TOPLING

USER GUIDE

Hot Water Boiler TKP Type

User Guide TKP

- 2 -

CONTENTS

Page

1. NOTES ON THIS USER GUIDE 3

1.1. Introduction notes 3

1.2. Structure of the User Guide 4

1.3. Glossary 5

2. SAFETY TIPS 6

2.1. Proper Use 6

2.2. Always present risks 7

2.3. Used warning and safety signs 8

2.4. Duty - be informed 9

3. DESCRIPTION AND PURPOSE OF BOILER 10

3.1. Introduction 10

3.2. Technical data 11

3.3. Installation of boiler TKP type 13

3.4. Declaration of conformity 22

4. BOILER MAINTENANCE 23

4.1. Frequency of cleaning and maintenance 23

5. POSSIBLE PROBLEMS IN FUNCTIONING 26

6. FIRST COMMISSIONING 27

6.1. Requirements for successful commissioning 27

7. DISPOSAL AFTER END OF LIFE 28

7.1. Dismantling of boiler 28

7.2. Disposal of boiler 28

8. WARRANTY 29

8.1. Warranty period 29

8.2. Warranty Terms & Conditions 29

8.3. The Warranty does not apply to 29

User Guide TKP

- 3 -

1. NOTES ON THIS USER GUIDE

1.1 Introductory

notes

EASY AND SAFE USE

READ USER GUIDE

TECHNICAL CHANGES

COPY RIGHT

This User Guide contains significant information for

appropriate and safe use of hot water boiler type TKP. If

you follow these Instructions, you can avoid risky

situations, reduce maintenance costs, avoid failures,

provide reliability and prolong boiler life.

This User guide must be read and applied by anyone

using the boiler type TKP.

We keep developing and enhancing our boilers. All

information regarding this Guide that are related to the

boiler type TKP are correct at the moment of printing.

Before the use, all details mentioned herein concerning

standards and legislation must be checked and

compared to standards and legislation applied in the

location where the boiler is to be installed.

We reserve the right to make changes on the boilers that

would differ in technical data and drawings herein.

Written approval of Topling d.o.o. to copy, store in

electronic form, transfer information in electronic

format, photography, translation of this manual in

whole or in part is required.

TKP User Guide

________________________________________________________________________________________

-4-

User Guide TKP

-5-

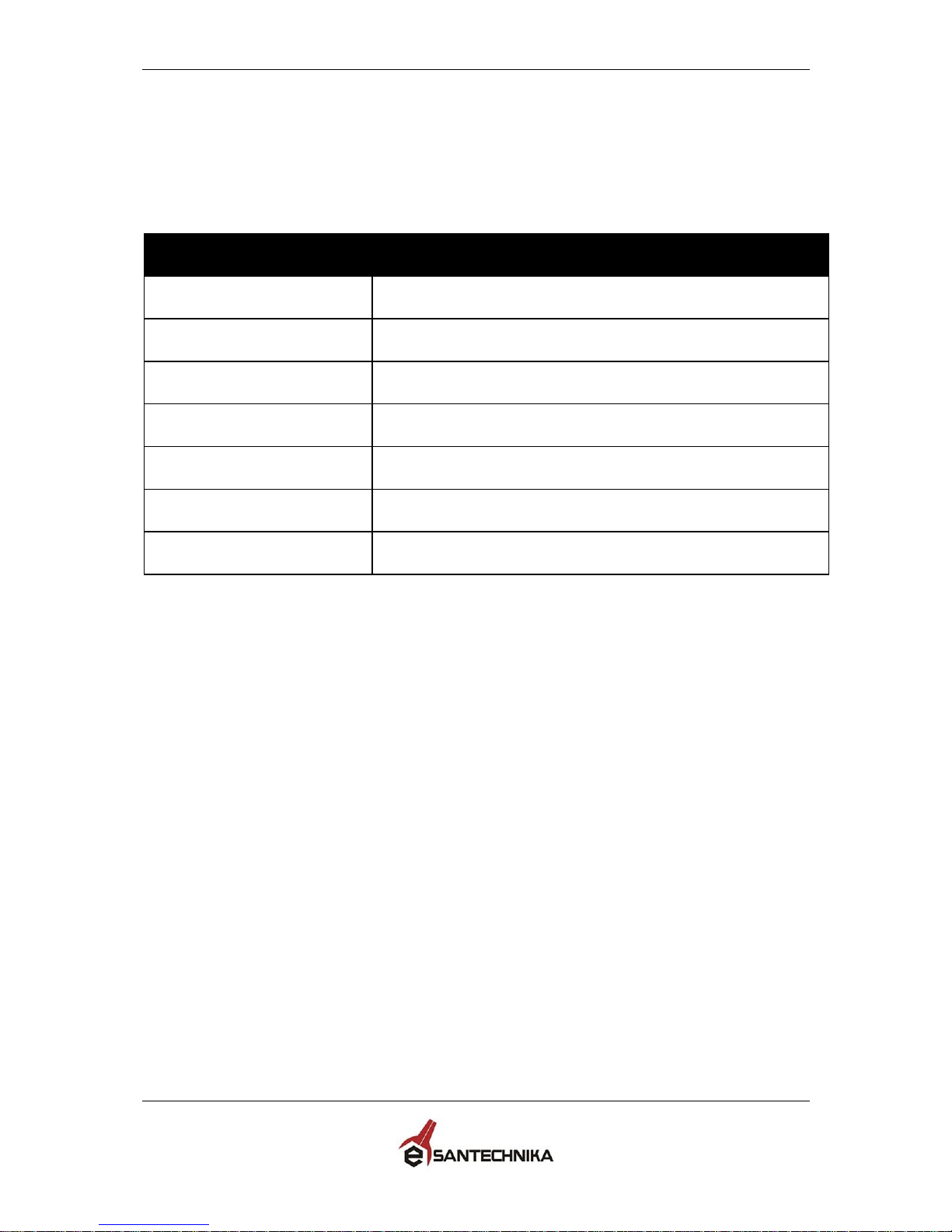

1.2 Structure of User guide

This User Guide consist of

Chapter

You can find the following herein.....

1. Notes on User Guide

... how to use the instructions.

2. Safety tips

...all related with safety use, what you should keep in mind

when using a boiler.

3. Description and purpose

of boiler

... structure and all about characteristics of boiler, technical

data, how to connect the boiler on central heating installation

4. Maintenance

... how to clean the boiler, the frequency of maintenance and

cleaning

5. Possible problems in

operating

...which problems can be experienced during boiler use

6. First boiler

commissioning

... requirements for successful commissioning

7. Disposal of boiler after

its life ends

... what should be taken into account when dismantling and

preparing of the boiler for disposal.

8. Warranty

... warranty terms and conditions

Table 1. Structure of the User guide

User Guide TKP

-6-

1.3 Glossary

Term

Explanation

TKP

The boiler intended for solid fuel combustion

Flue vent

The part of the boiler where flue gas comes out and enters the

chimney pipe

Draft regulator

Is used to regulate the amount of air which enters the boiler

through the flap on the lower door.

Flue gas pipe

Takes out flue gas from flue pipe to chimney

Boiler firebox

The place where solid fuel burns in the boiler

Solid fuel

Firewood, charcoal, wood briquettes

Safety valve

It is used for pressure relief in boiler water space when it is

exceeded

Table 2. Explanation of terms

User Guide TKP

-7-

2 SAFETY NOTES

2.1Proper use

MAIN PRINCIPLES

MAIN PRINCIPLES OF SYSTEM CONSTRUCTION

The boiler is made in accordance with the known principles of

safe use. Improper use may cause harm, injury or even death

to those who do not comply with safety guidelines as well as to

third parties, which may result in damage to the boiler, and

damage to other resources in the immediate environment.

Specialized person who made the boiler installation and

commissioning should demonstrate you how to use it.

Use boiler only when it is completely in order. Use it the right

way and for the purpose for which it is intended, always taking

care of your own safety and the safety of others and the safety

of property. Constantly comply with this manual.

Any defect which may impair safety must be immediately

removed.

USE OF BOILER

RELIABLE AND UNRELIABLE USE

The boiler is designed to burn solid fuel (firewood, charcoal,

wood briquettes).

Use of any other fuel is not allowed. The manufacturer is not

liable for any damages resulting from improper use. In case of

improper use the responsibility is borne by the one who used

boiler improperly.

User Guide TKP

-8-

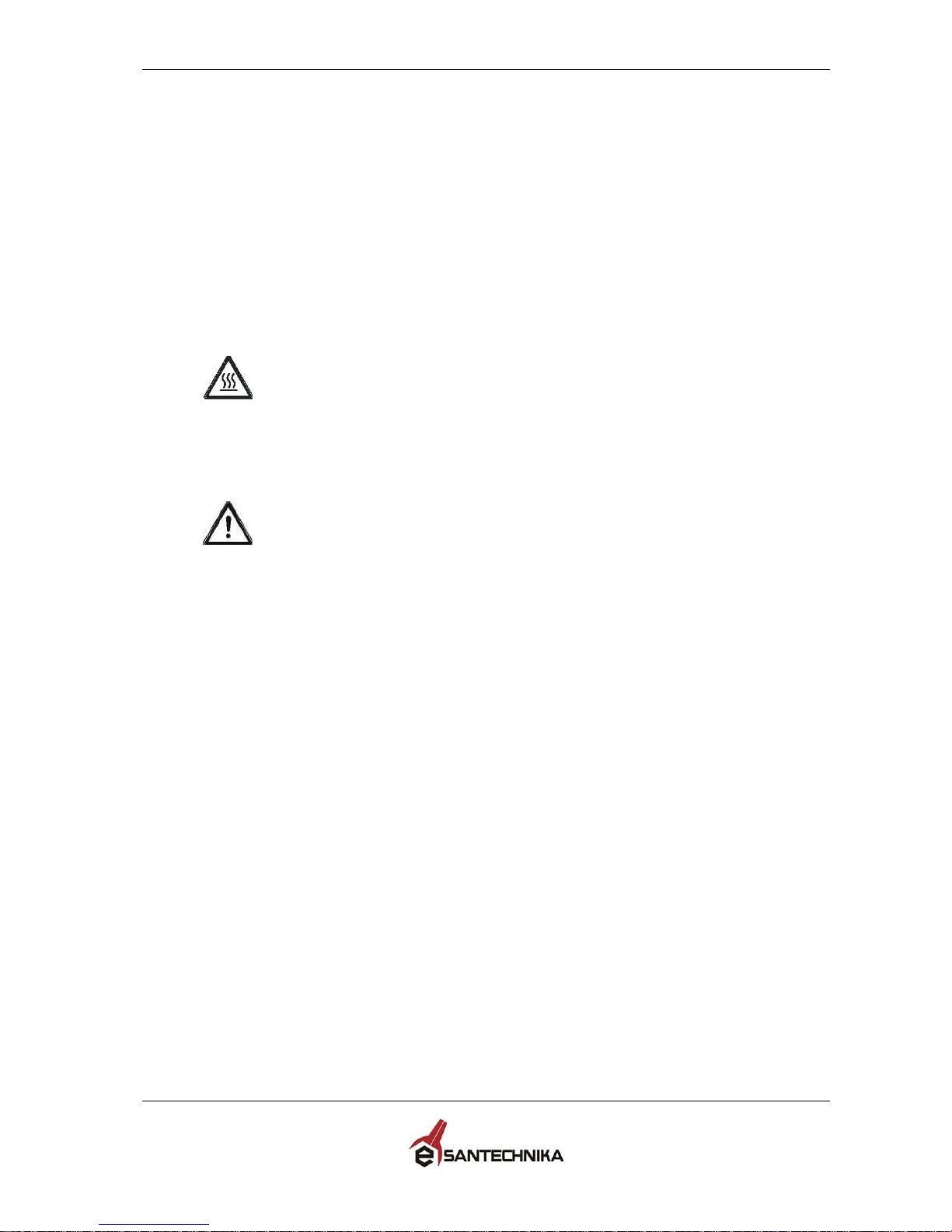

2.2 Always present risks

Despite of all precautions, the below given risks should be always considered:

Attention!

High temperature surfaces.

Contact with such surfaces may cause burns.

Wait for the boiler to cool to touch these uninsulated surfaces.

Warning!

Danger of choking carbon monoxide.

When boiler is used, carbon monoxide can be emitted through openings in the

boiler.

Do not leave boiler door open more than required.

.

User Guide TKP

-9-

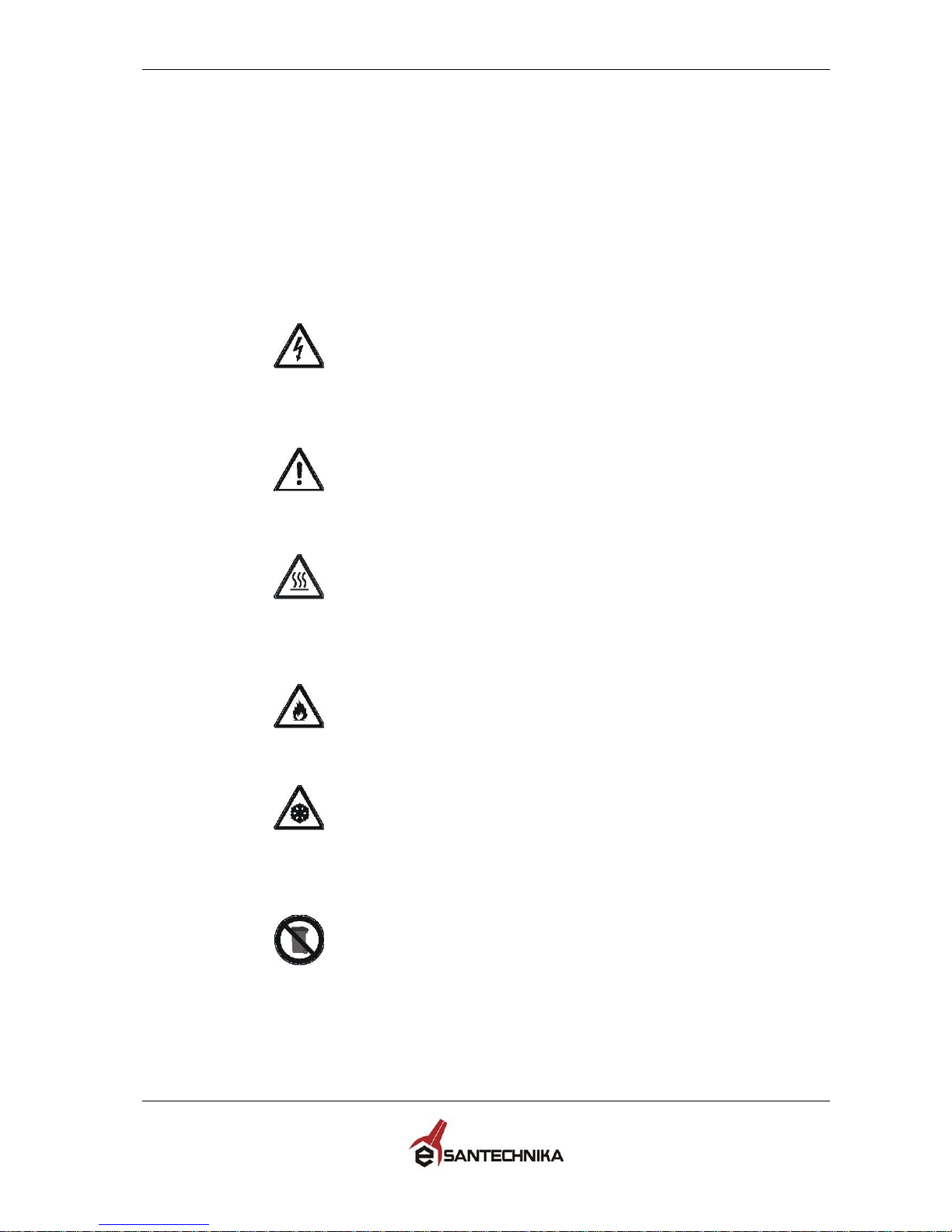

2.3 Used warning and safety signs

The following warning and safety signs are used in this User

Guide:

Danger!

Danger from electrical current.

Work on devices marked with this symbol is only

allowed for the qualified persons.

Warning

Work in areas that are marked with this symbol could

result in serious injury or create serious damage.

Attention

High temperature surfaces.

Work in areas marked with this symbol can lead to

burns.

Attention

Danger from fire.

Work in areas marked with this symbol can lead to fire.

Attention

Danger of freezing.

Work in areas marked with this symbol can lead to

freezing.

Notes on proper disposal.

Additional information for the operator.

User Guide TKP

-10-

2.4 Duty- be informed

READING

USER GUIDE Anyone who intends to use the boiler is required to read and understand

this manual, and special attention must be paid to the Chapter 2, Safety

instructions. This especially refers to those who only occasionally use the

boiler, for example, only when cleaning or other tasks related to the

maintenance of the boiler.

This manual must be constantly ''at hand'' where the boiler is installed.

Particular attention should be paid to the standards applicable

to the place where the boiler is installed.

_______________________________________________________________________________________

3. DESCRIPTION AND PURPOSE OF

BOILER

3.1. Introduction

Boiler types TKP have modern construction and design, and is made of quality certified

materials.

Boiler testing was done according to EN 303-5 and meets all requirements for connection to the

central heating system.

Hot water boiler is designed for heating of small residential units, family houses, shops and

small manufacturing units

It uses sold fuel. It is designed to operate in the temperature regime of 90/70.

The firebox and convective part of the boiler are made of high-quality boiler metal sheet using

welding technology. The boiler is well insulated with hard pressed mineral wool in quality sheet

boiler casing.

The installation and commissioning are simple and connectors are standard.

Boiler is attested by the Faculty of Mechanical Engineering in Banja Luka. Nominal power of

furnace is achieved with lignite "Stanari" which is of small thermal power, about 11 00 kJ/kg.

The boilers manufactured in the compliance with EC Directives : The Pressure Equipment

Directive

97/23/EC and

And applied harmonized standards, especially: EN 303-5:1999;

Other mentioned standards and technical specifications:

EN 287-1: 2004, EN 288-3:1992, EN ISO 7000 :2004;

EN 10204:2004;

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 12 --

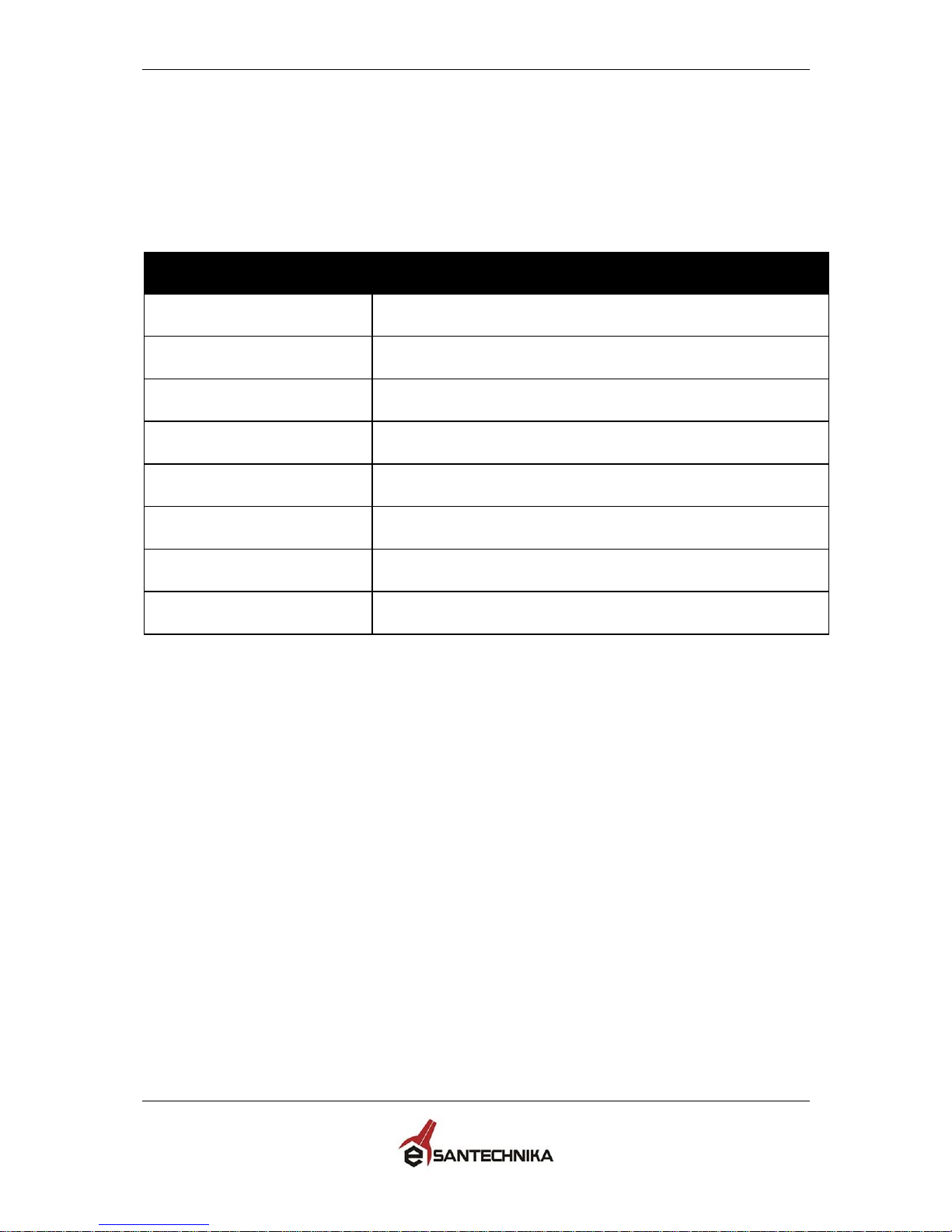

3.2. Technical data

Identification table for boilers

Identification of the boiler can be done with identification table on boiler flue vent>

Figure 1.Identification table of the boiler type TKP

Boiler technical data

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 13 --

Figure 2. Boiler TKP

TYPE

Power

rating

s

[kW]

DIMENSIONS

[mm]

CONNECTIONS

[col]

Draft

[Pa]

Mass

of the

boiler

[kg]

Water

Volume

inside

boiler

[l]

A B C D E H R1

R2

R3

TKP 20

20

465

705

1142

160

190

810

5/4

1/2

3/4

21

235

80

TKP 25

25

465

730

1250

160

190

950

5/4

1/2

3/4

22

258

85

TKP 30

30

495

775

1320

180

190

1030

5/4

1/2

3/4

23

305

109

TKP 35

35

550

785

1355

180

190

1040

5/4

1/2

3/4

25

336

135

TKP 40

40

590

760

1390

180

190

1050

5/4

1/2

3/4

26

362

140

TKP 50

50

710

785

1430

180

190

1090

5/4

1/2

3/4

28

380

150

TKP 65

65

748

890

1375

200

190

1040

6/4

1/2

3/4

30

480

200

TKP 80

80

765

990

1375

200

190

1040

6/4

1/2

3/4

35

595

220

Table 3. Characteristic dimension of boilers TKP type

TIP

TKP

20

TKP

25

TKP

30

TKP

35

TKP

40

TKP

50

TKP

65

TKP

80

Maximum power

[kW]

20

25

30

35

40

50

65

80

Heat output range

[kW]

10-20

12-25

15-30

17-35

20-40

25-50

30-65

40-80

Maximum operating

pressure [bar]

3 3 3 3 3 3 3

3

Maximum operating

temperature [°C]

90

90

90

90

90

90

90

90

Operating

temperature

interval [°C]

70-90

70-90

70-90

70-90

70-90

70-90

70-90

70-90

Class of the boiler

according to EN

303-5

3 3 3 3 3 3 3

3

Necessary draft

[Pa]

21

22

23

25

26

28

30

35

Temperature of flue

gases [°C]

- Maximum

250

250

250

250

250

250

250

250

Table 4. Technical data

Fuel

The boiler is intended for solid fuel combustion (firewood, wooden briquettes, wood waste,

lignite, coke, coal. Its design allows to feed large pieces of wood.

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 14 --

During the testing, power ratings of the boiler is achieved with "Stanari" lignite, whose thermal

power is about 11 000 kJ/kg.

3.3. Installation of the TKP type boilers

Assembly of the outer casing of the boiler TKP type

In order to prevent damage of metal casing which could occur during the transport and storage

of the TKP type boilers, final assembly of the boiler casing on the boiler body is done on the

location of the installation. The assembly of casing must be done in the compliance with the

scheme of assembly show in Figure 3.

Legend :

1. Cover of the casing

2. Right side of the casing

3. Left side of the casing

4. The back side of the casing

5. Front upper side of the casing

6. Front lower side of the casing

7. Protection of measuring and safety instruments

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 15 --

8. Upper door isolation

9. Lower door isolation

Figure 3. Scheme of the assembly of boiler casing

Order of assembly of the metal casing on the boiler body:

1. Assembly of the back side of the boiler casing (Figure 3, position 4) ,

2. Assembly of the sides (Figure 3, position 3and 4) ,

3. Assembly of the front lower side (Figure 3, position 6)

4. Assembly of the front upper side (Figure 3, position 5)

5. Assembly of the cover of the casing (Figure 3, position 1)

6. Assembly of the protection of measuring and safety elements (Figure 3, position 7)

7. Assembly of the upper and lower door insulation (Figure 3, position 6)

Handling the boilers can be done only by adults who have read and understood the technical

user guide. Incorrect handling of the boiler may result in injury, failure of boilers and

installations, as well as serious consequences for humans.

The boiler must be installed on a flat, stable surface. Water supply system connections,

connection or possible drainage, and connection to electrical network (220V, 50 Hz) must be

provided in the boiler room.

Also, the boiler should be installed on a non-combustible surface and the safety distances of

200 mm away from flammable materials must be complied with. This applies to boilers and flue

gas pipes located near flammable things and materials, flammability class B, C1 and C2.

Safe distance of 440 mm must be respected if the boiler is located along the material

flammability class C3.

The boiler room must be physically separated from other rooms (especially the rooms where

people live and sleep).

Safe distance must be complied with when setting the installation elements near to the boiler.

Boiler failures which occurred because of improper and

negligent handling of the boiler are not covered with the

Warranty.

Natural ventilation must be provided in the boiler room, which

is necessary for the proper operation of the boiler ( See table

5).

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 16 --

Q (kW)

15

25

30

35

40

50

65

80

A0 (cm2)

775

1000

1096

1184

1265

1415

1613

1789

aoxb0 (cm)

28x28

32x32

34x34

35x35

36x36

38x38

41x41

43x43

A1 (cm2)

258

334

365

395

422

472

538

597

a1xb1 (cm)

16x16

19x19

20x20

20x20

21x21

22x22

24x24

25x25

A0 = 200 , Q (kW) - air inlet opening

A0 (cm) – minimum effective area of the inlet opening for ventilation and combustion

A1 = 1/3 . A0 - drain opening

Openings should be protected with outside fixed louver in order to prevent entry of

rainfalls

Table 5. Dimensions of inlet and drain openings for natural ventilation of boiler room

Dimensions of the chimneys for boiler type TKP

The chimney must be sized according to the diagram in Figure No. 4.for good and safe

operation. The Figure 5 shows proper installation of the chimney regarding the roof

construction.

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 17 --

Figure 4 Selection of chimney section when using solid fuel - firewood (Schiedel)

Boiler power ratings in [kW]

Firewood boilers with

necessary draft and

temperature of flue gas on

the boiler exit tw<2500C

Light size of chimney in cm

Necessary pressure drop in the boiler [N/m

2

]

Useful height of the chimney in [m]

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 18 --

Figure 5 Proper installation of the chimney

When connecting boiler with the chimney, flue gas pipe must be installed rising and horizontally.

All connections must be good fixed.

The boiler must be installed by a qualified person in the compliance

with applicable regulations. Topling Compay cannot accept the

responsibility for the damage cased by improper installation.

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 19 --

Connecting the boiler on central heating installation

In the following part of this technical user guide it is show recommended connection of the boiler

type TKP on central heating installation,

Legend:

1- boiler

2- flue vent

3- draft regulator

4- radiator lock shield

valve

5- radiator valve

6- radiator

7- circulating pump

8- block valve

9- safety valve

10- closed expansion

container

11- the vent

12- manometer

13- thermometer

14- tap for filling and

emptying

15- thermo valve

16- drainage of waste

water

17- thermal protection of

boiler

Figure 6. Connecting the boiler on central heating installation

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 20 --

Figure 7. Connecting the boiler type on central heating installation with opened expansion

container

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 21 --

For extra protection against boiler overheating, caused by the stoppage of the circulating pump, the user

is suggested to install callefi valve, which releases cold water into the boiler if it reaches a temperature of

100 ° C, and sends hot water to drain. Scheme of the callefi valve installation is shown in Figure 8.

On boiler type TKP is necessary to install backup battery supply with converter, in order to power supply

pump.

Figure 8. Scheme of the connection of "callefi“ valve

Boiler should be placed as close as possible to the chimney.

Do not close the free air supply to the boiler

WARNING

1. The boiler must be installed on a stable, flat surface. Setting and

installation of the boiler must be done by a qualified person.

2. The boiler must be provided with a water supply system

connections, and connection for possible drainage, and

connection to the electrical network with the required

grounding.

3. The boiler room must have natural ventilation provided in order

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 22 --

to provide supply of fresh air.

4. Floor and interior the boiler room must be made of fireproof

material

It is preferable that there is no humidity in the boiler room in order to prevent the corrosion of

boiler metal part, and in order to prolong boiler life expectancy.

It is recommended to use softened water for feeding the boiler from the system.

Circulating pump is put into operation only after the heating system is filled with water, and

you must be sure that the system is vented.

In a closed heating system it is required to install attested safety valve of opening pressure of 3

bar and to install expansion container. Between the safety valve and expansion vessel must not

be installed blocking element.

The boiler water temperature must not fall below 55° C in order to

avoid condensation on the internal walls of the boiler

In the event of severe winter weather and low temperatures, and if the

boiler is not used it is necessary to remove water from the system and fill it

with liquid anti-freeze.

THE DANGERS OF FIRE

Flammable materials and liquid cannot be in immediate vicinity of the boiler.

Commissioning the boiler

Prior to commissioning of the boiler, is necessary to fill the system with water to vent it.

After that, you have to check the following:

- whether the he installation is done as designed.

- Water pressure in the boiler and installations;

- Installation of flue gas pipes and their tightness;

- Whether the draft regulator is properly installed and configured;

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 23 --

- Turn on the circulating pump and let the water from the boiler to the installation only

when the boiler water temperature reaches 60°C;

- Fully open the flap on the chimneys.

When he performed the above tests, it can be accessed by stoking the boiler and its

commissioning.

Adjusting proper operation of the boiler

Figure 9 shows the basic terms which are necessary for proper operation and maintenance of

the boiler

When making the fire in the boiler, you mustn’t use easily flammable

substances (for example petrol, gas, etc.)

In a closed heating system it is required to install attested safety valve

of opening pressure of 3 bar and to install expansion container.

Between the safety valve and expansion vessel must not be installed

blocking element.

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 24 --

Legend:

Door for adding fuel

Door for cleaning

Draft regulator

Thermometer

Valve for venting

Flue vent

Draft control damper

Figure 9. Boiler TKP

Door for adding fuel (Figure 9,postiion 1) and the door for cleaning (Fig. 9,pos. 2) have

mechanical shutter. When checking the fuel or when filling, it is necessary first to open the door

slightly, in order to enable the exchange of gases in the fuel, and after that open them

completely.

Regulation of the boiler power is controlled with draft regulator (Fig.9, pos. 3) which is screwed

into the body of the boiler.

Reading the water temperature is controlled with a thermometer (Fig. 9, pos. 4)

Add fuel and set the draft regulator so that its operating temperature does not fall below 550C.

In order to simply regulate the water temperature in the radiator when adding the fuel and to keep thet

temperature below 55°C ,it is necessary to install the at least the simplest manual control mixing valve or

thermostatic valves on radiators.

We warn the user of high temperature on the boiler door and chimneys.

Gloves are necessary for safe work

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 25 --

Prohibition

3.5Declaration of Conformity

EC Declaration of conformity

In compliance with EN45014:1998

We .................………………... : TOPLING

Vijaka bb

78430 Prnjavor

Bosna i Hercegovina

hereby declare under own responsibility that the product:

Mark ........ ................................... : hot water boiler

It is prohibited to:

- Perform any modifications that are not in compliance with this

technical user guide;

- Use other materials as the fuel which is not recommended by

the manufacturer;

- Overcharge boiler fuel;

- Use other tools and instruments for maintenance and cleaning

which are not recommended by the manufacturer.

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 26 --

Type / Model.. ......................................TKP15,TKP20,TKP25,TKP30,

TKP40,TKP50,TKP65,TKP80

Date of production ......................... : 2009 year

To which this Declaration applies to, is in the compliance with the following standard

documents:

In the compliance with EC Directives: EC Pressure Equipment Directive 97/23/E

Applied harmonised standards, in particular:

EN 303-5:1999;

Other mentioned standards and technical specifications:

EN 287-1: 2004, EN 288-3:1992, EN ISO 7000 :2004;

EN 10204:2004;

Applied procedure for conformity compliance: Module B1

Emission limit value of the combustion products (Class) 3

Certificates which are issued: EC Control of type – Certificate no.. 0745/0347/09

Accredited laboratory: TÜV Thüringen e. V. Service-Center Südthüringen

Industriestr. 13 98544 Zella-Mehlis

We hereby declare that the above named product in its concept and workmanship, is in

accordance with the security and safety standards that comply with the above directives and

standards.

Thereby all operating conditions and application requirements are in accordance with the User

guide and technical documentation.

Once a single change has been made to the product not in agreement with us, this

statement loses its importance.

Place and date Full name and title of signatory:

Prnjavor Zivanic Radislav, Director

................................................ ....................................................

Place and date Signature,seal

4. BOILER MAINTENANCE

4.1 The frequency of Cleaning and

Maintenance

In order to enable long life expectancy of the boiler without any operation interruptions, it is

necessary to regularly clean and maintain the boiler. In this way you will avoid costly repairs.

Keeping your firebox clean is the basic condition for the good boiler operation. A layer of soot

and tar accumulates on the firebox walls and it is necessary to mechanically clean the furnace..

Boiler cleaning

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 27 --

For proper operation of the boiler and extending the life expectancy, the boiler should be

regularly cleaned. Clean boiler saves the fuel. Only 1 mm of deposits on the walls of the firebox

increases fuel consumption by 5% to 10%. When the deposits is 3mm thick, which is not

uncommon after one heating season, heating costs are increased by 30%.

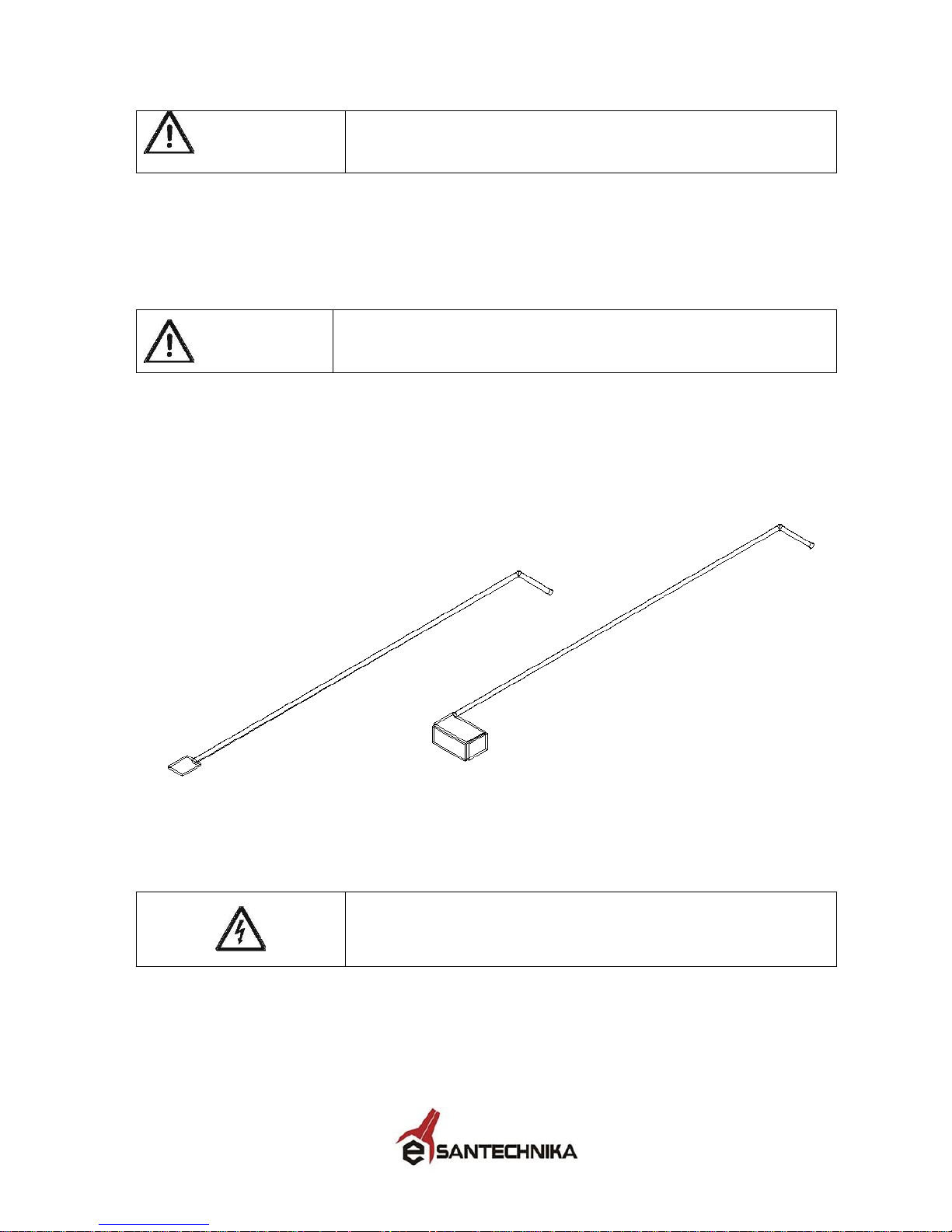

Clean the boiler using cleaning kit, which is the part of the standard equipment that is delivered

together with the boiler (Figure 10), remove layers of ash and soot from exchange surfaces..

(water-cooled grate, boiler walls, water-cooled rack) and flue vent

Figure10 boiler cleaning equipment

Low temperature corrosion

Boiler cleaning can be performed only when the fuel is

burned completely and the water temperature in the system is

below 35 °C

Clean the firebox at least once in a week, a clean thoroughly at

least once in two weeks.

When cleaning the boiler and flue gas pipes it is necessary to

check the chimney. Dirty chimney prevents the proper

operation of the boiler and can cause consequences on

human health and property.

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 28 --

Wood and coal contain a certain percentage of sulphur. As a product of combustion, sulphur

dioxide and sulphur trioxide are produced. In the chemical reaction between sulphur dioxide,

sulphur trioxide and water vapour which is contained in burned gases, sulphuric acid is

produced.

By cooling the flue gases on the boiler heating surface, vapours of sulphuric acid and water

vapour are condensed. Condensed sulphuric acid and water vapour deposit on the walls of the

boiler in the form of thin films and melt iron. As the product of the melting ,ferrous sulphate

occurs, which later turns into rust. High corrosiveness of sulphuric acid is that it is ageing rereleased by hydrolysis of ferrous sulphate.

In this way, a small amount of sulphuric acid can always participate in the corrosion process.

By reducing the temperature of flue gas, sulphuric acid vapour condensates. With the fall of the

temperature of flue gases, the speed of the creation of acid film and corrosion is increased.

Interval

Component

How it is performed

Upon completion of the heating season, the boiler must be

cleaned thoroughly in order to extend life expectancy of the

boiler.

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 29 --

Every seven days

Clean interior, exchange

surface of soot deposits

Use the cleaning kit, shown in Fig.8 to

scrape carbon deposits from the walls

of the boiler

Every 7 to 14 days

Cleaning the boiler

Use the cleaning kit, shown in Fig.8

scrape carbon deposits from the walls

of the boiler

Every six months

Check whether the flue

vent, flue pipe elbow, flue

gas pipe are clean and if

necessary clean them.

Wait for the boiler to cool down,

dismantle flue gas pipe and flue pipe

elbow and perform the cleaning with

the same kit which is delivered with the

boiler

When necessary, at

east once a year

Clean the flue gas pipes

and chimney

Authorized chimney sweeper should

perform cleaning of the chimney

Annually

Thorough annual cleaning

at the end of the heating

season.

Clean all the components described in

the upper part of the table

Tbale 6 Frequency of maintenance

When cleaning the furnace of ashes and soot deposits by vacuum cleaning, the ash has to be

cooled, i.e. to have the room temperature, in order to avoid the risk of the combustion of the

vacuum cleaner with which we suck up the ashes.

When cleaning chimney, flue pipe and the elbow there is a risk of burns because these

surfaces may have the temperature up to 200 °C during the operating regime. It is necessary to

leave enough time for cooling down.

When performing the cleaning works, there is a risk of carbon monoxide poisoning, if the

combustion process is not over and the clearing process is performed carelessly. In this case,

carbon monoxide is emitted through openings on the boiler (i.e. open doors, removed flue pipe,

or the elbow). Never leave the boiler door open longer than it is necessary.

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 30 --

5. POSSIBLE PROBLEMS IN

FUNCTIONING

Problem Cause

Elimination

The boiler

operates, but it

cannot achieve the

set temperature

The boiler is dirty

Clean the boiler and chimney

There is no enough fuel in the

firebox

Use enough amount of the fuel in the

firebox. Avoid wet fuel whose moisture

exceeds 35%

Boiler is getting

wet

Flue gas condensation

1. It is installed the excessive force of radiators.

The boiler does not have enough power.

Replace the boiler with a boiler of a higher

power or adjust the number of radiators with the

boiler power.

The boiler is damaged

It is necessary to weld the boiler. Only the

authorized service or the producer can perform

that.

The smoke returns

from the boiler

The chimney, flue vent or the

firebox are dirty

Clean

Too small opening of the

chimney

Adjust cross section of the chimney with the

boiler power

The boiler is

overheating

„shots“ can be

heard in the

boiler

There was a power failure,

the circulating pump is not

working and the boiler is

overheating. There is a

danger of explosion of the

boiler

In order to avoid this, the best solution is to

have spare battery power with converter.

If you do not have a backup power supply

for pump, it is necessary to flare embers

from the boiler and open the bypass valve,

which is connected in parallel with the

circulating pump on the piping system.

It is necessary also that thermal protection

if the boiler is connected (see Figure 6,

positions 15 and 17) as an additional

protection against overheating of the boiler.

Boiler achieves the

set

temperature, but

the radiators do

not heat

The pump does not operates,

but there is a voltage

The pump is bunt up,. It is necessary to

unscrew the cap of the pump and to try to

start it with the screwdriver. The producer is

not responsible for failures which occurred

on circulation pump because it is not the

constituent part of the boiler.

The pump has no voltage

Check pump fuse. The Manufacturer is not

responsible for this type of failure.

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 31 --

Table 7 Possible problems during the operation

6.THE FIRST COMMISSIONING

The boiler should be put into operation by a qualified person. If unqualified person performs the

putting into operation, there is the possibility of damage and complete destruction of the boiler.

Improper handling can cause injuries.

6.1. Requirements for successful

commissioning

The following conditions must be met before starting safe putting into operation of the boiler:

TURN OFF THE ELECTRICAL SUPPLY TO THE BOILER

Is the main swath for power supply to boiler turned off?

CHECK MECHANICAL COMPONENTS OF THE BOILER

Are all mechanical components properly implemented into the boiler?

Are all mechanical components properly and firmly fixed to each other?

CHECKING OF PIPING AND INSTALLED COMPONENTS

Is the circulation pump properly implemented?

Is the safety valve properly implemented?

Danger!

Risk of electric shock during the connection to circulating pump to electric network.

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 32 --

7. DISPOSAL AFTER END OF LIFE

7.1. Dismantling boiler

Danger!

The boiler must be disassembled by a professional.

Material damage and injury can occur if an unprofessional person disassembles the

boiler.

Dismantling of the boiler from central heating installations should be performed at

following stages:

1. Stop with adding fuel

2. Leave enough time for boiler and the boiler mechanism to burn the remains of fuel

and to cool down after that

3. Isolate boiler heating system by closing the valve, and then drain the water from the

boiler

4. Demount boiler casing

5. Separate mineral wool from the boiler

7.2. Disposal of boiler

The following components of the boiler are made of steel and must be handed to the

centre for collection of secondary raw materials.

The body of the boiler,

Casing of the boiler

Glass Braid (located on the door of the boiler), mineral wool and plastic parts, must be

separated and handed to the centre for collection of secondary raw materials.

Do not throw the boiler components in the dumpster.

Uputstvo za upotrebu TKP

________________________________________________________________________________________

_____________________________________________________________________________

-- 33 --

8.WARRANTY

8.1 The warranty period

You have a five-year warranty on the boiler type TKP.

8.2 Conditions of the warranty

The boiler must be properly installed on central heating installation

The boiler must be used in accordance with the recommendations stated in this

user guide

8.3. The Warranty is not applied to

The warranty is not valid if the damage is the result of the improper use

If the installation and putting into operation is performed by an unauthorized

persons

f the service is performed by an unauthorized persons

If the boiler is not maintained in the compliance with the recommendations

written in this guide

If the damage is caused by natural disasters (earthquakes, floods, fires, lightning,

etc.)

If the unoriginal spare parts are installed

f there is a power failure, and the circulating pump has no backup power source

If the failure occur because of the improper installations (circulation pump,

expansion, etc.), i.e. of the parts which are not the constituent part of the boiler,

but are the condition for the functioning of the boiler.

Because of improperly or incompletely filled Warranty sheet.

Loading...

Loading...