M

M

u

ullttii

L

L

o

o

a

a

d

d IIII

C

C

o

o

m

m

m

m

u

u

n

nii

c

c

a

attii

o

o

n

n

s

s

G

G

u

uii

d

d

e

e

IInncclluuddiinngg::

M

MuullttiiLLooaadd IIII

M

MuullttiiLLooaadd IIII SS

M

MPP

M

MuullttiiLLooaadd IIII SSCCSS

M

MuullttiiLLooaadd IIII

M

Moobbiillee

Part # 6077

Firmware Version 3/4.31.38

February 2018

2

Copyright Notice

Copyright © 2000 – 2018 Toptech Systems, Inc.

The information contained in this document is proprietary and confidential. No part of this document may be copied, reproduced, or

transmitted in any medium without the express written permission of Toptech Systems, Inc.

Disclaimer

Toptech Systems assumes no responsibility for damages resulting from installation or use of its products. Toptech Systems will not be liable

for any claims of damage, lost data, or lost time as a result of using its products.

Logos are registered trademarks of Toptech Systems, Inc.

Copyright © 2000-2018 Toptech Systems, Inc. All Rights Reserved.

3

Table of Contents

CHAPTER 1 PROTOCOL SPECIFICATION ..................................................................................................... 7

1.1 DEFINITIONS ............................................................................................................................................ 7

1.2 SMITH PROTOCOL .................................................................................................................................... 8

1.3 BROOKS PROTOCOL ................................................................................................................................. 8

1.4 DANIELS PROTOCOL ................................................................................................................................. 8

1.5 MODBUS-RTU PROTOCOL ........................................................................................................................ 9

1.5.1 Read Holding Registers (fn=3) .......................................................................................................... 9

1.5.2 Write Single Registers (fn=6)............................................................................................................. 9

1.5.3 Loopback/Maintenance (fn=8) ......................................................................................................... 10

1.5.4 Preset Multiple Registers (fn=16) .................................................................................................... 10

1.5.5 Error Responses (fn= +128) ............................................................................................................ 10

1.5.6 Modbus Register Map Summary ..................................................................................................... 11

1.5.7 Extended Services Register ............................................................................................................ 11

1.6 MODBUS-TCP/IP PROTOCOL ................................................................................................................. 12

1.6.1 Read Holding Registers (fn=3) ........................................................................................................ 13

1.6.2 Write Single Registers (fn=6)........................................................................................................... 13

1.6.3 Loopback/Maintenance (fn=8) ......................................................................................................... 13

1.6.4 Preset Multiple Registers (fn=16) .................................................................................................... 13

1.6.5 Error Responses (fn= +128) ............................................................................................................ 14

1.6.6 Modbus Register Map Summary ..................................................................................................... 15

1.6.7 Extended Services Register ............................................................................................................ 15

CHAPTER 2 MULTILOAD COMMAND RESPONSES ................................................................................... 16

CHAPTER 3 QUERY COMMAND: .................................................................................................................. 18

CHAPTER 4 FUNCTION COMMANDS: .......................................................................................................... 19

CHAPTER 5 TERMINAL COMMANDS: .......................................................................................................... 21

5.1 TERMINAL ESCAPE COMMANDS:.............................................................................................................. 21

CHAPTER 6 METER COMMANDS: ................................................................................................................ 26

6.1 AUTHORIZE PRESET (PRODUCT AND PRESET VOLUME): ........................................................................... 26

6.2 CLEAR ALARMS: ..................................................................................................................................... 26

6.3 ENABLE PRESET .................................................................................................................................... 26

6.4 END TRANSACTION ................................................................................................................................. 26

6.5 BATCH COMPLETE .................................................................................................................................. 27

6.6 BATCH END:........................................................................................................................................... 27

6.7 END BATCH:........................................................................................................................................... 27

6.8 PRESET MESSAGE: ................................................................................................................................ 28

6.9 PROVING TRANSACTION MODE: .............................................................................................................. 28

6.10 REQUEST STATUS & PRESET ALARMS: .................................................................................................... 29

6.11 REQUEST TANK STATUS & TANK ALARMS: ............................................................................................... 52

6.12 REQUEST SAMPLER STATUS & SAMPLER ALARMS: .................................................................................. 60

6.13 REQUEST SMP STATUS & PRESET ALARMS: ........................................................................................... 69

6.14 TRIP PRESET ALARMS: ........................................................................................................................... 69

4

6.15 REQUEST BAY ALARMS: ......................................................................................................................... 70

6.16 REQUEST COMPONENT ALARMS: ............................................................................................................ 71

6.17 REQUEST METER ALARMS: ..................................................................................................................... 72

6.18 REQUEST ADDITIVE ALARMS: .................................................................................................................. 73

6.19 REQUEST SAMPLER ALARMS: ................................................................................................................. 74

6.20 REQUEST TANK ALARMS:........................................................................................................................ 75

6.21 REMOTE TRANSACTION DATA: ................................................................................................................ 76

6.22 START PRESET FLOW: ............................................................................................................................ 77

6.23 STOP PRESET FLOW: ............................................................................................................................. 77

CHAPTER 7 REGISTER OPERATIONS: ........................................................................................................ 78

7.1 GENERIC REGISTERS ............................................................................................................................. 79

7.1.1 Register Data Types ........................................................................................................................ 79

7.1.2 000 – RCU Level Configuration Registers ...................................................................................... 91

7.1.3 100 – Bay Level Configuration Registers ........................................................................................ 94

7.1.4 101 – Preset Level Configuration Registers .................................................................................... 95

7.1.5 102 – Meter Level Configuration Registers ..................................................................................... 99

7.1.6 103 – Component Level Configuration Registers .......................................................................... 103

7.1.7 104 – Additive Level Configuration Registers ............................................................................... 106

7.1.8 108 –Trace Level Configuration Registers .................................................................................... 108

7.1.9 110 –Network Level Configuration Registers ................................................................................ 108

7.1.10 111 –Tank Level Configuration Registers ................................................................................. 109

7.1.11 115 –Sampler Level Configuration Registers ........................................................................... 110

7.1.12 116 –Security Level Configuration Registers ............................................................................ 110

7.1.13 117 –Report Level Configuration Registers .............................................................................. 112

7.1.14 105 – Custom Logic Definitions Registers ................................................................................ 113

7.1.15 107 – Custom Logic Value Registers ........................................................................................ 128

7.1.16 200 – Stand Alone BOL Definition Registers ............................................................................ 128

7.1.17 800 – Transaction Archive Registers ........................................................................................ 132

7.2 SPECIAL PURPOSE REGISTERS ............................................................................................................. 134

7.2.1 000 – MultiLoad Firmware Version ................................................................................................ 134

7.2.2 001 – Date and Time ..................................................................................................................... 134

7.2.3 003 – FCM Poll Rate ..................................................................................................................... 135

7.2.4 005 – Current BOL/Ticket Number ................................................................................................ 135

7.2.5 070 – Ethernet Enable ................................................................................................................... 135

7.2.6 071 – IP Address ........................................................................................................................... 135

7.2.7 072 – IP Mask ................................................................................................................................ 135

7.2.8 073 – IP Gateway .......................................................................................................................... 135

7.2.9 074 – IP Host ................................................................................................................................. 136

7.2.10 076 – ADMIN PASSWORD ....................................................................................................... 136

7.2.11 077 – USER PASSWORD ........................................................................................................ 136

7.2.12 085 – Modem Initialization String .............................................................................................. 136

7.2.13 091..093 – Communication Port Parameters ............................................................................ 136

7.2.14 094 – 095 Network Printer Number Of Copies ......................................................................... 137

7.2.15 112 - Real-Time Preset Total Gross Totalizers ......................................................................... 137

7.2.16 113 - Real-Time Preset Total Net Totalizers ............................................................................. 138

5

7.2.17 114 - Real-Time Preset Total Mass Totalizers .......................................................................... 138

7.2.18 120 - Real-Time Sampler Total Gross Totalizers ...................................................................... 138

7.2.19 129 – FCM Low Level Meter Status .......................................................................................... 139

7.2.20 133 – FCM IO Access ............................................................................................................... 139

7.2.21 134 – Discrete Parameter Security settings .............................................................................. 140

7.2.22 135 – Group Parameter Security settings ................................................................................. 140

7.2.23 136 – Access Parameter Security settings ............................................................................... 141

7.2.24 140 –Current Latitude/Longitude position Registers (MultiLoad Mobile Only) ......................... 142

7.2.25 141 – Current Transaction Latitude/Longitude/Site Index Registers (MultiLoad Mobile Only) . 142

7.2.26 400 - Preset Definition Registers .............................................................................................. 142

7.2.27 401 – External Preset Display Register .................................................................................... 143

7.2.28 402 – Tank Definition Register .................................................................................................. 143

7.2.29 500 - Product Definition Registers ............................................................................................ 144

7.2.30 600 - Standalone Driver Card Database ................................................................................... 144

7.2.31 605 Modbus Device Database .................................................................................................. 145

7.2.32 650 –GPS Site Database (MultiLoad Mobile Only) ................................................................... 145

7.2.33 700 - Configurable Language Prompts ..................................................................................... 146

7.2.34 710 - Bay Alarm Messages ....................................................................................................... 147

7.2.35 711 - Preset Alarm Messages ................................................................................................... 149

7.2.36 712 - Meter Alarm Messages .................................................................................................... 151

7.2.37 713 - Component Alarm Messages ........................................................................................... 153

7.2.38 714 - Additive Alarm Messages ................................................................................................ 155

7.2.39 716 - SamplerAlarm Messages ................................................................................................. 157

7.2.40 715 - TankAlarm Messages ...................................................................................................... 158

7.2.41 910 – Read Event Log Message Queue ................................................................................... 160

7.2.42 912 – Read W & M Change Log Message Queue .................................................................... 160

7.2.43 913 – Read AUDIT Log Message Queue ................................................................................. 160

7.2.44 950 - Current Driver Card Number ............................................................................................ 161

7.2.45 951..955 - Current Driver Prompt Information ........................................................................... 161

7.2.46 960 – Input Data ........................................................................................................................ 161

7.2.47 961 – Input Data Terminating Key ............................................................................................ 161

7.2.48 962 - Current Driver Card Data ................................................................................................. 162

7.2.49 998 – Bitmap Graphic Cache .................................................................................................... 163

CHAPTER 8 COMMUNICATION TRACE EXAMPLE ................................................................................... 164

8.1 STARTUP OF HOST SOFTWARE ............................................................................................................. 164

8.1.1 Update Date & Time ...................................................................................................................... 164

8.1.2 Update Product Definitions ............................................................................................................ 164

8.1.3 Update Preset Definitions .............................................................................................................. 165

8.1.4 Status Query .................................................................................................................................. 165

8.2 TRANSACTION AUTHORIZATION ............................................................................................................. 166

8.2.1 Process Driver Card In .................................................................................................................. 166

8.2.2 Authorize a Transaction on MultiLoad ........................................................................................... 167

8.2.3 Reading Totalizers ......................................................................................................................... 167

8.3 BATCH AUTHORIZATION ........................................................................................................................ 168

8.3.1 Authorize a Batch on MultiLoad ..................................................................................................... 168

6

8.3.2 Monitor Load During Delivery ........................................................................................................ 170

8.4 END OF BATCH PROCESSING ................................................................................................................ 170

8.4.1 Ending a Batch on MultiLoad ......................................................................................................... 170

8.5 END OF TRANSACTION PROCESSING ..................................................................................................... 171

8.5.1 Ending a Transaction on MultiLoad ............................................................................................... 171

8.6 SHUTDOWN OF HOST SOFTWARE .......................................................................................................... 171

CHAPTER 9 DATA COMMUNICATION NOTES AND RECOMMENDATIONS ........................................... 172

9.1 PROTOCOL SELECTION: RS-232 VS. RS-485 ........................................................................................ 172

9.1.1 RS-232 ........................................................................................................................................... 172

9.1.2 RS-485 ........................................................................................................................................... 172

9.2 CABLE SELECTION................................................................................................................................ 172

9.3 LINE TERMINATION IN MULTI-DROPPED COMMUNICATIONS ..................................................................... 172

9.4 OPTICAL ISOLATION .............................................................................................................................. 173

9.5 SHIELD GROUNDING ............................................................................................................................. 173

CHAPTER 10 PARAMETER ACCESS SECURITY .................................................................................... 174

10.1 UNDERSTANDING NEW USER AND SECURITY FEATURES ......................................................................... 174

Chapter 1 – Protocol Specification

7

CHAPTER 1 PROTOCOL SPECIFICATION

The MultiLoad auto-detects four low level computer protocols for host communications.

- Smith Protocol

- Brooks Protocol

- Daniels

- Modbus-RTU Protocol

- Modbus- TCP/IP Protocol

Note: All unknown or not allowed signal or code sequences are rejected and have no impact on the

software or measurement data.

Host communication can occur via multi-dropped RS-232/RS-485 serial on COM 1 or Ethernet 10/100 socket

communication on port 7734. Port 7735 supports SSL encryption (TLS v1.2 only for security reasons) and can

be enabled via the network setup screen.

1.1 DEFINITIONS

The non-printing characters that form the skeleton of the Smith and Brooks protocols are standard ASCII

(American Standard Code Information Interchange):

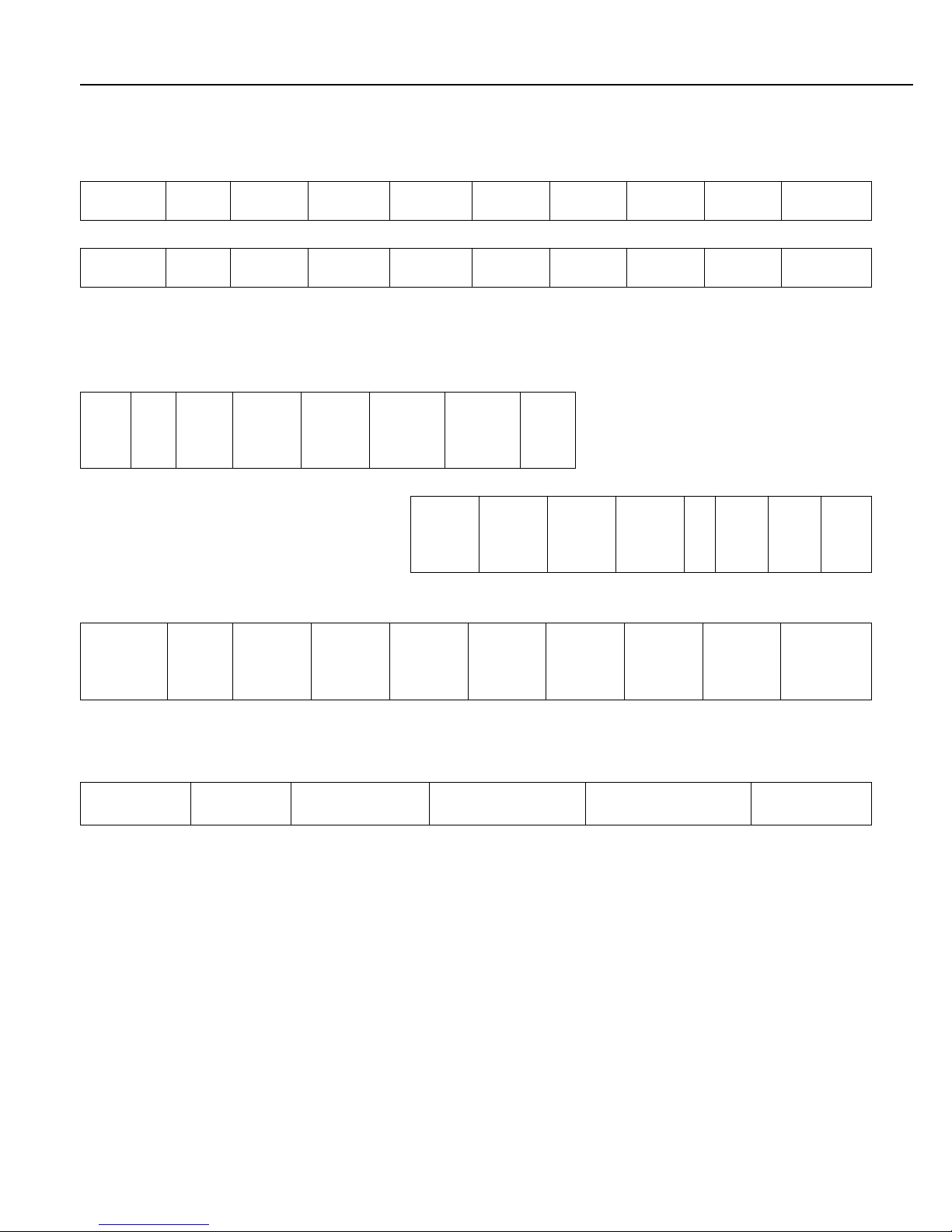

ASCII CHARACTER

DECIMAL

HEX

BINARY

NUL

0 0 00000000

STX

2 2 00000010

ETX

3 3 00000011

SOH

1 1 00000001

PAD

127

7F

01111111

CHARACTER

DESCRIPTION

BCC

Block Check Characters. The ASCII hex representation of the binary sum of all

the data in the message from the SOH through the ETX character.

LRC

Longitudinal Redundancy Check. The LRC is an ASCII character computed as

the exclusive or (XOR) sum of all characters following the STX and including

the ETX.

CRC

Cyclic Redundancy Check.

A1..A3

A 3-character ASCII unit address of the MultiLoad. Please refer to the

MultiLoad User Guide for configuring the unit address.

D1..Dn

Data field characters.

Fn

Function field code.

Adr

A single character binary unit address of the MultiLoad.

Chapter 1 – Protocol Specification

8

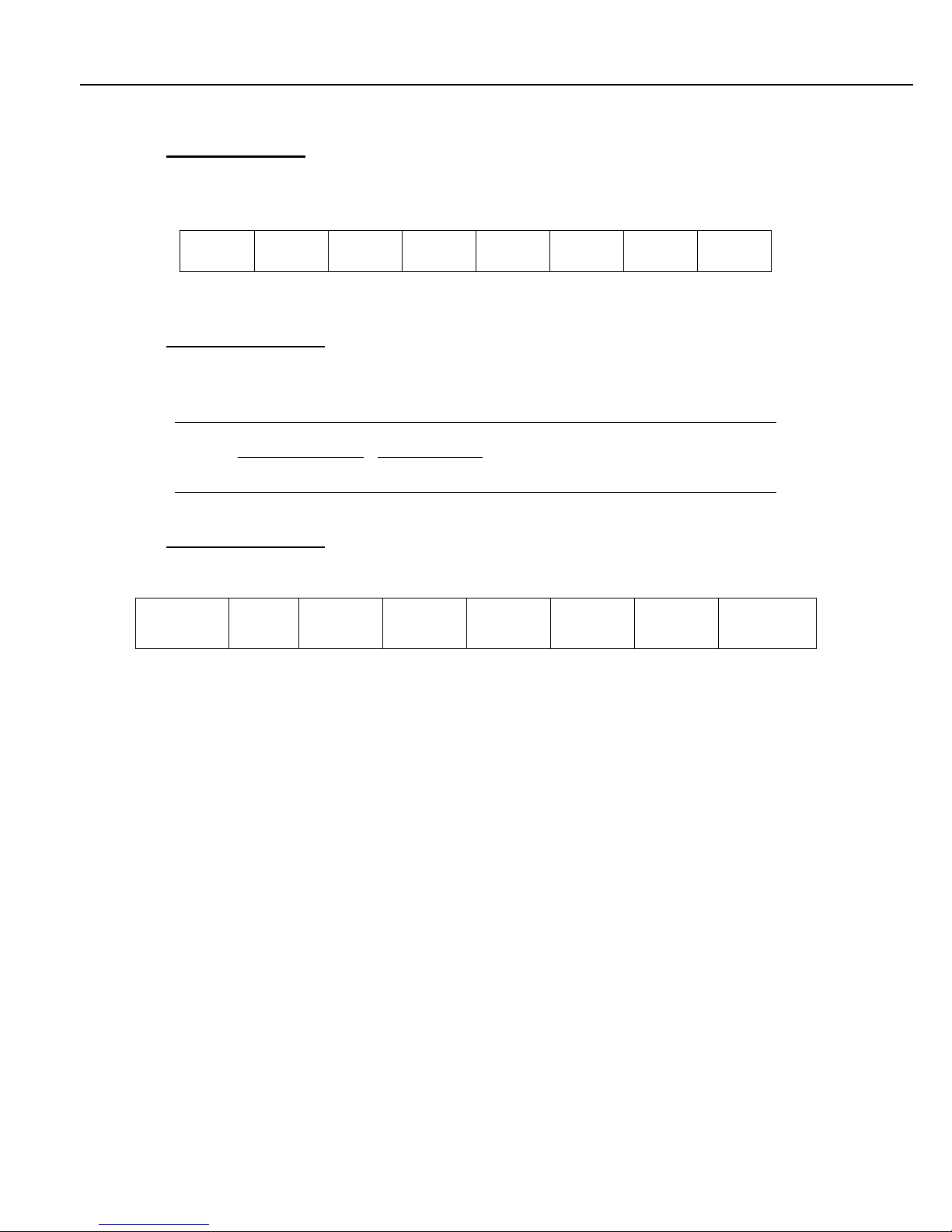

1.2 SMITH PROTOCOL

The Smith protocol is compatible with devices from Smith Meter, such as the Accuload I and Accuload II minicomputer modes of operation. Using this protocol, MultiLoad accepts data in the format:

NUL

STX

A1

A2

data

ETX

LRC

PAD

A1 and A2 are the last two digits of the unit address in the RCU configuration.

1.3 BROOKS PROTOCOL

The Brooks protocol is compatible with devices from Brooks Instruments such as their Petrocount RAU™ and

IMS Control™ units running in computer mode. Using this protocol, MultiLoad accepts data in the format:

SOH

DESTINATION SOURCE

A1 A2 A3 S1 S2 S3

STX data ETX

BCC1BCC

2

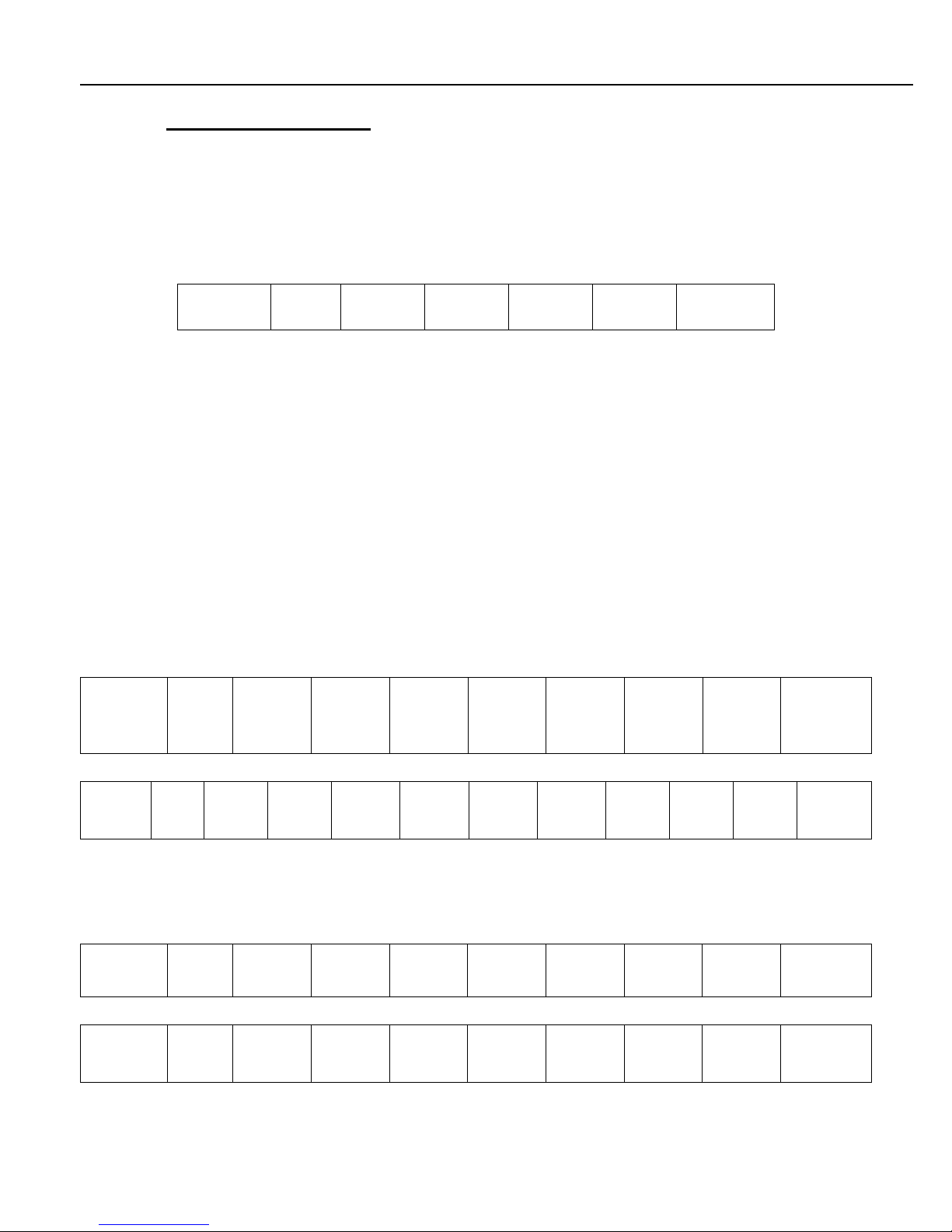

1.4 DANIELS PROTOCOL

The Daniels protocol is compatible with devices from Daniels Flow Products. Using this protocol, MultiLoad

accepts and responds with data in the format:

Quiet

Time

ADR

FN

LEN

(2 – 252)

D1...DN

CRC1

CRC2

Quiet

Time

Daniels protocol messages are framed by a quiet time of three and one-half characters.

ADR is binary character of the address of the MultiLoad. Typically 0x01.

Fn is expected to be 0x41/0x42 alternating on each command. Responses will have Fn as 0x41/0x42

for normal responses and 0xc1/0xc2 for exception responses.

D1…Dn is string data containing the commands listed in this manual.

Note: Modbus extension to return larger packet sizes: On messages with data packet sizes from 2 to 252

characters the Fn values of 0x41/0x42 will be returned. With messages outside this range, Fn will be the MSB

value of the data size and the Len will be LSB of the data size.

For Example:

Fn = 0x41, Len = 0x80, when data packet size = 0x0080,

Fn = 0x42, Len = 0x80, when data packet size = 0x0080,

Fn = 0x00, Len = 0xFF, when data packet size = 0x00FF ( 255),

Fn = 0x01, Len = 0x00, when data packet size = 0x0100 ( 256),

Fn = 0x01, Len = 0x01, when data packet size = 0x0101 ( 257),

Fn = 0x02, Len = 0x00, when data packet size = 0x0200 ( 512),

Fn = 0x04, Len = 0x00, when data packet size = 0x0400 (1024),

Fn = 0x08, Len = 0x00, when data packet size = 0x0800 (2048).

Chapter 1 – Protocol Specification

9

1.5 MODBUS-RTU PROTOCOL

The Modbus-RTU protocol has been implemented to be as compatible as possible with the original published

Modicon Modbus-RTU standard.

Note: The Modbus protocol allows parameter register access only as defined by the explicit mapping in

this manual. To send the ASCII commands (R000, T`A, MAM, MRS, etc.) that are handled by the other

three protocols, the Modbus Extended Services registers must be used.

Using the Modbus protocol, MultiLoad accepts data in the following format:

Quiet

Time

ADR

FN

...

CRC1

CRC2

Quiet

Time

Modbus-RTU protocol messages are framed by a quiet time of three and one-half characters.

ADR is binary character of the address of the MultiLoad. Typically 0x01.

Fn is the Modbus function. Functions implemented are as follows.

The formal specification of Modbus lists the starting Holding Register address as 40001. The Modbus

Holding Register functions (Fn 3, 6 and 16) all have an implied 4XXXX reference. Referencing Holding

Register 40001 is addressed as register 0000 in the register address field in the message for fn 3, 6, and

16.

Since Modbus addressing has been implemented in various ways over the years, to avoid confusion in

this manual, the Modbus Holding Register addresses listed are the value in the register address field in

the message. If it is necessary to know the formal Modbus Holding Register address, simply add 40001

to the register addresses listed in the manual.

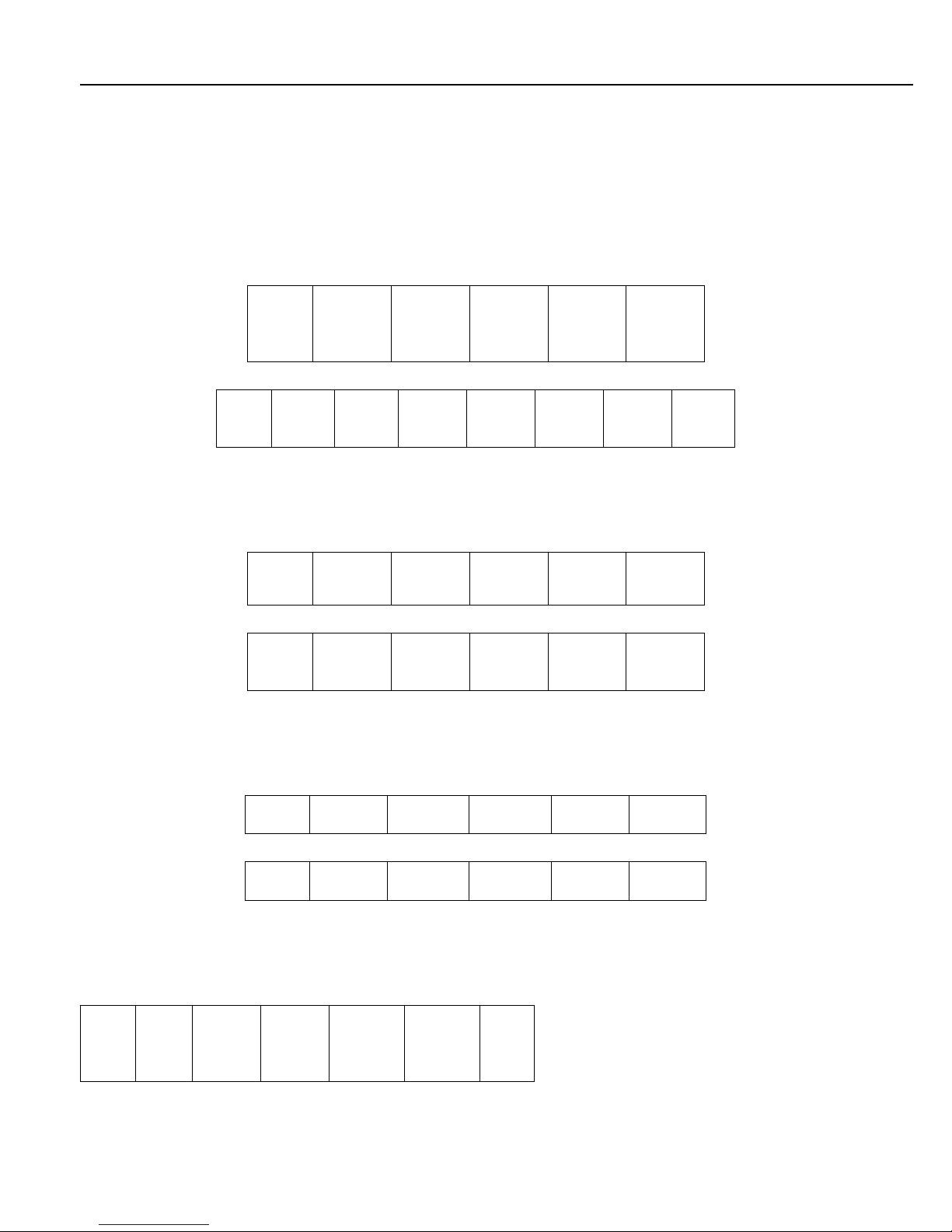

1.5.1 READ HOLDING REGISTERS (FN=3)

Note: Both Modbus registers MUST be read at the same time when reading 32-bit values.

Tx:

Quiet Time

ADR

FN=3

Start

Register

MSB

Start

Register

LSB

Number

Of

Registers

MSB

Number

of

Registers

LSB

CRC1

CRC2

Quiet Time

Rx:

Quiet

Time

ADR

FN=3

(+128 if

error)

Byte

Count

1st

Register

MSB

1st

Register

LSB

Next

Register

MSB

Next

Register

MSB

…

CRC1

CRC2

Quiet

Time

1.5.2 WRITE SINGLE REGISTERS (FN=6)

Note: cannot be used for 32-bit registers.

Tx:

Quiet Time

ADR

FN=6

Start

Register

MSB

Start

Register

LSB

Register

MSB

Register

LSB

CRC1

CRC2

Quiet Time

Rx:

Quiet Time

ADR

FN=6

(+128 if

error)

Start

Register

MSB

Start

Register

LSB

Register

MSB

Register

LSB

CRC1

CRC2

Quiet Time

Chapter 1 – Protocol Specification

10

1.5.3 LOOPBACK/MAINTENANCE (FN=8)

Note: only loopback of command supported.

Tx:

Quiet Time

ADR

FN=8

Diagnostic

Code MSB

Diagnostic

Code LSB

Data MSB

Data LSB

CRC1

CRC2

Quiet Time

Rx:

Quiet Time

ADR

FN=8

Diagnostic

Code MSB

Diagnostic

Code LSB

Data MSB

Data LSB

CRC1

CRC2

Quiet Time

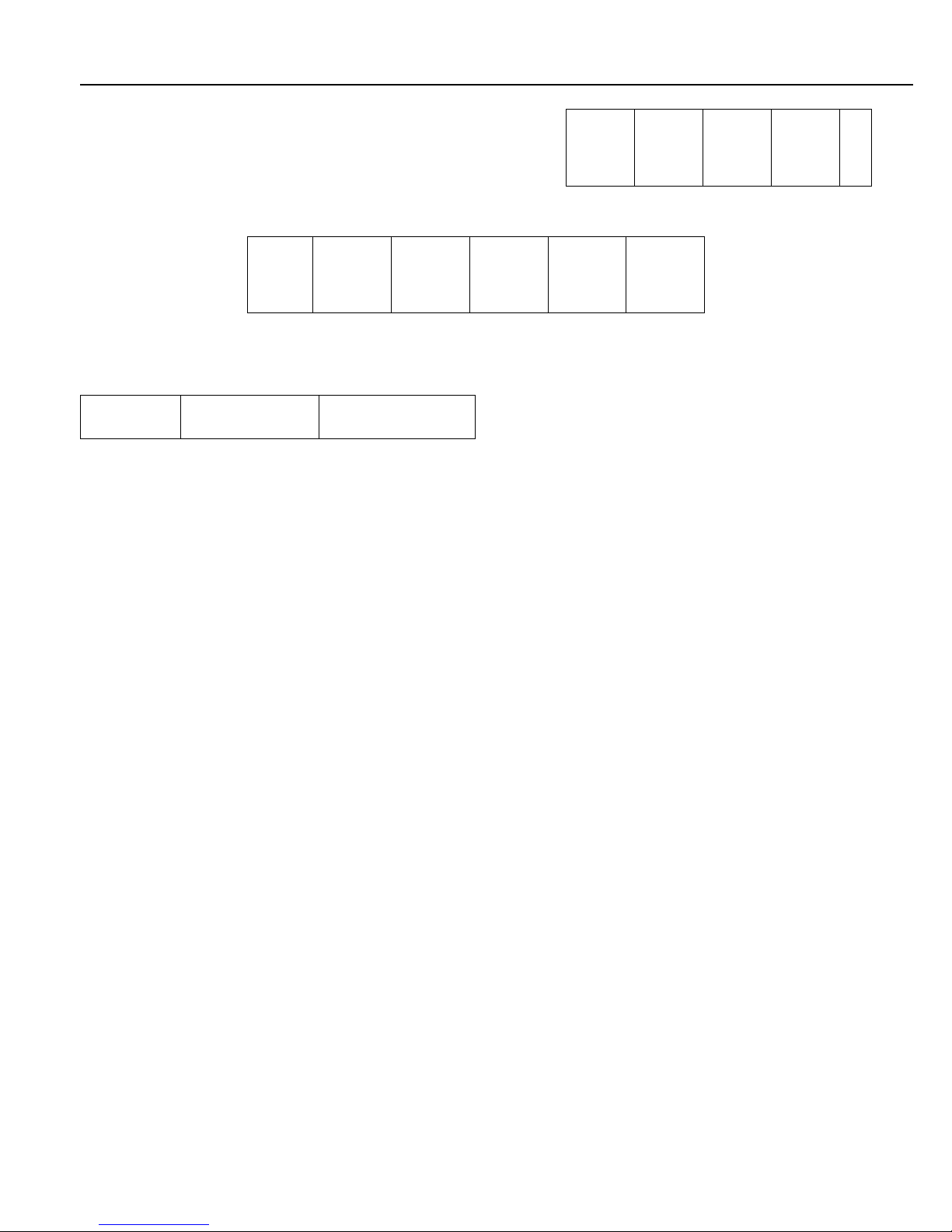

1.5.4 PRESET MULTIPLE REGISTERS (FN=16)

Note: Both Modbus registers MUST be written at the same time when writing 32-bit values.

Tx:

Quiet

Time

ADR

FN=16

Start

Register

MSB

Start

Register

LSB

Number

Of

Registers

MSB

Number

of

Registers

LSB

Byte

Count

1st

Register

MSB

1st

Register

LSB

Next

Register

MSB

Next

Register

MSB

…

CRC1

CRC2

Quiet

Time

Rx:

Quiet Time

ADR

FN=16

(+128 if

error)

Start

Register

MSB

Start

Register

LSB

Number

Of

Registers

MSB

Number

of

Registers

LSB

CRC1

CRC2

Quiet Time

1.5.5 ERROR RESPONSES (FN= +128)

Rx:

Quiet Time

ADR

FN+128

Error

Subcode

CRC2

CRC1

Error Sub codes are:

1 = Invalid Function Code. Indicates that the use of an invalid or unimplemented function has been

attempted.

2 = Invalid Address Field. Indicates that a read or write was made to an invalid address. Can also

indicate that a read or write to a single register of a 32-bit value has been attempted.

3 = Invalid Data Field. Indicates that an attempt to write an invalid value to a register has occurred.

This error code will also be returned if an attempt is made to change a value under Weights and Measures

control without with W&M switch being in the active state.

4 = Query Processing Failure. This code is not returned.

Chapter 1 – Protocol Specification

11

1.5.6 MODBUS REGISTER MAP SUMMARY

1 – 999 General, BOL Template, Misc. Configurations.

1000 – 1199 RCU Configurations

1200 – 1399 Bay Configurations

1400 – 1599 Preset Configurations

1600 – 1799 Meter Configurations

1800 – 1999 Component Configurations

2000 – 2199 Additive Configurations

2200 – 2999 Product, Alarm, Database, Misc. Configurations

3000 – 3999 Totalizers

4000 – 6000 Preset, Meter, Component and Additive Status

7000 – 7799 Status, Authorization Control and Alarms

7800 – 7999 Transaction Archive

8000 – 8999 Preset Definitions

9000-10999 Extended Services Register

Note: Tank and Sampler level is not available at the moment for Modbus. Use the custom logic mapping

tool for this.

1.5.7 EXTENDED SERVICES REGISTER

Not all commands native to the MultiLoad II have corresponding mapping to Modbus registers. The Extended

Services register was implemented as a way to support sending and receiving native Multiload II commands

across the Modbus RTU interface. Any native command listed can be sent to the MultiLoad via the extended

Services Register.

Modbus Registers:

Write Holding Register=9000, Len=1, 16-Bit Integer (Command Length)

Write Holding Register=9001, Max Len=999, Characters (Command Text)

Read Holding Register=9000, Len=2, 32-Bit Integer (Reply Length)

Read Holding Register=9001, Max Len=999, Characters (Reply Text)

Perform the following operations to use of the Extended Services Register:

1. Write the Command Length into the Holding Register 9000 (max value of 999 characters).

2. Write the Command Text into the Holding Register 9001 (max length of 999).

3. Command will execute when the final character of the Command Text is written (9001+Command

Length-1).

4. Read the Reply Length from the Holding Register 9000 (max value of 999 characters).

5. Read the Reply Text from the Holding Register 9001 (max length of 999).

Steps 1 & 2 can be done with a single Modbus Function 16.

Steps 4 & 5 can be done with a single Modbus Function 3.

Chapter 2 –MultiLoad Responses

12

1.6 MODBUS-TCP/IP PROTOCOL

The Modbus-TCP/IP protocol has been implemented to be as compatible as possible with the original published

Modbus-TCP/IP standard v1.0b.

Note: The Modbus protocol allows parameter register access only as defined by the explicit mapping in

this manual. To send the ASCII commands (R000, T`A, MAM, MRS, etc.) that are handled by the other

three protocols, the Modbus Extended Services registers must be used.

Using the Modbus tcp/ip-protocol, MultiLoad accepts data in the following format:

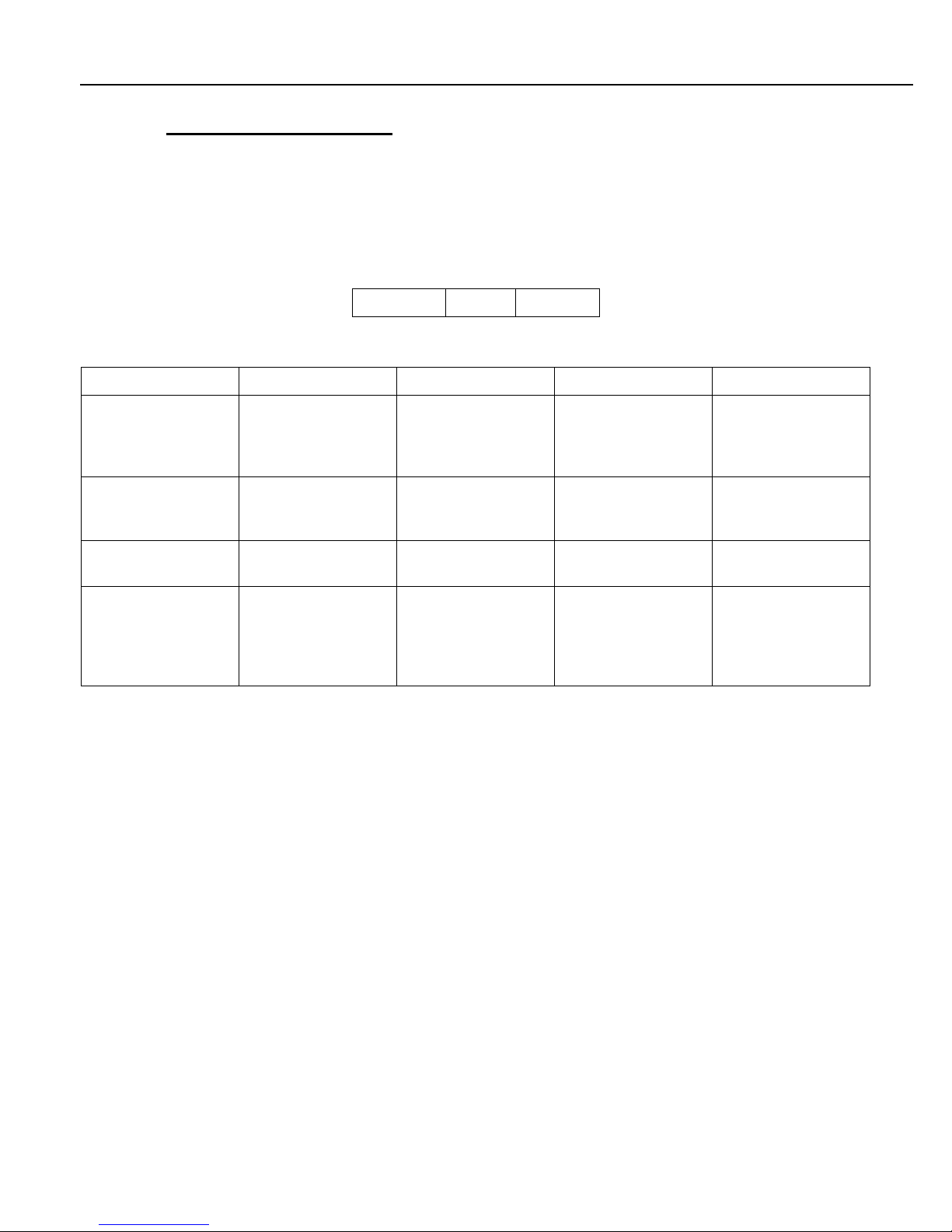

MBAP

FN

DATA

Modbus-TCP/IP protocol messages are framed by a MBAP-Header.

Fields

Length

Description

Client

Server

Transaction

Identifier

2 Bytes

Identification of a

MODBUS Request/

Response

transaction.

Initialized by the

client

Recopied by the

server from the

received request

Protocol Identifier

2 Bytes

0 = Modbus

Protocol

Initialized by the

client

Recopied by the

server from the

received request

Length

2 Bytes

Number of following

bytes

Initialized by the

client (request)

Initialized by the

server (Response)

Unit Identifier

1 Byte

Identification of a

remote slave

connected on a

serial line or on

other buses

Initialized by the

client

Recopied by the

server from the

received request

The header is 7 bytes long:

Transaction Identifier - It is used for transaction pairing, the MODBUS server copies in the response the

transaction identifier of the request.

Protocol Identifier – It is used for intra-system multiplexing. The MODBUS protocol is identified by the value 0.

Length - The length field is a byte count of the following fields, including the Unit Identifier and data fields.

Unit Identifier – This field is used for intra-system routing purpose. It is typically used to communicate to a

MODBUS+ or a MODBUS serial line slave through a gateway between an Ethernet TCP-IP network and a

MODBUS serial line. This field is set by the MODBUS Client in the request and must be returned with the same

value in the response by the server.

All MODBUS/TCP ADU are sent via TCP to registered port 502.

Remark : the different fields are encoded in Big-endian.

Fn is the Modbus function. Functions implemented are as follows.

The formal specification of Modbus lists the starting Holding Register address as 40001. The Modbus

Holding Register functions (Fn 3, 6 and 16) all have an implied 4XXXX reference. Referencing Holding

Register 40001 is addressed as register 0000 in the register address field in the message for fn 3, 6, and

16.

Chapter 2 –MultiLoad Responses

13

Since Modbus addressing has been implemented in various ways over the years, to avoid confusion in

this manual, the Modbus Holding Register addresses listed are the value in the register address field in

the message. If it is necessary to know the formal Modbus Holding Register address, simply add 40001

to the register addresses listed in the manual.

1.6.1 READ HOLDING REGISTERS (FN=3)

Note: Both Modbus registers MUST be read at the same time when reading 32-bit values.

Tx:

MBAP

FN=3

Start

Register

MSB

Start

Register

LSB

Number

Of

Registers

MSB

Number

of

Registers

LSB

Rx:

MBAP

FN=3

(+128 if

error)

Byte

Count

1st

Register

MSB

1st

Register

LSB

Next

Register

MSB

Next

Register

MSB

…

1.6.2 WRITE SINGLE REGISTERS (FN=6)

Note: cannot be used for 32-bit registers.

Tx:

MBAP

FN=6

Start

Register

MSB

Start

Register

LSB

Register

MSB

Register

LSB

Rx:

MBAP

FN=6

(+128 if

error)

Start

Register

MSB

Start

Register

LSB

Register

MSB

Register

LSB

1.6.3 LOOPBACK/MAINTENANCE (FN=8)

Note: only loopback of command supported.

Tx:

MBAP

FN=8

Diagnostic

Code MSB

Diagnostic

Code LSB

Data MSB

Data LSB

Rx:

MBAP

FN=8

Diagnostic

Code MSB

Diagnostic

Code LSB

Data MSB

Data LSB

1.6.4 PRESET MULTIPLE REGISTERS (FN=16)

Note: Both Modbus registers MUST be written at the same time when writing 32-bit values.

Tx:

MBAP

FN=16

Start

Register

MSB

Start

Register

LSB

Number

Of

Registers

MSB

Number

of

Registers

LSB

Byte

Count

Chapter 2 –MultiLoad Responses

14

1st

Register

MSB

1st

Register

LSB

Next

Register

MSB

Next

Register

MSB

…

Rx:

MBAP

FN=16

(+128 if

error)

Start

Register

MSB

Start

Register

LSB

Number

Of

Registers

MSB

Number

of

Registers

LSB

1.6.5 ERROR RESPONSES (FN= +128)

Rx:

MBAP

FN+128

Error

Subcode

Error Sub codes are:

1 = Invalid Function Code. Indicates that the use of an invalid or unimplemented function has been

attempted.

2 = Invalid Address Field. Indicates that a read or write was made to an invalid address. Can also

indicate that a read or write to a single register of a 32-bit value has been attempted.

3 = Invalid Data Field. Indicates that an attempt to write an invalid value to a register has occurred.

This error code will also be returned if an attempt is made to change a value under Weights and Measures

control without with W&M switch being in the active state.

4 = Query Processing Failure. This code is not returned.

Chapter 2 –MultiLoad Responses

15

1.6.6 MODBUS REGISTER MAP SUMMARY

1 – 999 General, BOL Template, Misc. Configurations.

1000 – 1199 RCU Configurations

1200 – 1399 Bay Configurations

1400 – 1599 Preset Configurations

1600 – 1799 Meter Configurations

1800 – 1999 Component Configurations

2000 – 2199 Additive Configurations

2200 – 2999 Product, Alarm, Database, Misc. Configurations

3000 – 3999 Totalizers

4000 – 6000 Preset, Meter, Component and Additive Status

7000 – 7799 Status, Authorization Control and Alarms

7800 – 7999 Transaction Archive

8000 – 8999 Preset Definitions

9000-10999 Extended Services Register

1.6.7 EXTENDED SERVICES REGISTER

Not all commands native to the MultiLoad II have corresponding mapping to Modbus registers. The Extended

Services register was implemented as a way to support sending and receiving native Multiload II commands

across the Modbus TCP/IP interface. Any native command listed can be sent to the MultiLoad via the extended

Services Register.

Modbus Registers:

Write Holding Register=9000, Len=1, 16-Bit Integer (Command Length)

Write Holding Register=9001, Max Len=999, Characters (Command Text)

Read Holding Register=9000, Len=2, 32-Bit Integer (Reply Length)

Read Holding Register=9001, Max Len=999, Characters (Reply Text)

Perform the following operations to use of the Extended Services Register:

6. Write the Command Length into the Holding Register 9000 (max value of 999 characters).

7. Write the Command Text into the Holding Register 9001 (max length of 999).

8. Command will execute when the final character of the Command Text is written (9001+Command

Length-1).

9. Read the Reply Length from the Holding Register 9000 (max value of 999 characters).

10. Read the Reply Text from the Holding Register 9001 (max length of 999).

Steps 1 & 2 can be done with a single Modbus Function 16.

Steps 4 & 5 can be done with a single Modbus Function 3.

Chapter 2 –MultiLoad Responses

16

CHAPTER 2 MULTILOAD COMMAND RESPONSES

<command_status> <rcu_status> <card_status> <command specific response data>

For MultiLoad to acknowledge a message two conditions must be met. First the message must fit the Message

Framing Protocol with a valid LRC, BCC or CRC. Second, the address specified in the first two characters of

the command must match the configured MultiLoad address. Any message that satisfies both of these

requirements will be sent a response.

Modbus:

If using the Modbus protocol, the Modbus Extended Services Registers must be used to pass in

these ASCII string commands.

The first three characters of every response will contain command, RCU and card status data as defined below.

enum

{

VALID_COMMAND = ‘0’,

INVALID_PARAMETER = ‘1’,

INVALID_COMMAND = ‘2’

} command_status;

enum

{

IDLE = '0',

AUTH_BAY = 4',

MENU_MODE = '9',

DIAG_MODE = '%',

AUTHORIZING_LOAD = 'A',

LOAD_AUTHORIZED = 'B',

COMPLETING_LOAD = 'C',

TRANSACTION_DONE = 'D',

TRANSACTION_CANCEL = 'E',

PULLING_TRANSACTION = 'P',

ARCHIVING_TRANSACTION = 'R',

TRANSACTION_AUTHORIZED = 'T',

RCU_NOT_CONFIGURED = '?',

RCU_POWER_UP = '!',

INITIALIZING = 'I',

NO_TRANSACTION = 'N',

REMOTE_AUTH_PRESET1 = 'a',

REMOTE_AUTH_PRESET2 = 'b',

REMOTE_AUTH_PRESET3 = 'c',

REMOTE_AUTH_PRESET4 = 'd',

REMOTE_AUTH_PRESET5 = 'e',

REMOTE_AUTH_PRESET6 = 'f',

Chapter 2 –MultiLoad Responses

17

REMOTE_AUTH_PRESET7 = 'g',

REMOTE_AUTH_PRESET8 = 'h',

REMOTE_AUTH_PRESET9 = 'i',

REMOTE_AUTH_PRESET10 = 'j',

REMOTE_AUTH_PRESET11 = 'k',

REMOTE_AUTH_PRESET12 = 'l',

REMOTE_AUTH_PRESET13 = 'm',

REMOTE_AUTH_PRESET14 = 'n'

} rcu_status;

Modbus:

Read Only Register=7000, Len=1, Character (rcu_status)

enum

{

CARD_NOT_INSERTED =’0’,

CARD_INSERTED =’1’,

CARD_SECOND_INSERTED =’2’

} card_status;

Modbus:

Read Only Register=7001, Len=1, Character (card_status)

In most cases a command will return additional information specific to the command. This information will

always follow the three status characters. For example if the following valid command to read the current

firmware version is sent:

Command => Response

R000 => 0?0000MultiLoad II v3.31.xx Jan xx 2014

With “0?0” as the three status characters and “000MultiLoad II v3.31.xx Jan xx 2014” as the command specific

response.

Chapter 3 – Query Command

18

CHAPTER 3 QUERY COMMAND:

Query Command => Response

Q => 0?0XXXX

Where:

XXXX = 4 digit hexadecimal number with bits representing the rcu_status as:

union

{

unsigned int value;

struct

{

unsigned char rcu_trans_header:1;

unsigned char proving_mode:1;

unsigned char power_up:1; // indicated system has been powered on

unsigned char configured:1; // indicates configuration state

unsigned char unassigned_keypress_on_load_screen:1;

unsigned char logmsg_queued:1; // a log message is available

unsigned char unused6:1;

unsigned char audit_logmsg_queued:1; // a audit message is available

unsigned char wm_logmsg_queued:1; // a w&m log message is available

unsigned char host_up:1; // host system is up, card in will be allowed.

Unsigned char input_in_progress:1;

unsigned char input_done:1;

unsigned char keypad_locked :1; // is keypad locked or not

unsigned char reserved13:1;

unsigned char wm_key:1; // W&M key is active

unsigned char program_key:1; // Program key is active

} flags;

} rcu_status;

This command also resets the Host Down Timer and should be issued periodically to notify MultiLoad that the

Host is still active.

Modbus:

Read Only Register=7002, Len=1, 16-Bit Integer (XXXX)

Chapter 4 – Function Commands

19

CHAPTER 4 FUNCTION COMMANDS:

FREBOOT = Performs a software reboot of the MultiLoad RCU.

FFACTORY = Restores all MultiLoad registers to factory defaults.

FUPDATEAPPFLASH = Updates the Flash with an uploaded image (req. W&M and a valid image)

Modbus:

Supported through Modbus Extended Services Registers.

FKEYPADON = Enables the keypad on the MultiLoad RCU (default it is active)

FKEYPADOFF = Disables the keypad on the MultiLoad RCU

Write Only Register=7008, Len=1, 16-Bit Integer (any value=FKEYPADON)

Write Only Register=7009, Len=1, 16-Bit Integer (any value=FKEYPADOFF)

FUNCONFIG = Clears the configured RCU status bit.

FRECONFIG = Sets the configured RCU status bit.

Modbus:

Write Only Register=7010, Len=1, 16-Bit Integer (any value=FUNCONFIG)

Write Only Register=7011, Len=1, 16-Bit Integer (any value=FRECONFIG)

FPOWERUP = Resets the power_up RCU status bit. This bit is set on power up.

Modbus:

Write Only Register=7012, Len=1, 16-Bit Integer (any value=FPOWERUP)

FHOSTUP = Sets the host_up RCU status bit. Cleared on power up or when host down

timeout expires between Q commands. Command should be issued when host

system starts communicating with MultiLoad.

Modbus:

Write Only Register=7013, Len=1, 16-Bit Integer (any value=FHOSTUP)

FHOSTDOWN = Clears the host_up RCU status bit. Command should be issued when host

system stops communicating with MultiLoad.

Modbus:

Write Only Register=7014, Len=1, 16-Bit Integer (any value=FHOSTDOWN)

FHOSTWAIT = Bypass host down timer once with alternate timeout.

Modbus:

Write Only Register=7015, Len=1, 16-Bit Integer (any value=FHOSTUP)

FEODLOG = Prints EOD-Report for all totalizers type by arm and also gives the throughput

between the feodlog commands

Modbus:

Write Only Register=7018, Len=1, 16-Bit Integer (any value=FEODLOG)

Chapter 4 – Function Commands

20

FPccc…. = Send ccc… characters to the attached printer port (if defined).

FCLEARPROD = Clear all product definitions (500 register) except for the 000-Unknown Product

definition.

FCLEARID = Clear Access ID and PIN database.

FCLEARCUSTOM = Clears all custom logic entries.

FCLEARAUDITLOG = Clear Audit Log Messages stored in Multiload.

Modbus:

Supported through Modbus Extended Services Registers.

Chapter 5 – Terminal Commands

21

CHAPTER 5 TERMINAL COMMANDS:

Ts…

Where:

s… = Any text string to display. Display string may contain one or more terminal escape commands.

5.1 TERMINAL ESCAPE COMMANDS:

<ESC><Terminal Escape Command and parameters >

Where Terminal Escape Commands are:

A Authorize Transaction:

Authorize MultiLoad Transaction. Will display load screen.

Modbus:

Write Only Register=7016, Len=1, 16-Bit Integer (any value=Authorize Transaction)

Cx Clear RCU counters

Where,

X = counter to clear, 1 = counter 1, 2 = counter 2

E Setup Data Entry

Used to display a flashing cursor (Setup Data Entry Length > 1) and allow user input. Data to be

retrieved at R960, R961.

F Turn on Big Font

Used to enable double size font.

F Turn off Big Font

Used to return to normal size font.

G Set Foreground/Background Text Colors

Where:

f = (character) 0x20 + Foreground Color Palette Index

b = (character) 0x20 + Background Color Palette Index

Pixel color palette index values defined as:

Black = 0x00

Blue = 0x01

Red = 0x02

Magenta = 0x03

Green = 0x04

Cyan = 0x05

Yellow = 0x06

White = 0x07

Custom 0 = 0x08 (Not available)

Chapter 5 – Terminal Commands

22

Custom 1 = 0x09 (Not available)

Custom 2 = 0x0a (Not available)

Custom 3 = 0x0b (Not available)

Custom 4 = 0x0c (Not available)

Custom 5 = 0x0d (Not available)

Flash 1 = 0x0e

Flash 2 = 0x0f

Example: To display a green word ‘Hello’ code the string as follows:

T<ESC>G$’Hello

$ = 0x20 + 0x04 (Green) ‘ = 0x20 + 0x07 (White)

H Home Cursor to Position (0,0)

Move cursor position to upper left corner of screen.

Ircle Set Reverse Video

Where:

r = (character) 0x20 + Top Text Row Position (0 = top, 15 = bottom)

c = (character) 0x20 + Left Text Column Position (0 = left, 39 = right)

l = (character) 0x20 + Length in Text Columns

e = “0” or “1” (0 = Set Inverse Text, 1 = Clear Inverse Text)

J Erase from Cursor to End of Line

Use with after <ESC>Y first to clear an entire line. Can be used as a CR since cursor will be positioned

on next line.

K Erase from Cursor to End of Screen

Use with after <ESC>H to clear entire screen.

Lxx Setup Data Entry Length

Where:

xx = Length of Data Entry Input Required (00-25) (0 = Key Press with No Flashing Cursor)

N Turn On Cursor

O Turn Off Cursor

R Reset the RCU Display

Modbus:

Write Only Register=7017, Len=1, 16-Bit Integer (any value=Reset RCU Display)

Yrc Set Cursor Position

Where:

r = (character) 0x20 + Top Text Row Position (0 = top, 15 = bottom)

c = (character) 0x20 + Left Text Column Position (0 = left, 39 = right)

X Clear Entire Display

Chapter 5 – Terminal Commands

23

< Unlock the Display

> Lock the Display

@ Turn Character Echo On

! Turn Asterisk Echo On

arcwh Draw Progress Box

Where:

r = (character) 0x20 + Top Text Row Position (0 = top, 15 = bottom)

c = (character) 0x20 + Left Text Column Position (0 = left, 39 = right)

w = (character) 0x20 + Width in Text Columns

h = (character) 0x20 + Height in Text Rows Down

brcwhp Update Progress Box

Where:

r = (character) 0x20 + Top Text Row Position (0 = top, 15 = bottom)

c = (character) 0x20 + Left Text Column Position (0 = left, 39 = right)

w = (character) 0x20 + Width in Text Columns

h = (character) 0x20 + Height in Text Rows Down

p = (character) 0x20 + Percent Value to Display (0 = None, 100 = Full)

crcpf Display Animation Frame

Where:

r = (character) 0x20 + Top Text Row Position (0 = top, 15 = bottom)

c = (character) 0x20 + Left Text Column Position (0 = left, 39 = right)

p = (character) 0x20 + Animation Picture Index

f = (character) 0x20 + Animation Frame Index

Note: Test only since Animation Picture Index and Animation Frame Index values may change between

firmware versions.

Df Display Factory Logo

Where:

f = (character) 0x20 + Factory Logo Index

Note: Test only since Factory Logo Index values may change between firmware versions.

Ercwd… Draw Display Graphic

Where:

r = (character) 0x20 + Top Text Row Position (0 = top, 15 = bottom)

c = (character) 0x20 + Left Text Column Position (0 = left, 39 = right)

w = (character) 0x20 + Width in Text Columns

d = (character) 0x20 + pixel color palette index values from left to right, top to bottom,

Note: Each text column = 16 pixels wide, each text row = 30 pixels high

Pixel color palette index values defined as:

Chapter 5 – Terminal Commands

24

Black = 0x00

Blue = 0x01

Red = 0x02

Magenta = 0x03

Green = 0x04

Cyan = 0x05

Yellow = 0x06

White = 0x07

Custom 0 = 0x08 (Not available)

Custom 1 = 0x09 (Not available)

Custom 2 = 0x0a (Not available)

Custom 3 = 0x0b (Not available)

Custom 4 = 0x0c (Not available)

Custom 5 = 0x0d (Not available)

Flash 1 = 0x0e

Flash 2 = 0x0f

Example: To position a small graphic starting at row 5, column 20, column width 2, code the string as

follows:

T<ESC>e%4” ’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’’’’’$$$’’’’’’’’’’’’’’’’$$$’’’’’

’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’’

’’’’’’’’’’’’’’$$$’’’’’’’’’’’’’’’

’’’’’$$’’’’’’’’’’’’’’’’’’$$’’’’’

’’’’’’’$$$$’’’’’’’’’’$$$$’’’’’’’

’’’’’’’’’’’$$$$$$$$$$’’’’’’’’’’’

Note: formatted for illustration only, there are no spaces or CRs in the above command.

‘%’ = 0x20 + 5 ‘4’ = 0x20 + 20 “ = 0x20 + 2

‘ = 0x20 + 0x07 (White) $ = 0x20 + 0x04 (Green)

grcwhc Fill Box with a Color

Where:

r = (character) 0x20 + Top Text Row Position (0 = top, 15 = bottom)

c = (character) 0x20 + Left Text Column Position (0 = left, 39 = right)

w = (character) 0x20 + Width in Text Columns

h = (character) 0x20 + Height in Text Columns Down

c = (character) 0x20 + color palette index value

Pixel color palette index values defined as:

Black = 0x00

Blue = 0x01

Red = 0x02

Magenta = 0x03

Green = 0x04

Cyan = 0x05

Yellow = 0x06

White = 0x07

Custom 0 = 0x08 (Not available)

Chapter 5 – Terminal Commands

25

Custom 1 = 0x09 (Not available)

Custom 2 = 0x0a (Not available)

Custom 3 = 0x0b (Not available)

Custom 4 = 0x0c (Not available)

Custom 5 = 0x0d (Not available)

Flash 1 = 0x0e

Flash 2 = 0x0f

hrcwhaaaaaaaa Display Graphic Cache

Where:

r = (character) 0x20 + Top Text Row Position (0 = top, 15 = bottom)

c = (character) 0x20 + Left Text Column Position (0 = left, 39 = right)

w = (character) 0x20 + Width in Text Columns

h = (character) 0x20 + Height in Text Columns

aaaaaaaa = 8 character hexadecimal cache offset start value.

See R/U 998 command for more details on cache offset.

Modbus:

Supported through Modbus Extended Services Registers.

Chapter 6 – Meter Commands

26

CHAPTER 6 METER COMMANDS:

6.1 AUTHORIZE PRESET (PRODUCT AND PRESET VOLUME):

MAMpppaiiivvvvvvvvvcc

Where:

ppp = The specified zero-based preset or load arm number (000-011).

A = Authorize bit, 0 = Cancel Authorization, 1 = Authorize.

Iii = Product Index (500 register) for the authorized product.

Vvvvvvvvv = Preset volume.

Cc = Compartment number.

Note: Will only accept Authorize Preset command when in REMOTE_AUTH_PRESET state or when preset is

authorized and a batch not already authorized.

Modbus:

Write Only Register=7500+5*ppp, Len=1, 16-Bit Integer (iii)

Write Only Register=7501+5*ppp, Len=2, 32-Bit Integer (vvvvvvvvv)

Write Only Register=7503+5*ppp, Len=1, 16-Bit Integer (cc)

Write Only Register=7504+5*ppp, Len=1, 16-Bit Integer (a)

Note: Last Authorize Preset Register Used=7559

6.2 CLEAR ALARMS:

MCAppp by preset

Where:

ppp = The specified zero-based preset or load arm number (000-011).

Modbus:

Write Only Register=7020+ppp, Len=1, 16-Bit Integer (any value)

MCBA by bay

Modbus:

Write Only Register=7019, Len=1, 16-Bit Integer (any value)

6.3 ENABLE PRESET

MEMpppa

Where:

ppp = The specified zero-based preset or load arm number (000-011).

A = Enable Flag, 0 = Disabled, 1 = Enabled/Not Available, 2 = Available

Modbus:

Write Only Register=7032+ppp, Len=1, 16-Bit Integer (a)

6.4 END TRANSACTION

MET

When an ET command is received, a forced card out will occur.

Chapter 6 – Meter Commands

27

Note: The Host will still need to send a MEB command for each preset that reaches a

PRESET_END_OF_BATCH state.

Modbus:

Write Only Register=7044, Len=1, 16-Bit Integer (any value)

6.5 BATCH COMPLETE

MBCppp

Where:

ppp = The specified zero-based preset or load arm number (000-011).

When a BC command is received, the preset flow will stop and the batch will be marked as complete. The

operator will not be able to restart the batch, but will be allowed to clear the batch and preset another (pending

Host authorization).

Modbus:

Write Only Register=7045+ppp, Len=1, 16-Bit Integer (any value)

6.6 BATCH END:

MBEppp

Where:

ppp = The specified zero-based preset or load arm number (000-011).

Command used to start end batch processing and to transition state to PRESET_END_OF_BATCH when flow

stops and final values are received.

Note: Typical end of batch command order is:

MSMppp (tell Multiload to stop flow)

MBCppp (tell Multiload to mark batch as complete, no further flowing on batch)

MBEppp (tell Multiload to get ready for total pickup)

wait for state==PRESET_END_OF_BATCH (ok to get totals)

MRSppp to get totals

MEBppp (ok to clear totals on Multiload)

Modbus:

Write Only Register=7057+ppp, Len=1, 16-Bit Integer (any value)

6.7 END BATCH:

MEBppp

Where:

ppp = The specified zero-based preset or load arm number (000-011).

Command is used to finish end-of-batch processing and that totals can be cleared.

Modbus:

Write Only Register=7069+ppp, Len=1, 16-Bit Integer (any value)

Chapter 6 – Meter Commands

28

6.8 PRESET MESSAGE:

MPMpppssssssssssddddddddddddddddddddddddddddddddddddddd

Where:

ppp = The specified zero-based preset or load arm number (000-011).

Ssssssssss = 10 Character Message.

Ddddddddddddddddddddddddddddddddddddddd = 39 Character Detail Message.

Displays a message for the particular preset. A detail message will be displayed when the preset is selected.

Driver and acknowledge and clear the message by pressing CLR key.

Modbus:

Only supported through Modbus Extended Services Registers.

6.9 PROVING TRANSACTION MODE:

MPTx

When:

x = Mode Status 0 = Off, 1 = On. Default Off when transaction is authorized.

Command is used to indicate when a card in is done with a proving card and meter proving may be done during

this transaction.

Modbus:

Write Only Register=7081, Len=1, 16-Bit Integer (x)

Chapter 6 – Meter Commands

29

6.10 REQUEST STATUS & PRESET ALARMS:

MRSpppxxxxyyyyzzzzaaaa => RSppp… (Requested parameters as listed below).

Where:

ppp = The specified zero-based preset or load arm number (000-011).

Xxxx = Optional response configuration bits #0 in hexadecimal as:

union

{

unsigned int value;

struct

{

unsigned int preset_state:1;

unsigned int preset_status_0:1;

unsigned int preset_alarms:1;

unsigned int volume_preset_whole:1;

unsigned int batch_gross_del_whole:1;

unsigned int batch_net_del_whole:1;

unsigned int batch_temp_tenths:1;

unsigned int batch_pressure_tenths:1;

unsigned int batch_gravity:1;

unsigned int gross_flow_rate:1;

unsigned int component_batch_gross_del_whole:1;

unsigned int component_batch_net_del_whole:1;

unsigned int component_batch_temp_tenths:1;

unsigned int component_batch_pressure_tenths:1;

unsigned int component_batch_gravity:1;

unsigned int additive_batch_gross_del_thous:1;

} flags;

} query_0; (default value 0x965f.)

Chapter 6 – Meter Commands

30

yyyy = Optional response configuration bits #1 in hexadecimal as:

union

{

unsigned int value;

struct

{

unsigned int preset_status_0:1;

unsigned int preset_status_1:1;

unsigned int preset_status_2:1;

unsigned int meter_status_0:1;

unsigned int meter_status_1:1;

unsigned int meter_status_2:1;

unsigned int component_status_0:1;

unsigned int component_status_1:1;

unsigned int component_status_2:1;

unsigned int additive_status_0:1;

unsigned int additive_status_1:1;

unsigned int additive_status_2:1;

unsigned int temp_press_in_hunds:1;

unsigned int component_current_temp_hund:1;

unsigned int component_current_pressure_hund:1;

unsigned int component_current_density_tenths:1;

} flags;

} query_1; (default value 0x0000.)

Chapter 6 – Meter Commands

31

zzzz = Optional response configuration bits #2 in hexadecimal as:

union

{

unsigned int value;

struct

{

unsigned int meter_batch_gross_del_whole:1; //Mass

unsigned int meter_gross_flow_rate:1; // Mass

unsigned int component_current_relative_density_tenthous:1;

unsigned int component_current_bsw_hund:1;

unsigned int component_current_api_gravity_tenths 1;

unsigned int component_batch_bsw_hund:1;

unsigned int component_batch_api_gravity_tenths:1;

unsigned int batch_mass_del:1;

unsigned int component_batch_mass_del:1;

unsigned int component_current_volume_correction_factor:1;

unsigned int component_current_temperature_correction_factor:1;

unsigned int component_current_pressure_correction_factor:1;

unsigned intsampler_batch_gross_del_thous:1;

unsigned intsampler_batch_current_target_samples:1;

unsigned int unused_14:1;

unsigned int unused_15:1;

} flags;

} query_2; (default value 0x0000.)

aaaa = Optional response configuration bits #3 in hexadecimal as:

union

{

unsigned int value;

struct

{

unsigned int component_meter_gross_del_whole:1;

unsigned int component_meter_net_del_whole:1; // Mass

unsigned int component_meter_batch_temp_tenths:1;

unsigned int component_meter_batch_pressure_tenths:1;

unsigned int component_meter_batch_gravity:1;

unsigned int component_meter_current_temp_tenths:1;

unsigned int component_meter_current_pressure_tenths:1;

unsigned int component_meter_current_gravity:1;

unsigned int component_meter_current_relative_density_tenthous:1;

unsigned int unused_9:1;

unsigned int component_meter_current_api_gravity_tenths:1;

unsigned int unused_11:1;

unsigned intcomponent_meter_batch_api_gravity_tenths:1;

unsigned int component_meter_mass_del:1;

Chapter 6 – Meter Commands

32

unsigned int unused_14:1;

unsigned int unused_15:1;

} flags;

} query_3; (default value 0x0000.)

Defaults are compatible with previous Multiload MRS replies.

To query for preset information only use: MRSppp03ff

To query for preset pressure only use: MRSppp0080

To query for additive delivered only use: MRSppp8000

RS = Request Status Response

ppp = The specified zero-based preset or load arm number (000-011).

Chapter 6 – Meter Commands

33

Query 0 and 1 Responses:

wwww= preset state in hexadecimal as:

enum

{

PRESET_IDLE = 0,

PRESET_LOW_FLOW = 1,

PRESET_HIGH_FLOW = 2,

PRESET_1ST_TRIP = 3,

PRESET_2ND_TRIP = 4,

PRESET_FINAL_TRIP = 5,

PRESET_START = 6,

PRESET_ALARM = 7,

PRESET_COMPLETE = 8,

PRESET_NOT_AUTH = 9,

PRESET_WAIT_TMS = 10,

PRESET_AUTH = 11,

PRESET_PRESET = 12,

PRESET_DISABLED = 13,

PRESET_STOP = 14,

PRESET_REMOTE_MSG = 15,

PRESET_END_OF_BATCH = 16,

PRESET_ARCHIVING = 17,

PRESET_CLEARING = 18,

PRESET_TRANS_DONE = 19,

PRESET_DIVERT = 20,

PRESET_NO_STATE = 99

} preset_state;

Chapter 6 – Meter Commands

34

xxxx= preset status #0 in hexadecimal as:

union

{

unsigned int value;

struct

{

unsigned char preset_enabled:1; // preset is enabled

unsigned char preset_host_enabled:1; // preset enabled by host

unsigned char authorized:1; // preset available for use

unsigned char flow_active:1; // flow state is not idle

unsigned char batch_authorized:1; // product & preset has been authorized

unsigned char remote_msg:1; // remote message active

unsigned char remote_desc:1; // remote descriptive message active

unsigned char load_complete:1; // no further loading on batch can be done

unsigned char end_batch:1; // MBE command processing started

unsigned char end_batch_done:1; // MBE command processing done

unsigned char tms_got_data:1; // MEB command received

unsigned char archived:1; // batch data has been archived into

transaction database

unsigned char batch_cleared:1; // batch has been cleared

unsigned char clearing_load:1; // load clear has been issued

unsigned char load_cleared:1; // load has been cleared

unsigned char trans_done:1; // transaction is done

} flags:

} preset_status_0;

Chapter 6 – Meter Commands

35

yyyy= preset alarms in hexadecimal as:

union

{

unsigned int value;

struct

{

unsigned char preset_fcm_com:1; // one or more FCMs that are required for

PRESET status or signals are in com

error.

Unsigned char preset_permissive:1; // preset permissive not active but preset is

authorized to load.

Unsigned char swing_arm_permissive:1; // swing arm not in bay and preset is

authorized to load.

Unsigned char line_not_flushed:1; // less than min_line_flush_vol has flowed

since a non-flush component has flowed

and batch was ended.

Unsigned char preset_block_valve:1; // block value status does not agree with

commanded valve position.

Unsigned char bay_alarm:1; // a bay level alarm currently exists.

Unsigned char component_alarm:1; // a component level alarm currently exists

for this preset.

Unsigned char additive_alarm:1; // a additive level alarm currently exists for

this preset.

Unsigned char meter_stop:1; // meter stop button for preset pressed

unsigned char preset_overrun:1; // preset delivered volume is over target

volume by overrun_alarm_vol.

unsigned char excess_flow:1; // preset flow rate has exceeded

excess_flow_alarm_rate.

Unsigned char unused11:1;

unsigned char unused12:1;

unsigned char unused13:1;

unsigned char unused14:1;

unsigned char configuration_error:1; // preset configuration has invalid data,

check message log for details

} flags;

} preset_alarms;

Chapter 6 – Meter Commands

36

qqqqqqqqq= preset quantity in whole units

ddddddddd = delivered gross quantity in whole units

ddddddddd = delivered net quantity in whole units

Note: if the Use Hundredths W&M RCU parameter is enabled, the gross and net quantity value will have an implied two decimal places.

Sddddd = signed batch average temp in tenths or hundredths

sddddd = signed batch average pressure in tenths or hundredths

dddddd = depending on API table selected,

batch average density in tenths OR

batch average relative density in ten thousands OR

batch average gravity in tenths

ddddd = preset gross flow rate in whole units

Modbus :

Where: p = preset (0-11)

Read Only Register=4000+p, Len=1, 16-Bit Integer (wwww)

Read Only Register=4012+p, Len=1, 16-Bit Integer (xxxx)

Read Only Register=4024+p, Len=1, 16-Bit Integer (yyyy)

Read Only Register=4036+p, Len=2, 32-Bit Integer (qqqqqqqqq)

Read Only Register=4060+p, Len=2, 32-Bit Integer (ddddddddd (gross))

Read Only Register=4084+p, Len=2, 32-Bit Integer (ddddddddd (net))

Read Only Register=4108+p, Len=2, 32-Bit Integer (sddddd (temp))

Read Only Register=4132+p, Len=2, 32-Bit Integer (sddddd (pressure))

Read Only Register=4156+p, Len=2, 32-Bit Integer (dddddd)

Read Only Register=4180+p, Len=1, 16-Bit Integer (ddddd (rate))

Chapter 6 – Meter Commands

37

per meter(5):

ddddddddd = meter delivered gross quantity in whole units

Note: if the Use Hundredths W&M RCU parameter is enabled, the gross quantity value will have an implied two decimal places.

Ddddd = meter gross flow rate in whole units

Modbus :

Where: p = preset (0-11), m = meter (0-4)

Read Only Register=4192+p*5+m, Len=2, 32-Bit Integer (ddddddddd (gross))

Read Only Register=4312+p*5+m, Len=1, 16-Bit Integer (ddddd (rate))

Chapter 6 – Meter Commands

38

per component(8):

ddddddddd = delivered gross quantity in whole units

ddddddddd = delivered net quantity in whole units

Note: if the Use Hundredths W&M RCU parameter is enabled, the gross and net quantity value will have an implied two decimal places.

Sddddd = signed component batch average temp in tenths or hundredths

sddddd = component batch average pressure in tenths or hundredths

dddddd = depending on API table selected,

component batch average density in tenths OR

component batch average relative density in ten thousands OR

component batch average gravity in tenths

sddddd = signed component current temp in hundredths

sddddd = signed component current pressure in hundredths

sddddd = signed component current density in tenths

sddddd = signed component current relative density in ten thousands

sddddd = signed component current bsw hund

sdddd = signed component current api gravity tenths

sddddd = signed batch average bsw hund

sdddd = signed batch average api gravity tenths

ddddddddd = component meter delivered gross quantity in whole units

ddddddddd = component meter delivered net quantity in whole units

sddddd = signed component meter batch average temp in tenths or hundredths

sddddd = component meter batch average pressure in tenths or hundredths

dddddd = depending on API table selected,

component meter batch average density in tenths OR

component meter batch average relative density in ten thousands OR

component meter batch average gravity in tenths

sddddd = signed component meter current temp in hundredths

sddddd = signed component meter current pressure in hundredths

sddddd = signed component meter current density in tenths

sddddd = signed component meter current relative density in ten thousands

sddddd = signed component meter current bsw hund

sdddd = signed component meter current api gravity tenths

sddddd = signed meter batch average bsw hund

sdddd = signed meter batch average api gravity tenths

ddddddddd = delivered mass quantity in whole units

Modbus :

Where: p = preset (0-11), c = component (0-7)

Read Only Register=4372+p*8+c, Len=2, 32-Bit Integer (ddddddddd (gross))

Read Only Register=4564+p*8+c, Len=2, 32-Bit Integer (ddddddddd (net))

Read Only Register=4756+p*8+c, Len=2, 32-Bit Integer (sddddd (component average temp))

Read Only Register=4948+p*8+c, Len=2, 32-Bit Integer (sddddd (component average pressure))

Read Only Register=5140+p*8+c, Len=2, 32-Bit Integer (dddddd (component average density/rel.

dens./gravity))

Read Only Register=5332+p*8+c, Len=2, 32-Bit Integer (sddddd (component current temp))

Read Only Register=5524+p*8+c, Len=2, 32-Bit Integer (sddddd (component current pressure))

Chapter 6 – Meter Commands

39

Read Only Register=5716+p*8+c, Len=2, 32-Bit Integer (sddddd (component current density))

Read Only Register=6292+p*8+c, Len=2, 32-Bit Integer (sddddd (component current relative density))

Read Only Register=6484+p*8+c, Len=2, 32-Bit Integer (sddddd (component current bsw))

Read Only Register=6676+p*8+c, Len=2, 32-Bit Integer (sddddd (component current api gravity))

NOT AVAILABLE Len=2, 32-Bit Integer (sdddd (component average api gravity))

Read Only Register=6868+p*8+c, Len=2, 32-Bit Integer (ddddddddd (gross))

Chapter 6 – Meter Commands

40

per additive(16):

ddddddddd = delivered quantity in thousands

Modbus :

Where: p = preset (0-11), a = additive (0-11)

Read Only Register=5908+p*16+a, Len=2, 32-Bit Integer (ddddddddd (delivered quantity in thousands))

per sampler(20)

ddddddddd = sampler batch gross delivered in thousandths

ddddddddd = sampler batch current target

Chapter 6 – Meter Commands

41

Query 1 Responses:

xxxx= preset status #0 in hexadecimal as:

union

{

unsigned int value;

struct

{

unsigned char preset_enabled:1; // preset is enabled

unsigned char preset_host_enabled:1; // preset enabled by host

unsigned char authorized:1; // preset available for use

unsigned char flow_active:1; // flow state is not idle

unsigned char batch_authorized:1; // product & preset has been authorized

unsigned char remote_msg:1; // remote message active

unsigned char remote_desc:1; // remote descriptive message active

unsigned char load_complete:1; // no further loading on batch can be done

unsigned char end_batch:1; // MBE command processing started

unsigned char end_batch_done:1; // MBE command processing done

unsigned char tms_got_data:1; // MEB command received

unsigned char archived:1; // batch data has been archived into

transaction database

unsigned char batch_cleared:1; // batch has been cleared

unsigned char clearing_load:1; // load clear has been issued

unsigned char load_cleared:1; // load has been cleared

unsigned char trans_done:1; // transaction is done

} flags:

} preset_status_0;

Chapter 6 – Meter Commands

42

xxxx= preset status #1 in hexadecimal as:

union

{

unsigned int value;

struct

{

unsigned char program_clear_errors:1; // command to clear errors

unsigned char remote_clear_errors:1; // command to clear errors

unsigned char driver_clear_errors:1; // command to clear errors

unsigned char clearing_errors:1; // currently clearing errors

unsigned char flow_batch:1; // command to flow/not flow product

unsigned char clear_batch:1; // command to clear batch

unsigned char clear_load:1; // command to clear load

unsigned char flush_stage_needed:1; // product flush stage required

unsigned char open_blk_val:1; // block valve open

unsigned char blk_val_status:1; // block valve status

unsigned char close_blk_val:1; // block valve close

unsigned char remote_start:1; // remote start button status

unsigned char swing_arm:1; // swing arm select status

unsigned char meter_stop:1; // meter stop button status

unsigned char alarm_out:1; // preset alarm output status

unsigned char permissive:1; // preset permissive input status

} flags:

} preset_status_1;

Chapter 6 – Meter Commands

43

xxxx= preset status #2 in hexadecimal as:

union

{

unsigned int value;

struct

{

unsigned char permissive_out:1; // preset permissive output status

unsigned char load_interrupted:1; // has loading been interrupted

unsigned char clearing_batch:1; // batch in process of clearing

unsigned char alt_high_flow:1; // alt_high_flow input active

unsigned char gross_value_measured_for_trade:1; // gross value is W&M approved

unsigned char wm_clear_errors:1; // command to clear errors

unsigned char batch_alarm:1; // one or more preset level alarms occurred

during the batch

unsigned char remote_clear:1; // remote clear from FCM input

unsigned char no_auto_batch_auth:1; // prevents batch reauthorization

unsigned char open_diverter_val:1; // divert valve open

unsigned char diverter_invalid_bsw:1; // divert alarm

unsigned char unused2_11:1; // future use

unsigned char unused2_12:1; // future use

unsigned char unused2_13:1; // future use

unsigned char unused2_14:1; // future use

unsigned char unused2_15:1; // future use

} flags:

} preset_status_2;

Modbus:

Supported through Modbus Extended Services Registers.

Chapter 6 – Meter Commands

44

Per meter(6):

xxxx= meter status #0 in hexadecimal as:

union

{

unsigned int value;