Toowoomba Foundry Southern Cross EF-D Instruction Manual

WffiWffiffiffi

MANLIFACTU*?"

* AUSTRALa

TOOWOOMBA

FOIINDRY

PTY.

tTD.

AND

MARKETED

BY

SOUTHERN

CROSS

MACHINBRY

COMPAMES

3+

DIF$[[

Tl\IOIN

E

ll/lARK

EF-II

4z

this

lnrtnrction

Manual

*

Read

through

)piraring

'l

canefully

before

Installing

or

O

:

your

Engine.

-

*.

Hang

this

Instruction

Manual

in

thc

,"

Errgirre

Roorn

fqr

Future

Reference'

3*n*ooJ

,

Remember

that

this

Engine.has

beea

carefully

built'

and

has

been

,rrr,

tr,f,'.,-ti""iiiig

iests

b"rore

-it

left

the

w""#r.

"eil

idjurt*"nts

are

correct

and

should

not

bQ,

altered.

A

new

Engine

req

i'ffi;^b;;;;;-,;ii;.

lirti

t"*

days

than

after

the

Part:

oughly

worked

in.

It will

take

a

few

days

for

the

various

working

parts

to

set

into

,,i."

rror#ii".;;iili;"'.*'co"r"q"""tly

iny

En-

li;;;;;l;

b".;;;;'irv

""a

carefullv

treated

at

first

wiil

rtrn

more

t*t[i[iv-,

itta

gttgtallv sive

more

satis-

factorv

results

over

a

longer

perrod

than

one

whith

has

il;;;";;l,oaded

at

first'

*

This

Instruction

Manual

ht'-!":"

preparedto.assist

in

the

In'

stallation,

O;;Joi,

"oa

rvr"i"l""t""e

'of

th3

E

tet":'

:"d

;ffi;;"#

;;i;ir"

u"r"re

proceedins

with

the

Installation'

SOATHERN

CROSS

DIESEL

ENGINES

Instollcrtion

r

Opercrtion

and

Mcrintencrnce

Imstructions

fur

Wffiffiffiffiffiffiffiffiffiffi

3*

H.P.

DIHSFL

HNGINE

MAR,K

EF.D

Page One

14.5/A

1250

r)]tu

rr.D&R

L

Page

Tu.,o

SOUTHERN CRO,SS

DIESEL

ENGINES

INSTATLATION

The

Foundation

The engine

should be set up on

a

firm foundation.

The recommended

foundation

is a block

of concrete

as

shown

in

the

illustration,

"Genetal

Arrangement

of 31

h.p.

Diesel Engine,

M'ark

EF-D", on

page

3.

The four

foundation bolts

supplied

with

the

engine should

be set

in

the

concrete block r'vhen

it is

made,

The illustration on

page

3 also

shows the

overall

sizes of the

engine and

the

positions

of

the foundation

bolts.

Engine Drive

Engines

are supplied

for

the

following

types of

dllysg;-

(a)

Belt driving from drive end

,of

Crankshaft

(either

flat or V-Belt

Pulley).

(b)

Belt driving

from

extension shaft

at

flyw,heel end

(V-Belt

Pulley).

(c)

Direct

coupling to

driven machine by

means of a

fiexible coupling.

(d)

Beit

driving from

2

: 1 reduction box

mounted on

engine

(either

flat

or V-Belt

Pulley). Pulley runs

in reverse direction of rotation to engine crankshaft.

(e)

Direct

coupling

by means,of a flexible coupling

from

2 : 1 reduction box mounted on engine.

Flexible coupling runs in

reverse d'irection

of

rota-

tion

to engine cranhshaft.

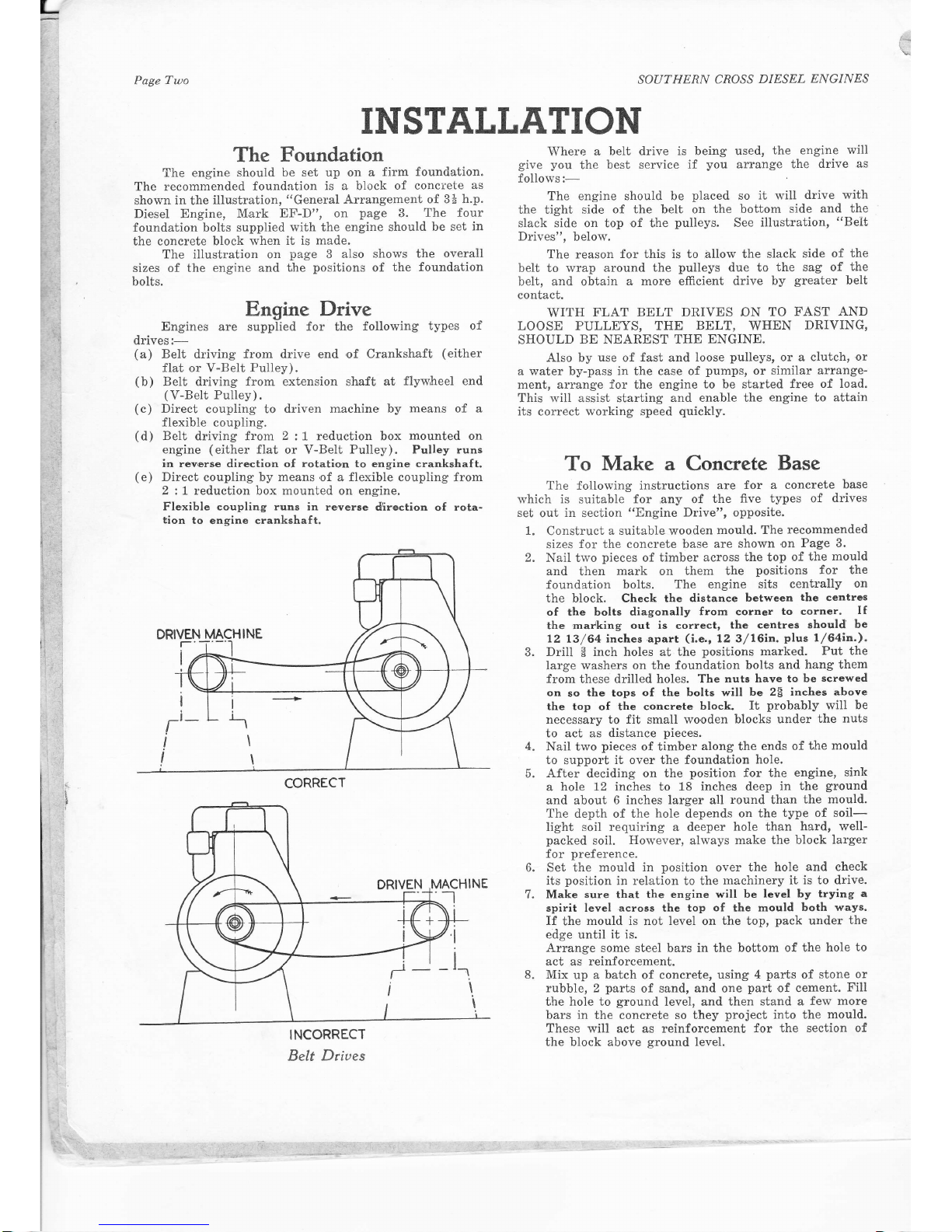

INCORRECT

Belt Dtiues

Where

a

belt drive is being used,

the engine

will

give you

the

best ser-vice if

you

arrange

the

drive

.as

follows:-

The engine should be

placed

so

it will

drive with

the tight

side of the belt on

the bottom

side and

the

slack side on top

,of

ihe

pulleys.

See

illustration,

"Belt

Drives",

belolv.

The reason

for this is to allow the

slack side

of the

belt to

rvrap around

the

pulleys

due to

the sag of

the

beit, and obtain

a more efficient drive

by

greater

belt

contact.

\,VITH

FLAT BELT DRIVES ON

TO

FAST

AND

LOOSE PULLEYS,

THE

BELT,

WHEN

DRIVING,

SHOULD

BE

NEAREST

THE

ENGINE.

Also by

use

of

fast

and

loose

puileys,

or a clutch,

or

a water by-pass in the case of

pumps,

or

similar arrange-

ment, arrange for

the

engine to

be started

free of load.

This will assist starting

and enable the

engine to attain

its correct rvorking speed

quickly.

To

Make a Concrete

Base

The

following instructions

are

for a concrete

base

which

is

suitable

for any of

the five

types of

drives

set

out

in section

"Engine

Drive", opposite.

1.

Construct

a suitable wooden

mould. The

recommended

sizes

for the concrete base

are shown

.on

Page 3.

Nail tu'o

pieces

of

timber across

Lhe top of

the

mould

and

then

mark

on

them the

positions

for the

foundation

bolts. The engine

sits

cenlrally

on

the block. Check

the distance

between

the centres

of the bolts diagonally

from corner

to corn€r.

If

the

maiking out is correct,

the centres

should

be

12

13/64

inches apart

(i.e.,

12 3/16in.

plus

1/64in.).

Drill

I

inch holes at

the

positions

marked.

Put the

large washers on the foundation bolls

and

hang them

from

these drilled

holes. The

nuts have

to be

screwed

on

so

the tops

of the bolts will

be 2E inches

above

the top of the concrete

block.

It

probably

will

be

necessary to fit small rvo'oden

blocks under

the

nuts

to act as

dislance

pieces.

Nail two

pieces

of timber

along

the

ends of

lhe

mould

to

support

it over the foundation

hole.

After

deciding

on the

position

for the

engine,

sink

a

hole 12 inches to 18 inches

deep in

the

ground

and about

6 inches larger all

round

than

the mould.

The depth of the

hole

depends

on the

type of soil-

light soil requiring a deeper

hole than

hard, well-

packed

soil.

Holever,

always

make the block

larger

for

preference.

Set the

mould in

position

over

the

hole and check

its

position

in relation to the

machinery it

is to drive.

Make

sure

that the

engine will

be level by

trying a

spirit level

across

the top

of

the

mould

both ways.

If

the

mould is

not

level on the top,

pack

under

the

edge until it is.

Arrange some steel bars in the

bottom of the

hole

to

act

as

reinforcement.

Mix

up a

batch

of concrete,

using

4

parts

of

stone

or

rubble, 2

parts

of sand, and one

part

of

cement,

Fili

the hole to

ground

level, and

then stand a

few more

bars

in

the concrete so

they

project

into the

mould.

These will act as reinforcement

for the section of

the

block above

ground

level.

DRIVEN

MACHINE

CORRECT

2.

4.

5.

6.

7.

8.

\J

SOATHERN

CROSS

DIESEL ENGINES

Page Three

I

I

VEE I

PULLEYS-l

ONLY

ON

THIS

END

'--78

t.2so"

1 24g"

DIA

t.

l""sounee

KEYWAYI

t249"

DIA

REDUCTION

-"

Box.

6

2.d-----i

L,

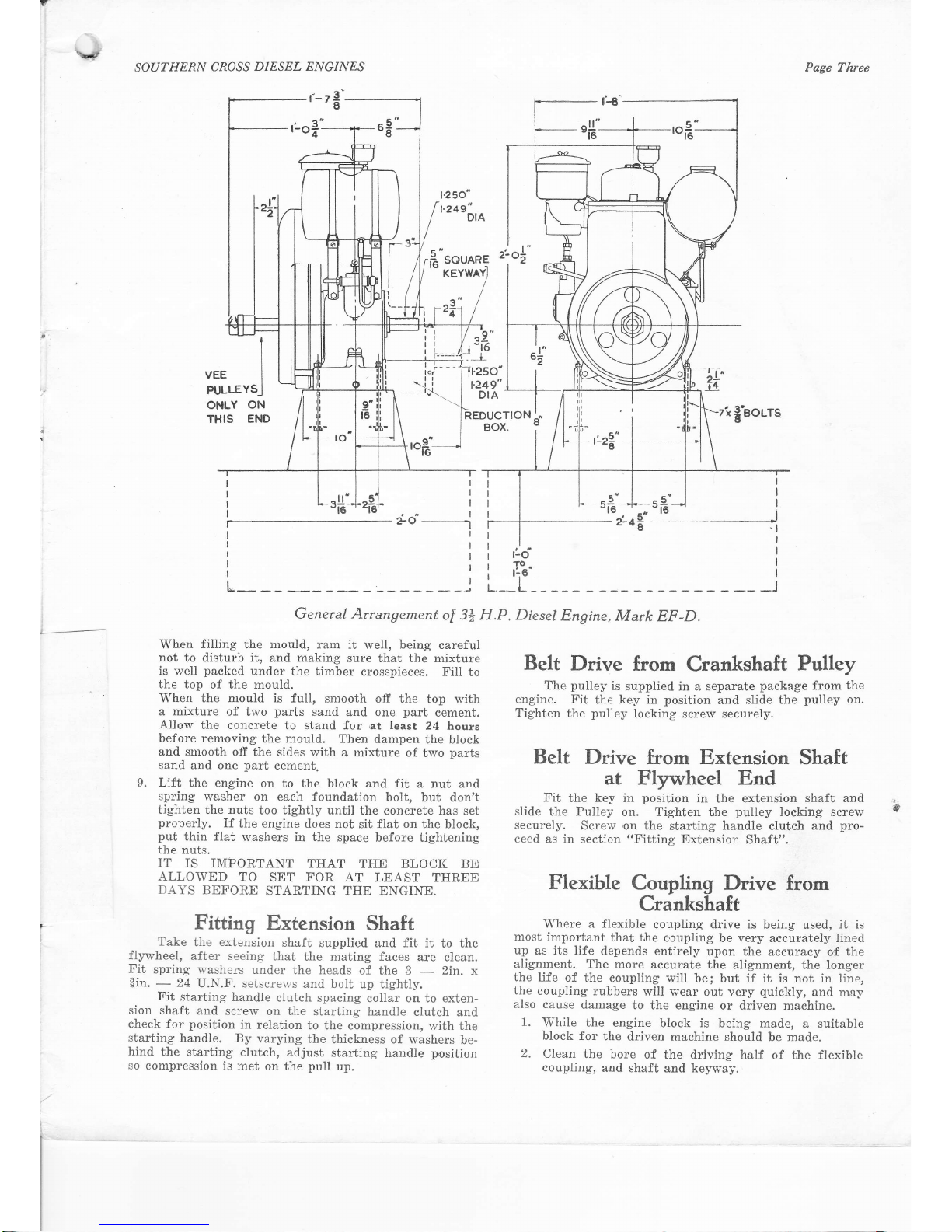

General Arrangement

of

jls

H.P. Dieset

Engine,

Mark

EF-D.

r:d

I

rcl

r.t6' I

__L__ ______l

When

filling

the

mould,

ram it weII, being

careful

not to disturb it,

and

making

sure

that the mixture

is weII

packed

under the timber

crosspieces.

Fill to

the top

of the mould.

When the mould

is full, smooth

off the

top with

a mixture

of two

parts

sand

and one

part

cement.

Allow

the concrete

to stand for

.at

least

24 hours

before rem,oving

the mould.

Then

dampen

the block

and

smooth off

the sides with

a mixture of

two

parts

sand

and one

part

cement.

9.

Lift

the engine

on to the block and fit

a nut and

spring

washer

on each foundation

bolt,

but don't

tighten the nuts

too

tightly

until the

concrete has set

properly.

If

the engine

does not

sit flat

on

the block,

put

thin flat

washers

in

the

space

before tightening

the

nuts,

IT

IS IMPORTANT

THAT

THE

BLOCK

BE'

ALLOWED

TO

SET

FOR AT

LEAST THREE

DAYS

BEFORE

STARTING THE ENGINE.

Fitting

Extension

Shaft

Take

the

extension

shaft

supplied and fit it

to the

flywheel,

after

seeing

that

the mating faces

are

clean.

Fit

spring rl'ashers

under

the heads

of

the 3

-

2in. x

3in.

-

24

U.N.F. setscrervs

and bolt

up tightly.

Fit

starting

handle

clutch

spacing

collar on to exten-

sion shaft

and

screw

on the

starting handle

ciutch

and

check

for

position

in

relation

to the

compression,

with the

starting

handle.

By

varying

the

thickness of washers

be-

hind the

starting

clutch, adjust

starting

handle

p,osition

so compression

is met

on the

pull

up.

s9"--L-s9"-J

I

jr.o8"

'"

-!

Belt

Drive

from

Crankshaft

Pulley

The

pulley

is supplied

in a separate

package

from

the

engine.

Fit

the key in

position

and slide

the

pulley

on.

Tighten

the

pulley

locking screw securely.

Belt

Drive

from Extension Shaft

at Flywheel

End

Fit

the

key

in

position

in

the extension

shaft and

slide

the Pulley

on. Tighten

the

pulley

locking screw

securely.

Screw

,on

the

starting

handle

clutch

and

pro-

ceed

as in section

ttFitting

Extension

Shaft".

Flexible

Coupling Drive

from

Crankshaft

Where

a

flexible

coupling drive is being

used,

it

is

most

important

that the

c'oupling

be

very

accurately lined

up as its

life

depends entirely

upon the

accuracy of

the

alignment.

The more

accurate

the alignment, the

longer

the

life of

the coupling

will be;

but

if

it is not in line,

the

eoupling

rubbers

will

wear out very

quickly,

and

rnay

also

cause

damage

to the engine

or driven machine.

1.

While

the engine

block is being made,

a suitable

block for

the

driven

machine should

be made.

2,

Clean

the bore

of

the driving half

of the flexible

coupling,

and

shaft

and

keyway.

i-

'*.-

Page Four

5.

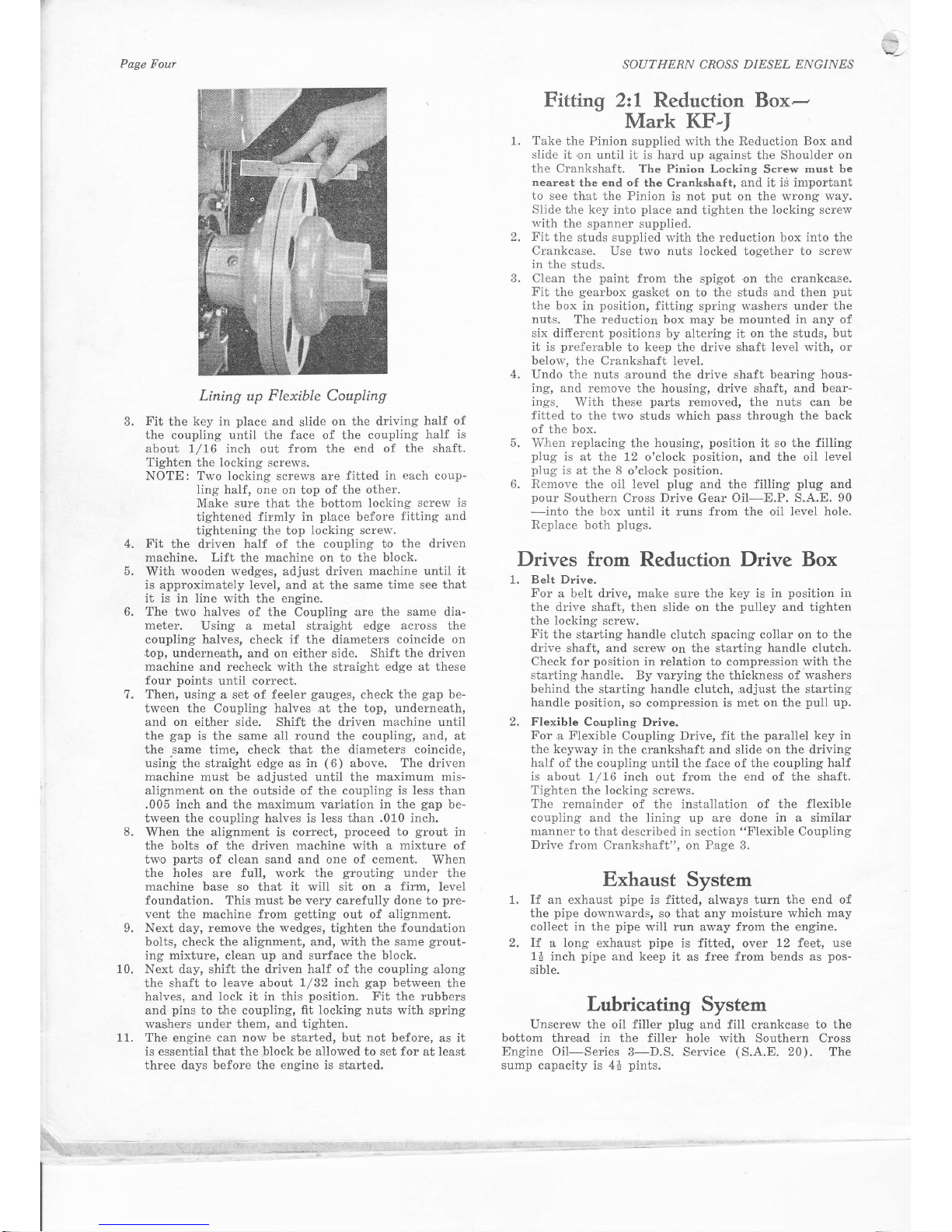

Lining up Flexible Coupling

Fit

the key in

place

and

slide

on the driving

half of

the

coupling until the face of the

coupling

half

is

about

1/16 inch out from the

end of the shaft.

Tighten the locking screws.

NOTE:

Two locking

scre\\,'s

are

fitted in

each

coup-

ling

half,

one on top of the

other.

M,ake sure that

the

bottom

locking

screw is

tightened firmly

in

place

before

fitting and

tightening

the top locking screrv.

Fit

the driven

half

of

the coupling to the

driven

machine. Lift

the

machine

on to the

block.

With

wooden wedges,

adjust driven

machine until it

is approximately level,

and at the

same time see

that

it is in line

with the engine.

The

two halves

of

the

Coupling

are the same dia-

meter.

Using a metal straigJit edge across the

coupling halves,

check

if the

diameters

coincide on

top, underneath,

and on either side. Shift

the

driven

machine

and recheck

with the

straight edge at these

four

points

until correct.

Then,

using a set'of feeler

gauges,

check the

gap

be-

tween the Coupling halves

,at

the

top, underneath,

and on either side.

Shift the

driven machine

until

the

gap

is

the same

.a11

round

the coupling,

and, at

the

.same

time, check that the diameters

coincide,

using

the str,aight edge as

in

(6)

above. The

driven

m.achine must be

adjusted

until

the

maximum mis-

aiignment on

the outside of the

coupling is less

than

.005

inch

and the maximum

variation in the

gap

be-

tween the coupling halves is less t,han

.010

inch.

When the aiignment is correct,

proceed

to

grout

in

the bolts

of

the driven

machine

with a

mixture

of

tw,o

parts

of cle,an sand and one of cement.

When

the holes are full, work

the

grouting

under

the

machine

base so that

it

will sit on a

firm,

level

foundation. This must be very carefully done to

pre-

vent

the

machine from

getting

out of alignment.

Next day,

remove

the

wedges,

tighten the

found,ation

bolts,

check the

alignment, and, with the same

grout-

ing mixture, clean up and surface the block.

Next

day, shift the driven half of the coupling ,al,ong

the

shaft

to

leave abofi

I/32

inch

gap

between

the

halves,

and lock it in this

position.

Fit the rubbers

and

pins

to the coupling,

fit locking

nuts with

spring

washers under them, and tighten.

The

engine

can now be started, but not before,

as it

is essential that

the block be allowed

to set

for

at least

three days

before the engine is started.

8.

SOUTHERN CROSS

DIESEL ENGINES

Eitting 2:l

Reduction

Box-

Mark KF-I

1.

Take

the

Pinion

supplied

*'ith the

Reduction Box and

slide it

,on

until it is hard

up

against

the Shoulder

on

the Crankshaft. The Pinion Locking

Screw

must be

nearest

th,e end

of

the

Crankstraft, and

it is important

to

see that the Pinion

is

not

put

on the

wrong way,

Slide

fhe key into

place

and tighten the

locking screw

rvith

the

spanner

supplied.

2, Fit

the studs supplied

with the reduction box

into

the

Crankcase.

Use two nuts locked together to

screw

in the studs.

3. Clean

the

paint

from the

spigot

,on

the crankcase.

Fit

the

gearbox

gasket

on

to

the studs

,and

then

put

the

box in

position,

fitting

spring washers under

the

nuts.

The reduction

box

may

be

mounted in any of

six different

positions

by altering it on the studs,

but

it is

preferabie

to keep the drive shaft level with,

or

below,

the Crankshaft level.

4.

Undo the nuts ,around

the

drive shaft bearing

hous-

ing, and

remove the housing,

drive

shaft, and

bear-

ings.

With these

parts

removed, the

nuts

c.an

be

fitted

to the two studs which

p,ass

through the back

of the box.

5. lVhen replacing

the housing,

position

it so

the filling

plug

is at

tlne 72 o'clock

position,

and

the oil

level

plug

is at

the

8

o'ci,ock

position.

6. Remove

the oii level

plug

and

the

filling

plug

and

pour

Southern Cross Drive Gear Oil-E.P. S.A.E.

90

-into

the box until

it

runs

from the

oil

level hole.

Replace

both

plugs,

Drives from

Reduction

Drive Box

1.

Belt Drive.

For

a belt drive, make

sure the

key is in

position

in

the drive shaf't,

then slide on

the

pulley

and

tighten

the locking screw.

Fit

the starling handle

clutch

spacing collar on to the

drive

shaft, and screw on the starting

handle clutch.

Check for

position

in relation to

compression

with the

starting

,handle. By

varying the thickness

of washers

behind the starting handle

clutch,

adjust the starting

handie

position,

so compression

is met on the

puli

up.

2. Flexible Co,upling

Drive.

For ,a

Flexible

Coupling

Drive, fit

the

parallel

key in

the

keyu'ay

in

the crankshaft and slide

,on

the

driving

half

of the coupling

until

the f,ace

of

the coupling

half

is about 1/16

inch out from the end of the shaft,

Tighten

the

locking

screws.

The remainder

of the installation of the

flexible

coupiing and

the lining up

,are

done

in a

similar

manner

to that described in section

"Flexible

Coupling

Drive

frorn Crankshaft",

on

P,age

3.

Exhaust

System

1.

If

an exhaust

pipe

is fitted, always turn the end of

the

pipe

downv'ards,

so that any

moisture which may

collect

in

the

pipe

will run away from the engine.

2, If.

a long exhaust

pipe

is fitted,

over

12 feet, use

11 inch

pipe

and

keep it as free

from

bends as

pos-

sible.

Lubricating System

Unscrew the

oil

filler

plug

and fill crankcase to

the

bottom

thread in the filler

hole

with

Southern Cross

Engine Oil-Series

3-D.S. Service

(S.A.E.

20).

The

sump

capacity is

4i

pints.

4.

6.

7.

o

10.

11,

SOL]THERN

CROSS

DIESEL

ENGINES

Fitting

Oil

Bath

Air

Cleaner

The Oil

gith

Ai" Cleaner

Assembly

is

to

be

fitted to

the

engine before

starting.

To do

this,

fit

the

Oil Bath

Air Clianer

Adaptor

to

the

studs

in the

Cylinder

Head,

and tighten

the

nuts.

IJnscrew

the

Wing

Nut

and remove

the Cover.

FiIl

Oil

B,ath

up

to the

oil

leve1

mark

with

clean

engine

oil

and

refit

the

element

and

cover.

Fuel

SYstem

FilI the

fuel

tank with

fuel

which

is clean

and

free

from

water.

(See

page

?

for

"Fuel

Recommendations"')

If in doubt

about

cleanliness

of

fuel,

strain

it

through

a

fine

gauze

strainer

before

filling into

tank'

18 Gallon

Fuel

Tank

(Supplied

as

o.

1.

an

Extra)

Disconnect

the

fuel tank

to

filter

tube

and

injector

,overflow

tube

and

remove'

taking

care

not to

lose

the

washers

from either

side

of

the banjos.

Remove

fuel

tank

,and

fuel

tank

brackets

from the

engine.

R,emove

banjo

and

collar

from

the

injector

overflow

tube by

holding

them

in

boiling

water

for

about

4

minute

and

then

withdr,awing

and

removing

them.

The

banjo

and collar

,are

to

be

fitted to

the end

of

the

longer

injector

overflow

tube,

supplied

with

the

Preparing

the

Engine

For

Running

T5 start

the

engine

for the

first time,

or after

an

overhaul,

or any

operation

during

whioh the

lubricating

oil

has been

drained

fr"om

the sump'

or

after the

fuel

tank

has been

ailowed

to

run dry,

the

following

instruc-

tions must

be carried

out

in the

order

given,

other^wise

the

engine

may not

statt, ot,

if it does,

it may

be dam,aged'

Check

the following

(see

Pages

4 and

5) :-

1. Fuel

in fuel tank.

2.

OiI

levei in

Engine Sump.

3. Oil

in Oil

Bath Air Cleaner.

Retarding

Iniection

Timing

(.Export

Engines

OnlY)

Diesel

fuels

obtainable

outside

Australia

vary con-

siderably.

To

assist

in starting

the

engine

the

injection

timing

may be

retarded

up to

5o

from

the factory

setting.

Degree

rnarkings

on the

flywheei

alongside

the

"Pump"

mark are

provided to assist

in this

'adjustment.

At the

factory,

the

injection timing

is set so that

the

fuel ceases

to

flow

when the

"pump"

mark

on the

flywheel

is opposite

the

mark

on the

fuel

pump

mounting

plate.

(See

illustration,

"Checking

Fuel Pump

Timing",

on

Page

Twelve.

)

To retard

the

injection

timing, adjust

the

fuel

pump

r"ocker

adjusting

screw.

Read

Section

(5),

"Check

Fuel

Pump Timing",

on

Page

Twelve.

Under

no circumstances

is the

fuel

pump

timing

to

be

retarded

beyond

the 5o

marking.

Priming

Fuel

System

IMPORTANT-If

you don't

follow

these

instructions

the engine

won't

start, as

the

fuel

system

must be abso-

lutely full

of

fuel and

free from

air.

1. Shift

fuel stop

cock

to

"on"

position

by

gripping

the

knurled

sleeve

and

sliding

it downwards

as

far

as

it will

go.

2. Disconnect

high

pressure tube from

pump

and

then

rernove delivery

valve

connection

("8"

on illustra-

tion)

and lift

the delivery

valve off

its seat.

Replace

valve and

connection

as so'on

as

fuel

flows without

air

bubbles,

and

be sure the

spring

is

in

position.

If

the

fuel

does not

flovr after

the

valve

has

been

removed,

rotate the

engine

about one

turn'

4.

,Page

Fiue

engine. Cut this

tube

to the

correct

length,

and

fit

the

double

banjo and

collar

supplied

with

the

tank to

the other

end.

To

do

this,

slide the

collar

back

about

6 inches

along the tube

and

then

immerse

about

1

inch

,of

the tube in

boiiing water

for

about

*

minute.

Quickly

withdraw

the

tube,

slide

the collar

to

,about

*

inch from the

end, and

push

the tube

on to

the

banjo.

Using

the brackets

provided,

mount the.

18

gallon

fuel

tank on.a

convenient

wall

with the

bottom

of

the

tank

at le.ast

12 inches

,above

the level

of the

pump

inlet.

Fit

the

fibre washer

provided

on

the

adaptor

fitting

and

screw it

into

the

bottom

of the

tank.

Fit

the

fibre

washer

provided

to

the

fuel stop

cock

and screw it

into

the

adaptor,

7.

Cut the

fuel

tank to

filter tube

to length

and fit

it

to the double

banjo on the

injector

overflow

tube,

and

the fuel stop

cock,

using

the

same

procedure

as

above'

Connect the

banj,o

fittings

to the filter and

injector,

fitting

fibre washers

on either

side

of each

banjo.

8. FilI the

fuel

tank

with

distillate

fuel,

which

is clean

and free from

water

(see

Page 7

for fuel

recom-

mendations,).

Never

fill the

t'ank without

pouring

the

fuel through

the strainer

provided

in

the

top

of

the

tank.

THE INSTALLATION

OF

THE

ENGINE

IS NOW

COMPLETE.

See

that

the

contro]

rod stop on the

fuel

pump

con-

trol rod is

in the

running

position

as

shown

at

"D"

on

iilustration

(page

6).

Rotate engine until

fuel

is

pumped

from the

top of

the fuel

pump.

Then fit

the high

pressure

pipe

and

tighten

nut at the

fuel

pump

end.

Leave the oiher

end of

the

pipe

undone.

Rotate the engine

until the

fuei is

pumped

from the

end of

the

pipe

wrlthout

air bubbles.

Then tighten

nut.

It is important to

see that no air

is

imprisoned

in

the fuel line, as

it

will

prevent

the engine

'from

starting.

Crank the

engine, and,

if the fuel is being

injected

pr'operly,

a decided vibration can be

heard and

felt

on

the high

pressure pipe,

but

if

air

is still

in

the

fuel

pipe,

the fuel

vrill not be injected,

and it

will

be necessary to further bleed the system.

The engine is now ready

to,start.

5.

6.

2.

RUNNING

INSTRUCTIONS

o.

4.

5.

6.

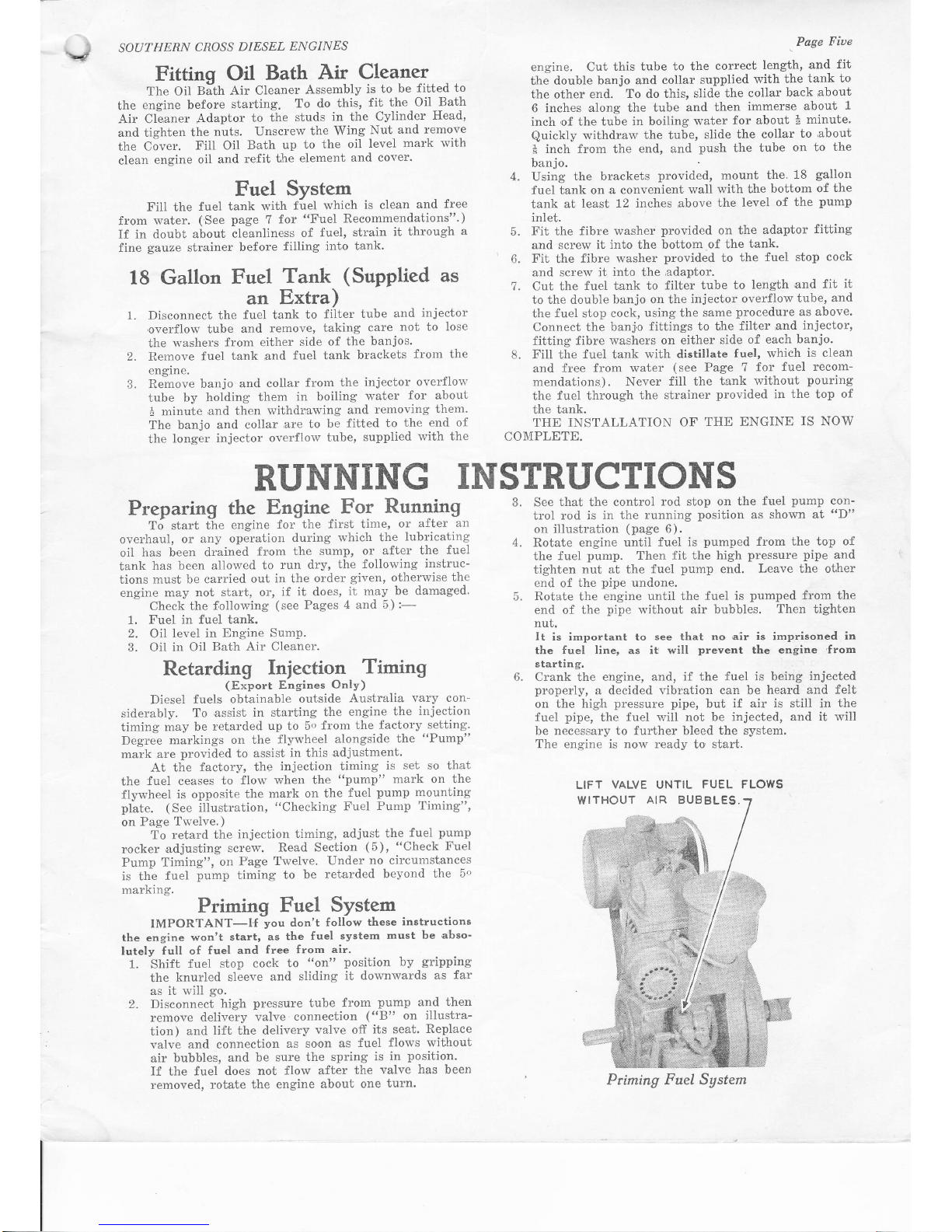

LIFT

VALVE

WITHOUT

UNTIL

FUEL FLOWS

AIR

BUBBLES.

Priming

Fuel Sgstem

I

SOUTHERN

CROSS

DIESEL

ENGINES

Page Sir.

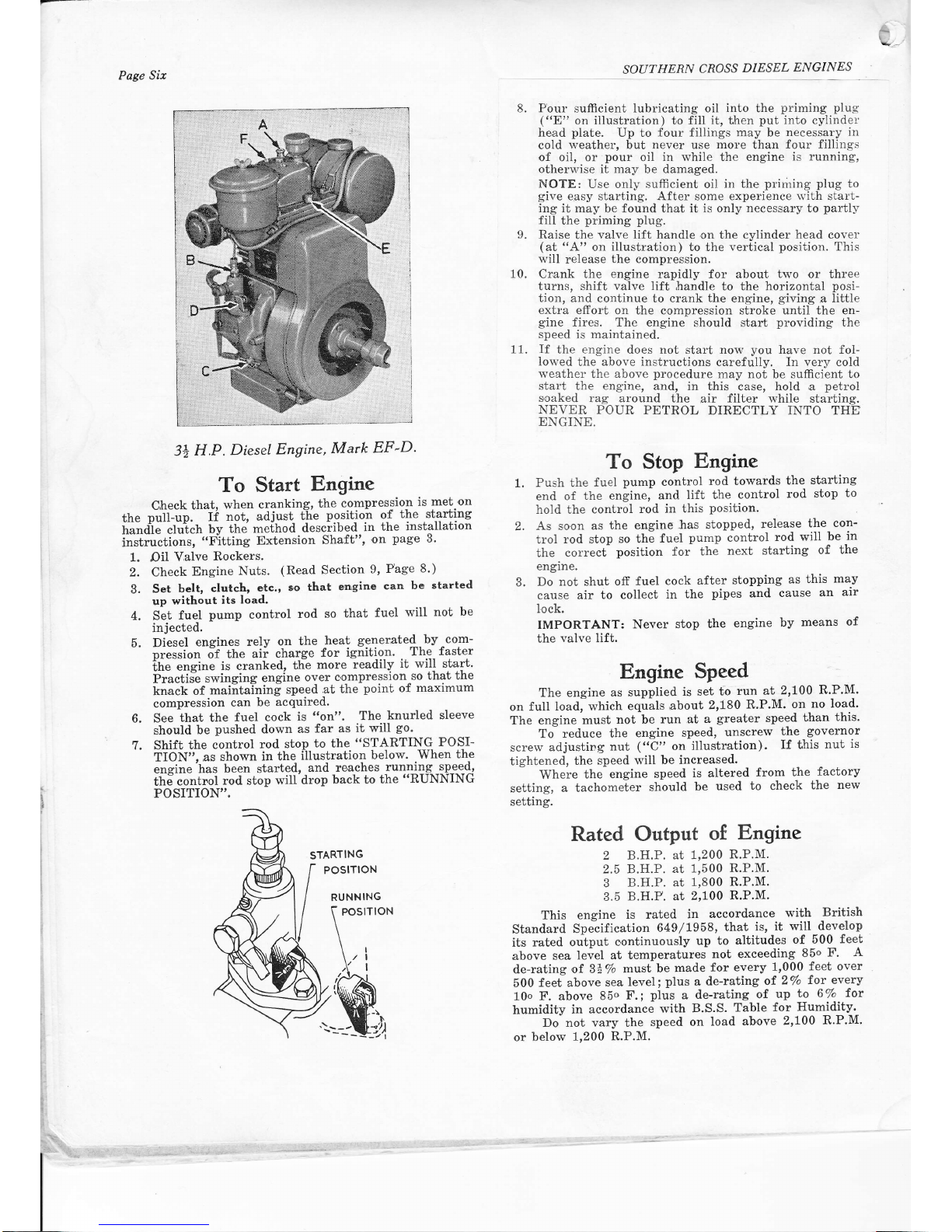

3+

H,P.

Diesel

Engine,

Mark

EF-D'

To

Start

Engine

C,heck

that,

when

cranking,

the

compression

is

met on

tfte

putLup.

If

not, adjust

t'iie

position

of

the

starting

rri"ai"-.ti,,iih

bv

the

me[hod

desciibed

in

the

installation

instrrrctions,

"Fitting

Extension

Shaft",

'on

page

3'

1. Oil

Valve

Rockers.

2. Check

Engine

Nuts.

(Read

Section

9,

Page

8')

3.

Set

belt,

clutch,

etc.,

oo that

engine

can

bc

started

up

without

its

load.

4. Set

fuel

pump

control

rod

so

that

fuel

will not

be

8. Pour sufficient

lubricating

oil

into

the

priming plug

("E"

on iilustration) to fill

it,

then

put

into cylindei'

head

plate.

Up to

four fillings may

be

necessary

in

cold

weather, but

never

use

more

than

four fillings

of oil, or

pour

oil

in while

the

engine

is running,

otheru'ise it may

be

damaged.

NOTE:

Use only

sufficient

oil

in the

priming plug

to

gil'e

easy starting. After

some

experience r.r'ith st.art-

ing it may be found that it is only

necessary

to

partll'

fill

the

priming plug.

Raise

the

val'r'e lift handle

on

the cylinder

head

cover

(at

"A"

on

illustr.ation)

to the vertical

position.

This

q'iil

release

the

compression.

Crank the

engine

rapidly for about

two

or three

turns, shift

valve lift

handle

to

the horizontal

posi-

tion, and

continue to crank

the

engine,

giving

a little

extra

efrort on the c'ompression stroke until the en-

gine

fires. The engine

should start

providing

the

speed

is

maintained.

If

the

engine

does not start norv

you

have not fol-

Iowed

the

above instructions

calefully, In very cold

weather

the above

procedure

may not be sufficient

to

start the engine,

and, in this

case,

hold

a

petrol

s'oaked

rag around the

air filter tvhile starting.

NEVER POUR

PETROL

DIRECTLY INTO THg

ENGINE.

o

10.

11.

injected.

Diesel

engines

rely

on

the

heat

generated-by

com-

"ression

if

ttre

aii

charge

for ignition'

The

faster

ltte eneine

is cranked,

the

more

readily

it will start'

Fiu.ilff

swinging

engine

over

c'ompression-so

that the

knack

of

maiitaining

speed

at the

point

of

maximum

compression

can

be

acquired.

See that

the

fuel cock

is

t'on".

The

knurled

sleeve

should

be

pushed

down

as

far

as it

will

go.

Shift

the

control

rod stop

to the

"STARTING

POSI-

iiOit'1, as

shown

in the

illustration

below.

.When

the

e Eine'has

been

started,

and reaches

running

speed,

th6

contnol

rod stop

wilt drop

back to the

"RUNNING

POSITION'"

1.

To Stop

Engine

Push the

fuel

pump

control

rod towards

the

starting

end of

the

engine,

and

lift the

control

rod

stop

to

hold the

control

rod

in this

position.

As soon

as

the engine

has stopped,

release

the

con-

trol

rod stop

so the

fuel

pump

control

rod

will

be

in

the correcC

position

for

the

next starting

of

the

engine,

Do

not shut

off fuel

cock

after

stopping

as

this

may

cause air

to collect

in

the

pipes

and

cause

an

air

lock.

IMPORTANT:

Never

stop

the

engine

by

means

of

the

valve

lift.

Engine

Speed

The engine

as supplied

is set to

run

at

2,100

R'P'M'

on full

load, which

equils

about

2,180

R.P.M'

on

no load'

The engine

must

not be

run at

a

greater

speed

Lhan

this'

To

reduce the

engine

speed,

unscrew

the

governor

screw

adjusting

nut

("C"

on

illustr,ation).

If this

nut

is

tightened,

the

speed

will be

increased'

Where

the

engine

speed

is altered

from

the

factory

setting,

a tachometer

should

be

used

to check

the

new

setting.

Rated Output

of

Engine

2 B.H.P.

at I,200

R.P.M'

2.5 B.H.P.

at

1,500

R.P.M.

3

B.H.P. at

1,800

R.P.M.

3.5

B.H.P. at

2,700

R.P.M'

This engine

is rated

in

accordance

with

British

Standard

Specification

649/L958,

that

is,

it

will develop

its rated

oulput

oontinuously

up

to

altitudes

of 500

feet

above

sea

level at

temperatures

not

exceeding

85o

F.

A

de-rating

of 3t%

must

be

made

for

every

1,000

feet over

500

feet above

sea

level;

plus

a

de-rating

of2/o

for every

10o

F. above

85o

F.;

plus

a

de-rating

of

up

to 6Vo

fot

humidity

in accordance

with

B.S.S.

Table

for

Humidity'

Do not vary the

speed

on

load

above

2'100

R'P.M'

or

below

1,200

R.P.M.

,

t.

5.

6.

7.

STARTING

POSITIoN

RUNNING

Loading...

Loading...