Page 1

Portable Sewing Machine

Innovative Products to Make Your Life Easier

Model SP-403

Owners Manual

x Sews Durable LockStitch

x Handheld or Table-Top Operation

x Operates on 4AA batteries (not included)

Page 2

Dear Valued Customer:

Thank you for purchasing your Portable

Sewing Machine from our rapidly growing Sew Pro line. Our firm

takes pride in providing products with quality and value while

offering excellent service.

The Portable Sewing Machine will become a

valuable tool that will keep your family’s wardrobe in shape. Although not designed to make complicated clothing from scratch,

it provides a durable LockStitch to complete your basic mending

jobs quickly and with a quality stitch. This machine was

specifically designed to be lightweight for easy portability. We

are confident you will enjoy the time you spend using our

product.

Top Innovations, Inc. would like to invite you to take advantage of

our customer support web site at www.topinnovations.com

. Here

you will find additional information about the many other exciting

Sew Pro and Steam Fast products that are available. We take

pride in our quality line of garment care and steam cleaning

products and hope you will visit our web site to review our

product line.

Benny Lee

Chairman & CEO, Top Innovations, Inc.

1

Page 3

CONTENTS

SAFETY INSTRUCTIONS 2

PARTS LISTING 3-4

ACCESSORIES 4

WINDING A BOBBIN 5

THREADING THE BOBBIN 6

INSERTING THE THREADED BOBBIN CASE 6

REMOVING BOBBIN & BOBBIN CASE 7

THREADING THE MACHINE 8

RAISING THE BOBBIN THREAD 9

ADJUSTING THREAD TENSION 10

START TO SEW—HANDHELD OPERATION 11

START TO SEW—TAPLE-TOP OPERATION 12

SECURING A SEAM; DARNING 13

TURNING A SQUARE CORNER 14

CHANGING NEEDLES 14

HOW TO REPLACE THE SLIDE PLATE 14

PERFORMANCE CHECKLIST 15

IMPORTANT SAFETY INSTRUCTIONS

WHEN USING THIS MACHINE, THE FOLLOWING BASIC SAFETY

PRECAUTIONS SHOULD ALWAYS BE FOLLOWED:

x DO NOT USE WITH BENT NEEDLE.

x WHEN SEWING, KEEP FINGERS AWAY FROM ALL MOVING

PARTS. SPECIAL CARE IS REQUIRED AROUND THE NEEDLE.

x CLOSE ATTENTION IS NECESSARY WHEN THE MACHINE IS

USED BY OR NEAR CHILDREN.

x WHEN THREADING OR CHANGING A NEEDLE, ALWAYS

SWITCH OFF THE POWER SUPPLY.

x NEVER PRESS OR PULL THE NEEDLE ARM DIRECTLY, AL-

WAYS USE THE HAND WHEEL TO MOVE IT.

2

Page 4

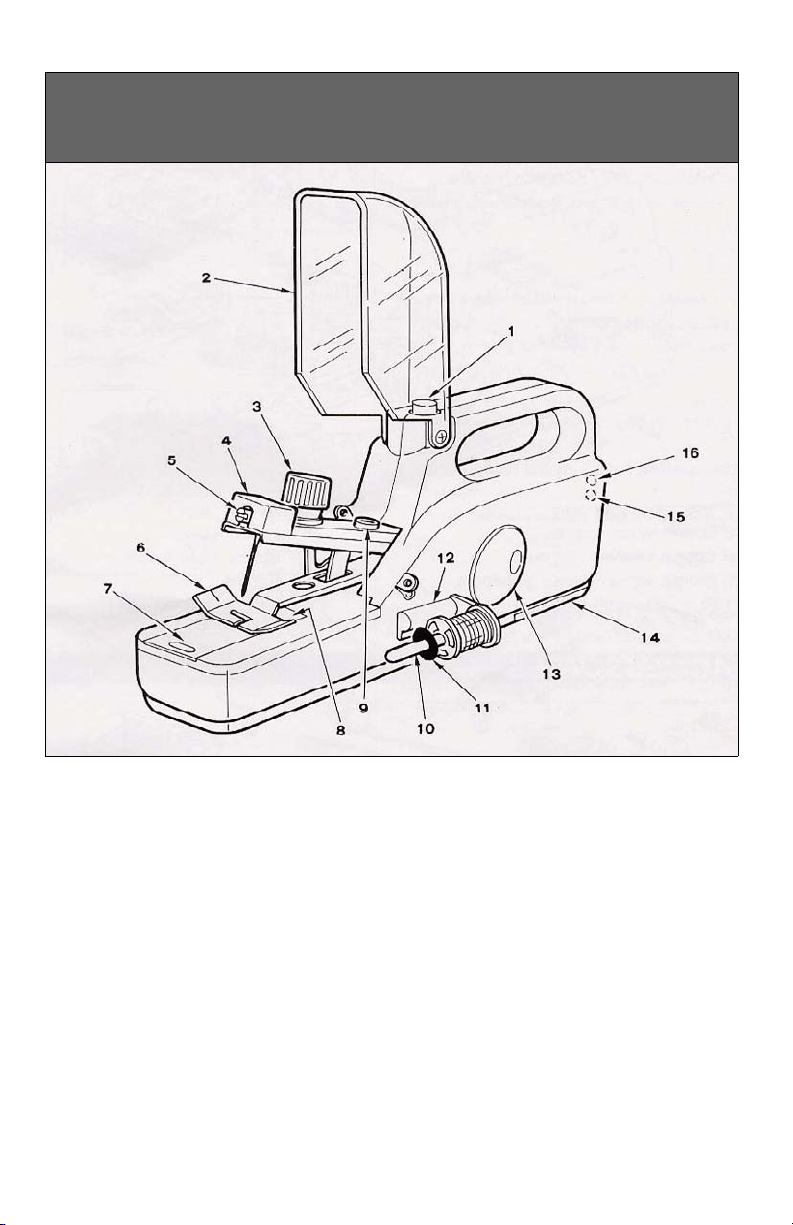

PARTS LISTING

1. On/Off Switch 11. Spool Holder Ring

2. Dust Cover 12. Spool Stand

3. Thread Tension Dial 13. Hand Wheel

4. Needle Arm 14. Battery Access

( 4 AA Batteries not included)

5. Needle Clamp Screw 15. AC Adaptor Socket

6. Presser Foot Rating: Input: 120V/ 60Hz

7. Slide Plate Output: 6 VDC, 600mA

8. Needle Plate 16. Foot Switch Socket

9. Pretension Stud

10. Spool Pin

3

Page 5

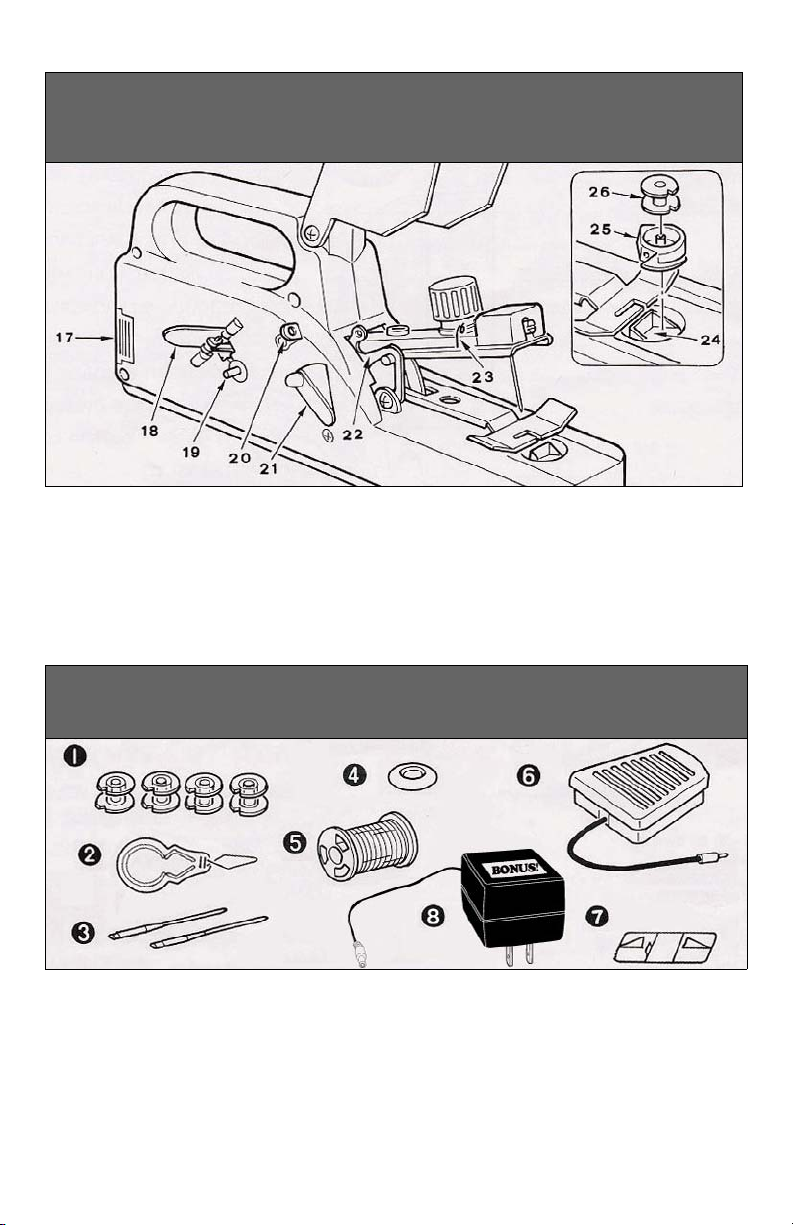

PARTS LISTING (cont’d)

17. Accessories Storage 22. Take-Up Lever

18. Bobbin Winder Cover 23. Thread Guide Wire Loop

19. Bobbin Winder 24. Bobbin Case Holder

20. Bobbin Winder Thread Guidepost

21. Presser Foot Lift Lever 26. Bobbin

25. Bobbin Case

ACCESSORIES

1. Bobbin x4 (1 in Machine) 5. Thread Spool (On Machine)

2. Needle Threader 6. Foot Switch

3. Needle x2 (1 in Machine)

(

Regular Needle No. 14 for General Sewing)

4. Spool Holder Ring (On Machine) 8. Bonus AC Adapter

7. Stabilizer (Table Top Operation)

4

Page 6

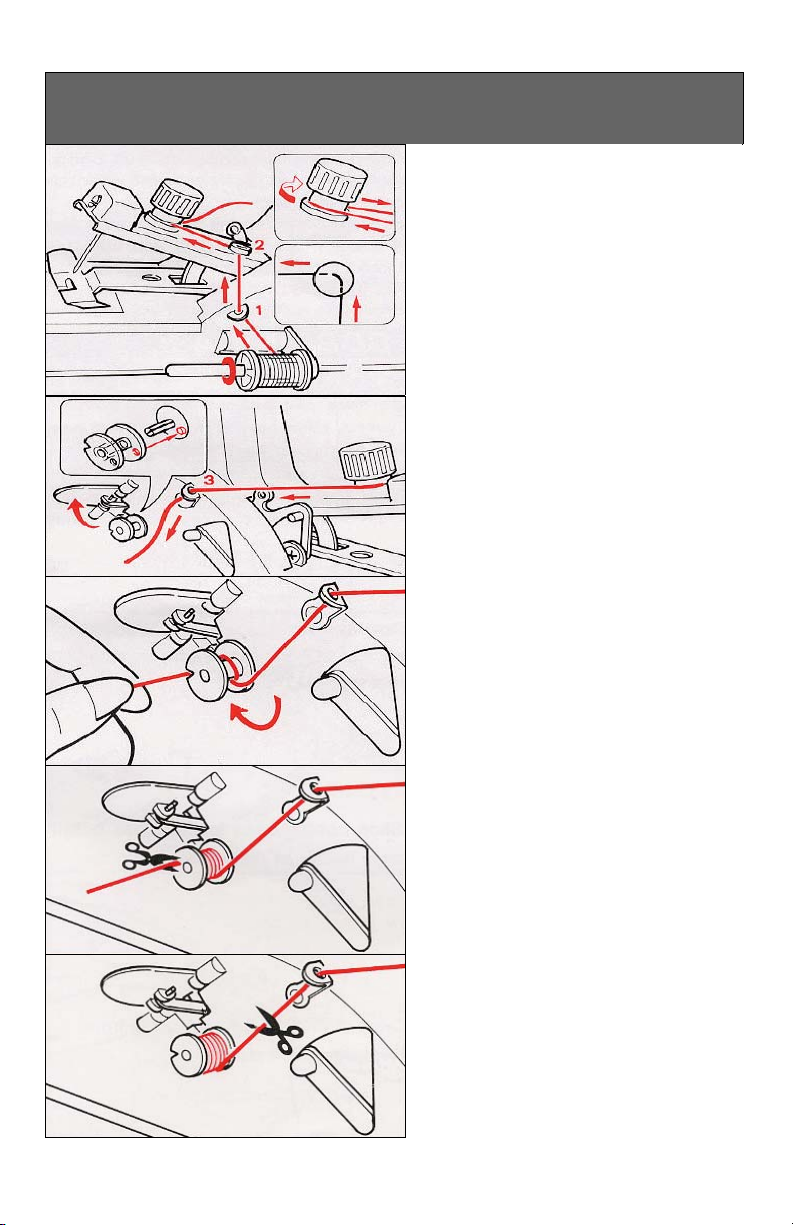

WINDING A BOBBIN

x Place spool of thread onto spool pin.

x Press spool holder ring against spool.

CAUTION: Spool of thread

should be rotated freely after

pressing the holder ring on.

x Lead thread to Guidepost (1) and draw

to the left under pretension stud (2).

x Draw thread between the two tension

discs of thread tension dial, then pull

thread to right as shown.

x Follow arrows. Guide thread through

guidepost (3).

x Open the bobbin winder cover and in-

sert a bobbin.

x Align the small bobbin hole on pin of

bobbin winder.

x Follow arrows. Manually wind thread

clockwise around the bobbin 3-5 turns,

then pass thread through the notch.

x Still holding end of thread, push on/off

switch and start to wind

x Trim the end of the thread after bobbin

is wound around a few times.

x Continue to wind bobbin until desired

amount is reached and cut thread.

CAUTION: Do not over-wind bobbin.

Over-winding causes thread jamming of

bobbin case.

5

(5-10 winds)

Page 7

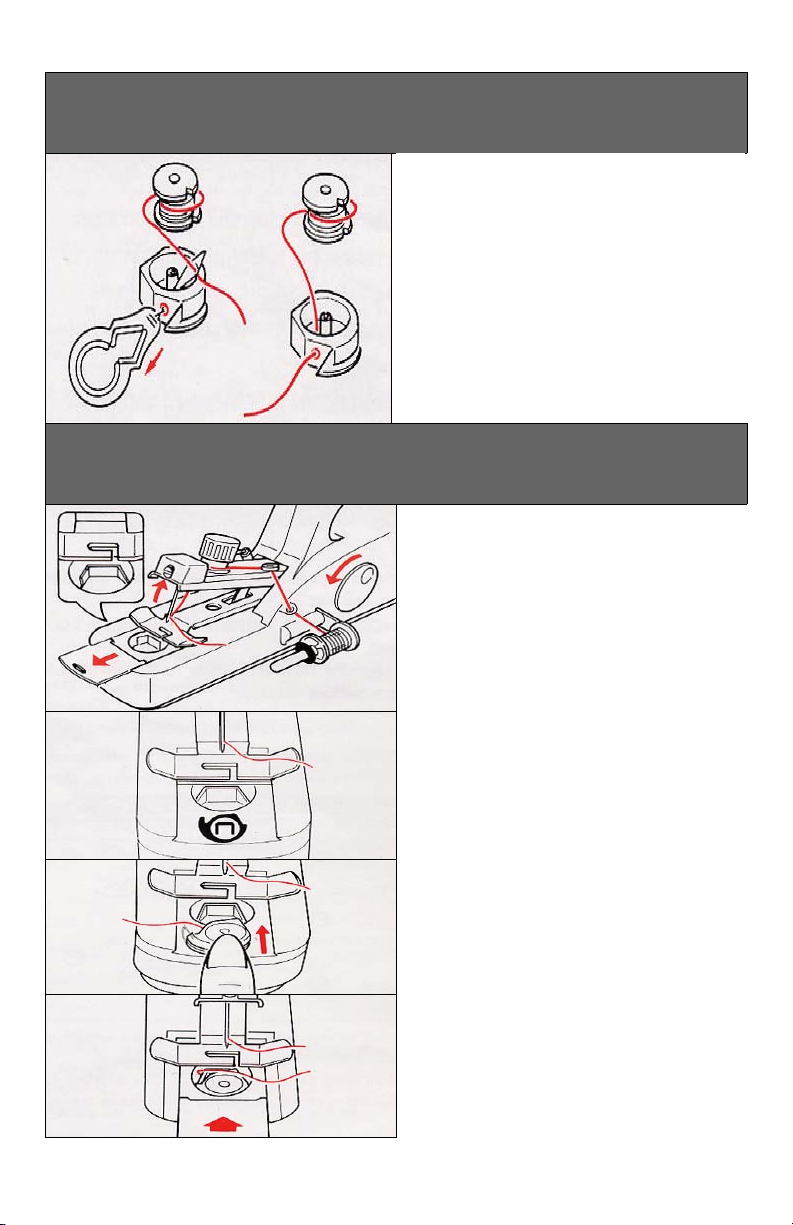

THREADING THE BOBBIN

x Use needle threader to pull bobbin

thread (bottom) from inside of bobbin

case hole

x Position bobbin in bobbin case and draw

2-3 inches of thread. You will feel thread

tension force while drawing.

CAUTION: Bobbin case tension was preset at factory and is not adjustable.

INSERTING THE THREADED BOBBIN CASE

x Be sure that the bobbin winder cover

is closed, raise needle to its highest po-

sition by turning hand wheel counter

clockwise.

x Fully open slide plate, and make sure

bobbin case holder is parallel to presser

foot edge by rotating hand wheel

slightly.

x Position and place threaded bobbin case

as per graphics shown on slide plate recess.

x Slide the bobbin case forward into the

bobbin case holder as arrow shown.

x Pull thread 2-3 inches to the front.

x Replace slide plate.

6

Page 8

REMOVING BOBBIN & BOBBIN CASE

x Be sure that bobbin winder

cover is closed, raise needle to

highest position by turning hand

wheel counter clockwise.

x Fully open slide plate, make sure

bobbin case holder is parallel to

presser foot edge by rotating

hand wheel slightly.

x Shake machine head to throw

the bobbin case out from its recess.

x Using a pin, insert into the hole

at the bottom of the bobbin case

and push bobbin out of bobbin

case.

7

Page 9

THREADING THE MACHINE

x Place spool of thread onto spool pin.

x Press spool holder ring against spool.

CAUTION: Spool of thread should be rotated freely after pressing the holder ring

on.

x Pull thread to Guidepost (1) and draw it

to left, under pretension stud (2).

x Draw thread between two tension discs

and then pull to right as shown.

x Follow arrows, guide thread into take-up

lever eyelet (3) and then backwards to

wire loop (4).

x Top view of threading.

x Slip thread through (5).

x Insert needle threader through needle

eye and pull thread through needle eye.

x Pull thread 2-3 inches to the front.

8

Page 10

RAISING THE BOBBIN THREAD

x Hold the needle thread (top) and

turn hand wheel counterclockwise

to lower needle, then raise to

highest position.

x Gently pull needle thread (top)

until bobbin thread (bottom)

comes up and forms a loop.

x Use a pin to pull up bobbin thread

loop (bottom).

x Place bobbin thread (bottom) un-

der presser foot.

9

Page 11

ADJUSTING THREAD TENSION

NOTE: Your machine’s tension has been

calibrated to ”5” in the factory to suit most

sewing applications.

x Always double check threading before

attempting to adjust thread tension.

x Make a test sample to find proper tension

before sewing on your fabrics.

A balanced stitch:

x A perfect, well balanced stitch will have

needle thread (top) and bobbin thread

(bottom) locked between two layers of

fabric with no loops on top or bottom and

no puckering.

Too much tension:

x Stitch locks appear on top side of fabric.

x To decrease tension, turn dial to a lower

number.

Too little tension:

x A loose stitch appears on bottom side of

fabric.

x To increase tension, turn dial to a higher

number.

10

Page 12

START TO SEW—HANDHELD OPERATION

x Insert four AA batteries or use bonus AC

adapter.

x Open dust cover.

x Raise needle to highest position by turn-

ing hand wheel counterclockwise.

x Move presser foot lift lever up to raise

presser foot.

x Place fabric under presser foot.

x Draw both the needle thread (top) and

the bobbin thread (bottom) 2-3 in. to the

left.

x Move presser foot lift lever down to

lower presser foot.

x Close dust cover.

11

x Press and hold the on/off switch.

x Guide fabric gently while sewing

x At the end of the seam, move presser

foot lift lever up to raise presser foot.

x Pull threads 2-3 in. forward, then cut.

Page 13

START TO SEW—TABLE-TOP OPERATION

x Insert four AA batteries or plug in bonus

AC adapter.

x Open dust cover.

x Raise needle to its highest position by

turning the hand wheel counterclockwise.

x Insert stabilizer when sewing heavier

fabrics.

x Move presser foot lift lever up to raise

presser foot.

x Place fabric under the presser foot.

x Draw both the needle thread (top) and

the bobbin thread (bottom) 2-3 in. to the

right.

x Move presser foot lift lever down to

lower presser foot.

x Plug foot pedal into back of unit.

x To begin sewing, slowly step on pedal.

x Hold onto both fabric ends while sewing

x At end of seam, move presser foot

lever up to raise the presser foot.

x Pull threads 2-3 in. forward, then cut.

12

Page 14

START TO SEW—HANDHELD OPERATION

x Insert four AA batteries or use bonus AC

adapter.

x Open dust cover.

x Raise needle to highest position by turn-

ing hand wheel counterclockwise.

x Move presser foot lift lever up to raise

presser foot.

x Place fabric under presser foot.

x Draw both the needle thread (top) and

the bobbin thread (bottom) 2-3 in. to the

left.

x Move presser foot lift lever down to

lower presser foot.

x Close dust cover.

11

x Press and hold the on/off switch.

x Guide fabric gently while sewing

x At the end of the seam, move presser

foot lift lever up to raise presser foot.

x Pull threads 2-3 in. forward, then cut.

Page 15

SECURING A SEAM

There are 2 methods for securing the threads:

Method #1: Back Stitching

x At start of seam, sew 1/2 in., then pull

fabric backwards to sew 4-5 back

stitches.

x Hold both fabric ends and continue sew-

ing forward to complete seam. Secure

end of seam by backstitching again.

Method #2: Tying Off

x When the seam is completed, use nee-

dle threader to pull needle thread (top)

to underside of fabric.

DARNING

13

x Tie a square knot with both threads un-

derside of the fabric.

x Place the area to be darned under

presser foot.

x Lower the presser foot and start stitch-

ing.

x Alternately guide fabric toward you and

gently pull it away from you.

x For additional strength, cover parallel

stitching area with crosswise stitching.

Page 16

TURNING A SQUARE CORNER

x Upon reaching the desired position, stop

stitching with the needle tip still in the

fabric.

x Move presser foot lift lever up.

x Turn fabric.

x Move presser foot lift lever down.

x Continue stitching the seam.

CHANGING NEEDLES

x Loosen needle clamp screw with a screw-

driver

x With flat shank face to the left side, insert

a new needle up into clamp as far as it

will go.

x Tighten needle clamp screw securely.

HOW TO REPLACE THE SLIDE PLATE

x Make sure dove tail side is facing up and

align slide plate to grooves.

14

Page 17

PERFORMANCE CHECKLIST

If stitch is not formed:

x Needle is not fully inserted into the needle clamp body.

x Needle is inserted into the wrong side.

x Needle is defective.

x Bobbin thread (bottom) is not threaded correctly into the bobbin case hole.

If machine skips stitches:

x Needle is not straight and sharp.

x Needle is inserted on wrong side.

x Machine is not properly threaded.

x Fabric is not firmly held down.

If needle thread (top) breaks:

x Machine is not properly threaded.

x Needle thread (top) tension is too tight.

x Thread is not freely unwinding from spool.

x Needle is inserted on wrong side.

If bobbin thread (bottom) breaks:

x Bobbin thread (bottom) is too tight.

x Thread is entangled in bobbin case.

x Bobbin thread (bottom) is threaded incorrectly into bobbin case.

If fabric does not feed:

x Presser foot is not lowered.

If needle breaks:

x Needle is defective.

x Needle is not inserted fully into needle clamp body.

x Fabric is pulled excessively while sewing.

x Needle thread (top) is caught somewhere.

x Needle thread (top) tension is too tight.

If needle does not move:

x Battery power is weak.

x Batteries are not inserted correctly.

x Foot switch plug is not inserted fully.

15

Page 18

TURNING A SQUARE CORNER

x Upon reaching the desired position, stop

stitching with the needle tip still in the

fabric.

x Move presser foot lift lever up.

x Turn fabric.

x Move presser foot lift lever down.

x Continue stitching the seam.

CHANGING NEEDLES

x Loosen needle clamp screw with a screw-

driver

x With flat shank face to the left side, insert

a new needle up into clamp as far as it

will go.

x Tighten needle clamp screw securely.

HOW TO REPLACE THE SLIDE PLATE

x Make sure dove tail side is facing up and

align slide plate to grooves.

14

Page 19

LIMITED WARRANTY

Top Innovations, Inc. will repair or replace, at its

option, without charge to the consumer any SEW PRO

product that fails, due to defect in material or workmanship

within 90 days following the initial consumer purchase.

This warranty does not cover damage caused by

commercial use, misuse, alteration, or modification.

Performance of any obligation under this warranty may

be obtained by returning warranted product with purchase

receipt, freight prepaid to:

®

TOP INNOVATIONS, INC.

Warranty Service Department

400 NW Platte Valley Drive

Riverside, MO 64150

If you have any questions about coverage under

this warranty, you may contact the Warranty Service

Department by telephone at (800) 711-6617 or e-mail

customerservice@topinnovations.com.

This warranty gives you specific legal rights, and

you may also have other rights which vary from state to

state.

16

Page 20

Notes19Notes

Page 21

20

Page 22

Top Innovations, Inc.

400 NW Platte Valley Drive Ɣ Riverside, MO 64150

(800) 711-6617 (816) 584-9700 Fax: (816) 584-9066

www.topinnovations.com

Printed in China

Loading...

Loading...