Top Gin TG250, TG300 User Manual

Notes:

Upon receipt of the inverter and before any operation, please carefully read this instruction manual

thoroughly, also keep this manual for reference in the future. If you have any question or problem,

please no hesitate to contact your local SHANGCHIN representative. Thanks!

PREFACE

TOP GIN TG-300 is an optimized inverter specifically designed for variable torque applications.

This instruction manual describes installation, maintenance and inspection, troubleshooting, and

specifications of the TG-300 Read this instruction manual thoroughly before operation.

SHANGCHIN ELECTRONICS CORP.

General Precautions

●Some drawings in this manual are shown with the protective cover or shields removed, in order to

describe detail with more clarity. Make sure all covers and shields are replaced before operating this

product.

●This manual may be modified when necessary because of improvement of the product,

modification, or changes in specifications.

Such modifications are denoted by a revised manual

●To order a copy of this manual, if your copy has been damaged or lost, contact your SHANGCHIN

representative.

●SHANGCHIN is not responsible for any modification of the product made by the user, since that

will void your guarantee.

1

CONTENTS

1 RECEIVING ··············································································································4

1.1 INSPECTION CHECKPOINTS ··························································································· 4

1.2 IDENTIFYING THE PARTS································································································5

2 INSTALLATION·······································································································6

2.1 LOCATION FOR THE INVERTER ·····················································································6

2.2 CLEARANCES ····················································································································7

3 WIRING······················································································································8

3.1 CONNECTION DIAGRAM································································································· 9

3.2 WIRING THE MAIN CIRCUIT ··························································································· 10

3.3 WIRING THE CONTROL CIRCUIT ··················································································· 13

3.4 WIRING INSPECTION········································································································ 14

4 OPERATION··············································································································15

4.1 OPERATION MODE SELECTION ····················································································· 16

4.2 TEST RUN CHECKPOINTS································································································ 17

4.3 SETTING THE LINE VOLTAGE USING JUMPER

(FOR 440V CLASS 18.5kW AND ABOVE) ··················································································· 17

4.4 TEST RUN···························································································································· 18

5 SIMPLE DATA SETTING ·······················································································23

5.1 DIGTAL OPERATOR KEY DESCRIPTION ······································································· 23

5.2 LED DESCRIPTION ············································································································ 24

6 PROGRAMMING FEATURES ··············································································26

6.1 CONSTANT SET-UP AND INITALIZATION ·····································································26

6.2 V/F PATTERN SETTING ····································································································· 26

6.3 OPERATION CONDITIONS ······························································································· 29

6.4 STOPPING METHOD·········································································································· 43

6.5 INTERFACE CIRCUITS WITH EXTERNAL DEVICES···················································· 46

6.6 ADJUSTING MOTOR TORQUE························································································· 56

6.7 MOTOR PROTECTION······································································································· 57

6.8 PID CONTROL ····················································································································59

6.9 ENERGY SAVING CONTROL···························································································· 61

6.10 MODBUS CONTROL·········································································································· 63

2

7 MAINTENANCE AND INSPECTION ··································································64

7.1 PERIODIC INSPECTION ···································································································· 65

7.2 PARTS REPLACEMENT SCHEDULE (GUIDELINES)····················································· 65

8TROBULESHOOTING·····························································································66

8.1 FAULT DIAGNOSIS AND CORRECTIVE ACTIONS ·······················································66

8.2 ALARM DISPLAY AND EXPLANATION ·········································································69

8.3 MOTOR FAULTS AND CORRECTIVE ACTIONS ···························································· 70

APPENDIX 1 SPECIFICATIONS ·············································································71

APPENDIX 2 DIMENSIONS (mm)···········································································72

APPENDIX 3 TYPICAL CONNECTION DIAGRAM···········································73

3.1 BRAKING RESISTOR UNIT······························································································· 73

3.2 BRAKING UNIT AND BRAKING RESISTOR UNIT ························································ 74

APPENDIX 4 CONSTANT LIST···············································································75

APPENDIX 5 DIGT AL OPERATOR MONITOR DISPLAY ································81

BRAKING UNIT APPLICATION LIST···································································83

SEPARATELY -INSTALLED TYPE BRAKING RESISTOR································84

3

1. RECEIVING

SOURC

CAUTION

●Do not install or operate any inverter which is damaged or has missing parts.

Failure to observe this caution may result in personal injury or equipment damage

This chapter describes how to inspect the inverter after delivery to the user.

1.1 INSPECTION CHECKPOINTS

(1)Receiving Checkpoints

Checkpoints Description

Does the inverter model number correspon

the purchase order?

Are any parts damaged?

Check the model number on the nameplate on the

side of the TG-300

Visually check the exterior and verify that there

was no damage during transport.

Is hardware properly seated and securely

tightened?

Was an instruction manual received?

Remover inverter front cover.

Check all visible hardware with appropriate tools.

TG-300 instruction manual

If any of the above checkpoints are not satisfactory, contact your SHANGCHIN representative.

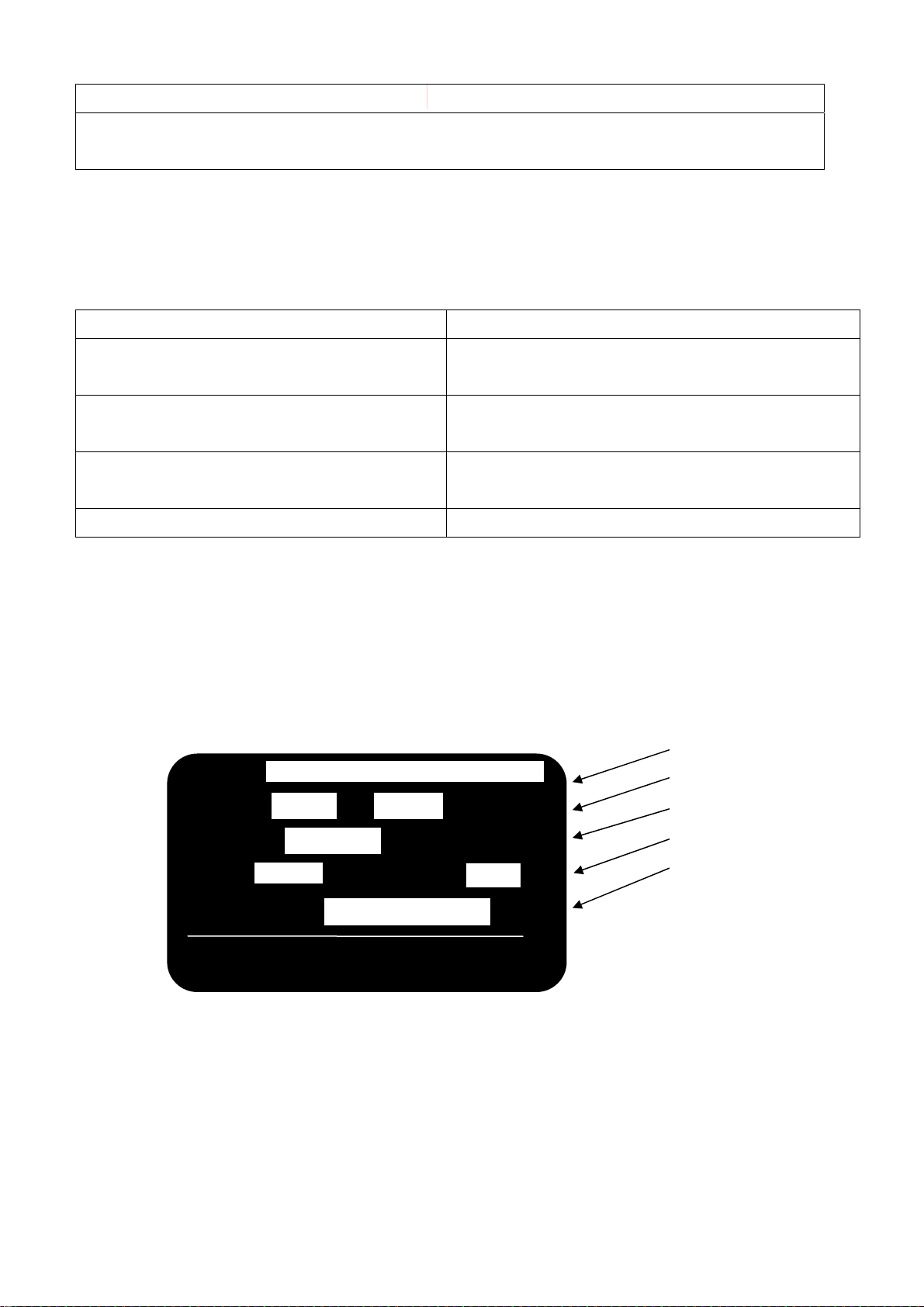

(2)Checking the Nameplate Data

(a)Nameplate Date

Example of TG-300

Model

TG 300 -

E V H z

CAPACITY kVA

Input power supply

Output capacity

Output power supply

Manuf. No.

VOLTS V CURRENTS A

SERIAL NO.

TOP GIN MADE IN TAIWAN

4

●Model Designation

TG – 300 – L 100 – A 2 T 1

TOP GIN

IGBT Series

Symbol Voltage

L

H

Max applicable motor

output (10Hp)

3φ220V Series

3φ440V Series

Symbol Enclosure

Braking

resitstor

A:

Without

B:With

Operator

1 Black

2 Digital with

VR

0 Open shdssis type (IP00)

1 Enclosed wall-mounted type(IP20)

Symbol Specification

T Standard

E CE mark

U UL

3 LCD with VR

1.2 IDENTIFYING THE PARTS

Front Cover

Protective Cover (top/bottom)

4 Mounting Holes

Digital Operator

Ventilation Slots

Flg. 4 Configuration of TG-300

5

2 . INSTALLATION

CAUTION

●Lift the cabinet by the base. When moving the unit, never lift by the front cover.

Otherwise, the main unit may be dropped causing damage to the unit.

●Mount the inverter on nonflammable material (i.e. metal).

Failure to observe this caution can result in a fire.

●When mounting units in an enclosure, install a fan or other cooling device to keep the intake air

temperature below 45℃.

Overheating may cause a fire or damage to the unit.

This chapter describes configuration, location and clearances when mounting the TG-300.

2.1 LOCATION FOR THE INVERTER

To ensure proper performance and long operating life, follow the recommendations below when

choosing a location for installing the TG-300. Make sure the inverter is protected from the following

conditions:

□ Extreme cold and heat.

□ Use only within ambient temperature range:-10℃ to +40℃

□ Rain, moisture. (For enclosed wall-mounted type)

□ Oil sprays, splashes

□ Salt spray

□ Direct sunlight. (Avoid using outdoors.)

□ Corrosive gases or liquids.

□ Dust or metallic particles in the air.(For enclosed wall-mounted type)

□ Physical shock, vibration.

□ Magnetic noise. (Example: welding machines, power devices, etc.)

□ High humidity.

□ Radioactive materials.

□ Combustibles:thinners, solvents, etc.

6

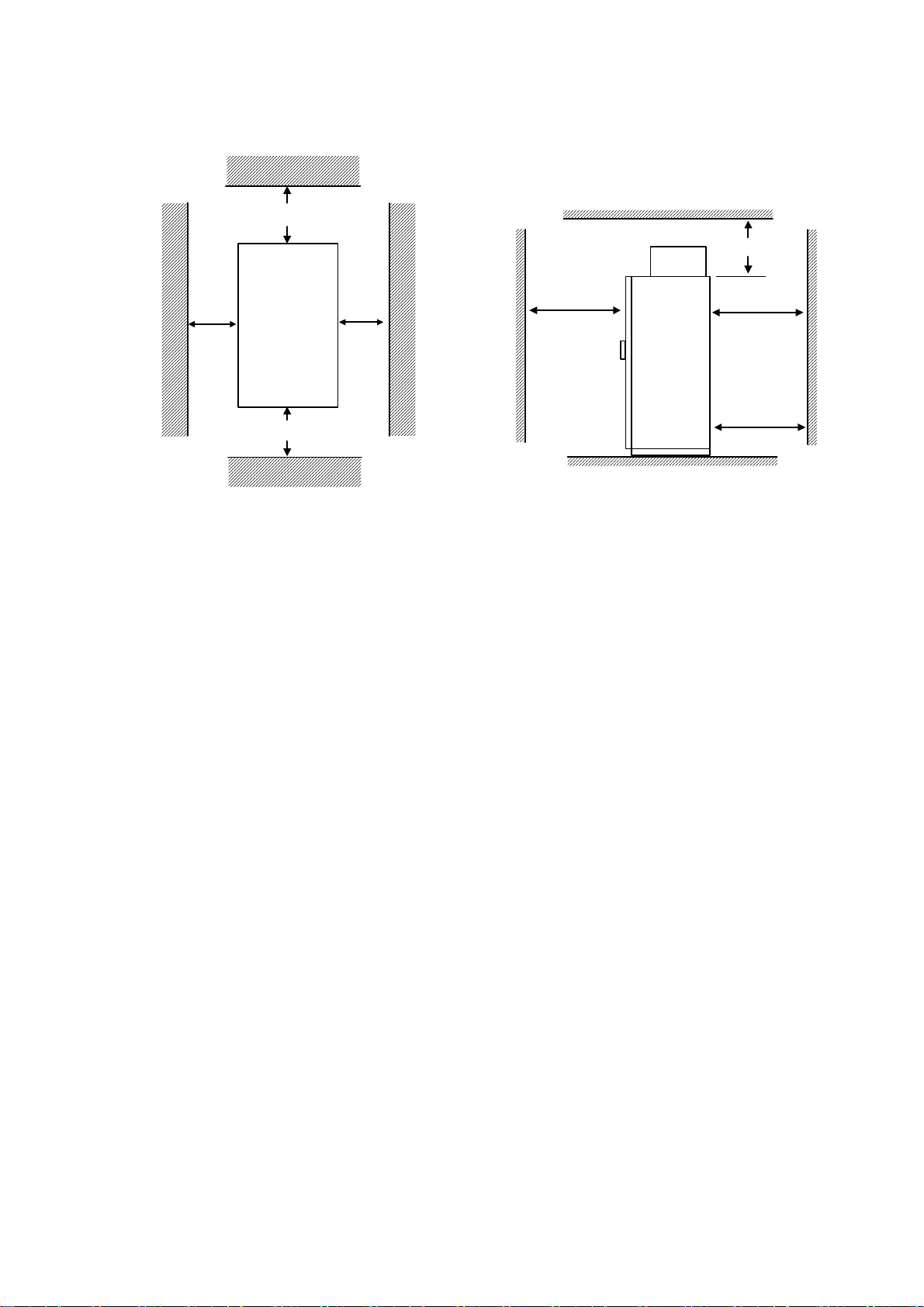

2.2 CLEARANCES

Install the TG-300 vertically and allow sufficient clearances for effective cooling as shown below.

Note:

150mm

Inverter

Front

face

100mm

150

500

Door width

50mm50mm

150

+ 100

500

For

front/rear

door

Door width

+ 100

1.The clearances required at top/bottom and both sides are common in open chassis type (IP00) and

enclosed wall-mounted type (IP20).

2.Remove the top and bottom covers to use the open chassis type of 220V/440V 15Kw or less.

3.For the external dimensions and mounting dimensions, refer to Appendix 2 “DIMENSIONS”.

4.Allowable intake air temperature to the inverter:

●Open chassis type :-10℃ to +45℃

●Enclosed wall-mounted type:-10℃ to +40℃

5. Ensure sufficient space for the sections at the upper and lower parts marked with * in order to permit

the flow of intake/exhaust air to/from the inverter.

7

3. WIRING

WA R IN G

●Only commence wiring after verifying that the power supply is turned OFF.

Failure to observe this warning can result in an electrical shock or a fire.

●Wiring should be performed only by qualified personnel.

Failure to observe this warning can result in an electrical shock or a fire.

●When wiring the emergency stop circuit, check the wiring thoroughly before operation.

Failure to observe this warning can result in personal injury.

CAUTION

●Verify that the inverter rated voltage coincides with the AC power supply voltage.

Failure to observe this warning can result in personal injure or a fire.

●Do not perform a withstand voltage test of the inverter.

It may cause semi-conductor elements to be damaged.

●To connect a braking resistor, braking resistor unit or braking unit, follow the procedures described

in APPENDIX 3.

Improper connection may cause a fire.

●Tighten terminal screws to the specified tightening torque.

Failure to observe this caution can result in a fire.

This chapter describes the main circuit wiring and the control circuit wiring of the TG-300.

8

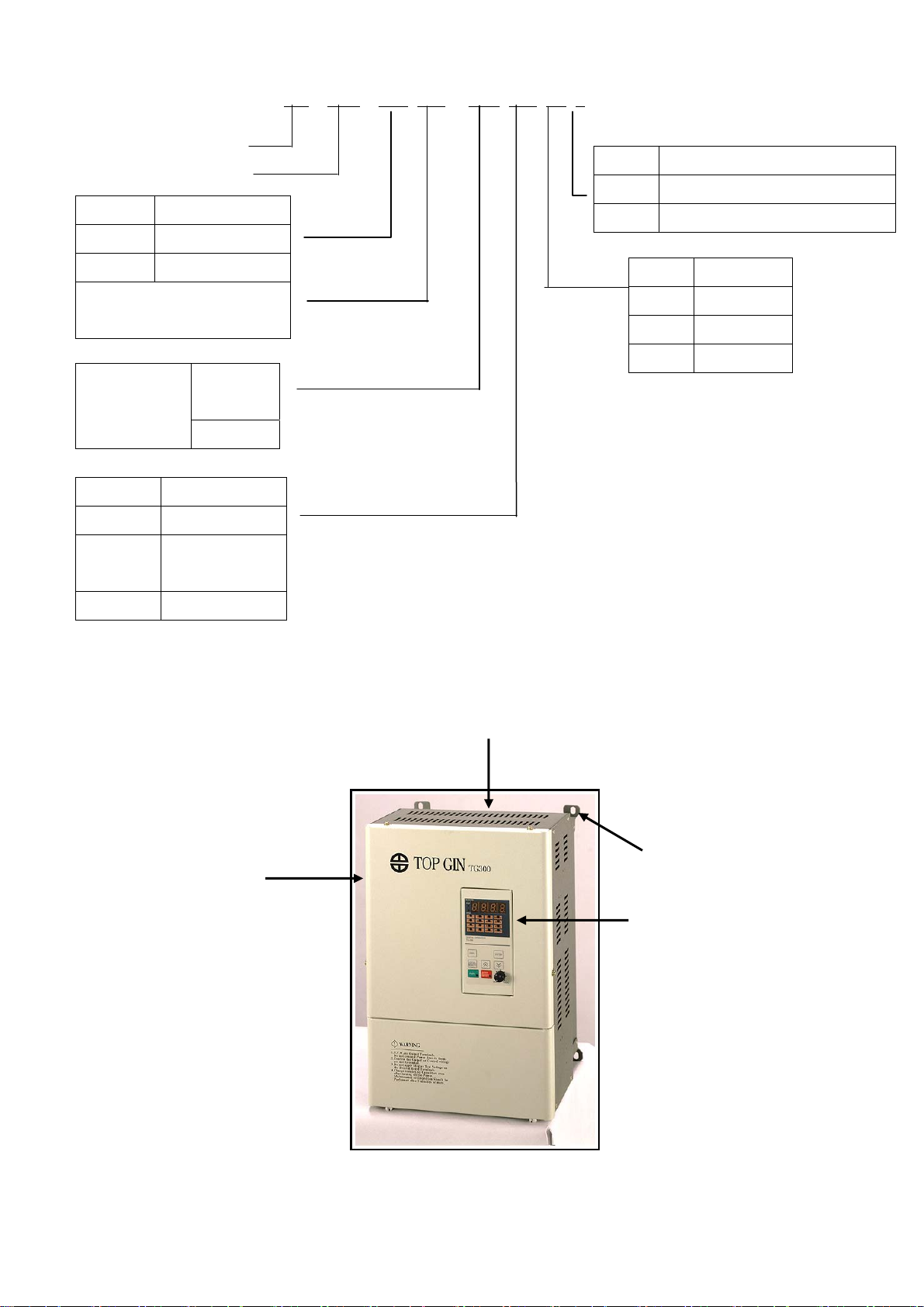

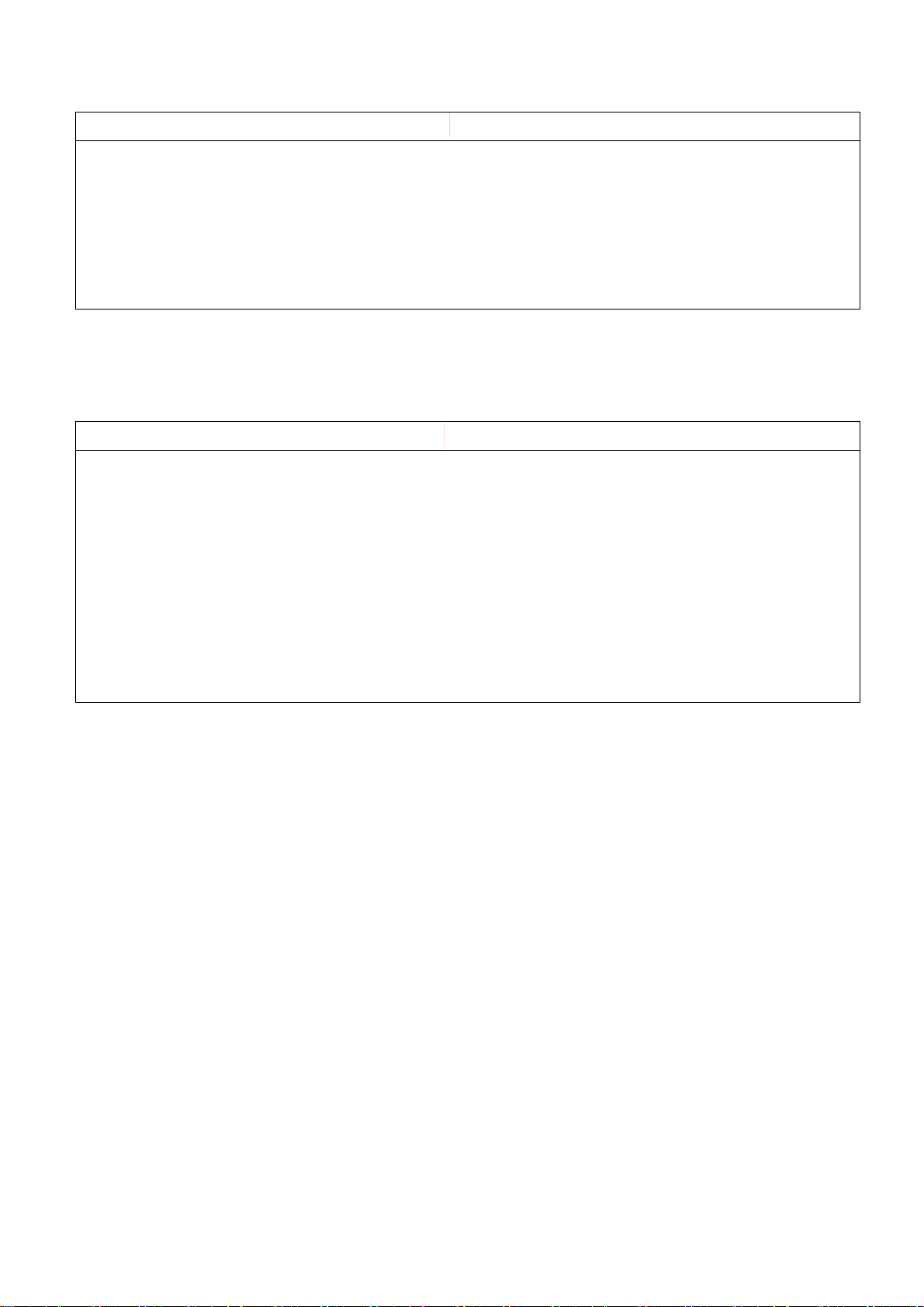

3.1 CONNECTION DIAGRAM

Below is connection diagram of the main circuit and control circuit. Using the digital operator, the

motor can be operated by wiring the main circuit only.

Breaking Resistor (Option)

3-Phase

Power Supply

200 to 240V

345 to 480V

50/60 HZ

Factory

Setting

Master

Frequency

Reference

MCCB

R

S

TL3(T)

Forward Run/Stop

Reverse Run/Stop

External Fault

Fault Reset

Multi-step Speed Setting 1

Multi-step Speed Setting 2

2kΩ

0 to +10V

4 to 20mA

0V

P

P

1

2

B1 B2

L1(R)

L2(S)

S1 Forward Run

when CLOSED

S2

S3

Multi-function

S4

Contact input

S5

S6

Sequence Commom

SC

Terminal (0V)

G

Shield Sheath

Connection

Terminal

Freq. Setting Power

FS

Supply +15V 20mA

FV

Master Freq. Ref.

0 to 10V (20kΩ)

FI

Master Freq. Ref.

4 to 20mA (250Ω)

[0 to 10V(20kΩ)input available]

FC

0V

Analog

Monitor

U(T1)

V(T2)

W(T3)

AM

AC

MA

MB

MC

M2

M3

TG 250

Motor

IM

Ground (100Ω or less)

Multi-function Analog Output 0

to +10V

+

-

(G)

Multi-function Contact Output

Contact Capacity:250 VAC 1A or less

30 VDC 1A or less

(Fault Output Signal at Factory Setting)

M1

Multi-function Contact Output

250 VAC 1A or less

30 VDC 1A or less

(Signal during Running at Factory Setting)

M4

OPEN COLLECTOR OUTPUT

(ZERO SPEED SIGNAL)

(OPTION)

(Output Frequency at Factory

FM

Setting)

TG 300

Connection Diagram

W2

ON OFF

G

S1 S2 S3 SC SC S4 S5 S6 FV FI FS FC AM AC M1 M2 MA MB MC

VR SET HZ W2 OFF

REMOTE SET HZ W2 ON

Note:

P

indicates shielded wires and

1.

indicates twisted-pair shielded wires.

2.Voltage or current input for the master frequency reference can be selected by constant H042.

Voltage reference input is preset at the factory.

3.Control circuit terminal FR of +15 V has a maximum output current capacity of 20 mA.

4.Multi-function analog output should be used for monitoring meters (e.g. output frequency meter)

and should not be used for feedback control system.

9

3.2 WIRING THE MAIN CIRCUIT

WA R NI N G

●Make sure to ground the ground terminal

(Ground resistance 220V class:100Ω or less. 440V class:10Ω or less)

Failure to observe this warning can result in an electrical shock or a fire.

CAUTION

●Never connect the AC main circuit power supply to output terminals U,V and W.

The inverter will be damaged and invalidate the guarantee.

(1)Wiring Precautions for Main Circuit Input

(a)Installation of Molded-case Circuit Breaker (MCCB)

Make sure to connect MCCBs of fuses between AC main circuit power supply and TG-300 input

terminals L1, L2 and L3 to protect wiring.

(b)Installation of Ground Fault Interrupter

When connecting a ground fault interrupter to input terminals L1, L2 and L3, select one that is not

affected by high frequency.

(c)Installation of Magnetic Contactor

Inverters can be used without a magnetic contactor (MC) installed at the power supply side. When

the main circuit power supply is shut OFF in the sequence, a magnetic contactor (MC) can be used

instead of a molded-case circuit breaker (MCCB). However, when a magnetic contactor is switched

OFF at the primary side, regenerative braking does not function and the motor coasts to a stop.

● The load can be operated/stopped by opening/closing the magnetic contactor at the primary side.

However, frequent switching may cause the inverter to malfunction.

● When using a braking resistor unit, use a sequencer to break power supply side on overload relay

trip contact. If the inverter malfunctions, the braking resistor unit may be burned out.

(d)Terminal Block Connection Sequence

Input power supply phases can be connected to any terminal regardless of the order of L1, L2 and L3

on the terminal block.

(e)Installation of AC Reactor

When connecting an inverter (220V/440V 15Kw or less) to a large capacity power supply

transformer (600Kva or more), or when switching a phase advancing capacitor, excessive peak

current flows in the input power supply circuit, which may damage the converter section. In such

cases, install a DC reactor (optional) between inverter 1 and 2 terminals or an AC reactor

(optional) on the input side. Installation or a reactor is effective for improvement of power factor on

the power supply side.

10

(f)Installation of Surge Suppressor

For inductive loads (magnetic contactors, magnetic relays, magnetic valves, solenoids, magnetic

brakes, etc.) connected near the inverter, use a surge suppressor simultaneously.

(g)Prohibition of Installation of Phase Advancing Capacitor

If a phase advancing capacitor or surge suppressor is connected in order to improve the power factor,

it may become overheated and damaged by inverter high harmonic components. Also, the inverter

may malfunction because of overcurrent.

(2)Wiring Precautions for Main Circuit Output

(a)Connection of Terminal Block and Load

Connect output terminals U, V and W to motor lead wires U, V and W. Verify that the motor rotates

in the forward direction (CCW:counterclockwise when viewed from the motor load side) with the

forward run command. If the motor rotation is incorrect, exchange any two of output terminals U,V

or W.

(b)Strict Prohibition of Connection of Input Power Supply to Output Terminals

Never connect input power supply to output terminals U, V and W.

(c)Strict Prohibition of Short Circuiting or Grounding of Output Circuit

Never touch the output circuit directly or put the output line in contact with the inverter case.

Otherwise, it may cause an electrical shock or grounding. In addition, never short circuit the output

line.

(d)Prohibition of Connection of Phase Advancing Capacitor or LC/RC Noise Fitter

Never connect a phase advancing capacitor or LC/RC noise, filter to the output circuit.

(e) Avoidance of Installation of Magnetic Starter

Do not connect a magnetic starter or magnetic contactor to the output, circuit.

If the load is connected while the inverter is running, the inverter overcurrent

protective circuit operates because of inrush current.

(f) Installation of Thermal Overload Relay

An electronic overload protective function is incorporated into the inverter.

However, connect a thermal overload relay when driving several motors with one inverter or when

using a multi-pole motor. When using a thermal overload relay, set inverter constant H033 to 0.

Additionally, for thermal overload relay, at 50Hz set the same rated current value as that described

on the motor nameplate, or at 60Hz 1.1 times larger than the rated current value described on the

motor nameplate.

11

(g) Wiring Distance between Inverter and Motor

If the total wiring distance between inverter and motor is excessively long and the inverter carrier

frequency (main transistor switching frequency) is high, harmonic leakage current from the cable

will adversely affect the inverter and peripheral devices.

If the wiring distance between inverter and motor is long, reduce the inverter carrier frequency as

described below. Carrier frequency can be set. by constant H050.

Wiring Distance between Inverter and Motor

Wiring Distance between

Up to 50m Up to 100m More than 100m

Inverter and Motor

Carrier Frequency

(Set value of constant H050)

15kHZ or less

(6)

10kHZ or less

(4)

5kHZ or less

(2)

(3)Grounding

●Ground resistance

220 V class:100Ω or less, 440 V class:10Ω or less

●Never ground TG-300 in common with welding machines, motors, or other large-current electrical

equipment. Run all the ground wires in a conduit separate from wires for large-current electrical

equipment.

●Use the ground wires described in tables below and keep the length as short as possible.

●When using several TG-300 units side by side, ground the units as shown below

(b)Acceptable(a)Acceptable

(c)Not Acceptable

Grounding of Three TG-300 Units

12

3.3 WIRING THE CONTROL CIRCUIT

The following table outlines the functions of the control circuit terminals

Wire according to each terminal function.

(1) Functions of Control Circuit Terminate

Control Circuit Terminals

Classification Terminal Signal Function Description Signal Level

S1 Forward run/stop

S2 Reverse run/stop

S3 External fault input

S4 Fault reset input

Sequence Input Signal

Analog Input Signal

Sequence Output Signal

S5

S6

SC

FS

FV

FI

FC

G

M1

M2

MA

MB

MC

AM Frequency meter output

AC Common

Analog

Output

Signal

Multi-step speed

reference 1

Multi-step speed

reference 2

Sequence control input

common terminal

+15V Power supply

output

Frequency reference

input (voltage)

Frequency reference

input (current)

Common terminal for

control circuit

Connection to shield

searth of signal lead

During running

(NO contact)

Fault contact output

(NO/NC contact)

Forward run when closed, stop

when open

Reverse run

when closed,

stop when open

Fault when

closed, normal

state when

open

Reset when

closed

Effective when

closed

Effective when

closed

For analog command +15V power

supply

0 to

+10V/100%

4 to

20mA/100%

Closed when

running

Fault when

closed between

terminals MA

and MC

Fault when

open between

terminals MB

and MC

0 to +

10V/100%

Freq.

Multi-function

contact inputs

(H035 to H039)

---

H042 = 0:FV

effective

H042 = 0:FI

effective

0V ---

--- ---

Multi-function

contact output

(H041)

Multi-function

contact output

(H040)

Multi-function

contact analog

monitor 1

(H048)

Photo-coupler

insolation

Input :+24VD

8mA

+15V

(Allowable

current 20mA

max.)

0 to +10V

(20 kΩ)

4 to 20mA

(250Ω)

Dry contact

Contact

capacity:

250VAC 1 A or

less

30VDC 1 A or

less

Dry contact

Contact

capacity:

250VAC 1 A or

less

30VDC 1 A or

less

0 to +10V 2mA

or less

13

(2) Wiring the Control Circuit Terminals

ON

Screwdriver Blade Width

Insert the wire into the lower part of the terminal block and connect it tightly with a screwdriver.

Wire sheath strip length must be 7 mm.

7mm

(3) Precautions on Control Circuit Wiring

●Separate control circuit wires from main circuit wires and other power cables to prevent erroneous

operation caused by noise interference.

●Use twisted shielded or twisicd-pair shielded wire for the control circuit line and connect the

shielded sheath to the inverter terminal G.

Wiring distance should be less than 50 m.

3.4 WIRING INSPECTION

After completing of installation and wiring, check for the following items. Never use

control circuit buzzer check-

□ Wiring is proper.

□ Wire clippings or screws are not left in the unit.

□ Screws are securely tightened.

□ Bare wire in the terminal does not contact other terminals

14

4 OPERATION

WA R NI N G

●Only turn ON the input power supply after replacing the front cover. Do not remove the cover

while current is flowing.

Failure to observe this warning can result in an electrical shock.

●When the retry function (H057) is selected, do not approach the inverter or the load, since it may

restart suddenly after being stopped.

(Construct machine system, so as to assure safety for personnel, even if the inverter should restart.)

Failure to observe this warning can result in personal injury.

●Since the stop button can be disabled by a function setting, install a separate emergency stop

switch.

Failure to observe this warning can result in personal injury.

CAUTION

●Never touch the heatsink or discharging resistor since the temperature is very high.

Failure to observe this caution can result in harmful burns to the body.

●Since it is easy to change operation speed from low to high speed, verify the safe working range of

the motor and machine before operation.

Failure to observe this caution can result in personal injury and machine damage

●Install a holding brake separately if necessary.

Failure to observe this caution can result in personal injury

●Do not change signals during operation.

The machine or the inverter may be damaged

●Ail the constants of the inverter have been preset at the factory. Do not change the settings

unnecessarily.

The inverter may be damaged. For supply voltage, follow Par. 4.3.

This chapter describes the basic operation procedures of the TG-300.

15

4 .1 OPERATION MODE SELECTION

The TG-300 has two operation modes, LOCAL and REMOTE, as described below. These two

modes can be selected by the digital operator "LOCAL/REMOTE" key only while the operation is

stopped. The selected operation mode can be verified by observing the digital operator SEQ and

REF LEDs as shown below. The operation mode is set to REMOTE (run by control circuit terminals

FV and FI frequency reference and run command from a control circuit terminal) prior to shipment.

Multi-function contact inputs from control circuit terminals S3 to S6 are enabled in both operation

modes LOCAL/REMOTE.

●LOCAL :Both frequency reference and run command are set by the digital operator. SEQ

and REF LEDs go OFF.

●REMOTE:Master frequency reference and run command can be selected as described below.

Reference Selection in REMOTE Mode (H002: Operation Method Selection)

Setting Operation Method Selection

0

1

2

3

4

Operation by run command from digital

operator

Operation by run command from control

circuit terminal ON

Operation by run command from digital

operator

Operation by run command from control

circuit terminal

Operation by run command from digital

operator

SEQ

LED

OFF

OFF

ON

OFF

Reference Selection

Master frequency reference

from digital operator

Master frequency reference

from

digital operator

Master frequency reference

from

control circuit terminals FV

and FI

Master frequency reference

from

control circuit terminals FV

and FI

Master frequency reference set

by serial communication

REF

LED

OFF

OFF

ON

ON

ON

5

6

7

8

Operation by run command from control

ON

circuit terminal

Operation by run command from serial

ON

communication

Operation by run command from serial

communication ON

Operation by run command from serial

communication

ON

Master frequency reference set

by serial communication

Master frequency reference set

by serial communication

Master frequency reference

from

digital operator

Master frequency reference

from

control circuit terminals FV

and FI

ON

ON

OFF

ON

16

4.2 TEST RUN CHECKPOINTS

To assure safety, prior to initial operation, disconnect the machine coupling so that the motor is

isolated from the machine. If initial operation must be performed while the motor is still coupled to

the machine, use great care to avoid potentially hazardous conditions. Check the following items

before a test run.

□ Wiring and terminal connections are correct.

□ No short circuit caused by wire clippings.

□ Screw-type terminals are securely tightened.

□ Motor is securely mounted.

□ All items are correctly earthed(grounded).

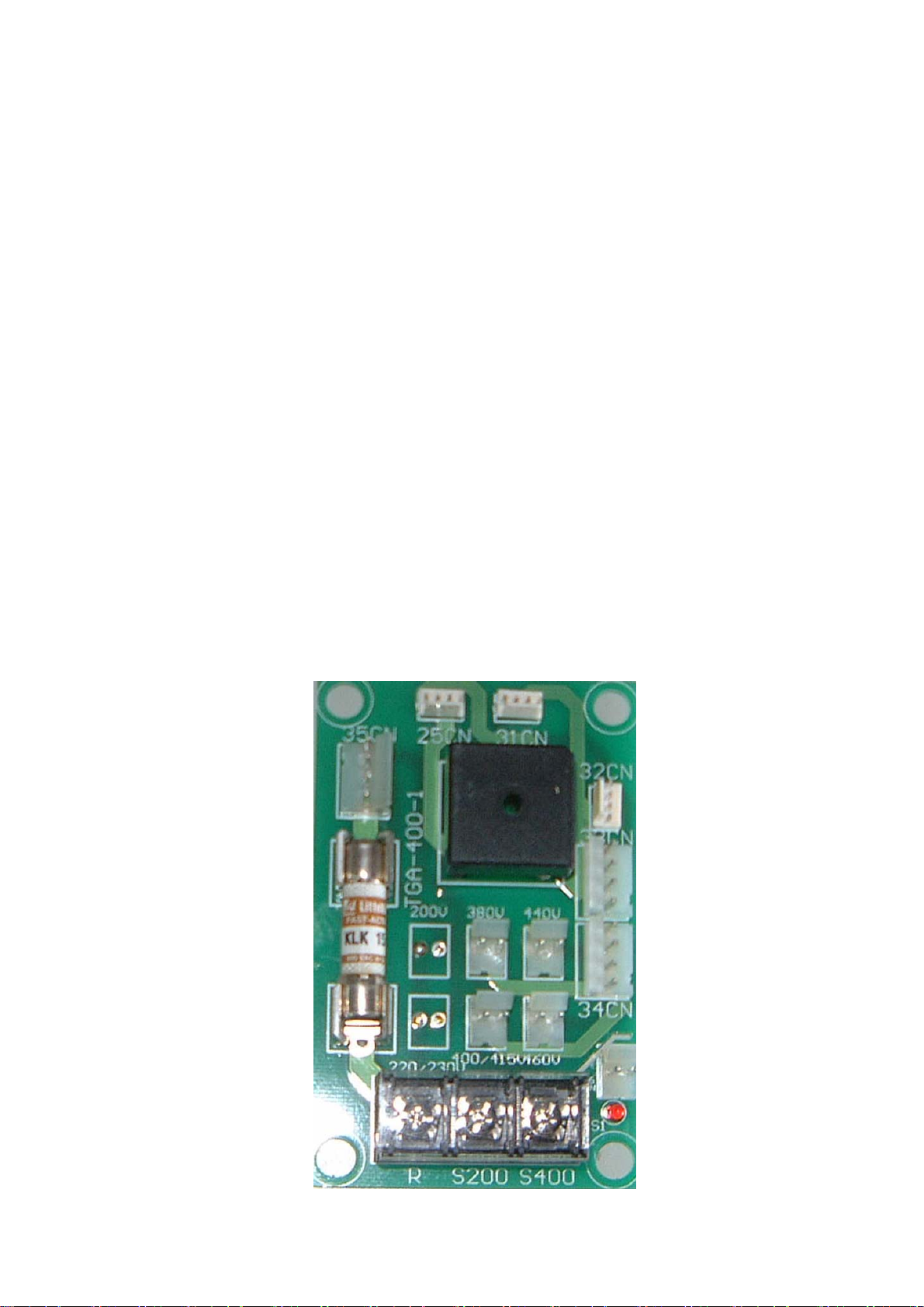

4.3 SETTING THE LINE VOLTAGE USING JUMPER

(FOR 440V CLASS 55kW AND ABOVE)

Set the line voltage jumper according to the main circuit power supply.

Insert the jumper at the appropriate location corresponding to the input line voltage

It has been preset at the factory to 440V.

Line Voltage Jumper (For 440V Class 55W to 300kW)

17

4.4 TEST RUN

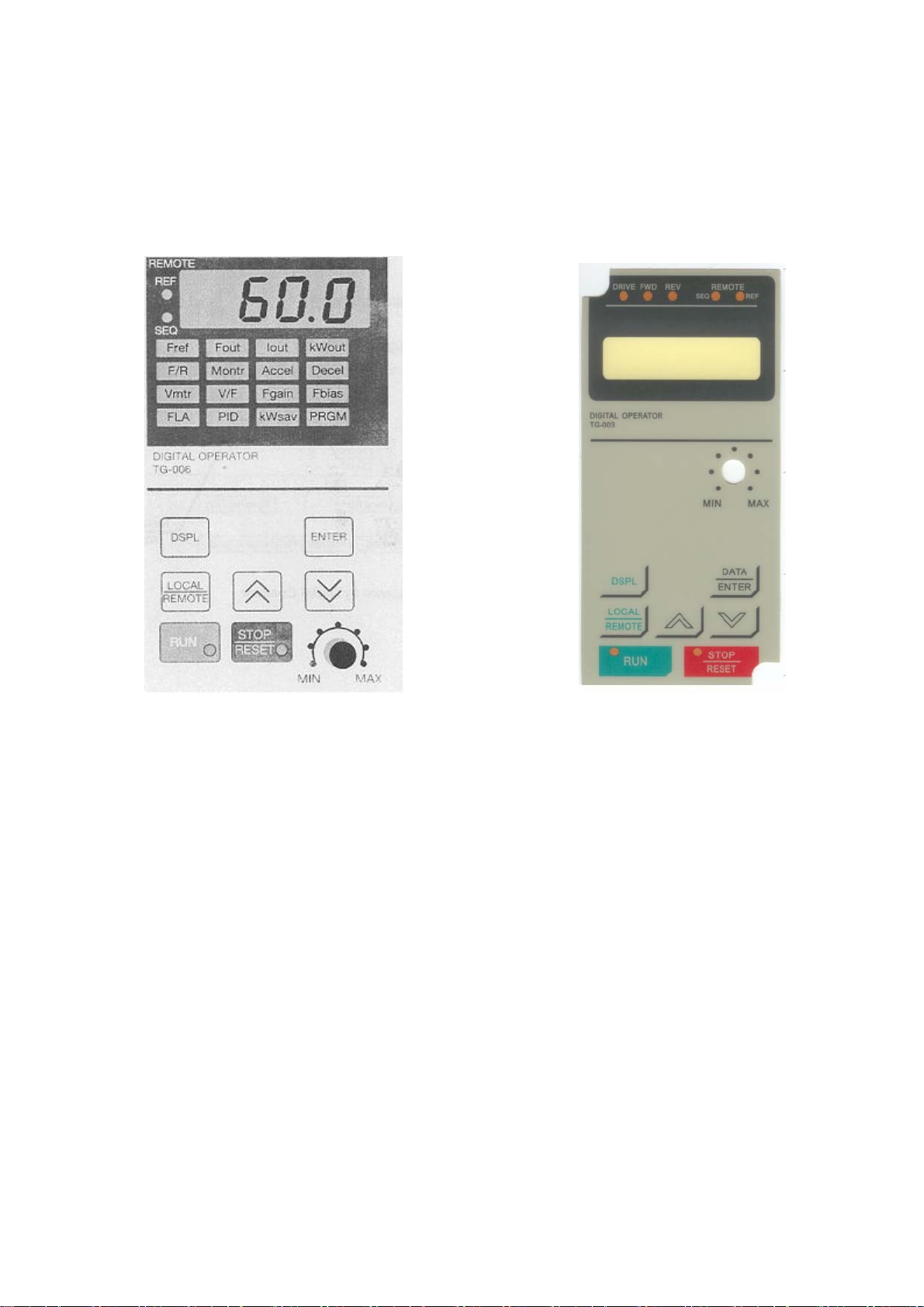

(1) Digital Operator Display at Power-up

When the system is ready for operation, turn ON the power supply. Verify that the inverter powers

up properly. If any problems are found, turn OFF the power supply immediately. The digital operator

display illuminates as shown below

Digital Operator Display Digital Operator Display

LED LCD

18

(2) Operation Check Points

Check the following items during operation

□ Motor rotates smoothly.

□ Motor rotates in the correct direction.

□ Motor does not have abnormal vibration or noise.

□ Acceleration and deceleration are smooth.

□ Current matches the load flow.

□ Status indicator LEDs and digital operator display are correct

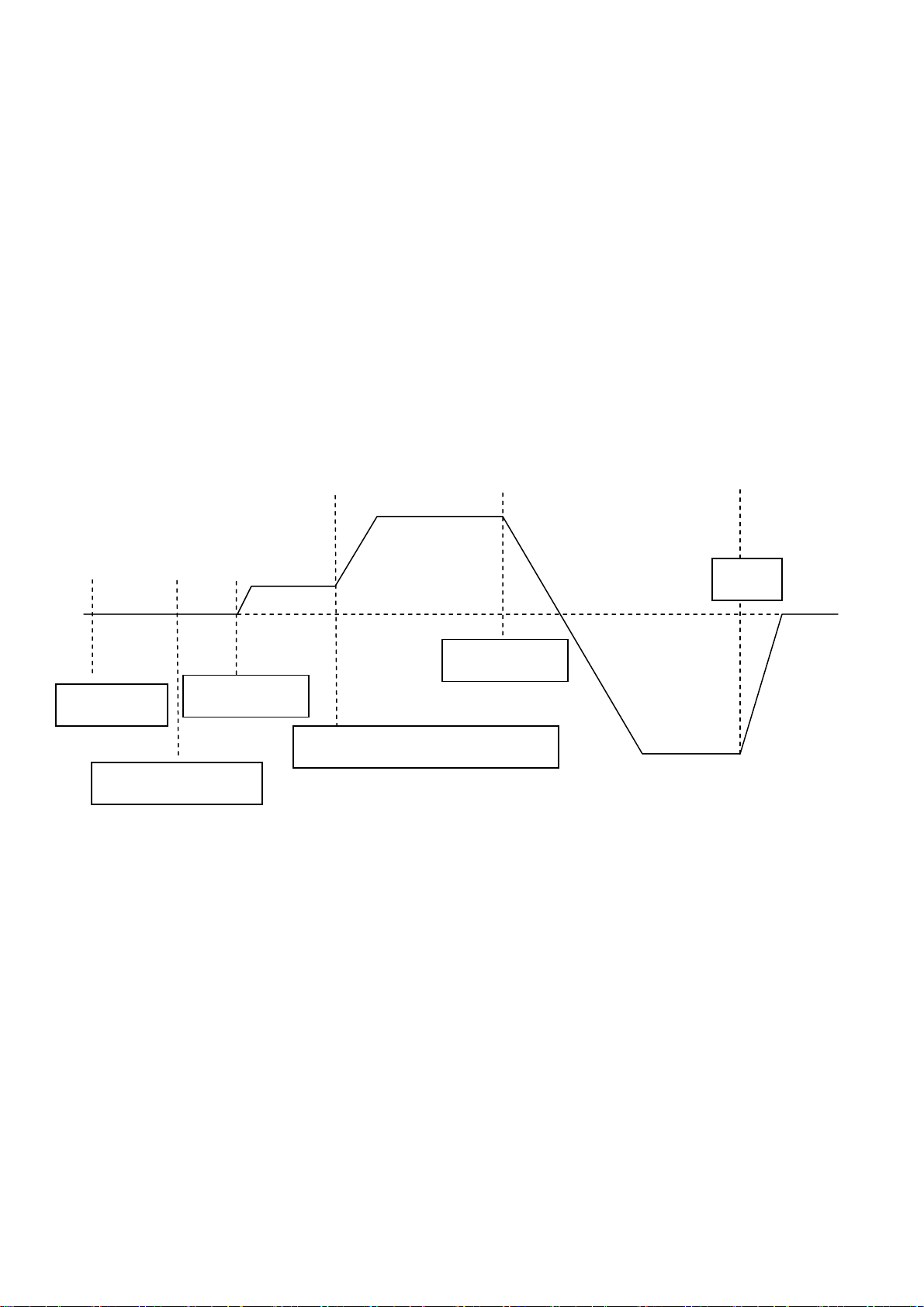

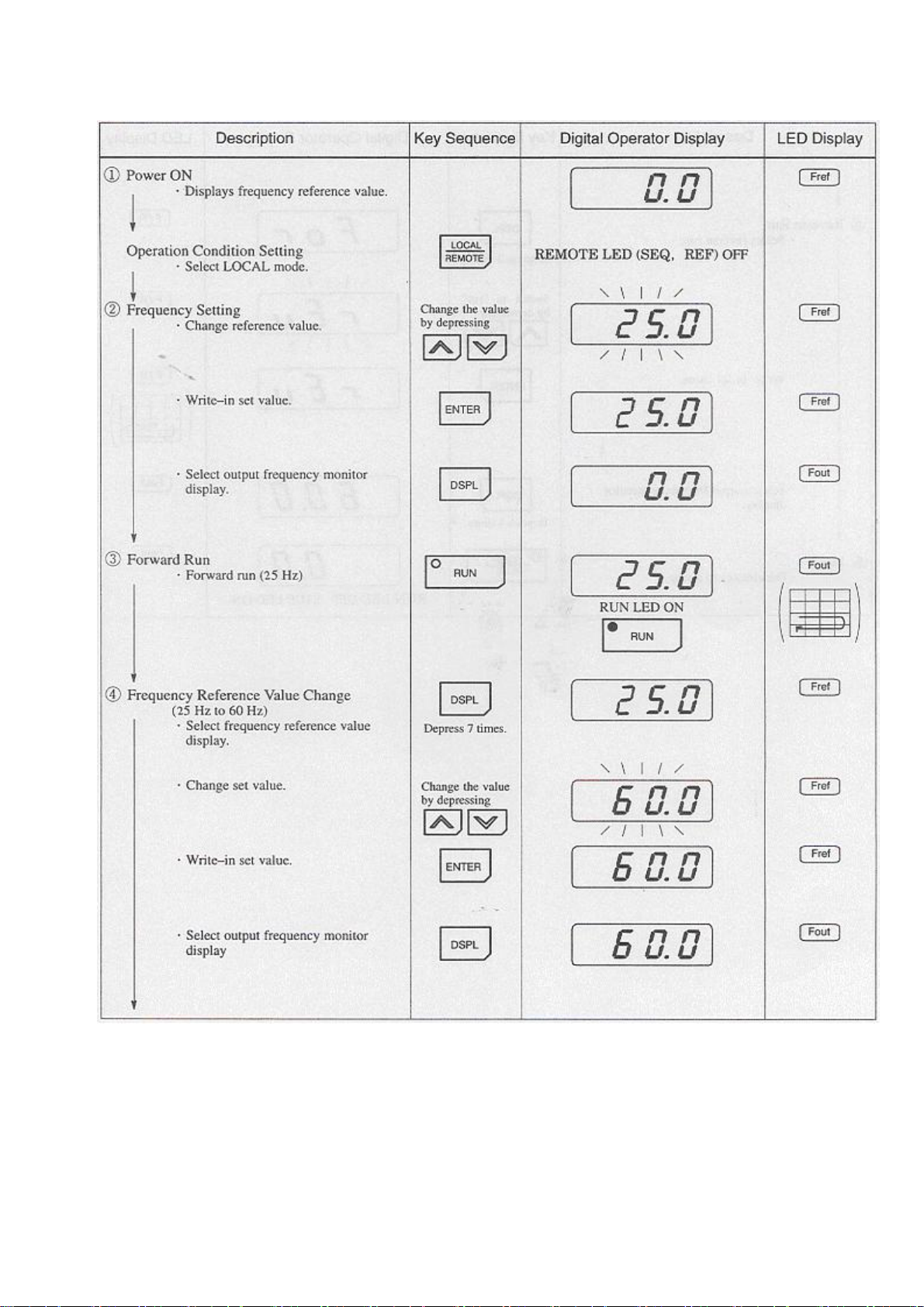

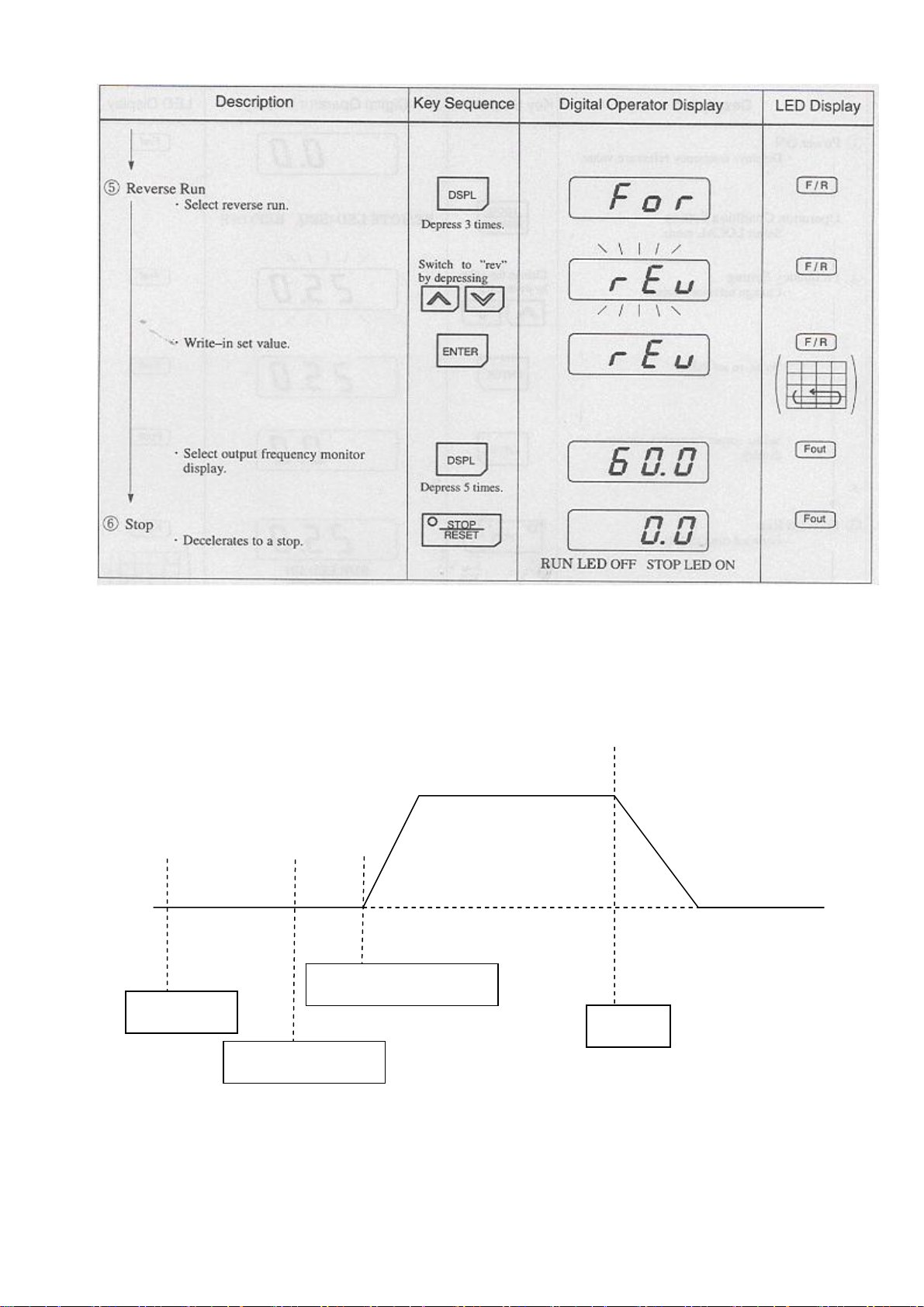

(3) Example of Basic Operation

(a) Operation by Digital Operator

The diagram below shows a typical operation pattern using the digital operator

f Forward g h

60 Hz

c d e Forward

25Hz

Power ON

Reverse

Forward Run

Frequency Reference Change

60 Hz

Frequency Setting

Operation Sequence by Digital Operator

Reverse Run

Stop

19

Typical Operation by Digital Operator

20

Typical Operation by Digital Operator (Cont’d)

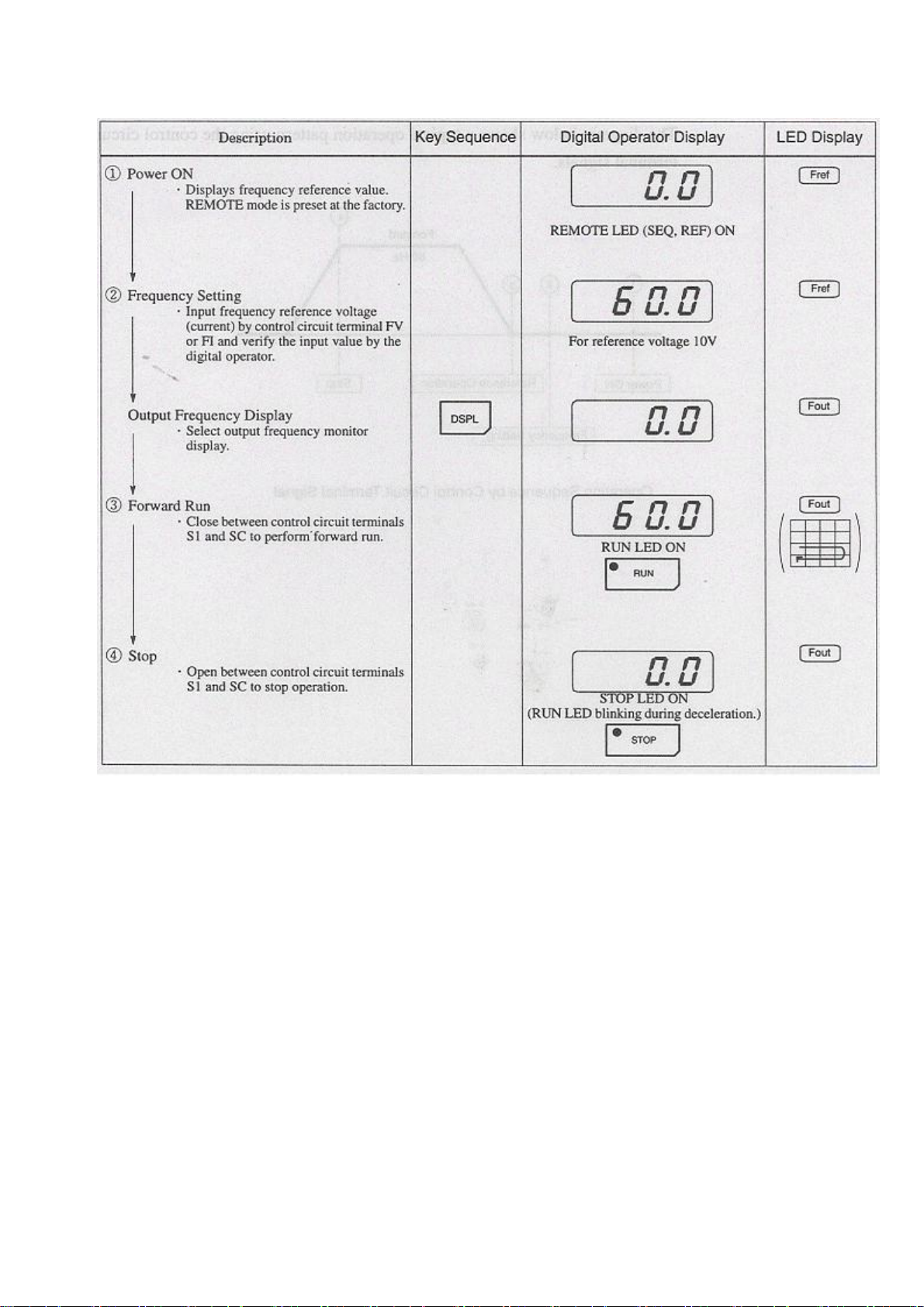

(b)Operation by Control Circuit Terminal Signal

The diagram below shows a typical operation pattern using the control circuit terminal signals.

f

Forward

60 Hz

c d e

Power ON

Reference Operation

Stop

Frequency Setting

Operation Sequence by Control Circuit Terminal Signal

21

Typical Operation by Control Circuit Terminal Signal

22

5 SIMPLE DATA SETTING

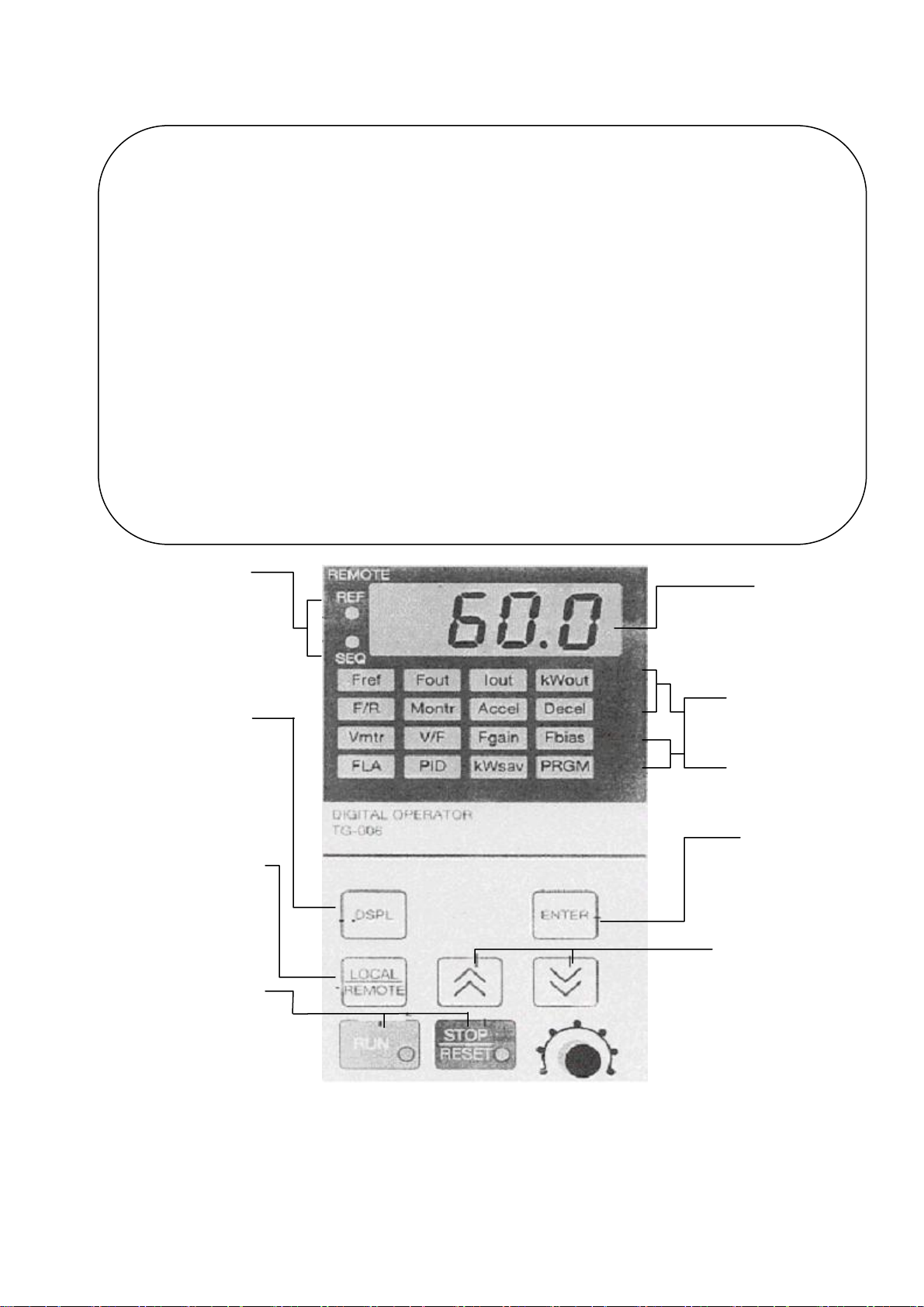

5.1 DIGITAL OPERAT KEY DESCRIPTION

Fref Fout Iout kwout

Frequency Output frequency Output current Output power

Reference monitor monitor monitor

Setting/monitoring

F/R Montr Accel Decel

FWD/REV run Monitor Acceleration Deceleration time

Command Selection Time

Selection

Vmtr V/F Fgain Fbias

Motor rated V/f pattern Frequency Frequency

Voltage selection Reference gain reference bias

FLA P/D Kwsalv PRGM

Motor rated current PID selection Energy saving

selection

Constant No/data

LED lights when inverter is controlled by

control circuit terminal commands.

SEQ:When RUN/STOP signal is through

terminals.

REF:When frequency reference is through

terminals.

Display Selection Key

Depressing this key changes the

display. See next page for

explanation

Operation Mode Selection Key

Mode Display LEDs

Depressing this key changes the mode

(LOCAL or REMOTE)

Operation Command Keys

Operation command keys operate the inverter.

Display

Displays the set value of each function and

monitor values such as output frequency and

output current (4 digits)

The selected function lights and allows changing

operation

Constants can be set only during a stop

Depressing this key recalls and

displays indicated data from

memory.

Depressing a second time enters the

displayed data into memory

Changes numbers such as set values

and constants

Λ:Increase Ⅴ:Decrease

Quick-Start LEDs

During Operation

Monitors/constants can be set during

During a Stop

Enter Key

Number Change keys

STOP/RESET Key:Stop command LED

Lights when STOP key is depressed. (It changes to

a reset key when a fault occurs.)

MIN MAX -----VR Set

RUN Key:Run command LED lights when the

RUN key is depressed.

23

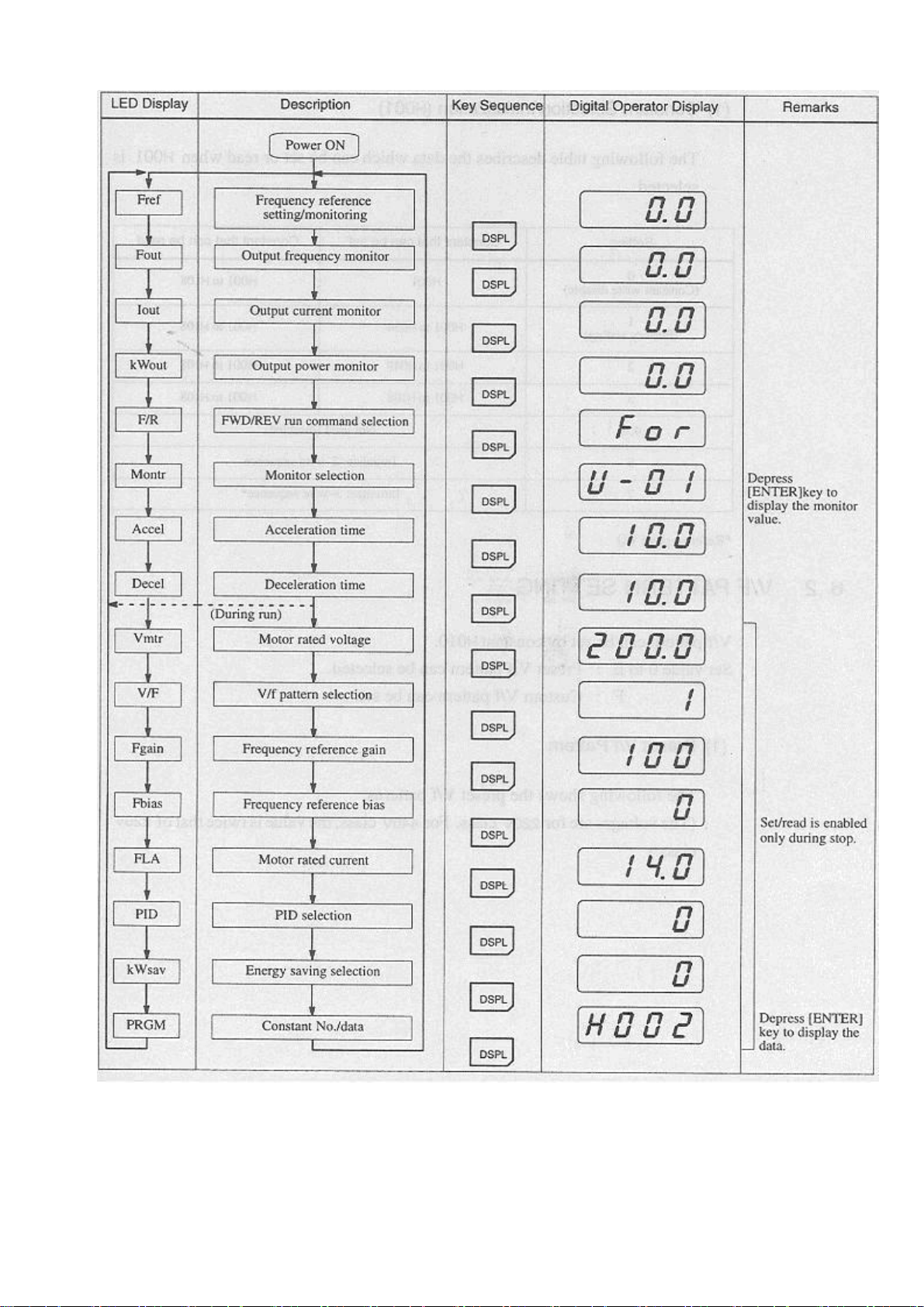

5 .2 LED DESCRIPTION

By using the quick-start LEDs on the digital operator, simple operation of the inverter is possible.

Each quick-start LED is selected each time [DSPL] key is depressed. Following is a flowchart

describing quick-start LED selection. (Example of model TG-300-L50B2T)

24

LED Description

25

6 PROGRAMMING FEATURES

6.1 CONSTANT SET-UP AND INITIALIZATION

(1) Constant Selection/Initialization (H001)

The following table describes the data which can be set or read when H001 is selected.

Setting Constant that can be set Constant that can be read

0

(Constant write disable)

1

(Factory setting)

2 H001 to H049 H001 to H108

3 H001 to H108 H001 to H108

4.5 Not used (disabled)

6

7

*Refer to page 60

6.2 V/F PATTERN SETTING

V/f pattern can be set by constant H010.

H001 H001 to H108

H001 to H034 H001 to H108

Initialize:2-wire sequence

Initialize:3-wire sequence*

Set value 0 to E:Preset V/f pattern can be selected

F:Custom V/f pattern can be set.

(1) Preset V/f Pattern

The following shows the preset V/f patterns.

(The voltages are for 220V class. For 440V class, the value is twice that of 220V class.)

26

Loading...

Loading...