TOP GUN WELDING TIG180D Assembly And Operating Instructions Manual

THANKS FOR PURCHASING OUR PRODUCT

ASSEMBLY AND OPERATING INSTRUCTIONS

INVERTER

DC TIG/ PULSE TI G /DC MMA

WELDING MACHINE

(be suitable for 1x220~240V)

SAFETY PRECAUTIONS

Follow these precautions carefully. Improper use of any welder can

result in injury or death.

1. ONLY CONNECT WELDER TO A POWER SOURCE FOR WHICH IT WAS

DESIGEND . The sp ecifi cati on pla te on the we lder li sts thi s infor matio n. When weld ing o utdo ors

only use an extension cord intended for such use.

2. ONLY OPERATE WELDER IN DRY LOCATIONS and on cement or masonry floor. Keep

area cl ean and uncluttered.

3. KEEP ALL COMBUSTIBLES AWAY FROM WORK SITE.

4. DO NOT WEAR CLOTHING THAT HAS BEEN CONTAMINATED with grease or oil.

5. KEEP CABLES DRY AND FREE FROM OIL AND GREASE and never coil around

shoulders.

6. SECURE WO R K WI TH CL AM P S or other me ans; don 't over reach when wo r k ing.

7. NEVER ST RIKE AN ARC ON A COMPRESS ED GAS CYLINDER

8. DON'T ALLOW THE INSULATED PORTION OF THE ELECTRODE HOLDER TO

TOUCH THE WELDING GROUN D WHI LE CU RREN T I S FLOWING.

9. SHUT OFF POWER AND UNPLUG MACHINE WHEN REPAIRING OR ADJUSTING.

Inspect before every use. Only use identical replacement parl.

10. FOLLOW ALL MANUFACTURER'S RULES on operating switches and making

adjustments.

11. ALWAYS WEAR PROTECTIVE CLOTHING when welding . This includes: long sleeved

shirt(leather sleeves), protective apron without pockets, long protective pants and boots. When

hand ing ho t materials, wear asb estos gloves.

12. ALWAYS WEAR A WELDER'S HELMET WITH PROTECTIVE EYE PIECE when

weld ing. Arcs may cause bli ndness. Wear a protecti ve cap underneath the helmet.

13. WHEN WELDING OVERHEAD, BEWARE OF HOT METAL DROPPINGS. Always

protect the head, hand , feet and body.

14. KEEP A FIRE EXT INGUISHER CLOSE BY AT ALL TIMES.

15. DO NOT EXCEED THE DUTY CYCLE OF THE MACHINE. The rated cycle of a welding

machin e is the percentag e of a te n minute pe riod th at the ma chine can operat e safely at a giv en

output setting.

16. KEEP ALL CHILDREN AWAY FROM WORK AREA. When storing equipment, make

sure it is out of reach of ch ildren.

17. GUARD AGAINST ELECTRIC SHOCK. DO not work when tired. Do not let

body come

In' c ontact with grounded surfaces.

1. MAIN USAGE AND THE RANGE OF USAGE(APPLICATIONS):

TIG180D inverse argon arc welder with international advanced technology is a new variety

of wel ding ma chine u sing MOSF ET(or IG BT). It has pe rforman ce and hi gh eff icien cy that the

tradit ional we lder can not be compared with. TIG1 80D weld er is triple fun ctiona l machin e

used as MMA/DC TIG,PULSE TIG welder. The welding current and pulse frequency is all

infinitely and independently adjustable. All ferrous metal, copper and stainless steel material can

be omnibear ing wel ding in all po si tion.T he weld ing cur rent is st able. The wel ding se am i s

nic e.few spat ters and low nois e occurs duri ng weldin g.It ha s high fre quency arc stri king.

The welder has outstanding feature of minimum current. The minimum current can be up to

5A.Protection measures of the welder are perfect. The welder is reliable,light in weight and

easy to use. It is particularly suitable for enterprise of plant and mine, build, decoration and

maintenance sectors.

2. MAIN TE CH NICA L SP EC IF I C AT IO NS

3. OPERATING CONDITION AND WORK SURROUNDING

1. Operating condit ion:

±

Voltage of power source: AC220/230/240V 10%

Model TIG180D

Power Supply Voltage AC 220/230/240V 50Hz

No-load Voltage 70V

Rated Output Cu rrent 180A

Rated Duty Cycle 35%

Peak Cu r. Adjustin g R an ge

5-180A(TIG)

5-160A(Stick)

base Amps 5-180A

Start cu rren t 5~150A

End cu rrent 5~150A

Pulse Widt h Ratio 5%-95%

Pulse Frequency 0.5 - 50 0Hz

TIG Arc starting mode high frequency arc striking

Up-slope,Down-slope time 0-25 S

Pre Flow Time 0~10S

Post Flow Time 0~25S

Mass 9.8kg

Protection Class of enclosure I P21S

Frequency: 50/60Hz

Reliable grounding protection

2. Work surrounding

≤≤℃

(1) relati ve humidity: 90%(aver age mo nthly t emperature 20 )

℃℃

(2) ambien t tempe rat ur e: -10 - 40

(3) The welding site should have no harmful gas, chemicals, molds and inflammable matter,

explosive and corrosive medium, no big vibration and bump to the we lder.

(4) Avoiding rain water. Operating in rain is not allowed.

4. DESC RIPTION OF THE ERECTION

a. Before w e l d in g , t h e operat or sho uld re ad the operation instr uction s and us es the w elder

correctly according to the process specification.

b. Checking the welder appearance for deformation and damage.

c. Fo r the safety of the equipment and the persons, the c u stomer must correctly make grounding

or pr otecting accord ing to the pow er supply system: using 4 mm

2

lead to connect the protection

grou nding of the welder.

d. Welding operation should be carried out in dry and good ventilating area. The surrounding

objects should be not less than 0.5m away from the welder.

e. Checking the welder output connector for tightness.

f. The welder can not be moved or the cover can not be opened during the power is on and

weld ing operati on is car ried out .

g. The weld er should be cared,used and managed by specialized person.

h. Confirmin g that the po we r so urce is 220

/230/240V

It can not be connected with 380V power abso lutely.

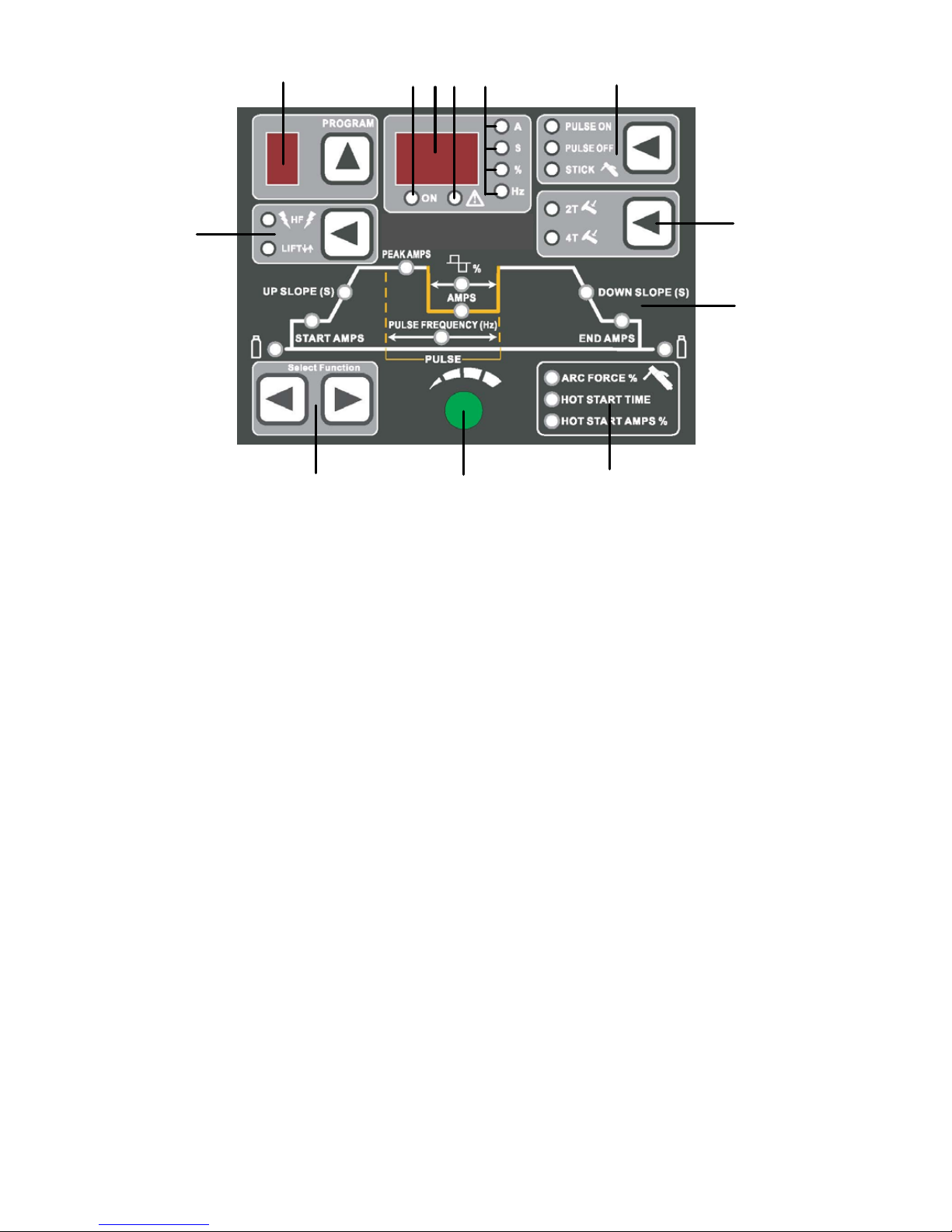

5. SKETCH OF THE PANEL FUNCTION

1. FRONT PANEL 2. BACK PANEL

20

24

21

22

7 8

4

9

10

1113

3

5

6

15

15

16

17

18 16

1

12

19

26

23

TIG180D

1.

Memory ch an el LED

2.

Data Display meter

3. Parameter Select function

4.indicating light of power

5. A --

unit of cur rent

S --

unit of up & downs lope time & pre& post flow ti me

% --

unit of

peak time on

Hz--

unit of

pulse freq.

(6. indicating light of Parameter Select function Pre-flow /Start current/Up slope/Welding Amps/Pulse peak amps/

peak time on/ pulse freq./down slope/end current/post flow)

8.warning indica t ing light

()9.indicating light of MMA Parameter Select function arcforce slector /Hot start time/hot start amp

10.Pulse on /pulse off/MMA sl ector

11.HF/LIFT sl ector

12. 2 steps/ 4 steps slector

13.

Data Display Adjustme nt Knob

() ( )15. output"-" Ground clamp 16. output"+" Welding holder

17.argon out 18.argon arc control (or remote control)

19.nameplate 20. power switch

21.argon inlet 22.power supply

23.safety earthing column 24.fan

12

3

4

6

13

10

11

12

8

9

5

TIG180D

Loading...

Loading...