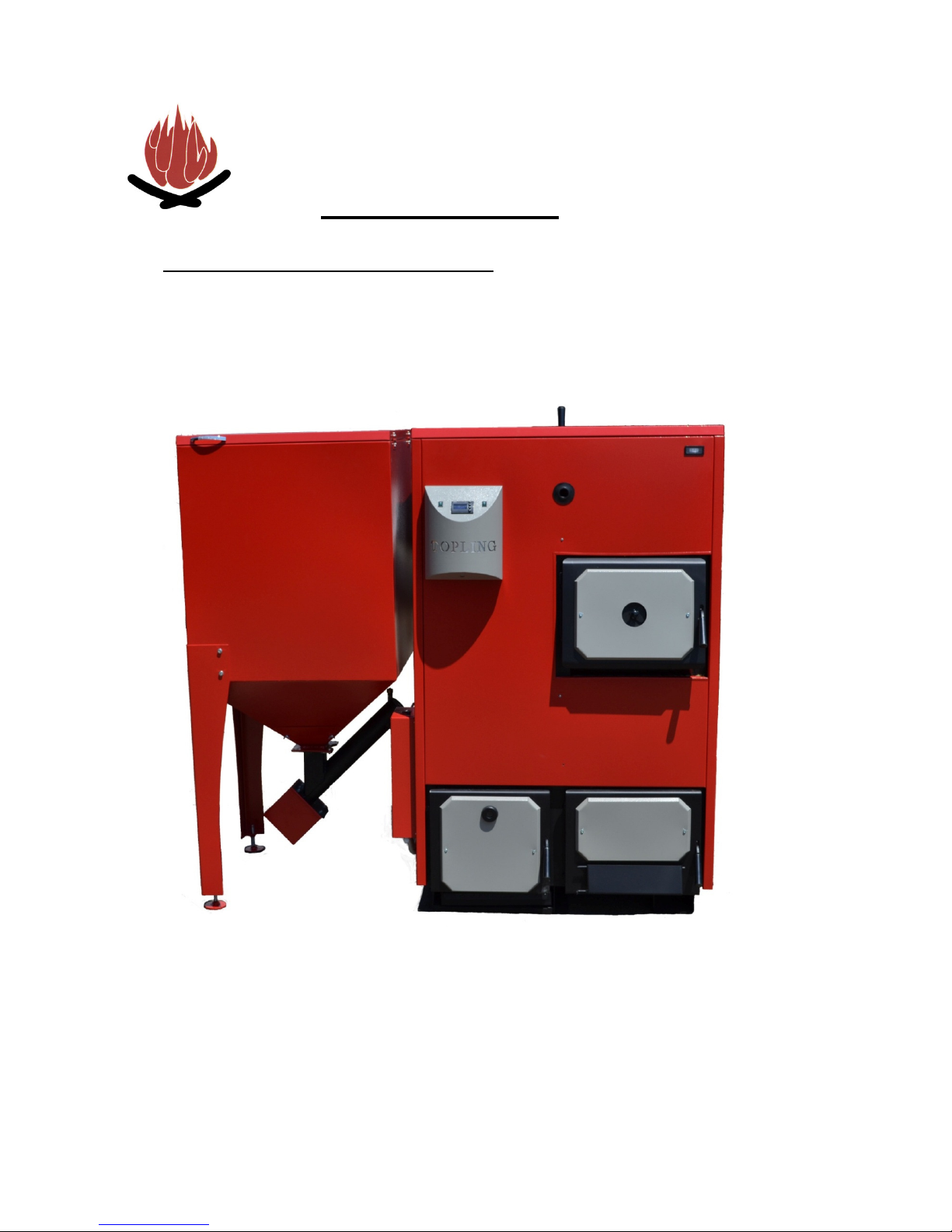

Topling 3BT 25 kW, 3BT 50 kW, 3BT 35 kW User Manual

User guide BIOTOPLING-3BT

_______________________________________________________________________________________

TOPLING

P R N J A V O R

www.topling.com; e-mail: topling@blic.net tel:00387-51/645-200;645-300

USER GUIDE

Combined pellet and solid fuel

hot water boiler

3BT 25 kW

3BT 35 kW

3BT 50 kW

User guide BIOTOPLING- 3BT

________________________________________________________________________________________

_____________________________________________________________________________

-2-

TOPLING JUNE 2012 3BT 25-50 kW

LIST OF CONTENTS

page

1. NOTES ON THIS USER GUIDE ..................................................................................... 3

1.1. Introduction ................................................................................................................ 3

1.2. Structure of the User guide........................................................................................ 4

1.3. Glossary ..................................................................................................................... 5

2. SAFETY TIPS ................................................................................................................. 6

2.1. Proper use ................................................................................................................. 6

2.2. Present risks .............................................................................................................. 7

2.3. Used warning and safety signs.................................................................................. 8

2.4. Duty-be informed ....................................................................................................... 9

3. DESCRIPTION AND PURPOSE OF BOILER ............................................................. 10

3.1. Summary ................................................................................................................. 10

3.2. How boiler operates ................................................................................................. 11

3.3. Technical data ......................................................................................................... 12

3.4. Requirements for pellet quality................................................................................. 13

3.5. Declaration of conformity.......................................................................................... 15

4. ASSEMBLY OF BOILER ............................................................................................... 16

4.1. Boiler connection to central heating system ............................................................ 16

5. COMMISSIONING......................................................................................................... 22

5.1. Main characteristics of controller ............................................................................. 22

5.2. Description of reglator operating .............................................................................. 23

6. BOILER MAINTENANCE .............................................................................................. 30

6.1. Cleaning and maintenace ......................................................................................... 30

7. POSSIBLE PROBLEMS IN FUNCTIONING.................................................................. 32

7.1 When can we expect the occurence of fire in pellet storage .................................... 33

7.2 Which steps are to be taken when thermal valve gets activated? ............................ 34

8. FIRST COMMISSIONING.............................................................................................. 35

8.1. Requirements for successful commissioning............................................................. 35

9. DISPOSAL AFTER END OF LIFE ................................................................................ 36

9.1. Dismantling boiler .................................................................................................... 36

9.2. Disposal of boiler...................................................................................................... 36

10. GUARANTEE................................................................................................................. 37

10.1. Period of guarantee.................................................................................................. 37

10.2. Terms of guarantee ...... .......................................................................................... 37

10.3. When the guarantee is not recognised.................................................................. 37

User guide BIOTOPLING- 3BT

________________________________________________________________________________________

_____________________________________________________________________________

-3-

TOPLING JUNE 2012 3BT 25-50 kW

1 NOTES ON THIS USER GUIDE

1.1 Introduction

EASY AND SAFE USE

READ USER GUIDE

TECHNICAL CHANGES

RIGHT TO COPY

This guide contain significant information for appropriate and

safe use of hot water boiler type 3BT. If you follow these

Instructions, you can avoid risky situations, reduce maintenance

costs, avoid failure, provide reliability and prolong boiler life.

This User guide must be read and applied by anyone using the

boiler type 3BT.

We keep developing and enhancing our boilers. All information

regarding this Guide that are related to the boiler type 3BT are

correct at the moment of print out.

Before use, all details mentioned herein concerning standards

and legistlation must be checked and compared to standards

and legislation applied in the location where the boiler is to be

installed.

We reserve the right to make changes to boilers that would differ in

technical data and drawings herein.

Written approval of Topling d.o.o. to copy, store in electronic

form, transfer information in electronic format, photography,

translation of this manual in whole or in part is required.

User guide BIOTOPLING-3BT

________________________________________________________________________________________

_____________________________________________________________________________

-4-

TOPLING JUNE 2012 3BT 25-50 kW

1.2 Structure of User guide

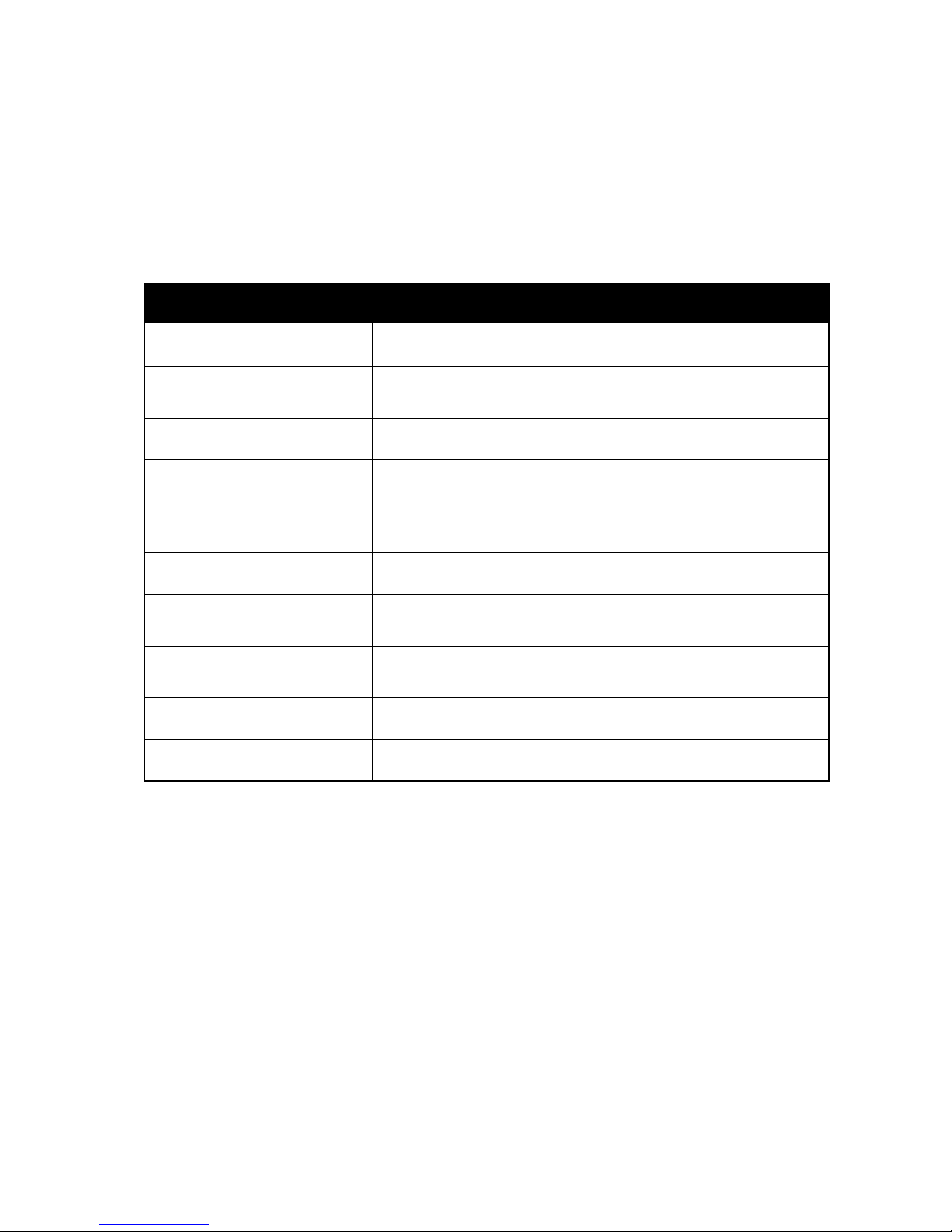

Tabel 1. Structure of User guide

Chapter

You can find the following here in.....

1. Notes on instructions ... how to use the instructions.

2.

Safety tips

...all related with safety use, what you shoud keep in mind when

using a boiler.

3.

Description and purpose

of boiler

... structure and all about characteristics of boiler, technical data,

what kind of pellet to be used

4.

Assembly of boiler

... how to connect boiler to central heating system.

5.

Commissioning

... how it is commissioned and how to set operating parameters.

6.

Maintenance

... who is in charge of maintance, how to clean and how often.

7.

Possible problems in

operating

...which problems can be experiences in boiler use.

8.

First boiler

commissioning

...requirements for successful commissioning

9. Disposal of boiler after

its life ends

... what should be taken into account when dismantling and

preparing of the boiler for disposal.

10.

Guarantee

... deadlines and terms of guarantee.

User guide BIOTOPLING-3BT

________________________________________________________________________________________

_____________________________________________________________________________

-5-

TOPLING JUNE 2012 3BT 25-50 kW

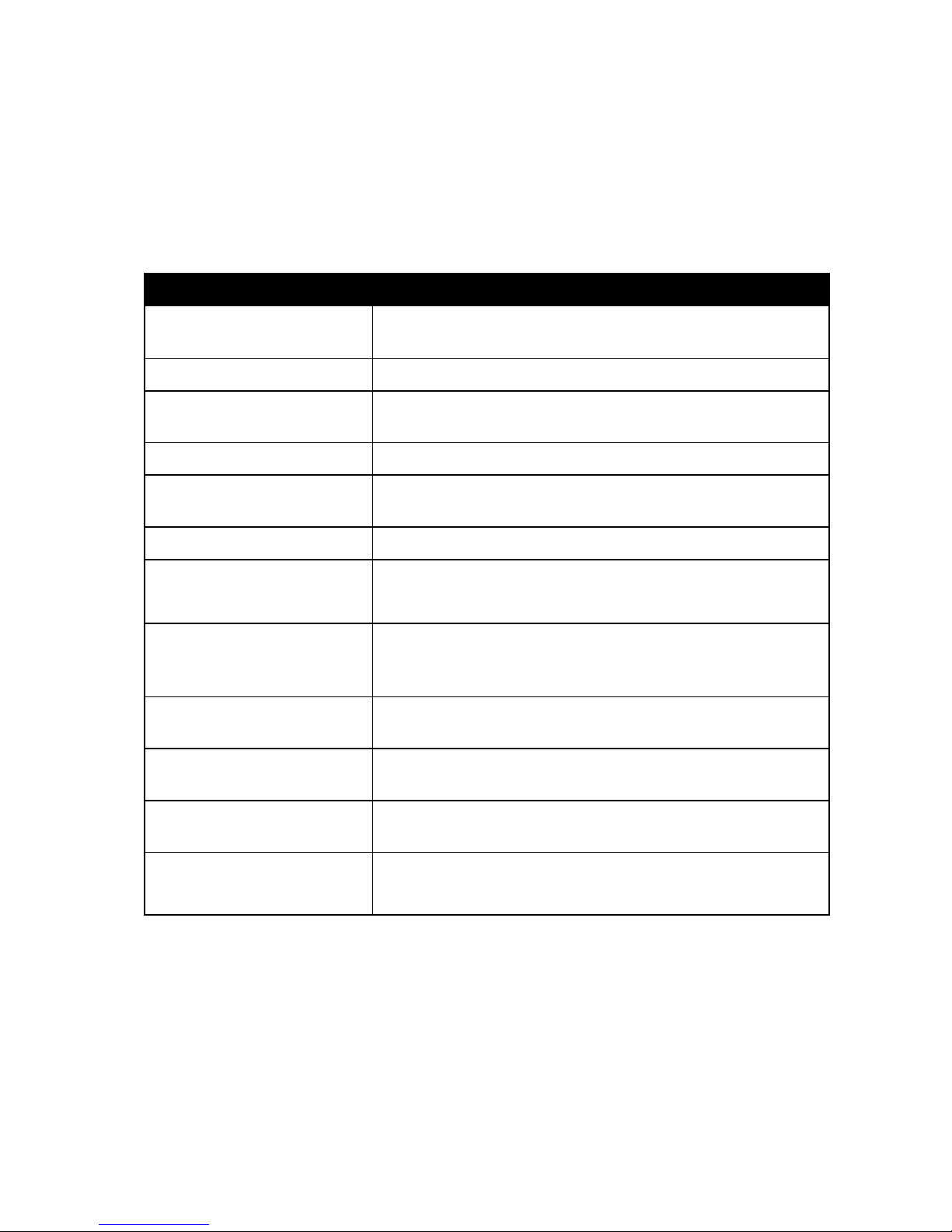

1.2 Glossary

Tabel 2. Explanation of terms

Explanation

Engine gear

Part of system intended for moving pellet screw conveyor.

Screw conveyor

Serves for pellet transporting from reservoire to firebox.

Automatic cleaning

Part of program intended for cleaning firebox just before

damping down a fire.

Display

Display of central unit for furnace operating control

3BT

Boiler with double firebox intended for pellet, solid fuel

(e.g.logs, coal) burning.

Central unit

Logical controller for operation management

Pelet

Type of solid fuel made of sawdust previously dried, then pressed

and in such manner making a cylindrical form with 6 mm diameter

and 20-50mm length.

PP set

System fof preventing fire in pellet reservoire. It is activated if

temperature in pellet feeder pipe exceedes 95˚C.

Draught controller Serves for regulating air quantity entering through bottom flap

into the furnace.

Solid fuel Logs, coal, wooden briquette.

Pellet reservoire

Reservoire for storing a pellet that is transported to firebox by

screw conveyor.

Probe

Serves for detecting certain parameters (temperature, feeder

level, etc.) and forwards them to the central unit for further

processing.

User guide BIOTOPLING-3BT

________________________________________________________________________________________

_____________________________________________________________________________

-6-

TOPLING JUNE 2012 3BT 25-50 kW

2 SAFETY TIPS

2.1 Proper use

MAIN PRINCIPLES

MAIN PRINCIPLES OF SYSTEM CONSTRUCTION

The boiler is made in accordance with the known principles of

safe use. Improper use may cause harm, injury or even death

to those who do not comply with safety guidelines as well as to

third parties, which may result in damage to the boiler, and

damage to other resources in the immediate environment

Specialized person who made the boiler installation and

commissioning should demonstrate you how to use it.

Use boiler only when it is completely in order. Use it the right

way and for the purpose for which it is intended, always taking

care of your own safety and the safety of others and the safety

of property. Constantly comply with this manual

Any defect which may impair safety must be immediately

removed.

USE OF BOILER

RELIABLE AND UNRELIABLE USE

The boiler is designed to burn pellet and solid fuel (e.g. wooden

logs, coal). This is possible because the boiler is designed with

double firebox (one for pellet, and other for wooden logs, coal)

Use of any other fuel is not allowed. The manufacturer is not

liable for any damages resulting from improper use. In case of

improper use the responsibility is borne by the one who used

boiler improperly.

As a user, you can enter or alter the operating parameters

within the limits prescribed by these instructions. Entering any

other value of the operating parameters that are not listed in

this leaflet, can lead to errors in the functioning of the system

User guide BIOTOPLING-3BT

________________________________________________________________________________________

_____________________________________________________________________________

-7-

TOPLING JUNE 2012 3BT 25-50 kW

ALLOWED FUEL

Only pellet that is made from sawdust is allowed to burn.

Pellet is cylindrically pressed into cylindrical shapes. It is made

from wood residues generated in wood processing. Pellet must

have a standard diameter and length. Chips from which the real

pellet is made, are pressed under high pressure and must have

a low percentage of humidity.

RECOMMENDED

CHARACTERISTICS OF PELET

’’Topling’’ recommends pellet of 6 mm diameter and a 10-30 mm

length. Quality and geometric characteristics of pellets are

prescribed by the German Standard DIN 51731 or Austrian

Standard ONORM 7135

Pay special attention to the quality of pellet, both when

ordering and admissioning.

Use pellet that meets the standards of DIN or ONORM.

For additional information regarding the pellet, see Section

3.4. Requirements regarding fuel quality.

2.2 PRESENT RISKS

Despite of all precautions, the below given risks should be always considered:

Attention!

High temperature surfaces.

Contact with such surfaces may cause burns.

Wait for the boiler to cool to touch these uninsulated surfaces.

Warning!

Danger of choking carbon monoxide.

When boiler is used, carbon monoxide can be emitted through

openings in the boiler.

Do not leave boiler doors open more than required.

User guide BIOTOPLING-3BT

________________________________________________________________________________________

_____________________________________________________________________________

-8-

TOPLING JUNE 2012 3BT 25-50 kW

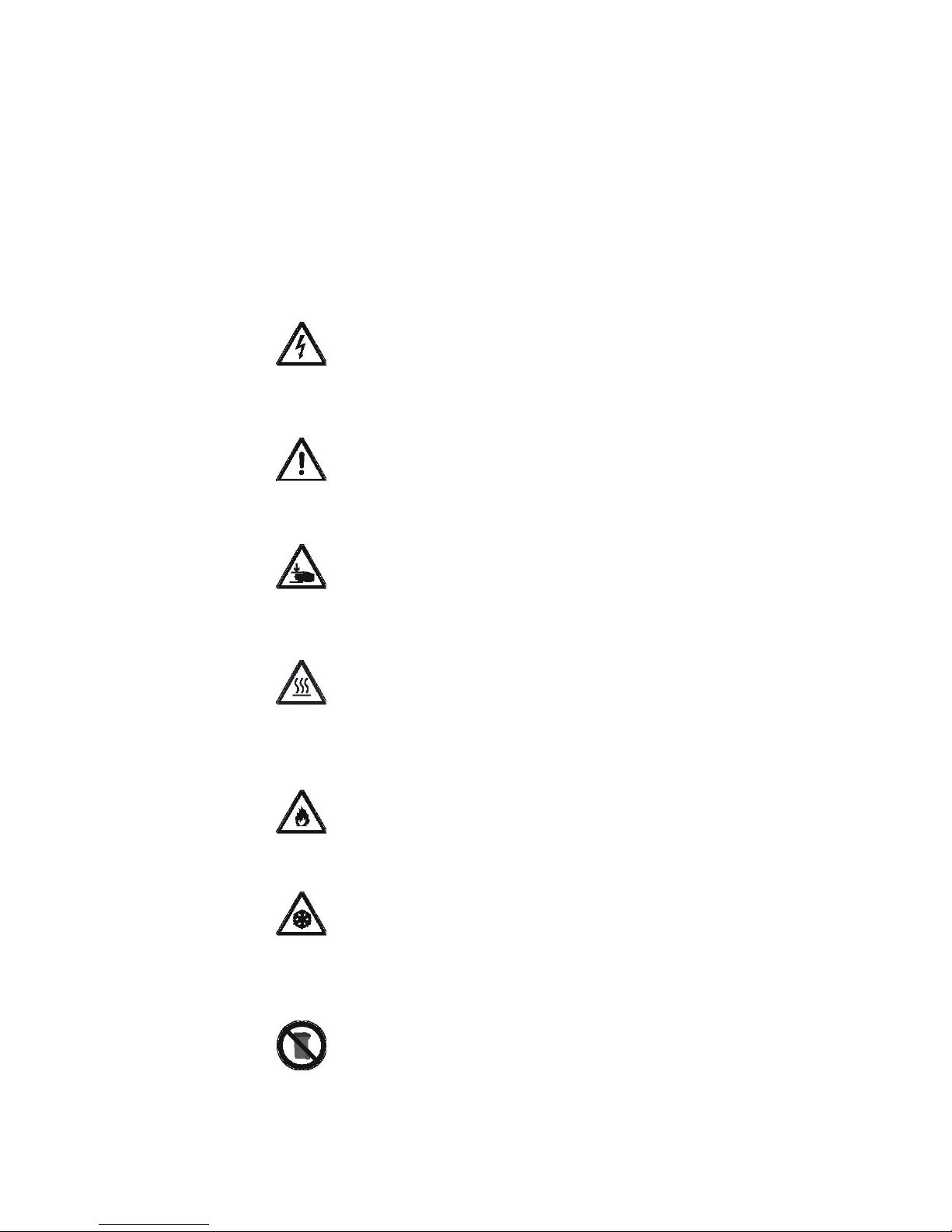

2.3 Used warning and safety signs

The below listed warning and safety signs are used in the

Instructions:

Danger!

Danger from electrical current.

Work on devices marked with this symbol is only

allowed for the qualified persons.

Warning

Work in areas that are marked with this symbol could

result in serious injury or create significant damage.

Attention

Possible hand injury.

Work in areas marked with this symbol can lead to

hand injuries.

Attention

High temperature surfaces.

Work in areas marked with this symbol can lead to

burns.

Attention

Flammable.

Work in areas marked with this symbol can lead to fire.

Attention

Danger of freezing.

Work in areas marked with this symbol can lead to

freezing.

Notes on proper disposal.

Additional information for operator.

User guide BIOTOPLING-3BT

________________________________________________________________________________________

_____________________________________________________________________________

-9-

TOPLING JUNE 2012 3BT 25-50 kW

2.4 Duty- be informed

READING

USER GUIDE Anyone who intends to use the boiler is required to read and understand

this manual, and special attention must be paid to the Chapter II, Safety

instructions. This especially referrs to those who only occasionally use

the boiler, for example, only when cleaning or other tasks related to the

maintenance of the boiler.

This manual must be constantly ''at hand'' where the boiler is installed.

Particular attention should be paid to the standards applicable

to the place where the boiler is installed.

User guide BIOTOPLING-3BT

_______________________________________________________________________________________

_____________________________________________________________________________

-- 10 --

TOPLING januar 2011 3BT 25 i 35

3. DESCRIPTION AND PURPOSE

3.1. Summary

Furnace ’’3BT’’ has a modern structure and design, made from quality certified material.

Construction of the boiler is compliant with European Directives:

2006/42/EC, PED 97/23/EC, LVD 2006/95/EC, EMC 2004/108/EC and

European Standards :

EN 303-5:1999; EN 60204-1 : 2006; EN 60335-1:2002; EN 50165:1997 +A1; EN 61000-63:2001; EN ISO 12100:2010;EN 287-1: 2004, EN 15014-1; EN10204:2004;EN ISO 7000 :2004

Boiler testing was done according to EN 303-5 and meets all requirements for connection to the

central heating system.

Hot water boiler is designed for heating of small residential units, family houses, shops and

small manufacturing units.

Automatic operation of the boiler provides the user with an enviable comfort considering that

you need to take into account only the charge of pellet reservoir, which makes it suitable for

widespread use.

Pellet is an environmentally clean fuel produced from sawdust. Sawdust is initially dried and

then pressed under high pressure. The final product is fuel of exceptional calorific power and

pure composition with no chemical additives. The percentage of ash in the combustion of pellets

is very low and amounts to 1%.

Calorific power of pellet is about

18000 k

J/kg

, which means that

2 kgs of

pel

let

corresponds to 1l of heating oil.

Operating the boiler is a very simple and means only turning on over the master switch and

setting the desired temperature.

From a functional point of view the pellet boiler is not behind the oil or gas heating systems,

while in fuel consumption it is significantly more cost-effective.

Compared to boilers with heating oil the savings with pellet boilers is up to three times. Pellet is

renewable, which means that, as such, is environmentally friendly.

Pellet tank is an integral part of the boiler plant and needs to be recharged as needed.

The firebox and convective part of boiler are made of quality sheet metal by welding

technology. The boiler is well insulated with hard-pressed mineral wool in a quality tin plating.

Assembly and commissioning of the furnace are simple, and the connectors are standard.

Boiler is tested for water resistance. Allowable working pressure is 2.5 bar.

User guide BIOTOPLING-3BT

________________________________________________________________________________________

_____________________________________________________________________________

-- 11 --

TOPLING JUNE 2012 3BT 25-50 kW

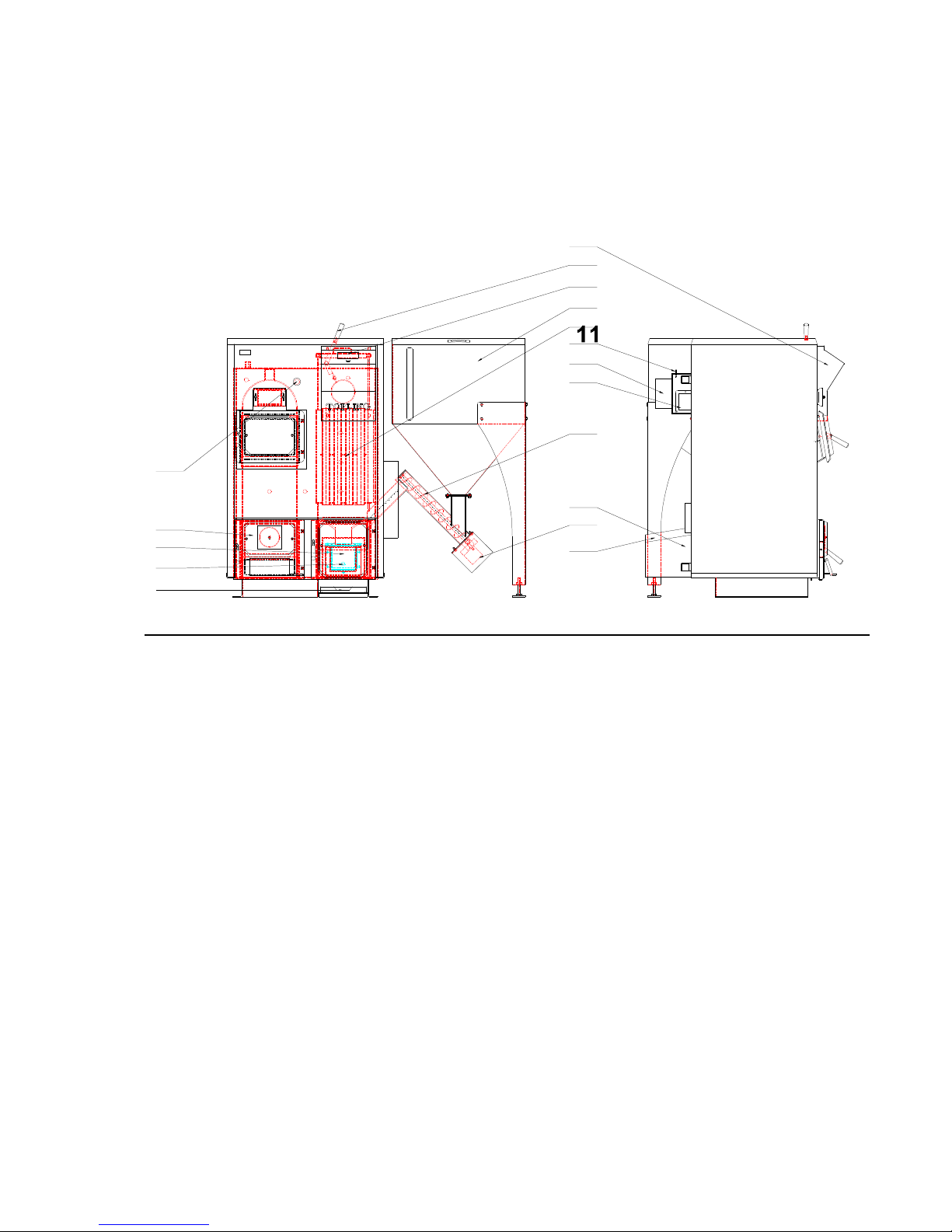

3.2. How the boiler operates

BOILER TYPE 3BT

12

15

6

3

2

13

10

4

8

5

7

9

1

16

14

17

Figure 1. Parts of boiler

LEGEND

1. firebox 9. firebox doors

2. convective beam 10. chimney

3. pellet reservoire 11. probe of flue gases

4. screw conveyor 12. box with operating display

5. motor of screw reductor 13. flue pipe

6. flap of convective beam 14. ash collector

7. air feeder 15. convective beam cleaning mechanism

8. fan 16. heater to fire pellet

17. connection for draught control

Boiler operation when pellet is used as fuel

From pellet reservoire Fig.1 pos.3 a screw conveyor Figure 1 position 4 inserts pellet into

firebox Fig.1 pos.1.

Electric heater, which is located in the firebox Fig.1 pos.16 is used to fire pellets. This occurs

only in the initial stage of commissioning of the boiler in operation and after a long break.

Fan Fig.1 pos.8 supports pellets burning in a way that it leads required amount of oxygen for

combustion into firebox.

User guide BIOTOPLING-3BT

________________________________________________________________________________________

_____________________________________________________________________________

-- 12 --

TOPLING JUNE 2012 3BT 25-50 kW

Boiler operation when wood or coal is used as fuel

In this case, the furnace firebox for wood or coal is active. The fire is put manually to the lower

door (Figure 1 position 9). Firing chopped wood or coal is done through the upper door of the

boiler. In this case, automatied functions of boiler are off. Feeding the boiler is done manually

and fuel should be filled every 2 to 5 hours, depending on the quality of the wood

(coal). Draught regulator (not supplied with the boiler) is set to the desired temperature of boiler

water which should be within the limits of between 60-90 0C.

A

B

H

R1

E

R1

R3

D

R2

C

Figure 2. External appearance of furnace

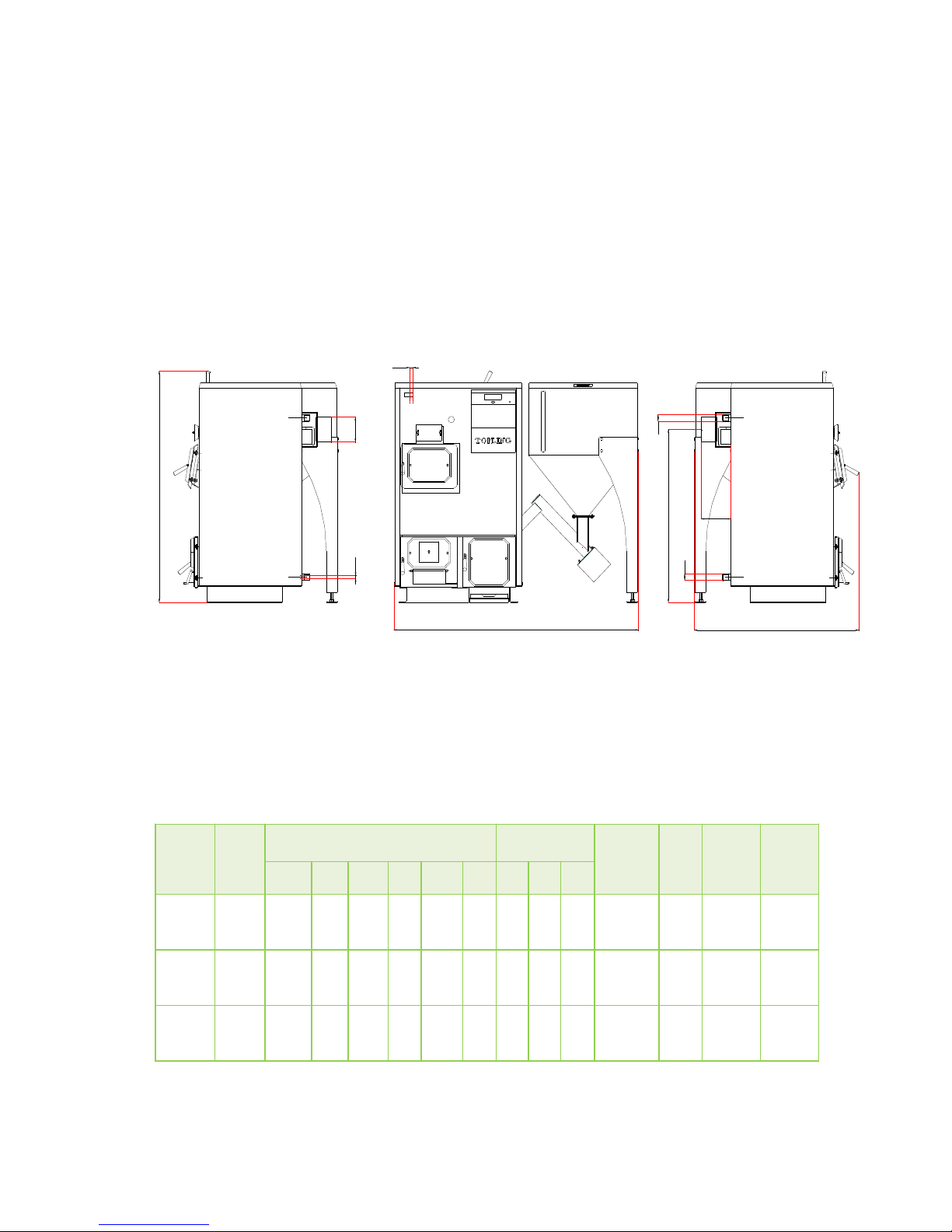

3.3. Technical data

Tabel 3. Technical data

TYPE

Power

[kW]

DIMENSIONS [mm]

ACCESORIES

[col]

Required

draught

[Pa]

Boiler

weight

+

reservoi

re

[kg]

Water

content

[ l]

Capacity

of pellet

reservoire

[kg]

A

B C D H E R1 R2 R3

3 BT-25 25

1623

1093

1474 160

1101

196 5/4 3/4

1/2

21

634 213 230

3 BT-35 35

1740

1100

1650 180

1286

230 6/4 3/4

1/2

25 890

310 290

3 BT-50 50

2135

1185

1752 200

1326

253 6/4 3/4

1/2

28 1025 410 290

Loading...

Loading...