INSTRUCTIONS FOR INSTALLATION AND USE

K140

AUTOMATION AND ELECTROMECHANICAL DRIVERS

FOR LINEAR SLIDING DOORS WITH ONE OR TWO PANELS

COD. 0P5501

EN

VER 0.0

REV 03.16

installer's manual/original instructions

EN

INDEX

3

EN

INSTRUCTIONS FOR INSTALLATION AND USE

K140

EN

1- GENERAL INFORMATION

1.1- General recommendations...............................................................................................................pag. 04

1.2- General safety rules ........................................................................................................................pag. 04

1.3- Installer.............................................................................................................................................pag. 04

1.4- User..................................................................................................................................................pag. 05

1.5- Servicing...........................................................................................................................................pag. 05

2- TECHNICAL DESCRIPTION

2.1- Rating place and “CE” marking .......................................................................................................pag. 05

2.2- Proper use .......................................................................................................................................pag. 05

2.3- Technical data .................................................................................................................................pag. 06

2.4- Packing ............................................................................................................................................pag. 06

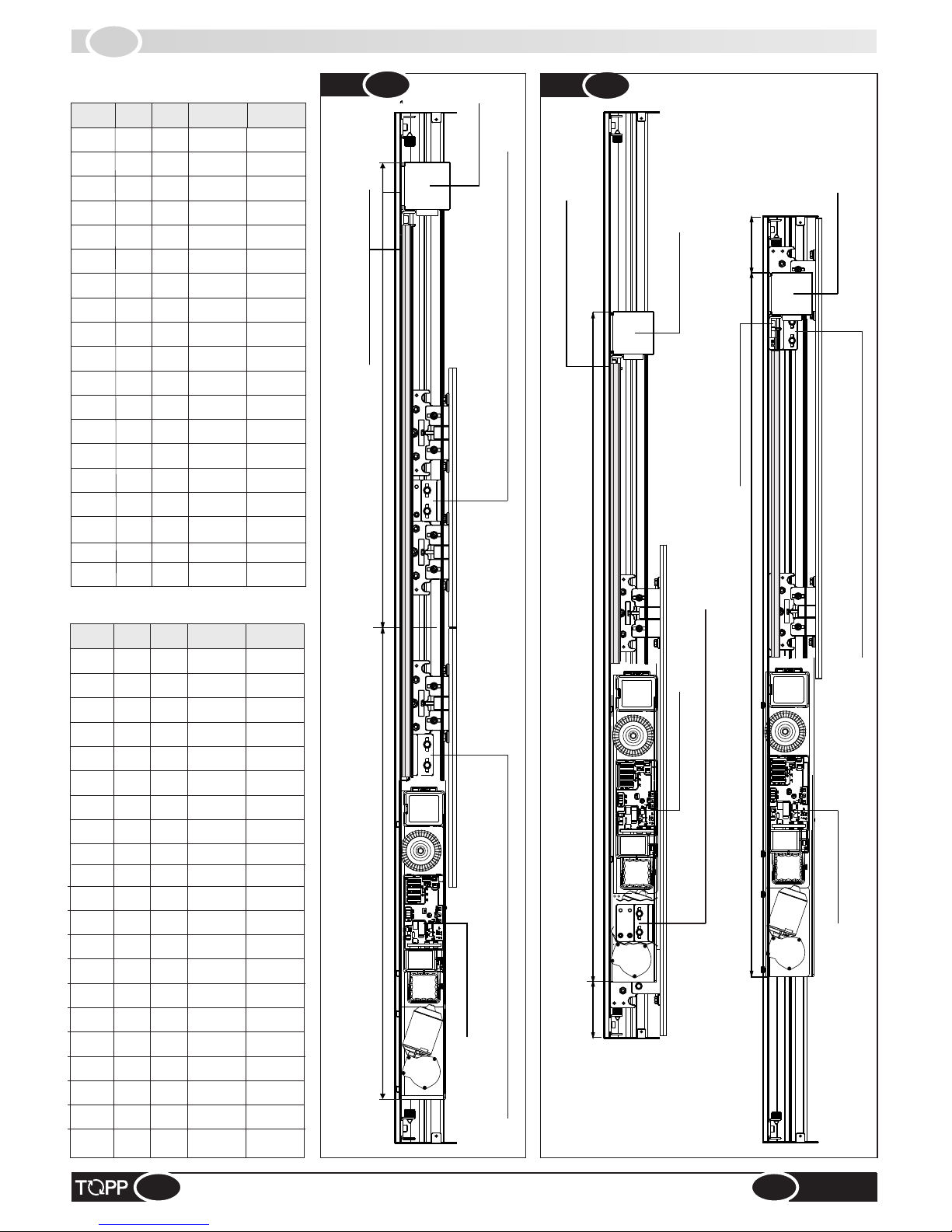

2.5- Models..............................................................................................................................................pag. 07

2.6- Sliding doors with one panel ...........................................................................................................pag. 08

2.7- Description of parts and dimensions ...............................................................................................pag. 09

3- INSTALLATION

3.1- General recommendations...............................................................................................................pag. 11

3.2- Installing the crossbar ......................................................................................................................pag. 11

3.3- Installing the adapter and track........................................................................................................pag. 12

3.4- Installing the carriages on the door..................................................................................................pag. 13

3.5- Fastening and adjustment of the sliding panels...............................................................................pag. 14

3.6- Installing the motor module, belt transmission, belt,logline..............................................................pag. 16

3.7- Fastening the drive brackets on the door panel...............................................................................pag. 18

3.8- Installing the door block ...................................................................................................................pag. 20

3.9- Installing the casing .........................................................................................................................pag. 21

4- ELECTRICAL CONNECTION

4.1- General recommendations...............................................................................................................pag. 22

4.2- Electrical connection ........................................................................................................................pag. 22

4.3- Electronic circuit board.....................................................................................................................pag. 23

4.4- Pre-wired electrical connections ......................................................................................................pag. 24

4.5- Electrical wiring diagram (flow chart) ...............................................................................................pag. 25

4.6- Connection of detection sensors .....................................................................................................pag. 26

4.7- Program selection with MS1 knob....................................................................................................pag. 41

4.8- DS2 digital connection .....................................................................................................................pag. 41

4.9- Connection of key device.................................................................................................................pag. 42

4.10-Antipanic connection.......................................................................................................................pag. 42

4.11- Connetion of door block and pharmacy function ...........................................................................pag. 43

5- USE AND OPERATION

5.1- Technical description .......................................................................................................................pag. 44

5.2- Emergency battery ..........................................................................................................................pag. 44

5.3- First card start-up ............................................................................................................................pag. 44

5.4- Reset phase: learning .....................................................................................................................pag. 45

5.5- restart in case of power failure:zero (near).......................................................................................pag. 45

5.6- Programming parameters ...............................................................................................................pag. 46

5.7- List of errors and warning ................................................................................................................pag. 47

5.8- Self restore management of errors C-D-E-K-N-P-Q ........................................................................pag. 48

5.9- Self restore management of errors F-G-H-I-J .........................................................................pag. 49

5.10- Self restore management after anti panic alarm ..................................................................pag. 49

5.11- self restore management after ........................pag. 49 opening fire or an opening of emergency

5.12- Digital switch .................................................................................................................................pag. 50

6- APPENDICES

6.1- Maintenance.....................................................................................................................................pag. 51

6.2- Spare parts and optional accessories ..............................................................................................pag. 51

6.3- Demolition ........................................................................................................................................pag. 52

6.4- Troubleshooting................................................................................................................................pag. 52

7- EC DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY ..........................pag. 53

IT

GENERAL INFORMATION

1

Before installing the automation the installer must read and understand all parts of this manual.

& This manual is an integral part of the automation unit and must be kept by the installer, with all the enclosed

documentation, for future reference.

& This manual provides all instructions necessary to ensure correct installation and maintenance of the automation:

TOPP srl is not liable for any damage to persons, animals and property caused by failure to follow these instructions.

& This manual was written by TOPP srl, which holds the copyright. No part of this manual may be reproduced or

published without the manufacturer's written authorization.

& TOPP srl reserves the right to amend or improve the manual and the products described therein at any time without

notice.

& The data contained in this manual were written and checked with the maximum care; TOPP srl is not liable for possible

errors due to omissions or printing errors, or errors in transcription.

1.1

GENERAL RECOMMENDATIONS

4

1.3

INSTALLER

1.2

GENERAL SAFETY RULES

& The personnel must be informed of the risks of accident, about the safety devices for the operators and about the

general rules for accident prevention foreseen by the international directives and laws in force in the country in which the

automation is installed. In any case, the personnel must comply scrupulously with the safety regulations for prevention of

accidents in force in the country in which the automation is installed.

& Any tampering with or unauthorized replacement of parts or components of the automation mechanisms and any use

of accessories or consumables other than the originals may represent a hazard and relieves the manufacturer of any civil

and penal liability.

& In order for the automation unit to operate correctly, we recommend carrying out periodical maintenance on it, as

indicated in par. 6.1 of this manual. Routine and extraordinary maintenance operations that require the automation unit to

be even partially disassembled should be carried out exclusively after the power supply to the same has been cut off.

& Cleaning and maintenance must not be carried out by unsupervised children.

& Do not remove or alter the plates and labels applied by the manufacturer on the automation and its accessories.

& Never try to oppose the movement of the door and work near the hinges or other mechanical moving parts in motion

(such as belts, carriages, etc.). The manufacturer is not liable for any damages caused by improper or unreasonable use

of the automation.

& When handling electric parts always wear grounded antistatic conductive bracelets as electrostatic charges can

damage the electronic parts on the circuits.

& The automation contains mobile mechanical parts, electrical connections and electronic circuits for control of door

movement; the automation must therefore be protected, along its entire length, by an aluminum casing.

& This device may be used by children no younger than 8 years of age, by people with reduced physical, sensory or

mental capacities and by inexperienced users, as long as they are supervised or as long as they have received

instructions on the safe use of the device.

& Children must not play with the device.

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

& Installation of the automation must be done exclusively by qualified technical personnel in possession of the

professional requisites foreseen by the laws in the country of installation.

& The installer must verify compliance with the current directives and regulations on the safe use of motorized doors.

& The installer must be able to install the automation, start it and operate it with the power on in electrical cabinets or

shunt boxes, and must be qualified to perform all actions of an electrical and mechanical nature and any kind of

adjustment.

& After installing the automation, the installer must analyze the system for risks and verify that the sliding door

installation does not present risks of crushing or shearing, adopting adequate corrective measures, if necessary, and

applying the warning signs foreseen by the laws in force to identify hazardous zones.

5

Contact the installation technician or retailer for assistance.

1.5

SERVICING

IT

TECHNICAL DESCRIPTION

2

2.1

RATING PLATE AND “CE” MARKING

The “CE” marking certifies the conformity of the machine to the essential health and safety requisites foreseen by the

European product directives.

It is formed of an adhesive plate made from polyester, screen-printed black, with the following dimensions: W=50mm H=36mm.

It should be applied by the installation technician in a clearly visible position on the outside of the automation unit.

1.4

USER

The user must be able to operate the automation under normal conditions and perform simple operations or startup or

resetting the automation following any forced interruptions, using the devices provided (digital switch, analogue switch,

etc.).

The user must not open the casing or perform any operations restricted to maintenance personnel or specialized experts.

In case of breakdown or malfunction of the door, the user should simply switch off the circuit breaker and abstain from any

attempt to repair the system.

Use of the automation must be exclusively permitted to users who comply with the instructions in this manual and in the

manuals of the TOPP devices connected to it.

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

& Every installer must provide visible annotation of the data identifying the drive system.

& The installer must also supply the owner with all information regarding automatic, manual and emergency function of

the automation.

& In order to assist installers in applying the European regulations and directives regarding the safety and use of the

motorized door, a special downloadable guide is available from our website www.topp.it.

& The installation technician shall accept full responsibility for any installation errors and for any failure to adhere to the

instructions provided in this manual. The installation technician shall therefore be exclusively liable for any damages

caused to users and/or third parties that may arise as a result of incorrect installation.

2.2

PROPER USE

The K200 automation mechanism was designed and produced exclusively to operate (open and close) linear sliding

doors in residential, public and industrial buildings.

It is strictly forbidden to use the automation for purposes other than those described herein, in order to guarantee at all

times the safety of the installer and user and the correct function of the automation.

The automation software is designed to perform automatic recovery in the instance where anomalous

events as described in chapters 5.8-5.10.

The automation in order to perform the above, if set in a mode other than "Closed", perform a reset called "Near"

that provides for the complete opening and closing of the doors at a low speed, before returning in the set state the

function selector.

The recovery action must be taken into account in applications where there are features that provide access

control with inputs different from those of the radar (example reader bedge) for which automation could not

ensure the operating mode set.

In case you want to exclude the auto recovery please contact support Topp Srl.

6

2.4

PACKING

Every standard product package (cardboard carton) contains:

% N.1 K140 automatic door (complete with motor unit and belt transmission preassembled on the crossbar, side caps,

casing, door stop limit switch, cable raceway, emergency battery,raceway, rubber cable sleeves);

% N.1 package of hardware consisting of , 2 self-tapping screws TC d6x70 and 2 nylon anchor bolts 10x60;

% N.2 Carriage units with relative hardware for fastening to the adapter;

% N.2 Supporting brackets on the crossbar;

% N.1 Adapter for framed door panels;

% N. 2 warning labels for moving wings that have to be sticked on the centre of the moving wings (refer to picture A);

Make sure the parts described above are in the package and that the automation has not undergone any damage in

shipment. If you find anything unusual, do not install the automation and request the service department of the local

retailer or the manufacturer.

The number of some of the parts described above may vary depending on the type of configuration (e.g. number of door

panels).If more parts are necessary, contact the manufacturer.

2.3

TECHNICAL DATA

Tab. 1 lists the technical data that characterize the K140 automation.

POWER SUPPLY

PROTECTION OF ELECTRIC DEVICES

WORKING TEMPERATURE

NUMBER OF DOOR PANELS

230V ~ 50Hz

24V 500mA max

0,32A

70W

Continuous

Adjustable 10 ÷ 80 cm/s

Adjustable 1 ÷ 5 cm/s

Adjustable 0 ÷ 60 s

IP X0

1 PANEL 2 PANELS

K140

MODEL

Tab.

1

PERIPHERAL POWER OUTPUT

POWER ABSORBED

ABSORPTION

OPENING/CLOSING SPEED

OPENING/CLOSING APPROACH SPEED

AUTOMATIC CLOSING TIME

TYPE OF USE

MAINS VOLTAGE FUSE 230V

OPENING/CLOSING ACCELERATION

Adjustable 1 ÷ 12

5 x 20 - T800 delayed

MAXIMUM CAPACITY

SIZE OF OPENING

140 kg

800÷2800 mm

70 + 70 kg

1000÷2800 mm

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

-20°C

50°C

warning l a b e l

for moving wings

Rif.

A

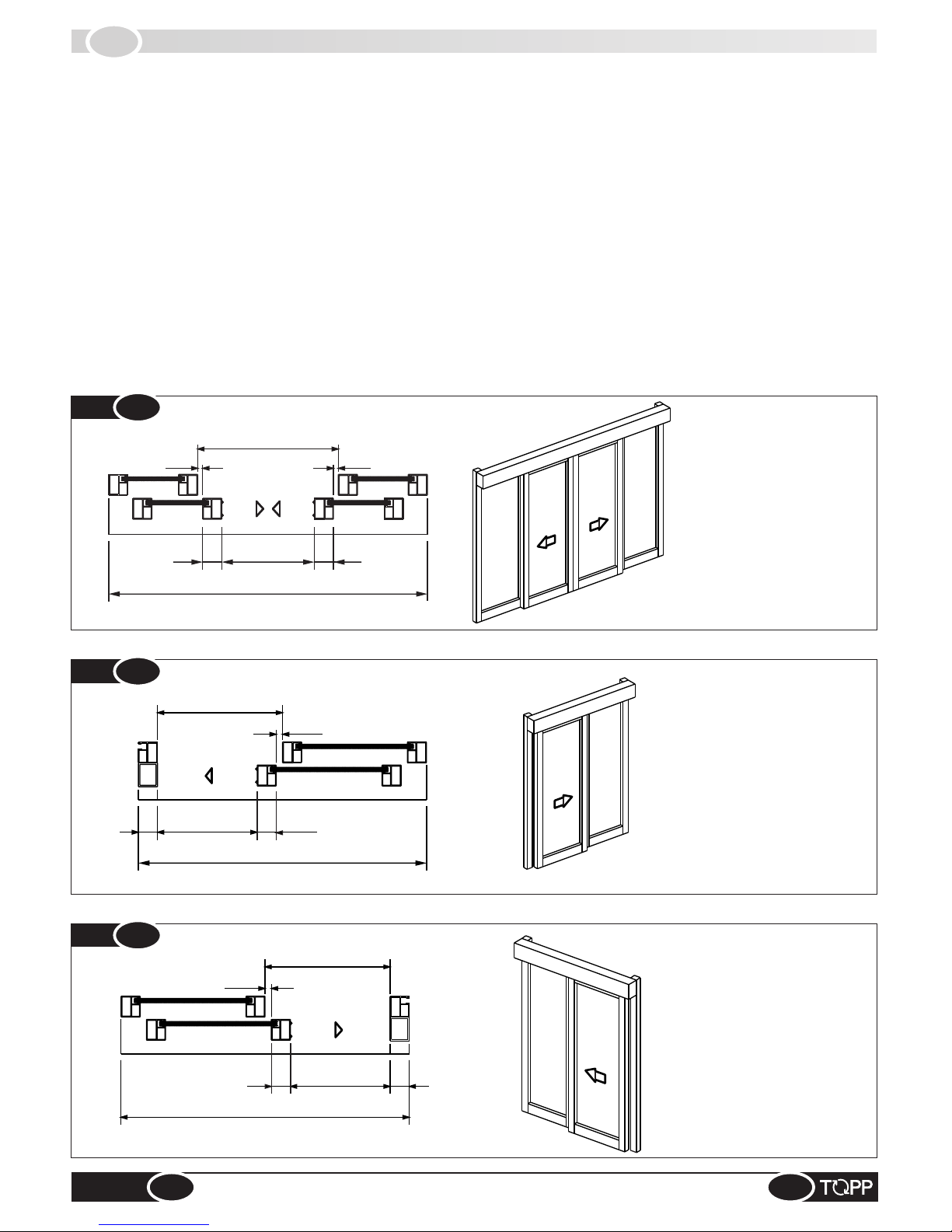

2.5

MODELS

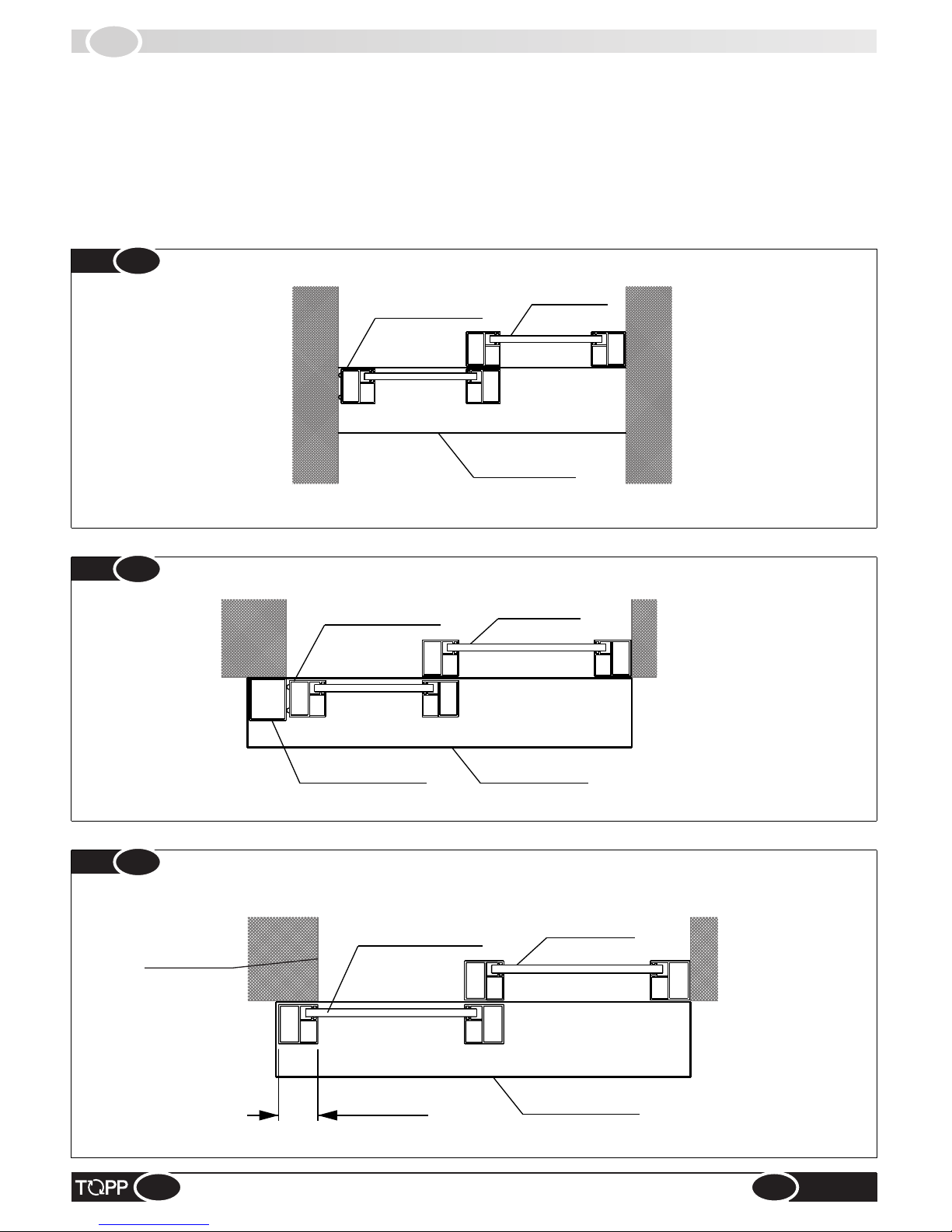

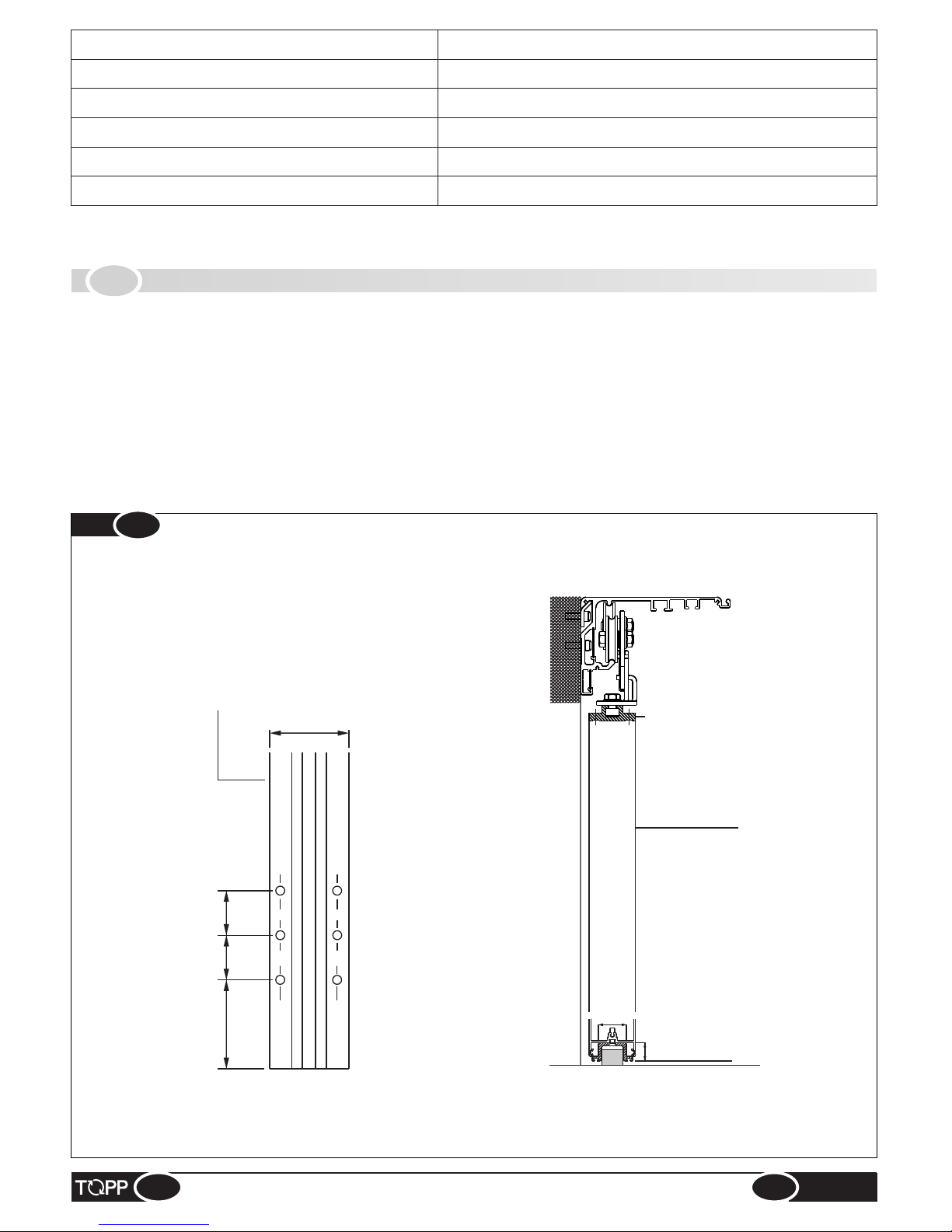

Two models of automation are available:

% automation with 2 door panels (Fig.2) which allows a pair of door panels to glide simultaneously in opposite directions;

% automation with 1 door panels which allows a single door panel to glide in one direction; Fig.3 shows an application

with a single door that opens toward the right (seen from the front of the automation); Fig.4, shows a single door that

opens toward the left (seen from the front of the automation).

@ When order a single door panel application, always specify the direction of opening of the door, seen from the front

of the automation.

@ To comply with the safety regulations, the glide of the door panel VPA must be less than the door opening width VL.

The glide of the door panel VPA is equal to VL when the upright on the door does not have any roundings and/or

protrusions that could cause a shearing effect.

VPA*

VL

LT/LC

25 25

75

75

VPA*

VL

LT/LC

25

75

75

VPA*

LT/LC

25

75

75

LT/LC

LT/

LC

PC

BP

PC

BP

PC

PC

LT

/

LC

LT/

LC

PC

BP

BP

PC

Fig.

2

Fig.

3

Fig.

4

7

VPA = net doorway width

VL = gross opening

LT/LC = automation length /

casing length

BP = rail + runner on the floor

PC = electric wire raceway

1 RIGHT DOOR PANEL

1 LEFT DOOR PANEL

2 DOOR PANELS

VPA = net doorway width

VL = gross opening

LT/LC = automation length /

casing length

BP = rail + runner on the floor

PC = electric wire raceway

VPA = net doorway width

VL = gross opening

LT/LC = automation length /

casing length

BP = rail + runner on the floor

PC = electric wire raceway

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

2.6

DESCRIPTION OF PARTS AND DIMENSIONS

To reduce the hazard of getting the fingers caught, we recommend the assembly type as shown in Fig.5a and Fig.5b,

where the wall and/or tubular frame act as a jamb and stop the door panel.

Alternatively, proceed as shown in Fig.6 overlapping the end of the wall (and/or closing upright) with the profile of the

sliding panel and moderating the closing speed and speed of approach of the door.

@ In some countries the laws forbid this type of assembly as there is a possible risk of getting the fingers caught.

Fixed door

panel

Sliding door panel

Automation

Fixed door panel

Sliding door panel

Tubular jamb

Automation

Fixed door panel

Sliding door panel

Overlap

Automation

Fig.

5a

Fig.

5b

Fig.

6

8

Wall end

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

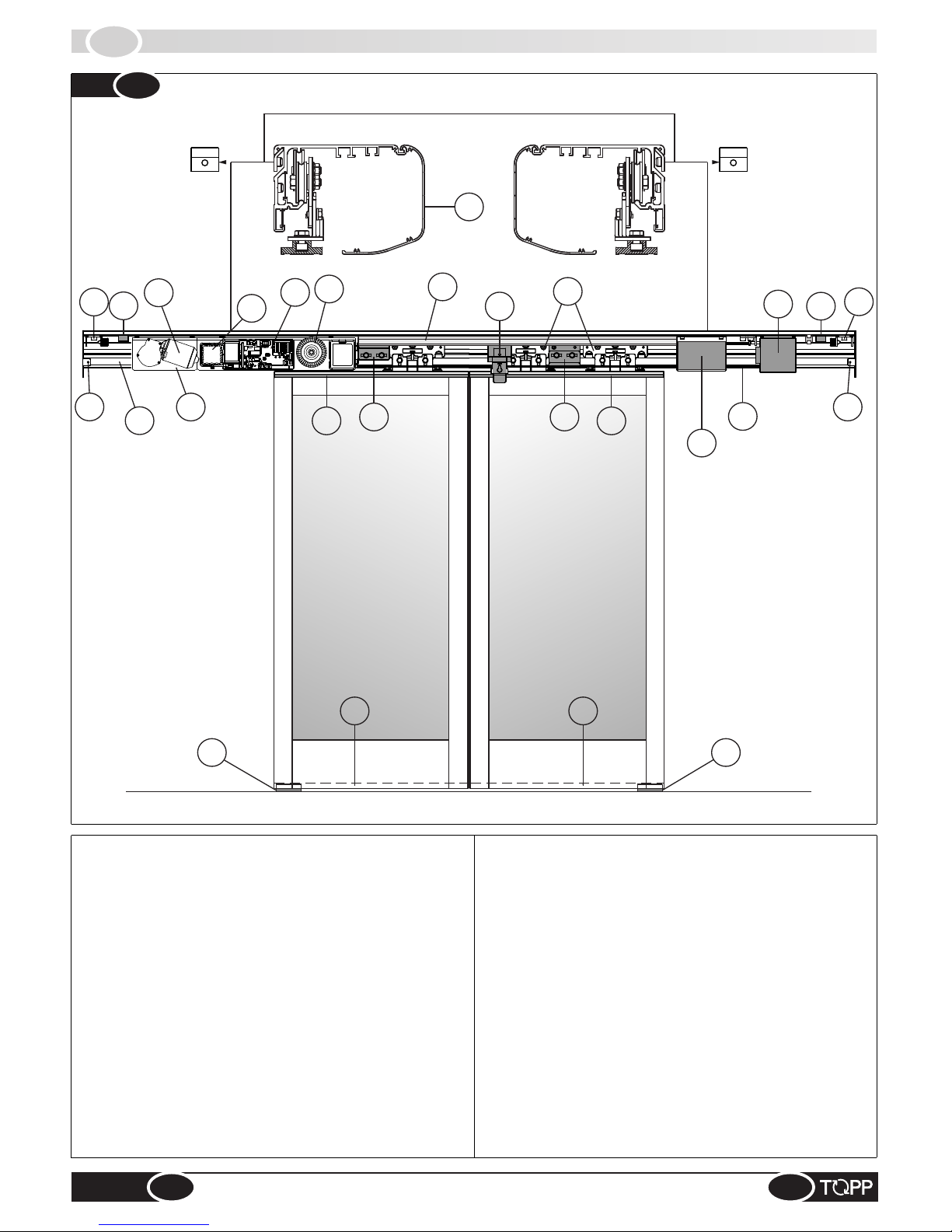

2.7

DESCRIPTION OF PARTS AND DIMENSIONS

1 -

2 -

3 -

4 -

5 -

6 -

7 -

Main crossbar

Carriage with double wheel

Adapter for door panel suspension

Casing

Toothed transmission belt

18 - Door stop

11 -

Door lock with manual release

12 -

13 -

Photocell control unit

14 -

15 -

Rail for door guide

16 -

Plastic runner on floor

17 -

Wire raceway

8 -

9 -

10 -

Door panel drive bracket

Belt transmission with pulley and encoder

Low voltage transformer

Electronic control circuit

Lateral case fastener

Emergency battery

Gearmotor

Metal motor module19 -

Crossbar supporting hooks

9

INSTRUCTIONS FOR INSTALLATION AND USE

5

Fig.

7

20 - Logline

15

15

16

16

13

4

4

9

6

7

6

3

19

3

2

18

18

12

11

8

10

14

1

20

EN

K140

17

17

255

20

Fig.

9

10

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

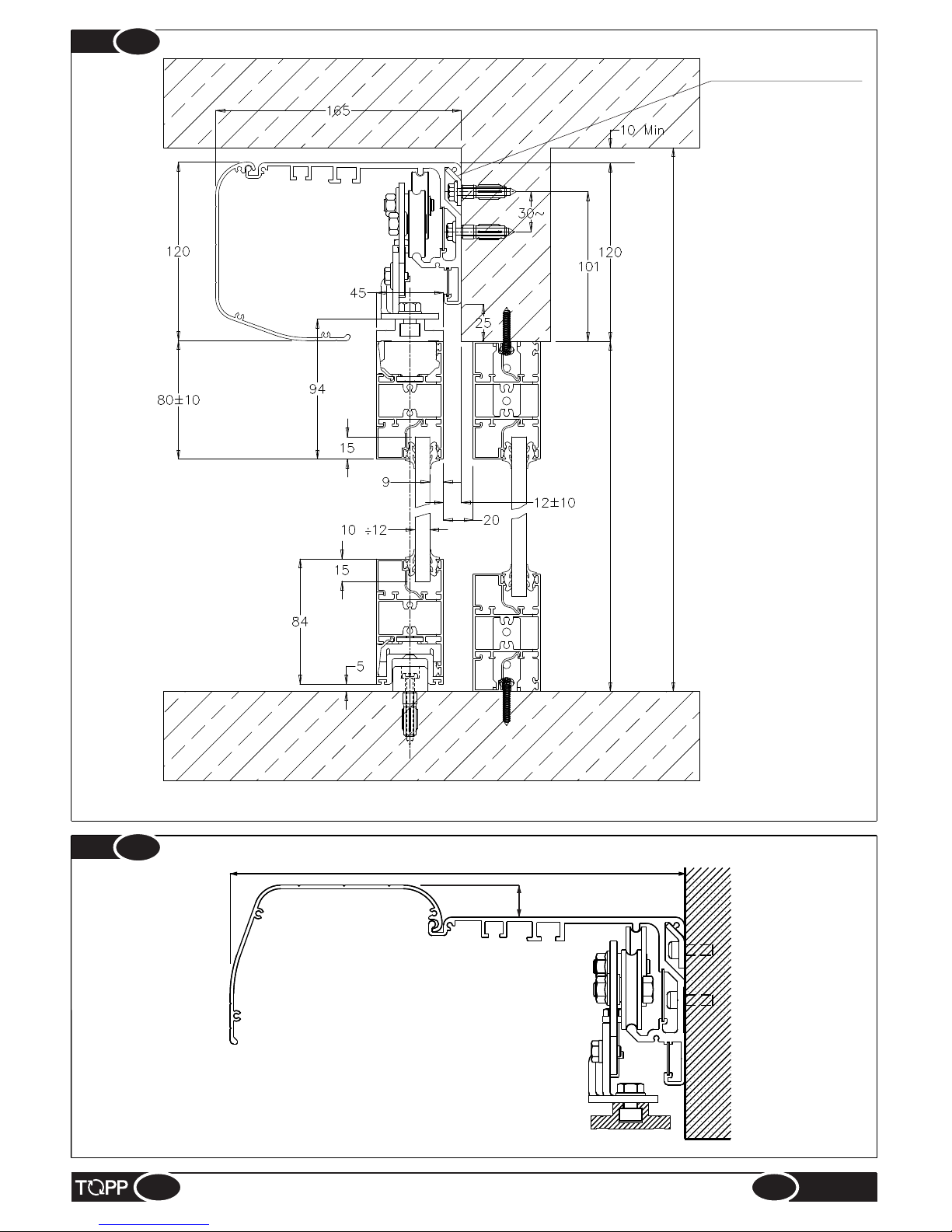

Ceiling height

Opening door height

Fig.

8

Crossbar supporting

bracket

IT

INSTALLATION

3

3.1

GENERAL RECOMMENDATIONS

The automation must be installed exclusively by competent, qualified technical personnel in possession of the

technical requisites foreseen by the legislation in force in the country of installation.

& Do not install the automation on the external wall of the building, subject to atmospheric agents (rain, snow, etc.).

& Do not use the automation in environments with a potentially explosive atmosphere.

& The zones in which there may be a danger of crushing, shearing, conveyance or other risks are signaled and

protected by means of special electronic safety devices, safety stops or barriers. These devices must be installed

depending on the environment and type of use and operating logic of the product.

& The forces developed by the complete system during operation must respect the regulations in force in the country of

installation; if this is not possible, protect and signal by means of electronic safety devices the zones affected by those

forces.

& Before installing the automation, verify that the structure to be automated is stable, sturdy and able to withstand the

weight of the automation and, if necessary, take steps to ensure that it is. Topp srl is not liable for failure to comply with the

rules of good workmanship in the construction of the door panels to motorize, or for any distortions that may develop with

use of the device.

(Model with two panels) To install the crossbar, proceed as follows:

% Mark the surface where the automation will be fastened at the center of the opening VL that is also the center of the

crossbar;

% Decide the position of fastening the crossbar supporting brackets, referring to the measurements shown in Fig.8;

@ If the floor is not perfectly flat, decide the position of the supporting brackets referring to the highest point of the floor.

% Fasten the crossbar supporting brackets to the wall using self-drilling/sell-tapping screws type d5.5 or d6,3;

% Remove the cover on the casing;

% Install the crossbar and make sure it is aligned;

% Fasten the crossbar to the wall with 3 self-tapping screws type d6.3 for every meter of crossbar and paying careful

attention not to damage the gliding base of the carriages with the drill spindle. In case of damage it will be necessary to

replace the entire crossbar;

% After fastening the crossbar clean the glide zone soiled by drilling residues.

3.2

INSTALLING THE CROSSBAR

((Model with 1 panel) To install the crossbar, proceed as follows:

% Mark the surface where the automation will be fastened at the center of the crossbar that corresponds:

Ÿ to the line of the wall end on the left of the doorway for application of 1 door panel with the opening toward the left;

Ÿ to the line of the wall end on the left of the doorway for application of 1 door panel with the opening toward the right;

% Decide the position of fastening the crossbar supporting brackets, referring to the measurements shown in Fig.8;

@ If the floor is not perfectly flat, decide the position of the supporting brackets referring to the highest point of the floor.

% Remove the cover on the casing;

% Fasten the crossbar supporting brackets to the wall using self-drilling/sell-tapping screws type d5.5 or d6,3.

% Install the crossbar and make sure it is aligned;

% Fasten the crossbar to the wall with 3 self-tapping screws type d6.3 for every meter of crossbar and paying careful

attention not to damage the gliding base of the carriages with the drill spindle. In case of damage it will be necessary to

replace the entire crossbar.

% After fastening the crossbar clean the glide zone soiled by drilling residues.

11

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

3.3

INSTALLING THE ADAPTER AND RAIL

70÷80

40

Door panel

40

45

Adapter

% Cut the adapter and rail to the measurement of the finished door width, removing another 2 mm from the jamb sider;

% Make sure the upper part of the panel crossbar is reinforced at the base (minimum thickness 3 mm);

% Drill the adapter and rail starting at about 70/80 mm from the end;

@ The number of fastening holes will depend on the size and weight of the door.

% Mark the fastening points on the door using the adapter and rail as a templat;

% Drill the door panel at the top and fasten the adapter using cylindrical M6 screws or cylindrical self-tapping d5.5 screws

depending on the type of material;

% Drill the door at the bottom and fasten the rail using flared self-tapping cylindrical screws diam. 4.8.

20

31

Rail

Fig.

10

12

IRON

2 mm (with lesser thickness use threaded rivets)

3 mm (with lesser thickness use threaded rivets)

100 mm

50 mm

Minimum thickness

Materials of the fastening surface

ALUMINUM

SOLID WOOD

REINFORCED CONCRETE

110 mm (with lesser thickness use chemical bolts)

PERFORATED CONCRETE

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

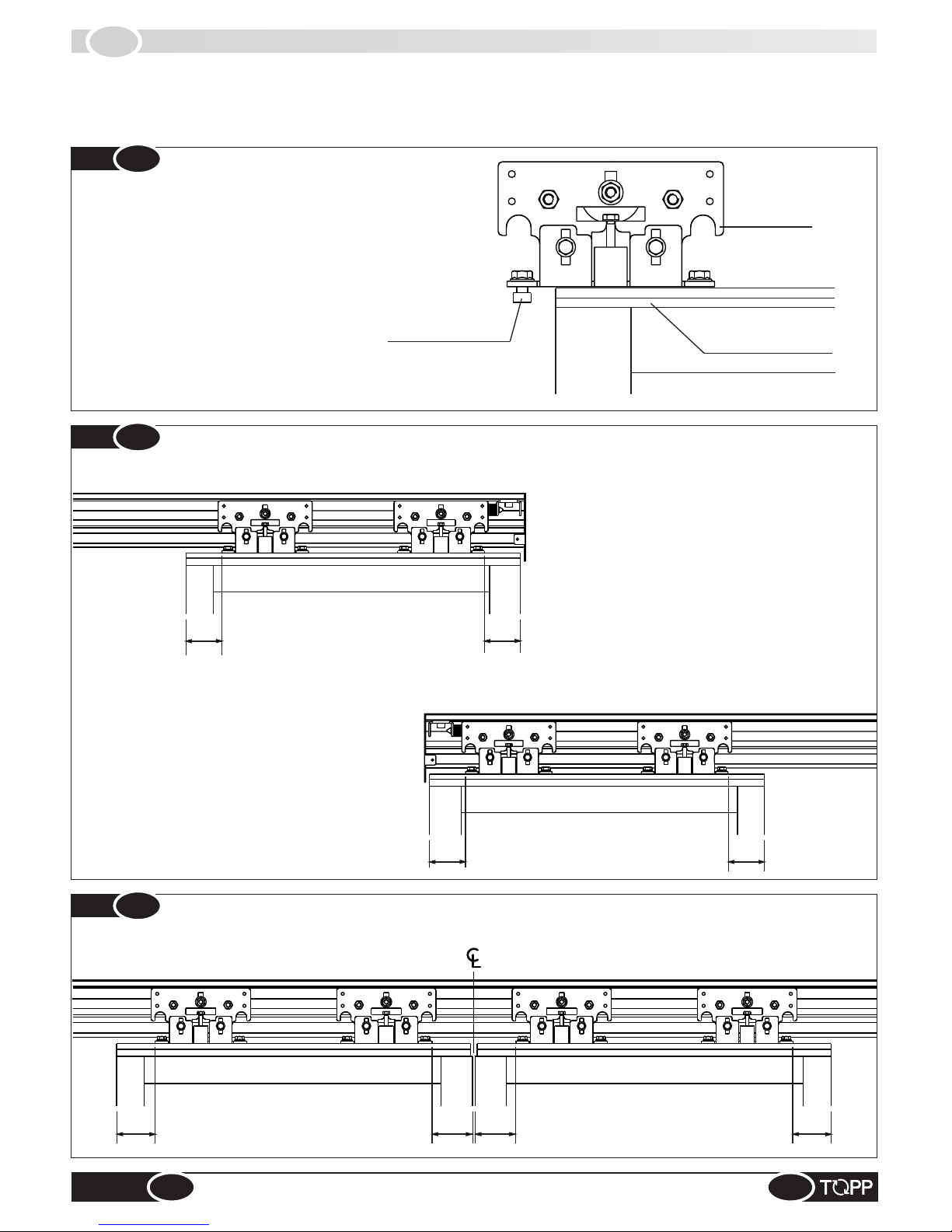

Install the carriages on the adapter as shown in the figure.

@ Make sure the carriages are installed correctly and are aligned with each other, with the adapter and with the

crossbar.

Standard adapter

Fastening nut

Carriage

70 70

7070

15÷70

70 70

15÷70

3.4

INSTALLING THE CARRIAGESON THE DOOR

Fig.

11

Installation by insertion

Fig.

12

Single door panel, opening toward the left

Single door panel, opening toward the right

Fig.

13

Double door panel, simultaneous opening toward the right and left

13

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

3.5

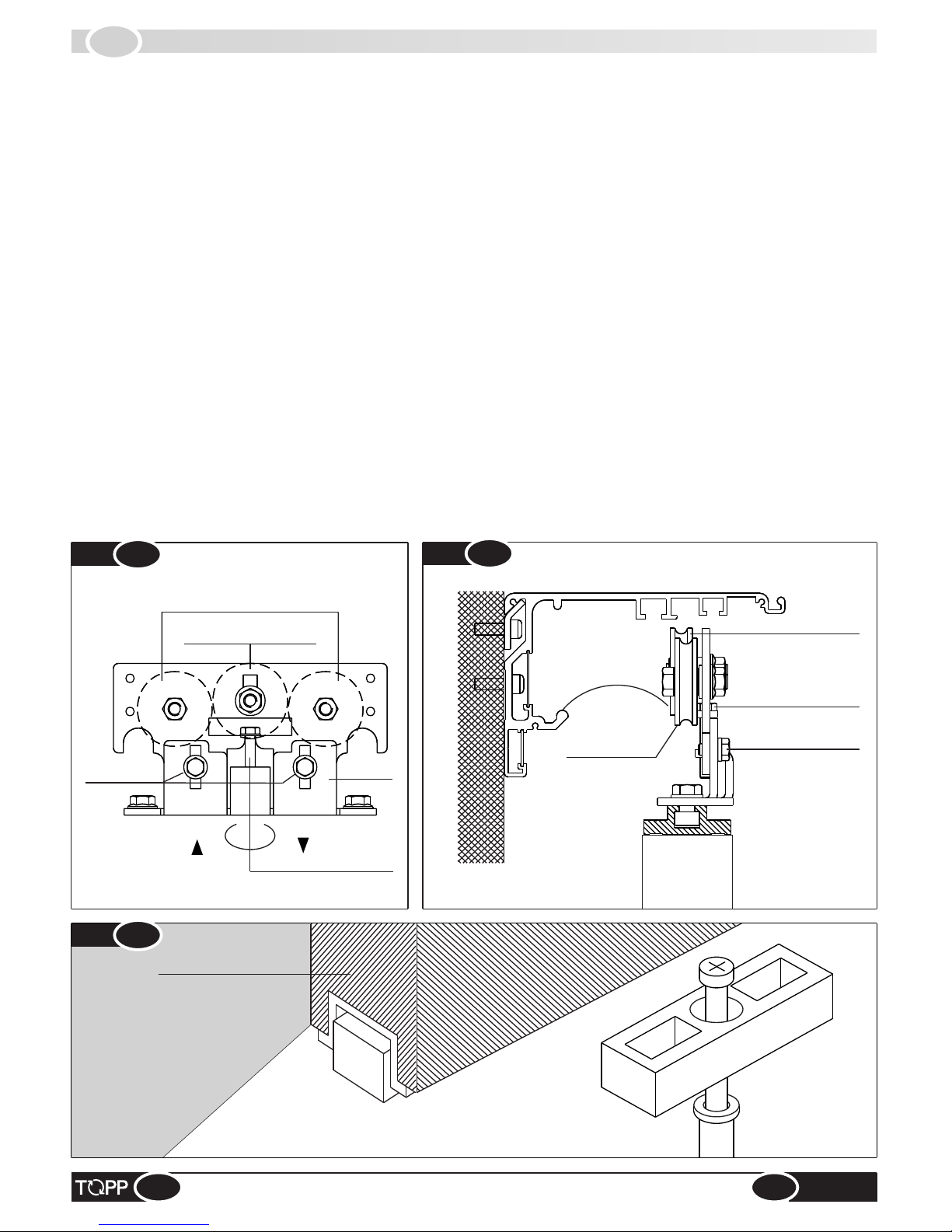

FASTENING AND ADJUSTMENT OF THE SLIDING PANELS

To fasten the sliding panels to the crossbar, proceed as follows:

% Lower the anti-derailing wheels of the carriages (Fig.14);

% Bring the panels to the crossbar and make sure the gliding base of the carriages is clean and free of any scraps;

% Fasten the door panel to the crossbar by raising it slightly and hooking it first on one side and then on the other, or both

sides at once (Fig.15);

% Loosen the fastening screws on the carriages and insert the no. 10 fixed wrench in the height adjustment screw on the

carriage and turn it to the left or right so that the door panel is about 5 mm off the floor (height for the standard runner);

% Determine the distance “A” for adjustment of the door panel (Fig. 17);

@ If an air seal brush must be installed between the sliding panel and the upright or wall, adjust the panel so that there is

a space of about 1 mm between it and the brush along the entire length;

% Fasten the runner to the floor at point “A” using the anchor bolt and self-tapping screw d 6x70 contained in the hardware

package (Fig.16).

% Adjust the distance “A” (Fig.17) by loosening the two screws that hold the lower bracket of the carriage to the adapter.

The holes on the brackets are in slot form to permit movement of the door by about 18 mm.

% Before tightening the screws make sure the carriages are aligned with each other and with the crossbar.

% Adjust the height of the sliding panels (Fig.18) using the special adjustment screws on the carriages (Fig.17). After

performing this operation, tighten the screws on the load-bearing wheels and raise the anti-derailing wheel.

@ Using the height adjustment screws on the carriages you can raise or lower the door by ±10mm (with the crossbar

installed on the basis of the measurements shown in Fig.8).

Load-bearing

wheels

Anti-derailing wheels

Height adjustment

Anti-derailing wheels

LEFT

Load-bearing wheels

Fastening screw

Adjustment screw

Carrello

RIGHT

Rear part of door panel

Fig.

15

Fig.

14

Fig.

16

14

Carriage Carriage

fastening screwfastening screw

Carriage

fastening screw

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

Lower carriage bracket

Standard adapter

Runner on floor

A

A

Fig.

17

LPF

Fig.

18

5

15

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

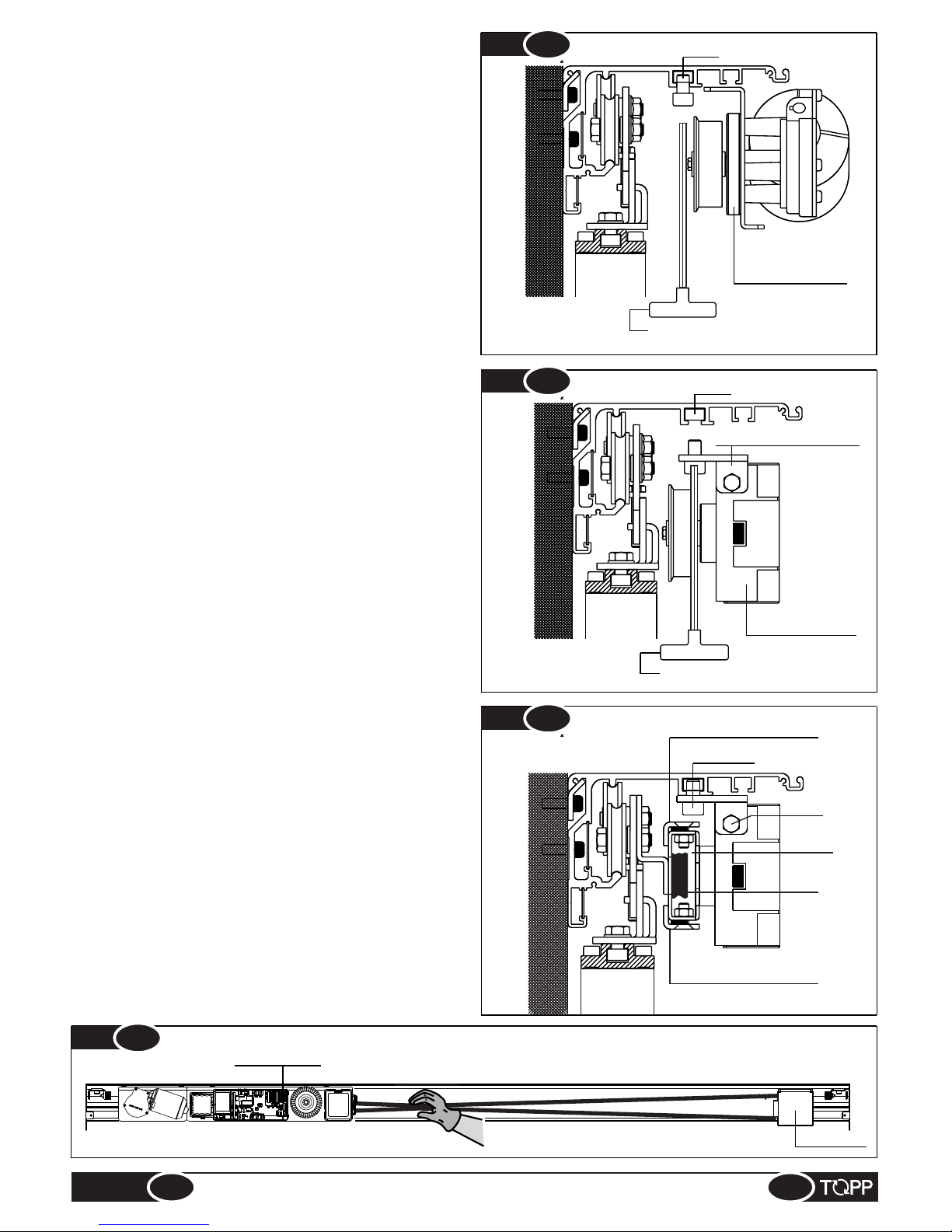

3.6

INSTALLING THE MOTOR MODULE, BELT TRANSMISSION, BELT,LOGLINE

2 DOOR PANELS

MOTOR MODULE

Lower belt bracket – front carriage – panel opening toward the right

Upper belt bracket – front carriage – panel opening toward the left

BELT TRANSMISSION

BELT TENSION ADJUSTMENT

MOTOR MODULE

1 RIGHT DOOR PANEL

Lower belt bracket – front carriage – panel opening toward the right

BELT TRANSMISSION

1 LEFT DOOR PANEL

MOTOR MODULE

Upper belt bracket – front carriage – panel opening toward the left

BELT TRANSMISSION

BELT TENSION ADJUSTMENT

BELT TENSION ADJUSTMENT

K140 - model with 2 door

panels (Fig.19)

K140 - model with

1 door panel (Fig.20)

16

INSTRUCTIONS FOR INSTALLATION AND USE

2700

1760

1760

2 x 3504

2800

1812 1812

2 x 3608

1000

876

876

2 x 1736

1100

928

928

2 x 1840

1200

980

980

2 x 1944

1300

1032

1032

2 x 2048

1400

1084

1084

2 x 2152

1500

1136

1136

2 x 2256

1600

1188

1188

2 x 2360

1700

1240

1240

2 x 2464

1800

1292 1292 2 x 2568

1900

1344

1344

2 x 2672

2000

1396

1396

2 x 2776

2100

1448

1448

2 x 2880

2200

1500

1500

2 x 2984

2300

1552

1552

2 x 3088

2400

1604

1604

2 x 3192

2500

1656

1656

2 x 3296

2600

1708

1708

2 x 3400

VPA

A

B

L Belt

L Logline

1700

120

1994

1 x 3976

1800

120

2098

1 x 4184

1900

120

2202

1 x 4392

2000

120

2306

1 x 4600

2100

120

2410

1 x 4808

2200

120

2514

1 x 5016

2300

120

2618

1 x 5224

2400

120

2722

1 x 5432

2500

120

2826

1 x 5640

2600

120

2930

1 x 5848

2700

120

3034

1 x 6056

2800

120

3138

1 x 6264

1000

120

1266

1 x 2520

1100

120

1370

1 x 2728

1200

120

1474

1 x 2936

1300

120

1578

1 x 3144

1400

120

1682

1 x 3352

1500

120

1786

1 x 3560

1600

120

1890

1 x 3768

VPA A

800

120

1058

1 x 2104

900 120

1162

1 x 2312

VPA

A

B

L Belt

L Logline

942

1046

1150

1254

1358

1462

1566

1670

1774

1878

1982

2086

2190

2294

2398

2502

2606

2710

2814

248

352

456

560

664

768

872

976

1080

1184

1288

1392

1496

1600

1704

1808

1912

2016

2120

2224

2328

C

L

B

B

A

A

B

Fig.

19

Fig.

20

A

EN

K140

Before installing the motor module, belt transmission and

belt on the crossbar, prepare and install the wires

necessary for the electrical connections and make sure the

carriages, door panels and runners on the floor have been

fully adjusted and positioned.

Installing the motor module (Fig.21):

% Mark the reference measurements on the crossbar using

the tables on page 16;

% Loosen the two VTF screws on the crossbar for fastening

the motor module;

% Fit the motor module with the slots provided for fastening

in the VTF screws, check the reference mark on the

crossbar once more and tighten the VTF screws.

Installing the belt transmission (Fig.22):

% Mark the reference measurements on the crossbar using

the tables on page 16;

% Remove the two VTF screws on the crossbar for

fastening the belt transmission;

% Fit the transmission with the specific fastening holes in

the VTF screws and tighten them;

% Adjust the position of the belt tension adjustment on the

crossbar.

Installing the transmission belt (Fig.23):

% Install the transmission belt on the motor and

transmission pulley making sure the belt junction

brackets are positioned as shown in Fig.23. (Upper

bracket for door opening to the left, lower bracket for door

opening to the right).

% Slightly loosen screws “A” on the tension adjustment,

take the belt transmission to the end of its run and tighten

screws “A”.

% To tighten the belt, loosen screws “B” on the transmission

and turn screw “C” to obtain the proper belt tension.To

check the tension, with the handshake bring the two

edges of the belt as shown in Figure 23a.The tension is

enough if there is some resistance before the contact of

the two edges.

% Tighten screws “B” after checking that the transmission is

aligned with the crossbar.

No. 6 hexagonal wrench

Motor module

No. 6 hexagonal wrench

Belt transmission

Belt tension adjustment

A - B

Lower belt bracket

Belt

Upper belt bracket

Pulley

C

Fig.

23

17

INSTRUCTIONS FOR INSTALLATION AND USE

Fig.

23a

belt trasmission

Motor module

EN

K140

VTF

VTF

Fig.

21

Fig.

22

3.7

FASTENING DOOR DRIVE BRACKETSE

2 DOORS – simultaneous opening toward the right and left

DOOR OPENING TO RIGHT DOOR OPENING TO LEFT

M6x8 screws

M6x10 screws

Upper belt bracket

M6x8 screws

M6x10 screws

Upper belt bracket

Left front door carriage

Right front door carriage

Horizontal adjustment slots

Door drive bracket

Horizontal adjustment slots

Door drive bracket

C

L

Fig.

24

18

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

1 LEFT DOOR – opening toward the left

1 RIGHT DOOR – opening toward the right

Front door carriage

Horizontal adjustment slots

Screws M6x8

Screws M6x10

Lower belt bracket

Door drive bracket

M6x8 screws

M6x10 screws

Upper belt bracket

Front door carriage

Horizontal adjustment slots

Door drive bracket

Fig.

25

Fig.

26

19

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

EN

K140

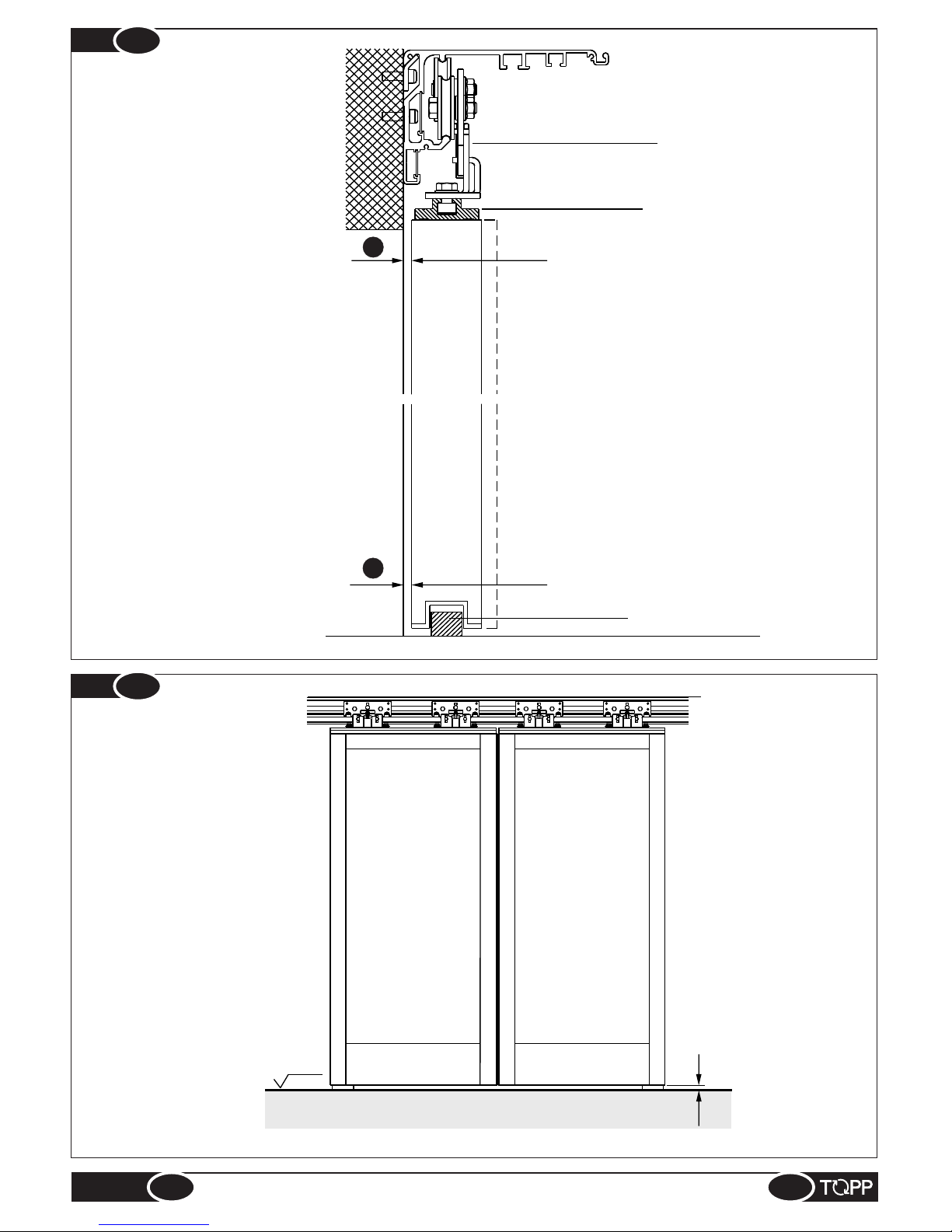

3.8

INSTALLING THE DOOR BLOCK

Right door front carriage

Door block with manual

release incorporated

Front carriage

Front carriage

Door block with manual

release incorporated

Door block with manual

release incorporated

2 DOOR PANELS

1 RIGHT DOOR PANEL

1 LEFT DOOR PANEL

Carriage block fastener

Manual release

Carriage block fastener

Fastening screw

During installation, make sure that when the door is closed with the block on, it must be possible to open the door manually

by at least 2-3 mm. This tolerance is necessary to enable the block to be released without difficulty.

Fig.

27

Fig.

28

Fig.

29

Fig.

30

To release and open the door, push the manual release

lever under the casing forward and, at the same time, pull

the door with your hand until it opens.

Fig.

31

20

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

3.9

INSTALLING THE CASING

21

INSTRUCTIONS FOR INSTALLATION AND USE

antivibration

felt

M3,5x9,5 screws for

fastening casing

A

Fig.

32

Fasten the lateral caps on the beam using 3 screws type TSP d3.5x9.5 for each cap, supplied in the hardware package.

Apply an antivibration felt strip every 300mm along the beam (Fig.32 Ref.1).

Fit the upper part of the casing in its housing on top of the beam, holding it in a tilted position at a 30° angle and insert it until

it is flush (Fig.32 Ref.2).

Fasten the casing to the beam using two more screws type TSP d3.5x9.5 (Fig.32 Ref.3).

If it should not be possible to fasten the casing from the side, proceed as follows:

% Drill symmetrical holes in the casing cover using a suitable drill with a Ø6.5 bit for aluminum, with the measurements

and position indicated in Fig.32 Ref.4

% Fasten the casing to the beam using the two screws type TCEI M5x10.

4

12mm

Ø6.5

1

2

3

M5x10 screws for

fastening casing

EN

K140

Rating place and “CE” marking

4.1

GENERAL RECOMMENDATIONS

IT

ELECTRICAL CONNECTION

4

Electrical connection of the automation must be made exclusively by qualified technical personnel in possession of

the professional requisites foreseen by the laws in the country of installation, who must issue the client a certificate

of conformity of the connection and/or installation made.

& Whatever type of electrical material is used for connection (plug, cord, terminals, etc.), it must be suitable for the use,

with the “CE” seal of approval and must comply with the requisites foreseen by the laws in force in the country of

installation. For the wiring, use cables with double insulation up to the immediate vicinity of the connectors.

& The electrical power line to which the control unit is connected must comply with the requisites foreseen by the laws in

force in the country of installation, and must comply with the technical requisites listed in table 1 and on the “CE” rating

plate.

& The mains to which the device will be connected must be equipped with a safety circuit breaker with contact opening

of at least 3mm. These devices must be installed in the power system in conformity with the requisites foreseen by the

legislation in force in the country of installation.

The installation must include a ground wire longer than the power cord so that, in case of traction, the ground wire is the

last to stretch.

& We recommend the following types of power cables: H05VV-F 3X0.75, H05RN-F 3X0.75.For the analogue switch

cable we recommend using a multipole 8 x 0.5 cable type LI-YY, and for the digital switch 4x0.5 LI-YY ( cable ‘shielding’

should only be used for cable lengths in excess of 20 meters).

& Before making electrical connection of the automation, make sure the power cord has not been damaged.

& The hole drilled on the profile for passage of the power cord must be made without any rough or sharp edges or sharp

corners that could damage the wire.

22

4.2

ELECTRICAL CONNECTION

INSTRUCTIONS FOR INSTALLATION AND USE

- Before fastening the door to the wall, drill a hole on the bottom of the crossbar (or more than one if you need to connect

accessories) where the power cables emerge from the wall. The holes should be 10 mm in diameter, fitted with the rubber

cable sleeves supplied.

- If the raceway has not already been installed, cut it to size in accordance with the tables in paragraph 3.6, and drill it as

shown on figure 1 by using an aluminium drill bit having diameter 6.5mm.

Then fasten it to the crossbar using the screws and nuts supplied, as shown in figure 2.

The spacing between nut and nut should be 400 mm.

- Make sure there is a switch with a contact opening of at least 3 mm between the automation and the mains, for omnipolar

disconnection of power.

- Thread the power cable through the cable sleeve as shown in figure 3.

Pass the cable towards the right along the track of the crossbeam, using the plates provided to keep the cables in their

housing. Make them come out near the right end-of-travel stop.

- Make sure the cables are securely fastened, possibly using special clamps to keep them in order.

- Pass the cables in the front section over the belt/encoder transmission, using the groove on the crossbar, and inside the

special raceway.

Insert the power supply cable into the dedicated band and secure it using the bolt provided. Connect it to the terminal after

having stripped the cable;

- Connect the cables of any accessories as described in the appropriate figures (see from fig. 35 to fig. 40)

Make sure that all the cables are inside the duct and that they cannot come into contact with moving parts once positioned.

During installation, make sure that the conductor cables are secured by an additional attachment near the terminals or

electrical connections, i.e. using bands.

Make sure that the cables are stripped near the terminals.

EN

K140

4.3

ELECTRONIC CIRCUIT BOARD

1. Infrared sensor input,

microwave sensors,

photocells, door opening

safety guard

2. Input for program selector

input with knob

3. Input for lateral guards,

antipanic device and test

sensors

4. Digital switch input

5. Input for air curtain, lamp,

key switch, emergency key,

smoke detectors

6. Emergency battery system

input

7. Gearmotor input

8. Door block 1 input

9. Door block 2 input

(pharmacy)

10. Transformer input

11. Lighted display

12. Encoder cord input

13. DOWN key

14. ENTER key

Fig.

33

23

INSTRUCTIONS FOR INSTALLATION AND USE

Figure 3

Figure 2

Hole ø 10 mm

with rubber cable

sleeves

Fig.

33

EN

K140

Figure 1

Screw M6x20

M6 Nut

Raceway

Spring

Ds2

Ds3

Ds4

10

9

8

5

3

1

2

4

12

PC

don’t touch

14

1

1

13

6

7

Ø6.5

30mm

400mm

400mm

400mm

400mm

30mm

4.4

PRE-WIRED ELECTRIC CONNECTIONS

TransformerTransformerTransformer

Fig.

34

24

INSTRUCTIONS FOR INSTALLATION AND USE

Circuit

Red

Blue

Black

BEL

T

TRANSMISSION

ENCODER

MOTOR

BATTER

Y

EN

K140

Red

1. SMOKE

FIRE SYSTEM

2. EMERGENCY

3. CLOSURE

KEY

4. OPENING

KEY

5. LAMP

6. AIR

CURTAINS

7. GND

8. 24V*

17. INTERNAL

SECURITY

18. INTERNAL

RADAR

19. GND

20. GND

21. EXTERNAL

SECURITY

22. EXTERNAL

RADAR

23. GND

24. 24V

Ÿ 24V

Ÿ GND

Ÿ SIGNAL A

Ÿ GND (shield)

Ÿ SIGNAL B

* Unregolated

25. RESET (NEAR)

26. OPEN

27. PARTIAL

28. EXIT ONLY

29. ENTER ONLY

30. CLOSED

31. GND

32. 24V

9. TEST+

10. TEST+

11. GND

12. ANTIPANIC

DEVICE

13. LATERAL

SAFETY 2

14. LATERAL

SAFETY 1

15. GND

16. 24V

F

N

1 9 17 25

2 10 18 26

3 11 19 27

4 12 20 28

5 13 21 29

6 14 22 30

7 15 23 31

8 16 24 32

START

2 Sensors

activation

1 Activation/Safety

Sensor

+1 Activation Sensor

+ Photocells

2 Activation/Safety

sensors

+1 Lateral sensor

1 Activation/Safety

sensor

+1 Activation Sensor

+ 2 Lateral sensors

+ Photocells

2 Activation/Safety

sensors

+ 2 Lateral sensors

WITHOUT IS5

LATERAL

2 Activation sensors

+

1 Lateral sensor

+ Photocells

2 Activation sensors

+ 2 Lateral sensor

+ Photocells

2 Sensors on

passenger cab

+

1 Lateral sensor

2 Sensors on

passenger cab

2 Sensors on

passenger cab

+

2 Lateral sensor

1 Activation/Safety

sensor

+1 Activation Sensor

+

1 Lateral sensor

+ Photocells

ONLY ACTIVATION

WITH IS5

LATERAL

ACTIVATION WITH

SAFETY SENSORS

ACTIVATION WITH SAFETY

SENSORS MONITORED

2 Activation/Safety

Sensors

2 Activation/Safety

Sensors +Photocells

A

M

C

D

E

G

I

F H

N

25

IT

K140

25

EN

K140

ELECTRICAL WIRING DIAGRAM (FLOW CHART)

4.5

Fig.

35

B

L

O

INSTRUCTIONS FOR INSTALLATION AND USE

Optex

Hotron

Mo Mh

Optex

Hotron

No Nh

Optex

Hotron

Oo Oh

4.6

CONNECTION OF DETECTION SENSORS

26

EN

K140

INSTRUCTIONS FOR INSTALLATION AND USE

¬Dig i tal pr o gra m s witc h m enu: PAR A METE RS> OT H ER

PARAMETERS> SAFETY SENSOR LOGIC: N.C. WITHOUT TEST

Or program parameter 9 with the dot

N.C. SIC

COM. SIC

NO ATT.

COM. ATT.

GND

+24V

N.C. SIC

COM. SIC

NO ATT.

COM. ATT.

GND

+24V

green/blackgreen/blackgreen/black

white/blackwhite/blackwhite/black

yellowyellowyellow

whitewhitewhite

greygreygrey

greygreygrey

Fig.

B

17

18

19

12 20

13 21

14 22

15 23

24

17

18

17

18

19

12 20

13 21

14 22

15 23

24

GND

+24V

greygreygrey

greygreygrey

whitewhitewhite

yellowyellowyellow

greygreygrey

greygreygrey

18

20

23

24

24 23

20

22

ACTIVATION

N.O.

GND

+24V

COM

Fig.

ACTIVATION

N.O.

COM

whitewhitewhite

yellowyellowyellow

A

19

19

20

20

21

22

23

23

24

24

¬Digital program switch menu: PARAMETERS> OTHER PARAMETERS>

SAFETY SENSOR LOGIC: N.C. WITHOUT TEST

Or program parameter 9 with the dot

IS2 INTERNAL ACTIVATION/SAFETY

SENSOR

IS2 EXTERNAL ACTIVATION/SAFETY

SENSOR

Is1 INTERNAL ACTIVATION/SAFETY

SENSOR

IS1 EXTERNAL ACTIVATION

SENSOR

green/blackgreen/blackgreen/black

white/blackwhite/blackwhite/black

yellowyellowyellow

whitewhitewhite

greygreygrey

greygreygrey

27

EN

K140

INSTRUCTIONS FOR INSTALLATION AND USE

¬Digital program switch menu:

PARAMETERS>OTHER PARAMETERS>

SAFETY SENSOR LOGIC: N.C. WITH TEST

Or program parameter 9 without the dot

F1-F2

PHOTOCELLS

CIRCUIT

RX1 - TX1 = First beam

RX2 - TX2 = Second beam

9

18

19

20

21

22

15 23

24

RX1RX1RX1

COM RXCOM RXCOM RX

RX2RX2RX2

TEST -TEST -TEST -

TEST +TEST +TEST +

TX1TX1TX1

COM TXCOM TXCOM TX

OUTOUTOUT

OUTOUTOUT

RX1RX1RX1

COM RXCOM RXCOM RX

RX2RX2RX2

TX1TX1TX1

RX1RX1RX1 RX2RX2RX2

TX1TX1TX1 TX2TX2TX2

redredred

whitewhitewhite

whitewhitewhite

TEST +TEST +TEST +

OUTOUTOUT

GNDGNDGND

TEST -TEST -TEST -

OUTOUTOUT

COM TXCOM TXCOM TX

redredred

Tx2Tx2Tx2

24V24V24V

ACTIVATION

GND

+24V

N.O.

COM

ACTIVATION

GND

+24V

N.O.

COM

yellowyellowyellow

whitewhitewhite

greygreygrey

greygreygrey

Fig.

C

TEST-TEST-TEST-

TEST+TEST+TEST+

24V24V24V

GNDGNDGND

OUTOUTOUT

OUTOUTOUT

18

20

23

24

23

24

20

22

9

24

15

23

19

21

18

20

22

23

21

19

yellowyellowyellow

whitewhitewhite

greygreygrey

greygreygrey

IS1 EXTERNAL ACTIVATION

SENSOR

IS1 INTERNAL ACTIVATION

SENSOR

28

EN

K140

INSTRUCTIONS FOR INSTALLATION AND USE

¬Digital program switch menu:

PARAMETERS>OTHER PARAMETERS>

SAFETY SENSOR LOGIC: N.C. WITHOUT TEST

Or program parameter 9 with the dot

F1-F2

PHOTOCELLS

CIRCUIT

RX1 - TX1 = First beam

RX2 - TX2 = Second beam

IS1 EXTERNAL ACTIVATION

SENSOR

17

18

19

12 20

13 21

14 22

15 23

24

RX1RX1RX1

COM RXCOM RXCOM RX

RX2RX2RX2

TEST -TEST -TEST -

TEST +TEST +TEST +

TX1TX1TX1

COM TXCOM TXCOM TX

OUTOUTOUT

OUTOUTOUT

RX1RX1RX1

COM RXCOM RXCOM RX

RX2RX2RX2

TX1TX1TX1

RX1RX1RX1 RX2RX2RX2

TX1TX1TX1 TX2TX2TX2

redredred

whitewhitewhite

TEST +TEST +TEST +

OUTOUTOUT

GNDGNDGND

TEST -TEST -TEST -

COM TXCOM TXCOM TX

redredred

Tx2Tx2Tx2

24V24V24V

GND

+24V

COM

N.C.

GND

+24V

N.O.

COM

N.O.

COM

ACT.

SIC.

ACT.

green/blackgreen/blackgreen/black

yellowyellowyellow

white/blackwhite/blackwhite/black

whitewhitewhite

whitewhitewhite

yellowyellowyellow

greygreygrey

greygreygrey

greygreygrey

24V24V24V

GNDGNDGND

OUTOUTOUT

OUTOUTOUT

OUTOUTOUT

whitewhitewhite

Fig.

D

17

19

18

20

20

23

22

24

23

24

greygreygrey

21

19

24

IS2 INTERNAL ACTIVATION/SAFETY

SENSOR

29

EN

K140

INSTRUCTIONS FOR INSTALLATION AND USE

17

18

11 19

12 20

13 21

14 22

15 23

16 24

GND

+24V

COM

N.C.

GND

+24V

N.O.

COM

N.O.

COM

ACT.

SIC.

ACT.

green/blackgreen/blackgreen/black

yellowyellowyellow

white/blackwhite/blackwhite/black

whitewhitewhite

whitewhitewhite

yellowyellowyellow

greygreygrey

greygreygrey

greygreygrey

TEST -TEST -TEST -

TX1TX1TX1

RX1RX1RX1

COM RXCOM RXCOM RX

RX2RX2RX2

TX1TX1TX1

RX1RX1RX1 RX2RX2RX2

TX1TX1TX1 TX2TX2TX2

TEST +TEST +TEST +

GNDGNDGND

TEST -TEST -TEST -

OUTOUTOUT

COM TXCOM TXCOM TX

redredred

Tx2Tx2Tx2

24V24V24V

GNDGNDGND

24V24V24V

OUTOUTOUT

OUTOUTOUT

+24V

GND

COM

+24V

GND

N.C.

COM

Fig.

E

OUTOUTOUT

redredred

whitewhitewhite

whitewhitewhite

24

24

23

23

22

20

20

greygreygrey

18

19

17

16

15

13

14

14

24

23

19

21

15

16

15

15

16

13

N.C.

F1-F2

PHOTOCELLS

CIRCUIT

Is5 LATERAL SENSOR 2 IS5 LATERAL SENSOR 1

RX1 - TX1 = First beam

Rx2 - TX2 = Second beam

IS1 EXTERNAL ACTIVATION

SENSOR

IS2 INTERNAL ACTIVATION/SAFETY

SENSOR

¬Digital program switch menu:

PARAMETERS>OTHER PARAMETERS> SAFETY SENSOR LOGIC: N.C. WITHOUT TEST

Or program parameter 9 with the dot

30

IT

K140

30

EN

K140

IS5 LATERAL SENSOR

INSTRUCTIONS FOR INSTALLATION AND USE

¬Digital program switch menu:

PARAMETERS>OTHER PARAMETERS>

SAFETY SENSOR LOGIC: N.C. WITHOUT TEST

Or program parameter 9 with the dot

IS2 EXTERNAL ACTIVATION/SAFETY

SENSOR

IS2 INTERNAL ACTIVATION/SAFETY

SENSOR

17

18

11 19

12 20

13 21

14 22

15 23

16 24

N.C.N.C.N.C.

24V24V24V

GNDGNDGND

Fig.

F

24V

GND

N.C.

COM

14

15

16

N.C. SIC

COM. SIC

NO ATT.

COM. ATT.

GND

+24V

N.C. SIC

COM. SIC

NO ATT.

COM. ATT.

GND

+24V

green/blackgreen/blackgreen/black

white/blackwhite/blackwhite/black

yellowyellowyellow

whitewhitewhite

greygreygrey

greygreygrey

17

18

19

19

20

20

21

22

23

23

24

24

green/blackgreen/blackgreen/black

white/blackwhite/blackwhite/black

yellowyellowyellow

whitewhitewhite

greygreygrey

greygreygrey

18

11 19

12 20

13 21

14 22

15 23

16 24

RX1RX1RX1

COM RXCOM RXCOM RX

RX2RX2RX2

TEST -TEST -TEST -

TEST +TEST +TEST +

TX1TX1TX1

COM TXCOM TXCOM TX

OUTOUTOUT

OUTOUTOUT

PHOTOCELLS

CIRCUIT

F1 - F2

RX1RX1RX1

COM RXCOM RXCOM RX

RX2RX2RX2

TX1TX1TX1

RX1RX1RX1 RX2RX2RX2

TX1TX1TX1 TX2TX2TX2

RX1 - TX1 = First beam

Rx2 - TX2 = Second Beam

whitewhitewhite

whitewhitewhite

TEST +TEST +TEST +

OUTOUTOUT

GNDGNDGND

TEST -TEST -TEST -

OUTOUTOUT

COM TXCOM TXCOM TX

redredred

Tx2Tx2Tx2

24V24V24V

ACTIVATION

GND

+24V

N.O.

COM

ACTIVATION

GND

+24V

N.O.

COM

¬ Digital program switch menu:

PARAMETERS>OTHER PARAMETERS>

SAFETY SENSOR LOGIC: N.C. WITHOUT TEST

Or program parameter 9 with the dot

yellowyellowyellow

whitewhitewhite

greygreygrey

greygreygrey

yellowyellowyellow

whitewhitewhite

greygreygrey

greygreygrey

24V

GND

N.C.

COM

Is5 LATERAL S.

Fig.

G

24V24V24V

GNDGNDGND

N.C.N.C.N.C.

Is1 INTERNAL ACTIVATION

SENSOR

Is1 EXTERNAL ACTIVATION

SENSOR

redredred

31

EN

K140

18

19

20

21

22

23

23

23

24

24

24

20

14

15

16

INSTRUCTIONS FOR INSTALLATION AND USE

17

18

11 19

12 20

13 21

14 22

15 23

16 24

¬ Digital program switch menu:

PARAMETERS>OTHER PARAMETERS>

SAFETY SENSOR LOGIC: N.C. WITHOUT TEST

Or program parameter 9 with the dot

24V

GND

N.C.

COM

24V

GND

N.C.

COM

IS5 S. LATERAL S. 2

IS5 LATERAL S. 1

Fig.

H

32

EN

K140

N.C. SIC

COM. SIC

NO ACT.

COM. ACT.

GND

+24V

N.C. SIC

COM. SIC

NO ACT.

COM. ACT.

GND

+24V

green/blackgreen/blackgreen/black

white/blackwhite/blackwhite/black

yellowyellowyellow

whitewhitewhite

greygreygrey

greygreygrey

IS2 INTERNAL ACTIVATION/SAFETY S.

IS2 EXTERNAL ACTIVATION/SAFETY S.

17

18

19

19

20

20

21

22

23

23

24

24

14

15

16

13

15

16

INSTRUCTIONS FOR INSTALLATION AND USE

green/blackgreen/blackgreen/black

white/blackwhite/blackwhite/black

yellowyellowyellow

whitewhitewhite

greygreygrey

greygreygrey

17

18

11 19

12 20

13 21

14 22

15 23

16 24

OUTOUTOUT

OUTOUTOUT

PHOTOCELLS

CIRCUIT

F1 - F2

RX1RX1RX1 RX2RX2RX2

TX1TX1TX1 TX2TX2TX2

RX1 - TX1 = First beam

Rx2 - TX2 = Second bam

TEST +TEST +TEST +

TEST -TEST -TEST -

OUTOUTOUT

COM TXCOM TXCOM TX

redredred

Tx2Tx2Tx2

24V24V24V

GNDGNDGND

24V24V24V

¬ Digital program switch menu:

PARAMETERS>OTHER PARAMETERS>SAFETY SENSOR LOGIC: N.C. WITHOUT TEST

Or program parameter 9 with the dot

24V

GND

N.C.

COM

IS5 LATERAL S.

Fig.

I

24V24V24V

GNDGNDGND

N.C.N.C.N.C.

33

EN

K140

redredred

whitewhitewhite

whitewhitewhite

GND

+24V

COM

N.C.

GND

+24V

N.O.

COM

N.O.

COM

ACT.

SIC.

ATT.

green/blackgreen/blackgreen/black

yellowyellowyellow

wite/blackwite/blackwite/black

whitewhitewhite

whitewhitewhite

yellowyellowyellow

greygreygrey

greygreygrey

greygreygrey

IS2 INTERNAL ACTIVATION/SAFETY S.

IS1 EXTERNAL ACTIVATION SENSOR

24

24

23

23

22

20

20

greygreygrey

18

19

17

14 15 16

OUTOUTOUT

19

21

2324

GNDGNDGND

RX1RX1RX1

COM RXCOM RXCOM RX

RX2RX2RX2

TX1TX1TX1

INSTRUCTIONS FOR INSTALLATION AND USE

18

11 19

12 20

13 21

14 22

15 23

16 24

RX1RX1RX1

COM RXCOM RXCOM RX

RX2RX2RX2

TEST -TEST -TEST -

TEST +TEST +TEST +

TX1TX1TX1

COM TXCOM TXCOM TX

OUTOUTOUT

OUTOUTOUT

SCHEDA

FOTOCELLULE

F1 - F2

TX1TX1TX1

RX1RX1RX1 RX2RX2RX2

TX1TX1TX1 TX2TX2TX2

RX1 - TX1 = First beam

Rx2 - TX2 = Second beam

whitewhitewhite

whitewhitewhite

TEST +TEST +TEST +

OUTOUTOUT

GNDGNDGND

TEST -TEST -TEST -

OUTOUTOUT

COM TXCOM TXCOM TX

redredred

Tx2Tx2Tx2

24V24V24V

ACTIVATION

GND

+24V

N.O.

COM

ACTIVATION

GND

+24V

N.O.

COM

¬ Digital program switch menu:

PARAMETERS>OTHER PARAMETERS>

SAFETY SENSOR LOGIC: N.C. WITHOUT TEST

Or program parameter 9 with the dot

yellowyellowyellow

whitewhitewhite

greygreygrey

greygreygrey

yellowyellowyellow

whitewhitewhite

greygreygrey

greygreygrey

24V

GND

N.C.

COM

IS5 LATERAL SENSOR

24V

GND

N.C.

COM

IS5 LATERAL SENSOR

Fig.

L

IS1 EXTERNAL ACTIVATION

SENSOR

IS1 INTERNAL ACTIVATION

SENSOR

redredred

34

EN

K140

24

23

21

19

RX1RX1RX1

COM RXCOM RXCOM RX

RX2RX2RX2

182022

23

24

23

24

22

20

18

20

13

16

16

15

14

INSTRUCTIONS FOR INSTALLATION AND USE

9 17

10 18

19

20

21

22

23

24

35

EN

K140

TST+

TST-

SECURITY

ACTIVATION

GND

+24V

TEST

+

-

ACTIVATION

GND

+24V

TEST

SECURITY

IS2 INTERNAL ACTIVATION/SAFETY

SENSOR MONITORED

N.C.

COM

COM

N.O.

TST-

TST+

N.C.

COM

COM

N.O.

¬ Digital program switch menu:

PARAMETERS>OTHER PARAMETERS> SAFETY SENSOR LOGIC:

N.C. WITH TEST

Or program parameter 9 without the dot

blackblackblack

redredred

rose rose rose

blueblueblue

yellowyellowyellow

greengreengreen

whitewhitewhite

brownbrownbrown

blackblackblack

redredred

roseroserose

blueblueblue

yellowyellowyellow

greengreengreen

whitewhitewhite

brownbrownbrown

Fig.

Mo

IS2 EXTERNAL ACTIVATION/SAFETY

SENSOR MONITORED

ELECTRICAL WIRING DIAGRAM FOR USING OPTEX

ACTIVATION/SAFETY SENSOR MONITORED

9

10

17

18

19

19

20

21

22

23

24

20

20

23

24

20

INSTRUCTIONS FOR INSTALLATION AND USE

¬ Digital program switch menu:

¬ PARAMETERS>OTHER PARAMETERS> SAFETY SENSOR LOGIC: N.C. WITH TEST

¬ Or program parameter 9 without the dot

Fig.

Mh

ELECTRICAL WIRING DIAGRAM FOR USING HOTRON

ACTIVATION/SAFETY SENSOR MONITORED

36

EN

K140

9 17

10 18

19

20

21

22

23

24

TST+

TST-

SECURITY

ACTIVATION

GND

+24V

TEST

+

-

ACTIVATION

GND

+24V

TEST

SECURITY

IS2 INTERNAL ACTIVATION/SAFETY

SENSOR MONITORED

N.C.

COM

COM

N.O.

TSTTST+

N.C.

COM

COM

N.O.

brownbrownbrown

greygreygrey

yellowyellowyellow

blueblueblue

greengreengreen

whitewhitewhite

blackblackblack

redredred

IS2 EXTERNAL ACTIVATION/SAFETY

SENSOR MONITORED

9

10

17

18

19

19

20

21

22

23

24

20

20

23

24

20

brownbrownbrown

greygreygrey

yellowyellowyellow

blueblueblue

greengreengreen

whitewhitewhite

blackblackblack

redredred

INSTRUCTIONS FOR INSTALLATION AND USE

9 17

10 18

11 19

20

13 21

22

15 23

16 24

¬ Digital program switch menu:

PARAMETERS>OTHER PARAMETERS> SAFETY SENSOR

LOGIC: N.C. WITH TEST

Or program parameter 9 without the dot

24V

GND

TST +

TST -

N.C.

COM

greengreengreen

redredred

blueblueblue

brownbrownbrown

whitewhitewhite

IS5 LATERAL S.

Fig.

No

SELECTRICAL WIRING DIAGRAM FOR USING OPTEX

ACTIVATION/SAFETY SENSOR MONITORED

37

EN

K140

TST+

TST-

SECURITY

ACTIVATION

GND

+24V

TEST

+

-

ACTIVATION

TEST

SECURITY

IS2 INTERNAL ACTIVATION/SAFETY

SENSOR MONITORED

N.C.

COM

COM

N.O.

blackblackblack

redredred

roseroserose

blueblueblue

yellowyellowyellow

greengreengreen

whitewhitewhite

brownbrownbrown

blackblackblack

redredred

roseroserose

blueblueblue

yellowyellowyellow

greengreengreen

whitewhitewhite

brownbrownbrown

IS2 EXTERNAL ACTIVATION/SAFETY

SENSOR MONITORED

9

10

17

18

19

19

20

21

22

23

24

20

20

23

24

20

orangeorangeorange

15 16 15 13 11

10

TST+

TST-

GND

+24V

N.C.

COM

COM

N.O.

INSTRUCTIONS FOR INSTALLATION AND USE

¬ Digital program switch menu:

PARAMETERS>OTHER PARAMETERS> SAFETY SENSOR

LOGIC: N.C. WITH TEST

Or program parameter 9 without the dot

Fig.

Nh

38

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K140

9 17

10 18

11 19

20

13 21

22

15 23

16 24

24V

GND

TST +

TST -

N.C.

COM

IS5 LATERAL S.

TST+

TST-

SECURITY

ACTIVATION

GND

+24V

TEST

+

-

ACTIVATION

GND

+24V

TEST

SECURITY

IS2 INTERNAL ACTIVATION/SAFETY

SENSOR MONITORED

N.C.

COM

COM

N.O.

TSTTST+

N.C.

COM

COM

N.O.

IS2 EXTERNAL ACTIVATION/SAFETY

SENSOR MONITORED

9

10

17

18

19

19

20

21

22

23

24

20

20

23

24

20

15 16 15 13 11 10

brownbrownbrown

greygreygrey

yellowyellowyellow

blueblueblue

greengreengreen

whitewhitewhite

blackblackblack

redredred

brownbrownbrown

greygreygrey

yellowyellowyellow

blueblueblue

greengreengreen

whitewhitewhite

blackblackblack

redredred

greengreengreen

redredred

blueblueblue

brownbrownbrown

whitewhitewhite

orangeorangeorange

ELECTRICAL WIRING DIAGRAM FOR USING HOTRON

ACTIVATION/SAFETY SENSOR MONITORED

9 17

10 18

11 19

20

13 21

14 22

15 23

16 24

¬ Digital program switch menu:

PARAMETERS>

OTHER PARAMETERS>

SAFETY SENSOR LOGIC:

N.C. WITH TEST

Or program

parameter 9 without the dot

+24V

GND

TST +

TST -

N.C.

COM

+24V

GND

TST +

TST -

N.C.

COM

brownbrownbrown

orangeorangeorange

blueblueblue

whitewhitewhite

redredred

greengreengreen

IS5 LATERAL S. 1 IS5 LATERAL S. 2

Fig.

Oo

ELECTRICAL WIRING

DIAGRAM FOR

USING OPTEX

ACTIVATION/SAFETY

SENSOR MONITORED

EN

K140

39

10

11

10

11

13

11

14

15

16

15

16

15

TST+

TST-

SECURITY

ACTIVATION

GND

+24V

TEST

+

-

ACTIVATION

GND

+24V

TEST

SECURITY

Is2 EXTERNAL ACTIVATION/SAFETY

SENSOR MONITORED

N.C.

COM

COM

N.O.

TST-

TST+

N.C.

COM

COM

N.O.

blackblackblack

roseroserose

blueblueblue

yellowyellowyellow

greengreengreen

whitewhitewhite

brownbrownbrown

10

17

18

19

20

21

22

23

24

20

20

23

24

20

9

19

redredred

Is2 INTERNAL ACTIVATION/SAFETY

SENSOR MONITORED

blackblackblack

roseroserose

blueblueblue

yellowyellowyellow

greengreengreen

whitewhitewhite

brownbrownbrown

redredred

brownbrownbrown

orangeorangeorange

blueblueblue

whitewhitewhite

redredred

greengreengreen

INSTRUCTIONS FOR INSTALLATION AND USE

¬ Digital program switch menu:

PARAMETERS>

OTHER PARAMETERS>

SAFETY SENSOR LOGIC:

N.C. WITH TEST

Or program

parameter 9 without the dot

Fig.

Oh

40

EN

K140

9 17

10 18

11 19

20

13 21

14 22

15 23

16 24

+24V

GND

TST +

TST -

N.C.

COM

+24V

GND

TST +

TST -

N.C.

COM

10

11

10

11

13

11

14

15

16

15

16

15

TST+

TST-

SECURITY

ACTIVATION

GND

+24V

TEST

+

-

ACTIVATION

GND

+24V

TEST

SECURITY

Is2 EXTERNAL ACTIVATION/SAFETY

SENSOR MONITORED

N.C.

COM

COM

N.O.

TST-

TST+

N.C.

COM

COM

N.O.

brownbrownbrown

yellowyellowyellow

blueblueblue

greengreengreen

whitewhitewhite

blackblackblack

redredred

10

17

18

19

20

21

22

23

24

20

20

23

24

20

9

19

greygreygrey

Is2 INTERNAL ACTIVATION/SAFETY

SENSOR MONITORED

INSTRUCTIONS FOR INSTALLATION AND USE

ELECTRICAL WIRING

DIAGRAM FOR

USING HOTRON

ACTIVATION/SAFETY

SENSOR MONITORED

brownbrownbrown

orangeorangeorange

blueblueblue

whitewhitewhite

redredred

greengreengreen

brownbrownbrown

orangeorangeorange

blueblueblue

whitewhitewhite

redredred

greengreengreen

IS5 LATERAL S. 1 Is5 LATERAL S. 2

brownbrownbrown

yellowyellowyellow

blueblueblue

greengreengreen

whitewhitewhite

blackblackblack

redredred

greygreygrey

25

26

27

28

29

30

31

32

4.7

PROGRAM SELECTION WITH MS1 KNOB/KS1

Fig.

36

111222333

444

555

666

777

888

KS1/MS1 SELECTION

KNOB CIRCUIT

RESETRESETRESET

OPENOPENOPEN

GNDGNDGND

CLOSEDCLOSEDCLOSED

ENTRANCEENTRANCEENTRANCE

EXITEXITEXIT

PARTIALPARTIALPARTIAL

32

+24V+24V+24V

25

26

27

28

29

30

31

4.8

DS2 DIGITAL CONNECTION

Fig.

37

+24V

Serial B

GND

Serial A

Shielding*

DS2 DIGITAL

SELECTOR CIRCUIT

Cable ‘shielding’ should only be used for cable lengths

in excess of 20 meters. For shorter cables cut the wire

at the level of the sheath

1

2

3

4

5

1

2

3

4

5

1 2 3 4 5

*

EN

K140

41

INSTRUCTIONS FOR INSTALLATION AND USE

9

11

12

15

16

ANTIPANIC CONNECTION

4.10

RX1RX1RX1

COM RXCOM RXCOM RX

TEST +TEST +TEST +

TX1TX1TX1

COM TXCOM TXCOM TX

OUTOUTOUT

OUTOUTOUT

PHOTOCELLS

CIRCUIT

F1 - F2

GNDGNDGND

24V24V24V

TEST +TEST +TEST +

OUTOUTOUT

OUTOUTOUT

¬ Digital program switch menu:

PARAMETERS>

OTHER PARAMETERS>

SAFETY SENSOR LOGIC:N.C. WITH

TEST

Or program parameter 9 without the dot

diagram of c on nection for us e co mb in ed w it h

monitored sensors

RX1RX1RX1

Tx1Tx1Tx1

RX1 - TX1 = First Beam

whitewhitewhite

redredred

TX1TX1TX1

RX1RX1RX1

COM RXCOM RXCOM RX

COM TXCOM TXCOM TX

42

EN

K140

Fig.

39

15

15

TEST -TEST -TEST -

9

11

12

16

1

2

3

4

5

6

7

8

4.9

KEY DEVICE CONNECTION

EMERGENCY

KEY

CLOSURE

KEY

GND

SINGLE

OPENING

KEY

KEY DEVICE

LAMP

Fig.

38

30V - 0.5A

EXIT OPENCOLLECTOR

AIR CURTAINS

+24v+24v+24v

CONNECTION FOR SMOKE

FIRE SYSTEM

8 6

5

7 3 7 4

7

1

2

INSTRUCTIONS FOR INSTALLATION AND USE

¬ Digital program switch menu:

PARAMETERS>

OTHER PARAMETERS>

SAFETY SENSOR LOGIC:

N.C. WITHOUT TEST

Or program parameter 9 with the dot

diagram of connection for use

combined with not monitored sensors

43

EN

K140

Fig.

40

Door block with

manual release

incorporated 1

Door block with

manual release

incorporated 2

pharmacy function

CONNETION OF DOOR BLOCK AND PHARMACY FUNCTION

4.11

11

12

15

16

RX1RX1RX1

COM RXCOM RXCOM RX

TEST +TEST +TEST +

TX1TX1TX1

COM TXCOM TXCOM TX

OUTOUTOUT

OUTOUTOUT

PHOTOCELLS

CIRCUIT

F1 - F2

GNDGNDGND

24V24V24V

TEST +TEST +TEST +

OUTOUTOUT

OUTOUTOUT

RX1RX1RX1

TX1TX1TX1

RX1 - TX1 = First Beam

whitewhitewhite

redredred

TX1TX1TX1

RX1RX1RX1

COM RXCOM RXCOM RX

COM TXCOM TXCOM TX

15

TEST -TEST -TEST -

16

11 12

INSTRUCTIONS FOR INSTALLATION AND USE

IT

USE AND OPERATION

5

5.1

TECHNICAL DESCRIPTION

The automation is electromechanical, without clutch or brakes, to prevent possible blockage of a continuous nature due to

damages or breakage of the structure.

The power supply is 230V~ 50/60 Hz with low voltage transformer 22V AC ~ 150VA.

The main section bar/crossbar of the automation is made of high resistance anodized extruded aluminum. The

gearmotor, toothed belt and electronic control circuit are incorporated in a covered casing in anodized extruded

aluminum, fastened by fitting for more rapid, simple access in case of maintenance.

The carriages supporting the door are made of sheet steel, and are equipped with high-density plastic wheels with lifetime

lubrication of the bearings, on a rail inside the main section bar/crossbar. The transmission and movement via gearmotor

function at 24V 45W on a wormscrew with lifetime lubrication and a toothed belt in anti-static rubber material with steel

cable strands that are long-lasting and wear-resistant.

The electronic control circuit is a microprocessor type with keys for adjustment of the parameters such as speed of

opening and closure, slowing space, low approach speed, automatic reclosing time and mode of operation.

The movement, position and speed of the door are managed by the electronic control circuit via a reading device and

optical encoder installed on the belt transmission.

Safety anti-crushing device on both closure and opening, that enables the door to reverse its movement if it meets an

obstacle.

5.2

EMERGENCY BATTERY

Automatic emergency opening or closure: The automation is equipped with a rechargeable emergency battery

that, in case of power outage on the 230V mains, automatically opens or closes the doors. After performing the

maneuver, the doors remain in this position until power is restored on the mains at 230V.

The automation will resume functioning in accordance with the program setting by the selection knob, after power has

been restored. Emergency opening or closure depends on the function entered in the program setting of the electronic

circuit board.

Supervision and automatic testing of the emergency battery: The emergency battery function is kept under constant

control by the electronic microprocessor control circuit. This supervision and test constantly verifies the efficiency of the

battery that, in case of malfunction, blocks the door and thereby signals the malfunction. Emergency opening or closure