Ed: 02/17

INSTRUCTION

Rev: 0000

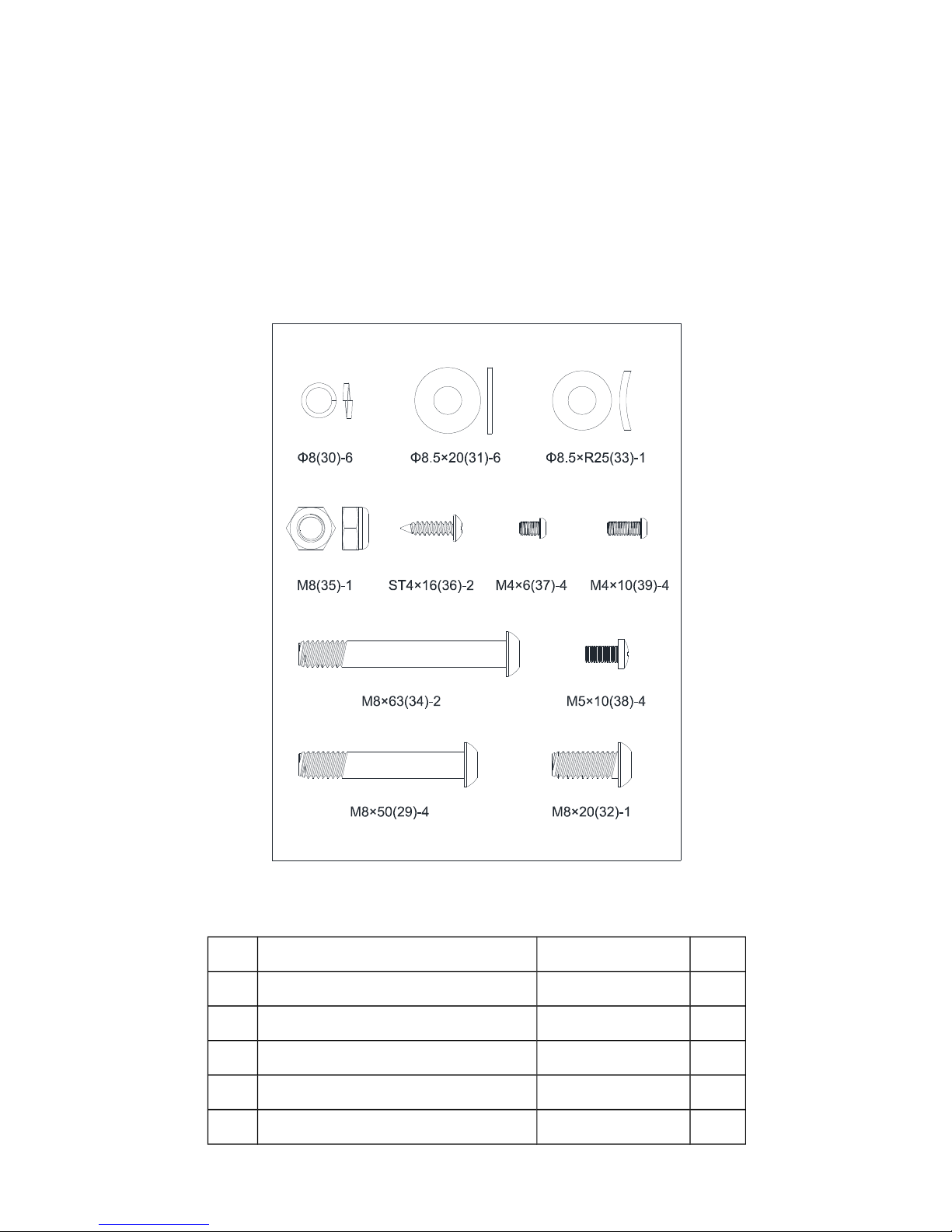

Pre-assembly Notes

Open the boxes:

Make sure to inventory all the parts that are included in the box. Check the hardware

chart

of a full count of the number of parts included for proper assembly . If any of the parts

are

missing, contact with the dealer.

NO. NAME SPECIFICATION QTY

29 Allen C.K.S. half thread screw M8×50×20 4

30 Spring washer Φ8 6

31 Flat washer Φ8.5×Φ20×t1.5 6

32 Allen C.K.S. full thread screw M8×20 1

33 Curved washer Φ8.5×R25×t2.0 1

2

34 Allen C.K.S. half thread screw M8×63×20 2

35 Hex self-locking nut M8 1

36 Philips C.K.S. self-tapping screw ST4×16 2

37 Philips pan head full thread screw M4×6 4

38 Philips pan head full thread screw M5×10 4

39 Philips pan head full thread screw M4×10 4

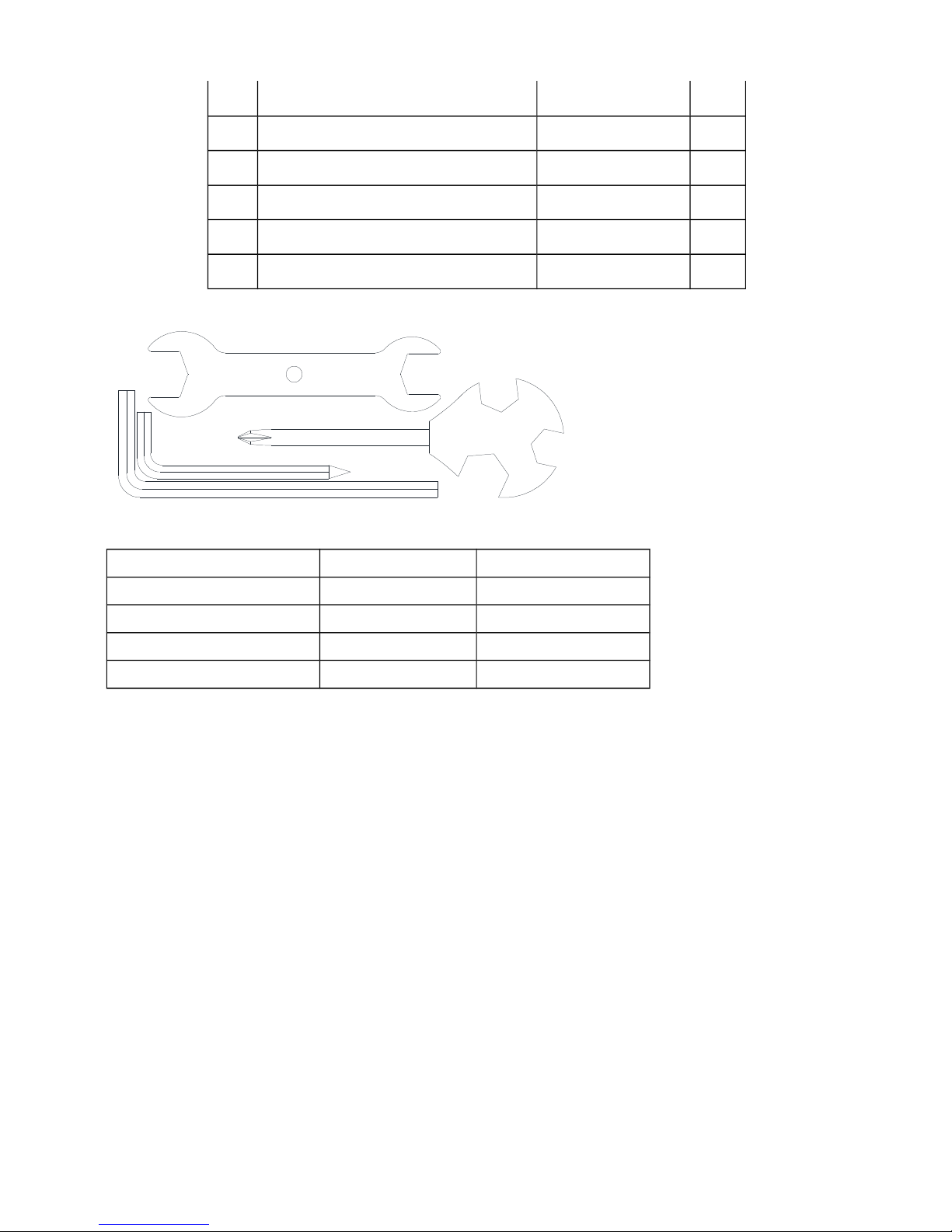

GATHER YOUR TOOLS

Before starting the assembly of your unit,gather the necessary tools.Having all of the

equipment at hand will save time and make the assembly quick and hassle-free.

CLEAR YOUR WORK AREA

Make sure that you have cleared away a large enough space to properly assemble the

unit. Make sure the space is free from anything that may cause injury during assembly.

After the unit is fully assembled, make sure there is a comfortable amount of free area

around the unit for unobstructed operation.

NOTE: Each step number in the assembly instructions tells you what you will be doing.

Read and understand all instructions thoroughly before assembling the treadmill.

Name Specification QTY

L-shape wrench 5×80×80S 1

L-shape wrench 6×40×120 1

Cross spanner 15#&17# 1

Cross open spanner 1

3

Product instruction

Technical information

4

Bottle holder

Handle bar

Controller

Motor belt

Pedal

Wheel

Front stabilizer

Rear stabilizer

Saddle

Console

DIMENSION Unfold

:

1100x530x1400mm

FLYWHEEL One -way, Φ280/6kg

RESISTANCE

FRAGMENT

32 levels

UP&DOWN 152.4 mm distance

FRONT&BACK 70mm distance

*WE

RESERVE THE RIGHT TO AMEND THE PRODUCT WITHOUT PRIOR NOTICE.

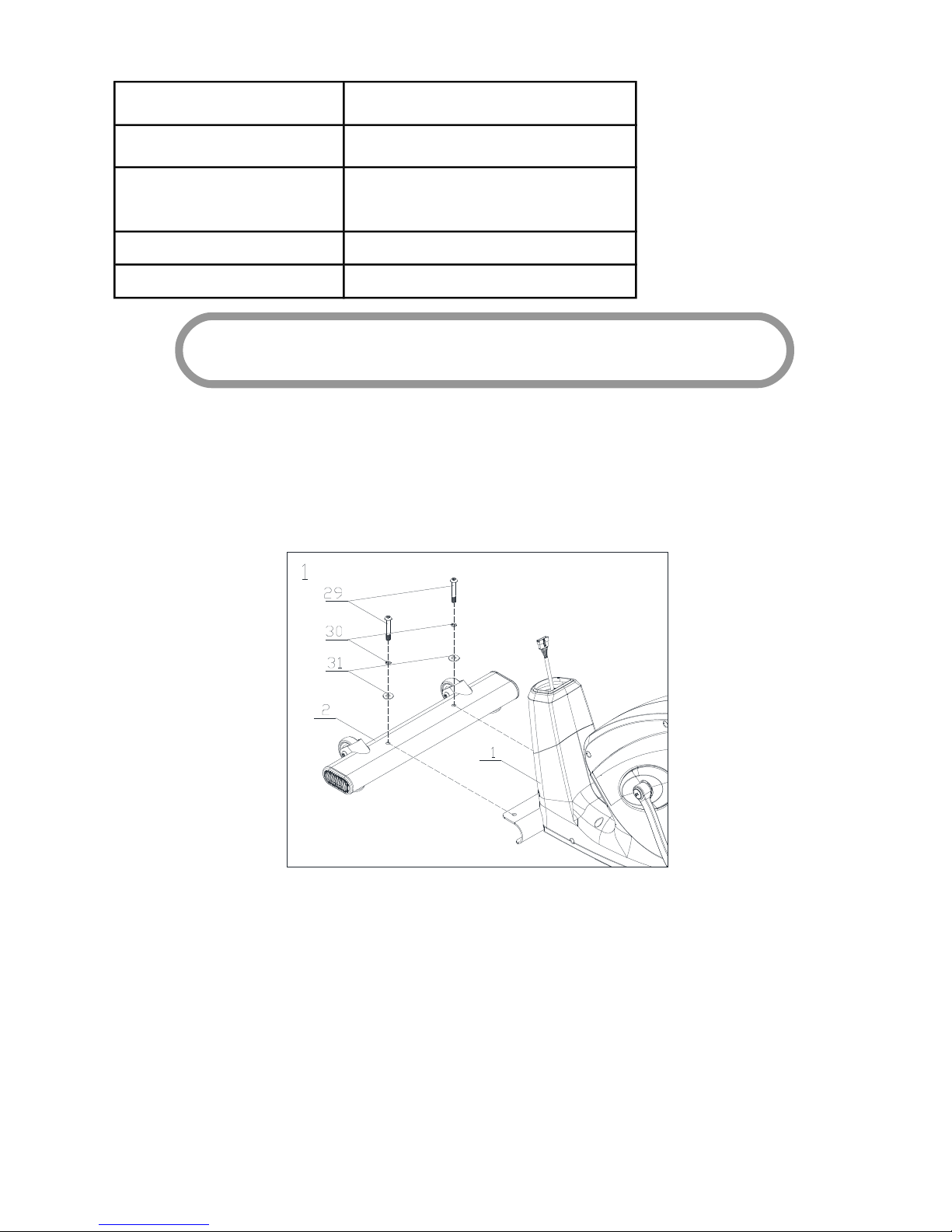

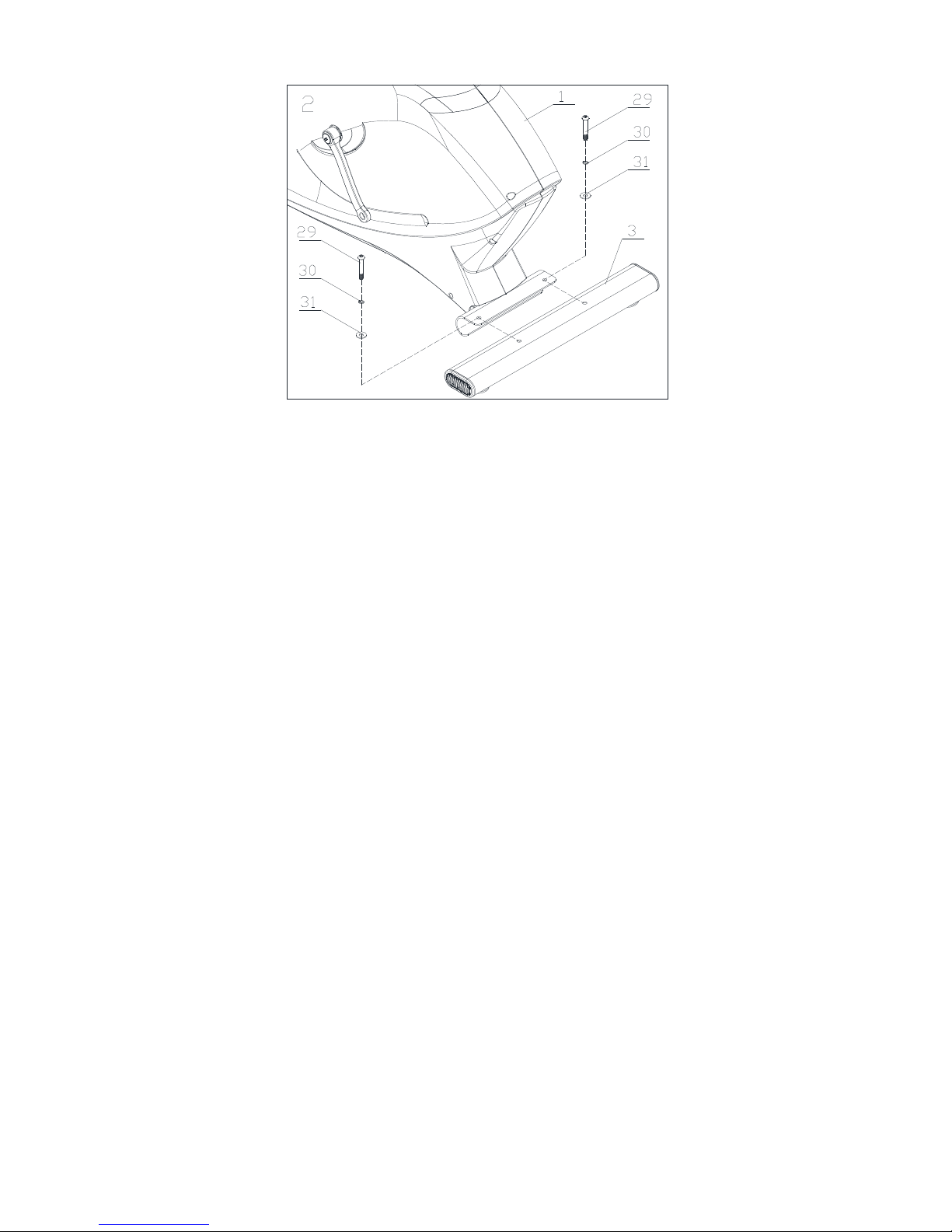

Step 1: Attach the front stabilizer (2) to the main frame (1) with flat washer(31), spring

washer(30) and Allen C.K.S. half thread screw(29).

Step 2: Attach the rear stabilizer (3) to the main frame (1) with flat washer(31), spring

washer(30) and Allen C.K.S. half thread screw(29).

5

ASSEMBLY INSTRUCTIONS

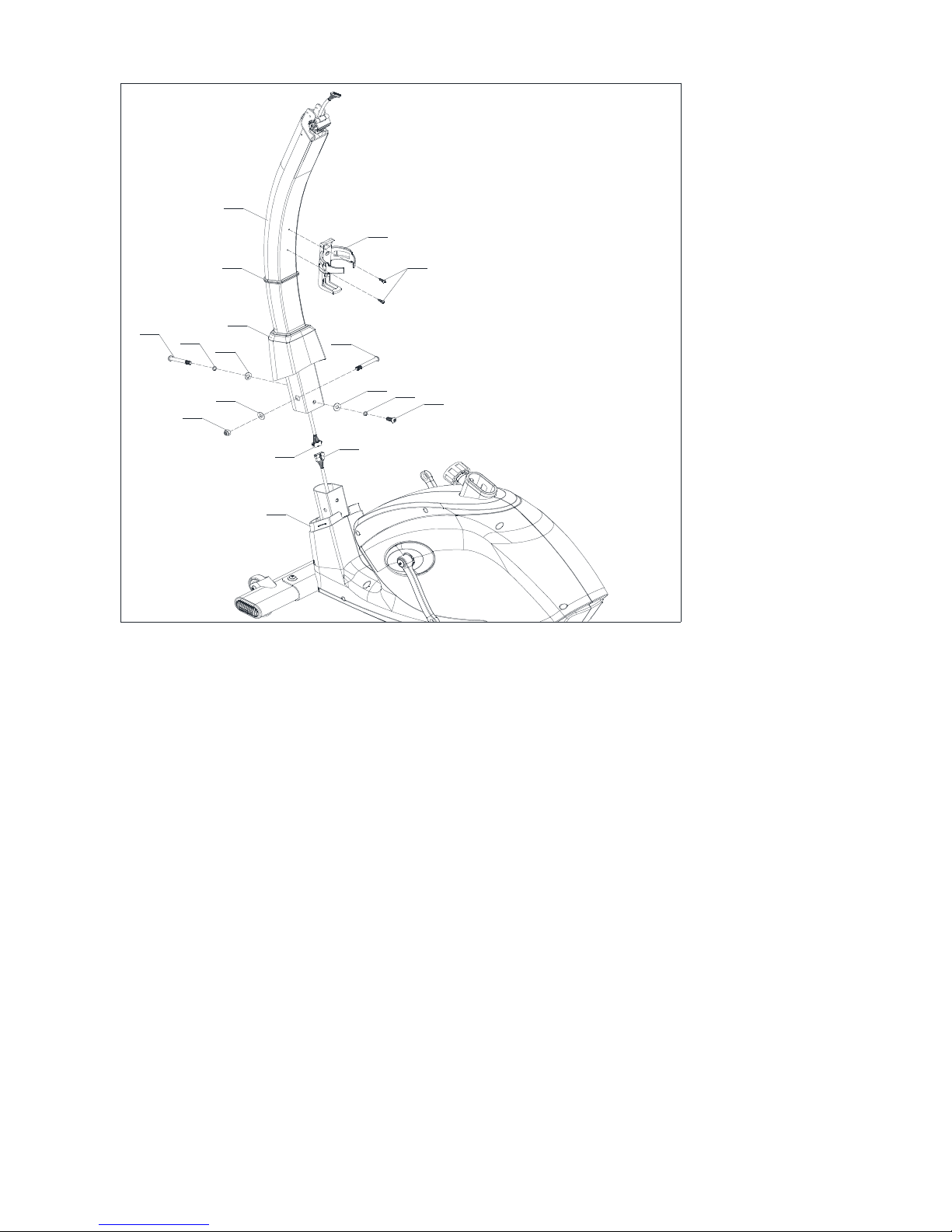

Step 3:

1.Attach the

Upright post decoration strip

(46) to the upper upright post(4),take upright

post cover(19) off from the main frame(1) and cover it on the upper upright post.(4)

2.Connect Motor communication wire (12) and Console communication wire (13).

3. Attach upper upright post(4) to the main frame(1) with Curved washer( 33), spring

washer(30), Allen C.K.S. half thread screw(34) and flat washer(31), spring washer(30),

Allen C.K.S. full thread screw(32) and flat washer(31),Allen C.K.S. half thread screw( 34),

Hex self-locking nut(35).

4.Attach upright post cover(19) and

Upright post decoration strip

(4 6 ) to the main

frame(1).

5.Attach bottle holder(20) to upper upright post(4) with Philips pan head full thread

screw(36).

Tip : Put the communication wires and r esistance adjust knob wire into the upright

post,and make sure all screws are in the hexagonal hole before tighten all the bolts.

6

31

30

32

35

31

34

19

1

33

30

34

3

13

12

4

46

20

36

Step 4:

Attach the Pedal(L)(5) and Pedal(R)(6) to the Main frame(1),then tighten the bolts.

7

Step 5:

1.

Loose the Rotary hand bolt(21),attach the Saddle post (7) to the

Main frame(1),then tighten the Rotary hand bolt(21).

5

7

1

21

Step 6:

8

1,Attach the saddle adjustment set (60) to the saddle post (7) and place it onto correct

position .Lock them with bushing (23) and rotary knob (22) .

2, Put the saddle (8) onto the saddle adjustment set (60) and lock it tightly .

3, Attach the saddle cover(L)(24) and saddle cover(L)(25) to the saddle post(7),and use

Philips pan head full thread screw(37) to tighten them.

6

8

25

37

37

24

7

21

23

22

60

Step 7:

1. Handle pulse connection wire

(16)

through the Upright post(4),and attach the

9

Handlebars(9) to Upright post(4),tighten with rotary knob(26).

2. Attach Console fixed piece(10) to the Upright post(4),tighten with Philips C.K.S. full

head screw(38).

Tip: Make sure all screws are in the hexagonal hole before tighten all the bolts.

7

4

38

38

10

9

26

16

Step 8:

10

1. C o n n e c t t h e Console communication wire( 1 3 ) a n d Console connection

wire(18),connect the Handle pulse connection wire(16) and Console outset(17).

2. Attach the Console(11) to the Console fixed piece(10),tighten with Philips C.K.S. full

head screw(40).

3. Att ac h the Handlebar cover(L)(2 7 ) a n d Handlebar cover(R)(28) through the

Handlebars(9) to the Upright post(4),tighten with Philips C.K.S. full head screw(39).

Tip: Make sure all screws are in the hexagonal hole before tighten all the bolts.

8

11

10

9

40

27

39

28

39

18

17

16

13

Workout tips:

1,User need to put the feet completely inside the pedal, and to adjust the resistance of

magnet control according to user.

2,Since the machine with double flywheels and it will have huge moment of inertia, when

the user stop before high speed, the user should minimize the resistance and lower the

speed, to avoid hurt the user’s leg by the moment of inertia of left and right pedal

3,The machine should be put on flat floor and have enough space for workout

Half-drawing for assembly

11

29

30

31

29

30

31

29

30

31

31

30

32

31

34

19

33

30

34

5

6

7

25

37

37

24

23

22

26

38

38

9

40

10

11

39

27

28

39

17

13

2

3

21

16

1

18

13

12

4

46

20

36

8

60

35

12

Part list

NO. NAME SPECIFICATION QTY

1

Main frame

1

2

Front stabilizer

1

3

Rear stabilizer

1

4

Upright post

1

5

Pedal(L)

1

6

Pedal(R)

1

7

Saddle post

1

8

Saddle

1

9

Handlebars

1

10

Console fixed piece

1

11

Console

1

12

Magnetic sensor wire

1

13

Console communication wire

1

14

Resistance adjust knob wire

1

15

Resistance adjust knob

1

16

Handle pulse connection wire

2

17

Console outset

2

18

Console connection wire

1

19

Upright post cover

1

20

Bottle holder

1

21

Rotary hand bolt

Φ56×M16×P1.5 1

13

22

Handlebar rotary knob

Φ60×31×M10×20 1

23

Bushing

Φ10.5×Φ14×10 1

24

Saddle cover(L)

1

25

Saddle cover(R)

1

26

Rotary knob

Φ54×82×M8×30 1

27

Handlebar cover(L)

1

28

Handlebar cover(R)

1

29

Allen C.K.S. half thread screw

M8×50×20 4

30

Spring washer

Φ8 6

31

Flat washer

Φ8.5×Φ20×t1.5 6

32

Allen C.K.S. full thread screw

M8×20 1

33

Curved washer

Φ8.5×R25×t2.0 1

34

Allen C.K.S. half thread screw

M8×63×20 2

35 Hex self-locking nut M8 1

36

Philips C.K.S. self-tapping screw

ST4×16 2

37

Philips pan head full thread screw

M4×6 4

38

Philips pan head full thread screw

M5×10 4

39

Philips pan head full thread screw

M4×10 4

40

Philips pan head full thread screw

M5×10 4

46

Upright post decoration strip

1

60

Saddle adjustment set

1

14

Drawig for assembly

15

16

59

15

14

13

91

65

51

85

32

35

64

51

66

63

35

73

75

76

62

62

63

63

67

69

68

70

72

52

74

84

31

57

58

35

32

31

47

48

48

2

50

49

47

51

31

30

29

30

29

31

86

29

30

31

29

30

31

3

31

30

32

4

33

30

34

38

38

40

10

11

39

27

28

39

17

46

19

81

44

81

81

88

89

43

43

44

61

67

36

36

36

36

41

67

83

71

83

71

42

6

5

7

25

37

23

22

24

80

79

87

87

37

77

60

8

35

51

54

53

56

78

1

9

21

81

18

12

82

55

36

45

36

92

20

36

26

90

94

93

31

34

35

16

Part list

NO. NAME SPECIFICATION QTY

1

Main frame

1

2

Front stabilizer

1

3

Rear stabilizer

1

4

Upright post

1

5

Pedal(L)

1

6

Pedal(R)

1

7

Saddle post

1

8

Saddle

1

9

Handlebars

1

10

Console fixed piece

1

11

Console

1

12

Motor communication wire

1

13

Console communication wire

1

14

Power communication wire

1

15

Magnetic sensor

1

16

Handle pulse connection wire

2

17

Console outset

2

18

Console connection wire

1

19

Upright post cover

1

20

Bottle holder

1

21

Rotary hand bolt

Φ56×M16×P1.5 1

17

22

Handlebar rotary knob

Φ60×31×M10×20 1

23

Bushing

Φ10.5×Φ14×10 1

24

Saddle cover(L)

1

25

Saddle cover(R)

1

26

rotary knob

Φ54×82×M8×30 1

27

Handlebar cover(L)

1

28

Handlebar cover(R)

1

29

Allen C.K.S. half thread screw

M8×50×20 4

30

Spring washer

Φ8 6

31

Flat washer

Φ8.5×Φ20×t1.5 7

32

Allen C.K.S. full thread screw

M8×20 6

33

Curved washer

Φ8.5×R25×t2.0 1

34

Allen C.K.S. half thread screw

M8×63×20 2

35

Hex self-locking nut

M8 8

36

Philips C.K.S. self-tapping screw

ST4×16 12

37

Philips pan head full thread screw

M4×6 4

38

Philips pan head full thread screw

M5×10 4

39

Philips pan head full thread screw

M4×10 4

40

Philips pan head full thread screw

M5×10 4

41

Crank(L)

1

42

Crank®

1

43

Crank cover

2

44

Philips C.K.S. self-tapping screw

ST4×12 4

18

45

Magnetic motor

1

46

Upright post decoration strip

1

47

End cap

4

48

Feet pad

Φ47×10.5×M10×20 4

49

Hex nut

Φ8×33×M6×15 2

50

Wheels

Φ55×25.8 2

51

Allen C.K.S. full thread screw

M6×15 5

52

Deep groove ball bearing

6203-2RS 1

53

Hex nut

M5 2

54

Allen C.K.S. full thread screw

M5×80 1

55

Philips C.K.S. self-tapping screw

ST4×12 1

56

Saddle post bushing

1

57

Crank axle

Φ17×154.3 1

58

Belt pulley

Φ263×19 1

59

Power adapter

1

60

Saddle adjustment set

1

61

Circlip shaft

Φ17 2

62

Circlip shaft

Φ12 2

63

Circlip shaft

Φ10 3

64

Tension pulley

Φ38×22 1

65

Tension spring

1

66

Brake tension spring

1

67

Deep groove ball bearing

6003-2RS 3

19

68

Magnetic control fixed axle

Φ12×50 1

69

Deep groove ball bearing

6300-2RS 1

70

Flat washer

Φ34×Φ25×t1.0 1

71

Crank cover

2

72

Unidirectional needle bearing

Φ35×Φ17×16 1

73

Small belt pulley set

Φ30×64 1

74

Deep groove ball bearing

6000-2RS 1

75

Flywheel axle

Φ10×109.5 1

76

Flywheel

Φ280/6kg 1

77

Square end cap

20×40×t1.5 1

78

Handle pulse set

2

79

Philips C.K.S. self-tapping screw

ST4×20 2

80

Round end cap

Φ25×t1.5 2

81

Philips C.K.S. self-tapping screw

ST4×25 7

82

Fixed magnet set

1

83

Allen C.K.S. full thread screw

5/16-18UNC-1" 2

84

Tension pulley

1

85

Magnetic control fixed axle

1

86

Motor belt

440PJ6 1

87

Foam grip

Φ22×t3.0×680 2

88

Cover(L

)

1

89

Cover(R

)

1

90

Saddle locking piece

1

20

91

Brake wire

1

92 Sensor wire fixed piece 1

93 Spring washer Φ10 1

94 Allen pan head full thread screw M8×38 1

Computer operation

BUTTON FUNCTION:

START/STOP To start or stop the system.

RESET

Reset: In stop mode, press the button to back to main menu and clear all set value;

Total Reset: At any time, hold the RESET key for 2 seconds, LCD full display 2s

And hen back to home page.

UP To select training mode and adjust the function or value up.

MODE In stop mode, confirm all exercise data setting(Time, DST,CAL, Pulse,

etc), and enter into program.

DOWN To select training mode and adjust the function or value down.

RECOVERY To test heart rate recovery status.

BODY FAT For body fat measurement.

DISPLAY FUNCTION

TIME Display range 0:00~99:59 ; Setting range 0:00~99:00 minutes

PULSE Display range P-30~230 ; Setting range 0-30~230

SPEED 0.0~99.9km/H

DISTANCE Display range 0.00~99.99 ; Setting range 0.00~99.9km

WATT Display range 0~999; Setting range 10~350

CALORIES Display range 0~9999; Setting range 0~9990 Cl

RPM 0~999

21

OPERATING PROCEDURE

1.POWER ON

When power on, buzzer sound for 1 second. At the same time, LCD full display 2 seconds (Picture 1).

Then enter into personal data setting.

Picture 1 Picture 2

2.USER PROFILE SETTING

When setting personal data, press UP or DOWN to select: USER U1~U4(Picture2), SEX,

AGE (Picture3), HEIGHT, WEIGHT. Press MODE to confirm. Then come to workout selection

page (Picture 4).

Picture 3 Picture 4

22

3.SELECT TRAINING MODE

When enter into training mode, Press UP or DOWN to choose: MANUAL→PROGRAM (Picture5)→

User program→H.R.C (Picture6)→WATT. Press MODE to confirm.

Picture 5 Picture 6

3.1.MANUAL MODE

When power on, user may press START/STOP to start workout directly in MANUAL MODE.

Before exercise in Manual mode, user can press UP or DOWN button to preset target TIME/

DISTANCE/CALORIES/PULSE. Press START/STOP to start workout.

In START mode, user can also press UP or DOWN button to adjust LOAD level (1~32).

3.2.PROGRAM MODE

In PROGRAM mode, user can press UP or DOWN button to choose program with P1~P12 and press

MODE to confirm. Press START/STOP to start workout.

In START mode, user can press UP or DOWN button to adjust LOAD level(UP to max.32, DOWN

to min.1).

3.3.User Program

User can press UP or DOWN button to create personal program profile with 20 segments and confirm

by pressing MODE. User may hold on pressing MODE button for 2 seconds to quit profile setting.

Then press START/STOP to start exercise. To pause workout halfway, hold MODE button for 2s.

3.4.H.R.C. MODE

In H.R.C mode, user need to set AGE first and confirm by ENTER. It will display preset value in

PULSE area according to AGE. If select TARGET, preset value 100 will display in PULSE area.

Press UP and DOWN button to adjust the target value from 30~240. Press START/STOP to start

workout. During this workout mode, user must wear chest belt or keep hands hold on hand bars.

23

3.5.WATT MODE

When entering WATT mode, preset value120 will display. User press UP or DOWN to adjust WATT

value. After Starting, system will adjust Load level automatically according to the WATT value user

inserted and exercise status. Press START/STOP to start workout.

4.RECOVERY MODE

After exercising for a period of time, keep holding on handgrips or wear chest belt. When there is

PULSE displayed, press “RECOVERY” button. All function display will stop except “TIME” that

will start counting down from 00:60 to 00:00. Screen will display your heart rate recovery status with

the F1, F2….to F6. F1 is the best, F6 is the worst.

During the recovery time, re-press “RECOVERY” and console will go back to previous page.

5.BODY FAT

In STOP mode, press the BODY FAT button to start body fat measurement.

During measuring, user have to hold both hands on handgrips. After 8 seconds, LCD will display

BODY .FAT advice in FAT% and BMI and the fat advice in different symbol. When user not

hold handgrips correctly, computer will display E-1; When BODY FAT advice exceed. Available area

which is fixed in the program, computer will display E-4.User may hold BODY FAT button for 2

seconds to reset individual data. After setting, system will directly measure BODY FAT.

6.USB power charger

The console provides USB power charger for tablet and smart phone only, requires DC 9V/1.3A.

Remarks:

1. Before exercise in MANUAL mode, user can press UP and DOWN button to adjust TIME

/DISTANCE/CALORIES/PULSE value.

2. In PROGRAM/User Program/H.R.C./WATT mode, user can only set TIME value.

3. Every time press UP or DOWN button, the value will increase/decrease 1 level; If hold for 1.5s,

the value will increase/decrease 8 levels per second and stop when releasing.

4. No signal(SENSOR, KEYBOARD, PULSE display) input over 4 minutes, system will go to

SLEEP MODE. All preset and calculated value will be saved. When power on, system will continue

with the calculated value.

24

GARLANDO SPA

Via Regione Piemonte, 32 - Zona Industriale D1

15068 - Pozzolo Formigaro (AL) - Italy

www.toorx.it - info@toorx.it

Loading...

Loading...