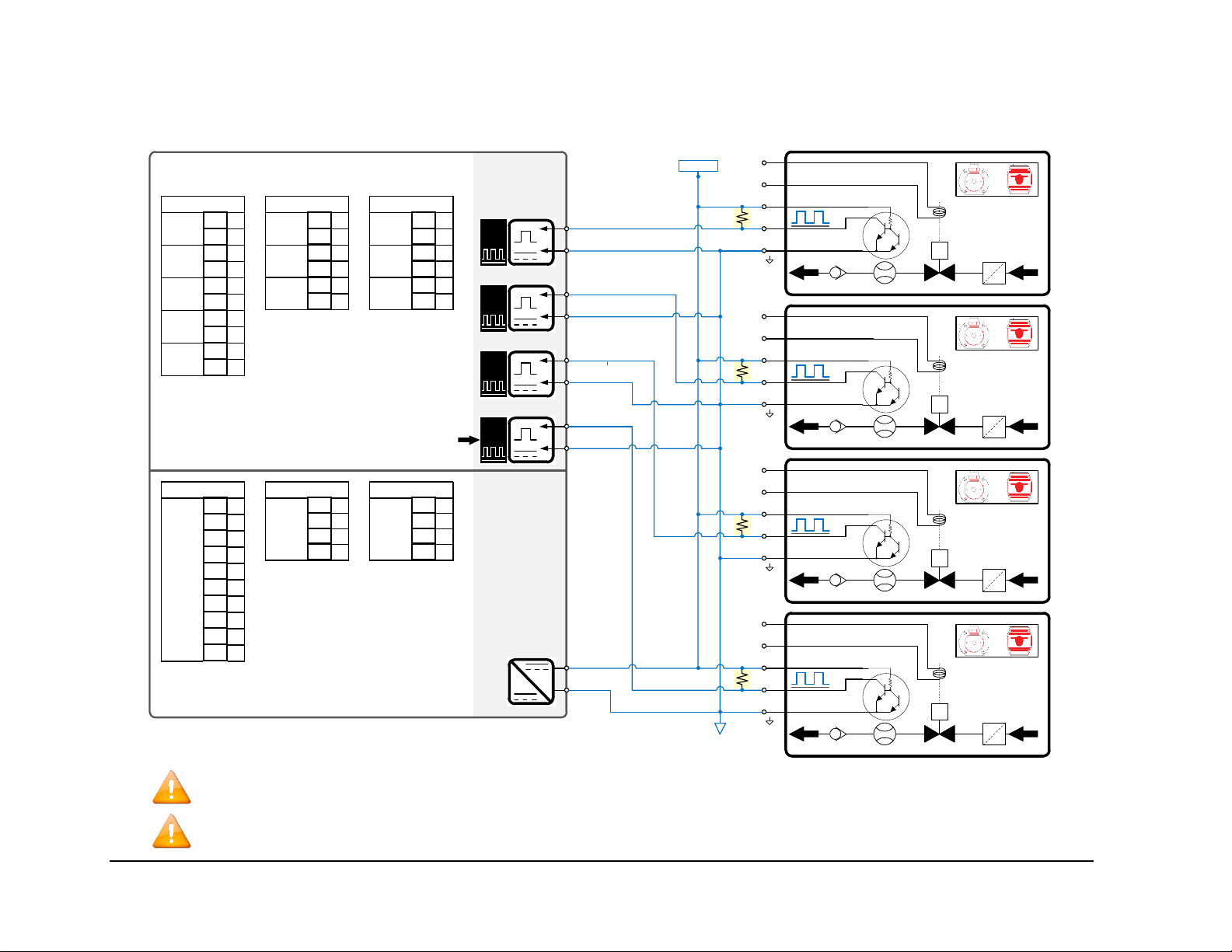

MultiLoad II Flow Meter and Control Valve Wiring ..................................... 36 5.4.1

MultiLoad II Additive Wiring: Outputs ........................................................ 37 5.4.2

MultiLoad II Additive Wiring: Inputs ........................................................... 38 5.4.3

MultiLoad II Analog Wiring ........................................................................ 39 5.4.4

5.4.4.1 RTD Wiring ............................................................................................ 39

5.4.4.2 MultiLoad II 4 – 20 mA Wiring ............................................................... 40

MultiLoad II AC Output Wiring ................................................................... 41 5.4.5

MultiLoad II AC Input Wiring ..................................................................... 42 5.4.6

MultiLoad II DC Permissive/Status Wiring ................................................. 43 5.4.7

MultiLoad II DC Output Wiring .................................................................. 44 5.4.8

MultiLoad II 2 Output Air Eliminator Wiring ................................................ 45 5.4.9

MultiLoad II Lectro Count Remote Display Wiring ................................... 46 5.4.10

RCU II DC Input Wiring ........................................................................... 47 5.4.11

RCU II AC Output Wiring ........................................................................ 48 5.4.12

Page 6

RCU II DC Output Wiring ........................................................................ 49 5.4.13

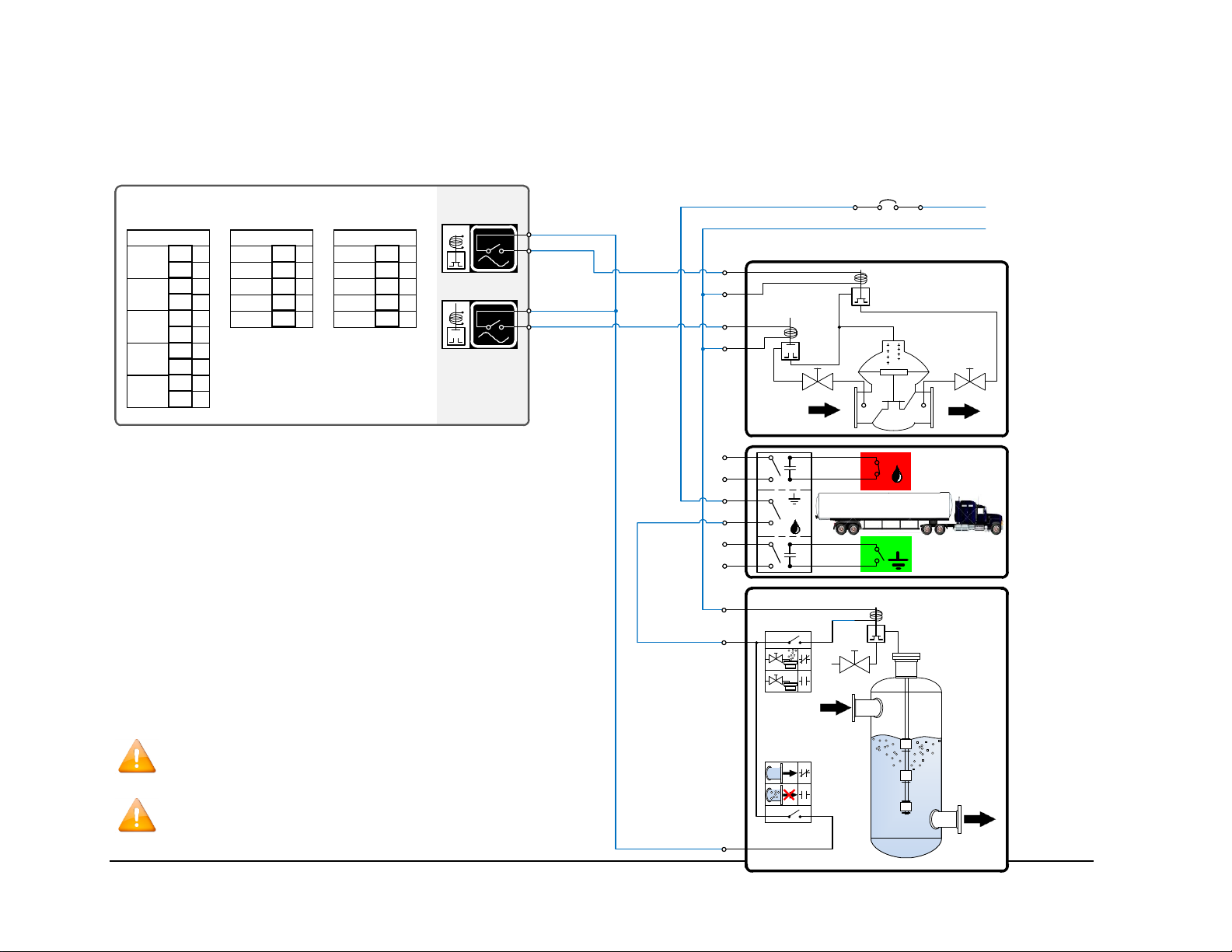

Typical 1 meter application wiring example IP&E Drawing (electrical wiring 5.4.14

schedule) ............................................................................................................. 50

Chapter 6 Configurations ..................................................................................... 51

Switch Access Control ..................................................................................... 51 6.1

External Switch Access Control (MultiLoad II Only) .................................. 51 6.1.1

External Type 1 Program / W&M switches ................................................ 52 6.1.2

External Type 2 Program / W&M switches ................................................ 52 6.1.3

External Type 3 Program / W&M switches ................................................ 54 6.1.4

Internal Switch Access Control ................................................................. 54 6.1.5

MultiLoad II/ RCU II DIV-2 Keypad .................................................................. 56 6.2

Menus and Screens ......................................................................................... 57 6.3

Field Modification and Data Entry .................................................................... 58 6.4

MultiLoad II/ RCU II Preliminary Configuration ................................................. 59 6.5

Verify Communications Between MultiLoad II/ RCU II And I/O Board .............. 62 6.6

Using I/O Diagnostics ...................................................................................... 63 6.7

Chapter 7 Service and Repair .............................................................................. 65

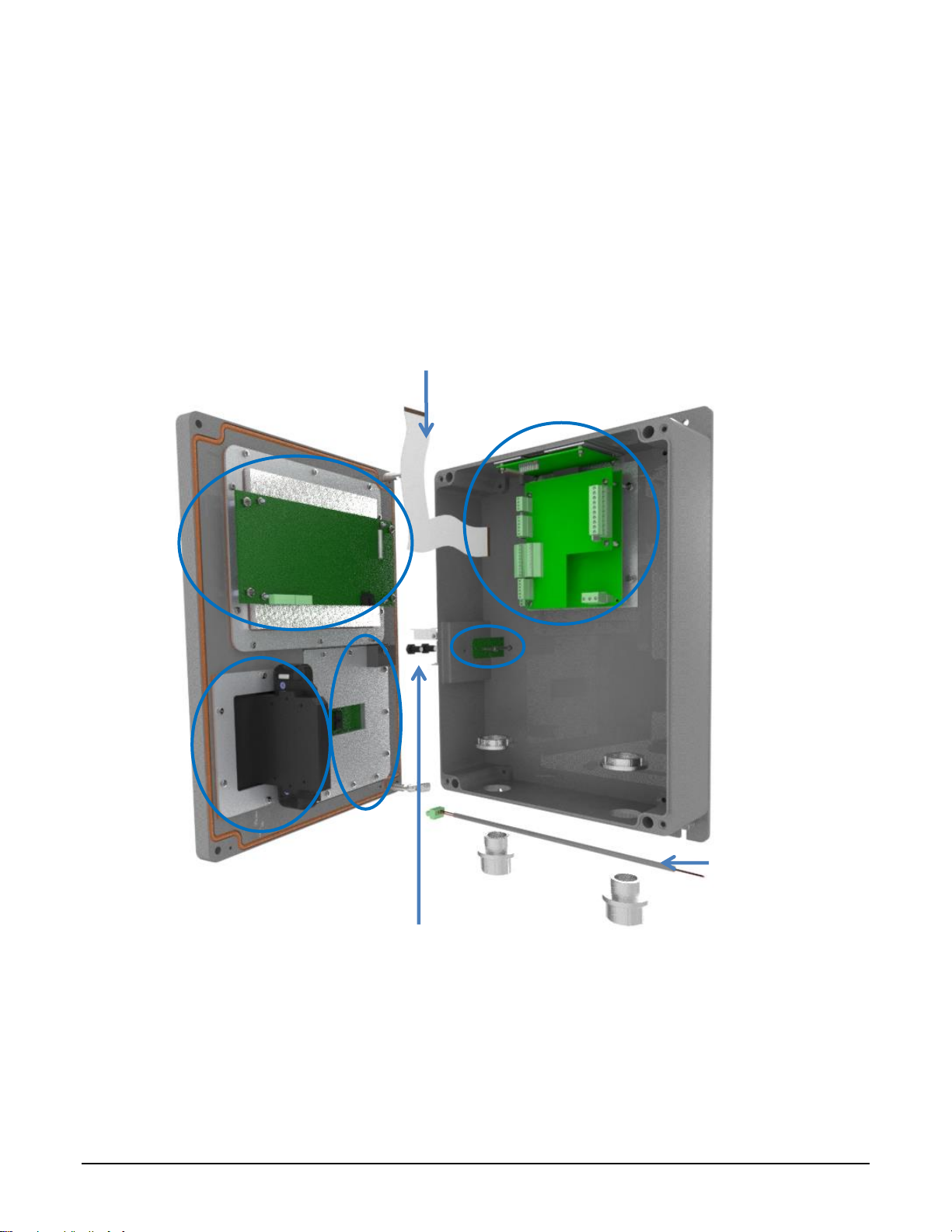

Overview and Subassemblies .......................................................................... 65 7.1

CPU Subassembly Removal and Replacement: .............................................. 67 7.2

Display Subassembly Removal and Replacement: .......................................... 69

7.3

Flat Display Cable connector : Remove and Connect .............................. 69 7.3.1

Keypad Removal and Replacement: ................................................................ 70 7.4

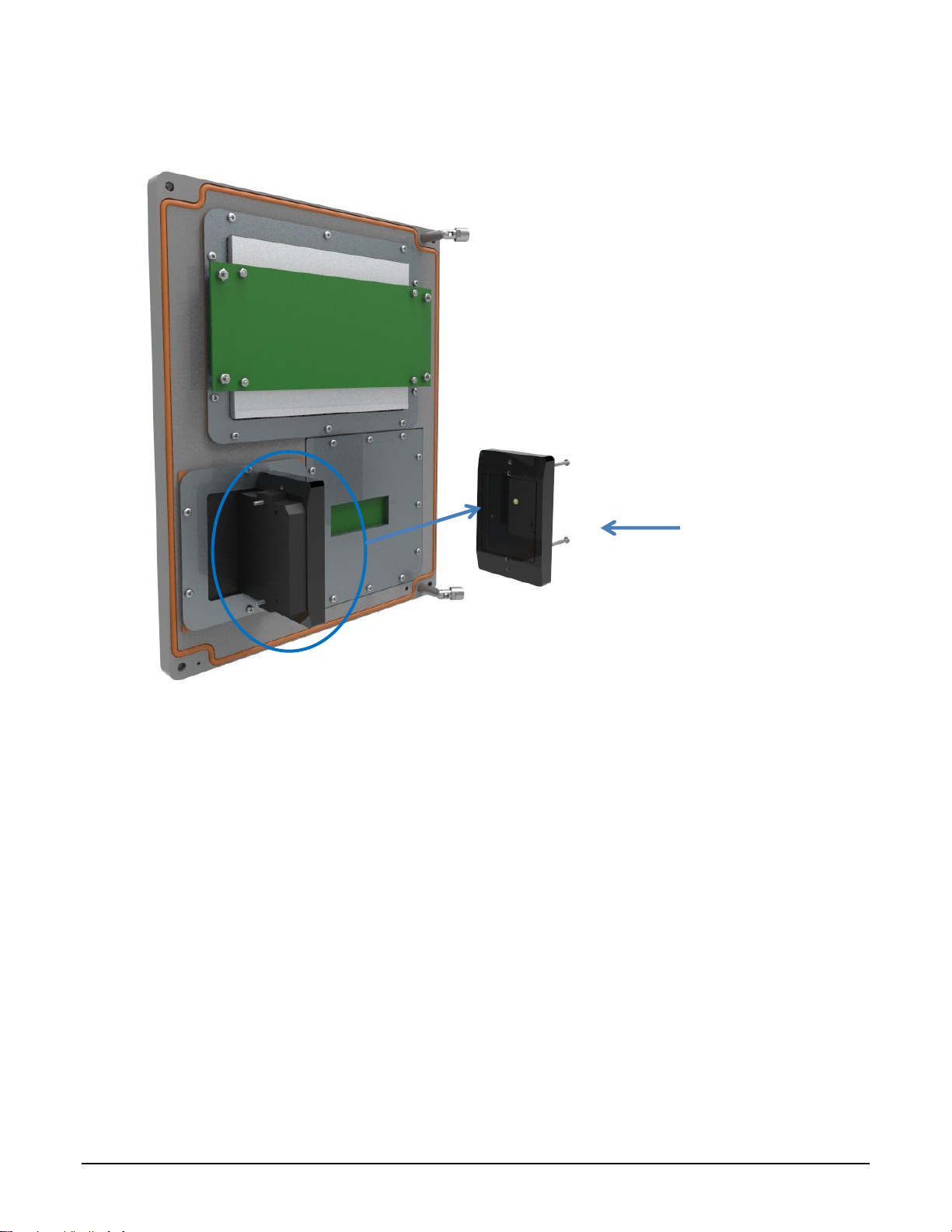

Card Reader Removal and Replacement ........................................................ 71 7.5

Slotted Card Holder Mounted Prox Reader Removal and Replacement: 7.5.1

(Current Model) ................................................................................................ ... 71

Bracket Mounted (Obsolete) Prox Reader Removal and Replacement: .... 72 7.5.2

Slotted Card Holder Mounted Prox Reader HID (Obsolete) Removal and 7.5.3

Replacement: ...................................................................................................... 73

Slotted Card Holder Mounted TWIC Reader (Obsolete) Removal and 7.5.4

Replacement: ...................................................................................................... 74

W&M switch assembly Removal and Replacement ......................................... 75 7.6

Ice Shield Removal and Replacement: ............................................................ 76 7.7

Overview Parts List and Partnumbers : ............................................................ 77 7.8

Chapter 8 Hardware Revision History & Compatibilty.......................................... 79

Chapter 9 Revision History .................................................................................. 80

Page 7

Hardware Revision .......................................................................................... 80 9.1

Manual Revision .............................................................................................. 81 9.2

Page 8

Table of Figures

Figure 2.1 MultiLoad II (ML II) / Remote Control Unit II (RCU II) Division 2 Unit ............ 7

Figure 2.2 Unit Outline Drawing – Front View ....................................................................... 8

Figure 2.3 Unit Outline Drawing – Back View ....................................................................... 9

Figure 2.4 Unit Outline Drawing – Bottom View -2 Hole Base ......................................... 10

Figure 2.5 Unit Outline Drawing – Bottom View - 5 Hole Base ........................................ 10

Figure 2.6 Unit Outline Drawing – Side View ...................................................................... 11

Figure 3.1 Suggested Mounting Position ............................................................................. 16

Figure 3.2 Screen Visible Area .............................................................................................. 16

Figure 3.3 MultiLoad II/ RCU II AC Power Supply/Comm Board ..................................... 18

Figure 3.4 DC Power Connections ....................................................................................... 19

Figure 4.1 FCM / PCM Connections ..................................................................................... 23

Figure 4.2 RS485 4-Wire, Host to a Single MultiLoad II/ RCU II (recommended) ........ 23

Figure 4.3 RS485 4-Wire, Host to Multiple MultiLoad II/ RCU IIs .................................... 24

Figure 4.4 RS485 2-Wire, Host to a Single MultiLoad II/ RCU II...................................... 24

Figure 4.5 RS485 4-Wire, Host to Multiple MultiLoad II/ RCU IIs .................................... 25

Figure 4.6 RS232, Host to a Single MultiLoad II/ RCU II .................................................. 25

Figure 4.7 RS232, Host to Multiple MultiLoad II/ RCU IIs ................................................. 26

Figure 4.8 Ethernet Connections .......................................................................................... 26

Figure 4.9 Ticket Printer / Data Logger Connections with Handshake ........................... 27

Figure 4.10 Ticket Printer / Data Logger Connections without Handshake ..................... 28

Figure 4.11 PTB Printer Connection with Handshake......................................................... 28

Figure 5.2 2 Meter I/O Board Terminal Block Assignments .............................................. 34

Figure 6.1 Type 1 Program / W&M Switches ...................................................................... 52

Figure 6.2 Type 2 Program / W&M Switches ...................................................................... 52

Figure 6.3 Type 3 Program / W&M Switch with Magnetic Bolts ....................................... 54

Figure 6.4 CPU DIP Switches for Program and W&M Access (rev 1.0) ......................... 56

Figure 6.5 CPU DIP Switches for Program and W&M Access (rev 2.0) Field Switch Access Control

(MultiLoad II Only) ....................................................................................................................... 56

Figure 7.1 MultiLoad II (ML II) / Remote Control Unit II (RCU II) Division 2 Unit .......... 65

Page 9

Figure 7.2 ML II/ RCU II Div2 Unit Assembly Slotted Card Holder with MT11 .............. 66

Figure 7.3 CPU Board, Power Supply / Comm Board, I/O Board with Chassis ............ 67

Figure 7.4 ML II/ RCU II Div2 Unit Cover Display Assembly ............................................ 69

Figure 7-5 Cam lock in the Open (Up) position Figure 7-6 Cam lock in the closed (down) 70

Figure 7-7 Display Cable Insertion ........................................................................................ 70

Figure 7.8 ML II/ RCU II Div2 Unit Cover Keypad Assembly ............................................ 71

Figure 7.9 Exploded View Front Cover Assembly: Slotted Card Holder with MT11 ..... 72

Figure 7.10 ML II/ RCU II Div2 Cover Assembly Prox Bracket Mount Thinline II (Obsolete) 73

Figure 7.11 ML II/ RCU II Div2 Cover with Slotted Card Holder Thinline II (Obsolete) .. 74

Figure 7.12 ML II/ RCU II Div2 Unit Assembly Prox/TWIC Slotted Card Holder RP15 (Obsolete)

75

Figure 7.13 ML II/ RCU II DIV2 W&M Assembly .................................................................. 76

Figure 7.14 Ice Shield Assembly Installation Slotted Card Holder .................................... 77

Page 10

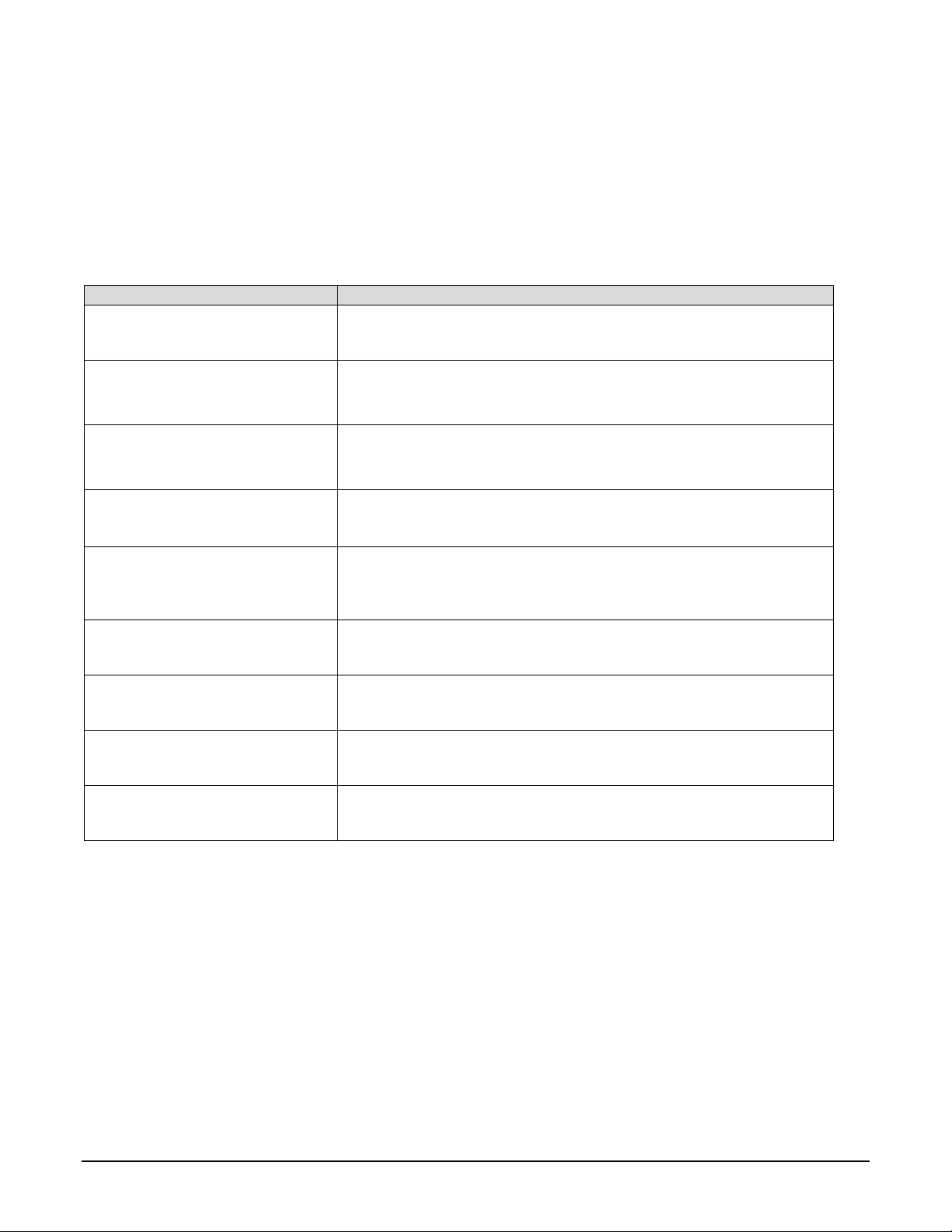

Chapter

Topics Covered

1.General Information and

Warnings

This chapter reviews safety and compliance information, as well as

instructions for receiving and returning products.

2.Operating Conditions &

Components

This chapter covers product outline and dimensions, as well as operating

characteristics of the unit.

3.Installing the MultiLoad II/RCUII –

DIV2

This chapter covers installation considerations and instructions for the

Division 2 (DIV2) Model.

4.Data Communication Interface

This chapter reviews hardware connections and communication

processes.

5.Connecting Field Devices to the

Internal I/O Board

This chapter covers the available I/O points per board, the terminal

arrangements per board, and then describes in detail how to connect

different field devices to the internal I/O Boards.

6. Configurations

This chapter describes how to navigate the system, select field

values, perform data entry, and toggle options on and off.

7. Service and Repair

This chapter describes how to service and repair the MultiLoad/

RCUII DIV-2 subassemblies and parts.

8. Hardware Revision History &

Compatibility

This chapter provides changes, modifications, and updates to the

hardware.

9. Revision History

This chapter provides further hardware revisions as well as revisions

made to this document.

Overview

This document is designed to guide individuals installing MultiLoad II/ RCU II DIV2 equipment, engineering

firms developing site electrical drawings, and users troubleshooting system operations such as managers,

system administrators, technicians, and meter proving personnel.

The following table provides an informative summary of the material available in this guide:

1

Page 11

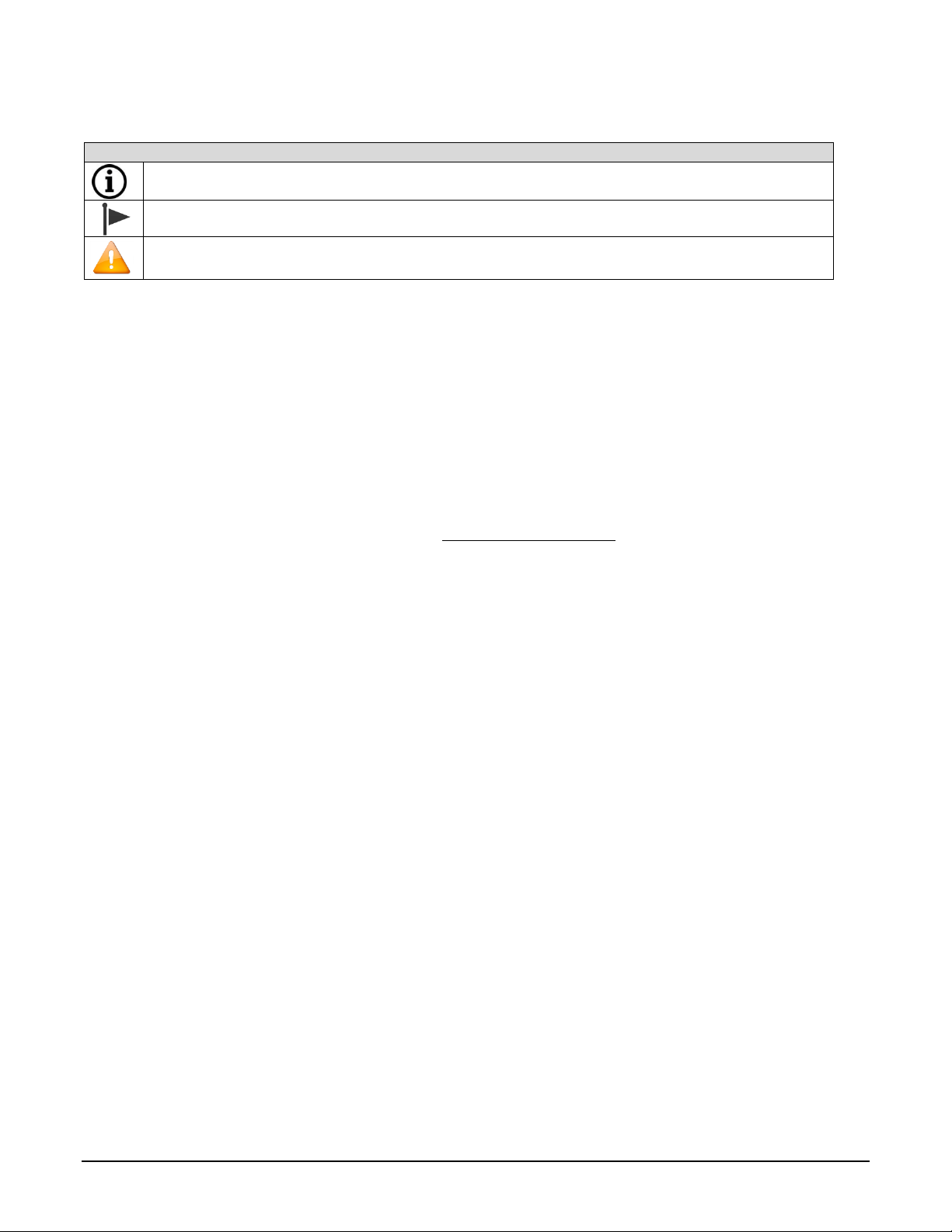

ICON KEY

Important information to enhance understanding and make better use of the product.

Indicates potential damage to hardware or loss of data.

Potential for property damage or that personal injury may occur. Pay close attention and

follow instructions when this symbol is displayed.

The following keys allow the user to locate information needed in this guide:

Typographical Conventions:

Boldface: Indicates what is pressed on the keypad. Example: Key in 00000.

Italics: Emphasizes a key product or industry term.

Example: the display features a pick-list style of item selection.

This guide covers RCU/MultiLoad DIV2 installation information only. For information about base MultiLoad

firmware, please consult the MultiLoad II User Guide. For information about wiring other models, please

consult the respective installation guides. For information about the MultiLoad register interface and Modbus

communication, please reference the MultiLoad II Communication Guide. Updated versions of all manuals,

including this one, are available on our website at http://www.toptech.com.

2

Page 12

Chapter

1

Chapter 1 General Information & Warnings

Receiving and/or Returning Equipment 1.1

At receipt, the MultiLoad II/ RCU II should be immediately inspected after opening the packaging case.

If any damage is visible, notify the carrier at once to establish liability.

Contact Toptech’s Return Materials Department to initiate timely repair or replacement of the unit.

A Return Materials Authorization (RMA) will be for the purpose of returning the product or parts

requiring repair. Do not return any material to Toptech without an RMA.

Contact Information for Americas:

Return Materials Department

Toptech Systems, Inc.

1124 Florida Central Pkwy

Longwood, FL 32750 USA

+1 (407) 332-1774

Contact Information for EMEA and Asia:

Return Materials Department

Toptech System NVs

Nieuwe weg 1- haven 1053

2070 Zwijndrecht, BELGIUM

+32 (0)3 250 60 60

Prior to installation, the MultiLoad II/ RCU II should be stored in its packing case and be protected from

damage due to handling and adverse weather conditions.

3

Page 13

Safety Warnings 1.2

NORTH AMERICAN INSTALLATIONS:

▲ This equipment is suitable for use in Class I, Division 2, Groups C and D locations, OR non-

hazardous locations.

▲ WARNING: EXPLOSION HAZARD. Do not disconnect equipment unless power has been

removed or the area is known to be non-hazardous.

▲ WARNING: EXPLOSION HAZARD. Substitution of components may impair suitability for

Class I, Division 2.

▲ WARNING: EXPLOSION HAZARD. The area must be known to be non-hazardous before

servicing/replacing the unit and before installing.

▲ CAUTION: Battery may explode if mistreated. DO NOT RECHARGE, DISASSEMBLE, OR

DISPOSE OF IN FIRE.

▲ CAUTION: Field wiring must have a temperature rating of 75 °C or greater.

▲ A battery is soldered to the processor board for retention of data, time, and date. This battery

should last more than ten years. Please return the board to Toptech Systems for battery

replacement. This battery must be replaced with Matsushita Electric, model BR2477A

only. Use of another battery may present a risk of fire or explosion.

▲ The installation of this product must be in conformity with NFPA 70 (US National Electric Code)

or CSA C22.1 (Canadian Electrical Code) as appropriate.

INSTALLATIONS NORD-AMÉRICAINES (FRANÇAIS)

▲ Cet équipement est compatible pour une installation en Classe I, Division 2, Groupes C & D ou

les emplacements non dangereux..

▲ AVERTISSEMENT: RISQUE D'EXPLOSION. Avant de déconnecter l’ équipement, couper

le courant ou s’assurer que l’emplacement est designe non dangereux.

▲ AVERTISSEMENT: RISQUE D'EXPLOSION. La substitution de composants peut render

ce materiel inacceptable pour les emplacements de Classe I, Division 2.

▲ AVERTISSEMENT: RISQUE D'EXPLOSION. Avant réparer ou remplacer l’équipement et

avant d’installer s’assurer que l’emplacement est designe non dangereux.

▲ PRUDENCE: La pile peut exploser si elle est maltraitée. NE PAS RECHARGER, NE PAS

DÉMONTER, ET NE PAS JETER DANS LE FEU.

▲ PRUDENCE: Câblage de terrain doit avoir un classement de température de +75 °C ou

plus.

▲ Une pile est soudée à la carte processeur pour la conservation des données, de l'heure, et de la

date. Cette pile devrait durer pendant plus que dix ans. Veuillez retourner la carte processeur à

Toptech Systems pour le remplacement de la pile. Remplacez la pile avec Matsushita

Electric, modèle BR2477A seulement. Utiliser une autre pile peut présenter un risque

d'incendie ou d'explosion.

▲ L’installation de ce produit doit se conformer avec le Code National d'Électricité, NFPA 70 ou le

Code Canadien d'Électricité, CSA C22.1 comme appropriée.

4

Page 14

ATEX AND IECEX INSTALLATIONS:

▲ This equipment is suitable for use in EX Zone 2 Group IIB Locations, OR non-hazardous

locations.

▲ WARNING: Do not open when an explosive atmosphere may be present.

▲ WARNING: Do not disconnect equipment unless power has been removed or the area is

known to be non-hazardous.

▲ WARNING: EXPLOSION HAZARD. The area must be known to be non-hazardous before

servicing/replacing the unit and before installing.

▲ CAUTION: Battery may explode if mistreated. DO NOT RECHARGE, DISASSEMBLE, OR

DISPOSE OF IN FIRE.

▲ CAUTION: Field wiring must have a temperature rating of 75 °C or greater.

▲ A battery is soldered to the processor board for retention of data, time, and date. This battery

should last more than ten years. Please return the board to Toptech Systems for battery

replacement. This battery must be replaced with Matsushita Electric, Model BR2477A

only. Use of another battery may present a risk of fire or explosion.

▲ The installation of this product must be in conformity with IEC/EN 60079-14.

Electrostatic Discharge (ESD) Protection 1.3

The MultiLoad II/ RCU II contains electronic components and assemblies subject to damage by ESD.

The MultiLoad II/ RCU II was designed to protect against ESD while the unit is closed and in normal

operation. Proper handling procedures must be observed during the removal, installation, repair and

other handling of printed circuit board assemblies, electronic devices and components. This includes:

1) Service to be performed by authorized personnel only.

2) The person performing the service must be grounded by an ESD grounding strap and

connected to ground.

3) While performing maintenance or repair, touch an unpainted metal of the MultiLoad II/ RCU

II surface prior to touching or handling any printed circuit boards or electronic components.

4) Printed circuit board assemblies must be placed in and transported in conductive bags or

other conductive containers.

5) Printed circuit boards must not be removed from the conductive container until time of use.

6) All other “best” practices for protecting devices from ESD must be observed.

5

Page 15

FCC Note 1.4

This equipment complies with the limits for a Class A Digital Device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct the

interference at theirexpense.

Modifications not approved by the manufacturer could void the user's authority to operate the

equipment under FCC rules.

6

Page 16

Chapter

2

Chapter 2 Operating Conditions and Components

Product Outline and dimensions 2.1

MultiLoad II/ RCU II – DIV2 Model - Picture

2.1.1

Figure 2.1 MultiLoad II (ML II) / Remote Control Unit II (RCU II) Division 2 Unit

7

Page 17

MultiLoad II/ RCU II – DIV2 Model – Dimensions

2.1.2

The dimensions in this section are indicated in inches and millimeters (in parenthesis).

2.1.2.1 Front View

Figure 2.2 Unit Outline Drawing – Front View

8

Page 18

RCUII/ ML II Div 2

MOUNTING TEMPLATE

2.1.2.2 Back View

Figure 2.3 Unit Outline Drawing – Back View

9

Page 19

2.1.2.3 Bottom View

2.1.2.3.1 2- Hole Base

2 x 1” NTP Aluminum HUBS

Figure 2.4 Unit Outline Drawing – Bottom View -2 Hole Base

2.1.2.3.2 5- Hole Base (Europe)

3xM20 and 2xM25

Figure 2.5 Unit Outline Drawing – Bottom View - 5 Hole Base

10

Page 20

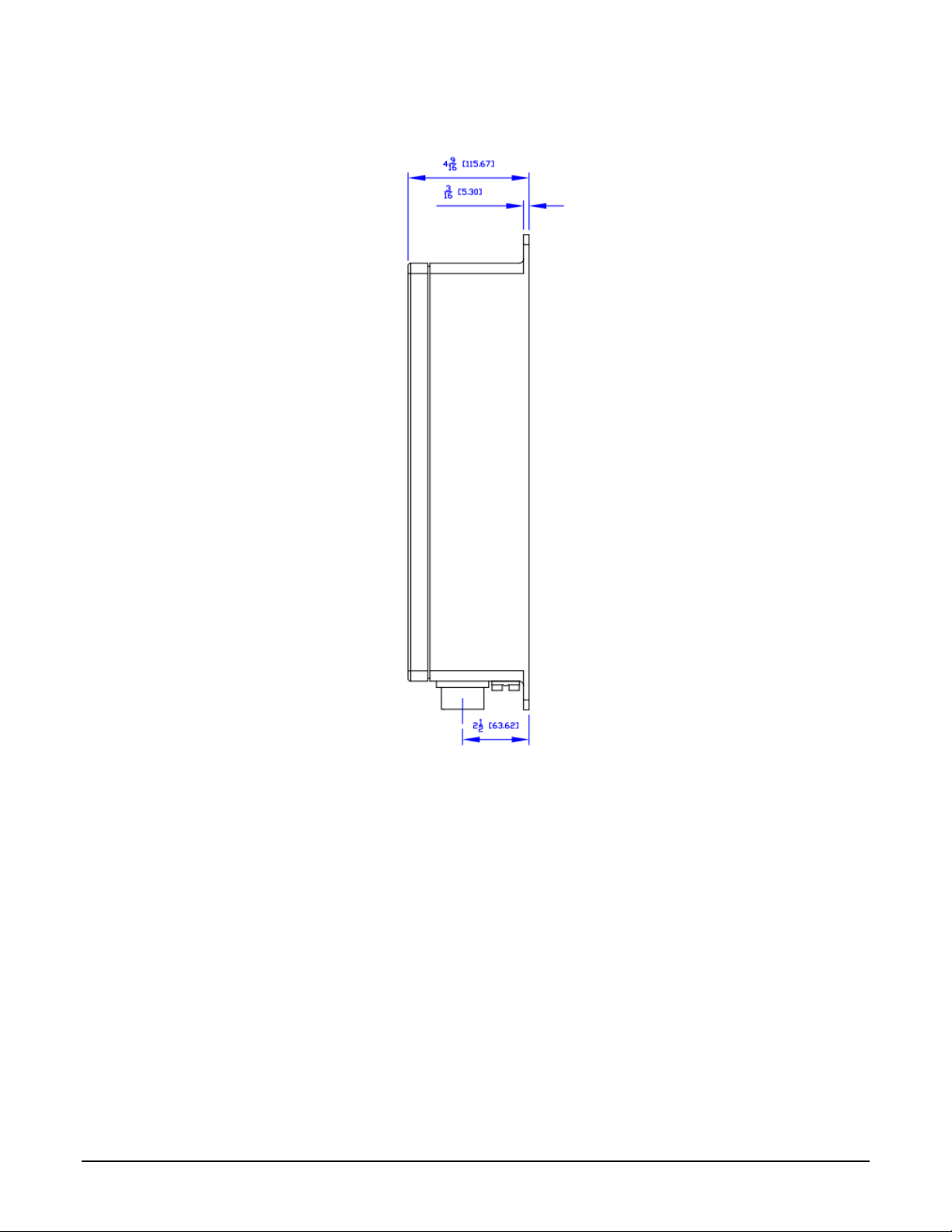

2.1.2.4 Side View

Figure 2.6 Unit Outline Drawing – Side View

11

Page 21

Characteristics

Description

Operating Voltage

85 - 250 Vac, 47-63 Hz, 300 – 150 mA

Voltage Option

9 - 30 Vdc, 600mA

Operating Temperature

40°F to 140°F: -40°C to 60°C

Enclosure

Type 4, IP65

ETL Listed (US, Canada) Class 1, Division 2, Groups C & D, T4

Weight

24 lbs : 11 kg

Display

Color 8.4” Diagonal VGA

Prox Card Reader

Captive or Non-captive: supports TWIC

Lockable External W&M Bolts

Program Access, Weights & Measures Parameter Access (on MultiLoad

only)

Keypad

47 Key Alpha/ Numeric Membrane Switch Keypad

Communications

3 serial ports (1 RS-485, 2 User Selectable RS-232 or RS-485)

1 Ethernet port 10/100 Mbps

Type I/O

Digital/ Analog I/O

Quantity, Location

2 Meter I/O Quantity,

Location

Electrical Rating

AC Outputs:

5 (TB1)

8 (TB2, TB3)

12 - 250 Vac rms, 500 mA (per point), TB1

AC Inputs

0

2 (TB1)

90 - 250Vac

DC Outputs:

3 (TB3)

2 (TB9)

0 - 30 Vdc, 600 mA (per point), TB3

DC Inputs:

5 (TB2-Right)

(2 High Speed)

6 (TB7, TB8)

(4 High Speed)

5 - 30Vdc, TB2B

Dual Channel flow meter inputs (1-5000Hz)

Miscellaneous signal inputs

12Vdc Source:

167mA Max Load

(TB2-Left)

250mA Max Load

(TB6)

Isolated Power Supply

Power for flow meter pulsers or preamps

RTD Input:

1 (TB4)

2 (TB4, TB5)

100-ohm platinum, four wire

Coefficient 0.00385 Ohm/Ohm/°C

Analog Input

1 (TB5)

0

4 - 20mA, 1.5V maximum burden

Analog Output

1 (TB6)

0

4 - 20mA, Requires 12Vdc – 30Vdc Supply

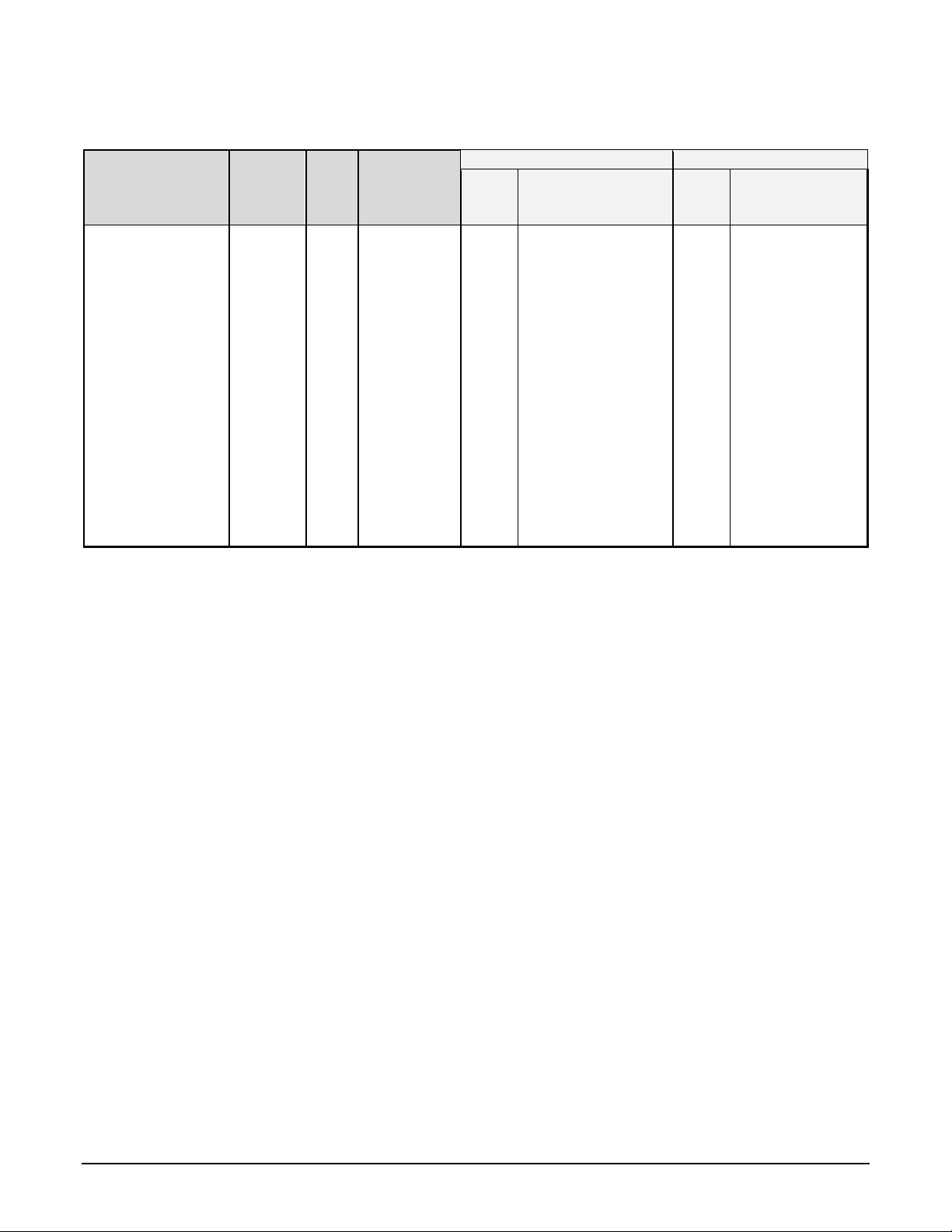

Operating Characteristics 2.2

The Remote Control Unit – Division 2 (DIV2) Model has the following characteristics:

Internal I/O Options: Two versions of an optional internal I/O board are available:

- the Digital/ Analog I/O board.

- the 2 Meter I/O board.

The quantity and electrical ratings of each I/O are described in the table below:

12

Page 22

I/O TYPE

Voltage

Freq

Dissipation

per Point

Digital/ Analog I/O

2 Meter I/O

# I/O

TOTAL

Dissipation

# I/O

TOTAL

Dissipation

[V]

[Hz]

[W] [W]

[W]

ACOUT

230

50

0.36 5 1.78

8

2.85

120

60

0.32 5 1.62

8

2.60

ACIN

230

50

0.73 0 2 1.46

120

60

0.44 0 2 0.89

DCOUT

5

--

0.02 3 0.07

2

0.05

12

--

0.02 3 0.07

2

0.05

24

--

0.02 3 0.07

2

0.05

30

--

0.02 3 0.07

2

0.05

DCIN

5

--

0.00 6 0.03

6

0.03

15

--

0.06 6 0.33

6

0.33

24

--

0.16 6 0.97

6

0.97

30

--

0.23 6 1.41

6

1.41

4-20 mA Input

--

--

0.03 1 0.03

0

--

Internal I/O Heat Dissipation:

*I/O points dissipating 1 mW or less are not reported

13

Page 23

Chapter

3

Chapter 3 Installing the MultiLoad II/RCUII DIV2

Tools Required 3.1

Installation

3.1.1

- ¼” Flat Head screw driver is required for tightening cover screws.

Servicing and Repair

3.1.2

- #2 Philips screwdriver for circuit board removal.

- ¼” socket wrench for CPU circuit board removal and a 5/16” socket wrench for display board

removal.

- #2 Philips screwdriver for removal of keypad plat screws.

Cover Closure and Bolt Replacement 3.2

When closing the cover, gently lift on the bottom of the cover when in position for starting one or two of

the right corner screws. This is done to assist the alignment of the cover and base holes for starting the

screws. The enclosure cover is secured to the housing by four 6mm slotted/Philips screws. When the

screws are removed, the front cover will swing left and hang from its hinges. The screws are captive

and will remain with the cover.

Cable Entries 3.3

Two 1” NPT conduit hubs are provided for the installation of conduit and cables.

No hubs are provided with the 5 hole base.

Mounting the MultiLoad II/ RCU II DIV-2 Enclosure 3.4

The DIV-2 enclosure should be located in a shaded area. Direct sunlight can increase internal

temperature to greater than 140°F or 60°C.

14

Page 24

Exterior dimensions of the standard MultiLoad II/ RCU II DIV-2 enclosure are shown in Figures 2.2 –

2.6. There is only one mounting orientation possible; reference Figure 2.2 for the MultiLoad II/ RCU II

DIV-2 Mounting Template. The cable entries are located at the bottom of the unit.

Appropriate fasteners must be selected to support the minimum weight of 24 lbs (11 kg). Toptech

offers the following mounting suggestions for three typical surfaces: drywall, wood, or concrete/cinder

block.

Drywall

3.4.1

Insert four fasteners through the corner mounting holes, shown in Figure 2.2. For the fasteners, use #14 x 1

¾” (M6 x 40 mm) Phillips pan head sheet metal screws inserted in #14 (M6) self-tapping nylon anchors.

Place one #14, 3/8” OD (M6, 10 mm 0D) flat washer under the head of the screw before inserting the screw

into the mounting hole.

Wood

3.4.2

Follow the instructions above for Drywall installation, substituting the #14 x 1¾” (M6 x 40 mm) wood screws

for the four sheet metal screws. Do not use the self-tapping nylon inserts.

Concrete or Cinder Block Walls

3.4.3

Follow the instructions above for Drywall installation, substituting the a 1/4 ” x1 3/4” Tapcon masonry fastener

for the four sheet metal screws. Do not use the self-tapping nylon inserts.

Drill pilot holes for the Tapcons using a 3/16” x 3 ½” masonry drill bit.

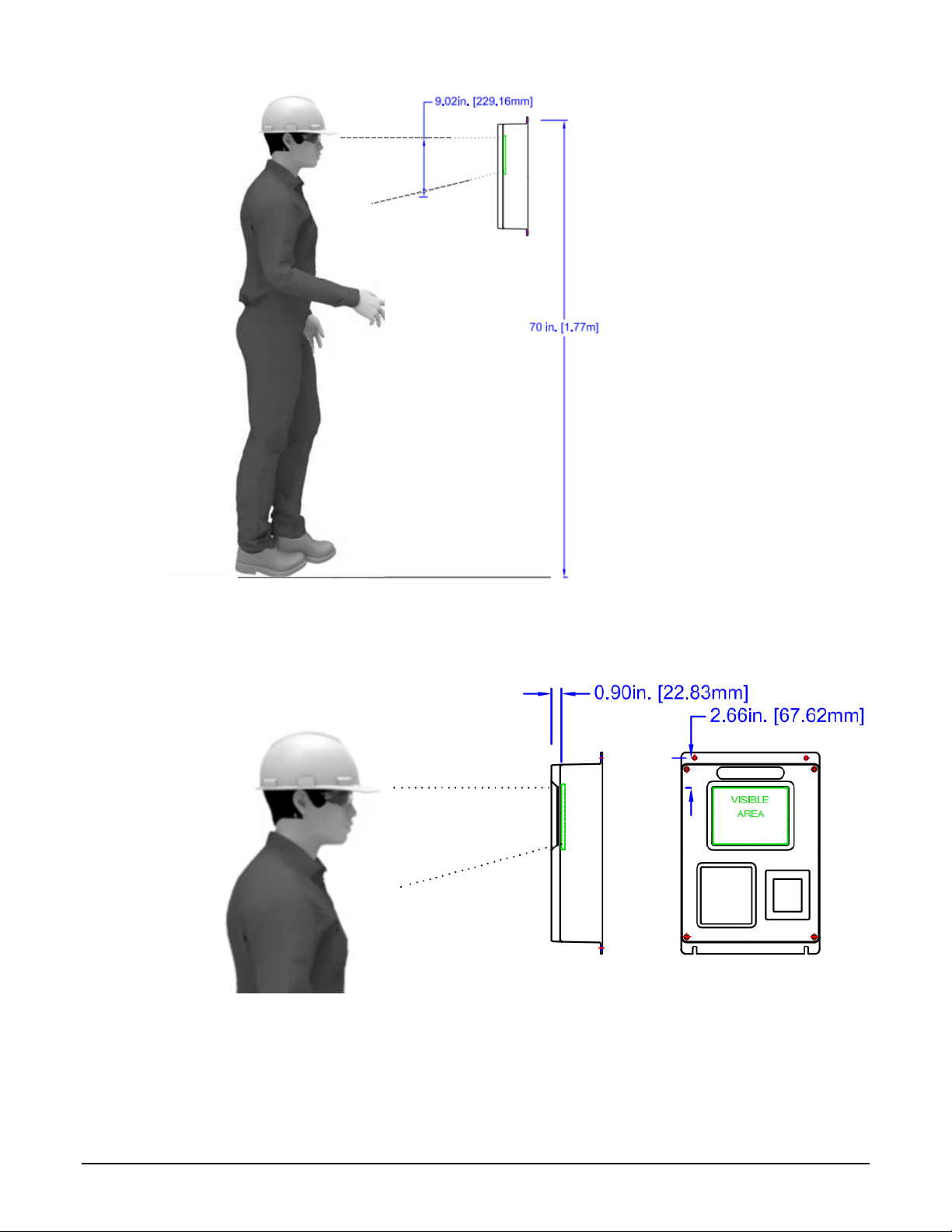

Mounting Height Considerations

3.4.4

When mounting the enclosure, be aware of the limitations that the cover places on screen visibility.

Because the display is inset about an inch [25mm] from the surface of Div-2 and SMP units and the

screen is inset an inch-and-one-half [39mm] in the EXL unit, the enclosure should be mounted so that

top of the screen’s visible area is at eye level of the tallest operator. Figure 3.1 shows the visible area

at arm’s length and the distance from the ground to the top mounting hole location for a six-foot [1.8m]

tall user. Figure 3.2 shows the offset of the top of the screen’s visible area from the top mounting bolt

and the depth of the screen within the unit.

15

Page 25

Figure 3.1 Suggested Mounting Position

Figure 3.2 Screen Visible Area

16

Page 26

Recommended Wire Sizes and Torque for All Terminal Blocks 3.5

Three sizes of terminal blocks are used in the MultiLoad II/ RCU II products: 7.62 mm pitch (supply

power), 5.08 mm pitch (line voltage switching), and 3.81 mm pitch (serial communication, analog or dc

voltages). The 7.62 and 5.08 mm terminal blocks have an allowable wire size of 24 AWG – 12 AWG

and should be tightened to 0.55 Nm +/-0.05 Nm (5 lb in +/- 0.4 lb in).

The 3.81 mm terminal blocks have an allowable wire size of 28 AWG – 16 AWG and should be

tightened to 0.23 Nm +/-0.02 Nm (2 lb in +/- 0.2 lb in).

Electrical Supply Connections 3.6

The MultiLoad II/ RCU II may be equipped for either 85 -250Vac or 24Vdc operation. Verify the

power type before making any connections.

Fiel Wiring must be rated 75°C or greater.

WARNING: If there are unused holes, blanking elements appropriate for the type enclosure

must be used.

Do not route AC and DC wiring in the same conduit.

All wiring must enter the MultiLoad II/ RCU II enclosure through conduit via entries in the bottom of the

enclosure. All conduits must be terminated at the enclosure by use of appropriately-rated conduit hubs

or glands.

Wires must be stripped ¼” and fully inserted into terminal block with no bare conductor exposed.

Review section 3.5 for recommended wire size and torque values.

Both ac and dc input models require a safety ground connection as described in section 3.6.3 below.

A service loop is recommended for all wires and cables entering the enclosure.

Do not allow service loop cables to overlap the circuit boards. Coil any cable length in the

bottom of the enclosure. Keep AC wiring separated from all other wiring in the enclosure by use

of the supplied partitions (see wire partition instructions below).

Wiring must comply with all local electrical codes.

17

Page 27

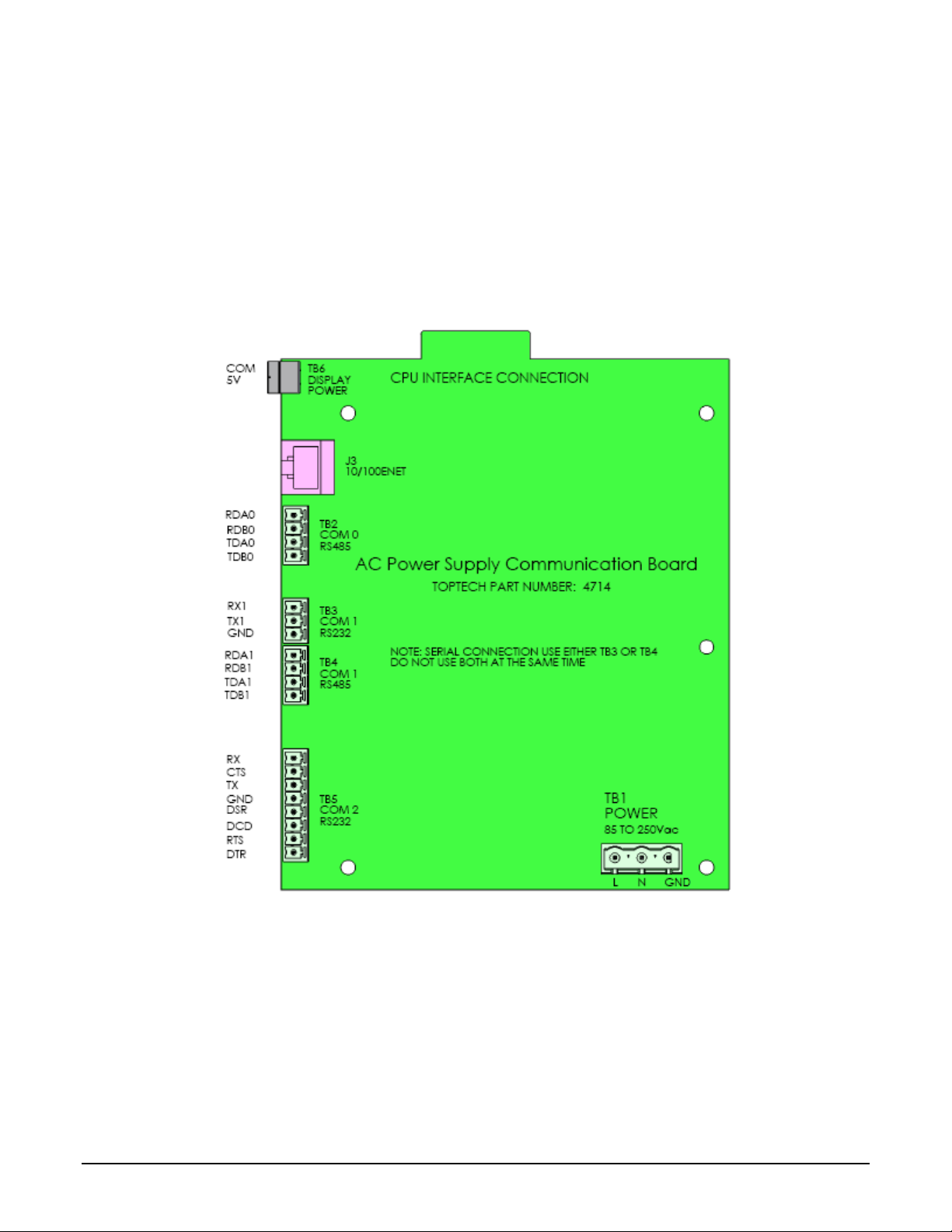

AC Powered Models

3.6.1

Provide over current protection using a 15 Amp circuit breaker or equivalent. The breaker also serves

as a means of disconnection from the operating supply as required by UL/ISA/IEC 61010-1 and

CAN/CSA-C22.2 NO. 61010-1. The disconnected device may not be blocked or be made difficult to

operate by the MultiLoad II/ RCU II or any other device. Note that installation of disconnects are

typically prohibited in Class I, Division 2 locations.

Power required: 85 – 250 Vac, 47 – 63 Hz, 300 mA @ 85Vac/ 150 mA @250Vac. The power

connector is located in the right hand, bottom corner of the Power Supply/Communication board as

shown in figure 3.3. Select supply wire rated 300V or better with a flammability rating of at least VW-1.

Figure 3.3 MultiLoad II/ RCU II AC Power Supply/Comm Board

DC Powered Models

3.6.2

The MultiLoad II/ and RCU II is optionally available with a 24 Vdc power supply. The power source

used to supply the MutliLoad II/RCUII must be rated 9 – 30 Vdc SELV, Limited Energy (Class 2). The

rated supply input current is 600mA. The supply should be protected by a 1.5 Amp fuse.

18

Page 28

Wire gauge (AWG)

Distance (feet)

24

50

22

100

20

150

18

250

16

400

Do not connect the power supply dc common to earth ground.

The 3-position terminal block is located in the right hand corner of the power supply/communication

board.

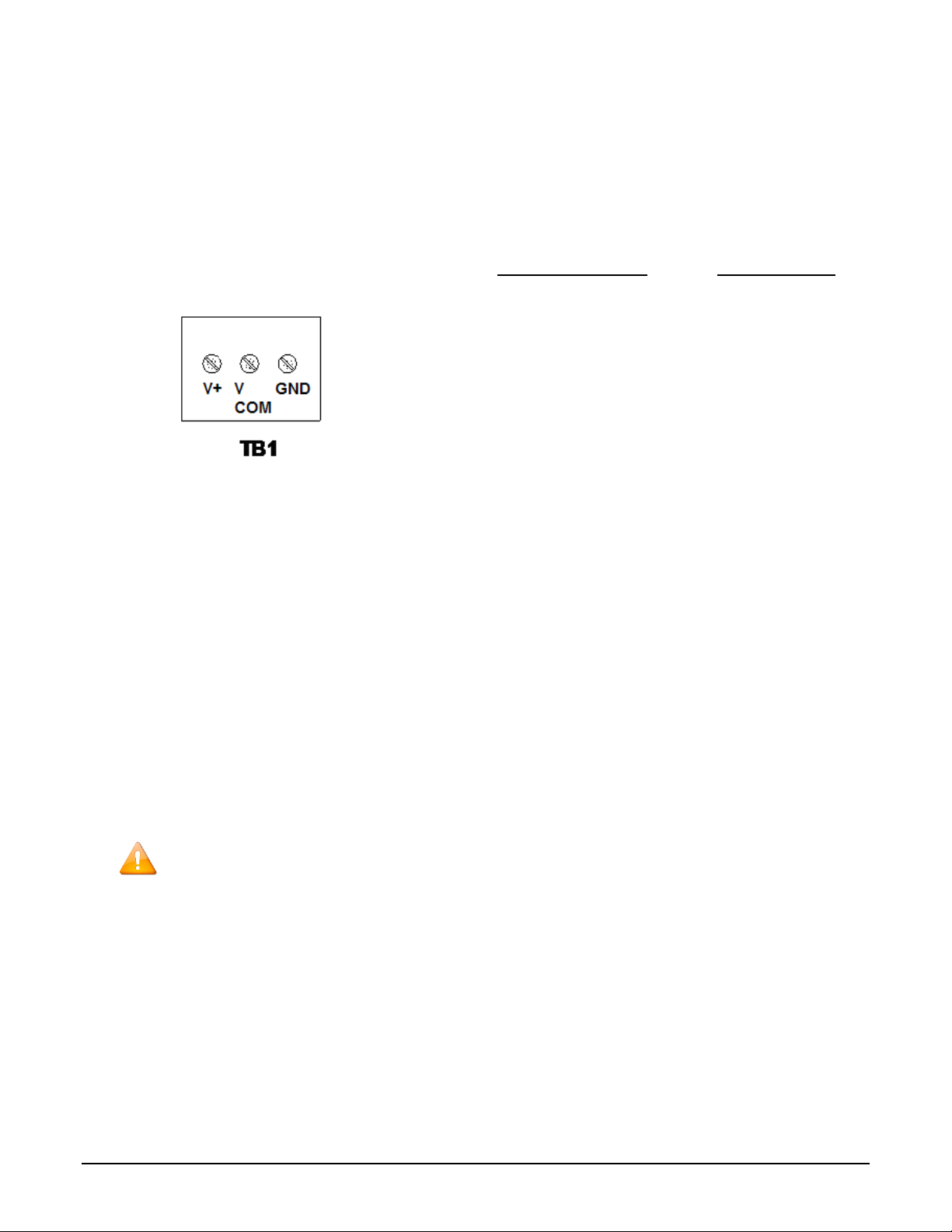

Figure 3.4 DC Power Connections

Equipment Grounding

3.6.3

A safety ground should be attached to terminal block TB1 (on both ac and dc input power models) to

maintain electrical safety in the event of a fault condition. Follow the terminal block wiring instructions

in section 3.6. Keep the required tightening torque in mind (section 3.5).

Wiring guidelines for using 24 Vdc power

supply:

The external ground connection is not provided for the attachment of the protective conductor (the

safety ground). Rather, it is provided only as a supplemental bonding connection where local

authorities permit or require such a connection: for example, as a means of equipotentiality. The wire

connection is on the bottom right exterior surface. The following wire sizes may be used: 10 AWG

(5.26 mm2) or 11 AWG (4.17 mm2).

19

Page 29

Communication

Port

Interface Type

Typical Function

Terminal (Figure 3.3)

Comm. Port 0

RS-485

Internal I/O board /

TB2

FCM I / FCM II / PCM

Communication

Comm. Port 1

RS-232 or RS-485

Host Communication (TMS) /

Printer

TB3 RS-232

TB4 RS-485

Comm. Port 2

RS-232 or RS-485 (2 wire)

Ticket Printer/Data Logger

TB5

Ethernet

10/100MBPS

Host Communication (TMS)

J3

Cat 5 (or

higher)Cable

If a service loop is used, the maximum wire length in the service loop should not exceed

3 inches [75mm].

Separate AC and DC wiring by at least 3 inches [75mm]. Do not allow excess wire in the

service loop to overhang printed circuit board.

Default settings in MultiLoad are: COM O – FCM ; COM 1- HOST , and COM2 – NA.See

the user guide for more details

Only one port may be defined as an FCM, Print or Alibi Log, otherwise, a ‘Port Usage

Conflict(s)’ message will display upon re-boot. See the user guide for more details

Chapter

4

Chapter 4 Data Communications Interface

The MultiLoad II/ RCU II has four (4) communications ports (see Figure3.3), each with a specific

purpose. The following section provides the information required to select and make the wiring

connections to the ports:

20

Page 30

Although a ground wire is not required, the common mode voltage between the MultiLoad

II/ RCU II and the field device must be within -7Vdc to 12Vdc. To correct situations

where this is not the case, the DC common is available on COM 0 and COM 1 by using

TB2, pin five (revision 1.1 Power Supply/Comm boards only) and TB 3, pin three.

Connect the MultiLoad II/ RCU II DC common to the signal ground of the field device.

Available Communications Protocol Selection and Wire Spec 4.1

This section describes the available communication protocols for MultiLoadII/RCU II.

RS-422/485

4.1.1

The RS-422/485 communications protocol is designed for multi-point (i.e. computer to multiple

devices, also called multi-dropped) communications up to 4,000 feet (1,220 Meters).

RS-422 requires 4-wires (2 twisted pair) for full duplex communications and utilizes a transmit pair

of wires (TDA & TDB) and a receival pair of wires (RDA & RDB).

RS-485 requires 2-wires (1 twisted pair) for half duplex communications and utilizes a single pair

of wires (TDA/RDA & TDB/RDB) for transmittal and receival

This manual will typically refer to both RS-422 and RS-485 as simply RS485 2 Wire or RS485 4

Wre.

Wire used must meet the following characteristics:

- 24 AWG stranded.

- 4-wire, two twisted pair with overall shield.

- 2-wire, one twisted pair with overall shield.

- 30 pF maximum between conductors.

- 1,000 ohm impedance.

- Maximum length: 4,000 feet (1,220 Meters).

- Maximum stub length: 15 feet.

All exposed shields must be properly insulated to prevent short circuits.

All shields must be continuous, soldered, and properly insulated.

RS-232

4.1.2

The RS-232 protocol is designed for point-to-point (i.e., computer to a single device)

communications limited to 50 feet requiring a minimum of 3 wires: transmit, receive and ground.

Additional wires are required for hardware handshaking when using printers and data loggers.

Wire used must meet the following characteristics:

- 24 AWG.

- 3 conductor with overall shield (data only) or 8 conductor with overall shield (full

handshaking).

21

Page 31

- 30 pF maximum between conductors.

Ethernet

4.1.3

The Ethernet controller on revision 2.0 CPU boards uses HP Auto-MDIX technology. By

automatically detecting the signaling on the connected device, the transceiver will configure the

port settings automatically. Thus, the choice of a straight through or cross over cable no longer

has to be made—either will work.

Ethernet is available on MultiLoad II/RCUII with revision 2.0 or higher CPU boards.

Wire used must meet the following characteristics:

- Ethernet wiring standard T568B - Cat5 cable (or greater).

Communication Connection Wiring 4.2

This section describes the wiring connections for each of the communication ports in order to function

for a specifc communication protocol.

FCM I / FCM II Communications (MultiLoad II Product Only) - COM 0 –Port – RS485

4.2.1

FCM I, FCM II and PCM modules communicate with the MultiLoad II using the COM0. This is a

dedicated communication line.

The FCMII modules linked to a specific MultiLoad II are all on a RS-485 bus connected this COM 0

port.

The TD and RD pairs are swapped at the MultiLoad II.

If an internal I/O board is installed, this board is already connected to COM 0 and is addressed as

FCM #0.

All FCMs must be uniquely addressed.

22

Page 32

TDA

TDB

RDA

RDB

RDA

RDB

TDA

TDB

FCM / PCM

#0

MultiLoad II

COM 0

RDA

RDB

TDA

TDB

FCM / PCM

#n

TDA

TDB

RDA

RDB

RDA

RDB

TDA

TDB

MultiLoad II/

RCU II #1 COM 1

Host/TMS

RS485

MultiLoad II/ RCU

II #n COM 1

MultiLoad II/ RCU

II COM 1

Figure 4.1 FCM / PCM Connections

Host/TMS Communications

4.2.2

A host/ TMS computer system can be connected to the MultiLoad II/ RCU II in various ways :

- RS485 4-wire on COM 1

- RS485 2-wire on COM1

- RS232 on COM1

- Ethernet on the ethernet port

4.2.2.1 COM 1 - RS-485 4-wire - Host/TMS Communications

A host/ TMS computer system can be connected to the MultiLoad II/ RCU II via RS485 4-wire on

COM 1.

The TD and RD pairs are swapped at the Host/TMS.

Host/TMS

RS485

Figure 4.2 RS485 4-Wire, Host to a Single MultiLoad II/ RCU II (recommended)

MultiLoad II/RCUII can be multridropped on the same communication line using a RS485 – 4 Wire

on COM 1 to communicate to a host system.

23

Page 33

TDA

TDB

RDA

RDB

RDA

RDB

TDA

TDB

RDA

RDB

TDA

TDB

TDA

TDB

RDA

RDB

RDA

RDB

TDA

TDB

RCU II COM 1

Figure 4.3 RS485 4-Wire, Host to Multiple MultiLoad II/ RCU IIs

4.2.2.2 COM 1 - RS-485 2-Wire: Host/TMS Communications

The Host/TMS Computer System can be connected to the MultiLoad II/ RCU II via RS485 2-Wire

on COM 1.

The TD and RD pairs tied together at the Host/TMS and all MultiLoad II/ RCU IIs.

Host/TMS

MultiLoad II/

RS485

Figure 4.4 RS485 2-Wire, Host to a Single MultiLoad II/ RCU II

24

Page 34

TDA

TDB

RDA

RDB

RDA

RDB

TDA

TDB

RDA

RDB

TDA

TDB

TX

RX

RX

TX

GND

GND

MultiLoad II/

RCU II #1 COM

Host/TMS

RS485

MultiLoad II/ RCU

II #n COM 1

MultiLoad II/

RCU II COM 1

Host/TMS

RS232

MultILoad II / RCU II can be multridropped on the same communication line using RS485 – 2 Wire

on COM 1:

Figure 4.5 RS485 4-Wire, Host to Multiple MultiLoad II/ RCU IIs

4.2.2.3 COM 1 - RS-232 - Host/TMS Communications

The Host/TMS Computer System can be connected to the MultiLoad II/ RCU II via RS232 on COM

1.

The TX and RX are swapped at the Host/TMS.

Figure 4.6 RS232, Host to a Single MultiLoad II/ RCU II

25

Page 35

1 White/org 1

7 White/Brown

6 Green

5 White/Blue

4 Blue

3 White/Grn

2 Org

8 Brown

6

7

8

5

4

3

2

Twisted Pairs

TX

RX

RX

TX

GND

GND

RX

TX

GND

MultiLoad II/

RCU II #1 COM

Host/TMS

RS232

MultiLoad II/ RCU

II #n COM 1

MultiLoad II/RCUII has the ability to multi-drop onto a RS232 line on COM 1:

Figure 4.7 RS232, Host to Multiple MultiLoad II/ RCU IIs

4.2.2.4 Ethernet – Host/TMS Communications

The Host/TMS Computer System can be connected to the MultiLoad II/ RCU II using Ethernet.

The Ethernet controller on revision 2.0 CPU boards uses HP Auto-MDIX technology. By

automatically detecting the signaling on the connected device, the transceiver will configure the

port settings automatically. Thus, the choice of a straight through or cross over cable no longer

has to be made—either will work.

Ethernet is available on MultiLoad II/RCUII with revision 2.0 or higher CPU boards.

Figure 4.8 Ethernet Connections

26

Page 36

RCU II COM 2

DB25 Connector

RX

CTS

TX

GND

DSR

(N/C) DCD

(N/C) RTS

(N/C) DTR

2 – TX

20 - DTR

3 – RX

7 – GND

4 – RTS

5 – CTS (N/C)

6 – DSR (N/C)

8 – DCD (N/C)

Host Ticket Printer/Data Logger

4.2.3

Ticket Printers or alibilog printers can be connected to the MultiLoad II/ RCU II in the following

ways:

- RS 232 on COM1

- RS 232 on COM2

- Ethernet on the ethernet port

4.2.3.1 COM2 – RS232 - Host Ticket Printer/Data Logger

A Ticket Printer or Data Logger can be connected to the MultiLoad II/ RCU II via RS232 on COM

2.

The TX and RX are swapped at the MultiLoad II/ RCU II.

Handshake lines MUST be connected or terminated, or a printer error will be reported.

MultiLoad II/ RCU II will monitor CTS, DSR and DCD for active signals.

MultiLoad II/

Printer/ Logger RS232

Figure 4.9 Ticket Printer / Data Logger Connections with Handshake

27

Page 37

RCU II COM 2

DB25 Connector

RX

CTS

TX

GND

DSR

DCD

RTS

(N/C) DTR

2 - TX

20 - DTR

3 - RX

7 – GND

4 – RTS

5 – CTS

6 – DSR

RCU II COM 2

RS232 DB25 Connector

RX

CTS

TX

GND

DSR

(N/C) DCD

(N/C) RTS

(N/C) DTR

2 – TX

20 - DTR

3 – RX

7 – GND

4 – RTS

5 – CTS (N/C)

6 – DSR (N/C)

8 – DCD (N/C)

MultiLoad II/

Figure 4.10 Ticket Printer / Data Logger Connections without Handshake

Printer Logger RS232

When Print or Alibi Log is configured to be on COM 2, the CTS handshake line MUST be

connected or a printer error will occur, preventing loading.

A Special variant of the ticket printing uses the PTB protocol.

A PTB printer can be connected to the MultiLoad II/ RCU II via RS232 on COM 2 or COM1:

MultiLoad II/

Figure 4.11 PTB Printer Connection with Handshake

PTB Printer/ Logger

28

Page 38

COMMUNICATION SETUP COM (1) .

Baud Rate: 9600

Parity : Even

Data Bits : 7 Data

Stop Bits : 1 Stop

Multidrop Single

Type : PTB

Next Prev Exit Enter

29

Page 39

Caution: Disconnect from the supply circuit before opening the enclosure. Keep

this tightly closed when circuits are live.

Chapter

5

Chapter 5 Connecting Field Devices to the I/O Board

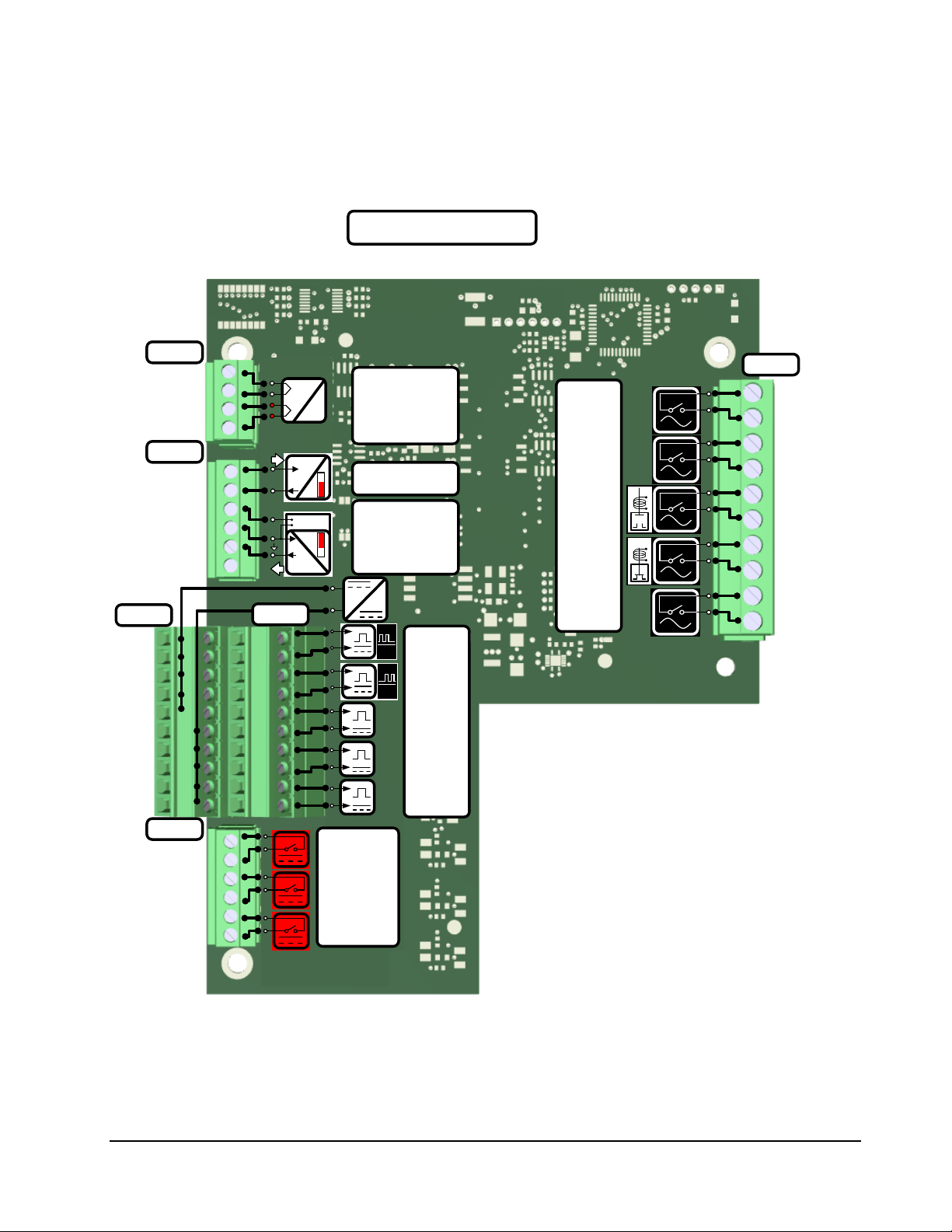

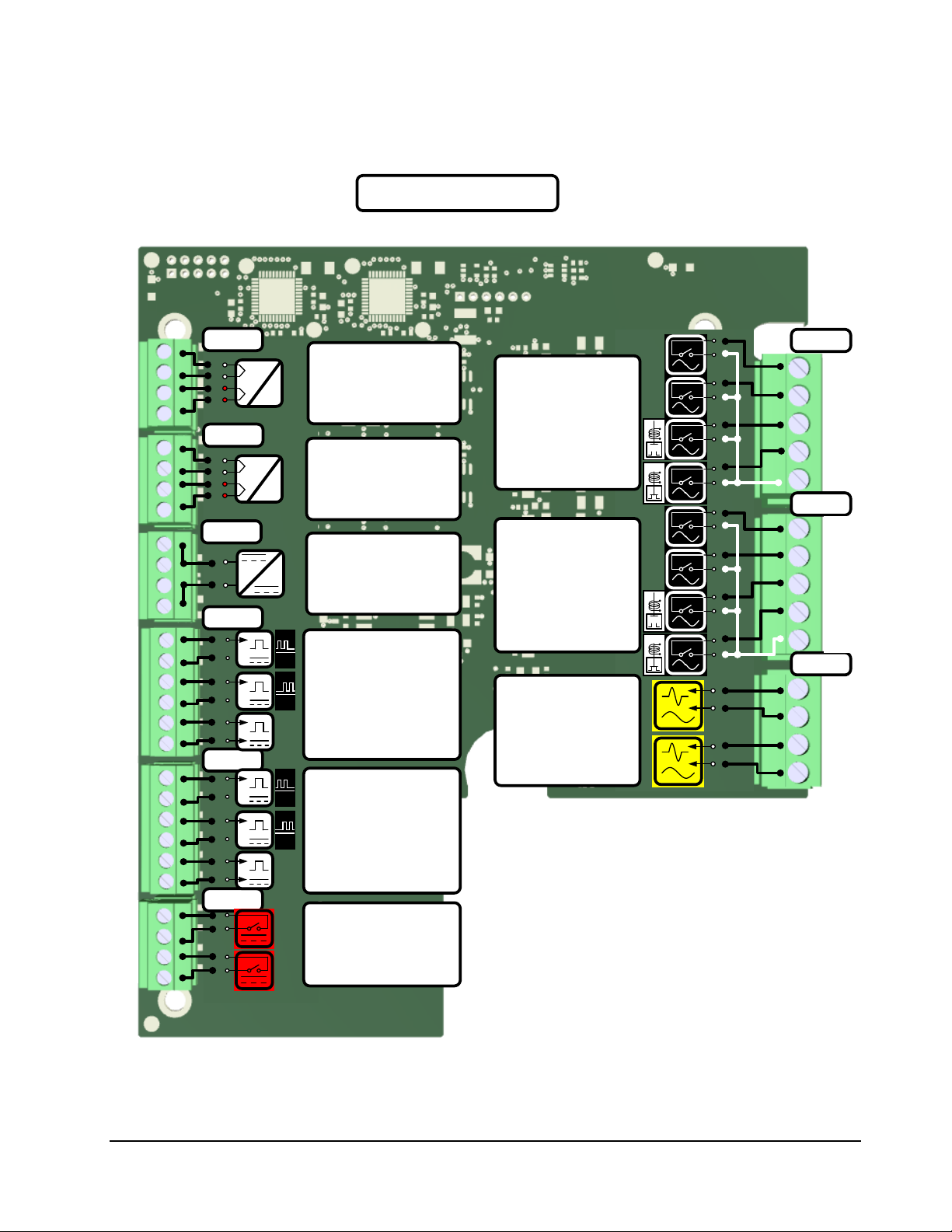

Two I/O board options are offered for use with the MultiLoad II. They are the Digital/ Analog I/O

Board and the 2 Meter I/O Board. They primarily differ in the number of I/O points, although the

latter can control two meters as its name implies. The RCU II only supports the Digital/ Analog I/O

Board. Figures 5.1 and 5.2 show the board’s terminal arrangements.

The 2 Meter I/O board treats its I/O in two groups corresponding to two different meters. In

the 2 Meter I/O wiring diagrams that follow, FCM 0 ports correspond to the first meter and

FCM 1ports correspond to the second meter. For more information, please consult the

MultiLoad II Users Guide.

Where to Find the Internal I/O Board 5.1

The I/O board is mounted above the Power Supply/Comm board. The I/O board is connected to

the Power Supply/Comm board at J4 & J5. Corresponding connections are on the bottom side of

the I/O board.

30

Page 40

TYPE I/O

DIGITAL/

ANALOG

2 METER

ELECTRICAL

CIRCUIT

I/O BOARD

I/O BOARD

RATING

SYMBOL

QUANTITY

QUANTITY

AC Outputs

5

8

12 - 250 Vac rms, 500 mA (per point),

TB1

AC Inputs

0

2

90 - 250Vac

DC Outputs

3

2

0 - 30 Vdc, 600 mA (per point), TB3

DC Inputs 5 6

5 - 30Vdc, TB2B

Dual Channel flow meter inputs (15000Hz)

Miscellaneous signal inputs

12Vdc

Source

167mA Max

Load

250mA Max

Load

Isolated Power Supply

Power for flow meter pulsers or preamp

RTD Input

1

2

100-ohm platinum, four wire

Coefficient 0.00385 Ohm/Ohm/°C

Analog

Input

1

0

4 - 20mA, 1.5V maximum burden

Analog

Output

1

0

4 - 20mA, Requires 12Vdc – 30Vdc

Supply

Available I/O Points per Board 5.2

The quantity and electrical ratings of the available I/O points per board are described in the table

below.

For easy recognition and use, a circuit symbol corresponding to its’ board is located in the last

column:

31

Page 41

TYPE I/O

CIRCUIT

SYMBOL

FUNCTION

AC Output

All AC outputs may be used as line voltage ON/ OFF control.

AC Output

If a digital valve control is used, PORT 2 is dedicated to control

the (N.O.) upstream solenoid.

AC Output

If a digital valve control is used, PORT 3 is dedicated to control

the (N.C.) downstream solenoid.

AC Output

S

1

If an additive injection control is used, the numbered AC output

must be paired with the corresponding numbered DC input.

DC Input

+

-

All DC inputs may be used as general digital signal inputs.

DC Input

+

-

A

0°

If a product meter pulser is used, PORT 4 is dedicated to the A

channel (single or optional quadrature).

DC Input

+

-

B

90°

If a product meter pulser is used, PORT 5 is dedicated to the B

channel (of optional quadrature).

DC Input

+

-

1

If an additive injection control is used, the numbered DC input

must be paired with the corresponding numbered AC output.

AC Input

L

N

All AC inputs may be used as line voltage digital inputs

(typically permissives).

DC Output

+

-

All DC outputs may be used as general digital outputs.

RTD Input

100Ω

°C

Pt

°F

The RTD input is reserved for MultiLoad temperature

compensation.

4-20 mA Analog

Input

i

4-20mA

%

The analog input can be used with configurable MultiLoad

inputs such as density, pressure, or temperature.

4-20 mA Analog

Output

i

4-20mA

%

(0 Vdc)

12-30 Vdc

The analog output can be used with configurable MultiLoad

outputs such as Analog Control Valve or Analog Pump.

Certain I/O circuit symbols have dedicated functions, which are described in the table below.

This list is not exhaustive, but contains those most frequently used:

32

Page 42

1

10

100Ω

°C

Pt

°F

+

+

+

-

+

+

+

-

+

-

5V

12V

TB2A

TB2B

TB1

1

6

TB3

1

6

TB6

1

4

TB4

10

1

IO_DA

RTD

4-20 mA IN

PORT 4

PORT 5

PORT 6

PORT 7

PORT 9

PORT 10

PORT 11

PORT 12

PORT 0

PORT 1

PORT 2

PORT 3

PORT 8

4-20 mA OUT

+

-

A

0°

+

-

B

90°

i

4-20mA

%

(0 Vdc)

12-30 Vdc

i

4-20mA

%

Terminal arrangements per Board 5.3

Digital Analog I/O Board (IO_DA)

5.3.1

Figure 5.1 Digital/ Analog I/O Board Terminal Block Assignments

33

Page 43

L

N

L

N

+

-

+

-

A

0°

+

-

B

90°

+

-

B

90°

+

-

5V

12V

100Ω

°C

Pt

°F

100Ω

°C

Pt

°F

1

6

TB4

5

1

TB5

TB6

TB7

TB8

TB9

TB3

TB2

TB1

+

-

+

-

A

0°

+

-

+

-

1

6

1

4

1

4

1

4

1

4

5

1

4

1

METER 0, RTD

METER 1, RTD

12 Vdc

METER 0, PORT 4

METER 0, PORT 5/6

METER 0, PORT 7

METER 1, PORT 4

METER 1, PORT 5/6

METER 1, PORT 7

METER 0, PORT 10

METER 1, PORT 10

METER 0, PORT 8

METER 1, PORT 8

METER 1, PORT 0

METER 1, PORT 1

METER 1, PORT 2

METER 1, PORT 3

LINE

METER 0, PORT 0

METER 0, PORT 1

METER 0, PORT 2

METER 0, PORT 3

LINE

IO_2M

2 Meter I/O Board (IO-2M)

5.3.2

Figure 5.2 2 Meter I/O Board Terminal Block Assignments

34

Page 44

How to Connect and Wire Field Devices to the I/O Boards 5.4

In this section of the chapter we will provide examples of commonly used devices that can get wired to

the I/O boards. This is not an exhaustive listing, but intended to provide you an example of how certain

types of I/O need to get wired into the various boards.

MultiLoad II Wiring Examples:

o Flow Meter and Control Valve

o Additive

o RTD

o Analog In & Analog Out

o AC Output Wiring

o AC Input Wiring

o DC Input Wiring: Permissives/Status

o DC Output Wiring

o 2 Output Air Eliminator Wiring

o Remote Display Wiring

RCUII Wiring Examples:

- DC Input Wiring

- AC: DC Output wiring

Typical Example:

- Typical single meter example

35

Page 45

L

N

15A

L

N

L

N

VCC

A

B

GND

B

A

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

PORT 2

PORT 5

PORT 4

&

PORT 3.IN/

PORT 3.OUT

PORT 2.OUT

LINE.IN

PORT 2.IN/

LINE.IN

PORT 3

+

-

A

0°

+

-

B

90°

+

-

5V

12V

PORT 4.+

IN 10

OUT 9

IN 8

OUT 7

IN 6

OUT 5

IN 4

OUT 3

IN 2

OUT 1

PORT 2

PORT 3

IO_DA TB1

PORT 0

PORT 1

PORT 8

PORT 0 OUT 5

PORT 1 OUT 4

PORT 2 OUT 3

PORT 3 OUT 2

LINE IN 1

IO_2M TB3

PORT 0 OUT 5

PORT 1 OUT 4

PORT 2 OUT 3

PORT 3 OUT 2

LINE IN 1

IO_2M TB2

+

1

-

2

+

3

()

-

4

()

+

5

-

6

+

7

-

8

+

9

-

10

IO_DA TB2B

PORT 4

PORT 5

PORT 6

PORT 7

PORT 9

+

1

+

2

+

3

+

4

+

5

-

6

-

7

-

8

-

9

-

10

IO_DA TB2A

12Vdc

+

1

-

2

+

3

()

-

4

()

+

5

-

6

IO_2M TB7

PORT 4

PORT 5

PORT 7

+ 1

+ 2

- 3

-

4

12Vdc

IO_2M TB6

+

1

-

2

+

3

()

-

4

()

+

5

-

6

IO_2M TB8

PORT 4

PORT 5

PORT 7

+ 1

+ 2

- 3

-

4

12Vdc

IO_2M TB6

PORT 4.-

PORT 5.+

PORT 5.-

Caution: Line voltage used to drive the Digital Valve Solenoids MUST be controlled by the Ground or Overfill monitor. In the event of a Ground loss or

Overfill detection, this voltage must be switched off to ensure a failsafe shutdown of the product flow.

MultiLoad II Flow Meter and Control Valve Wiring

5.4.1

36

Page 46

L

N

15A

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

PORT 1

PORT 3

PORT 2/

PORT 0.OUT

PORT 0.IN/

LINE.IN

PORT 0

S

1

S

2

S

3

S

4

+

L

N

S

#1

+

L

N

S

#2

+

L

N

S

#3

+

L

N

S

#4

IO_DA ONLY!

L

N

PORT 1.OUT

PORT 1.IN/

LINE.IN

IN 10

OUT 9

IN 8

OUT 7

IN 6

OUT 5

IN 4

OUT 3

IN 2

OUT 1

PORT 2

IO_DA TB1

PORT 0

PORT 1

PORT 3

PORT 8

PORT 0 OUT 5

PORT 1 OUT 4

PORT 2 OUT 3

PORT 3 OUT 2

LINE IN 1

IO_2M TB3

PORT 0 OUT 5

PORT 1 OUT 4

PORT 2 OUT 3

PORT 3 OUT 2

LINE IN 1

IO_2M TB2

PORT 3

PORT 2.OUT/

PORT 2.IN/

LINE.IN

PORT 3.OUT

PORT 3.OUT

PORT 3.IN

Note: The output port that is selected will dictate which port is used for the additive input. For example, if Port 0 is selected as the FCM Port#, the output will

be on port 0 and the corresponding input will be at port 7. See Table above for possible port assignments.

Output

Port

Input

Port

Injector #1 0 7

Injector #2 1 6

Injector #3 2 5

Injector #4 3 4

MultiLoad II Additive Wiring: Outputs

5.4.2

37

Page 47

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

PORT 4.+

PORT 4.-

PORT 5.+

PORT 5.-

+

-

1

PORT 4

+

-

2

+

-

3

+

-

4

+

L

N

S

#1

+

L

N

S

#2

+

L

N

S

#3

+

L

N

S

#4

PORT 5

PORT 6/

PORT 7

+

-

5V

12V

+

1

-

2

+

3

-

4

+

5

-

6

+

7

-

8

+

9

-

10

IO_DA TB2B

PORT 4

PORT 5

PORT 6

PORT 7

PORT 9

+

1

-

2

+

3

-

4

+

5

-

6

IO_2M TB7

PORT 4

PORT 5

PORT 7

+

1

-

2

+

3

-

4

+

5

-

6

IO_2M TB8

PORT 4

PORT 5

PORT 7

PORT 7

IO_DA ONLY!

PORT 7.+

PORT 7.-

PORT 6.+/

PORT 6.-/

PORT 7.+

PORT 7.-

+ 1

+ 2

- 3

-

4

IO_2M TB6

12Vdc

+ 1

+ 2

- 3

-

4

IO_2M TB6

12Vdc

+

1

+

2

+

3

+

4

+

5

-

6

-

7

-

8

-

9

-

10

12Vdc

IO_DA TB2A

~1 kΩ,

1/4W

~1 kΩ,

1/4W

~1 kΩ,

1/4W

~1 kΩ,

1/4W

12Vdc

*Note: Most additive injection meters only provide an Open-Collector (pull down) type output. Typically a 1,000 Ohm, ¼ watt pull-up resistor needs to be

added in the pulser junction box to pull this output to 12V+ when the output is off.

Note (I/O 2 METER Only): TB7 pins 3 and 4 can be configured as Port 5 or Port 6. It is only 1 port, but because of the logic in the firmware, it may be

necessary to address it as Port 5 or Port 6 in the configuration.

*

*

*

*

MultiLoad II Additive Wiring: Inputs

5.4.3

38

Page 48

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

RTD

RTD.V+

RTD

100Ω

°C

Pt

°F

100Ω

°C

Pt

°F

100Ω

°C

Pt

°F

α=0.00385

100 Ω

α=0.00385

100 Ω

α=0.00385

100 Ω

RTD

RTD.R+

RTD.RRTD.COM

RTD.V+

RTD.R+

RTD.RRTD.COM

RTD.V+

RTD.R+

RTD.RRTD.COM

V+ 1

R+ 2

R- 3

COM 4

IO_DA TB4

RTD

V+ 1

R+ 2

R- 3

COM 4

IO_2M TB5

RTD

V+ 1

R+ 2

R- 3

COM 4

IO_2M TB4

RTD

Note: All 4 wires MUST be run to the sensor. Do not simply jumper REF- to COM or REF+ to V+ at the FCM II. For 3-wire and 2 wire probes, the

connection of REF- to COM and REF+ to V+ should be as close as possible to the probe (within inches).

MultiLoad II Analog Wiring

5.4.4

5.4.4.1 RTD Wiring

39

Page 49

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

4-20 mA-IN

+

-

+

-

+

-

5V

12V

+

-

I+

4-20 mA

I-

V+

V-

I+

I-

+

-

4-20 mA

i

4-20mA

%

i

4-20mA

%

4-20 mA-IN

I+ 1

I- 2

V+ 1

COM 2

IOUT 3

N/A 4

4-20 mA

IN

4-20 mA

OUT

IO_DA TB6

4-20 mA IN.I+

4-20 mA IN.I-

4-20 mA IN.I+

4-20 mA IN.I-

4-20 mA OUT.I

4-20 mA OUT.GND

4-20 mA OUT.V+

4-20 mA OUT.I

4-20 mA OUT.V+

4-20 mA OUT.GND

I+ 1

I- 2

V+ 1

COM 2

IOUT 3

N/A 4

4-20 mA

OUT

IO_DA TB6

4-20 mA

IN

+

1

+

2

+

3

+

4

+

5

-

6

IO_DA TB2A

12Vdc

I-

I+

4-20 mA

I-

I+

4-20 mA

i

4-20mA

%

(0 Vdc)

12-30 Vdc

i

4-20mA

%

(0 Vdc)

12-30 Vdc

*Note: The 4-20 mA receiver does not contain a voltage source. The loop must be powered either by the transmitter or by an external power supply. The

I/O Board adds 75 Ohms to the loop.

*

*

‡Note: The 4-20mA output requires a power source (12-30vdc). The 12vdc output can be used as shown here.

12 – 30 Vdc

‡

‡

5.4.4.2 MultiLoad II 4 – 20 mA Wiring

40

Page 50

L

N

15A

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

PORT 1

PORT 0.IN/

PORT 0.OUT

PORT 1.OUT

LINE.IN

PORT 1.IN/

LINE.IN

PORT 0

L

N

N.O.

N.C.

C

PORT 3

PORT 2

PORT 8

PORT 0 OUT 5

PORT 1 OUT 4

PORT 2 OUT 3

PORT 3 OUT 2

LINE IN 1

IO_2M TB3

PORT 0 OUT 5

PORT 1 OUT 4

PORT 2 OUT 3

PORT 3 OUT 2

LINE IN 1

IO_2M TB2

IN 10

OUT 9

IN 8

OUT 7

IN 6

OUT 5

IN 4

OUT 3

IN 2

OUT 1

PORT 8

IO_DA TB1

PORT 0

PORT 1

PORT 2

PORT 3

IO_DA ONLY!

PORT 2.IN/

LINE.IN

PORT 3.IN/

LINE.IN

PORT 8.IN

PORT 2.OUT

PORT 3.OUT

PORT 8.OUT

COM

IN X

M

L

N

L

N

L

N

L

N

Note: This shows a typical configuration. AC outputs can be assigned to any unused AC output.

MultiLoad II AC Output Wiring

5.4.5

41

Page 51

L

N

15A

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

PORT 8

PORT 8.N

PORT 8.N

PORT 8.L

PORT 8.L

PORT 8

PORT 8

PORT 8.L

PORT 8.N

L 1

N 2

L 3

N 4

IO_2M TB1

PORT

1.8

L 1

N 2

L 3

N 4

IO_2M TB1

PORT

0.8

L

N

L

N

L

N

Note: This shows a typical configuration. AC Permissive/Status inputs can be assigned to any unused AC input.

MultiLoad II AC Input Wiring

5.4.6

42

Page 52

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

PORT 5

PORT 4.-

PORT 5.-

PORT 4.+

PORT 5.+

PORT 4

PORT 7

PORT 6

PORT 9

IO_DA ONLY!

PORT 6.+

PORT 7.+

PORT 9.+

PORT 6.-

PORT 7.-

PORT 9.-

+

1

-

2

+

3

-

4

+

5

-

6

+

7

-

8

+

9

-

10

IO_DA TB2B

PORT 4

PORT 5

PORT 6

PORT 7

PORT 9

+

1

-

2

+

3

-

4

+

5

-

6

PORT 5

PORT 7

IO_2M TB7

PORT 4

+

1

-

2

+

3

-

4

+

5

-

6

PORT 5

PORT 7

IO_2M TB8

PORT 4

IO_DA ONLY!

+

-

&

+

-

+

-

+

-

+

-

+

-

5 – 30 Vdc

M

L

N

L

N

Note: This shows a typical configuration. DC Permissive/Status inputs can be assigned to any unused DC input.

MultiLoad II DC Permissive/Status Wiring

5.4.7

43

Page 53

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

PORT 11

PORT 10.OUT/

PORT 11.OUT

PORT 10.IN/

PORT 11.IN

PORT 0.10

+

-

N.O.

N.C.

C

PORT 12

IO_DA ONLY!

PORT 12.IN

PORT 12.OUT

IO_DA ONLY!

M

+

-

N

+

-

5 – 30 Vdc

PORT 10.OUT/

PORT 10.IN/

PORT 1.10

+

-

+

-

+

-

+

-

IN 1

OUT 2

IN 3

OUT 4

IN 5

OUT 6

IO_DA TB3

PORT 10

PORT 11

PORT 12

COM

IN X

IN 1

OUT 2

IN 3

OUT 4

IO_2M TB9

PORT

0.10

IN 1

OUT 2

IN 3

OUT 4

IO_2M TB9

PORT

1.10

PORT 0.10.IN

PORT 1.10.OUT

PORT 1.10.IN

PORT 0.10.OUT

PORT 10/

PORT 10/

+

-

L

N

Note: This shows a typical configuration. DC outputs can be assigned to any unused DC output.

*Note: For I/O Board firmware v036 or greater, any DC output port can be configured as an output pulse.

*

MultiLoad II DC Output Wiring

5.4.8

44

Page 54

L

N

15A

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

PORT 2

&

PORT 3.IN/

PORT 3.OUT

PORT 2.OUT

LINE.IN

PORT 2.IN/

LINE.IN

PORT 3

IN 10

OUT 9

IN 8

OUT 7

IN 6

OUT 5

IN 4

OUT 3

IN 2

OUT 1

PORT 2

PORT 3

IO_DA TB1

PORT 0

PORT 1

PORT 8

PORT 0 OUT 5

PORT 1 OUT 4

PORT 2 OUT 3

PORT 3 OUT 2

LINE IN 1

IO_2M TB3

PORT 0 OUT 5

PORT 1 OUT 4

PORT 2 OUT 3

PORT 3 OUT 2

LINE IN 1

IO_2M TB2

L

N

L

N

N

L

1

2

3

Note: With only two states returned from the air eliminator, flow must be

completely stopped to purge air. To purge air by only slowing the rate, a 3

output air eliminator head must be used.

Note: When the level drops below Low, the power will be removed from the

digital valves, stopping flow before the air eliminator is completely drained.

MultiLoad II 2 Output Air Eliminator Wiring

5.4.9

45

Page 55

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

PORT 11/

PORT 0.10

+

-

5 – 28 Vdc

PORT 1.10

+

-

+

-

PORT 1.10.OUT

PORT 1.10.IN

PORT 11.OUT/

PORT 11.IN/

IN 1

OUT 2

IN 3

OUT 4

IN 5

OUT 6

IO_DA TB3

PORT 10

PORT 11

PORT 12

PORT 10/

PORT 0.10.OUT

PORT 0.10.IN

PORT 10.OUT/

PORT 10.IN/

IN 1

OUT 2

IN 3

OUT 4

IO_2M TB9

PORT

0.10

IN 1

OUT 2

IN 3

OUT 4

IO_2M TB9

PORT

1.10

≥ 500 mA

RESET

12 V COM

COUNT +

12 Vdc

Note: Use only model E1613. The Lectro Count +12Vdc, 12V common can be supplied by an external source.

Note (I/O DIGITAL/ ANALOG Only): Connect Port 10 to Lectro Count output pulse. Connect Port 11 to Lectro Count reset pulse.

Note (I/O 2 METER Only): Connect Port 0.10 to Lectro Count output pulse. Connect Port 1.10 to Lectro Count reset pulse.

5.4.10

MultiLoad II Lectro Count Remote Display Wiring

46

Page 56

VCC

A

B

GND

B

A

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

PORT 5

PORT 4

+

-

5V

12V

PORT 4.+

+

1

+

2

+

3

+

4

+

5

-

6

-

7

-

8

-

9

-

10

IO_DA TB2A

12Vdc

+ 1

+ 2

- 3

-

4

12Vdc

IO_2M TB6

+ 1

+ 2

- 3

-

4

12Vdc

IO_2M TB6

PORT 4.-

+

-

A

0°

+

1

-

2

+

3

-

4

+

5

-

6

IO_2M TB7

PORT 4

PORT 5

PORT 7

+

1

-

2

+

3

-

4

+

5

-

6

IO_2M TB8

PORT 4

PORT 5

PORT 7

+

1

-

2

+

3

-

4

+

5

-

6

+

7

-

8

+

9

-

10

IO_DA TB2B

PORT 4

PORT 5

PORT 6

PORT 7

PORT 9

12 Vdc

5.4.11

RCU II DC Input Wiring

47

Page 57

L

N

15A

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

PORT 1

PORT 0.IN/

PORT 0.OUT

PORT 1.OUT

LINE.IN

PORT 1.IN/

LINE.IN

PORT 0

PORT 0 OUT 5

PORT 1 OUT 4

PORT 2 OUT 3

PORT 3 OUT 2

LINE IN 1

IO_2M TB3

PORT 0 OUT 5

PORT 1 OUT 4

PORT 2 OUT 3

PORT 3 OUT 2

LINE IN 1

IO_2M TB2

IN 10

OUT 9

IN 8

OUT 7

IN 6

OUT 5

IN 4

OUT 3

IN 2

OUT 1

PORT 8

IO_DA TB1

PORT 0

PORT 1

PORT 2

PORT 3

L

N

N.O.

N.C.

C

N

L

L

N

L

N

Note: This shows a typical configuration. AC outputs can be assigned to any unused AC output.

5.4.12

RCU II AC Output Wiring

48

Page 58

I/O DIGITAL/

ANALOG

I/O 2 METER

METER 0 METER 1

PORT 10.OUT/

PORT 10.IN/

PORT 0.10

PORT 10.OUT/

PORT 10.IN/

PORT 1.10

+