FCM II

(Flow Control Module)

Installation Guide

Part # 2307

April 26, 2013

2

Notified Body(ies)

NMi Certin B.V., Number 0122

Hugo de Grootplein 1

3314 EG Dordrecht

The Netherlands

Notified Body(ies)

NMi Certin B.V., Number 0122

Hugo de Grootplein 1

3314 EG Dordrecht

The Netherlands

EC Declaration Of Conformity (Valid until April 20, 2016)

The signatory, representing the manufacturer, declares that the products listed below are in conformity with the essential requirements of the

following EC Directive(s) when installed in accordance with the product installation instructions:

2004/22/EC The Measuring Instruments Directive (and its amending directives)

2004/108/EC The Electromagnetic Compatibility Directive (and its amending directives)

2006/95/EC The Low Voltage Directive (and its amending directives)

Product: Distributed I/O Control System

Model name/number: FCM II

Conformity has been demonstrated with reference to the following documentation:

(MID) EC type-examination certificate TC7311

Compliance with the Essential Health and Safety Requirements has been assessed by reference to the following standards:

WELMEC guide 8.8 General and Administrative Aspects of the Voluntary System of Modular Evaluation of Measuring

instruments under MID

OIML R117-1:2007(E) Dynamic measuring systems for liquids other than water

EN 61000-6-4: 2007 Generic emissions for industrial operating environments

EN 61000-6-2: 2005 Generic immunity for industrial operating environments

IEC 61010-1: 2004 Electrical Equipment for Measurement, Control, and Laboratory Use; Part 1: General Requirements

Year of CE Marking: 2007

Name: William J. Porthouse Position: Director of Engineering & Production Date: 31-Oct-2012

EC Declaration Of Conformity

The signatory, representing the manufacturer, declares that the products listed below are in conformity with the essential requirements of the

following EC Directive(s) when installed in accordance with the product installation instructions:

2014/32/EU The Measuring Instruments Directive (and its amending directives)

2014/30/EU The Electromagnetic Compatibility Directive (and its amending directives)

2014/35/EU The Low Voltage Directive (and its amending directives)

Product: Distributed I/O Control System

Model name/number: FCM II

Conformity has been demonstrated with reference to the following documentation:

(MID) EC type-examination certificate TC7311

Compliance with the Essential Health and Safety Requirements has been assessed by reference to the following standards:

WELMEC guide 8.8 General and Administrative Aspects of the Voluntary System of Modular Evaluation of Measuring

instruments under MID

OIML R117-1:2007(E) Dynamic measuring systems for liquids other than water

EN 61000-6-4: 2007 Generic emissions for industrial operating environments

EN 61000-6-2: 2005 Generic immunity for industrial operating environments

IEC 61010-1: 2004 Electrical Equipment for Measurement, Control, and Laboratory Use; Part 1: General Requirements

Year of CE Marking: 2007

Name: William J. Porthouse Position: Director of Engineering & Production Date: 19-April-2016

FCM II Installation Guide: 20160419 - Part # 2307

ELECTRICAL CONSIDERATIONS AND REGULATORY REQUIREMENTS

Equipment Operation. If the equipment is used in a manner not specified in this installation guide,

the protection provided by the equipment may be impaired..

This equipment is suitable for use in Class I, Division 2, Groups C and D hazardous locations OR

non-hazardous locations only.

WARNING: EXPLOSION HAZARD, Do not disconnect equipment unless power has been

removed or the area is known to be non-hazardous.

WARNING: EXPLOSION HAZARD, Substitution of components may impair suitability for use in

Class I, Division 2 environments.

WARNING: EXPLOSION HAZARD, The area must be known to be non-hazardous before

servicing/replacing the unit and before installing.

CAUTION: Use supply wires suitable for 5°C above surrounding ambient.

!!!

!

4

Copyright Notice

Copyright © 2007-2016 Toptech Systems, Inc.

The information contained in this document is proprietary and confidential. No part of this document may be copied, reproduced, or

transmitted in any medium without the express written permission of Toptech Systems, Inc.

Disclaimer

Toptech Systems assumes no responsibility for damages resulting from installation or use of its products. Toptech Systems will not be liable

for any claims of damage, lost data, or lost time as a result of using its products.

A Unit of IDEX Corporation

logo is a registered trademark of Toptech Systems, Inc.

TMS™, TMS5™, TMS6™, RCU II Remote Control Unit™, Toptech MultiLoad II™, MultiLoad II -RCU™, RCU II™, FCM Flow Control

Module™, veriFID™, ACR™, ACR II™ are trademarks of Toptech Systems, Inc.

Copyright © 2016 Toptech Systems, Inc. All Rights Reserved.

FCM II Installation Guide: 20160419 - Part # 2307

5

Table of Contents

Electrical Considerations and Regulatory Requirements ................................................................................3

CHAPTER 1 General ...........................................................................................................................................8

1.1 Who Should Use This Guide ...................................................................................................................8

1.2 Information Alerts: ....................................................................................................................................8

1.3 Receiving and/or Returning Equipment: ................................................................................................8

1.4 Operating Characteristics: ......................................................................................................................8

1.4.1 Electrical Ratings: ...................................................................................................................................9

1.4.2 Operating Conditions: .......................................................................................................................... 10

1.5 Electrostatic Discharge (ESD) Protection: .......................................................................................... 10

CHAPTER 2 Installation .................................................................................................................................. 11

2.1 Module Installation ................................................................................................................................ 11

2.2 Module Removal .................................................................................................................................... 11

2.3 FCM II Panels And Enclosures: ............................................................................................................ 12

2.3.1 Panel Layouts: ..................................................................................................................................... 12

2.3.2 Panel Wiring......................................................................................................................................... 12

2.3.3 Enclosure Mounting ............................................................................................................................. 12

2.4 Electrical Supply Connections ............................................................................................................. 13

2.5 Serial Communication Connection ...................................................................................................... 14

2.6 Device Address Configuration ............................................................................................................. 15

2.7 Swing Arms ............................................................................................................................................ 16

CHAPTER 3 Field Wiring ................................................................................................................................ 18

3.1 Connection Requirements .................................................................................................................... 18

3.2 FCM II Field Device Connections ......................................................................................................... 18

3.2.1 Terminal Identification .......................................................................................................................... 19

3.2.2 Flow Meter and Control Valve Wiring .................................................................................................. 20

3.2.3 Additive Wiring ..................................................................................................................................... 21

3.2.4 RTD Temperature Probe Wiring .......................................................................................................... 22

3.2.5 4-20mA Input Wiring: LOOP CURRENT PROVIDED BY EXTERNAL POWER SUPPLY ................. 23

3.2.6 4-20mA Input Wiring: LOOP CURRENT PROVIDED BY TRANSMITTER ......................................... 24

3.2.7 4-20mAOutput Wiring .......................................................................................................................... 25

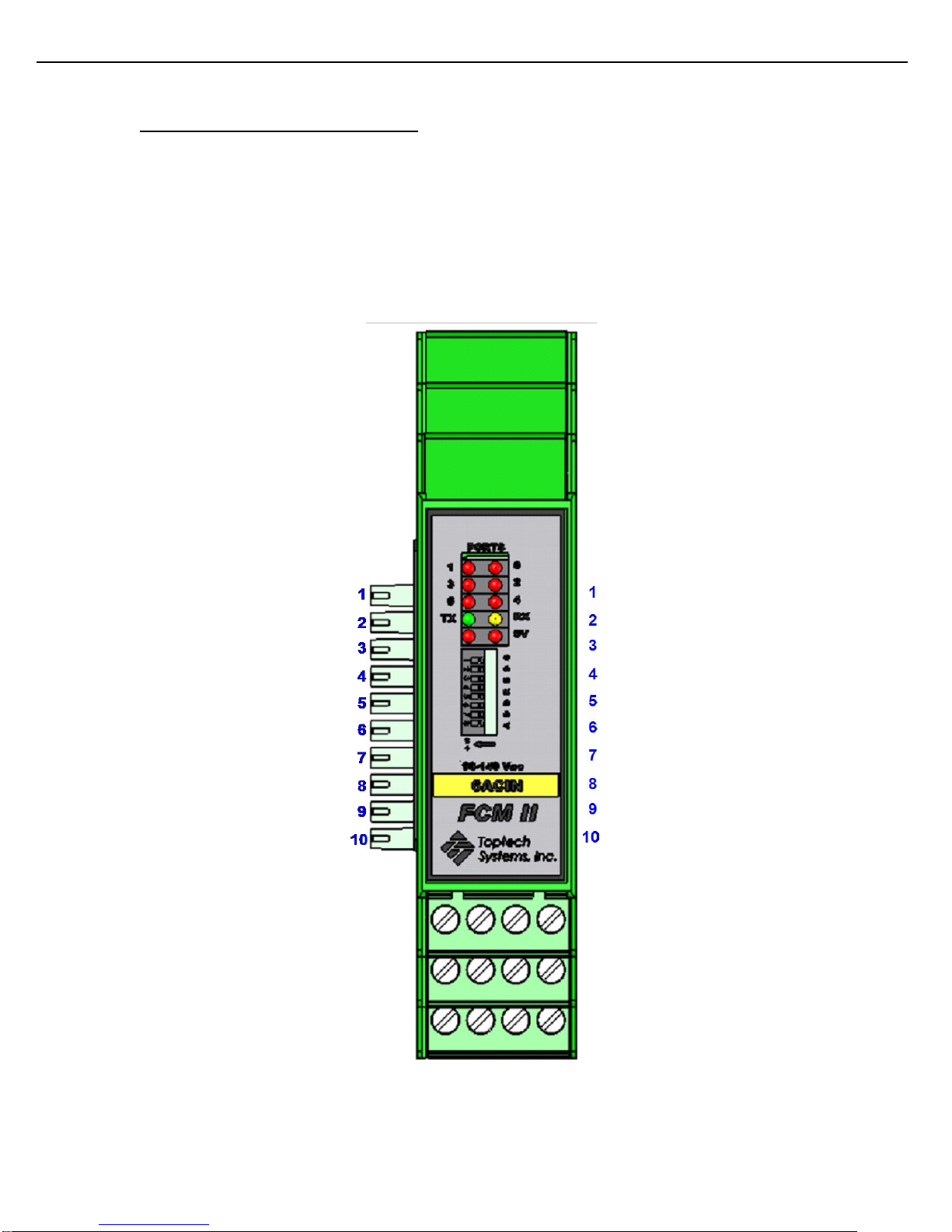

3.2.8 AC Permissive/Status Wiring (6ACIN) ................................................................................................. 26

3.2.9 AC Output Wiring (6ACOUT) .............................................................................................................. 27

3.2.10 DC Permissive/Status Wiring (6DCIN) ............................................................................................ 28

3.2.11 DC Permissive/Status Wiring (4DCIN/4ACOUT) ............................................................................. 29

3.2.12 AC Output Wiring (4DCIN/4ACOUT) ............................................................................................... 30

3.2.13 DC Output Wiring (6DCOUT) .......................................................................................................... 31

3.2.14 3 Output Air Eliminator Wiring ......................................................................................................... 32

3.2.15 2 Output Air Eliminator Wiring ......................................................................................................... 33

3.2.16 Lectro Count Remote Display Wiring .............................................................................................. 34

CHAPTER 4 Simulation................................................................................................................................... 35

4.1 Meter Simulation .................................................................................................................................... 35

4.2 Additive Simulation ............................................................................................................................... 35

4.3 Analog Simulation ................................................................................................................................. 35

4.4 Generic I/O Simulation .......................................................................................................................... 35

CHAPTER 5 Troubleshooting ........................................................................................................................ 36

5.1 Is The Module Powered?....................................................................................................................... 36

5.2 Is The Module Communicating? .......................................................................................................... 36

5.3 Are The Inputs Functioning? ................................................................................................................ 37

5.4 Are The Outputs Functioning? ............................................................................................................. 37

FCM II Installation Guide: 20160419 - Part # 2307

6

5.5 Are RTD Errors Present? ...................................................................................................................... 38

5.6 Are Other Errors Present? .................................................................................................................... 38

5.7 Is Technical Assistance Available? ..................................................................................................... 38

CHAPTER 6 Dimensions, Panel Layouts, Wiring Suggestions .................................................................. 39

6.1 Module Dimensions ............................................................................................................................... 39

6.2 Standard Panel Dimensions ................................................................................................................. 41

6.2.1 20 inch x 20 inch Panel ........................................................................................................................ 41

6.2.2 30 inch x 30 inch Panel ........................................................................................................................ 43

6.3 Panel Electrical Wiring Suggestions ................................................................................................... 45

6.3.1 Power and Communication Distribution .............................................................................................. 45

6.3.2 Wiring Terminal Identification .............................................................................................................. 47

6.3.3 Voltage Distribution .............................................................................................................................. 48

CHAPTER 7 Hardware Revision History ....................................................................................................... 49

CHAPTER 8 Manual Revision History ........................................................................................................... 50

FCM II Installation Guide: 20160419 - Part # 2307

7

Table of Figures

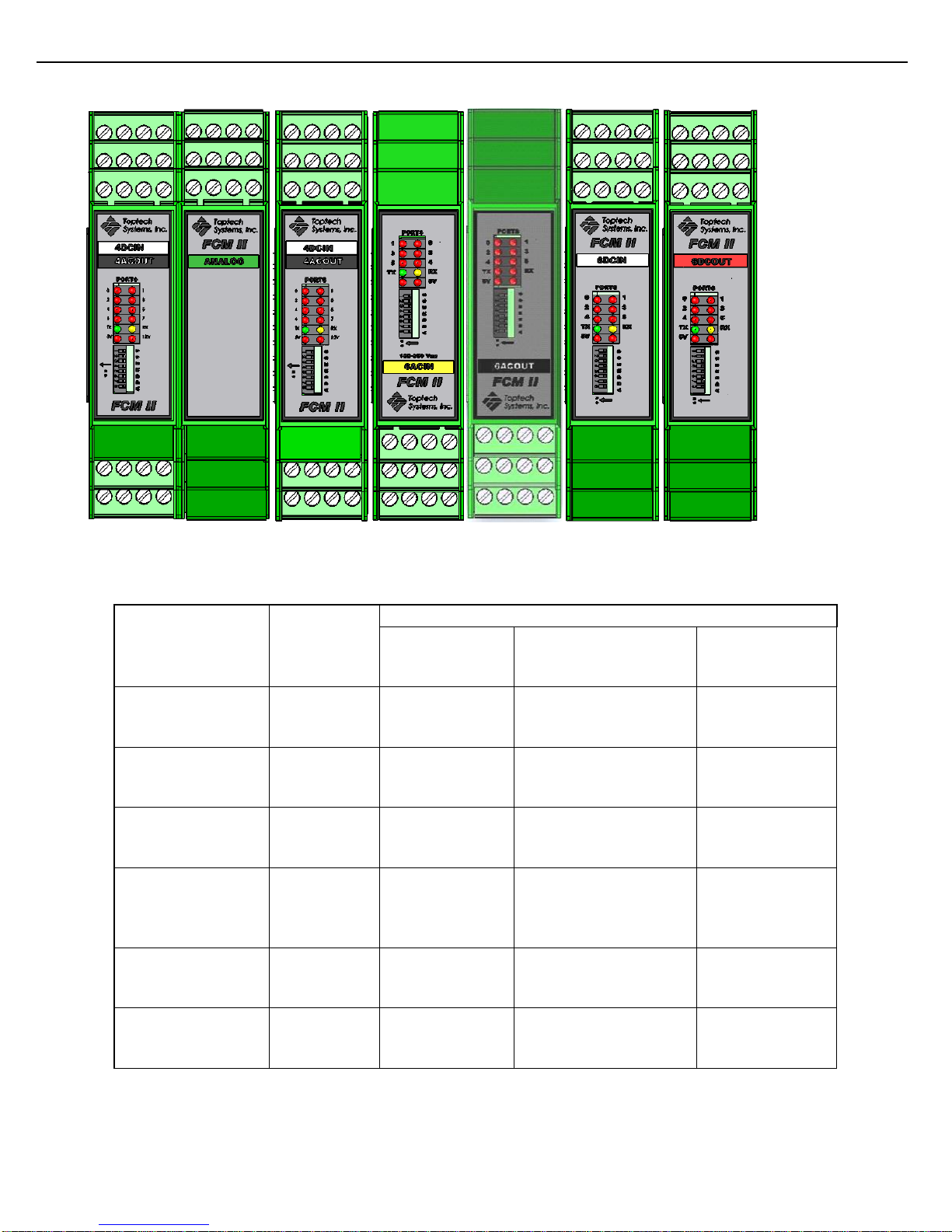

Figure 1.1 FCM II Module Comparison .............................................................................................................9

Figure 1.2 FCM II Module Electrical Ratings ....................................................................................................9

Figure 2.1 Engage Top Foot on Rail .............................................................................................................. 11

Figure 2.2 Snap Metal Foot to Rail ................................................................................................................. 11

Figure 2.3 Slide Modules Together ................................................................................................................ 12

Figure 2.4 Power / Com Connection Bus ...................................................................................................... 13

Figure 2.5 Module Status, Configuration Setting and Identification .......................................................... 15

Figure 2.6 DIP Switch Configuration Settings .............................................................................................. 16

Figure 2.7 Swing Arm Wiring of Shared FCM IIs .......................................................................................... 17

Figure 3.1 FCM II Single And Double Module Comparison ......................................................................... 19

Figure 3.2 FCM II Field Wiring Terminal Locations ...................................................................................... 19

Figure 3.3 FCM II Field Wiring: Flow Meter and Control Valve ................................................................... 20

Figure 3.4 FCM II Field Wiring: Additive Meters and Injection Valves ....................................................... 21

Figure 3.5 FCM II Field Wiring: RTD ............................................................................................................... 22

Figure 3.6 FCM II Field Wiring: 4-20mA Input ............................................................................................... 23

Figure 3.7 FCM II Field Wiring: 4-20mA Input ............................................................................................... 24

Figure 3.8 FCM II Field Wiring: 4-20mA Output ............................................................................................ 25

Figure 3.9 FCM II Field Wiring: AC Permissive/Status (6ACIN) .................................................................. 26

Figure 3.10 FCM II Field Wiring: AC Pump and Valve Control (6ACOUT) ......................................................... 27

Figure 3.11 FCM II Field Wiring: DC Permissive/Status (6DCIN) .................................................................. 28

Figure 3.12 FCM II Field Wiring: DC Input (4DCIN/4ACOUT) ......................................................................... 29

Figure 3.13 FCM II Field Wiring: AC Output (4DCIN/4ACOUT) ...................................................................... 30

Figure 3.14 FCM II Field Wiring: DC Output (6DCOUT) .................................................................................. 31

Figure 3.15 FCM II Field Wiring: 3 Output Air Eliminator ............................................................................... 32

Figure 3.16 FCM II Field Wiring: 2 Output Air Eliminator ............................................................................... 33

Figure 3.17 FCM II Field Wiring: Lectro Count Remote Display ................................................................... 34

Figure 5.1 FCM II Module Front Panel ............................................................................................................ 36

Figure 6.1 FCM II Single Module Dimensions .................................................................................................. 39

Figure 6.2 FCM II Double Module Dimensions ................................................................................................. 40

Figure 6.3 20 Inch x 20 Inch Panel Layout .................................................................................................... 41

Figure 6.4 20 Inch x 20 Inch Enclosure Dimensions .................................................................................... 42

Figure 6.5 30 Inch x 30 Inch Panel Layout .................................................................................................... 43

Figure 6.6 30 Inch x 30 Inch Enclosure Dimensions .................................................................................... 44

Figure 6.7 FCM II Power and Serial Communication Panel Wiring: Single Row ....................................... 45

Figure 6.8 FCM II Power and Serial Communication Panel Wiring: Two Rows, Two Serial Ports .......... 46

Figure 6.9 FCM II Power and Serial Communication Panel Wiring: Two Rows, One Serial Port ............ 47

Figure 6.10 FCM II Field Terminal Block Labels ............................................................................................. 48

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 1 – General

8

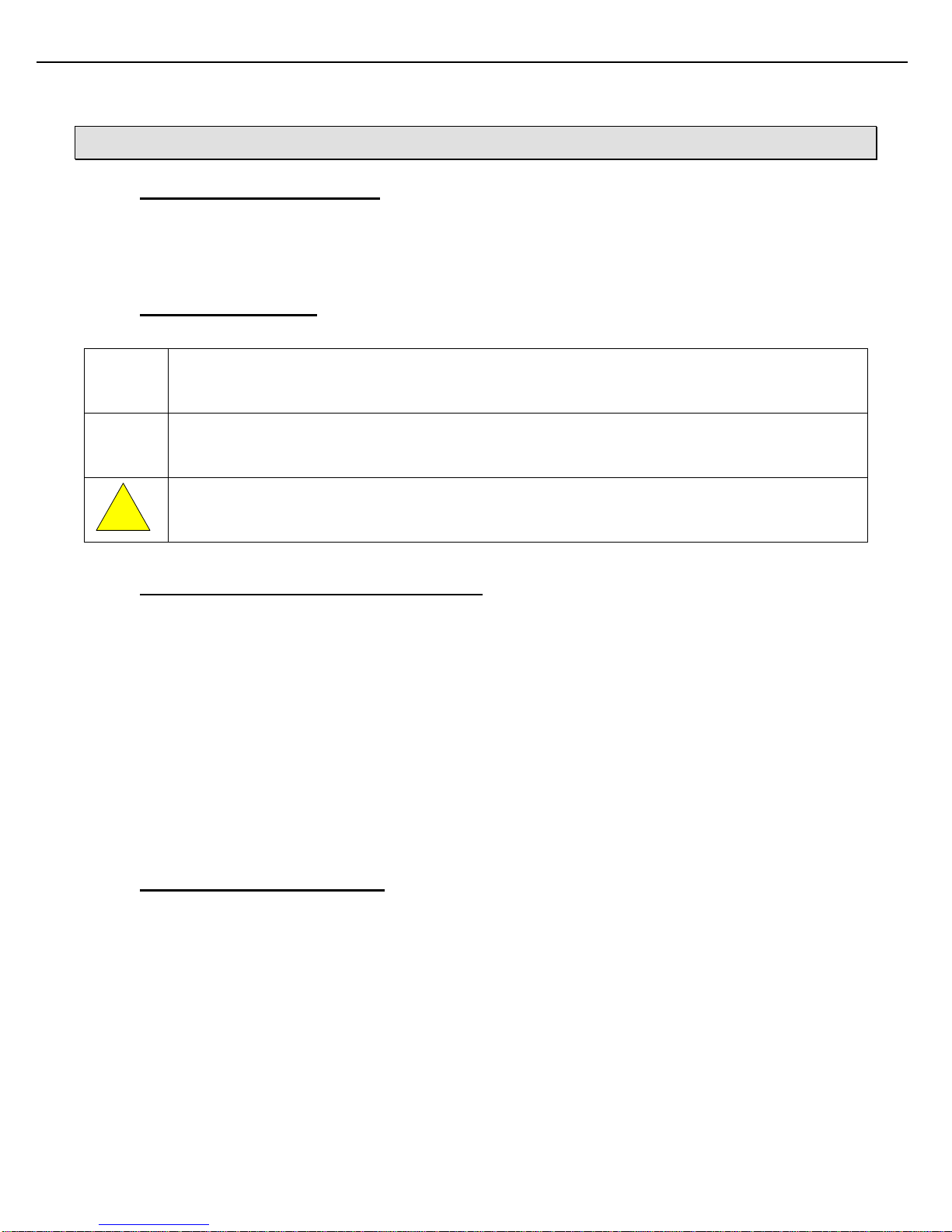

!

Important information to enhance understanding and make better use of the product.

Indicates potential damage to hardware or loss of data.

Potential for property damage or that personal injury may occur. Pay close attention and follow

instructions when you see this symbol.

CHAPTER 1 GENERAL

1.1 WHO SHOULD USE THIS GUIDE

This guide is intended for individuals installing FCM II panels, engineering firms fabricating FCM II panels, and

users troubleshooting system operation such as managers, system administrators, technicians, and meter proving

personnel.

1.2 INFORMATION ALERTS:

1.3 RECEIVING AND/OR RETURNING EQUIPMENT:

The FCM II should be immediately inspected after opening the packaging case. If any damage is visible notify the

carrier at once to establish liability. Contact Toptech Account Management to initiate timely repair or replacement

of the unit.

Account Management will issue a Return Materials Authorization (RMA) to return the product or parts requiring

repair. Do not return any material to Toptech without an RMA.

Account Management contact information:

Account Management

Toptech Systems

1124 Florida central Pkwy

Longwood, FL

(407) 332-1774

1.4 OPERATING CHARACTERISTICS:

FCM II is available in six varieties (see Figures 1.1 and 1.2 below). This modular construction simplifies the

process of FCM mapping to field devices by appropriating each FCM II model with just the right amount of I/O for

its designated purpose. In addition, FCM IIs are DIN rail (35mm) mountable and require no wiring between units;

24Vdc and serial communications are bussed. This substantially simplifies installation and wiring.

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 1 – General

9

Module

Supply

Voltage

Electrical Ratings

Auxiliary

Power Supply

Outputs

Inputs

FCM II 4DC IN/

4AC OUT

Min. 19 Vdc

Max. 36 Vdc

100mA Max

12 Vdc

167 mA Max

250 Vac

350 mA max.

6K Cycles, Pilot Duty

30 Vdc

SELV

Limited Energy

FCM II Analog

Min. 19 Vdc

Max. 36 Vdc

100mA Max

--

4-20 mA

SELV

Limited Energy

RTD, 4-20 mA

SELV

Limited Energy

FCM II 6 AC IN

Min. 19 Vdc

Max. 36 Vdc

100mA Max

--

--

250 Vac max.

Optically Isolated

Contact Closure

FCM II 6 AC OUT

Min. 19 Vdc

Max. 36 Vdc

100mA Max

--

250 Vac

350 mA max.

6K Cycles, Pilot Duty

--

FCM II DC IN

Min. 19 Vdc

Max. 36 Vdc

100mA Max

--

--

30 Vdc

SELV

Limited Energy

FCM II DC OUT

Min. 19 Vdc

Max. 36 Vdc

100mA Max

30 Vdc

250mA max.

6K Cycles, Pilot Duty

Figure 1.1 FCM II Module Comparison

1.4.1 ELECTRICAL RATINGS:

Figure 1.2 FCM II Module Electrical Ratings

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 1 – General

10

1.4.2 OPERATING CONDITIONS:

Operating temperature (surrounding air temperature) -40°F to 140°F (-40°C to 60°C).

Environmental Ratings: None. FCM II modules are classified as open equipment must be placed in a

suitable Type 4 (or IP 65) or better enclosure.

For product outline and dimensions see Figure 6.1 and Figure 6.2.

1.5 ELECTROSTATIC DISCHARGE (ESD) PROTECTION:

The FCM II contains electronic components and assemblies subject to damage by ESD. The FCM II was

designed to protect against ESD while the unit is mounted on an electrical panel and in normal operation. Proper

handling procedures must be observed during the removal, installation, repair and other handling of FCM II

modules summarized below.

1) Service must be performed by authorized personnel only.

2) The person performing the service must be grounded by an ESD grounding strap and connected to

ground.

3) The plastic enclosures offer a degree of protection of the inner printed circuit board assemblies

against ESD. However, the heat venting slots and the wiring terminals blocks do allow a possible path

for ESD when not fastened to the electrical panel. Therefore, a servicing technician is advised to

touch unpainted metal of the electrical panel prior to installing or replacing FCM II modules.

4) FCM II modules must be placed in and transported in conductive bags or other conductive containers.

5) FCM II modules must not be removed from the conductive container until time of use.

6) All other “best” practices for protecting devices from ESD must be observed.

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 2 – Installation

11

CHAPTER 2 INSTALLATION

2.1 MODULE INSTALLATION

FCM II modules are easily attached to 35mm DIN rails by tilting the top edge toward the panel and catching the

top edge on the rail (see Figure 2.1 below). Then the module is swung back down until the spring loaded metal

foot catches on the bottom edge of the rail (see Figure 2.2 below). The 24 Vdc power and RS-485

communication is connected by sliding adjacent FCM II’s together until the bus connectors click into place (see

Figure 2.3 below).

2.2 MODULE REMOVAL

Module removal is the reverse of installation. Power must be removed from the modules. Then, spread the

module to be removed from adjacent modules on either side. Disengage the spring loaded bottom catch by

inserting a ¼” Flat Head screwdriver and sliding the catch away from the rail and tilting the module top toward the

panel. With the bottom edge disconnected, the top foot may by moved off of the rail to free the module. Do not

attempt to open the module’s plastic housing.

Figure 2.1 Engage Top Foot on Rail

FCM II Installation Guide: 20160419 - Part # 2307

Figure 2.2 Snap Metal Foot to Rail

Chapter 2 – Installation

12

Figure 2.3 Slide Modules Together

2.3 FCM II PANELS AND ENCLOSURES:

2.3.1 PANEL LAYOUTS:

Toptech Systems assembles standard panel layouts which are shown in Chapter 6. These include a 20 inch by

20 inch panel with a single DIN rail of FCM IIs or a 30 inch by 30 inch panel with two DIN rails of FCM IIs.

Exterior dimensions of the panel’s associated enclosures are also shown in Chapter 6.

2.3.2 PANEL WIRING

The following guidelines are recommended when installing panels at a facility and making field connections.

1. Connect a safety ground to the panel. A copper post is provided for this.

2. Wiring must enter the enclosure through conduit entries. All conduits must be terminated at the enclosure

by use of appropriately rated conduit hubs or glands.

3. Avoid routing AC and DC wiring in the same conduit in order to minimize the disruption of DC and analog

voltage circuits by line voltage transients and surges.

4. Wiring must comply with all local electrical codes.

2.3.3 ENCLOSURE MOUNTING

Mounting instructions are provided with all panel assemblies shipped by Toptech. Whether installing a Toptech

supplied FCM II enclosure, or installing a customer sourced enclosure, follow the manufacturer’s mounting

instructions in order not to invalidate regulatory requirements.

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 2 – Installation

13

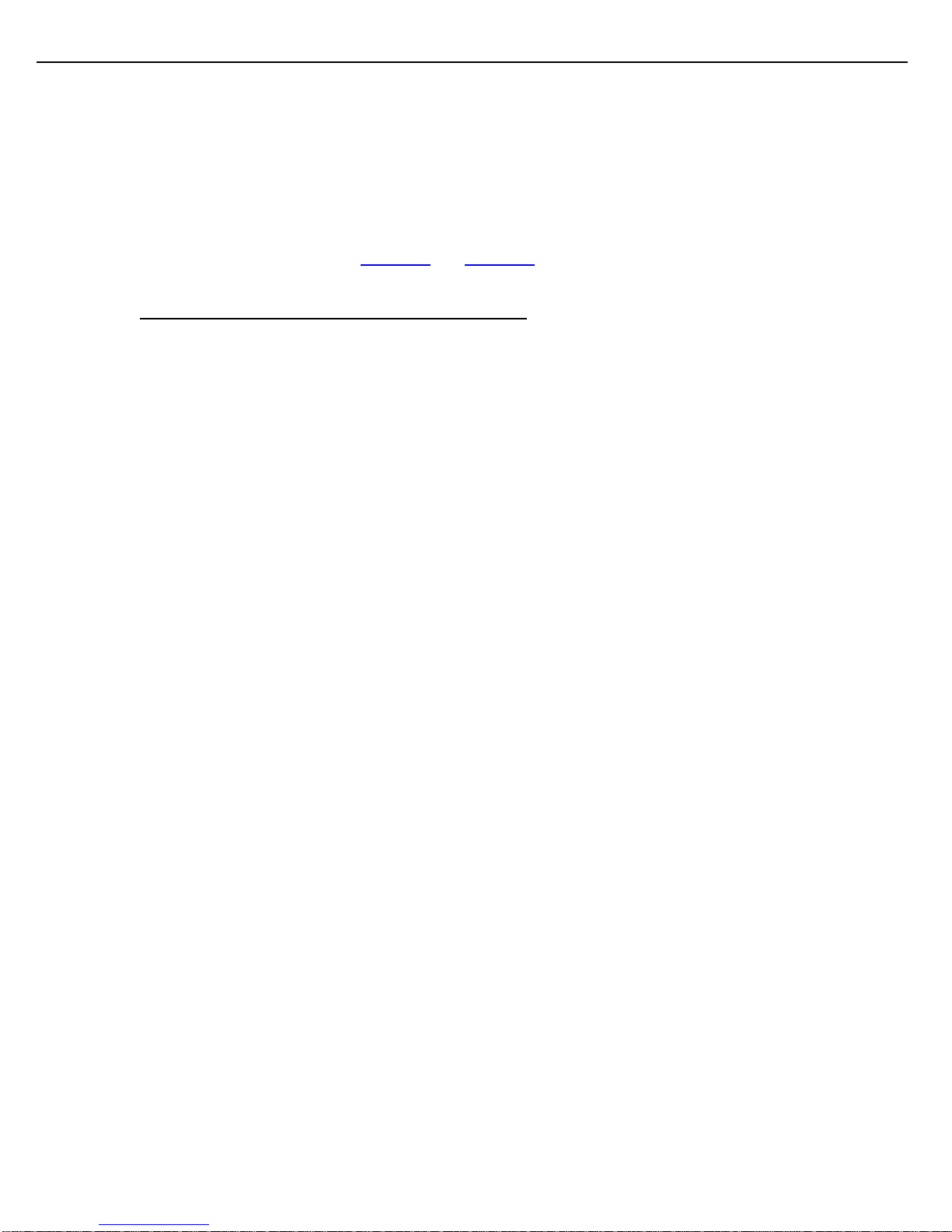

2.4 ELECTRICAL SUPPLY CONNECTIONS

FCM IIs require a supply of 19 – 36 Vdc, 100mA to power each module (200mA for a double). The power must

be from an isolated, SELV (Safety Extra Low Voltage) power supply, rated 36 VDC max.

Although the ten position power/communication bus terminal block is rated for solid or stranded copper wire 14 to

30 AWG [2.1 to 0.05 mm2], Toptech recommends using stranded 16 to 18 AWG [1.3 to 0.8 mm2] for power. See

section 2.5 regarding the choice of communication wire. The required screw tightening torque is 2 to 4 Lb-in. [0.2

to 0.5 Nm]. For terminal assignments, see Figure 2.4 below. Wires must be stripped ¼” and inserted into terminal

block leaving no bare conductor exposed. Only one of each of the three possible 24 VDC+/DC COMMON pairs

need be used; the rest are provided for bus capacity.

24 VDC + 24 VDC +

24 VDC + 24 VDC +

24 VDC + 24 VDC +

DC Common DC Common

DC Common DC Common

DC Common DC Common

RDA RDA

RDB RDB

TDA TDA

TDB TDB

Figure 2.4 Power / Com Connection Bus

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 2 – Installation

14

!

!

Note 1: If a disconnecting device is used, ensure that it is not blocked by FCMs or any other

device which would make it difficult to operate. If used, do not place the disconnect in a

Class I, Division 2 location.

Note 2: Do not place a thermal magnetic circuit breaker in a Class I, Division 2 location.

The installer should provide over current protection between the branch circuit and the supply according to the

power supply manufacturer’s recommendations; usually either an appropriately sized s low-blow fuse or a

characteristic B thermal magnetic circuit breaker. Because the primary side of the power supply is overcurrent

protected, it is not necessary to fuse the 24 Vdc output, unless it is used to supply power to field devices located

outside of the panel housing the FCM IIs.

2.5 SERIAL COMMUNICATION CONNECTION

RS-422/485 communications protocol is designed for multi-point (i.e. computer to multiple devices, also called

multi-dropped) communications up to 4,000 feet (1,220 Meters).

RS-422 requires 4-wires (2 twisted pair) for full duplex communications and utilizes a transmit pair of wires (TDA

& TDB) and a receive pair of wires (RDA & RDB).

Figure 2.4 shows the terminal assignments for the bus RS-485 serial connection. Either end may be connected

to a MultiLoad or other serial device as the bus supplies the serial connection to all modules that are joined

together. The TD and RD pairs are swapped at the MultiLoad II. Although the ten position terminal block is rated

for 14 to 30 AWG [2.1 to 0.05 mm2], a reliable serial connection will be achieved by the use of cable meeting the

following:

24 AWG [0.2 mm2] stranded.

4-wire, two twisted pair with overall shield.

30 pF maximum between conductors.

1,000 ohm impedance.

Maximum length: 4,000 feet (1,220 Meters)

Maximum stub length: 15 feet.

All exposed shields must be properly insulated to prevent short circuits.

All shields must be continuous, soldered and properly insulated.

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 2 – Installation

15

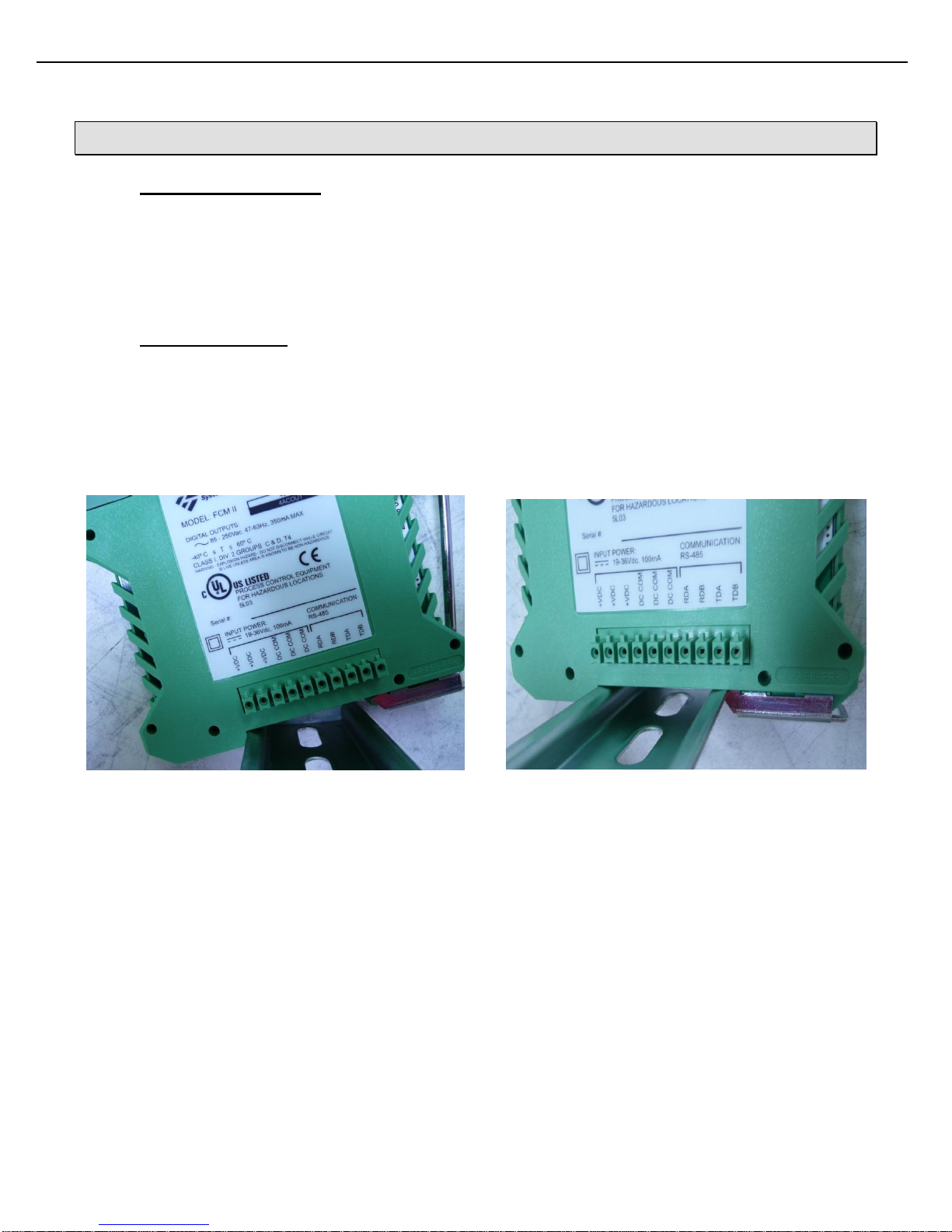

2.6 DEVICE ADDRESS CONFIGURATION

Figure 2.5 shows the locations of I/O, power, and communication status indicators and the location of DIP

switches used to set the module’s serial address. The table below provides the settings for FCM addresses 0 –

31.

Port 0 Status Port 1 Status

Port 2 Status Port 3 Status

Port 4 Status Port 5 Status

Port 6 Status Port 7 Status

TX Status RX Status

FCM 5V Power FCM 12V Output

FCM Address

Dip Switches

Figure 2.5 Module Status, Configuration Setting and Identification

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 2 – Installation

16

FCM

Address

Dip Switch Settings

8 7 6 5 4 3 2

1

0

0 0 0 0 0 0 0 0 1

0 0 0 0 0 0 0

1 2 0 0 0 0 0 0 1

0

3

0 0 0 0 0 0 1

1 4 0 0 0 0 0 1 0 0 5

0 0 0 0 0 1 0

1

6

0 0 0 0 0 1 1

0 7 0 0 0 0 0 1 1 1 8

0 0 0 0 1 0 0

0 9 0 0 0 0 1 0 0

1

10

0 0 0 0 1 0 1

0

11

0 0 0 0 1 0 1 1 12

0 0 0 0 1 1 0

0

13

0 0 0 0 1 1 0

1

14

0 0 0 0 1 1 1

0

15

0 0 0 0 1 1 1 1 16

0 0 0 1 0 0 0

0

17

0 0 0 1 0 0 0

1

18

0 0 0 1 0 0 1

0

19

0 0 0 1 0 0 1

1

20

0 0 0 1 0 1 0

0

21

0 0 0 1 0 1 0

1

22

0 0 0 1 0 1 1

0

23

0 0 0 1 0 1 1 1 24

0 0 0 1 1 0 0

0

25

0 0 0 1 1 0 0

1

26

0 0 0 1 1 0 1

0

27

0 0 0 1 1 0 1 1 28

0 0 0 1 1 1 0

0

29

0 0 0 1 1 1 0

1

30

0 0 0 1 1 1 1

0

31

0 0 0 1 1 1 1

1

0=Off (switch to the right), 1=On (switch to the left)

Figure 2.6 DIP Switch Configuration Settings

2.7 SWING ARMS

An industry practice of sharing loading equipment between two adjacent lanes is termed a “swing arm.” The

reference indicates the actual practice in which one load arm can be swung from one side of a loading bay to

another. To achieve this, the FCM II controlling the I/O associated with that field equipment must have its

communication switched between the MutliLoad II on each lane, depending on which lane the load arm resides

when in use. This communication is switched via a four pole relay and the ring switch attached to the swing arm

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 2 – Installation

17

Be aware of device addressing and ensure that duplicate addresses do not exist. The addresses

of shared FCM IIs must not be duplicated in either bay.

Control of the relay coils is to be wired by the customer to the arm ring switch. Note the voltage

available and match it to the relay coil voltage rating. If DC voltage is used, a reverse biased diode

is recommended to snub ringing voltage when the coil opens.

Although star wiring of FCM IIs is discouraged, star wiring of the shared modules is necessary

since switching of shared upstream modules would remove the connectivity of one of the

communication lines from the downstream modules in a daisy chain configuration.

is used to energize or de-energize that relay. Figure 2.7 shows the wiring required to achieve this. The following

guidelines are suggested.

Figure 2.7 Swing Arm Wiring of Shared FCM IIs

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

18

Note that the ANALOG board is factory assembled with a 4DCIN/4ACOUT module into a double

wide configuration. It is not possible to use the analog module as a single module, nor should the

analog board be disconnected from its attached 4DCIN/4ACOUT module.

CHAPTER 3 FIELD WIRING

3.1 CONNECTION REQUIREMENTS

Although each right angle, four position terminal block is rated for the use of solid or stranded copper 12 to 30

AWG [3.3 to 0.05 mm2], Toptech recommends using stranded copper wire 12 AWG to 24 AWG [3.3 to 0.2 mm2]

depending on the type of field device. The required screw tightening torque is 5 to 7 Lb-in. [0.6 to 0.8 Nm]. Wires

must be stripped ¼” and inserted into terminal block. Details concerning field wiring terminal assignments are

given later in this chapter.

3.2 FCM II FIELD DEVICE CONNECTIONS

FCM II consists of 6 different module types (see Electrical Ratings in section 1.1.1):

1. 4DCIN/4ACOUT: 4 DC Inputs (5-30 VDC), 4 AC Outputs (12-250 VAC),

12 Vdc Power Supply, 167 mA Max

2. 6ACIN: 6 AC Input (90-140 VAC) or (180-250 VAC)

3. 6ACOUT: 6 AC Outputs (12-250VAC)

4. 6DCIN: 6 DC Inputs (5-30 VDC)

5. 6DCOUT: 6 DC Outputs (0-30 VDC)

6. ANALOG/4DCIN/4ACOUT: RTD Input, 4-20mA Input, 4-20mA Out,

4 DC Inputs (5-30 VDC), 4 AC Outputs (12-250 VAC)

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

19

Figure 3.1 FCM II Single And Double Module Comparison

3.2.1 TERMINAL IDENTIFICATION

All DC Field Wiring Connections

Power/COM Connection Bus Power/COM Connection Bus

All AC Field Wiring Connections

Figure 3.2 FCM II Field Wiring Terminal Locations

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

20

Gnd/Overfill Switched

Line

N.O. Digital

Valve

Solenoid

N.C. Digital

Valve

Solenoid

Neutral

Meter

Pulser

12V +

Gnd

Pulse A

(Optional)Pulse B

Port 2 Output

Port 3 Output

Port 4 Input

Port 5 Input

Caution: Line voltage used to drive the Digital Valve

Solenoids MUST be controlled by the Ground/Overfill

monitor.

In the event of a Ground loss or Overfill detection, this

voltage must be switched off to ensure a failsafe

shutdown of the product flow.

- - + +

D4 D3 D2 D1

12Vdc

Top Side

Bottom Row

- + - +

E4 E3 E2 E1

() ()

Top Side

Middle Row

Port 5

Port 4

In Out In Out

A1 A2 A3 A4

Bottom Side

Bottom Row

Port 0

Port 1

In Out In Out

B1 B2 B3 B4

Bottom Side

Middle Row

Port 3

Port 2

A

B

E

D

F

Terminal

Number

- + - +

F4 F3 F2 F1

Top Side

Top Row

Port 7

Port 6

1234

1 2 3 4

3.2.2 FLOW METER AND CONTROL VALVE WIRING

Figure 3.3 FCM II Field Wiring: Flow Meter and Control Valve

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

21

Line

#3 Additive

Valve

Solenoid

#4 Additive

Valve

Solenoid

Neutral

12V+

Gnd

#1 Additive

Valve

Solenoid

#2 Additive

Valve

Solenoid

#1 Additive

Meter Pulser

or Switch

#2 Additive

Meter Pulser

or Switch

#3 Additive

Meter Pulser

or Switch

#4 Additive

Meter Pulser

or Switch

Port 0 Output

Port 1 Output

Port 3 Output

Port 2 Output

Port 7 Input

Port 6 Input

Port 5 Input

Port 4 Input

12V+

Gnd

- - + +

D4 D3 D2 D1

12Vdc

Top Side

Bottom Row

In Out In Out

B1 B2 B3 B4

Bottom Side

Middle Row

Port 3

Port 2

A

B

E

D

F

Terminal

Number

- + - +

E4 E3 E2 E1

Top Side

Middle Row

Port 5

Port 4

- + - +

F4 F3 F2 F1

Top Side

Top Row

Port 7

Port 6

In Out In Out

A1 A2 A3 A4

Bottom Side

Bottom Row

Port 0

Port 1

1234

1 2 3 4

3.2.3 ADDITIVE WIRING

Note: Most additive injection meters only provide an Open-Collector (pull down) type output. Typically a 1,000

Ohm, ¼ watt pull-up resistor needs to be added in the pulser junction box to pull this output to 12V+ when the

output is off.

Figure 3.4 FCM II Field Wiring: Additive Meters and Injection Valves

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

22

White

4-Wire

100 Ohm Platium RTD

Alpha = 0.0385

Note: All 4 wires MUST be run to the

sensor. Do not simply jumper REF- to

COM or REF+ to V+ at the FCM II.

For 3-wire and 2 wire probes, the

connection of REF- to COM and REF+ to

V+ should be as close as possible to the

probe (within inches).

White

Red

Red

White

Red

2-Wire RTD Connection

White

Red

3-Wire RTD Connection

Red

Com R- R+ V+

D4 D3 D2 D1

RTD

Top Side

Bottom Row

NC NC I- I+

E4 E3 E2 E1

Top Side

Middle Row

4-20 mA IN

Iout Rtn Com V+

F4 F3 F2 F1

Top Side

Top Row

4-20 mA OUT

E

D

F

Terminal

Number

1234

1 2 3 4

1234

3.2.4 RTD TEMPERATURE PROBE WIRING

FCM II Installation Guide: 20160419 - Part # 2307

Figure 3.5 FCM II Field Wiring: RTD

Chapter 3 – Field Wiring

23

4-20mA Transmitter

+

-

Iout Rtn Com V+

F4 F3 F2 F1

Top Side

Top Row

4-20 mA OUT

Terminal

Number

Com R- R+ V+

D4 D3 D2 D1

RTD

Top Side

Bottom Row

NC NC I- I+

E4 E3 E2 E1

Top Side

Middle Row

4-20 mA IN

E

D

F

1234

1 2 3 4

1234

External Power Supply

(+)(-)

I

3.2.5 4-20MA INPUT WIRING: LOOP CURRENT PROVIDED BY EXTERNAL POWER SUPPLY

NOTE: The receiver does not contain a voltage source. The loop must be powered either by the transmitter or by

Figure 3.6 FCM II Field Wiring: 4-20mA Input

an external power supply. The I/O Board adds 75 Ohms to the loop.

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

24

Iout Rtn Com V+

F4 F3 F2 F1

Top Side

Top Row

4-20 mA OUT

Terminal

Number

Com R- R+ V+

D4 D3 D2 D1

RTD

Top Side

Bottom Row

NC NC I- I+

E4 E3 E2 E1

Top Side

Middle Row

4-20 mA IN

E

D

F

1234

1 2 3 4

1234

External Power Supply

(+)(-)

I

I-

I+

4-20mA Transmitter

V+

V-

3.2.6 4-20MA INPUT WIRING: LOOP CURRENT PROVIDED BY TRANSMITTER

Figure 3.7 FCM II Field Wiring: 4-20mA Input

NOTE: The receiver does not contain a voltage source. The loop must be powered either by the transmitter or by

an external power supply. The I/O Board adds 75 Ohms to the loop.

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

25

4-20mA Receiver

+

-

Note: The 4-20mA output requires a

power source (12-30vdc). The 12vdc

output can be used as shown here.

Com R- R+ V+

D4 D3 D2 D1

RTD

Top Side

Bottom Row

NC NC I- I+

E4 E3 E2 E1

Top Side

Middle Row

4-20 mA IN

Iout Rtn Com V+

F4 F3 F2 F1

Top Side

Top Row

4-20 mA OUT

Terminal

Number

E

D

F

E

D

F

- - + +

D4 D3 D2 D1

Top Side

Bottom Row

12Vdc

- + - +

E4 E3 E2 E1

Top Side

Middle Row

Port 5

Port 4

- + - +

F4 F3 F2 F1

Top Side

Top Row

Port 7

Port 6

1234

1 2 3 4

1234

3.2.7 4-20MAOUTPUT WIRING

Figure 3.8 FCM II Field Wiring: 4-20mA Output

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

26

Line

Block Valve

Status

VRU/VCU

Neutral

Ground/

Overfill

ESD

Note: This shows a typical configuration.

AC Permissive/Status inputs can be

assigned to any unused AC inputs.

Pump

Status

Etc.

Port 5 Input

Port 4 Input

Port 3 Input

Port 2 Input

Port 1 Input

Port 0 Input

Caution: The 6ACIN module is available

in 90-140 VAC and 180-250 VAC

models.

VERIFY MODULE VOLTAGE LISTED!!!

L N L N

A1 A2 A3 A4

Bottom Side

Bottom Row

Port 0

Port 1

L N L N

B1 B2 B3 B4

Bottom Side

Middle Row

Port 2

Port 3

L N L N

C1 C2 C3 C4

Bottom Side

Top Row

Port 4

Port 5

Terminal

Number

1 2 3 4

3.2.8 AC PERMISSIVE/STATUS WIRING (6ACIN)

Figure 3.9 FCM II Field Wiring: AC Permissive/Status (6ACIN)

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

27

Component 1

Pump Run

Component 2

Pump Run

Component 3

Pump Run

Additive

Pump Run

Block Valve 1

Open

Block Valve2

Open

Line

Neutral

Note: This shows a typical configuration.

AC ouputs can be assigned to any

unused AC outputs.

In Out In Out

A1 A2 A3 A4

Bottom Side

Bottom Row

Port 0

Port 1

In Out In Out

B1 B2 B3 B4

Port 3

Port 2

Bottom Side

Middle Row

In Out In Out

B1 B2 B3 B4

Bottom Side

Top Row

Port 4

Port 5

A

B

C

Terminal

Number

1 2 3 4

3.2.9 AC OUTPUT WIRING (6ACOUT)

Figure 3.10 FCM II Field Wiring: AC Pump and Valve Control (6ACOUT)

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

28

5-30 Vdc

Power

Block Valve

Status

VRU/VCU

Common

Ground/

Overfill

ESD

Note: This shows a typical configuration.

DC Permissive/Status inputs can be

assigned to any unused DC inputs.

Pump

Status

Etc.

Port 0 Input

Port 1 Input

Port 2 Input

Port 3 Input

Port 4 Input

Port 5 Input

Terminal

Number

E

D

F

- + - +

D4 D3 D2 D1

Top Side

Bottom Row

Port 1

Port 0

- + - +

E4 E3 E2 E1

Top Side

Middle Row

Port 3

Port 2

- + - +

F4 F3 F2 F1

Top Side

Top Row

Port 5

Port 4

1234

3.2.10 DC PERMISSIVE/STATUS WIRING (6DCIN)

Figure 3.11 FCM II Field Wiring: DC Permissive/Status (6DCIN)

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

29

5-30 Vdc

Power

VRU/VCU

Common

Ground/

Overfill

ESD

Note: This shows a typical configuration.

DC Permissive/Status inputs can be

assigned to any unused DC inputs.

Etc.

Port 4 Input

Port 5 Input

Port 6 Input

Port 7 Input

Note: Ports 4-7 can be used for general DC inputs when not configured for additive or component

meter input.

L N L N

A1 A2 A3 A4

Bottom Side

Bottom Row

Port 0

Port 1

L N L N

B1 B2 B3 B4

Bottom Side

Middle Row

Port 2

Port 3

A

B

E

D

F

Terminal

Number

- - + +

D4 D3 D2 D1

Top Side

Bottom Row

12Vdc

- + - +

E4 E3 E2 E1

Top Side

Middle Row

Port 5

Port 4

- + - +

F4 F3 F2 F1

Top Side

Top Row

Port 7

Port 6

1234

1 2 3 4

3.2.11 DC PERMISSIVE/STATUS WIRING (4DCIN/4ACOUT)

Figure 3.12 FCM II Field Wiring: DC Input (4DCIN/4ACOUT)

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

30

Line

Port 3 Output

Open Block

Valve

Neutral

Component

Pump Run

Additive

Pump Run

Note: This shows a typical configuration.

AC ouputs can be assigned to any

unused AC outputs.

Etc.

Port 0 Output

Port 1 Output

Port 2 Output

Note: Ports 0-3 can be used for general

AC outputs when not configured for

additive or digital valve control.

- - + +

D4 D3 D2 D1

Top Side

Bottom Row

12Vdc

A

B

E

D

F

Terminal

Number

- + - +

E4 E3 E2 E1

Top Side

Middle Row

Port 5

Port 4

- + - +

F4 F3 F2 F1

Top Side

Top Row

Port 7

Port 6

In Out In Out

A1 A2 A3 A4

Bottom Side

Bottom Row

Port 0

Port 1

In Out In Out

B1 B2 B3 B4

Port 3

Port 2

Bottom Side

Middle Row

1234

1 2 3 4

3.2.12 AC OUTPUT WIRING (4DCIN/4ACOUT)

Figure 3.13 FCM II Field Wiring: AC Output (4DCIN/4ACOUT)

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

31

5-30 Vdc

Power

Open Block

Valve

Bay Active

Common

Component

Pump Run

Additive

Pump Run

Note: This shows a typical configuration.

DC ouputs can be assigned to any

unused DC outputs. Any DC output port

can be configured as an output pulse

Pulse Out

Etc.

Port 0 Output

Port 1 Output

Port 2 Output

Port 3 Output

Port 4 Output

Port 5 Output

E

D

F

Terminal

Number

In Out In Out

D4 D3 D2 D1

Top Side

Bottom Row

Port 1

Port 0

In Out In Out

E4 E3 E2 E1

Top Side

Middle Row

Port 3

Port 2

In Out In Out

F4 F3 F2 F1

Top Side

Top Row

Port 5

Port 4

1234

3.2.13 DC OUTPUT WIRING (6DCOUT)

Figure 3.14 FCM II Field Wiring: DC Output (6DCOUT)

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

32

Gnd/Overfill Switched

Line

N.O. Digital

Valve

Solenoid

N.C. Digital

Valve

Solenoid

Port 2 Output

Port 3 Output

Air Purge

Valve

Solenoid

Top Float Switch

Bottom Float Switch

Neutral

High

Low

Not Low Low

Air Eliminator

Neutral

Note 2: Port 1 configured as Alt. High Flow Rate Inversed. When this signal is removed,

the flow rate will drop to the Alt. High Flow Rate.

Note 1: When the level drops below Low Low, the power will be removed from the digital

valves, stopping flow before the air eliminator is completely drained.

L N L N

A1 A2 A3 A4

Bottom Side

Bottom Row

Port 0

Port 1

L N L N

B1 B2 B3 B4

Bottom Side

Middle Row

Port 2

Port 3

L N L N

C1 C2 C3 C4

Bottom Side

Top Row

Port 4

Port 5

A

B

Terminal

Number

A

B

C

In Out In Out

A1 A2 A3 A4

Bottom Side

Bottom Row

Port 0

Port 1

In Out In Out

B1 B2 B3 B4

Bottom Side

Middle Row

Port 2

Port 3

1 2 3 4 1 2 3 4

3.2.14 3 OUTPUT AIR ELIMINATOR WIRING

Figure 3.15 FCM II Field Wiring: 3 Output Air Eliminator

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

33

Gnd/Overfill

Switched

Line

N.O. Digital

Valve

Solenoid

N.O. Digital

Valve

Solenoid

Neutral

Port 2 Output

Port 3 Output

Air Purge

Valve

Solenoid

Top Float Switch

Neutral

High

Low

Air Eliminator

Note 2: With only two states returned from the air eliminator, flow must be completely stopped to

purge air.

To purge air by only slowing the rate, a 3 output air eliminator head must be used.

Note 1: When the level drops below Low, the power will be removed from the digital valves, stopping

flow before the air eliminator is completely drained.

A

B

Terminal

Number

In Out In Out

A1 A2 A3 A4

Bottom Side

Bottom Row

Port 0

Port 1

In Out In Out

B1 B2 B3 B4

Bottom Side

Middle Row

Port 2

Port 3

1 2 3 4

3.2.15 2 OUTPUT AIR ELIMINATOR WIRING

Figure 3.16 FCM II Field Wiring: 2 Output Air Eliminator

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 3 – Field Wiring

34

Counter Increment

Pulses (White)

Counter Reset Pulse

(Green)

E

D

F

1234

Ground/Common (Black)

- + - +

E4 E3 E2 E1

Top Side

Middle Row

Port 5

Port 4

- + - +

F4 F3 F2 F1

Top Side

Top Row

Port 7

Port 6

E

D

F

1234

+12VDC (Red)

(Output Pulse Port)

(Batch Authorized Inverse Port)

MODEL: E1613

Note:

1. Use only model E1613.

External

Power Supply

(-)(+)

Terminal

Number

3.2.16 LECTRO COUNT REMOTE DISPLAY WIRING

Figure 3.17 FCM II Field Wiring: Lectro Count Remote Display

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 4 – Simulation

35

!

Do not make connections to field terminals. UNEXPECTED OPERATION MAY RESULT. The I/O

is close looped in logic.

CHAPTER 4 SIMULATION

The FCM II simulator is a special version of an FCM II 4DCIN, 4ACOUT module. The FCM II simulator differs

from an FCM 1 simulator in that it is configured entirely from MultiLoad (no keyboard or display required). This

simulator is able to perform most all of the FCM I simulator functions with the exception of forcing error conditions

and looping back outputs to inputs. Loopbacks may be wired externally however.

4.1 METER SIMULATION

Product flow control loops can be run in a demonstration mode by imitating a “virtual” flow meter (single or

quadrature) and its associated “virtual” Digital Control Valve. Product flow simulation is automatically enabled

when a meter is assigned to the simulator. Ports 2 and 3 will be automatically assigned and actuated to simulate

the upstream and downstream solenoids of an associated Digital Control valve. Port 4 will be assigned as the

primary meter pulser and the module will behave as if pulses were actually received on Port 4. A quadrature

meter will be simulated if the 'Quad Check Enable' parameter is set in MultiLoad and the secondary meter

channel will be assigned to Port 5.

When ports 2 & 3 are both activated product flow will ramp up. When port 2 is active and port 3 is inactive, flow

will remain constant. When both ports are inactive, flow rate will ramp down to zero.

4.2 ADDITIVE SIMULATION

Up to 4 channels of additive control (Solenoid or Piston type) may also be simulated. If an additive meter is

selected, it will be simulated with a 100 Hz pulser input.

4.3 ANALOG SIMULATION

If analog functions are enabled in MultiLoad such as RTD temperature input, or 4-20mA current input, the

simulator places fixed analog values into these input registers. For the RTD, the fixed temperature is 28.5°C. For

the 4-20mA current input the value is fixed at 12.800mA. The later input provides simulation of a density or

pressure sensor input.

4.4 GENERIC I/O SIMULATION

I/O lines not used for Product or Additive simulation are available as general purpose DC inputs or AC outputs.

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 5 – Troubleshooting

36

CHAPTER 5 TROUBLESHOOTING

Port 0 Status Port 1 Status

Port 2 Status Port 3 Status

Port 4 Status Port 5 Status

Port 6 Status Port 7 Status

TX Status RX Status

FCM 5V Power FCM 12V Output

FCM Address

Dip Switches

Figure 5.1 FCM II Module Front Panel

5.1 IS THE MODULE POWERED?

All standalone FCM II modules have a front panel LED that shows the power status of its 5V power. In addition,

the 4DCIN/4ACOUT module has a 12V indicator LED showing the status of its onboard 12 Vdc supply used to

power field device dc inputs. The modules must be powered from the BUS rail with a DC voltage source of 19 –

36 Vdc. If required, verify the output voltage and current capacity of the power supply used to power the FCM IIs.

5.2 IS THE MODULE COMMUNICATING?

The quickest check that an FCM II module is communicating with a MultiLoad or other serial device is to look for

the module’s front panel TX LED to flash. The RX LED on all modules will flash when the MultiLoad or other line

master sends a message to any multidropped FCM.

For a more in depth communication status indication, the MultiLoad’s Diagnostic Menu may be used. This menu

is accessible from within the MultiLoad’s configuration mode.

1) Enter program mode by pressing 00000 on the keypad, then press Next key.

2) Select diagnostics from main menu.

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 5 – Troubleshooting

37

D I A G N O S T I C S M E N U

Next Prev Exit Enter

004 FCM COM DIAGNOSTICS

Exit

3) Select FCM COM

Card Reader Meters

COM Loopback Components

Serial Ports Additives

Network Test Custom Logic

Keypad

Display

Unicode

FCM Com

PCM Com

FCM Health

PCM Health

RCU

Bay

Preset

00-Ok

01-Ok

02-Ok

4) If screen display is the same as above, the FCM IIs are communicating with the MultiLoad II.

5) If an FCM II is not communicating, the message XX-ERR appears where XX is the address of the FCM that is

not communicating.

6) For a log of the occurances of dropped communications (including the registration as com loss when the

module has been powered down), select the menu option FCM HEALTH.

Should a module have a “ERR” state, double check that the device address has been set correctly and that two

devices do not share a duplicate address. If all modules have an “ERR” state, check the bus communication

wiring (see section 2.5).

5.3 ARE THE INPUTS FUNCTIONING?

An input LED will only illuminate when a voltage of 5 – 30 Vdc appears across the input’s terminal pair. If a

problem occurs, verify the wiring shown in chapter 3.

5.4 ARE THE OUTPUTS FUNCTIONING?

The output LED will illuminate in response to an output commanded on. If necessary, check the output terminal

with a voltmeter.

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 5 – Troubleshooting

38

PRE #1 MTR #1 TEMPERATURE

Temperature Unadjusted: -1.87C

[1]Temperature Offset: +0.00C

[2]Temperature Adjusted: -1.87C

Next Prev Exit

5.5 ARE RTD ERRORS PRESENT?

Selecting Temperature from the “Views and Inquiries” menu allows for viewing of each meter’s temperature

grouped by preset. At the meter level, the screen below is available. The normal message on the fifth line is

“Status OK.” In event of an error, there are two messages:

Probe Error: The probe is faulty, there is a wire break, or no cable connection.

Module Has Bad AD Converter: Damage of the electronics within the RTD analog circuitry has occurred.

The unit must be returned to Toptech for repair or replacement.

Status Ok

5.6 ARE OTHER ERRORS PRESENT?

Please consult the MultiLoad User Manual for further errors that are not covered here. The MultiLoad User

Manual describes in great detail how to configure an FCM II panel for most kinds of control applications as well as

how to troubleshoot those setups.

5.7 IS TECHNICAL ASSISTANCE AVAILABLE?

Technical assistance may be obtained during business hours (or during extended hours by arrangement) from

Toptech System’s Support Department by dialing 407-332-1774 x381 or x382.

In Europe, assistance may be obtained during business hours (or during extended hours by arrangement) from

Toptech Europe by dialing +32 (0)3 250 60 60.

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 6 – Dimensions, Panel Layouts, Wiring

39

CHAPTER 6 DIMENSIONS, PANEL LAYOUTS, WIRING SUGGESTIONS

6.1 MODULE DIMENSIONS

Figure 6.1 FCM II Single Module Dimensions

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 6 – Dimensions, Panel Layouts, Wiring

40

Figure 6.2 FCM II Double Module Dimensions

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 6 – Dimensions, Panel Layouts, Wiring

41

The maximum number of FCM IIs on this panel is the equivalent of 12 single wide modules.

Toptech recommends mounting the power supply on the DIN rail with the FCM IIs as most DIN rail

power supplies require vertical mounting and top/bottom clearance for proper cooling.

6.2 STANDARD PANEL DIMENSIONS

6.2.1 20 INCH X 20 INCH PANEL

Figure 6.3 20 Inch x 20 Inch Panel Layout

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 6 – Dimensions, Panel Layouts, Wiring

42

Figure 6.4 20 Inch x 20 Inch Enclosure Dimensions

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 6 – Dimensions, Panel Layouts, Wiring

43

The maximum number of FCM IIs on this panel is the equivalent of 18 single wide modules per row

(36 total).

Toptech recommends mounting the power supply on the DIN rail with the FCM IIs as most DIN rail

power supplies require vertical mounting and top/bottom clearance for proper cooling.

Each row of FCM IIs requires its own power supply.

6.2.2 30 INCH X 30 INCH PANEL

Figure 6.5 30 Inch x 30 Inch Panel Layout

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 6 – Dimensions, Panel Layouts, Wiring

44

Figure 6.6 30 Inch x 30 Inch Enclosure Dimensions

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 6 – Dimensions, Panel Layouts, Wiring

45

6.3 PANEL ELECTRICAL WIRING SUGGESTIONS

6.3.1 POWER AND COMMUNICATION DISTRIBUTION

FCM II modules were designed to minimize 24 Vdc input power and serial communication wiring by employing a

distribution buss in the base of the modules. Therefore, considerations only have to be made as to which side of

a DIN rail assembly the power and communication cable should attach (left side female plug or right side male

plug). Note also that star wiring should be avoided, so communication cable extension to adjacent rows ought to

use the opposite end of the joined modules than the end from which communication enters.

Toptech also recommends using one power supply for each DIN rail assembly. See Figures 6.7 to 6.9 for the

various configurations of FCM II power and serial communication wiring schematics.

Figure 6.7 FCM II Power and Serial Communication Panel Wiring: Single Row

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 6 – Dimensions, Panel Layouts, Wiring

46

Figure 6.8 FCM II Power and Serial Communication Panel Wiring: Two Rows, Two Serial Ports

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 6 – Dimensions, Panel Layouts, Wiring

47

Figure 6.9 FCM II Power and Serial Communication Panel Wiring: Two Rows, One Serial Port

6.3.2 WIRING TERMINAL IDENTIFICATION

Figure 6.10 shows the terminal block labeling of field connections. All modules follow the convention of labeling

bottom side plugs from A to C as the staircase to the top and D to F for the top side plugs as they staircase to the

top. Numbers one through 4 are arranged from left to right when viewing the plug from its wire entry side. To

differentiate terminals of different modules, Toptech recommends a module.slot.number identification scheme

where

module is the FCM’s address,

slot is either 0 or 1 depending on whether the terminals are attached to the left or right board in a double wide

housing, and

number is the terminal A to F, 1 to 4.

As an example, an ANALOG/4DCIN/4ACOUT module at address 0, would have its Port 0 line voltage terminal

labeled 0.0.A1 and the loop voltage for the RTD would be labeled 0.1.D1. See Figure 3.5.

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 6 – Dimensions, Panel Layouts, Wiring

48

!

Note: Do not use FCM II ac outputs to directly run pumps. Use an interposing relay. The

rated currents of the ac output modules should be sufficient for most types of solenoid

valves but note the ratings as shown in Figure 1.2 and section 3.2.

Figure 6.10 FCM II Field Terminal Block Labels

6.3.3 VOLTAGE DISTRIBUTION

The common practice of installing a MultiLoad panel usually involves bringing all field devices directly into the

enclosure. But note that DC and AC output modules only switch the voltage and do not distribute Neutral or dc

common voltages. For this reason, Toptech recommends the installation of bussed DIN mounted terminal blocks

to distribute Neutrals and dc commons.

Two ac line voltages are also distributed through the panels. One is normal 120V line voltage switched to additive

injectors, motor operated valves, VRU/VCOs, and pump run signals. The second line voltage to be distributed is

the Ground/Overfill output required by digital control valves.

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 7 – Hardware Revision History

49

Date

Description

01/31/2008

Initial product release with C/US UL Listing.

11/26/2008

Modification of board to board header updating i2c expansion: analog, 4IN/4OUT

09/21/2011

Approved alternate bottom terminal block.

05/11/2012

Replaced AC relay assemblies with discrete triacs (4IN/4OUT, 6ACOUT).

05/11/2012

Replaced DC relay assemblies with discrete MOSFETs (6DCOUT).

10/01/2014

Improved RTD filtering (IO_DA rev 1.3, IO_2M rev 1.2)

CHAPTER 7 HARDWARE REVISION HISTORY

FCM II Installation Guide: 20160419 - Part # 2307

Chapter 8 – Manual Revision History

50

Revision

Date

Description

1.0

09/30/2009

Remove FCMII configuration from chapter 4 of MultiLoad II install guide to its own

install guide.

1.1

06/23/2011

Added Swing Arm configuration.

04/26/2013

Added LectroCount wiring

04/26/2013

Dropped revision number control; control by release date

04/26/2013

Added 12Vdc supply load rating

04/26/2013

Updated European DOC

04/19/2016

Revised Declaration of Conformity (new directive dates in effect 4/20/2016)

CHAPTER 8 MANUAL REVISION HISTORY

FCM II Installation Guide: 20160419 - Part # 2307

Loading...

Loading...