TOP GUN WELDING AC/DC200D Operating Manual

THANKS FOR PURCHASING OUR PRODUCT

DC INVERTER

AC TIG/DC TIG/MMA

WELDING

MACHINE

OPERATING MANUAL

(

SUITABLE FOR 1x220V~240V

)

SAFETY PRECAUTIONS

Follow these precautions carefully. Improper use of any welder can

result in injury or death.

1. ONLY CONNECT WELDER TO A POWER SOURCE FOR WHICH IT WAS DESIGNED.

The specification plate on the welder lists this information. When welding outdoors, only use an

extension cord intended for such use.

2. ONLY OPERATE WELDER IN DRY LOCATIONS and on concrete floor. Keep area clean and

uncluttered.

3. KEEP ALL COMBUSTIBLES AWAY FROM WORK SITE

4. DO NOT WEAR CLOTHING THAT HAS BEEN CONTAMINATED with grease or oil.

5. KEEP CABLES DRY AND FREE FROM OIL AND GREASE and never coil around shoulders.

6. SECURE WORK WITH CLAMPS or other means; don't over reach when working.

7. NEVER STRIKE AN ARC ON A COMPRESSED GAS CYLINDER

8. DON'T ALLOW THE INSULATED PORTION OF THE ELECTRODE HOLDER TO TOUCH

THE WELDING GROUND WHILE CURRENT IS FLOWING.

9. SHUT OFF POWER AND UNPLUG MACHINE WHEN REPAIRING OR ADJUSTING. Inspect

before every use. Only use identical replacement parts.

10. FOLLOW ALL MANUFACTURER'S RULES on operating switches and making adjustments.

11. ALWAYS WEAR PROTECTIVE CLOTHING when welding. This includes: long sleeved

shirt (leather sleeves), protective apron without pockets, long protective pants and boots. When

handling hot materials, wear asbestos gloves.

12. ALWAYS WEAR A WELDER'S HELMET WITH PROTECTIVE EYE PIECE when welding.

Arcs may cause blindness. Wear a protective cap underneath the helmet.

13. WHEN WELDING OVERHEAD, BEWARE OF HOT METAL DROPPINGS. Always protect

the head, hand, feet and body.

14. KEEP A FIRE EXTINGUISHER CLOSE BY AT ALL TIMES.

15. DO NOT EXCEED THE DUTY CYCLE OF THE MACHINE. The rated cycle of a welding

machine is the percentage of a ten minute period that the machine can operate safely at a given

output setting.

16. KEEP ALL CHILDREN AWAY FROM WORK AREA. When storing equipment, make sure it is

out of reach of children.

17. GUARD AGAINST ELECTRIC SHOCK. Do not work when tired. Do not let body come in

contact with grounded surfaces.

I.

MAIN USAGE AND THE RANGE OF USAGE

AC/DC200D Welder is a triple functional machine used as DC MMA, AC TIG, DC/PULSE TIG

Welder. All ferrous metals, copper, aluminium, titanium and stainless steel material can be welded

from all positions. The welding current is stable and the stepless is adjustable. Few spatter and low

noise occurs during welding. The welder is compact, light in weight and easy to move. It is suitable

for pressure vessel, building, shipping and petrochemical industries. It is the priority product to replace

the NSA series welding machine.

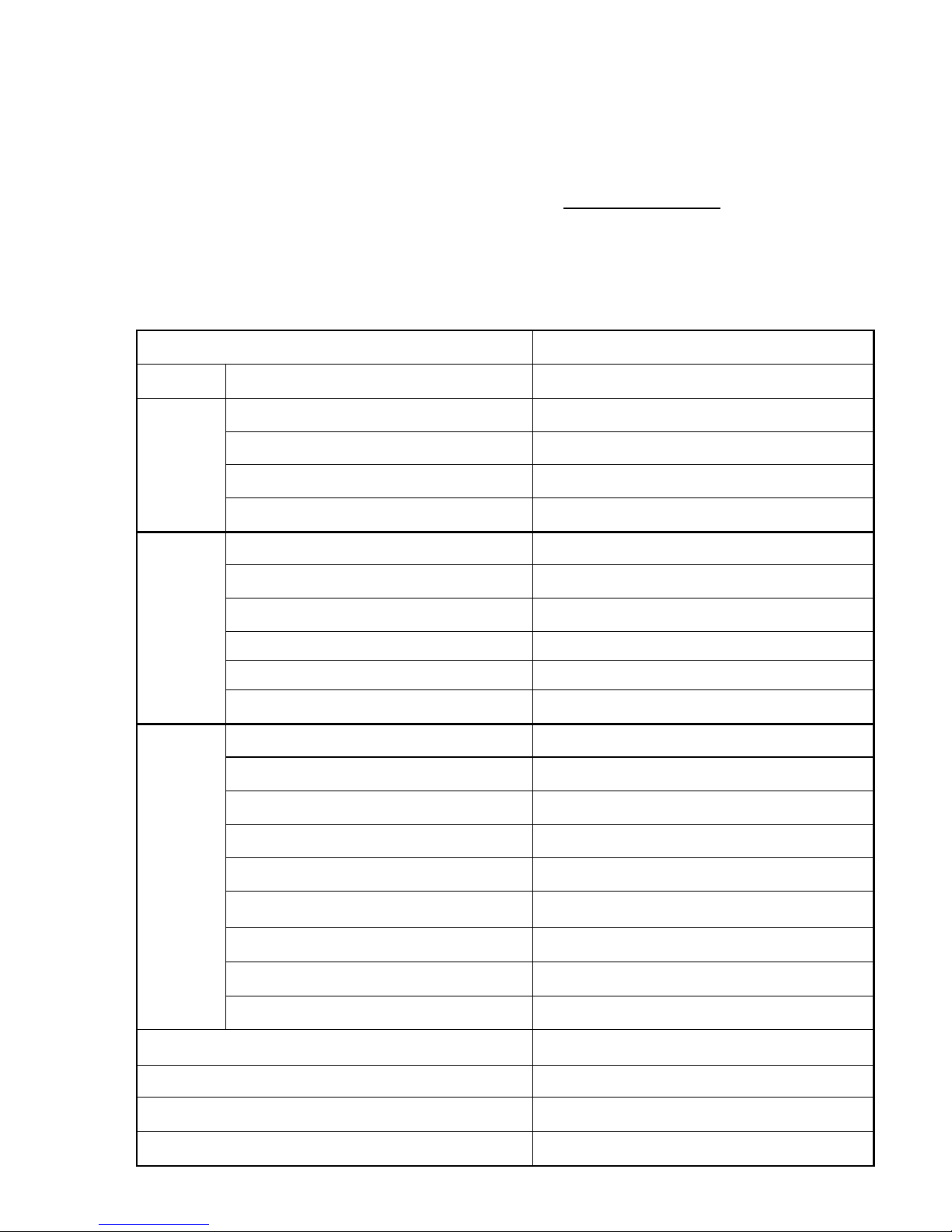

MAIN TECHNICAL SPECIFICATIONS

MODEL

AC/DC200D

INPUT

Voltage

AC 220/230/240V 50Hz

DC

MMA

No-load Voltage

70V

Base current Adjusting Range

5~160A

Rated Output Current

160A

Rated Duty Cycle

35%

AC

TIG

No-load Voltage

70V

Current Adjusting Range

20~200A

Initial current/crater-fill current

20-150A

SP % (AC balance)

10~90

AC Square Wave Frequency

20~150Hz

Rated Duty Cycle

60%

DC

PULSE

TIG

BASE/PULSE Current Adjusting Range

5~200A

Rated Duty Cycle

35%

Current UP/Down-slope Time

0~10S

Pulse freq.

0.5~25Hz

Pulse width

5%~95%

Initial current/crater-fill current

10A~150A

Pre gas Flow Time

0~10s

Post gas Flow Time

0~25s

Arc starting Mode

high frequency arc striking

Efficiency

≥

80%

Mass

25kg

Protection Class of enclosure

IP21S

Outline Dimensions mm

3

430x200x290

4 3 16

7 8

26

6

5

15

13 11 19

9

10 1

12

OPERATING CONDITIONS AND WORK SURROUNDING

1. Operating condition:

Voltage of power source: AC 220 V/230V/240V。

Frequency: 50/60Hz

Reliable grounding protection

2.Work environment

① Relative humidity: not more than 90 %( average monthly temperature not more than 20C);

② Ambient temperature:-10C - 40C;

③ The welding site should be free of harmful gases, chemicals, molds and flammable, explosive

or corrosive materials;

④ Avoid operating in damp or wet conditions

OPERATING INSTRUCTIONS

1. Before welding, the operator should read the operation instructions.

2. Check the welder appearance for any damage before operation.

3. To ensure safe operation, the welder must be grounded correctly according to your local

power supply system using a 4mm

2

lead to connect the welder to the ground.

4. Welding should only be carried out in dry and well ventilated areas. Surrounding objects should

not be less than 0.5m away from the welder.

5. Check the welder output connector for tightness.

6. The welder cannot be moved and the cover cannot be opened while the power is on and

welding operation is carried out.

7. The welder should be cared for, used and managed by trained personnel.

8. Current of the distribution board: not less than 40A

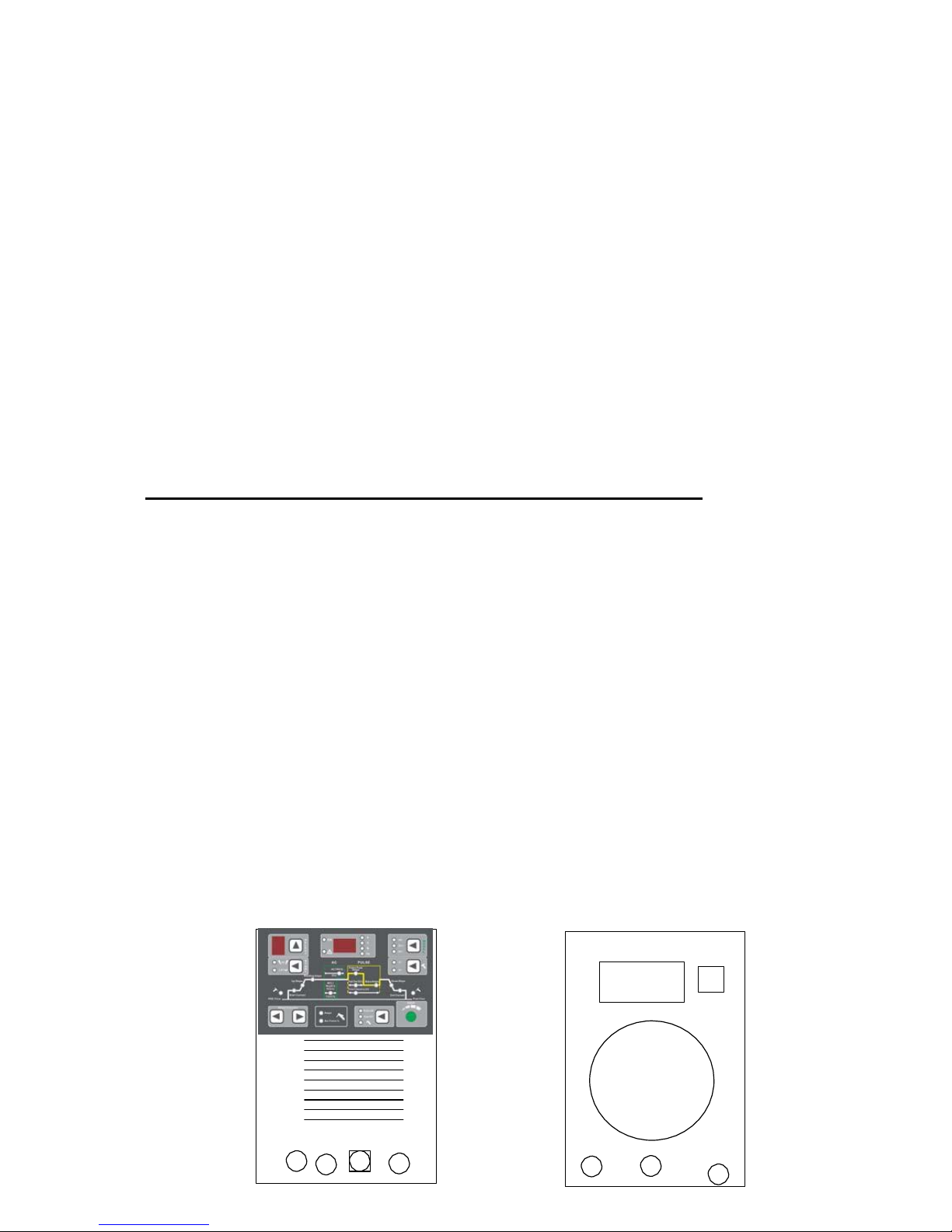

SKETCH THE PANEL FUNCTION

1. FRONT PANEL 2. BACK PANEL

19

20

24

15

17

18 16

23

21

22

Loading...

Loading...