INSTRUCTION

GRLDTOORXSRX70S

00

09/18

Ed : Rev : Cod :

4

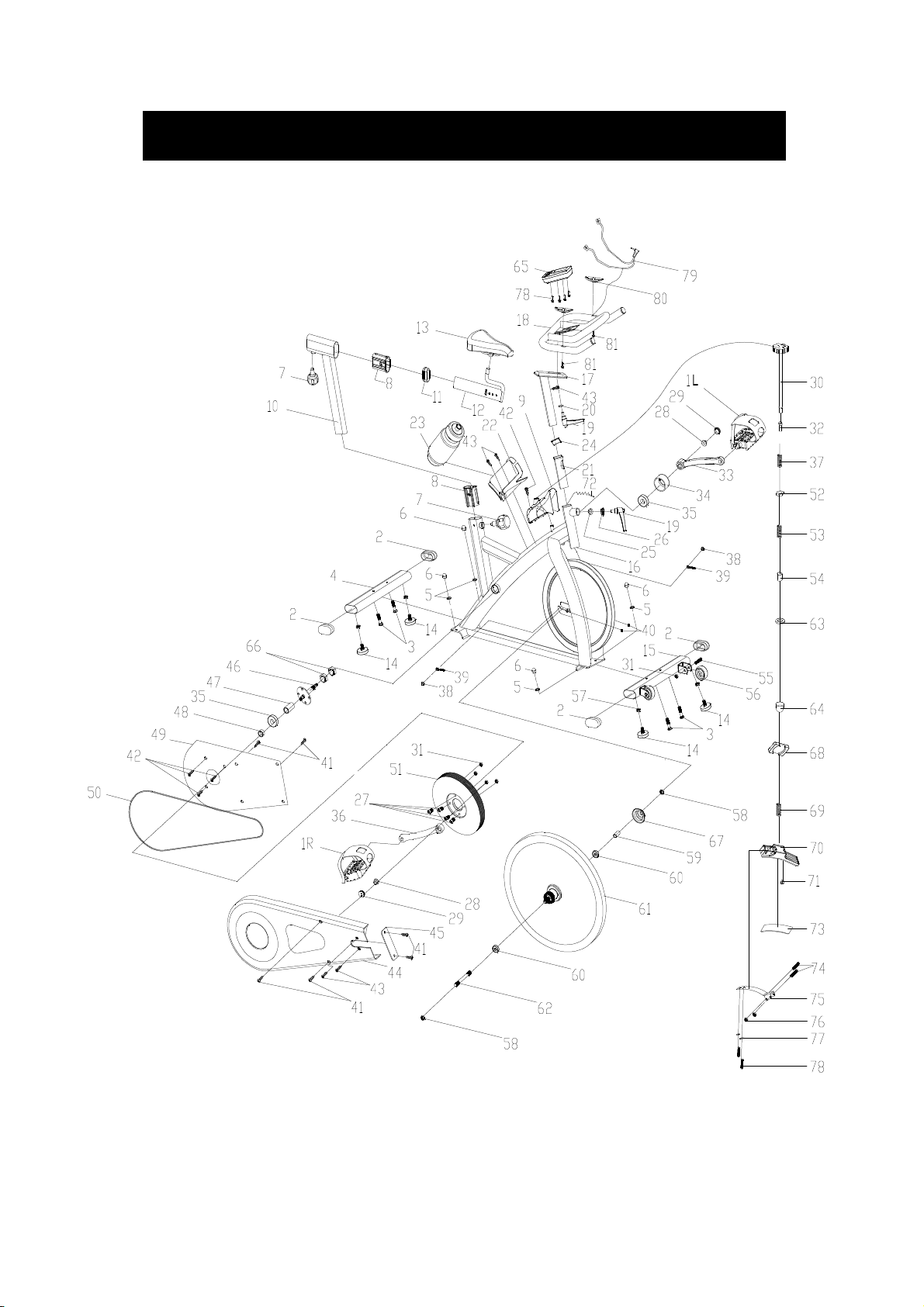

EXPLODED-VIEW & PARTS LIST:

5

NO NAME

(H=16mm)

(H=16mm)

1 PEDAL 1

2 END CAP1 4 80*40*1.5

3 CARRIAGE BOLT 4 GB/T 12-1988 M8*52

4

5 FLAT WASHER 8 GB/T 95-2002 8

6 DOMED NUT 4

7 SPRING ADJUSTMENT KNOB 2 φ50*82 (M16*1.5)

8 PLASTIC SLEEVE 1 2 70*30*1.5

9 KNOB COVER 1 177X142X187

10

11 END CAP 2 1 70*30*1.5

12 SEAT POST 1 WELDING

13

14 STOPPER 4 φ32*37/(M8X25)

15

16

17 HANDLEBAR POST 1 WELDING

18 HANDLE BAR 1 WELDING

19 L SHAPE KNOB 2 M10*25

20 FLAT WASHER 1 1 φ45*φ10.5*5

21 PLASTIC SLEEVE 2 1 38*38*1.5

22 B0TTLE HOLDER 1 117*85*90

23 B0TTLE 1 XS-003(1#) 500ML

24 END CAP 3 1 38*38*1.5

25 FIXING SHAFT 1 φ22*23 (V)

26 FIXING NUT 1 Q235/32*12

27 BOLT 4 GB/T 70.2-2000 M8*15

28 FIXING NUT 1 2 GB/T 6177.2-2000 M10*1.25

29 CRANK END CAP 2 φ23*7.5

30 KNOB 1

31 LOCK NUT 6 GB/T 889.1-2000 M8

32 BUSHING 1 φ18*φ10*10

33 LEFT CRANK 1 170*27

34 CRANK COVER 1 φ56*28

35 BEARING 2 6004ZZ

36 RIGHT CRANK 1 170*27

37 SPRING 1 1 δ1.8X40

38 FIXING NUT 2 2

39 FIXING BOLT 2 M6*57

40 NUT 2 GB/T 889.1-2000 M6

REAR STABILIZER

VERTICAL SEAT POST

SEAT

FRONT STABILIZER

MAIN FRAME

QUANTITY SPEC

JD-301(9/16"

1 WELDING

GB/T 802-1988 M8

1 WELDING

1 DD-2681

1 WELDING

1 WELDING

φ40*180 (φ10

GB/T 802-1988 M12X1.25

)

)

6

NO NAME

41 SCREW 1 8 GB/T 845-1985 ST4.2*19

42 SCREW 2 6 GB/T 15856.1-2002 ST4.2X19

43 SCREW 3 2 GB/845-85 ST4.8X13

44 OUTER CHAIN COVER 1 654*263*49 (507g)

45 LITTLE CHAIN COVER 1 108*37*3 (7g)

46 AXIS 1 φ20*162

47 LONG FIXING TUBE 1 φ25*φ20.5*41

48 SHORT FIXING TUBE 1 φ25*φ20.5*9

49 INNER CHAIN COVER 1 451*260*2 (250g)

50 BELT 1

51 BELT WHEEL 1 φ200*24

52 FIXING NUT 2 1

53 SPRING 2 1 φ1.0X55

54 SHORT FIXING TUBE 1 φ14*φ10.2*25.5

55 BOLT 2 GB/T 5780-2000 M8*40

56 WHEEL 2 φ50*23

57 NUT 4 GB/T 41-2000 M8

58 FIXING NUT 2 2 M12X1.25 H=6

59 FIXING TUBE 1 φ16*φ12.1*35

60 BEARING 2 6001ZZ

61 FLYWHEEL 1 HT250/φ453*72

62 FLYWHEEL SHAFT 1 φ12*160

63 FLAT WASHER 1 1 GB/T 95-2002 6

64 DOMED NUT 1 1 GB/T 802-1988 M6

65 COMPUTER 1

66 FIXING NUT 2

67 FLYWHEEL COVER 1 φ59*35

68 SPRING COVER 1 32*23*2

69 SPRING 3 1 φ2.2

70 PLASTIC FRAME 1 200*47*30

71 LITTLE PLASTIC 1 14*9*14

72 SENSOR 1 SR-202

73 WOOLLY BLOCK 1 113*25*6

74 BOLT 1 2 GB/T 5780-2000 M5*30

75 SPRING BRAKE 1 δ1.0

76 LOCK NUT 2 GB/T 889.1-2000 M5

77 SPRING WASHER 1 2 GB/T 859-1987 5

78 BOLT 2 2 GB/T 5780-2000 M5*10

79 PULSE WIRE 1 L=800

80 PULSE 2

81 SCREW 5 2 GB/845-85 ST4.2X25

QUANTITY SPEC

5PK53

16X16X5 (M10

ST-6527(ST-7607)

27*M20*1(5mm

)

)

7

ASSEMBLY INSTRUCTION:

1.PREPARATION:

A. Before assembling make sure that you will have enough space around the item.

B. Use the present tooling for assembling.

C. Before assembling please check whether all needed parts are available (at the above

of this instruction sheet you will find an explosion drawing with all single parts (marked

with numbers) which this item consists of.

2.ASSEMBLY INSTRUCTION:

:

FIG.1

FIG.1:

Attach the Front Stabilizer (pt.15)

to the Main Frame (pt.16) using two

sets of Ø8 Flat Washers (pt.5), M8

Domed Nut (pt.6) and M8*52 Carriage

bolt (3).

Attach the Rear Stabilizer (pt.4) to the

Main Frame (pt.16) using two sets of

Ø8 Flat Washers (pt.5), M8 Domed Nut

(pt.6) and M8*52 Carriage bolt (3).

FIG.2:

Slide the seat post (12) into the vertical

Seat post (10) and, at the desired

position, align holes and fix in place with

the Spring Adjustment Knob (pt.7)

fix the Seat (13) to the seat post (12) as

shown. Insert the vertical Seat Post (10)

into the main frame (16) and line up the

holes. Secure the saddle in position

with the Adjustment Knob (7). The correct

height for the seat can be adjusted after

the bike is fully assembled.

. Now

FIG.2

8

FIG.3

FIG.4

FIG.3:

Slide the Handlebar Post (pt.17) into the

handlebar post housing on the main

frame(pt.16). You will have to slacken the

knurled section of the L Shape Knob

(pt.19) and pull the knob back and then

select the desired height. Release the

knob and retighten the knurled portion.

Then fix the Handlebar (pt.18) with a flat

washer 1 (20) and L Shape knob (19)

ATTENTION: YOU SHOULD FIX

THE HANDLEBAR TIGHTLY

Fix the Computer (pt.65) onto the

Computer Holder of handlebar

(pt.18) with bolt(pt.78)

Insert the sensor cable (a) into the

bushing located on the backside of the

computer (65).

FIG.4:

The Pedals (pt.1 L & pt.1 R) are

marked "L" and "R" - Left and Right.

Connect them to their appropriate

crank arms. The right crank arm is on

the right- hand side of the cycle as you

sit on it.

Note that the Right pedal should be

threaded on clockwise and the Left

pedal anticlockwise.

9

A.) Adjusting the Tension:

Increasing or decreasing the tension

allows you to add variety to your

workout sessions by adjusting

the resistance level of the bike.

To increase tension and increase

resistance (requiring more strength

to pedal), turn the Emergency

Brake & Tension Control Knob (#30)

to the right.

To decrease tension and increase

resistance (requiring less strength to

pedla), turn the Emergency

Brake & Tension Control Knob (#30)

to the left.B.) Using the Emergency

Brake Function:

The same knob that allows you to

adjust the tension of the bike also

doubles as the Emergency

Brake. Use this safety feature in any

situation where you would need to

get off the bike and/or

stop the bike’s flywheel.

To use the Emergency Brake

function in any situation you would

need it in, firmly press down

on the Emergency Brake & Brake

Control Knob (#30).

GARLANDO SPA

Via Regione Piemonte, 32 - Zona Industriale D1

15068 - Pozzolo Formigaro (AL) - Italy

www.toorx.it - info@toorx.it

Loading...

Loading...