Page 1

OPERATING MANUAL

(Original Instructions)

Label printing & lamination station

Version: 2017-04-01

Machine number: 2016705-01

toptack GmbH

Bachleiten 3 | D-93455 Traitsching

Page 2

Label printing & lamination station - Version: 2017-04-01

Page 2

Table of contents

Introduction ........................................................................................................................ 4

Basic notes ......................................................................................................................................................... 4

Copyright ........................................................................................................................................................... 4

Spare parts management................................................................................................................................... 4

Warranty ............................................................................................................................................................ 5

Manufacturer and service .................................................................................................................................. 5

EC declaration of conformity according to the EC machinery directive 2006/42/EC, Annex II A....................... 6

Rating plate ........................................................................................................................................................ 7

Equipment .......................................................................................................................... 8

Function description .......................................................................................................................................... 8

Intended use ...................................................................................................................................................... 8

Description of the machine ................................................................................................................................ 9

Operating elements with switching cabinet ................................................................................................................... 10

Pneumatic distributor block ........................................................................................................................................... 10

Cylinder unit with vacuum lance .................................................................................................................................... 10

Thermal transfer printer ................................................................................................................................................ 11

Laminate dispenser ........................................................................................................................................................ 11

Protective housing with safety door .............................................................................................................................. 12

Dimensions ...................................................................................................................................................... 13

Technical data .................................................................................................................................................. 14

Processable materials ...................................................................................................................................... 14

Introduction

Safety ............................................................................................................................... 15

General safety notes ........................................................................................................................................ 15

Operator's obligations ..................................................................................................................................... 15

Obligations of the operating and maintenance staff ....................................................................................... 16

Residual dangers .............................................................................................................................................. 17

Personal protection equipment ....................................................................................................................... 17

Safety devices .................................................................................................................................................. 18

Operating elements ........................................................................................................... 19

Operating elements at the control cabinet ...................................................................................................... 19

Brush at the laminate dispenser ...................................................................................................................... 21

Operating elements at the laminate dispenser ............................................................................................... 22

Operating processes .......................................................................................................... 23

Turning on the label printing & lamination station .......................................................................................... 23

Loading the printer label (layout) and specifying the piece number ............................................................... 25

Turning off the label printing & lamination station ......................................................................................... 29

Reset emergency off ........................................................................................................................................ 30

Maintenance ..................................................................................................................... 31

Maintenance plan ............................................................................................................................................ 32

Maintenance work ............................................................................................................ 34

Activate or deactivate manual mode ............................................................................................................... 34

Activating manual mode ................................................................................................................................................ 34

Deactivating manual mode ............................................................................................................................................ 34

Replacing the roll of protective laminate at the laminate dispenser ............................................................... 35

Page 3

Label printing & lamination station - Version: 2017-04-01

Page 3

Replacing the label roll at the thermal transfer printer ................................................................................... 36

Replacing the ink ribbon at the thermal transfer printer................................................................................. 39

Cleaning the printing head of the thermal transfer printer ............................................................................. 42

Disposal ............................................................................................................................ 44

Annex ............................................................................................................................... 45

Introduction

Page 4

Introduction

Label printing & lamination station - Version: 2017-04-01

Page 4

INTRODUCTION

Basic notes

The complete technical documentation is part of the machine according to the EC machinery

directive 2006/42/EC and must be kept near the described machine at all times.

Before commissioning of the machine, this operating manual must be read with care and

completely by the staff. No liability is assumed for any damage and operating faults that result

from non-observance of the instruction texts!

Copyright

Copyright © (2017) toptack GmbH

This operating manual is intended for the operator's staff.

The operating manual must only be reproduced or passed on to any third parties with written

permission. This applies even if only excerpts from the operating manual are copied or

forwarded.

Spare parts management

These operating instructions contain no information on spare parts of the machine.

All information that is needed to order spare parts can be taken from the separate spare parts

list.

If spare parts are used that have not been expressly released by toptack GmbH, this may impair

the safety of the machine!

Page 5

Label printing & lamination station - Version: 2017-04-01

Page 5

Warranty

toptack GmbH's liability period shall be 12 months.

Any liability on the side of toptack GmbH shall be excluded upon:

Use of spare parts that have not been expressly released by toptack GmbH.

Injury and property damage caused by unauthorised or untrained staff.

Injury and property damage caused by unauthorised conversions.

Injury and property damage caused by non-observance of the operating manual.

Injury and property damage caused by work that is not described in this manual and

therefore performed without authorisation.

Manufacturer and service

If you have any questions about the delivered machine, please contact us directly:

Introduction

toptack GmbH

Managing director: Rüdiger Horn

Bachleiten 3

D-93455 Traitsching

Phone: +49 (0) 9974 / 9048 - 477

Telefax: +49 (0) 9974 / 9048 - 479

Email: horn.r@toptack.de

Internet: http://www.toptack.de

Page 6

Introduction

Label printing & lamination station - Version: 2017-04-01

Page 6

EC declaration of conformity according to the EC machinery directive

2006/42/EC, Annex II A

We hereby declare that the following machine corresponds to the basic safety and health

requirements of the EC directive 2006/42/EC in its design and build and in the version marketed

by us. In case of changes to the machine that have not been coordinated with us, this

declaration shall lose its validity.

Manufacturer:

toptack GmbH

Bachleiten 3

D-93455 Traitsching

Description and identification of the machine:

Designation: Label printing & lamination station

Machine number: 2016705-01

Year of build: 04/2017

Person authorised for the technical documentation:

Mr Rüdiger Horn, toptack GmbH, Bachleiten 3, D-93455 Traitsching

Managing director:

Mr Rüdiger Horn, toptack GmbH, Bachleiten 3, D-93455 Traitsching

Traitsching, 01 April 2017

Signature (Rüdiger Horn)

Page 7

Label printing & lamination station - Version: 2017-04-01

Page 7

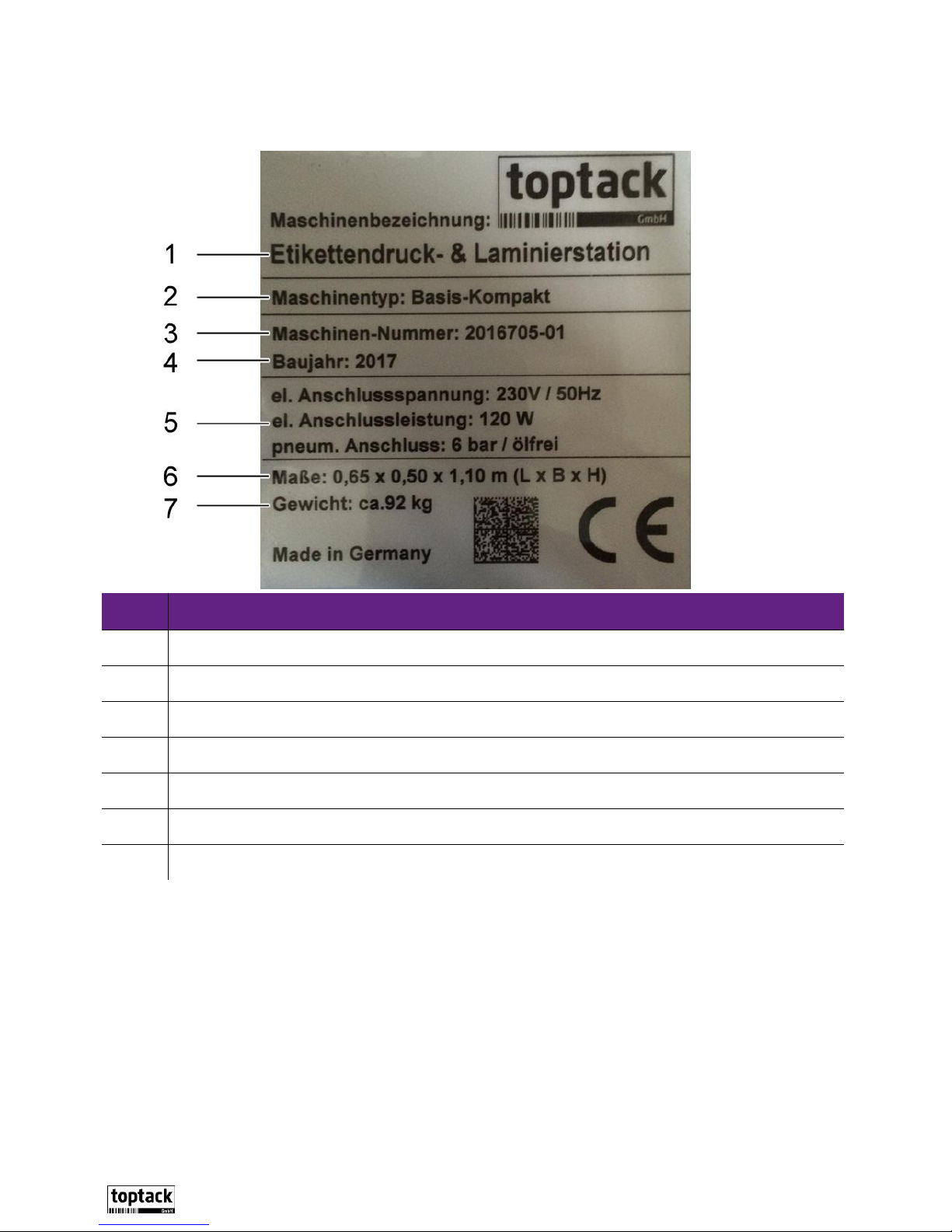

Rating plate

No.

Designation

1

Machine designation

2

Machine type

3

Machine number

4

Year of build of the machine

5

Technical information (electr. supply voltage & power, pneumatics) of the machine

6

Technical information (dimensions, L x W x H) of the machine

7

Technical information (weight) of the machine

Introduction

Page 8

Equipment

Label printing & lamination station - Version: 2017-04-01

Page 8

EQUIPMENT

Function description

The label printing & lamination station can be used to apply labels with different print images

(layout) and provide them with a protective lamination. The print images can be selected from

an internal storage medium. The printed images can be transferred from a network or an

external computer to the station (see Appendix 7 to this manual). The finished labels must be

removed by the operating staff by hand, or can be wound up for later processing.

Intended use

The label printing & lamination station serves only for printing and lamination of labels. The

station must only be operated with materials that can be processed according to the section

"Technical data". The user must also ensure that the required personal protection equipment is

worn so that no danger to himself and to others occurs.

Inadmissible working method:

Processing of any other materials than described in item "Processable materials".

Page 9

Label printing & lamination station - Version: 2017-04-01

Page 9

Description of the machine

No.

Designation

1

Operating elements with switching cabinet

2

Pneumatic distributor block

3

Cylinder unit with vacuum lance

4

Thermal transfer printer

5

Laminate dispenser

6

Protective housing with safety door

6

5

4 3 2

1

Equipment

Page 10

Label printing & lamination station - Version: 2017-04-01

Page 10

Operating elements with switching cabinet

Figure

Description

The operating elements applied to the machine can be used to

perform the different functions.

For a complete description of the operating elements,

see chapter "Operating elements".

All work on electrical facilities must only be performed

by trained, certified electricians licensed according to

the applicable provisions!

Figure

Description

Three electro-pneumatic directional valves are used.

The 5/2 directional valve serves to control the cylinder unit (upand downwards movement of the cylinder).

A 3/2 directional valve is used to control the Venturi nozzle that

generates the vacuum for the vacuum lance (fastening of the

laminate upon movement at the vacuum lance).

A 3/2 directional valve switches the supporting air "on" when

dispensing the laminate, and "off" again after dispensing.

Figure

Description

The vacuum lance of the cylinder unit takes the laminate at the

dispenser and presses it onto the printed label. The laminate is

held during the downwards movement by the vacuum of the

lance. After bonding the laminate, the vacuum is turned off and

the lance will move up again.

Pneumatic distributor block

Equipment

Cylinder unit with vacuum lance

Page 11

Label printing & lamination station - Version: 2017-04-01

Page 11

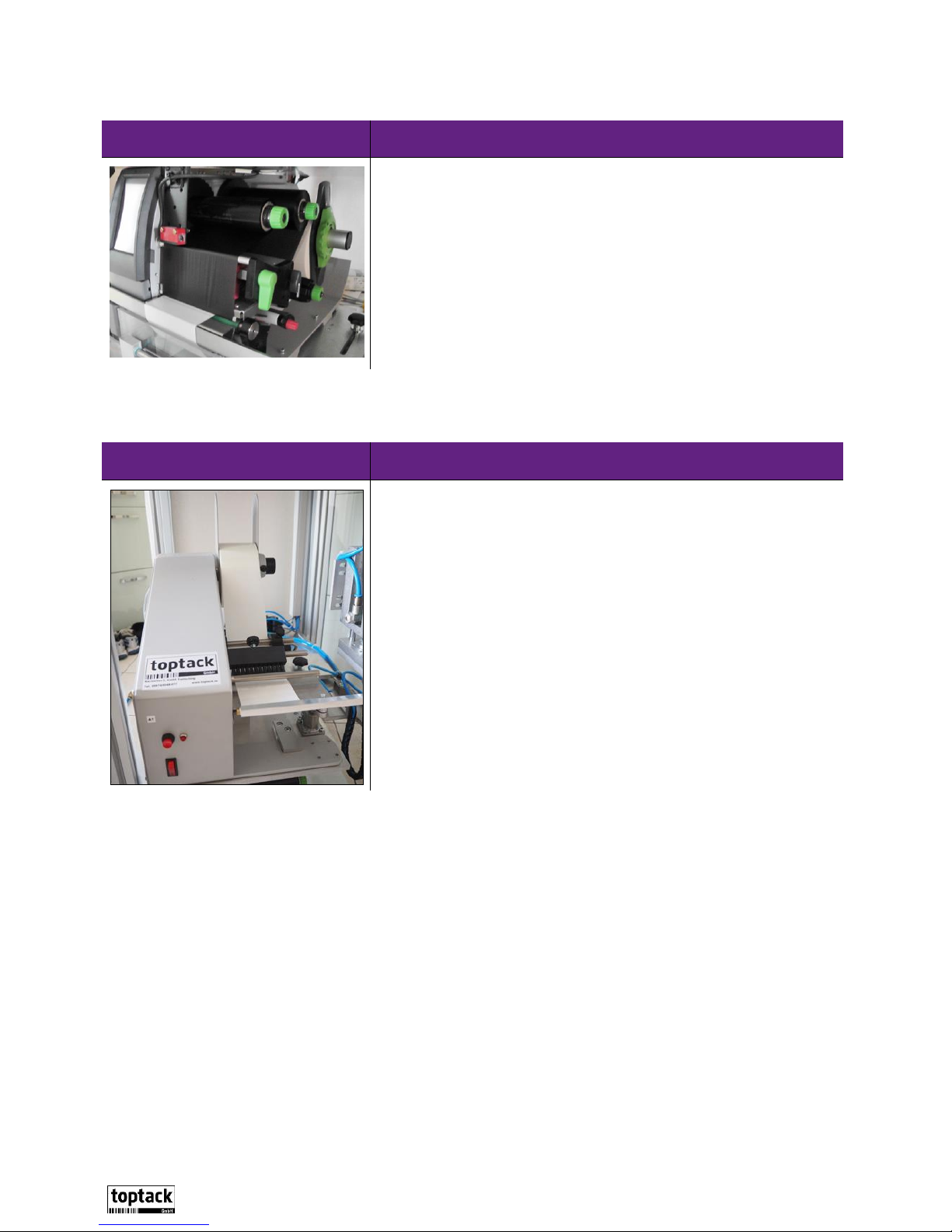

Thermal transfer printer

Figure

Description

Different label layouts can be chosen and printed with the

thermal transfer printer. For each production with internal

memory, the number of pieces to be printed must also be

entered. A memory card that can be plugged in on the rear of the

printer serves as data carrier for the different label layouts. (With

external data connection of the printer, see Appendix 7).

The printer has a coloured touch display. All input and settings at

the printer must be made directly at the display by touching with

a finger.

Figure

Description

The laminate dispenser provides the protective laminate for the

printer labels at the dispensing edge for collection by the vacuum

lance.

Laminate dispenser

Equipment

Page 12

Label printing & lamination station - Version: 2017-04-01

Page 12

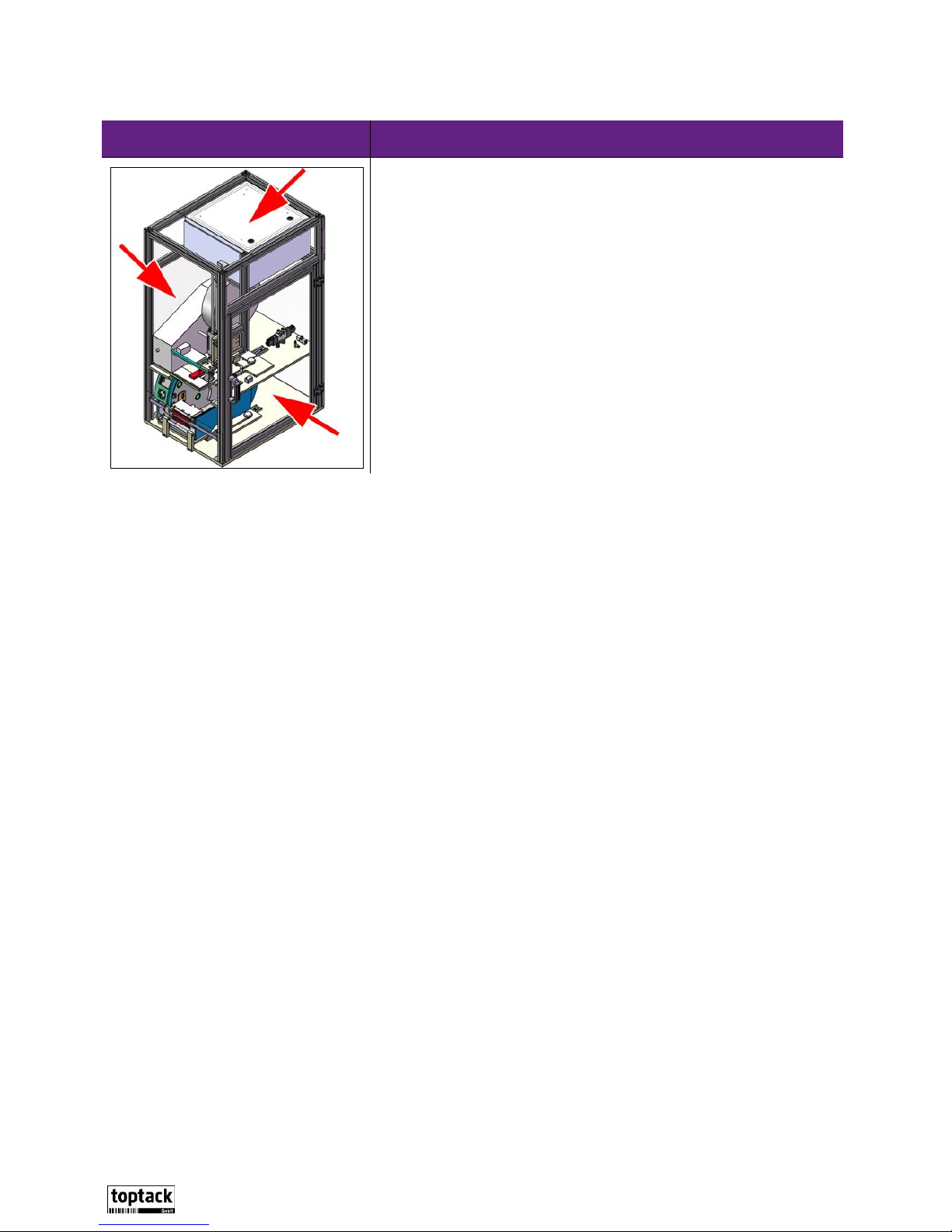

Protective housing with safety door

Figure

Description

The protective housing of Plexiglas protects from crushing at the

label printing & lamination station during machine operation.

The safety door must be closed and locked during

production!

Equipment

Page 13

Label printing & lamination station - Version: 2017-04-01

Page 13

Dimensions

View

Top view

Designation

Value

Length (L):

500 mm

Width (B):

650 mm

Height (H):

1,100 mm

Equipment

Page 14

Label printing & lamination station - Version: 2017-04-01

Page 14

Technical data

Designation

Value

Total weight

approx. 92 kg

Recommended working pressure of the pneumatic

system

6 bar

Necessary minimum pressure of the pneumatic

system

4.5 bar

Electrical connection value

230 V AC, 50 - 60 Hz, 120 W

Admissible ambient temperature

min. 10 °C, max. 25 °C

Designation

Property

Laminate

Self-adhesive, as rolled goods

Format:

min. 10 x 10 mm to max. 12 x 100 mm*

Thickness:

Up to max. 0.5 mm

*expansible to 100 x 100 mm (constructional action of the

manufacturer required)

Label material

Self-adhesive with or without glue, as rolled

goods.

Format:

min. 20 x 12 mm up to max. 100 x 100 mm

Thickness:

Up to max. 0.5 mm

Processable materials

Equipment

Page 15

Label printing & lamination station - Version: 2017-04-01

Page 15

SAFETY

General safety notes

The delivered machine corresponds to the state of the art and is operationally safe. This

machine may pose dangers if it is used by untrained staff, improperly or in a non-intended

manner.

The machine must only be taken into operation by trained staff.

Intended use also includes compliance with the operating and maintenance instructions.

In order to avoid injury, conversions or changes at the machine are only permitted with

express written release from toptack GmbH.

Operator's obligations

The staff must be able to access the operating instructions at any time.

Safety

Every person who is charged with operation and maintenance of this machine in the

user's company must read and understand the entire documentation, and specifically

the safety notes.

No working method is permitted that would impair or endanger the safety of man and

material.

The operator must ensure cleanliness and a good overview of the workplace.

The operator must keep all safety and danger notes attached to the machine in a legible

condition and replace them if necessary.

The operator must ensure that the staff wear approved and tested personal protection

equipment.

The operator must ensure that only such staff work at the machine who meet the

requirements listed in the following sections and who have the required qualifications.

Page 16

Label printing & lamination station - Version: 2017-04-01

Page 16

Obligations of the operating and maintenance staff

Every person who is charged with operation and maintenance of this machine must read

and understand the entire operating manual.

The operating staff must report any unknown or unusual sounds and operating

conditions of the machine that occur to their supervisory at once.

The effectiveness of operating and adjustment parts must not be impaired or influenced.

Before starting any work on the machine, observe the following provisions:

o Do not wear loosely hanging clothing!

o Cover long hair with a hair net!

o Take off loose jewellery, rings and other personal objects that may be caught by

the machine!

Protective devices must only be removed for maintenance purposes:

o At machine standstill,

o with the main switch turned off and secured against unauthorised reactivation.

Before activation of the machine after maintenance work, check that all safety devices

have been properly attached or closed and are fully functional,

Safety

Regionally applicable safety and accident prevention provisions must be observed.

Page 17

Label printing & lamination station - Version: 2017-04-01

Page 17

Residual dangers

Electrical dangers

Danger to life from contact with parts that are subject to high electrical voltage!

Observe warning notes on control cabinet doors and operating panels!

Disconnect the power supply before conducting any maintenance work!

All work must only be performed by trained, certified electricians licensed

according to the applicable provisions!

Danger of crushing

Danger of crushing injury at the label printing & lamination station!

Before activating the station, ensure that the safety door is closed and the lock

locked! The key must be worn "on the person".

Danger of tripping and slipping

Observe all edges, attachment and lines in the machine area.

Remove contamination on the floor (e.g. waste) at once in order to avoid

tripping and slipping hazards!

Wear personal protection equipment

The staff must wear personal protection equipment when operating and working on

the label printing & lamination station:

Wear close-fitting work clothing and a safety hood.

Additionally observe the current operational provisions.

Safety

Personal protection equipment

Page 18

Label printing & lamination station - Version: 2017-04-01

Page 18

Safety devices

Figure

How

Main switch with emergency off function (type B)

Switches the entire power supply of the label printing &

lamination station on or off. The facility cannot be operated in

the deactivated condition.

Disassembly, damage or decommissioning of the main

switch are forbidden!

Perform a visual inspection for proper condition and

inspection of the function at least once per year and

after any maintenance work!

Control cabinet (type A)

Protects from electric shock at electrical facility.

Operation of the label printing & lamination station with

the control cabinet doors open is forbidden!

Access to the control cabinet is only permitted to

electrical specialists!

Disassembly, damage, decommissioning of the control

cabinet are forbidden!

Perform a visual inspection for proper condition at least

once per year and after any maintenance work!

Protective housing of Plexiglas (type A)

Protects from crushing injury at the label printing & lamination

station.

The station must not be operated with the protective

housing disassembled or defective!

Disassembly, damage or decommissioning of the

protective housing are forbidden!

Perform a visual inspection for proper condition at least

once per year and after any maintenance work!

Type of safety devices:

Type A: Separating safety device

Type B: Non-separating safety device

Type C: Deflecting safety device

Safety

Page 19

Label printing & lamination station - Version: 2017-04-01

Page 19

OPERATING ELEMENTS

No.

Function

1

Main switch with EMERGENCY OFF function.

Switches the entire power supply of the label printing & lamination station on or off. The

machines cannot be turned on in the OFF position.

The main switch must be turned off before any work (e.g. maintenance, repair,

troubleshooting, etc.) and secured against unauthorised reactivation with a padlock.

2

Setting the operating mode at the label printing & lamination station:

0 = No operating mode

1 = Operating mode manual mode (operating elements no. 3 - no. 8 active)

2 = Operating mode automatic (controlled production)

Operating elements at the control cabinet

Operating elements

Page 20

Operating elements

Label printing & lamination station - Version: 2017-04-01

Page 20

No.

Function

3

Pushbutton, manual mode: Printing label.

Note: Function of the pushbutton only in operating mode "Manual mode" (no. 2).

4

Pushbutton, manual mode: Infeed laminate dispensing.

Note: Function of the pushbutton only in operating mode "Manual mode" (no. 2).

5

Pushbutton, manual mode: Moves the cylinder up.

Note: Function of the pushbutton only in operating mode "Manual mode" (no. 2).

6

Pushbutton, manual mode: Moves the cylinder down.

Note: Function of the pushbutton only in operating mode "Manual mode" (no. 2).

7

Latching switch, manual mode: Supporting air "on" / "off".

Note: Function of the latching switch only in operating mode "Manual mode" (no. 2).

8

Latching switch, manual mode: Vacuum "on" / "off".

Note: Function of the latching switch only in operating mode "Manual mode" (no. 2).

Page 21

Label printing & lamination station - Version: 2017-04-01

Page 21

Brush at the laminate dispenser

No.

Function

1

The brush produces a lane tension and thus ensures a controlled production of the laminate

dispenser. The lane tension can be adjusted by releasing the knurled screw and increasing or

reducing the brush pressure on the material lane.

Operating elements

Page 22

Label printing & lamination station - Version: 2017-04-01

Page 22

Operating elements at the laminate dispenser

No.

Function

1

Turning the laminate dispenser on or off.

2

Activating permanent operation or confirming fault.

3

LED fault: Lights up in case of a fault at the laminate dispenser.

Operating elements

Page 23

Label printing & lamination station - Version: 2017-04-01

Page 23

OPERATING PROCESSES

Danger of injury from turning on of the label printing & lamination station!

Before activating the label printing & lamination station, ensure:

That no persons are working in the danger area!

That all safety devices are ready for operation or closed!

That no loose foreign bodies are present within the label printing & lamination

station!

Figure

How

1. Before activation of the main switch at the label printing &

lamination station, ensure that the thermal transfer printer

and the laminate dispenser are on and ready for operation.

2. Before activating of the main switch at the label printing &

lamination station, ensure that the safety door is closed and

the lock locked! The key must be worn "on the person".

3. Before activation of the main switch at the label printing &

lamination station, turn on the compressed air and check it.

Turning on the label printing & lamination station

Operating processes

Page 24

Operating processes

Label printing & lamination station - Version: 2017-04-01

Page 24

Figure

How

4. Turn on the main switch of the label printing & lamination

station.

For external data connection of the printer, see Appendix 7

to the operating instructions:

> Controlling the printer via an external computer <

5. Select the required label layout at the printer and load it; see

work description "Loading the printer label (layout) and

specifying the piece number".

6. Specify the required label layout at the printer

see work description "Loading the printer label (layout) and

specifying the piece number".

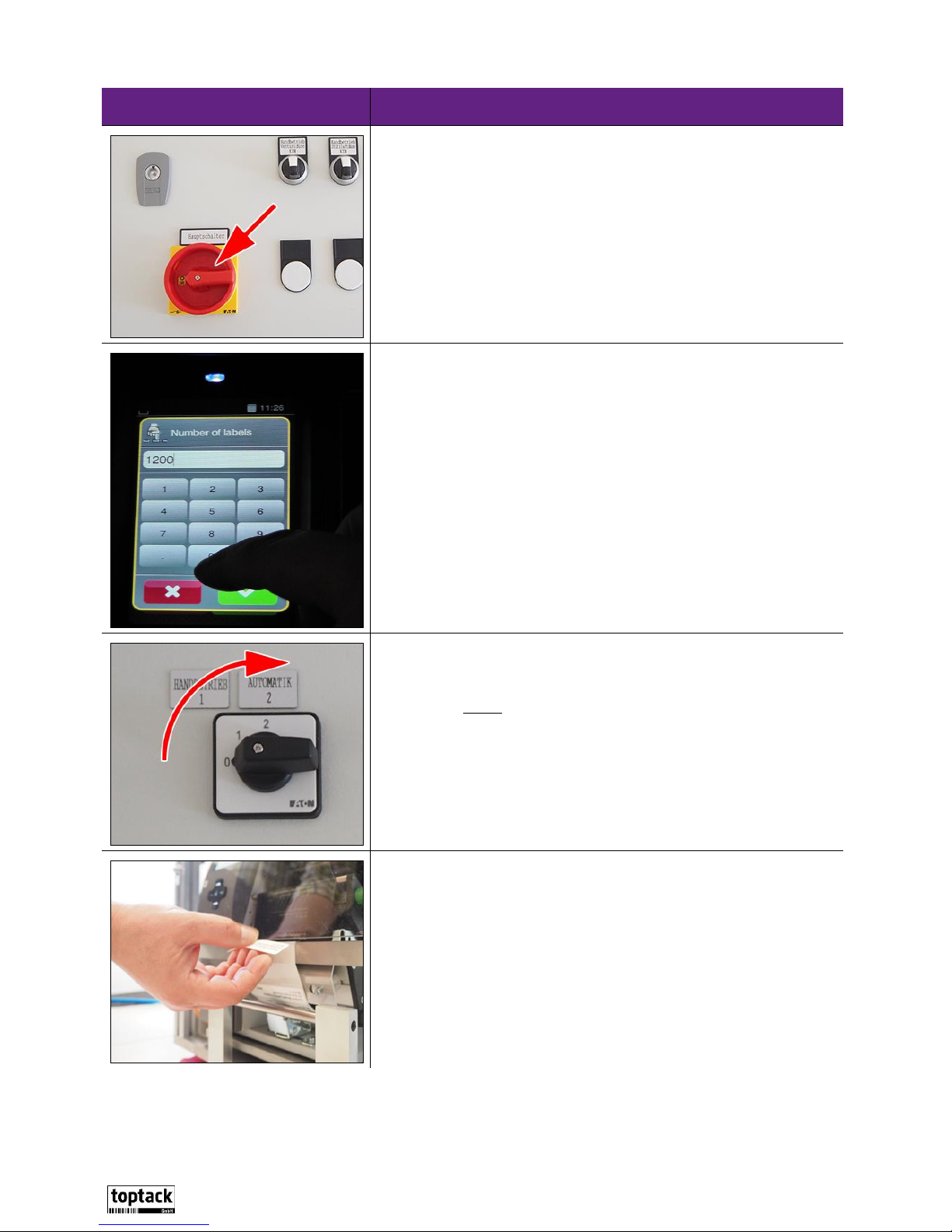

7. Start automatic mode of the main switch of the label printing

& lamination station.

Note: For this, turn the swivel switch to position "2 -

Automatic".

The label printing & lamination station is now

running in automatic mode. The pre-set printer label

(layout) is produced in the required piece number

and provided with laminate.

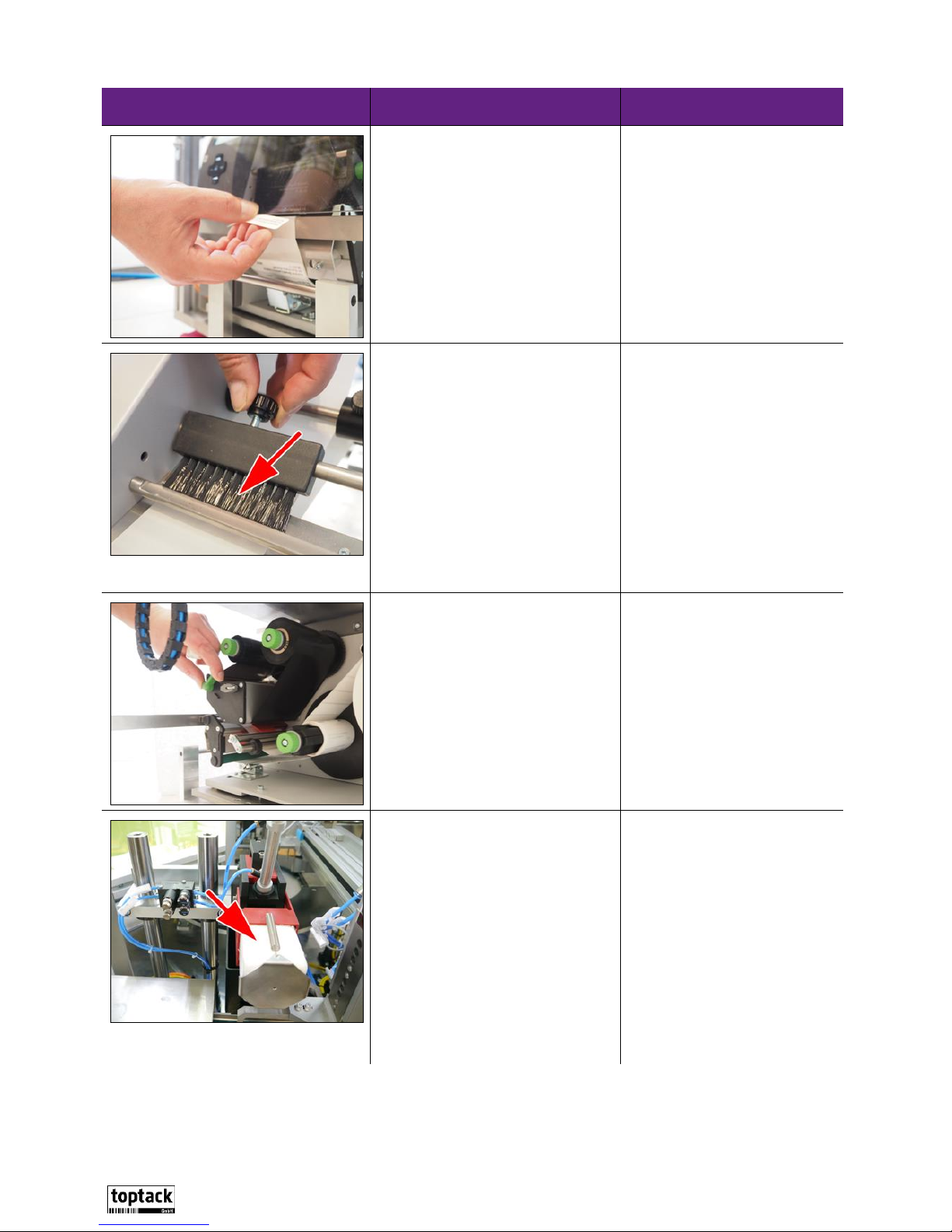

8. The laminated labels must be manually removed at the

output slot.

Page 25

Operating processes

Label printing & lamination station - Version: 2017-04-01

Page 25

Figure

How

1. After activation of the label printing & lamination station, the

required printer label (layout) must be loaded and the piece

number to be produced must be specified*.

* When controlling the printer with data from a network or

an external computer, see Appendix 7 to the operating

instructions:

> External data connection of the printer <

2. Push the symbol with the "gear" 1x.

Loading the printer label (layout) and specifying the piece number

Different printer labels (layouts) can be printed with the thermal transfer printer. For every

production, a piece number must be set as well. A memory card that can be plugged in on the

rear of the printer serves as data carrier for the different printer labels (layouts). However, print

data and quantity can also be sent from an external computer to the printer (see appendix 7 to

the operating instructions > External data connection of the printer <).

Page 26

Operating processes

Label printing & lamination station - Version: 2017-04-01

Page 26

Figure

How

3. Push the symbol with the designation "storage" 1x in order

to select the inserted memory card at the rear of the printer.

4. Push the symbol line "Load label" 1x in order to get to the

table of the layout selection on the memory card.

5. Select the desired printer label manually (touch) in the

display line from the displayed overview of all stored printer

labels (layouts). The selected printer label is displayed with a

yellow background.

Only one printer label can be selected. The selection can be

changed after the first selection by touching another line or a

displayed printer label.

Page 27

Label printing & lamination station - Version: 2017-04-01

Page 27

Figure

How

6. Confirm the label selection. After selection of the desired

printer labels, confirm your selection by pushing the green

"OK" symbol 1x.

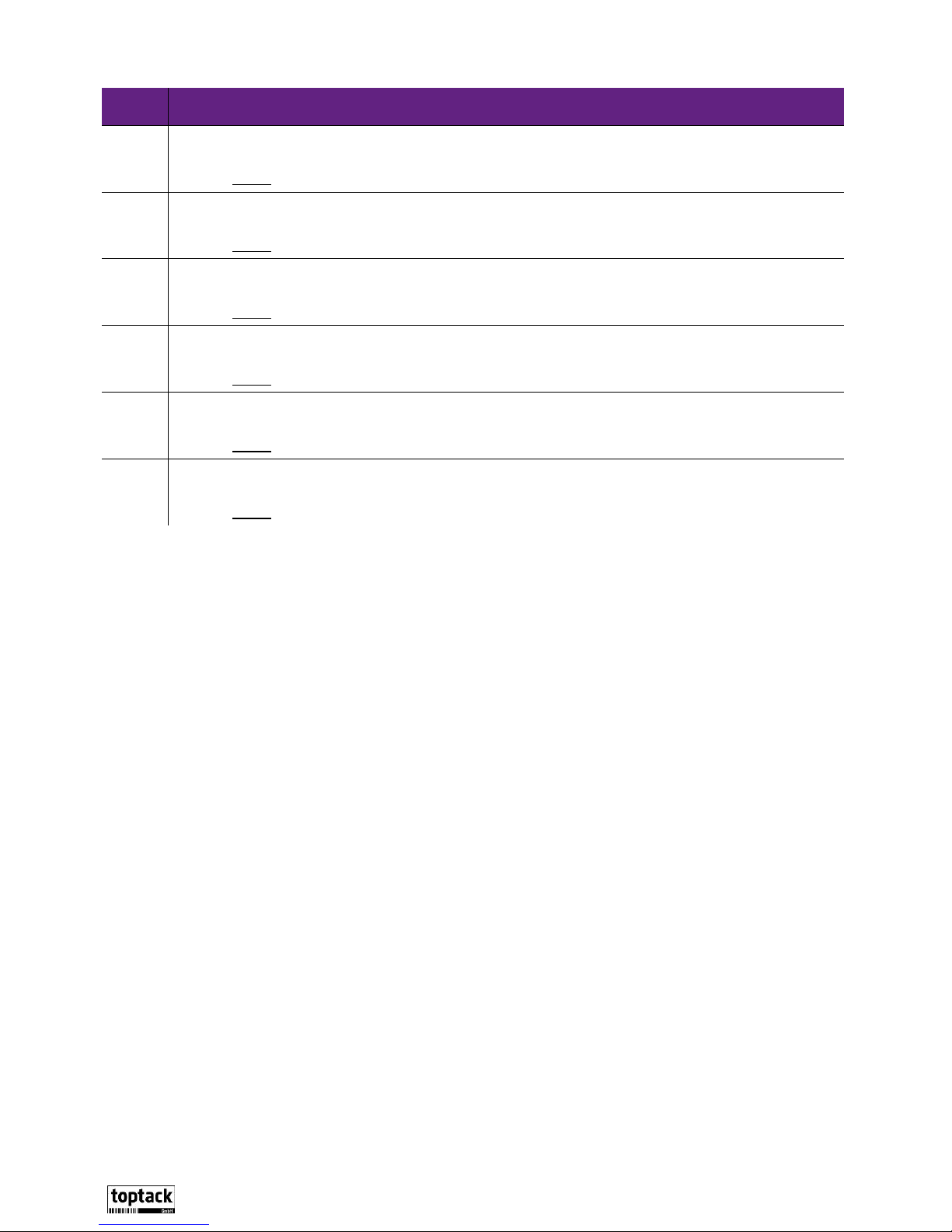

7. Set the label piece number.

Note: The input value has 5 digits; up to 99,999 labels

can be entered and printed in one production run.

The number of labels to be printed must be entered

via the display keyboard. Wrong inputs can be

deleted by pushing the red "X". The value can be

entered anew then.

8. Confirm the label piece number. After entering the number

of the labels to be printed, confirm your input by pushing the

green "OK" symbol 1x.

Operating processes

Page 28

Operating processes

Label printing & lamination station - Version: 2017-04-01

Page 28

Figure

How

9. Starting production; see work description "Turning on the

label printing & lamination station".

Page 29

Label printing & lamination station - Version: 2017-04-01

Page 29

Turning off the label printing & lamination station

Figure

How

1. Take the last printed and laminated labels from the output

manually.

2. End automatic mode of the main switch of the label printing

& lamination station.

Note: For this, turn the swivel switch to position "0 -

Off".

3. Turn off the main switch of the label printing & lamination

station and secure it against reactivation with the locked

padlock; remove the key.

4. Turn off the operating air pressure.

Operating processes

Page 30

Label printing & lamination station - Version: 2017-04-01

Page 30

Reset emergency off

Danger of severe injury from movement of the label printing & lamination station!

Before resetting the emergency off at the label printing & lamination station,

ensure:

That no persons are working in the danger area!

That all safety devices are ready for operation or closed!

That no loose foreign bodies are present within the label printing & lamination

station!

Figure

How

1. The label printing & lamination station is equipped with a

main switch with EMERGENCY OFF function.

Note: In case of danger, deactivate the main switch

with the EMERGENCY OFF function!

Confirmation of the EMERGENCY OFF function is not

necessary (see work description "Activation

sequence").

Operating processes

Page 31

Maintenance

Label printing & lamination station - Version: 2017-04-01

Page 31

Danger of severe injury from movement of the label printing & lamination station!

All maintenance work must be performed with the machine turned off!

During maintenance work that requires movements at the machine

components, the machine must be switched into manual mode!

MAINTENANCE

Maintenance work may be performed by operating and maintenance staff. The maintenance

plan specifies who is allowed to perform what work.

Operating staff are staff who:

are authorised by the operator,

may only perform operating work and simple maintenance measures,

must have been instructed by toptack GmbH or the operator.

Maintenance staff are staff who:

are authorised by the operator,

may perform further maintenance work,

Is trained by toptack GmbH for the respective work or, as far as required, or trained,

certified and licensed for this work according to the regionally applicable provisions.

All maintenance work must be performed in a timely and binding manner. In order to permit

evidence of this, the operator of the label printing & lamination station should maintain a

maintenance booklet in which the maintenance work performed is listed. Indications on the

type of work and the execution responsibility with the execution time complete the

maintenance booklet.

The maintenance booklet can supply toptack GmbH with important notes for continuous

improvement of the machine quality.

The maintenance evidence must be kept clearly visible and accessible to the staff close to the

machine and protected from dirt together with the maintenance plan.

Page 32

Label printing & lamination station - Version: 2017-04-01

Page 32

Maintenance plan

Figure

Interval / Who

How

Before production and on

demand.

To be performed by:

Operating staff

General control of the facility

and all components for

proper condition and poss.

cleaning (do not use any

compressed air).

Before production and on

demand.

To be performed by:

• Maintenance staff

The light beam of the laser

control button "B4" must hit

the label gap in focus when

the printer stands still. The

integrated LED display of the

laser button must be

permanently lit "green".

Before production and on

demand.

To be performed by:

• Maintenance staff

If the light beam of the laser

control button "B4" hits the

label surface, the LED display

of the laser button must be

lit "yellow".

When printing each label, the

LED display of the laser

button "B4" must switch

from "green" to "yellow" and

back to "green".

Calibrate the laser control

button "B4", see "annex 1" of

this manual

Laser control button

Maintenance

Page 33

Maintenance

Label printing & lamination station - Version: 2017-04-01

Page 33

Figure

Interval / Who

How

Continually during production.

To be performed by:

Operating staff

Check the printing result and

application of the protective

laminate.

Before production and at least 1x

week.

To be performed by:

Operating staff

Clean the brush of adhesive

residues and replace the

brush if necessary.

Before production and at least 1x

week.

To be performed by:

Maintenance staff

Clean the thermal transfer

printer, see work description:

"Clean thermal transfer

printer"

When the label, protective

laminate material or ink ribbon

have been used up.

To be performed by:

Operating staff

Replace the rolls of the label,

protective laminate material

or ink ribbon; see work

descriptions:

"Replacing the roll of

protective laminate at the

laminate dispenser"

"Replacing the label roll"

"Replacing the ink ribbon

roll"

Page 34

Maintenance work

Label printing & lamination station - Version: 2017-04-01

Page 34

Figure

How

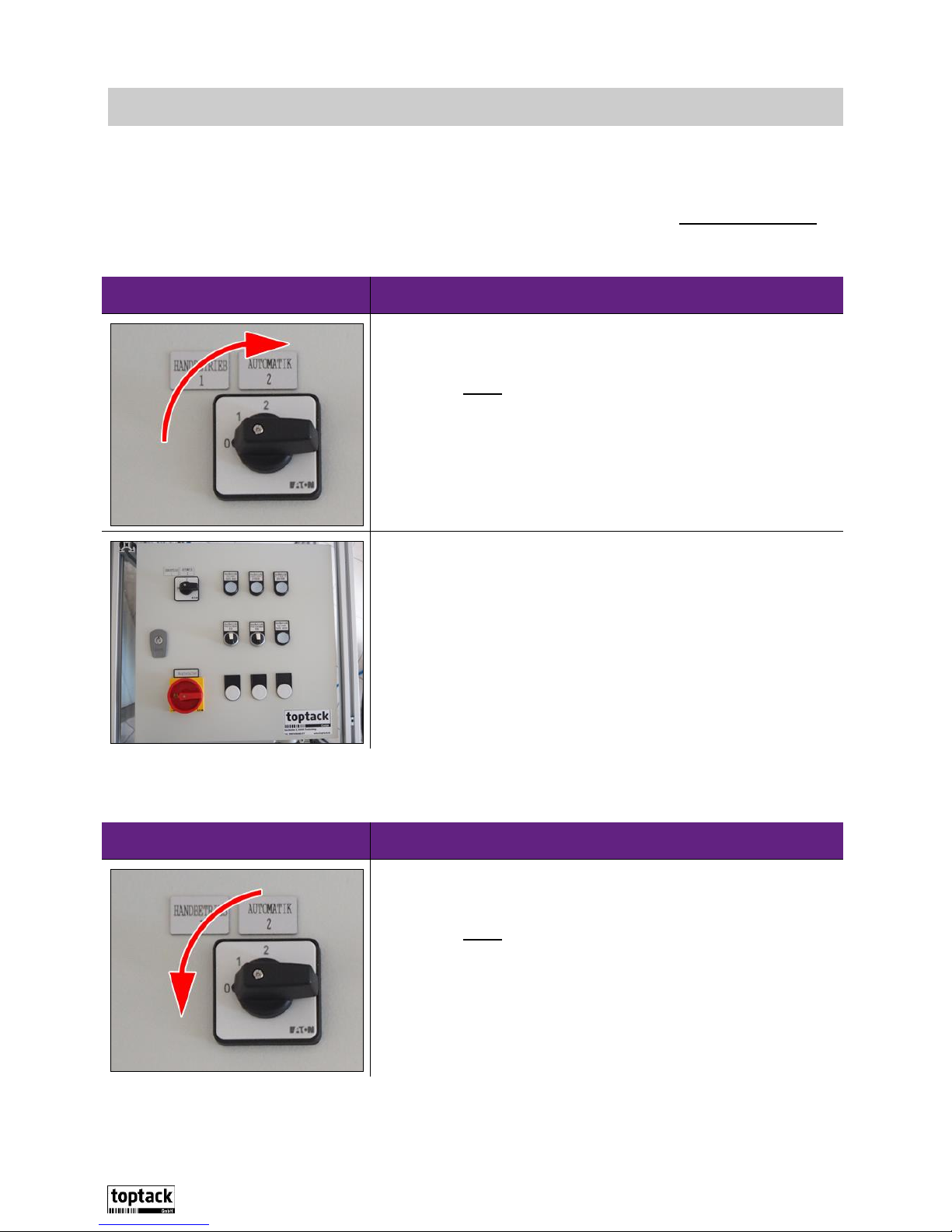

1. Activating manual mode of the main switch of the label

printing & lamination station.

Note: For this, turn the swivel switch to position "1 -

Manual mode".

2. The label printing & lamination station is now running in

manual mode. The individual machine components can be

operated with the operating elements.

Figure

How

1. Ending manual mode of the main switch of the label printing

& lamination station.

Note: For this, turn the swivel switch to position "0 -

Off".

MAINTENANCE WORK

Activate or deactivate manual mode

Maintenance work that requires manual mode must only be performed by maintenance staff.

Activating manual mode

Deactivating manual mode

Page 35

Maintenance work

Label printing & lamination station - Version: 2017-04-01

Page 35

Danger of crushing injury at the label printing & lamination station!

Before replacing the protective laminate roll, turn off the main switch of the

station and secure it against reactivation!

Figure

How

1. Remove the front safety wing, remove the laminate roll no

longer needed or the remaining material from the dispenser.

2. Insert a new laminate roll.

3. Push the wing onto the axis and fasten it.

4. Guide the laminate band through under the deflection and

set the lateral guides.

5. Guide the laminate band through under the brake brush.

Fasten the brake brush so that a light pressure onto the band

from above occurs.

6. Guide the laminate band around the dispensing edge.

7. If necessary, remove any release paper already present from

the shaft of the rolling shaft by pulling out the fastening pin.

8. Sling the release paper around the rolling shaft and clamp it

to the rolling shaft with a fastening pin.

Replacing the roll of protective laminate at the laminate dispenser

Page 36

Label printing & lamination station - Version: 2017-04-01

Page 36

Replacing the label roll at the thermal transfer printer

Danger of crushing injury at the label printing & lamination station!

Before replacing the label roll, turn off the main switch of the station and

secure it against reactivation!

Figure

How

1. Open the flap of the printing head. Pull the lever (green) up;

the printing head opens.

2. Remove the safety wing. For this, open the fastening (green

disc) by turning it to the left and then remove the safety wing

from the shaft.

3. Remove the roll that is no longer needed. Cut or separate the

carrier band if necessary and remove any present residual

material (carrier band) from the printer. Remove wound

carrier band from the winding shaft.

Maintenance work

Page 37

Maintenance work

Label printing & lamination station - Version: 2017-04-01

Page 37

Figure

How

4. Push the new label roll onto the shaft.

5. Push the safety wing onto the shaft and fasten it on the shaft

by turning the fastening (green disc) to the right.

6. Pull the label band off the roll, guide it through under the

deflection shaft and under the printing head.

7. Guide the label band over the front label dispensing edge.

Page 38

Maintenance work

Label printing & lamination station - Version: 2017-04-01

Page 38

Figure

How

8. Guide the label band back under the label dispensing edge

towards the winding shaft of the printer.

9. Guide the label band clockwise under the holding bracket to

the winding shaft.

10. After turning the winding shaft clockwise, wind up the label

band until it is slightly tensed.

11. Close the printing head by pushing the lever (green) down.

Page 39

Label printing & lamination station - Version: 2017-04-01

Page 39

Replacing the ink ribbon at the thermal transfer printer

Danger of crushing injury at the label printing & lamination station!

Before replacing the ink ribbon, turn off the main switch of the station and

secure it against reactivation!

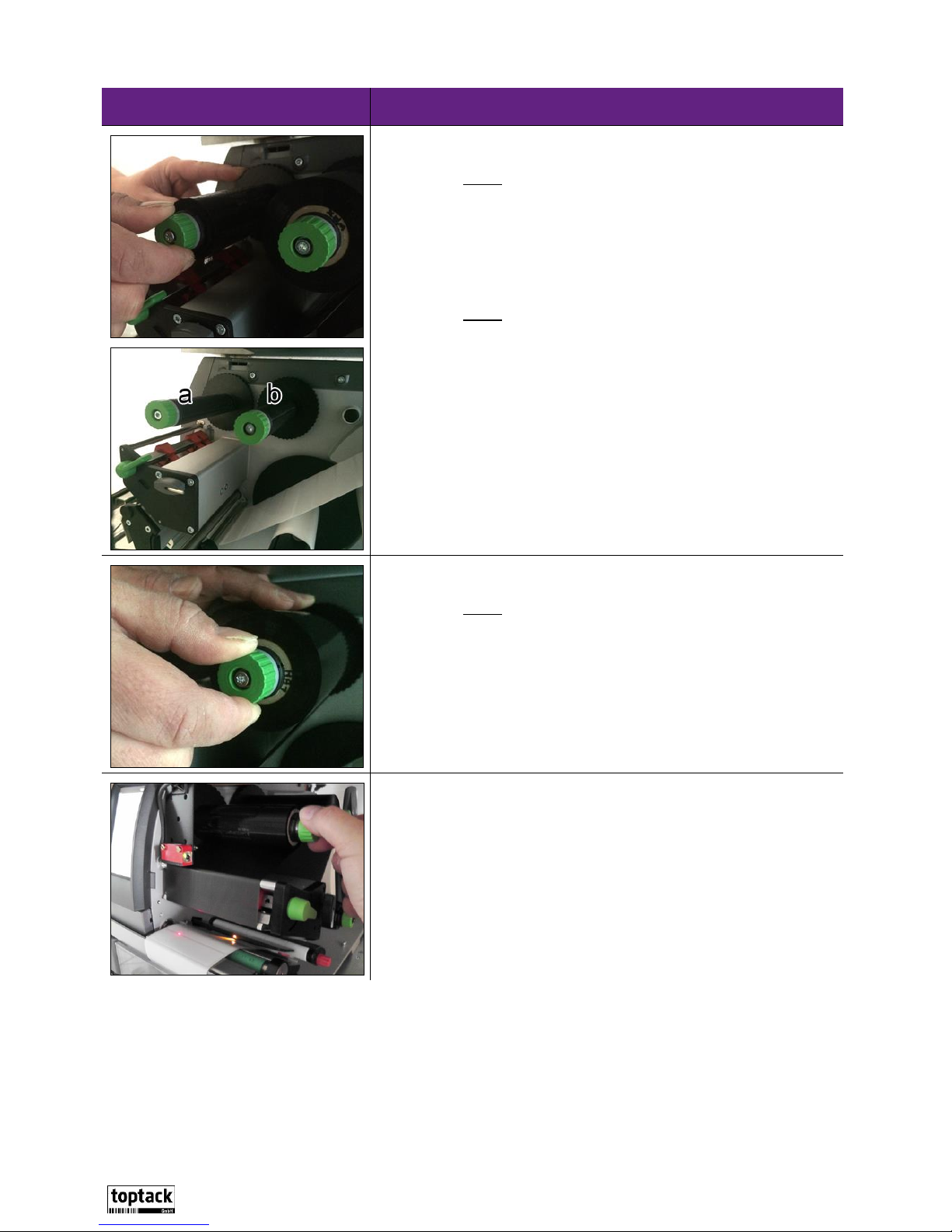

Figure

How

1. Open the flap of the printing head.

2. Release the fastening of the ink ribbon sleeves at the shafts.

Note: Turn the green knurled screws clockwise to

release the clamp of the roll at the shaft.

3. Pull the ink ribbon winding and unwinding sleeve from the

shaft.

Maintenance work

Page 40

Maintenance work

Label printing & lamination station - Version: 2017-04-01

Page 40

Figure

How

4. Push new ink ribbon roll onto the shafts.

Note: Push the roll with the ink ribbon onto the rear

unwinding shaft (b), attach the start of the ink ribbon

to an empty sleeve (ink side of the ink ribbon

towards the label material), guide it through under

the printing head and push it onto the front winding

shaft (a).

Note: The ink ribbon has one side with and one

without ink. The ink ribbon must be inserted so that

the ribbon side with ink is on the surface of the label.

5. Fasten the ink ribbon roll and winding sleeve to the shafts.

Note: Turn the green knurled screws counter-

clockwise to clamp the sleeves at the shafts.

6. Align the ink ribbon. Manually wind up ink ribbon at the

winding shaft (turn counter-clockwise!) until the ink ribbon

runs through under the printing head again smoothly and at

the full width.

Page 41

Maintenance work

Label printing & lamination station - Version: 2017-04-01

Page 41

Figure

How

7. Close the flap of the printing head.

Page 42

Label printing & lamination station - Version: 2017-04-01

Page 42

Cleaning the printing head of the thermal transfer printer

Danger of crushing injury at the label printing & lamination station!

Before cleaning the thermal transfer printer, turn off the main switch of the

station and secure it against reactivation!

Figure

How

1. Open the flap of the printing head.

2. Carefully push the thermal transfer printer to the side.

3. Carefully clean the printing head with a lint-free cleaning rag

(cotton cloth) soaked in isopropanol.

Note: A defective printing head must be replaced by

trained specialists!

This maintenance work must only be performed by maintenance staff.

Maintenance work

Page 43

Maintenance work

Label printing & lamination station - Version: 2017-04-01

Page 43

Figure

How

4. Push the thermal transfer band back again and turn the

winding shaft counter-clockwise to wind up ink ribbon until it

is perfectly smooth and placed across the entire printing

width.

5. Close the flap of the printing head by moving the lever down.

Page 44

Disposal

Label printing & lamination station - Version: 2017-04-01

Page 44

DISPOSAL

The label printing & lamination station is characterised by a long service life.

If the label printing & lamination station must be scrapped after the end of its service life, all

parts must be sorted by material classes. Only this way can subsequent reuse of differentiated

scrapping be permitted.

Observe the international provisions and the standards applicable in the destination country for

disposal. Observe all relevant environmental protection standards as well.

Page 45

Label printing & lamination station - Version: 2017-04-01

Page 45

ANNEX

No.

Designation

1

Circuit diagram for electrical system of the label printing &

lamination station

2

Overview plan of the pneumatic system of the label printing &

lamination station

3

"Annex 1" Description and operation of the laser control button

4

Operating manual of the thermal transfer printer

5

Operating manual of the laminate dispenser

6

Spare parts list of the label printing & lamination station

7

External data connection of the printer

Annex

Loading...

Loading...