ORIGINAL

INSTALLATION AND USE INSTRUCTIONS

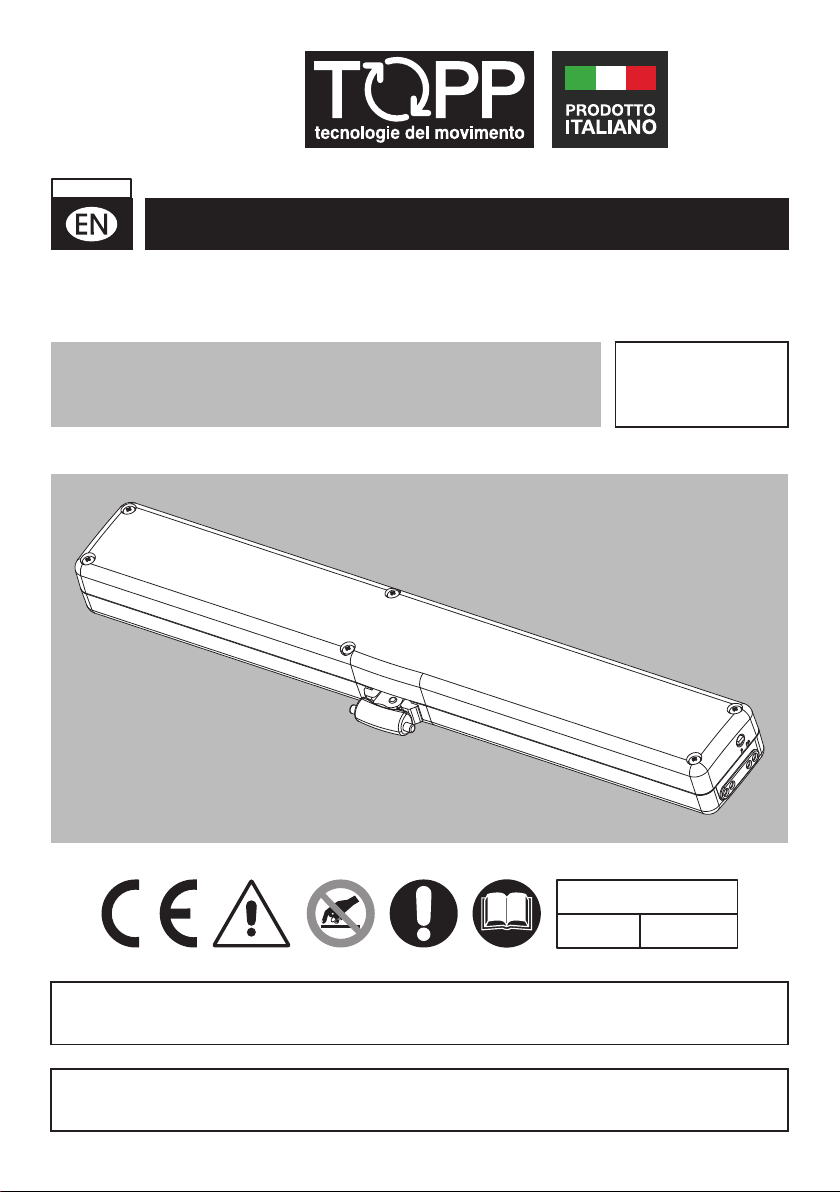

CHAIN ACTUATOR FOR

WINDOW AUTOMATION

C20

PATENTED

COD. 0P5186

VER.0.0 REV.09.13

BEFORE INSTALLING AND USING THE ACTUATOR, IT IS

COMPULSORY FOR THE INSTALLER AND THE USER TO READ

AND UNDERSTAND THIS MANUAL IN ALL ITS PARTS.

THIS MANUAL IS INTEGRAL PART OF THE ACTUATOR

AND MUST BE PRESERVED FOR FUTURE REFERENCE

UNTIL DEMOLITION OF THE SAME.

C20

INDEX

1- DECLARATION OF “CE” CONFORMITY

........................................................................................................................page 04

2- GENERAL REMARKS

2.1- General instructions..........................................................................................page 05

2.2- Installer and user..............................................................................................page 05

2.3- Warranty...........................................................................................................page 05

2.4- Technical assistance.........................................................................................page 05

2.5- Reserved rights ................................................................................................page 05

2.6- Description of personnel...................................................................................page 06

3- TECHNICAL DESCRIPTION

3.1- Rating plate and “CE” marking .........................................................................page 07

3.2- Denomination of the components and dimensions ..........................................page 08

3.3- Technical data...................................................................................................page 10

3.4- Formulas for the calculation of thrust force or tractive force.............................page 11

3.5- Destination of use.............................................................................................page 11

3.6- Use Limits.........................................................................................................page 12

3.7- Package ...........................................................................................................page 12

4- SAFETY

4.1- General instructions .........................................................................................page 14

4.2- Safety Devices .................................................................................................page 14

4.2.1- Protections against electric hazard .......................................................page 14

4.3- Safety plates.....................................................................................................page 15

4.4- Residual risks ...................................................................................................page 15

5- INSTALLATION

5.1- General instructions .........................................................................................page 16

5.2- Top hung windows ............................................................................................page 20

5.3- Bottom hung windows ......................................................................................page 21

Dome windows

5.4- .................................................................................................page 22

5.5- Electrical Connections......................................................................................page 24

5.6- Control devices.................................................................................................page 24

5.7- Correct assembly of the actuator on the window frame ...................................page 25

5.8- Emergency procedures ....................................................................................page 26

6- USE AND OPERATION

6.1- Use of the actuator ...........................................................................................page 27

7- MAINTENANCE

7.1- General instructions .........................................................................................page 28

8- DEMOLITION

8.1- General instructions .........................................................................................page 28

9- SPARE PARTS AND ACCESSORIES UPON REQUEST

9.1- General instructions .........................................................................................page 29

9.2- Brackets for vertical assembly..........................................................................page 29

Quick coupling with integrated release push-button ARP

9.3- “ ”..............................page 30

Dome windows

9.3.1- ......................................................................................page 30

9.3.2- Emergency procedures .........................................................................page 31

FIGURES

........................................................................................................................page 32

CERTIFICATE OF GUARANTEE

........................................................................................................................page 39

VER.0.0

REV.09.13

INSTALLATION AND USE ISTRUCTIONS

3

1- DECLARATION OF “CE” CONFORMITY

TOPP S.p.A.

via L. Galvani, 59

36066 Sandrigo (VI)

ITALIA

declares that the electrical device

called: CHAIN ACTUATOR FOR WINDOW AUTOMATION

type: C20

models: C20/230V - C20/24V

Serial n° and year of manufacture: see data plate and CE marking applied to

the device

complies with the requirements of the following directives:

2006/95/CE

Low Voltage Directive: electrical material for use within certain voltage limits.

2004/108/CE

Electromagnetic Compatibility Directive - Concerning the approximation of the laws of

Member States relating to electromagnetic compatibility.

C20

and also declares that the following harmonised standards have been applied:

EN55014-1

EN55014-2

EN61000-6-3

EN61000-6-2

EN50366

EN60335-1

Date: Sandrigo, 10/01/2008

Matteo Cavalcante .....................................................

INSTALLATION AND USE INSTRUCTIONS

4

VER.0.0

REV.09.13

C20

GENERAL REMARKS -2

2.1- GENERAL INSTRUCTIONS

BEFORE INSTALLING AND USING THE ACTUATOR, IT IS COMPULSORY THAT THE

INSTALLER AND THE USER CAREFULLY READ AND UNDERSTAND THIS MANUAL IN

ALL ITS PARTS.

THIS MANUAL IS INTEGRAL PART OF THE ACTUATOR AND MUST COMPULSORILY BE

PRESERVED FOR FUTURE REFERENCE.

THE MANUFACTURER HAS NO LIABILITY FOR ANY EVENTUAL DAMAGE TO PERSONS,

ANIMALS AND THINGS DUE TO THE INOBSERVANCE OF THE PRESCRIPTIONS

DESCRIBED IN THIS MANUAL.

2.2- INSTALLER AND USER

THE ACTUATOR INSTALLATION CAN BE PERFORMED EXCLUSIVELY BY COMPETENT

AND QUALIFIED TECHNICAL PERSONNEL SATISFYING THE PROFESSIONAL AND

TECHNICAL REQUIREMENTS FORESEEN BY THE LAWS IN FORCE IN THE COUNTRY OF

INSTALLATION.

THE ACTUATOR CAN BE USED EXCLUSIVELY BY A USER ACTING IN COMPLIANCE WITH

THE INSTRUCTIONS CONTAINED IN THIS MANUAL AND/OR IN THE MANUAL OF THE

ACTUATOR CONTROL DEVICE (E.G.: CONTROL UNIT).

2.3- WARRANTY

THE ACTUATOR WARRANTY EXPIRES, IF ITS USE DOES NOT COMPLY WITH THE

INSTRUCTIONS AND PRESCRIPTIONS DESCRIBED IN THIS MANUAL, AS WELL AS IF

NON-ORIGINAL COMPONENTS, ACCESSORIES, SPARE PARTS, AND CONTROL

SYSTEMS ARE USED.

2.4- TECHNICAL ASSISTANCE

For the technical assistance apply to your Dealer or to the Manufacturer.

2.5- RESERVED RIGHTS

The reserved rights on this manual "Installation and use instructions" remain property of

the Manufacturer.

Each information herein contained (text, drawings, diagrams, etc.) is reserved.

None part of this manual can be reproduced and disclosed (totally or partially) by any

reproduction means (photocopies, microfilms or other) without written authorization of

the Manufacturer.

VER.0.0

REV.09.13

INSTALLATION AND USE INSTRUCTIONS

5

2- GENERAL REMARKS

2.6- DESCRIPTION OF PERSONNEL

USERS MUST NEVER PERFORM OPERATIONS RESERVED FOR MAINTENANCE

PEOPLE OR SPECIALISED TECHNICIANS. THE MANUFACTURER DECLINES ALL

LIABILITY FOR DAMAGE DERIVING FROM FAILURE TO OBSERVE THE ABOVE

REQUIREMENTS.

Specialised electrician:

A specialised electrician must be able to install the actuator, start it and operate it both

in normal conditions and in the maintenance mode; he/she is qualified to perform all

electrical and mechanical adjustment and maintenance operations. He/she is allowed

to work on live electrical cabinets and junction boxes.

User:

specialised person capable of operating the actuator under normal conditions by using

the relative controls. He/she must also be able to operate with the actuator under

“maintenance” in order to perform simple routine maintenance operations (cleaning),

and start or reset the actuator following an unscheduled stop.

C20

6

INSTALLATION AND USE ISTRUCTIONS

VER.0.0

REV.09.13

C20

TECHNICAL DESCRIPTION -3

3.1- RATING PLATE AND “CE” MARKING

The “CE” marking certifies the compliance of the machine with the essential safety and

health requirements foreseen by the product European Directives.

The rating plate is an adhesive plate in polyester, silk-screen printed in black, having the

following size: L=36 mm - H=50 mm.

It is applied externally on the actuator. The plate (Fig. 1) bears in readable and indelible

way the following data:

• logo and address of the manufacturer

• type and model

• voltage and intensity of power supply (V - A)

• absorbed electric power P (W)

• thrust and tractive force F (N)

• type of service S (min)

• idle translation speed (mm/s)

• protection degree (IP)

• “CE” marking

• symbol of WEEE Directive 2002/96/CE

• symbol of double insulation (only for mod. C20/230V)

• serial number

2

VER.0.0

REV.09.13

Fig. 1

Sandrigo - made in Italy

N:0910TA12000

Sandrigo - made in Italy

N:0910TA12000

INSTALLATION AND USE ISTRUCTIONS

C20

230V~ 50Hz

I = 0,12A

P = 25W

F = 300N

S2 = 4min

8 mm/s

IP30

C20

24V

I = 0,43A

P = 9W

F = 300N

S2 = 4min

7,5 mm/s

IP30

7

3- TECHNICAL DESCRIPTION

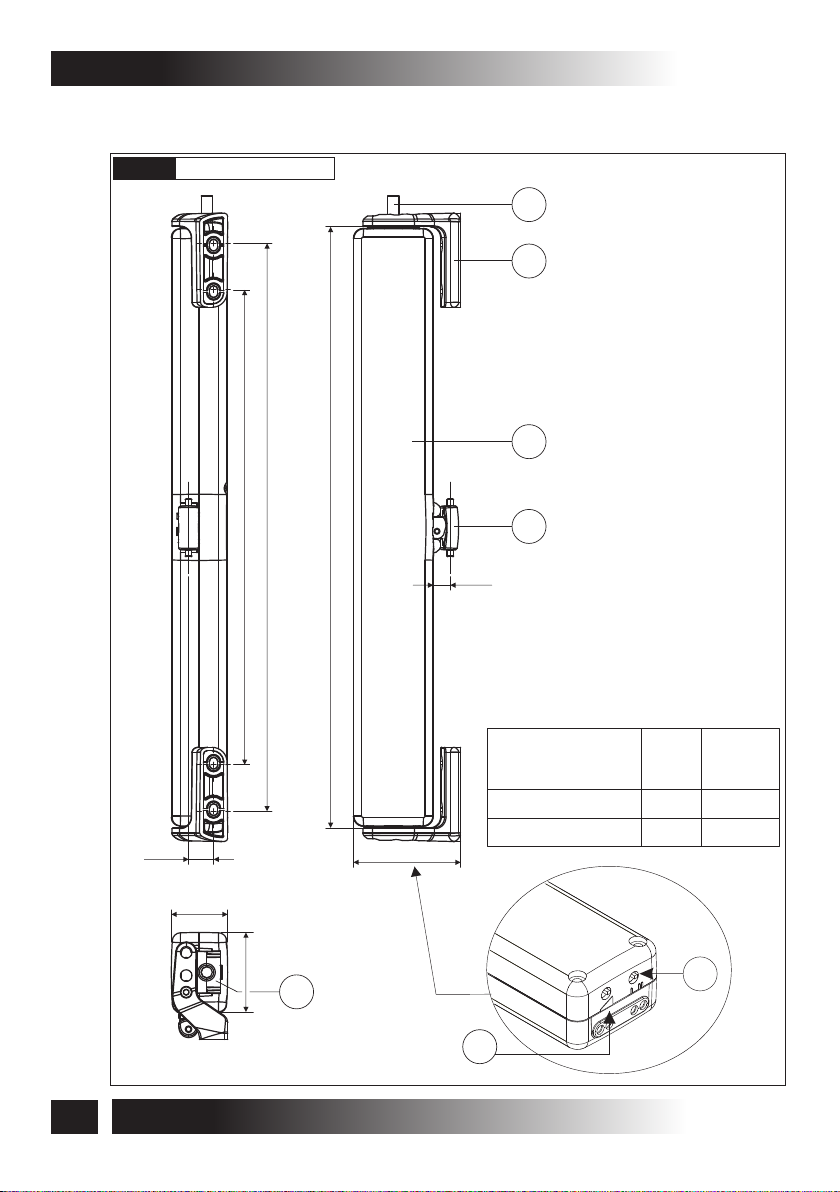

3.2- DENOMINATION OF THE COMPONENTS AND DIMENSIONS

C20

Fig. 2a

Dimensions in mm

342

286

1

2

3

362

4

10.3

LEGEND:

1) Power supply cable

2) Window frame connection brackets (right-left)

3) Actuator

4) Chain end

5) Electric connector

6) Switch I=240 mm; II=360 mm

15.1

34

48

5

INSTALLATION AND USE INSTRUCTIONS

8

64.5

Dip switch power

7)

7

Min

(-)

Max

(+)

Thrust

force

150 N

300 N

Tractive

force

100 N

200 N

6

+

-

VER.0.0

REV.09.13

C20

TECHNICAL DESCRIPTION -3

Fig. 2b

42

Dimensions in mm

.5

10

80

27

11

2

1

8615

3

4

17

42

11

15

8.4

14

16

5

36

15

51.8

13.313

(43)

30

9.5

2.5

85

VER.0.0

REV.09.13

LEGEND:

1) Bracket for bottom hung opening

Quick coupling to the window frame “ARS”

2)

3) Release side indicator

4) Bracket for vertical assembly “A”

5) Bracket for vertical assembly “B”

INSTALLATION AND USE ISTRUCTIONS

19.5

2

3

16.8

35

24±0,1

17.5

2

(4)

9

3- TECHNICAL DESCRIPTION

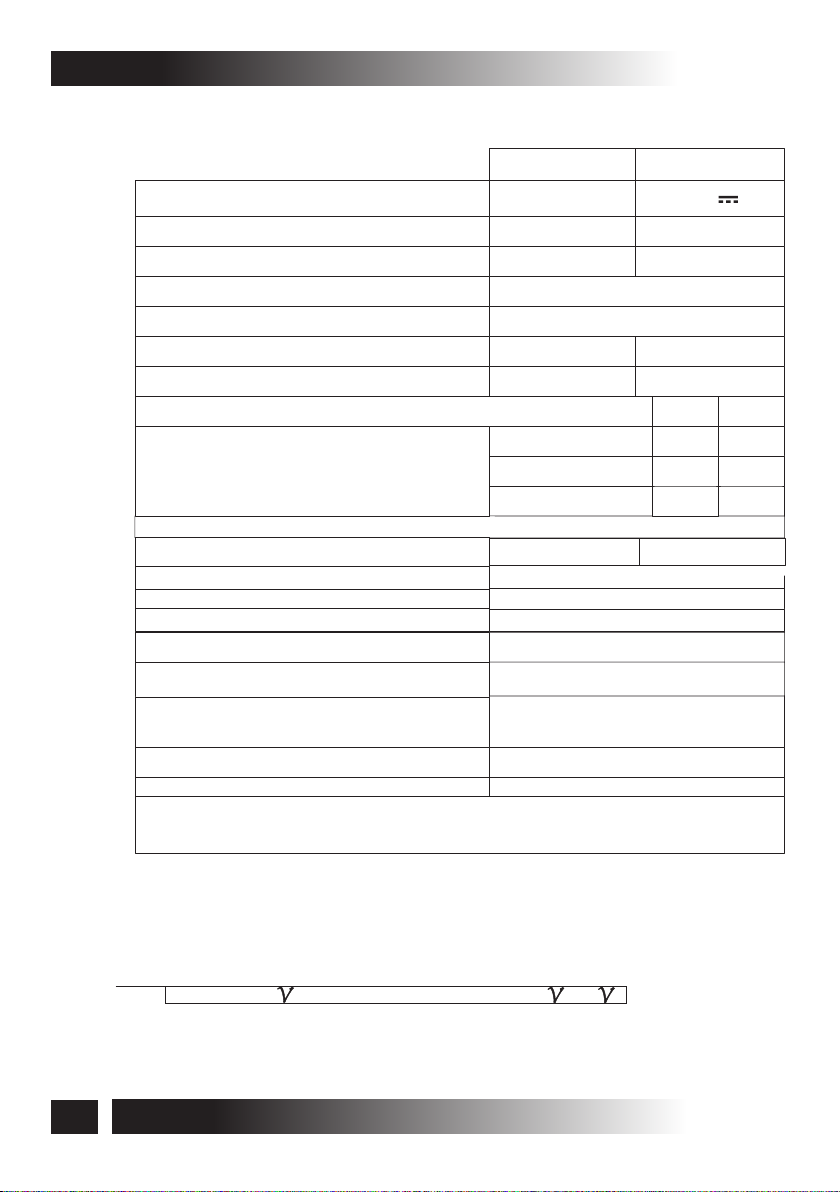

3.3- TECHNICAL DATA

Tab. 1 contains the technical data characterising the actuators.

Tab. 1

Power supply voltage

Absorbed current

Absorbed power with load

Thrust force

Tractive force

Idle translation speed

Duration of the idle stroke (360 mm)

Operation stroke length (mm)

Minimum window

frame height (mm)

(2)

Limit switch: Electronic for opening - by amperometric absorption for closing.

Protection against electric shock

Type of service S

(3)

2

Operating temperature

Protection degree of electric devices

Adjustment of the window frame connection

Parallel electric connection of more

actuators on the same window

Parallel electric connection of more

actuators on different windows

Actuator weight with brackets

Gross weight

(1)

Tolerance on the precision of limit switch tripping at output: +/- 2 cm.

(2)

Actuator distance from the window frame opening hinge

(3)

Service of limited duration according to EN 60034

(1)

C20/230V

230 V - 50 Hz

0,12 A

25 W

8 mm/s

46 s

Top hung

Bottom hung

Dome

Classe II

- 5 + 50 ºCºC

(see wiring diagram)

300 N

200 N

4 min

IP 30

NO

NO

Yes

0,97 kg

1,15 kg

C20/24V

24 V

0,43 A

9 W

7,5 mm/s

48 s

240

250

500

300

Classe III

C20

360

360

900

400

Compatibility of actuators connected in parallel

ACK4 T50 C20 C25 C30 C40 SL60 T80 C240 C20T

C20

10

INSTALLATION AND USE INSTRUCTIONS

VER.0.0

REV.09.13

C20

TECHNICAL DESCRIPTION -3

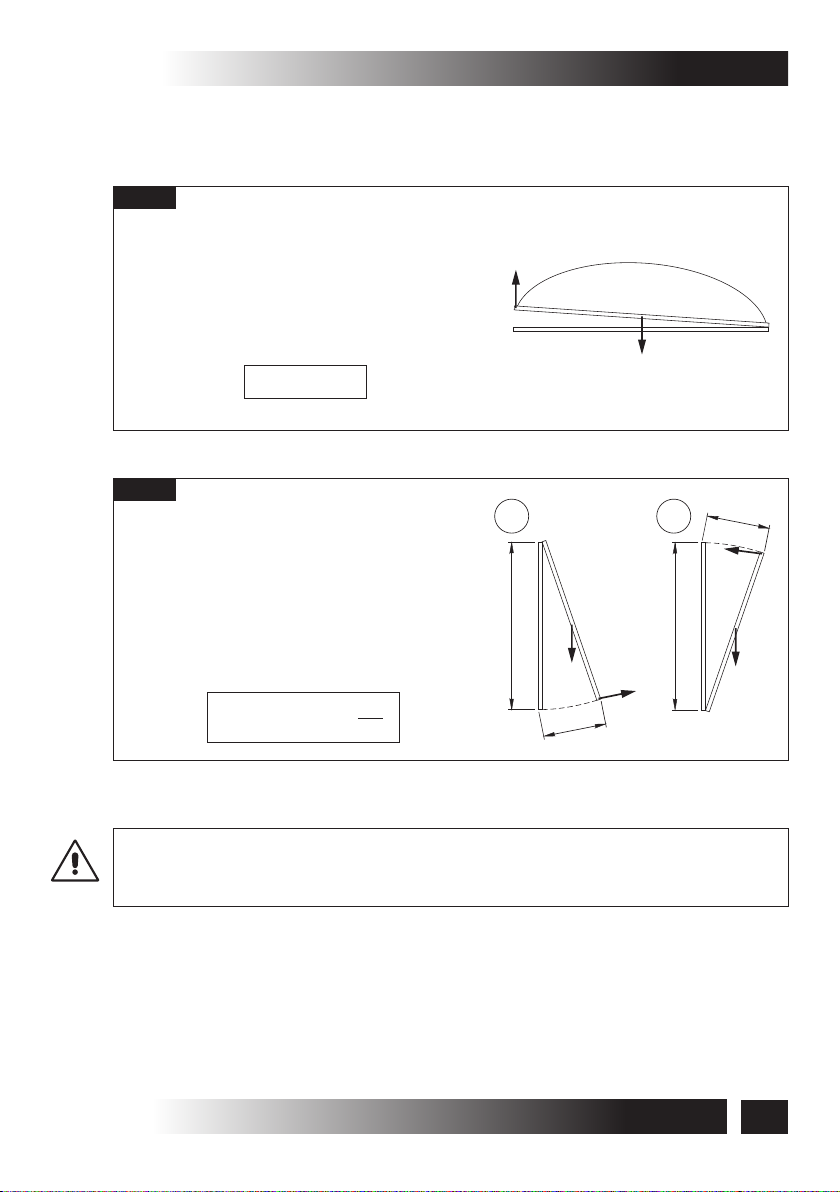

3.4- FORMULAS FOR THE CALCULATION OF THRUST AND TRACTIVE

FORCE

Fig. 3

Horizontal domes or skylights

F= Force necessary for opening or

closing

P= Weight of the skylight or dome

(Only movable part)

F = 0.54 x P

Fig. 4

Top hung windows (A) or

bottom hung windows (B)

F = Force necessary for opening or

closing

P = Weight of the window

(Only movable part)

C = Window opening stroke

H = Window height (Only movable part)

F = (0.54 x P) x ( )

C

H

F

P

A

H

P

C

B

H

F

C

F

P

3.5- DESTINATION OF USE

THE ACTUATOR HAS BEEN DESIGNED AND MANUFACTURED TO PERFORM

AUTOMATICALLY, BY MEANS OF A COMMAND DEVICE, THE OPENING AND CLOSING

OF TOP HUNG WINDOWS, BOTTOM HUNG WINDOWS, PIVOT WINDOWS, AND

SKYLIGHTS.

VER.0.0

REV.09.13

INSTALLATION AND USE ISTRUCTIONS

11

3- TECHNICAL DESCRIPTION

3.6- USE LIMITS

The actuator has been designed and manufactured exclusively for the destination of

use given in par. 3.5, therefore, any other type of use is strictly forbidden in order to

assure in any moment the safety of the installer and of the user, as well as the efficiency

of the actuator itself.

IT IS STRICTLY FORBIDDEN TO USE THE ACTUATOR FOR IMPROPER USES, I.E. OTHER

THAN THE ONE FORESEEN BY THE MANUFACTURER (SEE PAR. 3.5).

IT IS STRICTLY FORBIDDEN TO INSTALL THE ACTUATOR ON THE EXTERNAL SIDE OF

THE WINDOW FRAME SUBJECT TO ATMOSPHERIC AGENTS (RAIN, SNOW, ETC.).

THE USE OF THE ACTUATOR IN ENVIRONMENTS WITH POTENTIALLY EXPLOSIVE

ATMOSPHERE IS STRICTLY FORBIDDEN.

EX

IT IS COMPULSORY TO KEEP THE PACKAGE AND THE ACTUATOR OUT OF REACH OF

CHILDREN.

3.7- PACKAGE

Each package of the product (cardboard box) contains (Fig. 5):

• No. 1 Actuator equipped with power supply cable (with electric connector);

• No. 2 Window frame connection brackets (right-left) (Ref. A);

• No. 1 Bracket for bottom hung opening (Ref. B);

• No. 1 Adhesive drilling template (Ref. C);

• No. 1 Small parts package for aluminum windows (No. 2 screws for lateral fastening of

connection brackets to the window, No. 7 screws AF Ø 4,8 x 16 mm and No. 2 screws

AF Ø 4,2 x 19 mm for the fastening of the brackets to the window frame and for ARS

coupling fastening) (Ref. D);

• No. 1 ARS coupling release tool (Ref. D-1);

• No. 1 ARS coupling (Ref. D-2);

• No. 1 Installation and use instructions (Ref. E);

• No. 1 Safety plate (Fig. 6);

C20

MAKE SURE THAT THE ABOVE DESCRIBED COMPONENTS ARE CONTAINED IN THE

PACKAGE, AS WELL AS THAT THE ACTUATOR HAS NOT BEEN DAMAGED DURING

TRANSPORT.

SHOULD ANY ANOMALY BE DETECTED, IT IS FORBIDDEN TO INSTALL THE ACTUATOR,

AND IT IS COMPULSORY TO REQUIRE TECHNICAL ASSISTANCE FROM YOUR DEALER

OR THE MANUFACTURER.

THE PACKAGING (PAPER, PLASTIC, ETC.) HAS TO BE DISPOSED ACCORDING TO THE

LAWS IN FORCE.

12

INSTALLATION AND USE INSTRUCTIONS

VER.0.0

REV.09.13

C20

TECHNICAL DESCRIPTION -3

Fig. 5

A

8

.

3

.8

3

Ø

O

T

NA

T

I

A

N

M

RS

NT

LI

I

E

ME

E

R

.8

Ø3

ÂT

V

IO

B

NST

A

RRA

E

L

E

DU

S F

D

INFER

E

EL SE

R

A

D

'S

ISS

URE

O

F

E

RT

E

E

O PA

T

MEN

A

RR

NA SE

IXE

F

TER

'S

N

W

I

O

EA

IN

L

WIND

F

INE O

EN F

L L

TZ

NA

SE

E

G

INTER

ST

FE

S

E

D

IE

TRE

IN

E

N

NL

E

FE

N

E

IN

E D

R

IEU

ER

T

A

N

E I

IGN

L

E LA VENT

IOR D

ER

NT

I

LINEA

3.8

RE

E

G

R

G

O A SPO

T

FNUN

N

F

E

E

O

N

RAM

R

TE

E

UN

R S

IT

M

PE

A

ER

T

SIV

S

E

N

D

W

E

A

F

A

DO

IM

ER

D

FU

E

N

O

L

INGED WIN

H

AB

P

AR

CH

T

L

BS

O TO

SA

T

LE

E

K

T

RE

A

A

A

PL

M

E

TAN

T

N

E

IVE

V

A

ES

R

DH

C

A

E

SIVA PA

ROJ

E

H

P

A

E

AD

A

R

L

ET

TIL

AN

FEN

PL

OUR

P

IF

ES

H

D

A

IT

GABAR

.8

3

Ø

3.8

Ø

L

GE

A

CAL

I

CA

I

T

T

NT

R

NTING

R

E

U

MO

VE

VE

AL

E

MO

E

JE

T

IC

3.8

Ø

CH

TAG

CAL

ERT

I

T

V

ON

MONTA

R

A

M

VE

R

R

GGIO

SENKRE

U

PA

OR

.8

NTA

F

VA

3

I

F PO

O

I

Ø

FUER

M

S

ES

E

LATE

NE

H

P

ER

DH

M

LO

P

AD

E

B

A

T

T

IV

LLA A

E

RI

CHA

V

TI

I

S

BA

.8

DES

A

ES

A

EB

LAN

G

H

P

KL

MA

I

AD

D

E

F

AF

T

NE S

IO

SIZ

O

P

IT

S

O

S P

KET

BRAC

IENTO D

M

A

ION

POSIT

ER

N D

SITIO

O

P

DES ET

N

IO

IT

POS

.8

3

Ø

Ø3.8

Ø3

AS

T

ASIS

V

ING

T

A

N

GIO

OU

G

A

DOW M

MONT

A

R

T

E

WIN

D

AL

P

GE

HIN

UELLE

E F

OM

D

A

N

TA

O BOTT

T

N

VEN

IO

A

R

A

R

TE

NS

E

ESTAFA P

PF

E LA

R KIP

FÜ

N

E

L

FLET

SO

F

N

U

O

O

A S

RE

ONTAGEK

ET

N

M

R FE

U

O

S P

R

RIE

RE

E

G

R

SPO

ING

GIO A

T

G

A

T

OUN

N

W M

R MO

O

D

R

FE PE

AF

SALTA

E

INGED WIN

E ST

N

A R

P H

O

NA

TA

O T

N

POSIZIO

E

N T

IO

A V

R

IT

A

R

P

OS

TE

S

FA

S P

TA

EN

KET

PF

ES

P

AC

BR

E LA

KLA

R

TO D

N

IEN

EN FÜ

L

CTIO

AM

SO

E

N

N

IO

OJ

O

R

P

POSIT

E A

R

ONTAGEK

NET

M

FE

ER

R

D

U

N

O

IO

P

IT

RS

IE

POS

R

ET

DES

N

IO

POSIT

.8

3

Ø

N

TIO

O

T

MEN

A

R

AL SER

CO

AC

OEC

TT

LB

E

I A

D

EG

E

U

FL

ASS

IK

T

AS

PL

R

E

D

E

S

H

IS

C

A

AX

'S

G

SIN

A

C

A

W

O

TAN

IND

EN

W

LA V

A

AJE

ET

FIS

E

EN

EJE D

A LA F

E

AG

ATTEL

DE

E

AX

ALE

IC

T

R

VE

GIO

G

A

ING

R MONT

E

E P

OUNT

F

AL

F

A

T

TIC

ICAL M

T

ER

ER

E V

V

R

SIZIONE S

TAJ

O

N

F

PO

O

M

ION

ARA

SIT

P

O

A

AF

ST

TAGE

ACKETS P

R

LA E

B

E MON

T

H

NTO DE

IE

KREC

NAM

N

ICAL

T

R SE

SITIO

O

P

E VER

FÜ

N

AG

T

N

POSITIO

R MO

U

EN

L

SO

S PO

N

IER

KO

R

T

N DES E

SITIO

O

P

Ø

N

E

H

KC

E

R

3.8

Ø

3

Ø

P

O

T

N

E

M

RA

NA SER

R

E

T

'S MO

W

IN

A

INE

L

WINDO

F

E O

L LIN

HEN

A

N

IC

L

ER

EG

INT

BEW

S

E

D

IE

IN

NT

E

ENL

V

N

A

IN

E L

D

R

ERIO

NE

INT

A

FE

INE

L

.8

3

RE DE

Ø

ERIEU

T

N

E I

LIGN

.8

RI

Z

ME

RI

RT

A

PA

D

FE

IORE D

R

FE

R

F

IN

S

E

IN

STER

GREN

EN

F

A

N

RTE MO

A

FE

ANA PARTE M

TRE M

E

E

T

E

I

NF

M

DOW

EE

IX

I

ER

E I

MIT

L

I

T

I

L

A

IJ

F

WIN

RTE

A

P

UNT

LIM

AS

T

IS

AS

V

A

TO

EN

M

RA

R

E

S

ER

ER

T

NS

E

SIVA P

E

PF

IP

AD

IND

K

R

IMA

D W

E

D

G

E FUE

IN

N

H

M

O

T

ABLO

T

O

B

UELLE AL

BSCH

E

TO

E

KL

AT

PL

TANA DE F

M

EN

L

V

F

A

IVE TE

S

AR

E

DH

A SOUF

A

IVA P

E

ES

TR

H

E

D

N

A

E

LA

R F

U

TIL

AN

PL

SIF PO

ADHE

IT

E

R

IL

B

BA

A

G

RT

A

P

G

IN

V

TERS

NS

OBIL

E

IL

B

O

Ø

8

Ø3.

.8

.8

3

Ø

3

.8

3

Ø

W

O

A

T

T

E

Ø

B

C

A

2

PATENTED

BEFORE INSTALLING AND USING THE ACTUATOR, IT IS

COMPULSORY FOR THE INSTALLER AND THE USER TO READ

AND UNDERSTAND THIS MANUAL IN ALL ITS PARTS.

THIS MANUAL IS INTEGRAL PART OF THE ACTUATOR

AND MUST BE PRESERVED FOR FUTURE REFERENCE

UNTIL DEMOLITION OF THE SAME.

INSTALLATION AND USE INSTRUCTIONS

CHAIN ACTUATOR FOR

C20

WINDOW AUTOMATION

COD. 0P5152

VER.0.0 REV.09.13

VER.0.0

REV.09.13

D E

INSTALLATION AND USE ISTRUCTIONS

13

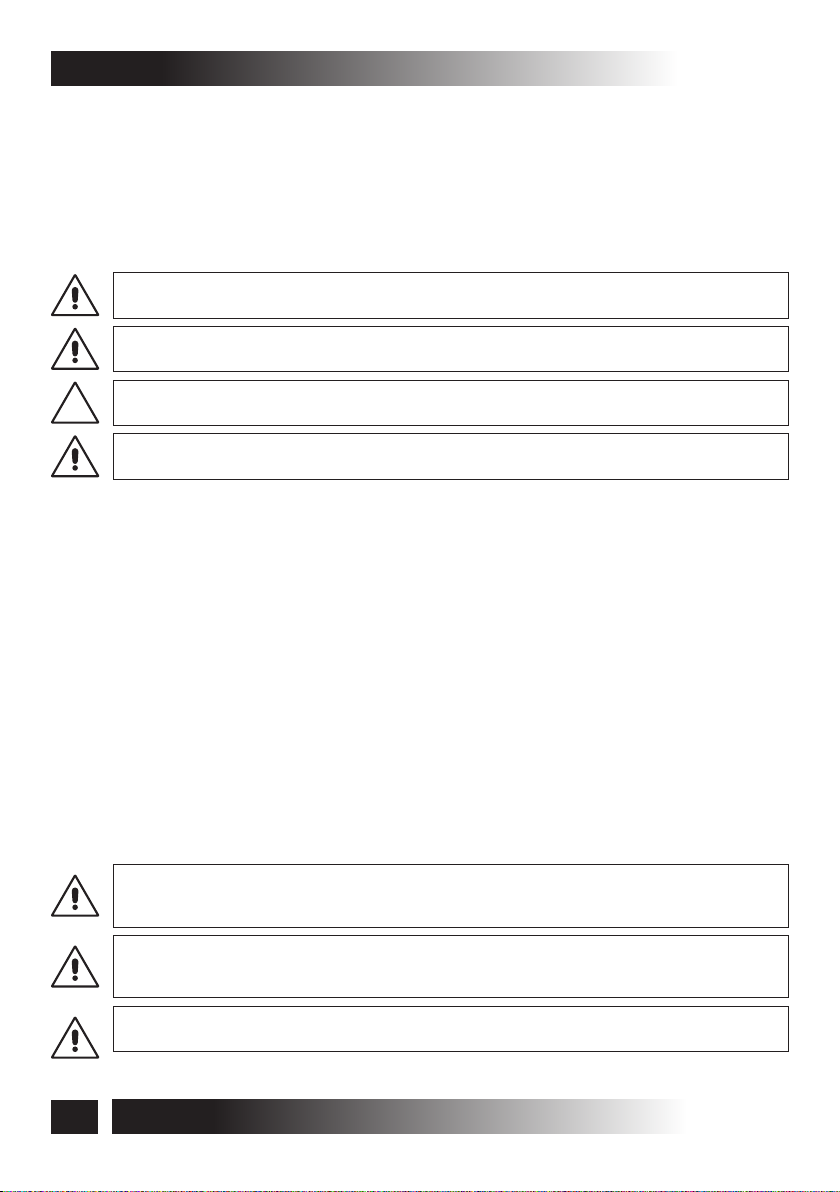

4- SAFETY

GENERAL INSTRUCTIONS

4.1-

OPERATORS MUST BE INFORMED OF ACCIDENT RISKS, SAFETY DEVICES AND THE

GENERAL ACCIDENT PREVENTION REGULATIONS ESTABLISHED BY INTERNATIONAL

DIRECTIVES AND BY THE LAW IN FORCE IN THE COUNTRY OF USE.

ALL OPERATORS MUST STRICTLY COMPLY WITH THE ACCIDENT PREVENTION

REGULATIONS IN FORCE IN THE COUNTRY OF USE.

DO NOT REMOVE OR ALTER THE PLATES PLACED ON THE ACTUATOR BY THE

MANUFACTURER.

IF THE WINDOW FRAME IS ACCESSIBLE FROM OR INSTALLED AT A HEIGHT OF LESS

THAN 2.5 m FROM THE GROUND, AND IF IT CAN BE COMMANDED BY AN UNTRAINED

USER OR WITH A REMOTE CONTROL DEVICE, FIT AN EMERGENCY STOP SYSTEM

WHICH AUTOMATICALLY CUTS IN TO PREVENT THE RISK OF CRUSHING OR

DRAGGING PARTS OF THE BODY INSERTED BETWEEN THE MOVING AND FIXED PARTS

OF THE WINDOW FRAME.

ANY TAMPERING WITH OR UNAUTHORISED REPLACEMENT OF ONE OR MORE PARTS

OR COMPONENTS OF THE ACTUATOR, OR THE USE OF UNORIGINAL ACCESSORIES

AND CONSUMABLES, MAY INCREASE THE RISK OF ACCIDENT AND THUS RELIEVES

THE MANUFACTURER OF ALL CIVIL AND PENAL LIABILITY.

EXTRAORDINARY AND ROUTINE MAINTENANCE OPERATIONS INVOLVING THE TOTAL

OR PARTIAL DISMOUNTING OF THE ACTUATOR MAY ONLY BE PERFORMED AFTER

DISCONNECTING IT FROM THE POWER SUPPLY.

C20

THIS APPLIANCE MAY NOT BE USED BY PERSONS (CHILDREN INCLUDED) WITH

REDUCED PHYSICAL, SENSORIAL OR MENTAL CAPACITIES, OR INEXPERT PEOPLE,

UNLESS THEY ARE SUPERVISED AND TAUGHT HOW TO USE IT BY A PERSON

RESPONSIBLE FOR THEIR SAFETY. CHILDREN MUST BE CONTROLLED TO MAKE

SURE THEY DO NOT PLAY WITH THE APPLIANCE.

SAFETY DEVICES

4.2-

4.2.1- PROTECTION AGAINST ELECTRIC HAZARD

The actuator is protected against electric hazard due to direct and indirect contacts.

The protection measures against direct contacts aim at protecting people against

hazards due to contact with active parts, usually live parts; while the protection

measures against indirect contacts aim at protecting people against hazards due to

conducing part, which are usually insulated, but could become live in case of failure

(insulation failure).

The adopted protection measures are the following:

1) Insulation of live parts by means of a plastic material body;

2) Enclosure with suitable protection degree;

14

INSTALLATION AND USE ISTRUCTIONS

VER.0.0

REV.09.13

C20

SAFETY -4

3) Only for Mod. C20/230 V equipped with double insulation: Protection of passive

type given by the use of components with double insulation, also called components of

class II or with equivalent insulation. (It is forbidden to connect the actuators equipped

with double insulation to the earth plant.

SAFETY PLATES

4.3-

IT IS FORBIDDEN TO REMOVE, MOVE, SPOIL OR IN ANYWAY REDUCE THE VISIBILITY

OF THE SAFETY PLATES. FAILURE TO OBSERVE THE ABOVE MAY CAUSE SERIOUS

HARM TO PEOPLE AND DAMAGE TO PROPERTY. THE MANUFACTURER DECLINES ALL

LIABILITY FOR ANY DAMAGE CAUSED BY THE FAILURE TO OBSERVE THE ABOVE

REQUIREMENT.

Fig. 6 illustrates the safety plate: this must applied directly to the outside of the actuator

or near it and always in a position where it can be seen by the installer and/or operator.

4.4- RESIDUAL RISKS

The installer and the user are herewith informed that after the actuator has been

installed on the window, the actuator drive can accidentally generate the following

residual risk:

Residual risk: Hazard of squashing or dragging of body parts inserted between the

movable and the fix part of the window frame.

Exposure frequency: Accidental and when the installer or the user decides to perform

a wrong voluntary action.

Severity of the damage: Light lesions (usually reversible).

Adopted measures: Before enabling the device, it is compulsory to verify that near the

window there are not persons, animals or things whose safety may be accidentally

jeopardized. During actuator operation, it is compulsory to be in a safe control position

assuring visual control on the window movement (see par.6.1).

VER.0.0

REV.09.13

Fig. 6

MACCHINA AD AVVIAMENTO AUTOMATICO

AUTOMATIC MACHINE

PRIMA DI INSTALLARE E UTILIZZARE L'ATTUATORE È OBBLIGATORIO CHE L'INSTALLATORE E L'UTILIZZATORE

LEGGANO E COMPRENDANO IN TUTTE LE SUE PARTI IL MANUALE

THE INSTALLER AND USER MUST READ AND UNDERSTAND ALL PARTS OF THIS MANUAL BEFORE INSTALLING

AND USING THE ACTUATOR.

PERICOLO ATTENZIONE ALLE MANI

BEWARE OF YOUR HANDS

ATTENZIONE MACCHINA AD AVVIAMENTO AUTOMATICO CON COMANDO A DISTANZA

ATTENTION! AUTOMATIC MACHINE WITH REMOTE CONTROL DEVICE

INSTALLATION AND USE ISTRUCTIONS

IT

EN

15

5- INSTALLATION

5.1- GENERAL INSTRUCTIONS

THE ACTUATOR INSTALLATION CAN BE PERFORMED EXCLUSIVELY BY COMPETENT

AND QUALIFIED TECHNICAL PERSONNEL SATISFYING THE PROFESSIONAL AND

TECHNICAL REQUIREMENTS FORESEEN BY THE LAWS IN FORCE IN THE COUNTRY OF

INSTALLATION.

THE ACTUATOR PERFORMANCE MUST BE SUFFICIENT TO ASSURE THE CORRECT

MOVEMENT OF THE WINDOW. IT IS COMPULSORY TO VERIFY THE THRUST OR

TRACTIVE FORCE ACCORDING TO THE TYPE AND WEIGHT OF THE WINDOW (PAR. 3.4).

IT IS FORBIDDEN TO EXCEED THE LIMITS SET IN TAB. 1 CONCERNING TECHNICAL

DATA (PAR. 3.3).

THE ACTUATOR INSTALLATION MUST BE PERFORMED EXCLUSIVELY WITH CLOSED

WINDOW OR SKYLIGHT.

BEFORE PERFORMING THE INSTALLATION OF THE ACTUATOR ON BOTTOM HUNG

WINDOWS, VERIFY THAT ON BOTH SIDES OF THE WINDOW TWO COMPASS STROKE

LIMIT DEVICES ARE INSTALLED IN ORDER TO AVOID THE ACCIDENTAL FALL OF THE

WINDOW.

FOR CORRECT OPERATION OF THE ACTUATOR, THE WINDOW FRAME MUST HAVE A

MINIMUM HEIGHT VALUE INCLUDED IN THE RANGE STATED IN TABLE FIG. 7a FOR TOP

HUNG ASSEMBLY, IN TABLE FIG. 7b FOR BOTTOM HUNG ASSEMBLY, AND IN TABLE FIG.

7c FOR THE DOME ASSEMBLY.

THE STROKE SELECTION HAS TO BE CARRIED OUT WITH SWITCHED OFF ACTUATOR

ONLY BY COMPETENT AND QUALIFIED TECHNICAL PERSONNEL.

C20

VERIFY THAT THE POSITIONS OF THE LABELS LOCATED ON THE QUICK COUPLING

CORRESPOND TO THE LABELS ON THE ACTUATOR: RED LABEL WITH LETTER “A”

FOR THE TOP HUNG ASSEMBLY, GREEN LABEL WITH LETTER “B” FOR VERTICAL

ASSEMBLY.

VERIFY THAT DISTANCE “D” BETWEEN THE ACTUATOR SHELL AND THE CHAIN END

(FIG. 7a/7b/7c) IS GREATER THAN 5 mm.

IF THE WING AND THE FRAME ARE COPLANAR PROCEED WITH THE ASSEMBLY

ACCORDING TO FIG. 7.

THE FITTING SURFACE FOR THE ARS RAPID COUPLING DEVICE MUST BE PERFECTLY

FLAT AND/OR SMOOTH.

16

INSTALLATION AND USE INSTRUCTIONS

VER.0.0

REV.09.13

C20

INSTALLATION -5

Fig. 7a

18.3

Dimensions in mm

50

WING

10

FRAME

POS.

B

B

A

Pos.A1Pos.B2Pos.

-10-10

TOP HUNG OPENING

ROTATION

AXIS

1

2

1

Pos.

B1

B1

72.5

38.5

-5

A B

D>5

POS. FROM THE

WINDOW FRAME

COPLANAR

-10 mm

-5 mm

3

Flat and/or

smooth surface

1

2

STROKE (mm)

VER.0.0

REV.09.13

240

360

MIN. WINDOW

GAP (mm)

250

360

OPENING

ANGLE

55°

60°

THE RELEASE SIDE INDICATOR (REF. 3) IN THIS ASSEMBLY TYPE HAS TO BE ON THE

RIGHT.

USE ONLY A SCREW IN POSITION “A” OR “B”.

IF THE WINDOW FRAME IS COPLANAR, REMOVE THE ACTUATOR FROM THE WINDOW

FRAME USING THE APPLICATIONS OF THE ABOVE GIVEN TABLE.

INSTALLATION AND USE ISTRUCTIONS

17

5- INSTALLATION

C20

Fig. 7b

Dimensions in mm

FRAME

26.6 31 ±1

WING

BOTTOM HUNG OPENING

50

D>552.5

B

25

1

15.4

5.4

A

15

STROKE (mm)

240

360 31.6

USE ONLY A SCREW IN POSITION “A”.

18

INSTALLATION AND USE INSTRUCTIONS

MIN. WINDOW

GAP (mm)

500

900

80

OPENING

ANGLE

26°

22°

"B" MOTOR OVERALL

DIMENSIONS (mm)

33.6

VER.0.0

REV.09.13

C20

INSTALLATION -5

Fig. 7c

Dimensions in mm

50

1

DOME OPENING

11.7

WING

FRAME

MIN. 33

60

72

D>5

30

A

10.5

VER.0.0

REV.09.13

B

35.5

STROKE (mm)

240

360 43

THE RELEASE SIDE INDICATOR (REF. 1) IN THIS ASSEMBLY TYPE HAS TO BE ON

THE LEFT.

USE ONLY A SCREW IN POSITION “A”.

MIN. WINDOW

GAP (mm)

300

400

OPENING

ANGLE

48°

55°

50

"B" MOTOR OVERALL

DIMENSIONS (mm)

40

INSTALLATION AND USE ISTRUCTIONS

19

5- INSTALLATION

C20

5.2- TOP HUNG WINDOWS

Fig. 8

(Fig. 8 and Fig. 19 ÷ 27)

1) Open the package (par. 3.7) and extract the various

components;

2) Fig. 19- With a pencil draw the centre line “X” of the

window frame;

3) Fig. 20- Apply the adhesive template (Ref. 1) on the

window frame aligning it with the previously drawn

centre line “X”;

CAUTION: FOR NON-COPLANAR WINDOW FRAMES, IT IS NECESSARY TO CUT THE

ADHESIVE TEMPLATE CONCERNED PART AND TO APPLY IT ON THE WINDOW FRAME

PAYING ATTENTION TO KEEP IT IN THE SAME REFERENCE POSITION.

4) Fig. 21- With a suitable drill, create on the window frame holes having the related

diameter, given on the adhesive template;

5) Fig. 22÷24- With the suitable screws tighten the brackets for window frame

connection (right - left) and the quick coupling;

6) Fig. 25/26- After having connected the electric connector in the actuator, perform the

electric connections according to the provisions of par. 5.5, as well as with reference

to the wiring diagram. Let the chain come out for at least 5 cm of stroke, then

disconnect the connector;

7) Fig. 26- Connect the chain end to the quick coupling;

8) Fig. 27- Fasten the actuator to the brackets for connection to the window frame using

the suitable screws;

VERIFY IN Fig. 7a THE CORRECT FASTENING POSITIONING OF THE ACTUATOR.

MAKE SURE THAT THE RED LABEL LOCATED ON THE QUICK COUPLING

CORRESPONDS TO THE SAME LABEL ON THE ACTUATOR.

VERIFY THAT AFTER THE TIGHTENING THE CONNECTION BRACKETS TO THE WINDOW

FRAME ADHERE TO THE ACTUATOR IN ORDER TO ASSURE A CORRECT APPLICATION.

9) Fig. 27- Select the wished stroke (I= 240 mm - II= 360 mm) using the switch (Ref. 1)

located on one side of the actuator. The actuator is supplied with the stroke set on 240

mm.

TO CHANGE THE PRE-SET STROKE, USE A SCREWDRIVER (FIG. 27) WITH SUITABLE

TIP. MAKE SURE TO INSERT THE TIP UP TO THE MICROSWITCH BASE AND TO SHIFT IT

COMPLETELY. AN INCORRECT IN-BETWEEN POSITION STALLS THE ACTUATOR.

10) Fig. 25- Insert the electric connector;

20

INSTALLATION AND USE INSTRUCTIONS

VER.0.0

REV.09.13

C20

THE STROKE SELECTION HAS TO BE CARRIED OUT WITH SWITCHED OFF ACTUATOR

ONLY BY COMPETENT AND QUALIFIED TECHNICAL PERSONNEL.

FOR A CORRECT ADJUSTMENT OF THE WINDOW FRAME CLOSING SEE THE

INDICATIONS GIVEN IN PAR. 5.7.

INSTALLATION -5

5.3- BOTTOM HUNG WINDOWS

Fig. 9

(Fig. 9 and Fig. 28 ÷ 41)

1) Open the package (par. 3.7) and extract the various

components;

2) Fig. 28- With a pencil draw the centre line “Y” of the

window frame;

3) Fig. 29- Apply the adhesive template (Ref. 1) on the

window frame aligning it with the previously drawn

centre line “Y”;

CAUTION: FOR NON-COPLANAR WINDOW FRAMES, IT IS NECESSARY TO CUT THE

ADHESIVE TEMPLATE CONCERNED PART AND TO APPLY IT ON THE WINDOW FRAME

PAYING ATTENTION TO KEEP IT IN THE SAME REFERENCE POSITION.

4) Fig. 30- With a suitable drill, create on the window frame holes having the related

diameter, given on the adhesive template;

5) Fig. 31÷33- With the suitable screws tighten the brackets for window frame

connection (right - left) and the bottom hung opening bracket;

6) Fig. 34/35- After having connected the electric connector in the actuator, perform the

electric connections according to the provisions of par. 5.5, as well as with reference

to the wiring diagram. Let the chain come out for at least 5 cm of stroke, then

disconnect the connector;

7) Fig. 36- Connect the chain end to the bottom hung bracket;

8) Fig. 37- Fasten the actuator to the brackets for connection to the window frame using

the suitable screws;

VERIFY IN Fig. 7b THE CORRECT FASTENING POSITIONING OF THE ACTUATOR.

VERIFY THAT AFTER THE TIGHTENING THE CONNECTION BRACKETS TO THE WINDOW

FRAME ADHERE TO THE ACTUATOR IN ORDER TO ASSURE A CORRECT APPLICATION.

9) Fig. 37- Select the wished stroke (I= 240 mm - II= 360 mm) using the switch (Ref. 1)

located on one side of the actuator. The actuator is supplied with a stroke set on

240 mm;

VER.0.0

REV.09.13

INSTALLATION AND USE ISTRUCTIONS

21

5- INSTALLATION

TO CHANGE THE PRE-SET STROKE, USE A SCREWDRIVER (FIG. 37) WITH SUITABLE

TIP. MAKE SURE TO INSERT THE TIP UP TO THE MICROSWITCH BASE AND TO SHIFT IT

COMPLETELY. AN INCORRECT IN-BETWEEN POSITION STALLS THE ACTUATOR.

10) Fig. 34- Insert the electric connector;

THE STROKE SELECTION HAS TO BE CARRIED OUT WITH SWITCHED OFF ACTUATOR

ONLY BY COMPETENT AND QUALIFIED TECHNICAL PERSONNEL.

FOR A CORRECT ADJUSTMENT OF THE WINDOW FRAME CLOSING SEE THE

INDICATIONS GIVEN IN PAR. 5.7.

C20

5.4- DOME WINDOWS

Fig.10

(Fig. 10 and Fig. 38 ÷ 49)

1) Open the package (par. 3.7) and extract the various

components;

2) Fig. 38- With a pencil draw the centre line “Z” of the

window frame;

3) Fig. 39- Apply the adhesive template (Ref. 1) on the

window frame aligning it with the previously drawn

centre line “Z”;

CAUTION: FOR NON-COPLANAR WINDOW FRAMES, IT IS NECESSARY TO CUT THE

ADHESIVE TEMPLATE CONCERNED PART AND TO APPLY IT ON THE WINDOW FRAME

PAYING ATTENTION TO KEEP IT IN THE SAME REFERENCE POSITION.

4) Fig. 40- With a suitable drill, create on the window frame holes having the related

diameter, given on the adhesive template;

5) Fig. 41 ÷ 46- With the suitable screws, fasten the brackets for vertical assembly

(Ref. A or Ref. B), the quick coupling and eventually the hole covering plate

(Fig. 44 -Ref. 1);

6) Fig. 47/48- After having connected the electric connector in the actuator, perform the

electric connections according to the provisions of par. 5.5, as well as with reference

to the wiring diagram. Let the chain come out for at least 5 cm of stroke, then

disconnect the connector;

7) Fig. 48- Connect the chain end to the quick coupling;

8) Fig. 49- Fasten the actuator to the brackets for vertical assembly (Ref. A or Ref. B)

using the suitable screws;

VERIFY IN Fig. 7c THE CORRECT FASTENING POSITIONING OF THE ACTUATOR.

MAKE SURE THAT THE GREEN LABEL LOCATED ON THE QUICK COUPLING

CORRESPONDS TO THE SAME LABEL ON THE ACTUATOR.

VERIFY THAT AFTER THE TIGHTENING THE CONNECTION BRACKETS TO THE WINDOW

FRAME ADHERE TO THE ACTUATOR IN ORDER TO ASSURE A CORRECT APPLICATION.

22

INSTALLATION AND USE INSTRUCTIONS

VER.0.0

REV.09.13

C20

INSTALLATION -5

9) Fig. 49- Select the wished stroke (I=240 mm - II=360 mm) using the switch (Ref. 1)

located on one side of the actuator. The actuator is supplied with a stroke set on 240

mm.

TO CHANGE THE PRE-SET STROKE, USE A SCREWDRIVER (FIG. 27) WITH SUITABLE

TIP. MAKE SURE TO INSERT THE TIP UP TO THE MICROSWITCH BASE AND TO SHIFT IT

COMPLETELY. AN INCORRECT IN-BETWEEN POSITION STALLS THE ACTUATOR.

10) Fig. 47- Insert the electric connector;

THE STROKE SELECTION HAS TO BE CARRIED OUT WITH SWITCHED OFF ACTUATOR

ONLY BY COMPETENT AND QUALIFIED TECHNICAL PERSONNEL.

FOR A CORRECT ADJUSTMENT OF THE WINDOW FRAME CLOSING SEE THE

INDICATIONS GIVEN IN PAR. 5.7.

VER.0.0

REV.09.13

INSTALLATION AND USE ISTRUCTIONS

23

5- INSTALLATION

5.5- ELECTRIC CONNECTIONS (Wiring diagram)

THE CONNECTION OF MODEL C20/24V HAS TO BE CARRIED OUT WITH VERY LOW

VOLTAGE SAFETY FEEDER PROTECTED AGAINST SHORT CIRCUIT.

THE ELECTRIC CONNECTION OF THE ACTUATOR CAN BE PERFORMED ONLY BY

COMPETENT AND QUALIFIED TECHNICAL PERSONNEL FORESEEN BY THE LAW IN

FORCE IN THE COUNTRY OF INSTALLATION WHO CAN ISSUE TO THE CUSTOMER A

DECLARATION OF CONFORMITY FOR THE CONNECTION AND/OR PLANT CARRIED

OUT.

BEFORE PERFORMING THE ELECTRIC CONNECTION OF THE ACTUATOR, VERIFY THE

CORRECT INSTALLATION ON THE WINDOW.

THE MAINS TO WHICH THE ACTUATOR IS CONNECTED MUST COMPLY WITH THE

REQUIREMENTS OF THE LAWS IN FORCE IN THE COUNTRY OF INSTALLATION, AS

WELL AS SATISFY THE TECHNICAL FEATURES GIVEN IN TAB. 1 AND ON THE RATING

PLATE AND THE “CE” MARKING (PAR. 3.1), AS WELL AS BE EQUIPPED WITH A

SUITABLE “EARTHING PLANT”.

THE SECTION OF THE MAINS CABLES MUST BE PROPERLY SIZED ACCORDING TO THE

ABSORBED ELECTRIC POWER (SEE RATING PLATE AND “CE” MARKING).

ANY TYPE OF ELECTRIC MATERIAL (PLUG, CABLE, TERMINALS, ETC.) USED FOR THE

CONNECTION MUST BE SUITABLE FOR THE USE, WITH “CE” MARKING, AND

COMPLYING WITH THE REQUIREMENTS FORESEEN BY THE LAWS IN FORCE IN THE

COUNTRY OF INSTALLATION.

TO ASSURE AN EFFICIENT SEPARATION FROM THE MAINS, IT IS COMPULSORY TO

INSTALL UPSTREAM OF THE DEVICE A TEMPORARY BIPOLAR SWITCH (PUSHBUTTON) OF APPROVED TYPE. UPSTREAM OF THE COMMAND LINE, IT IS

COMPULSORY TO INSTALL AN UNIPOLAR MAIN SWITCH WITH OPENING OF CONTACTS

OF AT LEAST 3 mm.

C20

BEFORE MAKING ANY ELECTRICAL CONNECTIONS ON THE ACTUATOR, MAKE SURE

THE POWER SUPPLY CABLE IS NOT DAMAGED. IF THE CABLE IS DAMAGED, THEN IT

MUST BE REPLACED BY THE MANUFACTURER THROUGH THE TECHNICAL

ASSISTANCE SERVICE OR BY TECHNICAL OPERATORS.

5.6- COMMAND DEVICES

THE CONTROL DEVICES USED TO DRIVE THE ACTUATOR MUST ASSURE THE SAFETY

CONDITIONS FORESEEN BY THE LAWS IN FORCE IN THE COUNTRY OF USE.

According to the different type of installations, the actuators can be driven by the

following control devices:

1) MANUAL PUSH-BUTTON:

;

24

Bipolar switch button with central OFF position, with biased-off switch

INSTALLATION AND USE INSTRUCTIONS

VER.0.0

REV.09.13

C20

INSTALLATION -5

2) CONTROL AND FEEDING UNIT:

Microprocessor control units (e.g.: Mod. TF, etc.)

controlling the single actuator or

more than one actuator simultaneously by means of one or more manual pushbuttons, an infrared remote control or a 433 Mhz radio control.

To these control units, it is possible to connect rain sensors , wind sensor

(RW)

and brightness sensor.

TO ASSURE A CORRECT OPERATION OF THE ACTUATOR, THE COMMAND AND

FEEDING UNITS EVENTUALLY USED HAVE TO PROVIDE POWER SUPPLY TO THE

ACTUATOR FOR MAX. 120 sec.

BEFORE OPERATING THE ACTUATOR, THE USER MUST COMPULSORILY VERIFY THAT

NEAR AND/OR UNDER THE WINDOW THERE ARE NOT ANY PERSON, ANIMAL AND

THING WHOSE SAFETY MAY BE ACCIDENTALLY JEOPARDISED (SEE PAR. 4.4).

(RD - 12V)

5.7- CORRECT ASSEMBLY OF THE ACTUATOR ON THE WINDOW FRAME

THE CORRECT ADJUSTMENT OF THE WINDOW FRAME CLOSING ASSURES THE LIFE

AND THE TIGHTNESS OF THE SEALS, AS WELL AS THE GOOD OPERATION OF THE

ACTUATOR.

1) With open window frame, verify that the selected stroke is some centimetre lower

than the stroke limited by window frame mechanical limit devices;

VERIFY THAT THE CHAIN END IS ON THE SAME AXIS OF THE QUICK COUPLING.

OTHERWISE, LOOSEN THE TIGHTENING SCREWS AND POSITION CORRECTLY. WHEN

THE DEVICES ARE NOT COAXIAL, DAMAGES TO THE ACTUATOR AND THE WINDOW

FRAME MAY ARISE (FIG. 11).

2) Verify that the two support brackets of the actuator are aligned to each other and the

four tightening screws are well tightened. Between the two brackets and the actuator

there must not be any clearance.

Fig. 11

YES

A

B

VER.0.0

REV.09.13

NO

A

B

INSTALLATION AND USE ISTRUCTIONS

25

5- INSTALLATION

5.8- EMERGENCY PROCEDURES

Should it be necessary to close the window manually, due to power supply failure or

mechanism block, follow these instructions:

BEFORE PERFORMING ANY TYPE OF TRIPPING ON THE ACTUATOR AND ON THE

WINDOW, IT IS COMPULSORY TO DISCONNECT THE POWER SUPPLY OF THE

ACTUATOR AND TO PUT ON “0” THE EVENTUAL SWITCHES OF THE CONTROL

DEVICES.

IT IS COMPULSORY TO PADLOCK THE MAIN SWITCH OF THE DISCONNECTION DEVICE

INSTALLED ON THE MAINS IN ORDER TO AVOID ANY UNEXPECTED START. IF THE MAIN

SWITCH CANNOT BE PADLOCKED, IT IS COMPULSORY TO PLACE A SIGN FORBIDDING

THE ENABLING.

• Top hung: Fig. 12- Insert the release tool (Ref. 1) in the openings (Ref. 2) as shown in

figure, disconnect the chain end from the ARS coupling and extract the actuator;

• Bottom hung opening: Fig. 13- Insert a screwdriver between the bottom hung

opening bracket and the chain end, then lever until the chain end is released from the

above mentioned bracket.

SHOULD IT BE IMPOSSIBLE TO CARRY OUT THE ABOVE MENTIONED MANOEUVRES,

EXTRACT THE ACTUATOR FROM THE BRACKETS PROVIDING CONNECTION TO THE

FRAME BY UNSCREWING THE PROPER SCREWS.

C20

26

Fig. 13Fig. 12

1

22

RED LABEL

INSTALLATION AND USE INSTRUCTIONS

VER.0.0

REV.09.13

C20

USE AND OPERATION -6

6.1- USE OF THE ACTUATOR

THE ACTUATOR CAN BE USED EXCLUSIVELY BY AN USER ACTING IN COMPLIANCE

WITH THE INSTRUCTIONS CONTAINED IN THIS MANUAL AND/OR IN THE MANUAL OF

THE ACTUATOR CONTROL DEVICE (e.g.: WIND AND RAIN CONTROL UNIT).

BEFORE USING THE ACTUATOR, IT IS COMPULSORY FOR THE USER TO READ AND

UNDERSTAND IN ALL ITS PARTS THIS MANUAL, AS WELL AS THE EVENTUAL MANUAL

OF THE INSTALLED CONTROL DEVICE TYPE.

BEFORE OPERATING THE ACTUATOR, THE USER MUST COMPULSORILY VERIFY THAT

NEAR AND/OR UNDER THE WINDOW THERE ARE NOT ANY PERSON, ANIMAL AND

THING WHOSE SAFETY MAY BE ACCIDENTALLY JEOPARDISED (SEE PAR. 4.4).

DURING THE OPERATION OF THE ACTUATOR CONTROL DEVICE, THE USER HAS TO

COMPULSORY OCCUPY A SAFE CONTROL POSITION ASSURING VISUAL CONTROL ON

THE WINDOW MOVEMENT.

IT IS COMPULSORY TO VERIFY CONSTANTLY IN TIME THE FUNCTIONAL EFFICIENCY

AND THE RATED PERFORMANCE OF THE ACTUATOR, OF THE WINDOW FRAME WHERE

IT IS INSTALLED AND OF THE ELECTRIC PLANT, PERFORMING WHEN NECESSARY

INTERVENTIONS OF ROUTINE OR SUPPLEMENTARY MAINTENANCE ASSURING

OPERATION CONDITIONS COMPLYING WITH SAFETY REGULATIONS.

ALL ABOVE MENTIONED MAINTENANCE INTERVENTIONS CAN BE PERFORMED ONLY

BY COMPETENT AND QUALIFIED TECHNICAL PERSONNEL MEETING THE

PROFESSIONAL AND TECHNICAL REQUIREMENTS FORESEEN BY THE LAW IN FORCE

IN THE COUNTRY OF INSTALLATION.

The use of the actuator allows to control automatically the opening and closing of the

window according to the type of control device installed (see par. 5.6).

VER.0.0

REV.09.13

INSTALLATION AND USE ISTRUCTIONS

27

7- MAINTENANCE

GENERAL INSTRUCTIONS

7.1-

IF THE ACTUATOR WORKS INCORRECTLY, CONTACT THE MANUFACTURER.

ANY WORK ON THE ACTUATOR (E.G.: POWER CABLE, ETC.) OR ITS COMPONENTS MAY

ONLY BE CARRIED OUT BY PERSONNEL QUALIFIED BY THE MANUFACTURER.

TOPP DECLINES ALL LIABILITY FOR WORK PERFORMED BY UNAUTHORISED PEOPLE.

The actuator incorporates components that do not require significant routine or

extraordinary maintenance operations.

In heavy-duty conditions (e.g.: very dirty work areas, frequent use, elevated

temperature changes, load variations caused by wind or snow, etc.) make sure, at least

once every 6 months, that the actuator assembly components are clean, the fixing

systems (brackets and screws) are tight, the window frame is not deformed and the

seals are tight, and check the cables and connectors.

If any malfunctions arise after cleaning or inspection, contact the TOPP technical

assistance service.

C20

8- DEMOLITION

8.1- GENERAL INSTRUCTIONS

THE DEMOLITION OF THE ACTUATOR MUST OCCUR IN COMPLIANCE WITH THE LAWS

IN FORCE ON ENVIRONMENT PROTECTION.

DIFFERENTIATE THE PARTS MAKING UP THE ACTUATOR ACCORDING TO THEIR

DIFFERENT MATERIAL TYPE (PLASTIC, ALUMINIUM, ETC.).

28

INSTALLATION AND USE ISTRUCTIONS

C20

VER.0.0

REV.09.13

C20

SPARE PARTS AND ACCESSORIES UPON REQUEST -9

9.1- GENERAL INSTRUCTIONS

THE USE OF “NON-ORIGINAL” SPARE PARTS AND ACCESSORIES WHICH MAY

ENDANGER THE SAFETY AND THE EFFICIENCY OF THE ACTUATOR IS FORBIDDEN.

THIS ACTION SHALL INVOLVE THE WARRANTY EXPIRATION.

ORIGINAL SPARE PARTS AND ACCESSORIES HAVE TO BE REQUESTED EXCLUSIVELY

TO YOUR DEALER OR TO THE MANUFACTURER STATING TYPE, MODEL, SERIAL

NUMBER, AND YEAR OF CONSTRUCTION OF THE ACTUATOR.

IN CASE OF REPLACEMENT OF THE POWER SUPPLY CABLE, IT IS NECESSARY TO USE

A CABLE TYPE HOS-VVF 3 x 0.75.

THE REPLACEMENT CAN BE PERFORMED EXCLUSIVELY BY COMPETENT AND

QUALIFIED TECHNICAL PERSONNEL MEETING THE PROFESSIONAL AND TECHNICAL

REQUIREMENTS FORESEEN BY THE LAWS IN FORCE IN THE COUNTRY OF

INSTALLATION.

BRACKETS FOR VERTICAL ASSEMBLY9.2 -

Fig. 15Fig. 14

VER.0.0

REV.09.13

INSTALLATION AND USE ISTRUCTIONS

29

9- SPARE PARTS AND ACCESSORIES UPON REQUEST C20

9.3 - QUICK COUPLING WITH INTEGRATED RELEASE PUSH-BUTTON

”ARP”

This connection allows the application in case of top hung and dome assemblies.

Unlike the quick coupling to the frame (ARS) inserted in the standard supply, the ARP is

equipped with a push-button (Fig. 16 - Ref. 1) for the quick release in case of

emergency manoeuvres.

CODES TO ORDER THE ARP

CODE COLOUR TYPE OF APPLICATION

1UA010

1UA011

1UA012

Black

White

Grey

DOME/SKYLIGHT

(Vertical assembly application)

9.3.1- DOME WINDOWS

(Fig. 16 ÷ 18, Fig. 10)

Follow the procedure described in par. 5.4 up to Fig. 42, and then correctly position

the ARP coupling on the frame as shown in Fig. 17.

Fig. 16

Fig. 17

1

Use 4,2 x 19 mm screws

30

INSTALLATION AND USE ISTRUCTIONS

VER.0.0

REV.09.13

C20

SPARE PARTS AND ACCESSORIES UPON REQUEST -9

9.3.2- EMERGENCY MANOEUVRES (Fig. 18)

Should it be necessary to close the window manually, due to power supply failure or

mechanism block, follow these instructions:

BEFORE PERFORMING ANY TYPE OF INTERVENTION ON THE ACTUATOR AND ON THE

WINDOW, IT IS COMPULSORY TO DISCONNECT THE POWER SUPPLY OF THE

ACTUATOR AND TO SET ON “0" THE EVENTUAL SWITCHES OF THE CONTROL

DEVICES.

IT IS COMPULSORY TO PADLOCK THE MAIN SWITCH OF THE DISCONNECTION DEVICE

INSTALLED ON THE MAINS IN ORDER TO AVOID ANY UNEXPECTED START. IF THE MAIN

SWITCH CANNOT BE PADLOCKED, IT IS COMPULSORY TO PLACE A SIGN FORBIDDING

THE ENABLING.

• Fig. 18- Press the push-button (Ref. 1) to release the chain end, and therefore to allow

the release of the actuator.

SHOULD IT BE IMPOSSIBLE TO REACH THE PUSH-BUTTON AND PERFORM THE ABOVE

MENTIONED PROCEDURE, EXTRACT THE ACTUATOR FROM THE BRACKETS

PROVIDING CONNECTION TO THE ACTUATOR UNSCREWING THE PROPER SCREWS.

Fig. 18

VER.0.0

REV.09.13

1

INSTALLATION AND USE ISTRUCTIONS

31

Fig. 19 Fig. 20

C20INSTALLATION ON TOP HUNG WINDOWS

1

X

Fig. 21

G

TIN

L

AGE

N

ALE

U

ICA

ONT

O

AL

TIC

R

M

IC

ERT

L

E M

A

VE

ERT

IC

JE V

CHT

A

ERT

AGGIO

AGE V

T

.8

ENKRE

MONT

N

OR V

ONT

A

S

Ø3

O

M

M

Ø3.

AR

ER

8

TE F

R

A

ER

U

A P

DIMA A

FU

PL

IV

E

A P

DES

S

M

PO

IVA

IV

KLEBSC

E

PE

E

ON

IF

R S

H

L

T

ERRAMENTO A SP

HABLONE FUER FENST

ES

ES

.8

ADH

AB

AD

Ø3.

ESI

H

A

8

VE TEMPLATE TO TOP H

Ø3

DH

SIVE

A AD

OR

E

PLA

GE

SC

ILL

NTI

ER MIT

RE

H

IT A

B

LLA AD

DIM

D

UN

HESIVA

A

TEN

LE

GABARIT

ANT

ING

OEFFN

K

L

PARA VE

ED

ADH

WIN

P

ABAR

UN

G

ESI

DO

G

NT

W

F P

ANA

OU

A

.8

R FENETRE A PRO

RESAL

3

TAR

Ø

Ø3.

8

JEC

TION

POSIZIONE S

TAFFE PER

BRAC

KE

Ø3.8

TS POSIT

MONT

PO

AG

SIT

ION TO BO

GIO A

IONAMIEN

V

ASIST

TT

POSIT

TO

OM HING

AS

DE

ION DE

LA ES

ED W

PO

R M

TA

SIT

INDOW

FA PARA

ON

ION DE

TA

GE

MO

V

KO

S E

UNTIN

ENTANA DE FU

NS

TRIERS P

OL

G

EN

FÜR K

OUR FENET

ELLE AL

IPPFENS

RE

TA

TE

A

SO

R

UFFL

ET

POSIZIONE S

Ø3.8

TAFFE PER MONTAG

BR

ACKETS

PO

ASSE D

PO

SIT

SIT

ION TO TO

GIO

I A

ION

TT

A SP

AM

ACCO AL S

ACH

IEN

P HING

ORGE

PO

SE DER

TO DE

SITION DE

RE

ED

ERR

LA ES

W

PLASTIKFLUEGE

WIN

IND

AMENT

POSITION

R M

TAFA

OW MOUNTING

DOW C

ONTA

P

O

AR

DES ETRIER

GE

ASING

A V

KO

EJE DE

ENTA

NS

LBO

'S A

OL

ECK

NA

FIS

XIS

EN

S P

A RE

FÜR K

CH

AJE

OUR F

AXE

EN

SA

A LA VEN

LAPP

LT

EN

AR

ET

FENS

RE A

TER

PR

OJ

ECTIO

N

Fig. 23 Fig. 24

RED LABEL

LINEA INT

DE

ATTELAG

TA

ERN

NA

INT

A SERR

E A

ERN

LA FENET

PO

AL

SIZIONE STAFFE PER

AMENT

LIN

INNENL

E OF WIND

RE

O PAR

BR

Ø3.

INIE

AC

TE FISSA

8

KE

OW

DE

TS PO

LIGNE

MO

'S F

S F

NT

EST

PO

KO

PO

IXED PAR

SITION

INT

AGGIO

SIT

GE

ERI

ION

FO

SETZEN

VE

EUR

LIN

AM

IEN

TO

NS

OL

ENPO

SITION FÜ

SIT

ION DES ETRIERS P

T

R V

RTICALE

EA INT

E D

ER

FE

TIC

E F

DE LA

NSTERS

ERIOR

AL MO

ENE

TRE FIX

ES

UN

DE

TA

TIN

FA

G

PAR

R S

A MON

EN

KREC

TAJE

VE

HT

OUR MONTAGE VE

E MONTAGE

RT

ICA

L

RTICA

L

TO

LA VE

EE

NTANA

EN

PARTE FIJ

M

RS

A

E

A

R

IMIT

R

L

A

ST

Ø3.

R

N

8

SE

TAN

FE

EL

ÂTI

D

ES

U B

VEN

D

RE

A

INFERIO

L

'S

ZE

E

N

RE D

ERIO

E

M

A

R

R DE

Ø3.

R

8

RIEU

INF

F

E

E G

Ø3.8

RIO

F

R

W

ITE

Ø3.

LINEA INTERNA S

N

O

8

I

TE

NFE

LIM

N

INTERN

IND

E I

ITE

U

ERRAM

W

IT

AL

LIN

ENTO P

LIM

INNENL

E O

IM

F WIND

L

AR

INIE

TE

Ø3.

OW'S MOVING PA

MO

DES B

8

LIN

BILE

EA

EWEG

INT

ERI

LICHEN FENST

OR DE LA VENT

LIGNE

RT

INT

ERI

ERS

EUR

ANA

E DE F

PA

RTE

ENE

MO

TRE

BIL

MO

BIL

E

DIM

Ø3.8

A A

DES

IVA

KLE

PER S

BSC

3.8

ERRAM

HAB

Ø

LONE F

ADHESIVE

ENTO A VASIS

UER

KIP

TEM

PLA

PFENST

PLA

TAS

NTI

Ø3.

TE TO

LLA AD

8

ER

GA

BO

BAR

HESIVA PARA

TTOM H

IT

ADHESIF P

INGED WINDO

VENTANA

OUR FENE

3.8

DE FU

W

Ø

TRE A

ELLE A

SO

LTA

UFF

LET

3.8

Ø

Fig. 22

E

ING

E

L

TAG

AL

N

L

ICA

RTIC

MO

MOUNT

L

ERT

TICA

TE

VE

H

ER

ICA

IO V

T

AJE

EC

G

R

E V

T

R

E

G

N

G

K

A

V

A

O

T

N

.8

R

E

N

3

Ø

ONT

FO

RA M

R S

E

Ø3.

R MO

8

T

R M

UE

PA

A

LA

F

PE

OU

E

MP

P

N

SIVA

TE

SIF

BLO

DHESIV

.8

DE

3

A

HE

Ø3.8

A

Ø

LA

CHA

ESIVE

AD

IMA

H

IT

TIL

D

EBS

R

N

AD

A

A

KL

B

PL

GA

.8

Ø3

Ø3.8

PO

SIZ

ION

E STAFF

BR

ACKE

E P

Ø3.

ER

TS

MO

8

PO

NT

PO

SITION

AG

SITIONAMIENTO DE LA

GIO A

TO

BO

V

AS

TT

PO

IST

OM HI

SITION

AS

NGED

DE

ESTA

PO

R MONTAGE

W

SIT

IND

FA

ION

PA

OW

DE

RA V

MOUN

KO

S E

EN

NS

TR

TIN

TANA DE FU

OL

IER

G

EN FÜR K

S P

OU

R FEN

EL

IPP

LE

FENS

ALTA

ET

RE

TER

A SOUF

FLET

PO

SIZ

ION

E S

TAFF

BR

AC

KETS

PO

PO

SITION

SITION

AMIENTO DE

PO

SIT

ION

DER M

POSIT

ION DES E

X

DIM

A ADESIVA PE

KLEBSCHABLON

R S

ERRAM

ADHESI

ENT

E F

O A

UER FE

VE

SP

TEM

OR

PLA

NST

PLATE

GE

NTI

ER

RE

LLA AD

MIT UN

TO

TOP H

HES

TEN

GA

INGED

IVA

BARIT

OE

PA

FFN

RA

ADHESI

WINDO

UNG

VENTANA

W

F POUR F

A RES

ENE

AL

TA

TRE A

R

PROJEC

TIO

N

Ø3.

8

E P

ER

MO

ASSE D

NT

AG

GIO A SP

I ATT

TO TO

ACCO A

ACHSE DER PL

ORGERE

P H

INGED

L SERRAM

LA

WINDOW MO

ESTAFA

WIN

ASTIKFLUE

ENTO

DOW C

ON

P

TA

ARA VEN

GE

UN

ASING

GE

KO

TING

EJE

NS

LBO

TRIERS P

DE

'S AXIS

TANA

OLEN FÜR KLAPPFE

ECKCHEN

FIS

A RE

AJE A

OU

AXE DE

SA

R F

LT

EN

AR

ETRE

NSTE

A

PROJEC

R

TIO

N

LIN

LA

EA INT

VENTA

ATTEL

ERNA SERRAMENTO P

NA

AG

INTERNAL

E A LA

PO

FE

SIZION

NET

LINE O

INN

E S

RE

ENLINIE DE

TA

F W

BR

Ø3.8

ARTE

FF

AC

IND

E P

KE

OW

FIS

ER

TS

LIG

MO

SA

'S FIXED P

S FEST

POSIT

NE INTERI

NTAG

PO

SIT

ION

GESETZEN FENST

GIO VE

IONAM

ART

FO

EUR

LIN

R V

RT

EA INT

IENTO DE

E D

ER

KO

ICALE

TIC

NSOL

E F

ERIOR DE LA

AL

ENETRE

MO

LA

EN

PO

SITION

DE

ERS

ESTA

PO

UN

SITION FÜ

TING

FA P

ARA M

R S

S E

EN

ONTA

TR

KR

IER

EC

JE VE

S POU

HT

E M

RTICA

R M

ON

ON

L

TA

GE

TA

GE VERT

ICAL

O

FIXEE

VE

NT

NT

ANA PARTE

S

IT

AME

FIJA

ER

T

ERR

Ø3.8

R LIM

NA

NS

S

I

A

RIO

NT

S FE

E

BÂT

F

E DEL

N

A VE

E DE

IOR

E DU

E L

E'S I

R

UR

D

FE

Ø3.

IE

N

RAM

8

ER

E GRENZ

E I

Ø3.8

F

ERIOR

Ø3.8

LIN

N

ER

F

EA

I

IMIT

INT

DOW F

L

ERNA S

INT

E IN

ITE

UNT

ERN

ERR

WIN

AL

AM

IM

LIN

ENTO PARTE MO

L

INNENLINIE DES BEWEG

E OF W

IMIT

L

IND

OW'S MOV

LINEA INT

BIL

E

ING

ERI

LIC

PA

OR

LIG

HEN

RT

DE LA

NE INTERIEURE D

FE

NST

VE

ERS

NTANA

PARTE

E FENETRE MO

MO

BIL

BILE

DIM

Ø3.

A A

8

DES

IVA

KLE

PER S

BSCHABLONE FUER KIPPFE

ERR

AM

ADHESIVE

ENT

O A VASISTAS

TEMPLATE TO BO

PLANTILLA

NSTER

ADHES

GABARIT

TTO

IVA

ADH

M HING

PA

RA

ESI

VENTANA DE

ED

F P

OU

WIN

R FENETRE A SO

DOW

FU

ELL

E ALT

UFF

A

LET

Use 4,8 x 16 mm screws

Ø3.

8

.8

Ø3

Ø3.

8

.8

Ø3

Ø3.8

32

Use 4,2 x 19 mm screws

INSTALLATION AND USE INSTRUCTIONS

VER.0.0

REV.09.13

C20

INSTALLATION ON TOP HUNG WINDOWS

Fig. 25 Fig. 26

Fig. 27

m

c

. 5

min

RED LABEL

VER.0.0

REV.09.13

1

INSTALLATION AND USE ISTRUCTIONS

33

INSTALLATION ON BOTTOM HUNG WINDOWS

C20

Fig. 28

Fig. 30

Fig. 29

Y

G

E

IN

L

E

T

L

TAG

N

L

OUN

RTICA

ICA

MO

M

RTICA

E

T

L

E

R

TE

A

V

IC

JE V

CH

VE

IO

T

E

E

TA

R

G

G

E

N

KR

O

N

TAG

3.8

E

NTA

N

Ø

OR V

Ø3.8

O

RA M

F

R S

A

MO

E

E

R M

R

P

U

AT

A

L

IV

E FU

A PE

N

MP

ES

IF PO

IV

E

DH

ES

ES

BLO

3.8

A

H

D

Ø

IVE T

A A

A

S

L

CH

A

S

IL

IT AD

HE

IM

B

R

D

D

NT

A

A

BA

KLE

L

A

P

G

.8

Ø3.

8

Ø3

PO

SIZ

ION

E STA

FFE P

BRAC

ER MO

KETS PO

NTAG

SITION

GIO A VASIS

POSIT

TO BO

IONAMIEN

TT

TA

OM HINGED

S

TO DE LA ESTA

PO

SIT

ION

W

DE

INDOW

R MONTA

FA PA

PO

SITION

MOUNTING

RA

GE

V

DE

ENTA

KONS

S E

NA

OLEN

TR

DE

IER

FU

FÜ

S P

ELLE AL

R KIPP

OU

R F

FE

EN

TA

NSTE

ET

RE A

R

SO

UF

FLET

Y

DIMA A

DES

IVA

PE

KLEBSC

R SERR

HABLONE FUER FE

AM

ENT

ADHESIVE TEMPLA

O A

SPOR

GERE

NST

Ø3.

ER

PLA

8

MIT UNTENOEFFN

TE

NTI

TO

LLA AD

TOP HINGED

HES

GABAR

IVA

UN

PA

WIN

G

RA

IT

DO

VENT

ADH

W

ESIF POUR FENE

ANA A

RESALTA

R

TRE

A PROJEC

TION

Ø3.

8

Ø3.8

PO

ASS

SIZION

E D

I A

E S

TT

TA

ACC

FF

BR

ACH

O A

E P

AC

ER

L S

SE

KETS PO

MONTAG

ERR

DER

AM

PL

SITION TO

ENTO

AST

GIO

POSIT

WIN

A

IKF

DO

SP

IONAMIENTO DE

TOP HINGED W

OR

GE

RE

POSIT

LA ES

ION DE

IND

OW

TA

R M

MO

FA

PO

P

ON

UN

SITION

ARA V

TA

TING

GEKO

DE

EN

TANA A

S E

NS

OL

TR

EN FÜR KLA

IER

RESA

S POUR FEN

LTAR

PP

FENS

ETRE

TER

A PR

OJEC

TIO

N

LINEA

LUE

W CASING'S A

GE

INTERN

LBOECK

EJE DE

A S

XIS

INTERN

CH

ERR

FISAJE

EN

AMENTO P

AL

A LA VEN

LIN

AXE

E O

DE ATTELAG

INN

AR

F W

TE

TA

ENLINIE

IND

NA

FISSA

OW

DE

Ø3.8

E A

'S F

S F

LA

IXED PAR

LIGNE INT

EST

FE

NETRE

GE

SETZEN FENSTERS

T

ERIEUR

POSIZ

LIN

O

E DE F

EA INTERI

ION

E S

ENE

TAFF

BR

E P

ACKE

ER MO

TS

POSIT

NT

AG

GIO

POSIT

ION FO

VE

IONAM

RT

R VERTIC

ICA

LE

IEN

TO

KO

AL

DE

MO

NSOL

LA ES

UN

EN

TIN

POSIT

TA

G

FA PAR

PO

ION

SIT

ION DE

FÜR SENKR

A MONTAJE VE

S ETR

EC

IER

HTE M

RT

S P

OU

ONTAGE

R MON

TAGE

VERTICA

L

NT

TRE FIXEE

OR DE

E

LA VE

S

NTANA

R

AM

E

PA

IMIT

RTE

FIJ

L

RR

ST

A

NA

R

N

I

TA

IO

L SE

R

E

S FE

BÂT

DE

E

VEN

A

ICAL

INF

RE

Ø3.

8

E DU

ZE D

E L

IO

R

R

D

ME'S

EN

E

A

F

IEU

IOR

R

Ø3.

GR

8

IN

E

FR

R

F

E

W

RE

F

ITE

IN

TE

Ø3.

DO

IM

IN

8

L

ITE

IN

UN

ITE

LIN

W

IM

EA

Ø3.

INT

L

IM

8

ERN

Ø3.

L

A SERRAMENTO P

8

INTERNAL LIN

E O

INN

ARTE MOBIL

F W

ENL

IND

INIE

OW

DE

'S M

E

S BEW

LIN

OV

ING PA

EA

EG

INT

LIC

ERIOR DE

RT

HEN FE

LIG

NSTERS

NE INT

LA

VE

NT

ERI

ANA

EUR

PARTE MO

.8

E DE F

Ø3.8

3

ENE

BIL

Ø

TRE

DIMA ADESIVA

MOBILE

PE

KLE

R SERR

BSCHABLONE F

AM

ENT

ADHESI

O A VA

Ø3.

UER

8

SIS

VE TEMPLA

KIP

TAS

PFENST

PLANTI

TE

ER

LLA

TO

.8

BO

ADHESIVA

GA

3

TTOM HING

BAR

Ø

IT ADH

PARA

ED WIN

ESIF P

VENT

DO

OUR F

ANA DE

W

ENETRE A

FUELLE ALT

SO

A

UFF

LET

.8

Ø3

1

Fig. 31

GE

L

A

LE

A

NTING

A

NT

L

U

IC

O

T

IC

T

R

ICA

M

MO

R

E

E

L

RT

V

T

A

E

E

H

J

IO VE

TIC

A

EC

T

R

R

GE V

N

GG

K

A

A

VE

.8

R

MO

NT

DIM

Ø3

Ø3

A

ONT

A ADES

SEN

.8

O

R

FO

R

IVA

PE

KLE

R S

TE

BSCHAB

R M

ERRAMENT

UE

UR M

E

LON

F

O

ADH

O A

E F

IVA PA

P

PLA

E

UER FE

SP

ESI

S

ORGERE

VE

M

TEM

NST

E

Ø3.

IF P

IVA

ON

PLATE TO

ER

PLANTI

8

MIT

S

S

L

TE

UN

.8

LLA

E

E

TOP H

B

TENOE

ADHES

E

ADH

ING

FFNUNG

Ø3

GA

IVA PA

ED

HA

DH

BARIT

WINDOW

RA VE

SIV

C

A AD

ADHESI

E

NTANA

F POU

H

TILLA

BS

A RES

RIT A

R FENETRE

DIM

E

N

AL

A

TAR

L

AD

B

K

A

PRO

PLA

JEC

GA

TIO

N

Ø3.8

Ø3.8

PO

Ø3.8

SIZION

E S

TAFFE P

BR

ACKETS

ER MONT

PO

AGGIO

SIT

PO

ION TO BO

SITION

A

VASISTAS

AMIEN

TT

OM

TO

HI

PO

DE LA ES

NG

SITION DE

ED

WIND

TAFA PA

R MONTAGEKO

OW MO

POSIT

RA

ION DES ETR

UNTIN

VEN

TANA

G

NSOL

DE

EN

IER

FU

FÜR K

S P

OUR FEN

IPP

FENS

ETRE

A SOUFFL

Ø3.

EL

8

LE

AL

TA

TER

POSIZ

ASSE DI ATT

ET

IONE STAFFE P

ACCO A

BRAC

ACHSE DER PLAST

ER

L SERR

KE

MO

TS

NT

POSIT

AMENT

AGGIO

POSITION

WINDOW C

ION

O

A SP

IKF

TO TO

ORGERE

AMIEN

P H

ING

TO

PO

ED

DE

SITION

WINDOW MOUNTIN

LA ESTAFA P

DE

R M

POSIT

ONTAGE

AR

ION DE

A V

G

ENTA

KONS

S E

NA A RESA

OL

TR

EN

IER

FÜ

S P

R K

OU

LT

AR

LA

R F

PP

ENET

FE

NS

RE A

TE

R

PROJ

ECTIO

N

LINEA INTERNA SERR

LUE

GE

ASI

LBO

NG

EJE DE FIS

ECKCH

'S AXIS

INT

ERN

EN

AM

AJE

AL LIN

ENTO PARTE

A

AXE DE

LA

E OF WIND

VENTANA

INNENL

AT

TEL

FISSA

INIE

OW'S F

AGE A LA FE

DE

Ø3.

S F

8

IXE

LIG

ESTGE

D P

NE

NETRE

ART

INTERI

SETZEN

EURE D

PO

LINEA INTERI

SIZIONE STA