Page 1

software-version C30

06/2014

Version: 14

Guidance - Supplement to the manual of instructions

Microprocessor

Temperature Controller MP-888

Page 2

Guidance MP-888 - Supplement to the manual of instructions 2/10

HINWEIS

This guidance provides specific information to the temperature controller.

Observe the General Safety Information in the manual of instructions to the

TOOL-TEMP machine!

General information

This documentation is copyrighted. Unauthorised duplication is prohibited by law. To the best of our

knowledge and belief, the information contained in this documentation is true and correct as of the

date of publication. The contents, however, do not constitute a binding obligation on the part of

TOOL-TEMP AG and are subject to change without notice.

In case of inconsistencies in the English translation, the German version shall prevail.

© Copyright 2013 TOOL-TEMP AG

Contents

1. Overview MP-888 ........................................................................................................................... 3

2. Overview controller programmes ................................................................................................ 5

3. Selection of the controller programme ....................................................................................... 7

4. Navigation in the controller .......................................................................................................... 7

5. Parameter – Overview ................................................................................................................... 8

Page 3

Guidance MP-888 - Supplement to the manual of instructions 3/10

1

Display of set value

2

Display of actual value

3

Flow control

Display of the current flow in litres/min, English or American gallons/min.

4

Up arrow Raise of set value

5

Down arrow Reduction of set value

6

Program button

7

Flow control

Flow control active LED green

Alarm flow control LED red

8

LED Cooling

Lights up when the cooling relay is activated

9

LED Heating

Lights up when the heating relay is activated

10

LED Sensor failure

Lights up when the sensor is intermitted

11

LED Temperature deviation control

Lights up when the difference between set and actual temperature is too high

12

LED Maximum temperature

Lights up when the maximum temperature has been reached

13

LED External temperature control

Lights up when the set value is applied from extern

1. Overview MP-888

Page 4

Guidance MP-888 - Supplement to the manual of instructions 4/10

1

Possible supply voltages (factory adjusted)

2

Possible temperature sensor (factory adjusted)

3

Version of the controller

4

Temperature sensor connection

21+23 Temperature sensor – note + / 22 Pt-100 compensation

5

Flow control – encoder signal

6

Connection external set point

26+28 Analog input 4- 20mA

27+28 Analog input 0 - 10 V

7

Connection actual value - output

29+30 Analog output 0 - 10V

8

Power supply

1 230V AC

2 Neutral

3 PE

9

Flow control (alarm)

10

Temperature monitoring, temperature deviation alarm

11

Cooling (command)

12

Heating (command)

Page 5

Guidance MP-888 - Supplement to the manual of instructions 5/10

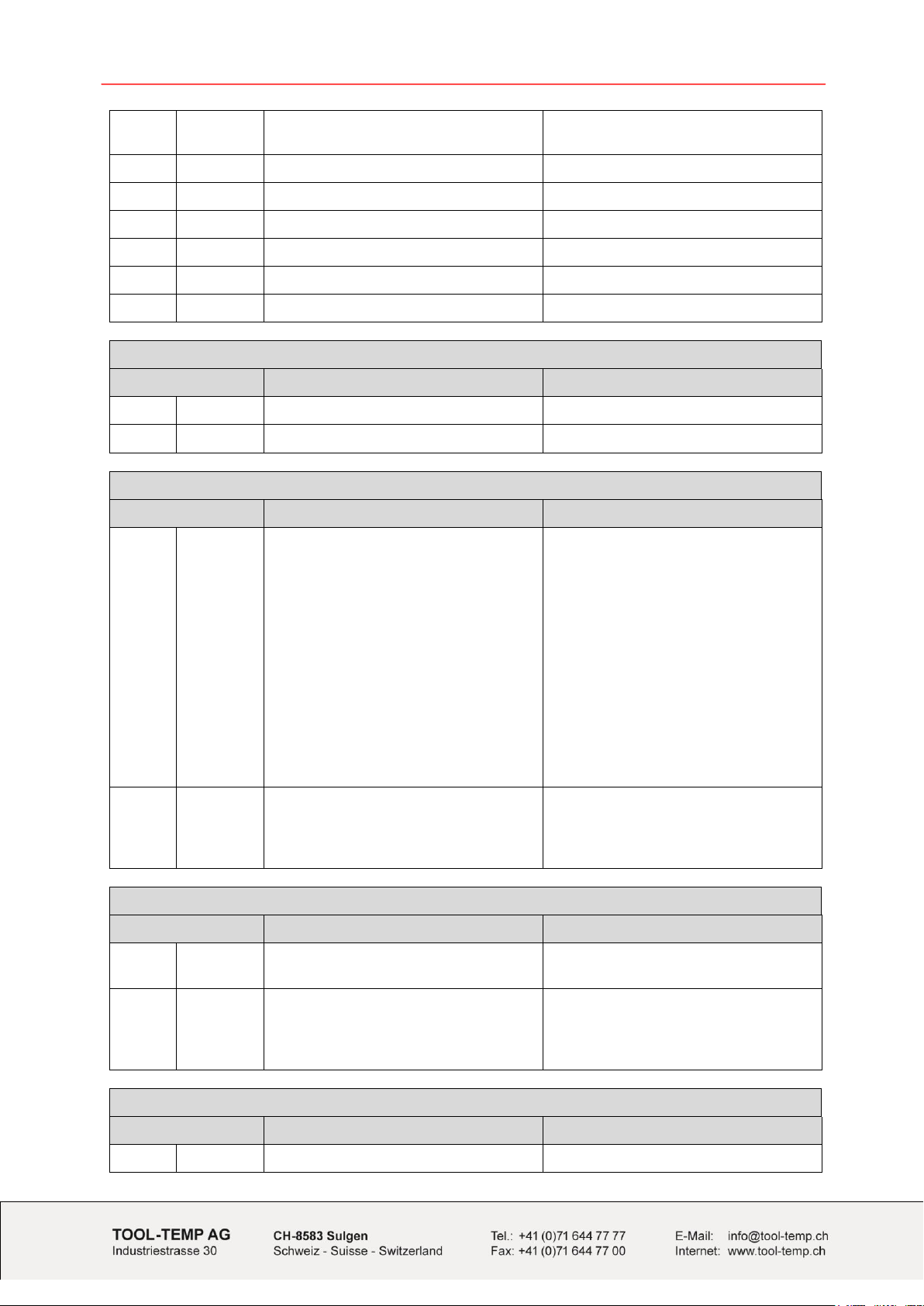

Temperature Control Units without flow control

Programme

New models

Old models

P 41

P US 41

TT-180, TT-181

TT-155, TT-156, TT-157 E, TT-162 E,

TT-162H

P 42

P US 42

TT-170 L, TT-100 K-E, TT-100 KB-E

TT-162 E/PHE, TT-162 H/PHE,

TT-162 E/A, TT-162 H/A, TT-154 E,

TT-113 K, TT-103 K FeKo

P 43

P US 43

TT-130, TT-131, TT-132, TT-133,

TT-134, TT-139

P 44

P US 44

TT-220, TT-230, TT-240, TT-245

P 45

P US 45

TT-260, TT-270, TT-280, TT-280/2

P 46

P US 46

TT-360, TT-370, TT-380, TT-380/2,

TT-380 / 48 kW

P 47

P US 47

TT-300, TT-301, TT-302, TT-303,

TT-304, TT-305, TT-500, TT-700

Temperature Control Units with flow control

Programme

New models

Old models

P 72

P US 72

TT-DW160 9kW

P 73

P US 73

TT-1358

P 74

P US 74

TT-1398

TT-148

P 75

P US 75

TT-108 E / 6 - 18 kW / Pt-100

P 76

P US 76

TT-108 K / 18 - 45 kW / Pt-100

P 77

P US 77

TT-1000

P 78

P US 78

TT-137 B/BP, TT-138 B/BP

P 79

P US 79

TT-188, TT-168 E special unit

1,5 – 35 l/min

P 80

P US 80

TT-188, TT-168 E, TT-168 H

P 81

P US 81

TT-168 E/A, TT-168 H/A,

TT-168 E/PHE, TT-168 H/PHE,

TT-168 E/A/PHE, TT-168 H/A/PHE

P 82

P US 82

TT-118 K, TT-1038 K, TT-108 K FeKo

P 83

P US 83

TT-1548 E

P 84

P US 84

TT-137 N-B, TT-138 N-B,

TT-142 N-B, TT-142 B/BP

TT-143

P 85

P US 85

TT-288, TT-288/2

P 86

P US 86

TT-1368

P 87

P US 87

TT-388, TT-388/2, TT-390, TT-390/2

2. Overview controller programmes

Once the „US-programs“ are set, the corresponding parameters are adjusted automatically on USGallons per minute and degree Fahrenheit.

Page 6

Guidance MP-888 - Supplement to the manual of instructions 6/10

P 88

P US 88

TT-388 / 48 kW, TT-608 Z

TT-380 / 48 kW with flow control

P 89

P US 89

TT-508 X, TT-510 X

TT-500 with flow control

P 90

P US 90

TT-708 Y

TT-700 with flow control

P 91

P US 91

TT-248

P 92

P US 92

TT-407 Z, TT-409 Z

TT-408

P 93

P US 93

TT-410 X

P 94

P US 94

TT-30/160

Heating- and cooling unit:

Programme

New models

Old models

P 09

P US 09

TT-13‘502 10 - 90°C

P 10

P US 10

TT-13‘502 10 - 40°C

Water chillers without flow control

Programme

New models

Old models

P 11

P US 11

TT-29‘000, TT-54‘000, TT-54‘000 WK,

TT-54‘000 OT, TT-108‘000,

TT-108‘000 WK, TT-108‘000 OT,

TT-216‘000, TT-216‘000 WK,

TT-216‘000 OT, TT-14‘000 E/LC

TT-4‘500, TT-5‘000, TT-9‘500,

TT-11‘000, TT-11‘000 WK,

TT-12‘000, TT-12‘000 WK,

TT-14‘000, TT-14‘000 WK,

TT-20‘000, TT-23‘000,

TT-23‘000 WK, TT-25‘000,

TT-28‘000, TT-28‘000 WK,

TT-29‘000 WK, TT-40‘000,

TT-41‘000, TT-57‘000,

TT-57‘000 WK, TT-70‘000,

TT-80‘000, TT-80‘000 WK,

TT-95‘000, TT-95‘000 WK,

TT-110‘000, TT-110‘000 WK,

TT-160‘000, TT-160‘000 WK

P 12

P US 12

TT-5‘000 H, TT-14‘000 H,

TT-28‘000 H, TT-5‘000 E/LC

TT-4‘500 H, TT-9‘500 H,

TT-11‘000 H, TT-12‘000 H ,

TT-14‘000 H, TT-20‘000 H,

TT-23‘000 H, TT-25‘000 H

Water chillers with flow control

Programme

New models

Old models

P 13

P US 13

TT-5‘500 E, TT-14‘500 H,

TT-14‘500 H/WK

P 14

P US 14

TT-28‘500, TT-28‘500 WK,

TT-28‘500 OT, TT-29‘500 WK,

TT-54’500, TT-54’500 WK,

TT-54‘500 OT, TT-58‘500 WK

For all units with a special programming

Programme

New models

Old models

P 100

Special programming

Page 7

Guidance MP-888 - Supplement to the manual of instructions 7/10

By starting the controller, the software-version is first shown (C-30) and afterwards the programme

number (P80).

Each temperature control unit or water chiller requires a different programming of the parameters.

The different parameters adjustments are saved in each program.

Start the unit, on the display follows…

up: Software-version (C30)

down left: Temperature unit in °C

down right: Flow unit in liters per minute

P80 Software-version

Press button twice

With the arrow buttons choose the required programme

(see overview controller programmes)

Press button once to save

4. Navigation in the controller

Enter into the controller and navigate to the different parameter:

To enter into the programme of the controller, the program button has to be pressed

for 3 seconds.

To move from parameter to parameter, press the programme button.

Setting the parameter value:

With the two arrow buttons the value of the parameters can be adjusted.

Save the parameter settings:

To save the parameter settings and get back to the control function, the flow button

must be pressed.

To save the parameter settings and move to the next parameter, the programme

button must be pressed.

For all units with special programming P100:

If a parameter will be changed the controller shows P100. Controllers with a

special programing have a written the parameters on a label on the

controller and in the manual of the model.

3. Selection of the controller programme

Page 8

Guidance MP-888 - Supplement to the manual of instructions 8/10

Function

Factory adjusted

User

Agent

TOOL-TEMP

Description

P1

Maximum

temperature

Setting depends

on model

(0.0...400.0°C)

(32.0...752.0°F)

If the maximum temperature exceeds,

the heating and cooling are inactive and

the maximum temperature LED lights up

on the controller.

P2

Temperature

deviation control

(Deviation between

set and actual

temperature)

5.0°C / 9.0°F

(0…20.0°C)

(0…36.0°F)

The limit determines the maximum

deviation from the nominal value, which

is still tolerated. If the actual temperature

outside the set point window the alarm

will sound and the Temperature

deviation control LED lights. If the restart

lock (P24) is turned on, the temperature

deviation control is active only when it

reaches the set temperature. A set point

changes the start-up lock again.

P3

Flow measurement

function

0: Manuel

1: Automatic

If the automatic flow measurement is

enabled, after 20s the measured flow is

stored and monitoring is enabled. The

green LED lights up.

P4

Alarm value flow

8.0 L

(0.1…999.9 L)

(P3) set to manual

Alarm is triggered when the set value is

exceeded.

P20

Temperature unit

1: °C

2: °F

Change the temperature unit:

When the unit started the selected unit

will be indicated for a short time.

P21

Temperature sensor

Setting depends

on model

1: Fe-Ko J

2: NiCr-Ni K

3: Pt 100 2-Draht

4: Pt 100 3-Draht

Selection of temperature sensor

P22

Temperature

adjustment on Pt 100

0.7°C / 33.3°F

(0.0...130.0°C)

(0.0...234.0°F)

When using very long sensor lines

(Pt 100) the resistor of the line can be

compensated. A compare measurement

is needed. For example:

measured temperature: 100°C

indicated temperature: 108°C.

-> set 8°C (difference)

P23

Analog input

1: Voltage 0-10V

2: Current 0-20 mA

3: Current 4-20 mA

Analog input for setpoint selection.

0-10 V (switching threshold <0.1V)

0-20 mA (switching threshold <0.5mA)

4-20 mA (switching threshold <0.1mA)

P24

Starting interlock for

temperature deviation

control

0: OFF

1: ON

see P2

5. Parameter – Overview

Page 9

Guidance MP-888 - Supplement to the manual of instructions 9/10

P25

Setting range FROM

Setting depends

on model

(-50.0...399.0°C)

(-58.0...750.2°F)

This temperature value limits the lowest

temperature that can be adjusted.

P26

Setting range TO

Setting depends

on model

(-49.9...400.0°C)

(-57.8...752.0°F)

This temperature value limits the highest

temperature that can be adjusted.

P27

Temperature

at 0 V INPUT

0.0°C / 32°F

(-50.0...399.9°C)

(-58.0...751.8°F)

Lower scaling point of the voltage

analog input

0 V corresponds to 0°C

P28

Temperature

at 0 V INPUT

400.0°C / 752°F

(-49.9…400.0°C)

(-57.8…752.0°F)

Upper scaling point of the voltage

analog input

10 V corresponds to 400°C

P29

Temperature

at 0/4 mA INPUT

0.0°C / 32°F

(-50.0...399.9°C)

(-58.0...751.8°F)

Lower scaling point of the voltage

analog input

4 mA corresponds to 0°C

P30

Temperature

at 20 mA INPUT

400.0°C / 752°F

(-49.9…400.0°C)

(-57.8…752.0°F)

Upper scaling point of the voltage

analog input

20 mA corresponds to 400°C

P31

Temperature

at 0 V OUTPUT

0.0°C / 32.0°F

(-50.0…399.9°C)

(-58.0…751.8°F)

Lower scaling point of the voltage

analog output

0 V corresponds to 0°C

P32

Temperature

at 10 V OUTPUT

400.0°C / 752°F

(-49.9…400.0°C)

(-57.8…752.0°F)

Upper scaling point of the voltage

analog output

10 V corresponds to 400°C

P33

Output function

0: P31,P32

1: 10V=100%

2: 5V=0%

3: Durchfluss

voltage analog output

0 : actual value P31…P32 -> 0…10V

1 : variable 0…100% -> 0...10V

2 : variable -100…0...100% -> 0...5...10V

3 : flow 0...P65 -> 0...10V

P38

Amplification factor

I-proportion (KI),

controller parameter

Setting depends

on model

(1...100%)

Constant of integration of the PID

control

controls the sensitivity / reactivity of the

controller

P39

Integration speedlimiting band,

controller parameter

Setting depends

on model

(0.0...5.0°C)

(0.0...9.0°F)

Prevents overshooting of the

temperature

P41

P-Band heating,

controller parameter

Setting depends

on model

(1.0...35.0°C)

(1.8...63.0°F)

Within the proportional band controlling

is accomplished by PID-Algorithm

P42

Delta-W – Cooling

Setting depends

on model

(-9.9...9.9°C)

(-17.8...17.8°F)

Starting point of cooling:

If the actual temperature is higher by

this value as the set temperature,

cooling starts

Page 10

Guidance MP-888 - Supplement to the manual of instructions 10/10

P43

Hysteresis cooling

Setting depends

on model

(0.2...25.0°C)

(0.4...45.0°F)

Period between ON and OFF of cooling.

This value has to be adjusted correctly

according to the controller adjustment

tables for temperature control units and

chillers.

P44

Differential portion

heating and cooling,

controller parameter

Setting depends

on model

(0...100%)

Differential portion of the PID control.

Controls the max. speed of the

controller

P45

Relation between

cooling- and heating

capacity

0

(1...50)

Adjusting of the cooling capacity

0: 2-point cooling (Standard)

1: cooling = heating capacity

50: cooling > heating capacity

P47

Minimal switching

time cooling,

controller parameter

1s

(0.5...9s)

Minimal switching time for cooling relay.

Only active if P45 is higher than 0

P48

Minimal switching

time heating,

controller parameter

2s

(1...9s)

Minimal switching time for heating relay.

If P45 = 0, so also relevant for the

cooling relay

P49

Cycle time,

controller parameter

15s

(6...255s)

Controller time base of PWM-outputs

Time of the analyse of the control

system to define the variable

P53

Flow unit

0: Flow OFF

1: Impulse (Hz)

2: litres/min

3: US gallons/min

4: Imperial gal./min

Flow unit to display

1 US gallon = 3.785 litres

1 Imperial gallon = 4.546 litres

P60

Flow measurement

Calibration table

0 = Manual

1 = Small units 1

2 = Medium units

3 = Large units

4 = Reserved

5 = Small units 2

6 = Reserve

Selection of the calibration table for flow

measurement

P61

Flow measurement

point 1

x Hz

y l/min

Relevant calibration curve for flow

measurement depending on P60

P62

Flow measurement

point 2

x Hz

y l/min

Relevant calibration curve for flow

measurement depending on P60

P63

Flow measurement

point 3

x Hz

y l/min

Relevant calibration curve for flow

measurement depending on P60

P64

Flow measurement

point 4

x Hz

y l/min

Relevant calibration curve for flow

measurement depending on P60

P65

Flow measurement

point 5

x Hz

y l/min

Relevant calibration curve for flow

measurement depending on P60

P66

Lower alarm limit

(P61)

30%

Only valid for automatic node (P3=1) to

calculate the alarm point

P67

Upper alarm limit

(P65)

10%

Only valid for automatic mode (P3=1) to

calculate the alarm point

Loading...

Loading...