Topcnc TC5510, TC5522, TC5530, TC5530R, TC5522R User Manual

TC5510/TC5522/TC5530/TC5522R/TC5530R

TC5510/TC5522/TC5530/TC5522R/TC5530R

TC5510/TC5522/TC5530/TC5522R/TC5530R

TC5510/TC5522/TC5530/TC5522R/TC5530R

Motion

Motion

Motion

Motion Controller

Controller

Controller

Controller (Stepping

(Stepping

(Stepping

(Stepping Motor

Motor

Motor

Motor Controller)

Controller)

Controller)

Controller) Manual

Manual

Manual

Manual

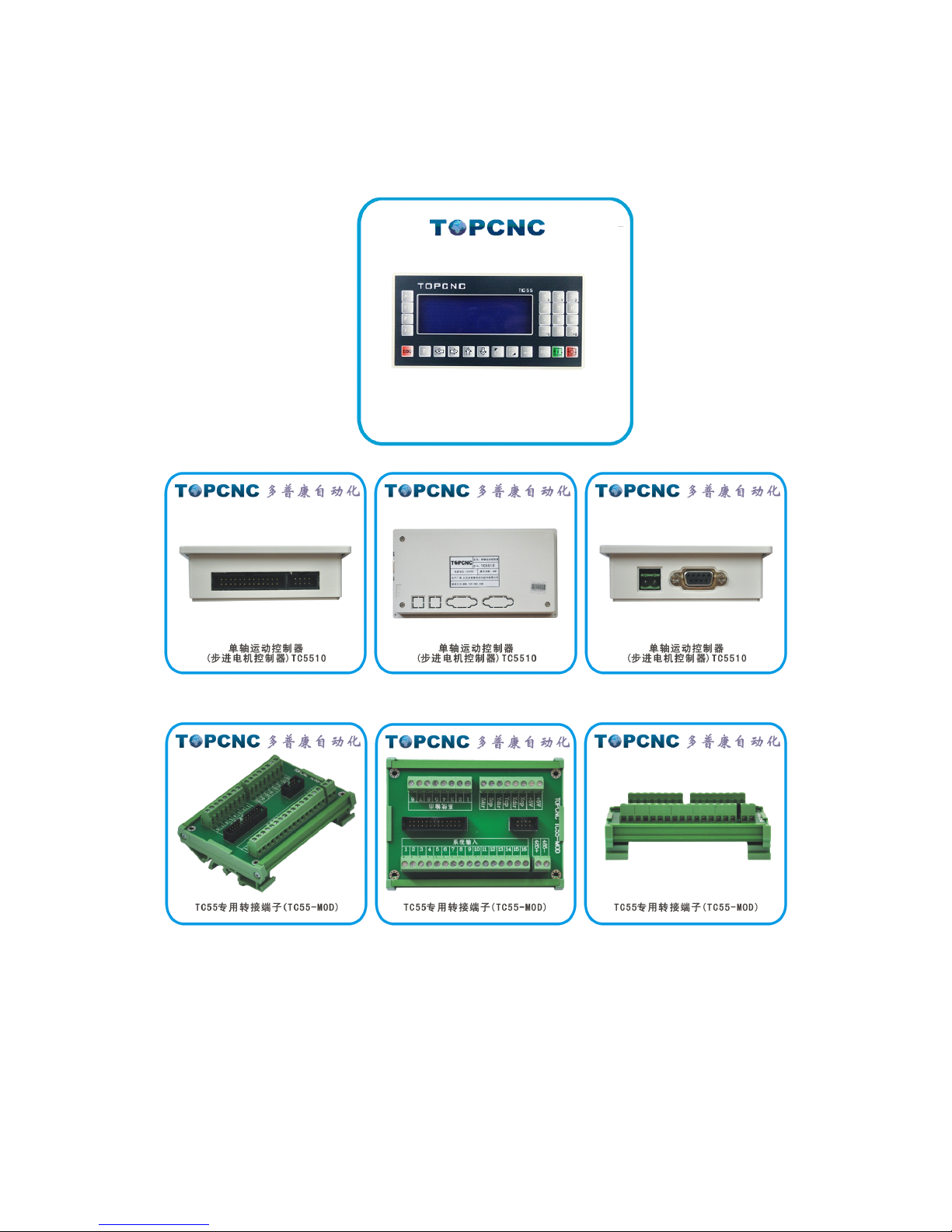

Full figure

Left View Back view Right View

TC55 Breakout Board (TC55-MOD)

Note:

Note:

Note:

Note: The

The

The

The TC55

TC55

TC55

TC55 series

series

series

series are

are

are

are exactly

exactly

exactly

exactly the

the

the

the same

same

same

same panel

panel

panel

panel size

size

size

size and

and

and

and shell

shell

shell

shell film.

film.

film.

film.

TC55-MOD

TC55-MOD

TC55-MOD

TC55-MOD is

is

is

is an

an

an

an optional

optional

optional

optional product.

product.

product.

product.

1. Outline .................................................................................................................................................................... 3

2. Connection .............................................................................................................................................................. 6

3. Operation ................................................................................................................................................................ 9

3.1 AutoExec(Automatically execute) .............................................................................................................. 14

3.1.1 Actl Run(Actual running) ................................................................................................................ 14

3.1.2 Mt Run(Empty running) .................................................................................................................. 15

3.1.3 SS Mo(Single-step execution) ......................................................................................................... 16

3.1.4 TrmtProg(Terminate program) ......................................................................................................... 16

3.2 Man Op(Manual operation) ........................................................................................................................ 17

3.2.1 Man HSpd(Manual high speed) ....................................................................................................... 17

3.2.2 Jog Op(Jog operation) ..................................................................................................................... 18

3.2.3 BkTProg0(Back to program zero) ................................................................................................... 19

3.2.4 BkTMech0(Back to mechanical zero) ............................................................................................. 19

3.3 ProgMgmt(Program Management) ............................................................................................................. 22

3.3.1 Ed Prog(Edit program) .................................................................................................................... 22

3.3.2 Prog RI(Program read-in) ................................................................................................................ 26

3.3.3 Del Prog(Delete program) ............................................................................................................... 26

3.3.4 Sv Prog(Save program) ................................................................................................................... 27

3.4 Pars Set(Parameters settings) ...................................................................................................................... 28

3.4.1 Sys Pars(System parameters) ........................................................................................................... 29

3.4.2 Sys SC(System self-check) .............................................................................................................. 33

3.4.3 IO Set(IO settings) ........................................................................................................................... 38

3.4.4 Usr Mgmt(User management) ......................................................................................................... 42

4. Programming ........................................................................................................................................................ 44

5. Appendix .............................................................................................................................................................. 70

6. Acronyms and Abbreviations ................................................................................................................................ 73

1.

1.

1.

1. Outline

Outline

Outline

Outline

The TC55 panel-type motion controller (CNC system) uses high-performance

32-bit CPU. The drive device adopts subdivision stepping motor or AC servo motor.

It is equipped with LCD monitor and fully enclosed touch-type operating keyboard.

The system has high reliability, high precision, low noise, easy to operate etc. This

controller can control 1-3 motor motion and realize Point to Point, linear interpolation,

circular interpolation and other operations. It has loop, jump and simple PLC

functions etc. Simple and clear parameters bring you convenient and fast operation.

Input/output setting functions are convenient for your to use and maintain

,

and

applicable to all kinds of 1-3 axis motion device.

Product

Product

Product

Product features:

features:

features:

features:

The boot screen can be modified

Controller or upper computer dual-mode programming

Independent 24V power supply reverse connection protection

IO optically-coupled isolation

Output short circuit protection

Manual positive or reverse rotation can be controlled by the external switches

synchronously

Simple PLC logic

The parameter area password can be set

Applicable product type:

l CNC drilling machine system, CNC lathe system, CNC milling machine system,

CNC grinding machine system

l cutting machine control system, welding control system, dispenser control system,

feeding control system

l displacement platform, one-dimensional control platform, two-dimensional

control platform, three-dimensional control platform

l threading machine control system, screwdriving machine control system

l spraying production line control system, assembly production line control system,

the meter counter control system

Technical

Technical

Technical

Technical characteristics:

characteristics:

characteristics:

characteristics:

�

Automatically execute

:

Actual running, Empty running, Single-step execution,

Terminate program, Start and Pause function

�

Manual operation

:

Manual high speed, Manual low speed, Jog operation, Back to

program zero, Back to mechanical zero

�

Program management

:

Edit program, Program read-in, Delete program, Save

program

�

Parameter settings

:

Set various control parameters of processing and operation,

get the best status of processing effect

System

System

System

System parameters:

parameters:

parameters:

parameters:

High-performance, high-speed 32-bit CPU

High-grade black and white double color LCD monitor (resolution: 192 × 64)

Special motion control chip (signal output: 5V TTL)

Universal customizable input / output (16 photoelectric isolated 24V inputs, 8 relay

outputs)

User processing program memory (can store 20 programs)

Minimum data unit 0.001 mm

Maximum data size ± 99999.999mm

Maximum pulse output frequency 150KHz

System main functions are automatic, manual, program editing, system parameters,

self-check, settings, etc.

Installation:

Installation:

Installation:

Installation:

panel type installation structure

dimension 172 x 94 x 30, installing size 164 x 86

Power supply requirements

≥ DC 24V/40W

Environmental requirements

working temperature: 0 ~ 60

℃

relative humidity: 5 ~ 90% no condensation

2.

2.

2.

2. Connection

Connection

Connection

Connection

2.1

2.1

2.1

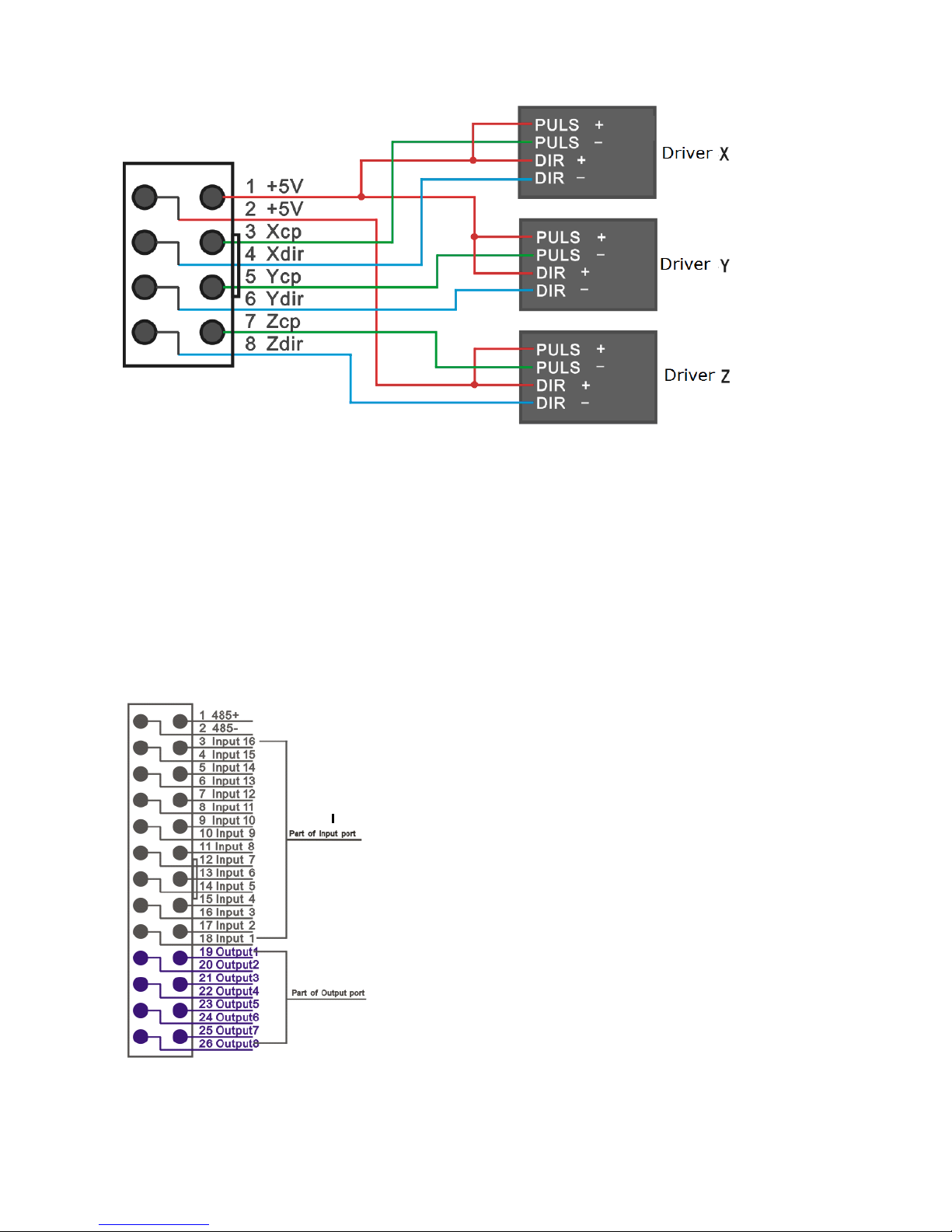

2.1 Pulse

Pulse

Pulse

Pulse interfaces

interfaces

interfaces

interfaces and

and

and

and drives

drives

drives

drives wiring

wiring

wiring

wiring diagram

diagram

diagram

diagram

Note:

Note:

Note:

Note: the

the

the

the red

red

red

red line

line

line

line is

is

is

is No.1

No.1

No.1

No.1 pin

pin

pin

pin

TC5510

TC5510

TC5510

TC5510 only

only

only

only take

take

take

take the

the

the

the first

first

first

first 4

4

4

4 wires

wires

wires

wires or

or

or

or terminals

terminals

terminals

terminals of

of

of

of

8P.

8P.

8P.

8P.

Similarly

Similarly

Similarly

Similarly TC5522

TC5522

TC5522

TC5522 or

or

or

or

TC5522R

TC5522R

TC5522R

TC5522R only

only

only

only take

take

take

take the

the

the

the first

first

first

first 6

6

6

6 wires

wires

wires

wires or

or

or

or terminals

terminals

terminals

terminals of

of

of

of

8P.

8P.

8P.

8P.

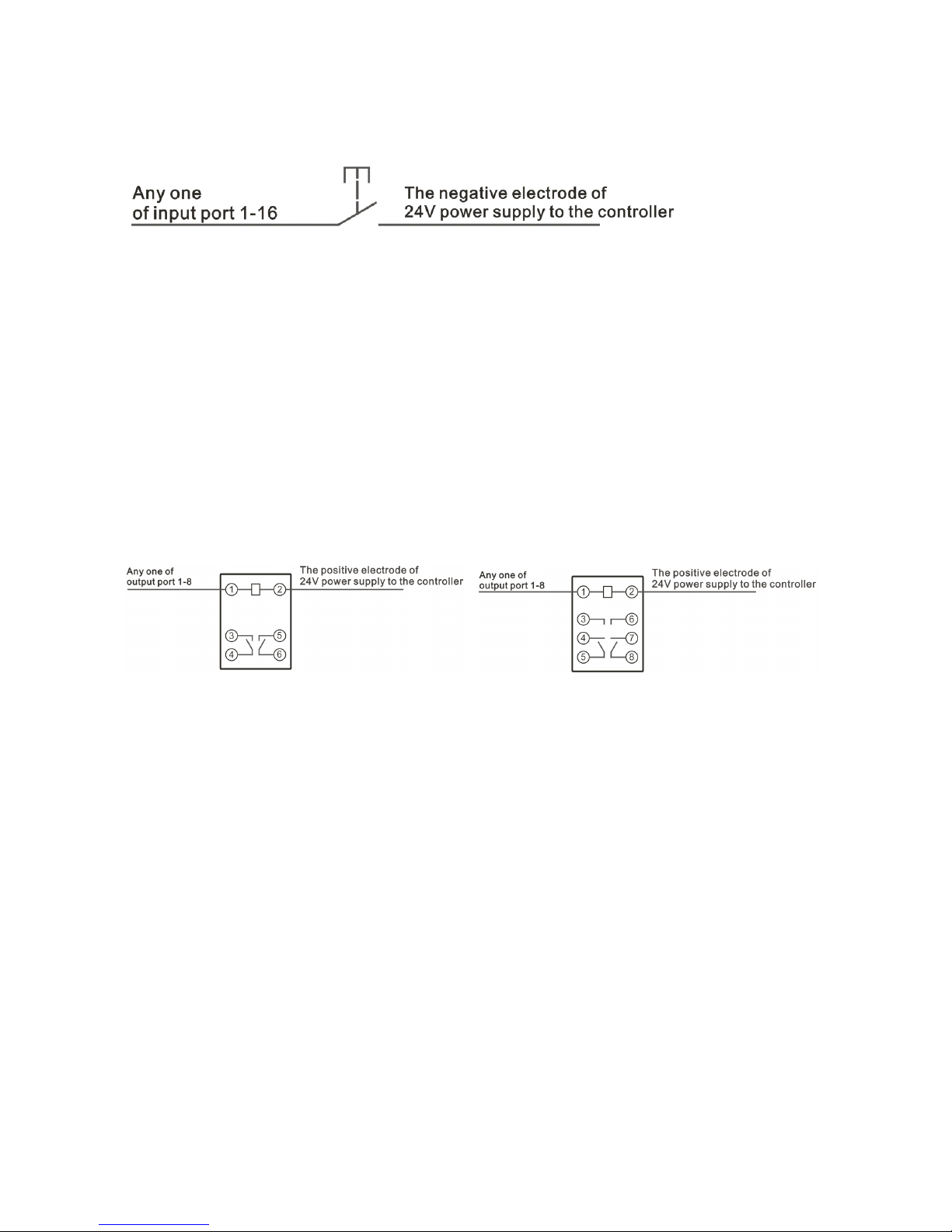

2.2

2.2

2.2

2.2 Input/output

Input/output

Input/output

Input/output and

and

and

and switches

switches

switches

switches and

and

and

and relays

relays

relays

relays wiring

wiring

wiring

wiring diagram.

diagram.

diagram.

diagram.

2.2.1

2.2.1

2.2.1

2.2.1 Input

Input

Input

Input wiring

wiring

wiring

wiring diagram

diagram

diagram

diagram

Any

Any

Any

Any one

one

one

one of

of

of

of input

input

input

input port

port

port

port 1-16

1-16

1-16

1-16

The

The

The

The negative

negative

negative

negative electrode

electrode

electrode

electrode of

of

of

of 24V

24V

24V

24V power

power

power

power supply

supply

supply

supply to

to

to

to the

the

the

the controller

controller

controller

controller

The picture shows the two-wire standard mechanical switch and photoelectric

switch connection method. One end of the switch is connected to the selected and

defined input line. The other end of the switch must be connected to the negative

electrode of 24V power supply to the controller.

Note: the photoelectric switch must be NPN type.

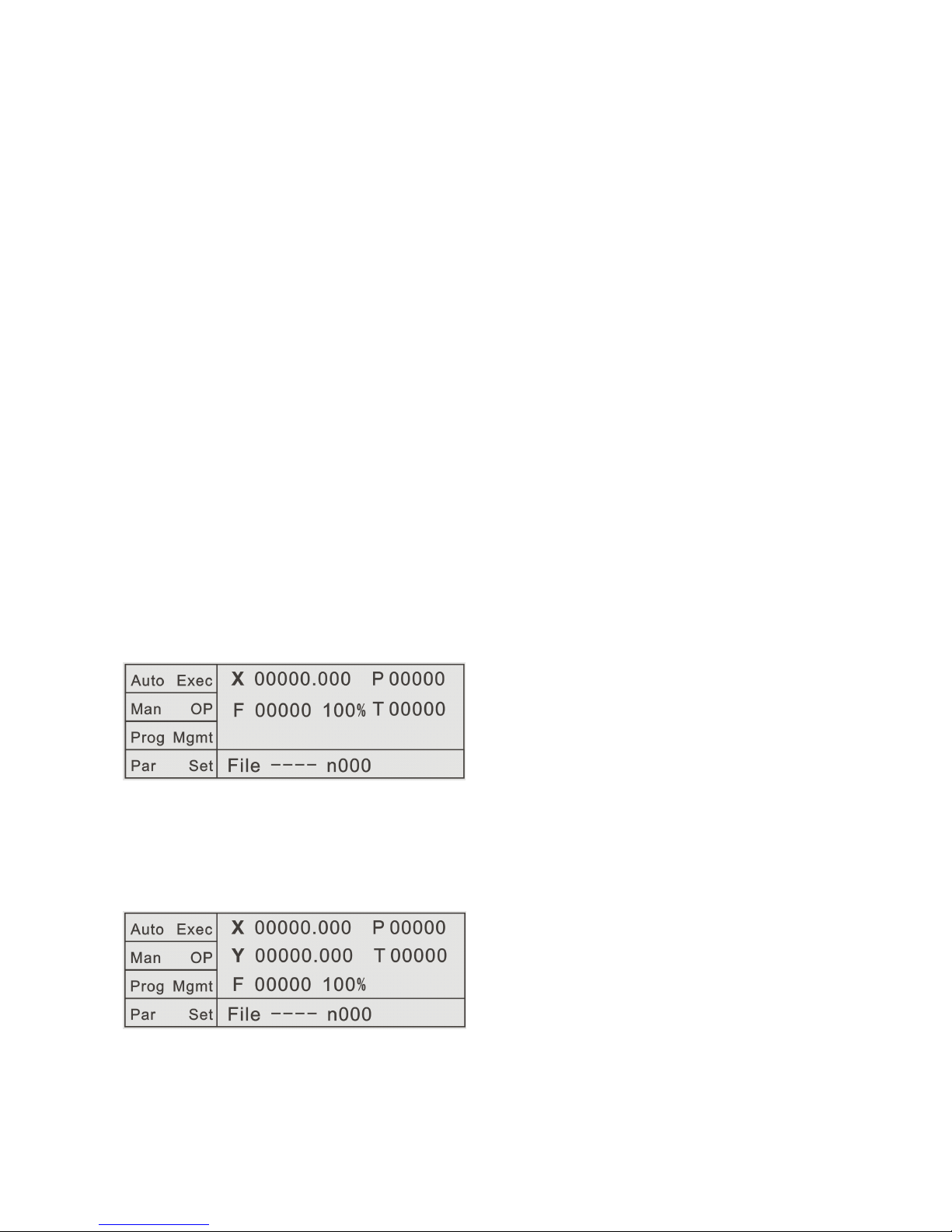

2.2.2

2.2.2

2.2.2

2.2.2 Output

Output

Output

Output line

line

line

line wiring

wiring

wiring

wiring diagram

diagram

diagram

diagram

Any

Any

Any

Any one

one

one

one of

of

of

of output

output

output

output port

port

port

port 1-8

1-8

1-8

1-8

The

The

The

The positive

positive

positive

positive electrode

electrode

electrode

electrode of

of

of

of 24V

24V

24V

24V power

power

power

power supply

supply

supply

supply to

to

to

to the

the

the

the controller

controller

controller

controller

As shown in figure, contacts 1 and 2 are the coil contacts of relay.

Output line is connected to one end of the relay coil. The other end of the coil is

connected to the positive electrode of 24V power supply to the controller.

Note

Note

Note

Note 1:

1:

1:

1: If

If

If

If the

the

the

the connected

connected

connected

connected relay

relay

relay

relay or

or

or

or other

other

other

other electrical

electrical

electrical

electrical component

component

component

component is

is

is

is required

required

required

required for

for

for

for

power

power

power

power supply

supply

supply

supply positive

positive

positive

positive or

or

or

or negative

negative

negative

negative access,

access,

access,

access, then

then

then

then wire

wire

wire

wire according

according

according

according to

to

to

to the

the

the

the electrical

electrical

electrical

electrical

diagram

diagram

diagram

diagram of

of

of

of the

the

the

the relay

relay

relay

relay or

or

or

or the

the

the

the electrical

electrical

electrical

electrical component.

component.

component.

component.

Note

Note

Note

Note 2:

2:

2:

2: the

the

the

the red

red

red

red line

line

line

line is

is

is

is No.1

No.1

No.1

No.1 pin

pin

pin

pin

Any

Any

Any

Any one

one

one

one of

of

of

of input

input

input

input port

port

port

port 1-16

1-16

1-16

1-16 can

can

can

can be

be

be

be connected

connected

connected

connected to

to

to

to one

one

one

one end

end

end

end of

of

of

of the

the

the

the switch.

switch.

switch.

switch. The

The

The

The

specific

specific

specific

specific switch

switch

switch

switch definition

definition

definition

definition depends

depends

depends

depends on

on

on

on the

the

the

the input

input

input

input parameter

parameter

parameter

parameter values

values

values

values of

of

of

of IO

IO

IO

IO settings

settings

settings

settings of

of

of

of

the

the

the

the controller

controller

controller

controller parameters

parameters

parameters

parameters area.

area.

area.

area. The

The

The

The other

other

other

other end

end

end

end of

of

of

of the

the

the

the switch

switch

switch

switch must

must

must

must be

be

be

be connected

connected

connected

connected to

to

to

to

the

the

the

the negative

negative

negative

negative electrode

electrode

electrode

electrode of

of

of

of 24V

24V

24V

24V power

power

power

power supply

supply

supply

supply to

to

to

to the

the

the

the controller.

controller.

controller.

controller.

Any

Any

Any

Any one

one

one

one of

of

of

of output

output

output

output port

port

port

port 1-8

1-8

1-8

1-8 can

can

can

can be

be

be

be connected

connected

connected

connected to

to

to

to one

one

one

one end

end

end

end of

of

of

of the

the

the

the relay

relay

relay

relay coil.

coil.

coil.

coil.

The

The

The

The specific

specific

specific

specific output

output

output

output port

port

port

port definition

definition

definition

definition depends

depends

depends

depends on

on

on

on the

the

the

the output

output

output

output parameter

parameter

parameter

parameter values

values

values

values of

of

of

of

IO

IO

IO

IO settings

settings

settings

settings of

of

of

of the

the

the

the controller

controller

controller

controller parameters

parameters

parameters

parameters area.

area.

area.

area. The

The

The

The other

other

other

other end

end

end

end of

of

of

of the

the

the

the relay

relay

relay

relay coil

coil

coil

coil

must

must

must

must be

be

be

be connected

connected

connected

connected to

to

to

to the

the

the

the positive

positive

positive

positive electrode

electrode

electrode

electrode of

of

of

of 24V

24V

24V

24V power

power

power

power supply

supply

supply

supply to

to

to

to the

the

the

the

controller.

controller.

controller.

controller.

Controller

Controller

Controller

Controller power

power

power

power supply

supply

supply

supply interface

interface

interface

interface definition

definition

definition

definition is

is

is

is on

on

on

on the

the

the

the back

back

back

back of

of

of

of the

the

the

the controller

controller

controller

controller

shell.

shell.

shell.

shell. Please

Please

Please

Please wire

wire

wire

wire according

according

according

according to

to

to

to the

the

the

the mark

mark

mark

mark on

on

on

on the

the

the

the back.

back.

back.

back. The

The

The

The power

power

power

power supply

supply

supply

supply is

is

is

is 24V

24V

24V

24V

DC.

DC.

DC.

DC. Power

Power

Power

Power is

is

is

is not

not

not

not less

less

less

less than

than

than

than 40W.

40W.

40W.

40W.

3.

3.

3.

3. Operation

Operation

Operation

Operation

Boot and enter into the main operation interface after showing the boot screen

AutoExec Automatically execute

Man OP Manual operation

ProgMgmt Program management

File

Pars Set Parameter settings

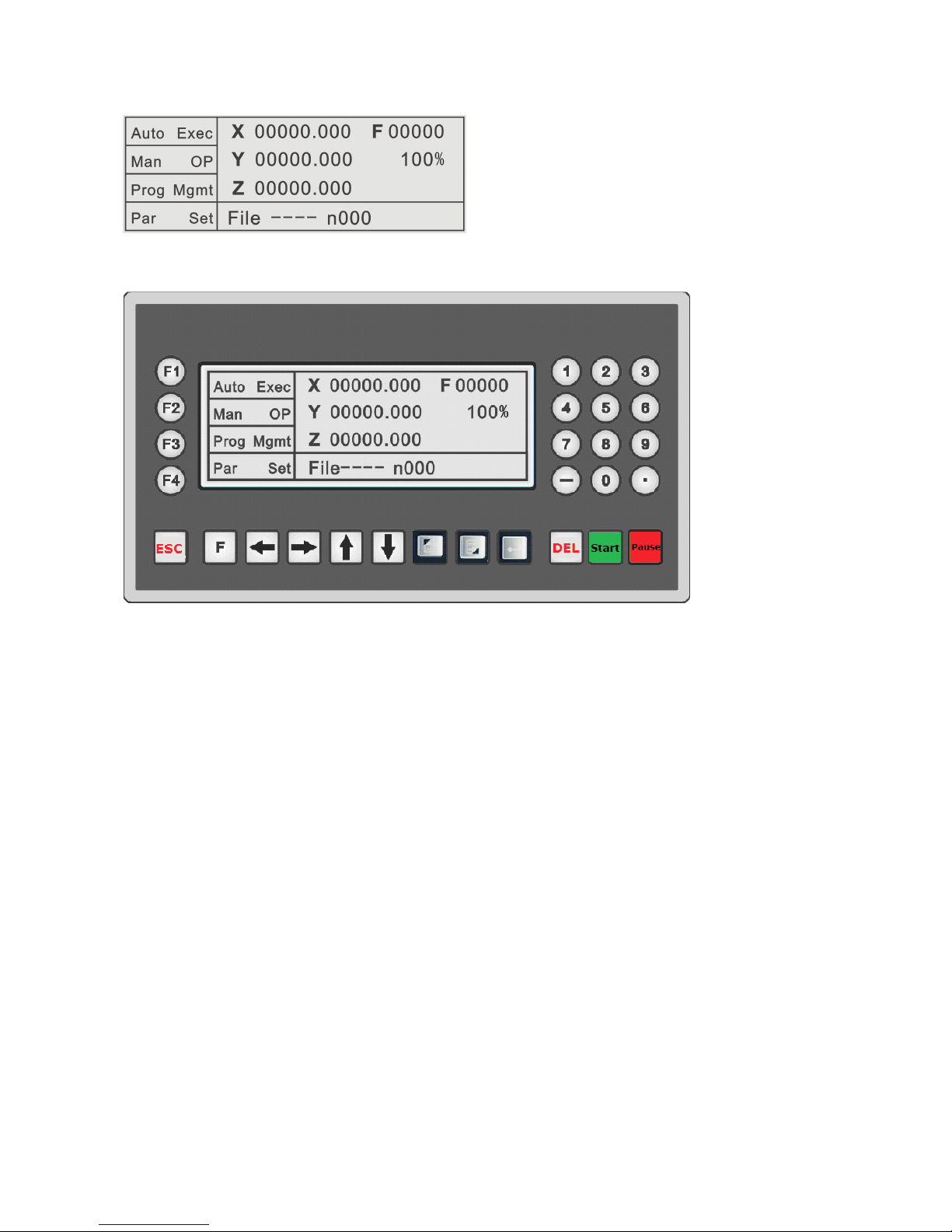

The picture shows the main interface of TC5510 after boot.

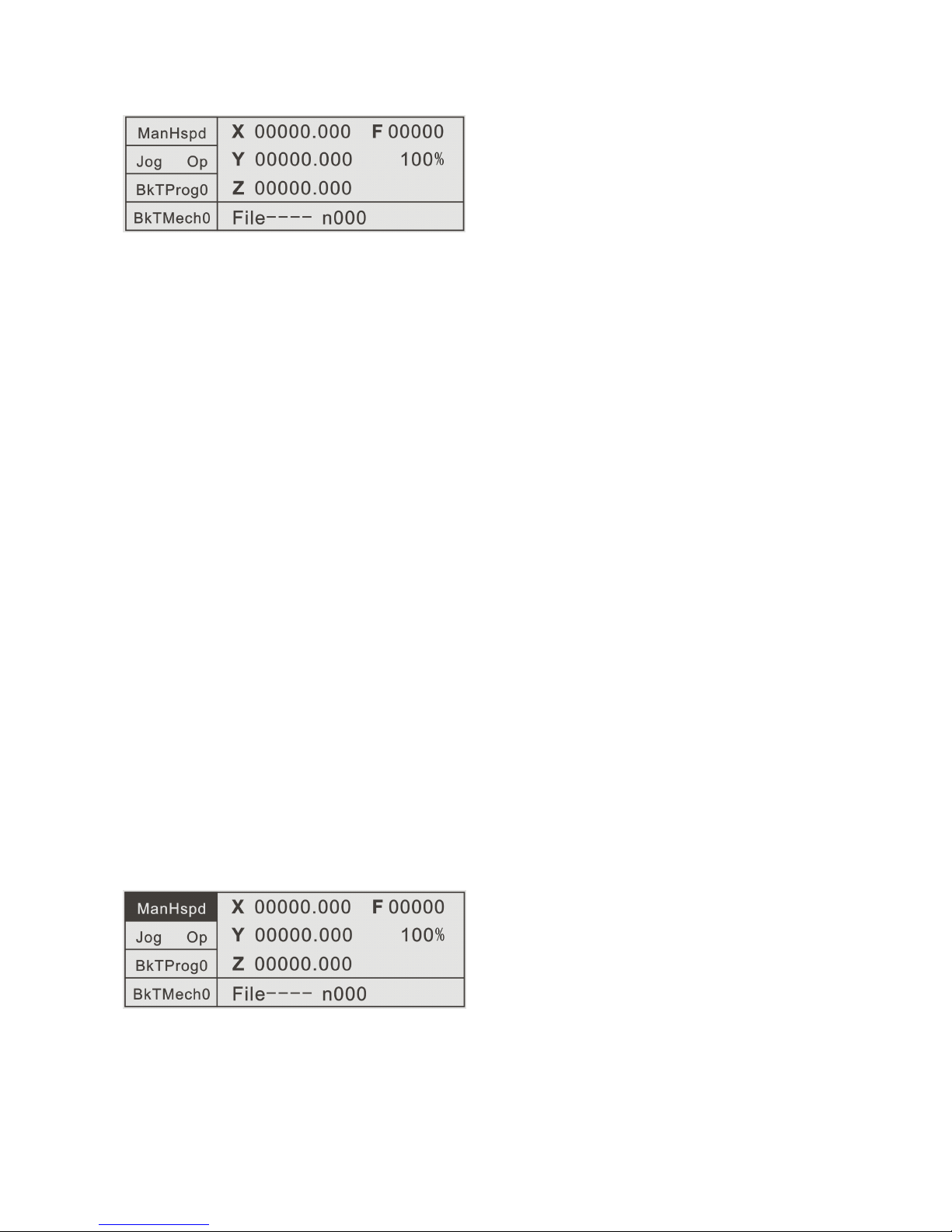

The picture shows the main interface of TC5522 or TC5522R after boot.

The picture shows the main interface of TC5530 or TC5530R after boot.

1.

1.

1.

1. The

The

The

The screen

screen

screen

screen area

area

area

area

AutoExec

:

Automatically execute. Click to enter the program execution interface,

including the default Actl Run(Actual running), Mt Run (Empty running),

SS Mo(Single-step mode running), TrmtProg(Terminate program).

Man OP: Manual operation. Click to enter the manual operation interface, including

the default Man LSpd(Manual low speed), Man HSpd(Manual high

speed), Jog Op(Jog operation), BkTProg0(Back to program zero),

BkTMech0(Back to mechanical zero).

ProgMgmt: Program management. Click to enter the program editing interface,

including Ed Prog(Edit program), Prog RI(Program read-in), Del

Prog(Delete program), Sv Prog(Save program).

Pars Set: Parameters settings. Click to enter the parameter setting interface, including

Sys Pars(System parameters), Sys SC(System self-check), IO Set(IO

settings), Usr Mgmt(User management).

X

X

X

X

:

The current coordinate position

Y

Y

Y

Y

:

The current coordinate position

Z

Z

Z

Z

:

The current coordinate position

F

F

F

F

:

The current running speed

Unit: subject to the selected electronic gear calculation formula. When electronic gear

default is 1:1, the unit default is the pulse number.

100%

100%

100%

100%

:

the speed percentage (rate) of the current F value

P

P

P

P

:

the countdown of loops

T

T

T

T

:

the countdown of delay time

2.

2.

2.

2. The

The

The

The Key

Key

Key

Key area

area

area

area

F1

F1

F1

F1

:

In the current state, the function key corresponding to the F1 key position, is

valid in the current state.

F2

F2

F2

F2

:

In the current state, the function key corresponding to the F2 key position, is

valid in the current state.

F3

F3

F3

F3

:

In the current state, the function key corresponding to the F3 key position, is

valid in the current state.

F4

F4

F4

F4

:

In the current state, the function key corresponding to the F4 key position, is

valid in the current state.

0-9

0-9

0-9

0-9

:

Valid in the Ed Prog(Edit program) state or Pars Set(Parameters settings) state.

(

0

、

1

、

2

、

3

、

4

、

5

、

6

、

7

、

8

、

9

)

1-3

1-3

1-3

1-3

:

In the Man Op(Manual operation) state, long press 1 key for three seconds, you

can modify the X-axis coordinate to "X-axis mechanical reference point value",

which is set in the Sys Pars(System parameters) area of Pars Set (Parameters

settings) area. In the Man Op(Manual operation) state, long press 2 key for

three seconds, you can modify the Y-axis coordinate to "Y -axis mechanical

reference point value", which is set in the Sys Pars(System parameters) area of

Pars Set (Parameters settings) area. In the Man Op(Manual operation) state,

long press 3 key for three seconds, you can modify the Z-axis coordinate to

"Z-axis mechanical reference point value", which is set in the Sys Pars(System

parameters) area of Pars Set (Parameters settings) area. The three values

defaults are 0.

“

“

“

“ -

-

-

- ”

”

”

”

:

In the Ed Prog(Edit program) state, it is used to distinguish between movement

direction. In the Man Op(Manual operation) state, it is used to operate the

Z-axis reverse rotation.

“

“

“

“ .

.

.

. ”

”

”

”

:

In the Ed Prog(Edit program) state, it is used to distinguish between numerical

accuracy. In the Man Op(Manual operation) state, it is used to operate the

Z-axis forward rotation.

Exit

Exit

Exit

Exit : Invalid in the program running process and valid in the rest of the state. It is

used to return to previous operation interface.

“←”

“←”

“←”

“←”

:

In the Man Op(Manual operation) state, X-axis is reverse rotation. It is valid in

the ProgMgmt(Program management) state or Pars Set(Parameters settings)

state and used to move the cursor.

“→”

“→”

“→”

“→”

:

In the Man Op(Manual operation) state, X-axis is forward rotation. It is valid in

the ProgMgmt(Program management) state or Pars Set(Parameters settings)

state and used to move the cursor.

“↑”

“↑”

“↑”

“↑”

:

In the Man Op(Manual operation) state, Y -axis is forward rotation. It is valid in

the ProgMgmt(Program management) state or Pars Set(Parameters settings)

state and used to move the cursor.

“↓”

“↓”

“↓”

“↓”

:

In the Man Op(Manual operation) state, Y-axis is reverse rotation. It is valid in

the ProgMgmt(Program management) state or Pars Set(Parameters settings)

state and used to move the cursor.

PgUp

PgUp

PgUp

PgUp : PageUp. In the main interface, AutoExec(Automatically execute) or Man

Op(Manual operation) state

,

it is the rate+ key of the speed F value and used to

increase rate of the current speed F value, maximum to 150%. In the

ProgMgmt(Program management) state or Pars Set(Parameters settings) state,

it is used to page up the current page.

PgDn

PgDn

PgDn

PgDn : PageDown. In the main interface, AutoExec(Automatically execute) or Man

Op(Manual operation) state

,

it is the rate- key of the speed F value and used to

reduce rate of the current speed F value, minimum to 10%. In the

ProgMgmt(Program management) state or Pars Set(Parameters settings) state,

it is used to page down the current page.

Cfm:

Cfm:

Cfm:

Cfm: Confirm. Valid in the Pars Set(Parameters settings) state. When modifying

parameters or entering password for user login, press the Cfm(Confirm) key to

determine to modify parameters or user login successfully.

Spc: Space. It is valid in the Ed Prog(Edit program) state or Pars Set(Parameters

settings) state and used to clear(delete) the value of the current cursor position.

St: Start. It is valid in the AutoExec(Automatically execute) state and used to start the

execution of the current program file.

Paus: Pause. It is valid in the AutoExec(Automatically execute) state and used to

pause the execution of the current program file.

3.1

3.1

3.1

3.1 AutoExec(Automatically

AutoExec(Automatically

AutoExec(Automatically

AutoExec(Automatically execute)

execute)

execute)

execute)

(TC5530R is used as an example)

3.1.1

3.1.1

3.1.1

3.1.1 Actl

Actl

Actl

Actl Run(Actual

Run(Actual

Run(Actual

Run(Actual running)

running)

running)

running)

In the main interface, press the left F1 key to enter the AutoExec(Automatically

execute) interface. At this time, the Actl Run(Actual running) key color is negative

display, and the system default is in the Actl Run(Actual running) state in the

program continuous running mode.

Actl Run (Actual running)

Mt Run(Empty running)

SS Mo (Single-step mode)

TrmtProg (Terminate program)

In this state, by pressing the St(Start) key on the controller panel or the external

input line St(Start) key defined in the IO set(IO settings) area of Pars Set (Parameters

settings) area, the controller begins running with the default last read-in program file.

Press the Paus(Pause) key to pause the running program.

To

continue to execute the

paused program file, press the St(Start) key again.

To

exit the program and remain in

the AutoExec(Automatically execute) interface, press the TrmtProg(Terminate

program) key. If want to direct exit to the main interface, the program must be in the

Paus(Pause) or TrmtProg(Terminate program) state, then press the Exit key to return

to the main interface, or the Exit key is invalid.

3.1.2

3.1.2

3.1.2

3.1.2 Mt

Mt

Mt

Mt Run(Empty

Run(Empty

Run(Empty

Run(Empty running)

running)

running)

running)

In the AutoExec(Automatically execute) interface, press the left F2 key to enter

the Mt Run(Empty running) state. At this time, the controller Mt Run(Empty running)

key color is negative display, and the system is in the Empty running state in the

program continuous running mode.

Cont Mo (Continuous mode)

In this state, press the St(Start) or Paus(Pause) key on the controller panel or the

external input line St(Start) or Paus(Pause) defined in the IO set(IO settings) area of

Pars Set (Parameters settings) area, to operate Empty running on program. At this

time, the controller program runs normally without any external action. It is often

used for simulation test after program editing and before actual running.

3.1.3

3.1.3

3.1.3

3.1.3 Single-step

Single-step

Single-step

Single-step execution

execution

execution

execution

In the Actl Run(Actual running) or Mt Run(Empty running) state, if SS

Mo(Single-step mode) is not chosen, the system default is in the program continuous

running mode and the SS Mo(Single-step mode) key color is not negative display. If

press the left F3 key corresponding to SS Mo(Single-step mode), the SS

Mo(Single-step mode) key color is negative display and in the Actl Run(Actual

running) or Mt Run(Empty running) state, program runs with Single-step mode. Each

step of the program running is controlled by the St(Start) key on the controller panel

or the external input line St(Start) defined in the IO set(IO settings) area of Pars Set

(Parameters settings) area. Press the key, the current file executes a line of program,

press again, then continues to execute next line of program.

3.1.4

3.1.4

3.1.4

3.1.4 TrmtProg(T erminate

TrmtProg(T erminate

TrmtProg(T erminate

TrmtProg(T erminate program)

program)

program)

program)

In the program pause or running state, by pressing this key, the program stops

and jumps to the first line of the program in the AutoExec(Automatically execute)

interface.

3.2

3.2

3.2

3.2 Man

Man

Man

Man Op(Manual

Op(Manual

Op(Manual

Op(Manual operation)

operation)

operation)

operation)

In the main interface, press the left F2 key to enter the Man Op

(

Manual

operation

)

interface.

Man HSpd(Manual high speed)

Jog Op(Jog operation)

BkTProg0(Back to program zero)

BkTMech0(Back to mechanical zero)

At this time, the default is Man LSpd(Manual low speed). The speed parameter

is set in the Spd Pars(Speed parameters) area of the Pars Set(Parameters settings)

area, and is the fixed mode(the rate key is valid ).

Through the keys

(

‘←’‘→’‘↑’‘↓’‘ - ’‘ . ’

)

on the controller panel or the direction

keys of external IO settings, the forward or reverse rotation of the motor can be

controlled.

3.2.1

3.2.1

3.2.1

3.2.1 Man

Man

Man

Man HSpd(Manual

HSpd(Manual

HSpd(Manual

HSpd(Manual high

high

high

high speed)

speed)

speed)

speed)

In the Man Op(Manual operation) interface, press the left F1 key to enter the

Man HSpd(Manual high speed) interface. At this time, the Man HSpd(Manual high

speed) key color is negative display, and the system is in the Manual high speed state.

The speed parameter is set in the Spd Pars(Speed parameters) area of the Pars

Set(Parameters settings) area, and is the fixed mode(the rate key is valid ).

Through the keys

(

‘←’‘→’‘↑’‘↓’‘ - ’‘ . ’)on the controller panel or the keys of external

IO settings, the forward or reverse rotation of the motor can be controlled.

3.2.2

3.2.2

3.2.2

3.2.2 Jog

Jog

Jog

Jog Op(Jog

Op(Jog

Op(Jog

Op(Jog operation)

operation)

operation)

operation)

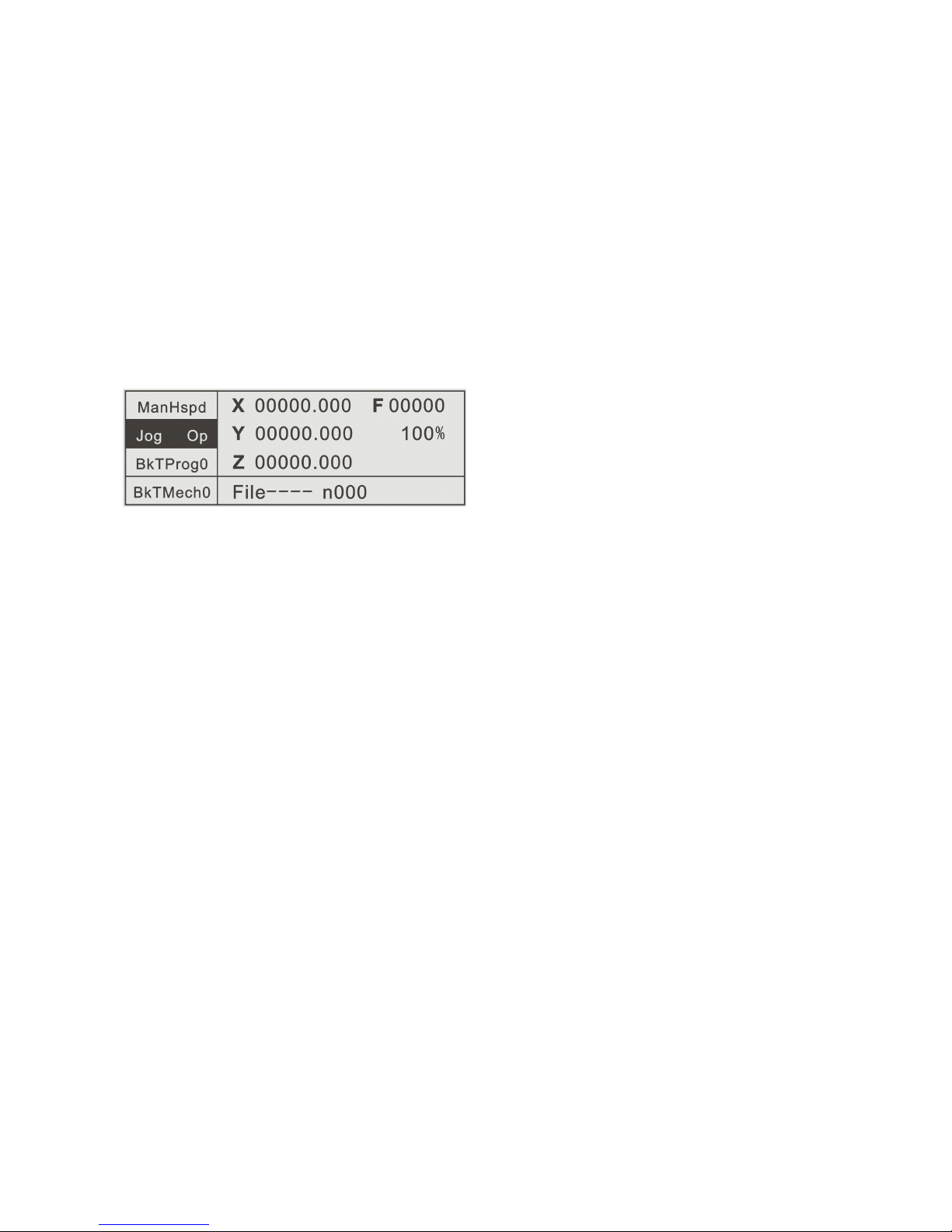

In the Man Op(Manual operation) interface, press the left F2 key to enter the Jog

Op(Jog operation) interface. At this time, the Jog Op(Jog operation) key color is

negative display, and the system is in the Jog operation state. The Jog increment

parameter is set in the CtrlPars(Control parameters) area of the Pars Set(Parameters

settings) area, and is the fixed mode.

Through the keys

(

‘←’‘→’‘↑’‘↓’‘ - ’‘ . ’

)

on the controller panel or the keys of

external IO settings, the forward or reverse rotation of the motor can be controlled

with the already set displacement increment.

3.2.3

3.2.3

3.2.3

3.2.3 BkTProg0(Back

BkTProg0(Back

BkTProg0(Back

BkTProg0(Back to

to

to

to program

program

program

program zero)

zero)

zero)

zero)

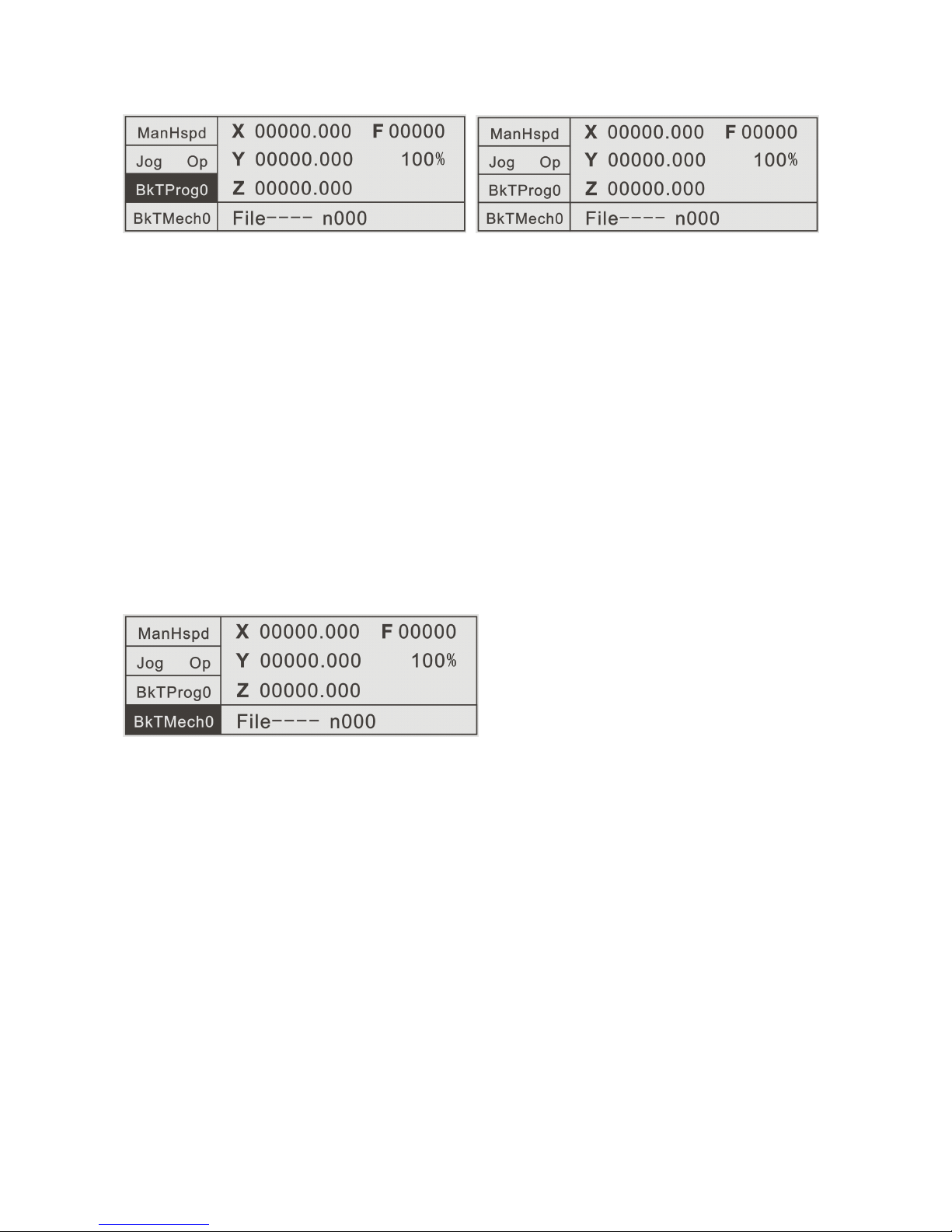

In the Man Op(Manual operation) interface, press the left F3 key to enter the

BkTProg0(Back to program zero) interface. At this time, the BkTProg0(Back to

program zero) key color is negative display, and the system is in the BkTProg0(Back

to program zero) state. The speed parameter is set in the Spd Pars(Speed

parameters) area of the Pars Set(Parameters settings) area, and is the resultant

speed of the system high speed. That is, returning back to the program coordinates

zero in linear interpolation (start at the same time, stop at the same time) mode. At

this time, only Pause is valid. After returning back to the coordinates zero, the key

color negative display is back to the normal status.

3.2.4

3.2.4

3.2.4

3.2.4 BkTMech0(Back

BkTMech0(Back

BkTMech0(Back

BkTMech0(Back to

to

to

to mechanical

mechanical

mechanical

mechanical zero(mechanical

zero(mechanical

zero(mechanical

zero(mechanical reference

reference

reference

reference point))

point))

point))

point))

In the Man Op(Manual operation) interface, press the left F4 key to enter the

BkTMech0(Back to mechanical zero) interface. At this time, the BkTMech0(Back to

mechanical zero) key color is negative display, and the system is in the

BkTMech0(Back to mechanical zero) state. The Bk0 HSpd(Back to zero high speed)

or Bk0 LSpd(Back to zero low speed) speed parameter of Back to mechanical

zero (

(

(

( reference point )

)

)

) is set in the Spd Pars(Speed parameters) area of the Pars

Set(Parameters settings) area, and is the fixed mode(the rate key is valid ).

Through the keys

(

‘←’‘→’‘↑’‘↓’‘ - ’‘ . ’

)

on the controller panel or the direction

keys of external IO settings, the single direction Back to mechanical zero(mechanical

reference point) operation of the motor can be controlled. Before completing the

BkTMech0(Back to mechanical zero) operation, only the Paus(Pause) key is valid.

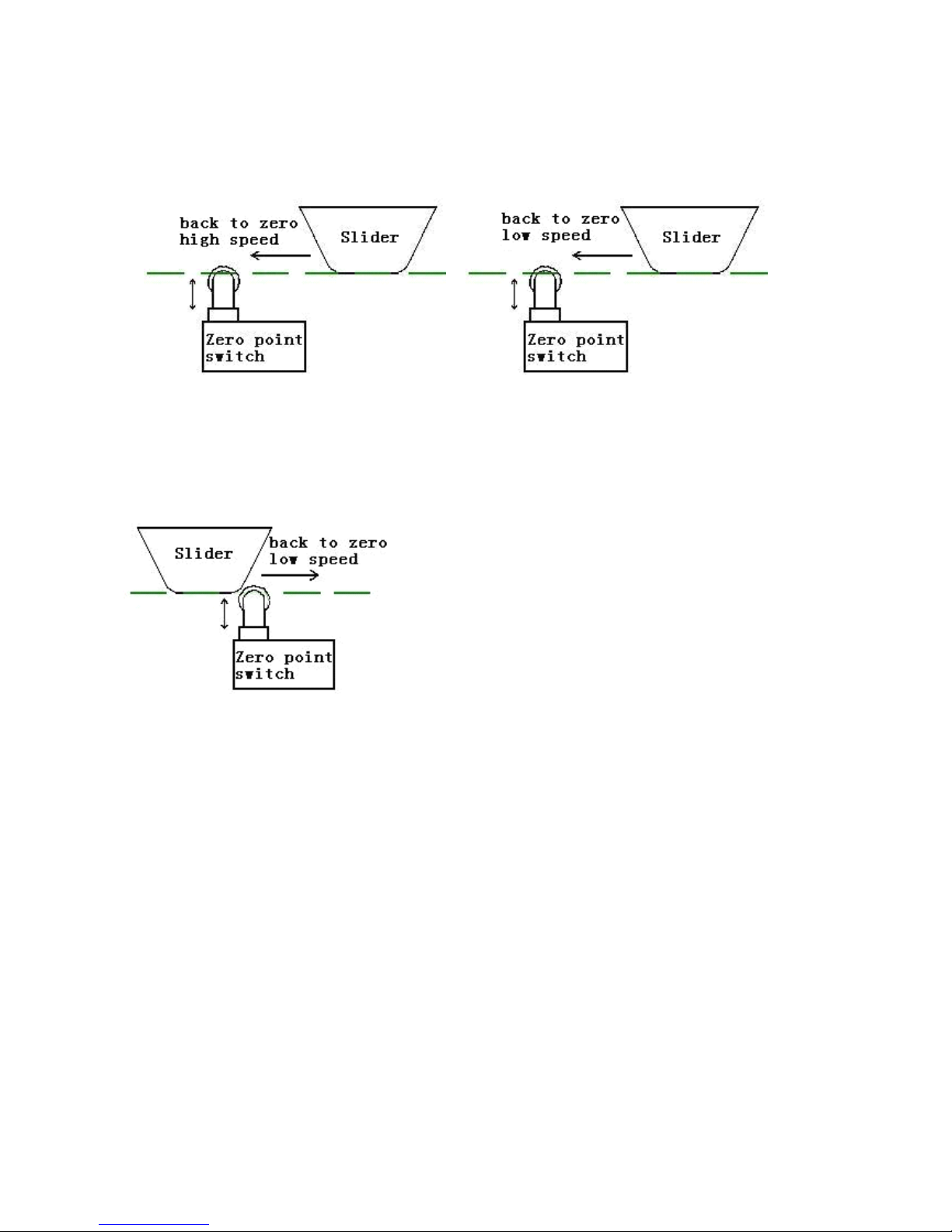

Back to mechanical zero is a set of combined actions. The premise is first to set

a set of zero point switches(both mechanical and photoelectric switches are allowed),

assuming that the switches are in the N.O.(Normally open) state.

1

)

.Firstly move to the pressed key direction (or the direction specified by the

program instructions) with Bk0 HSpd(Back to zero high speed), until touch the zero

point switch of the axis and the switch status changes from Open to Closed.

2

)

.After touching the zero point switch, move with the speed quickly reduced to Bk0

LSpd(Back to zero low speed), until pass the switch and the switch status changes

from Closed to Open.

3

)

. After the switch status changes to Open, the axis will automatically continue to

reverse move with Bk0 LSpd

(

Back to zero low speed

)

, until press the switch again

and the switch changes from Open to Closed secondly. At this time, stop instantly, the

action of Back to mechanical zero is completed and the axis coordinate on the

controller interface changes to the axis reference point value. The axis reference point

value is set in the CtrlPars (Control parameters) area of the Pars Set(Parameters

settings) area.

Note: The machine tool limit switch is used as an example in the above figures. Also

the photoelectric switch can be used as the zero point switch, similarly.

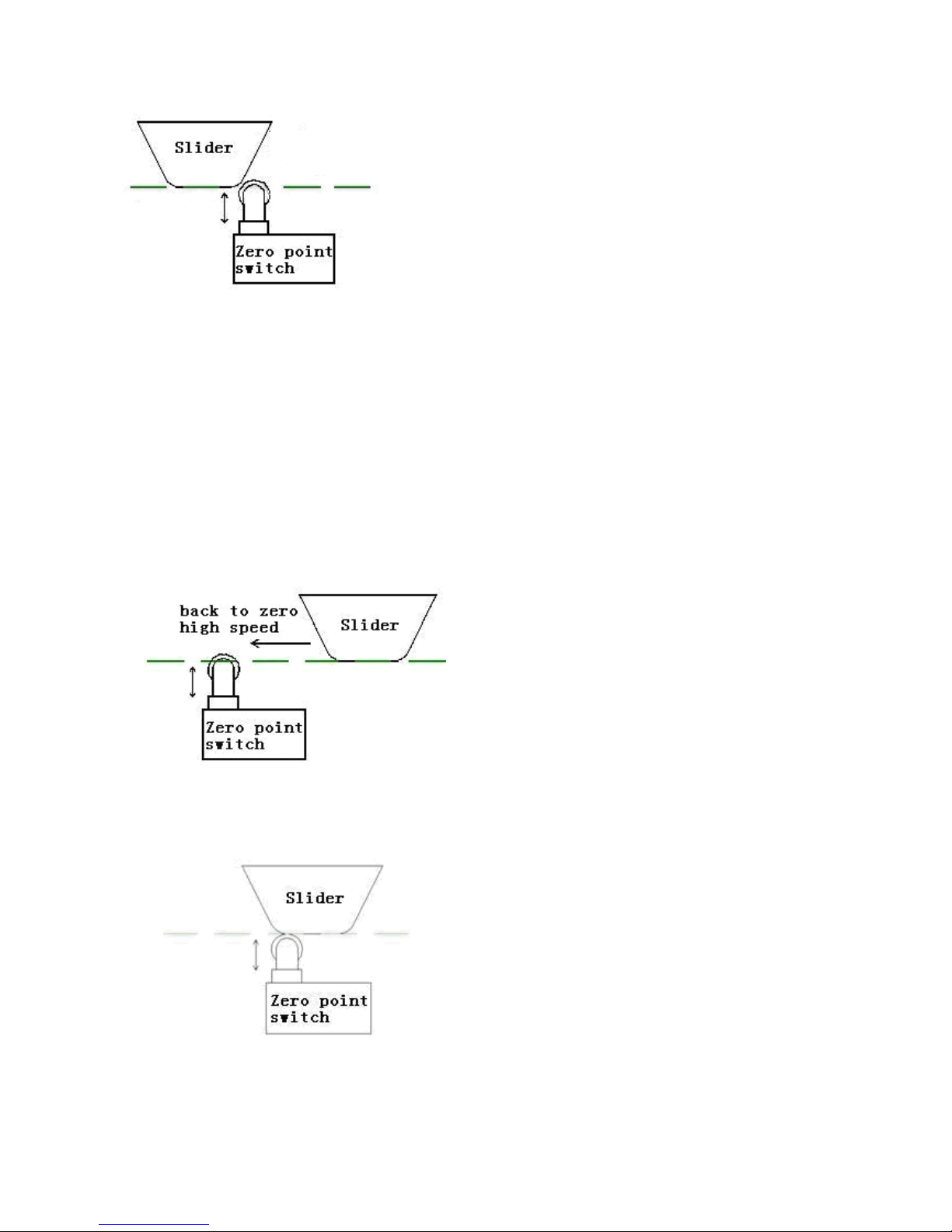

Back to zero mode II:

1). Firstly move to the pressed key direction(or the direction specified by the program

instructions) with Bk0 HSpd(Back to zero high speed), until touch the zero point

switch of the axis and the switch status changes from Open to Closed.

2). After the zero point switch is touched, the speed is quickly reduced to zero.

3). Automatically reverse move with Bk0 LSpd

(

Back to zero low speed

)

, until the

switch changes from Closed to Open. At this time, stop instantly, the action of Back

to mechanical zero is completed and the axis coordinate on the controller interface

changes to the axis reference point value. The axis reference point value is set in the

CtrlPars (Control parameters) area of the Pars Set(Parameters settings) area.

Note: Back to zero mode II has some risk. If adopting this mode, propose that Bk0

HSpd(Back to zero high speed) is set smaller to avoid the slider exceed the zero point

switch when back to zero.

3.3

3.3

3.3

3.3 ProgMgmt(Program

ProgMgmt(Program

ProgMgmt(Program

ProgMgmt(Program Management)

Management)

Management)

Management)

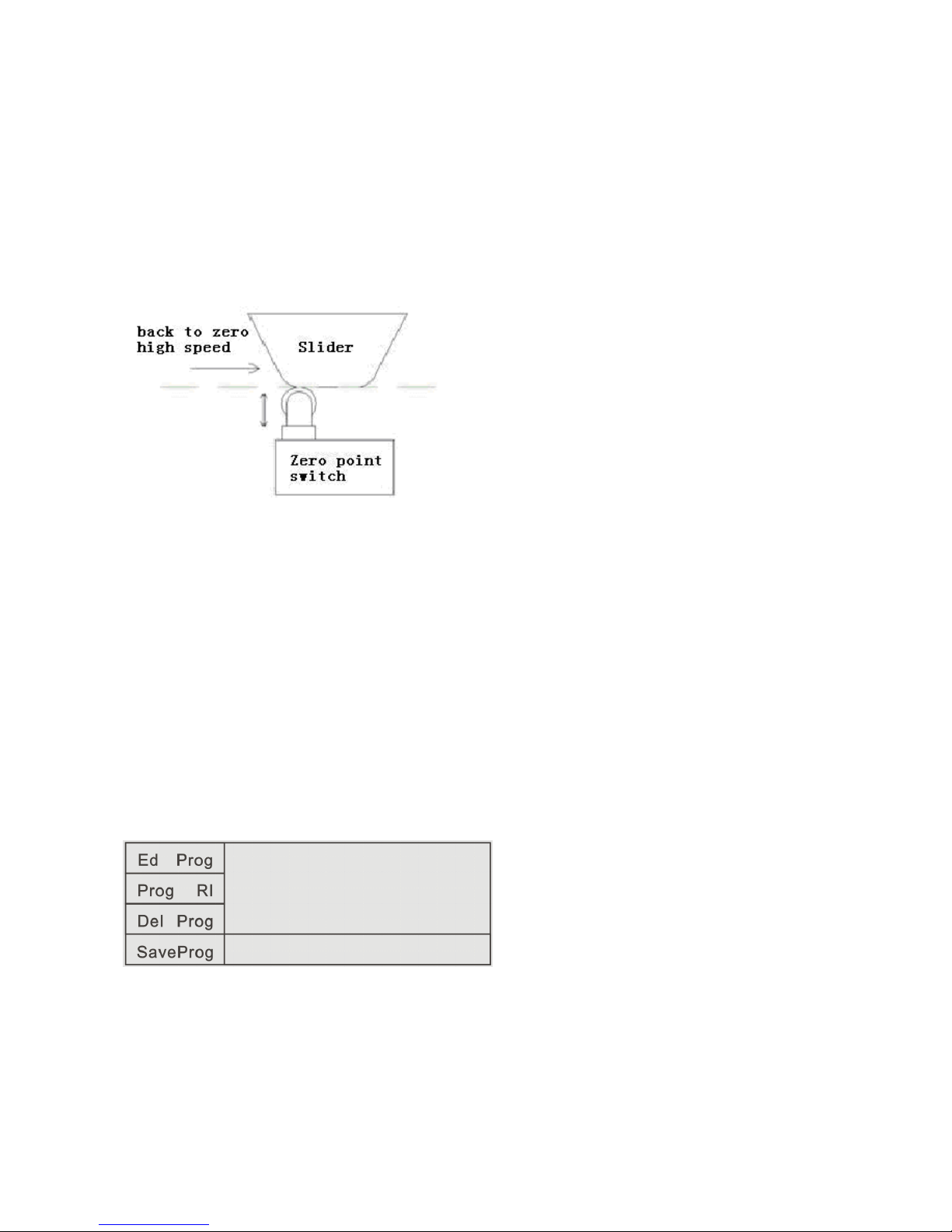

In the main interface, press the left F3 key to enter the ProgMgmt(Program

Management) interface. In this interface, we can operate program to edit, read-in,

delete and save.

Ed Prog Edit program

Prog RI Program read-in

Del Prog Delete program

Sv Prog Save program

3.3.1

3.3.1

3.3.1

3.3.1 Ed

Ed

Ed

Ed Prog(Edit

Prog(Edit

Prog(Edit

Prog(Edit program)

program)

program)

program)

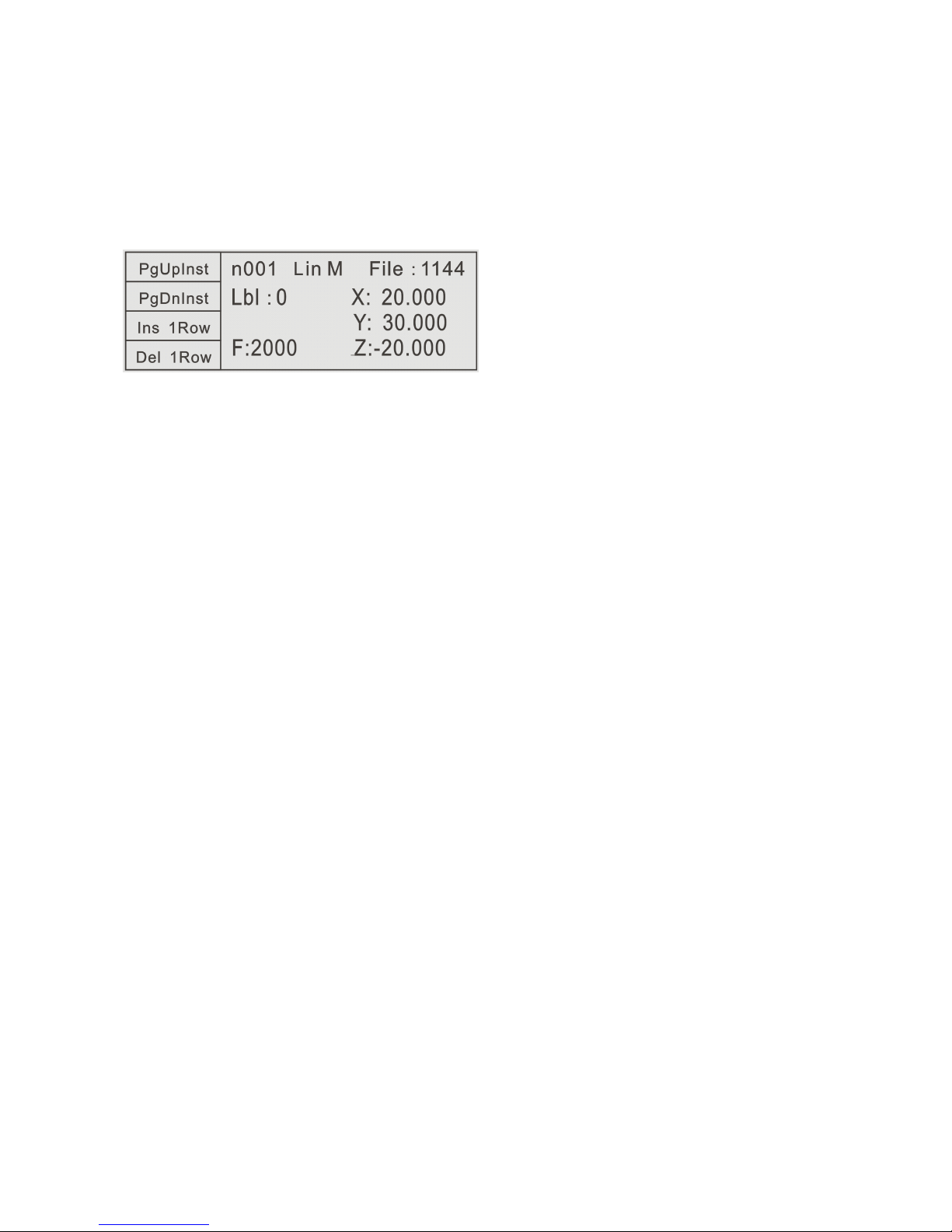

In the ProgMgmt(Program Management) interface, press the left F1 key to enter

the Ed Prog(Edit program) interface. In this interface, we can modify or rebuild the

read-in file or the last open file before the shutdown.

PgUpInst Page up instruction

PgDnInst Page down instruction

Ins 1Row Insert a row

Del 1Row Delete a row

Lin M Linear motion

Lbl Label

Abs M Absolute motion

PTP M Point to Point motion

End End

3.3.1.1

3.3.1.1

3.3.1.1

3.3.1.1 PgUpInst(Page

PgUpInst(Page

PgUpInst(Page

PgUpInst(Page up

up

up

up instruction):

instruction):

instruction):

instruction): In the current line number, through this key,

we can page up all Instruction Names controlled and applied by the controller.

Example:

In the interface,

n001 Lin M File:1144

press PgUpInst once, then becomes

n001 Abs M File: 1144

That is, in the n001 line

,

modify the old Lin M(Linear motion) instruction to the Abs

M

(

Absolute motion

)

instruction, and new instruction parameter shows

simultaneously.

3.3.1.2

3.3.1.2

3.3.1.2

3.3.1.2 PgDnInst(Page

PgDnInst(Page

PgDnInst(Page

PgDnInst(Page down

down

down

down instruction):

instruction):

instruction):

instruction): In the current line number, through this

key, we can page down all Instruction Names controlled and applied by the controller.

Loading...

Loading...