Tool Connection Laser 5258 User Manual

ALWAYS

• Keep tool clean and dust free.

• Keep force screw thread clean and well lubricated (light machine oil).

• Wear eye protection when using.

B

A

5258

Valve Spring Compressor

For universal use on SOHC and DOHC engines

Designed to allow the removal of valve springs and valve stem oil seals

with the cylinder head in place.

Combustion chamber is pressurised via the supplied spark plug air line adaptor

which holds the valve in place during the valve spring compression operation.

• Fast set up time due to the twin rail pivot system.

• Single handed operation.

C

C

C

E

F

D

E

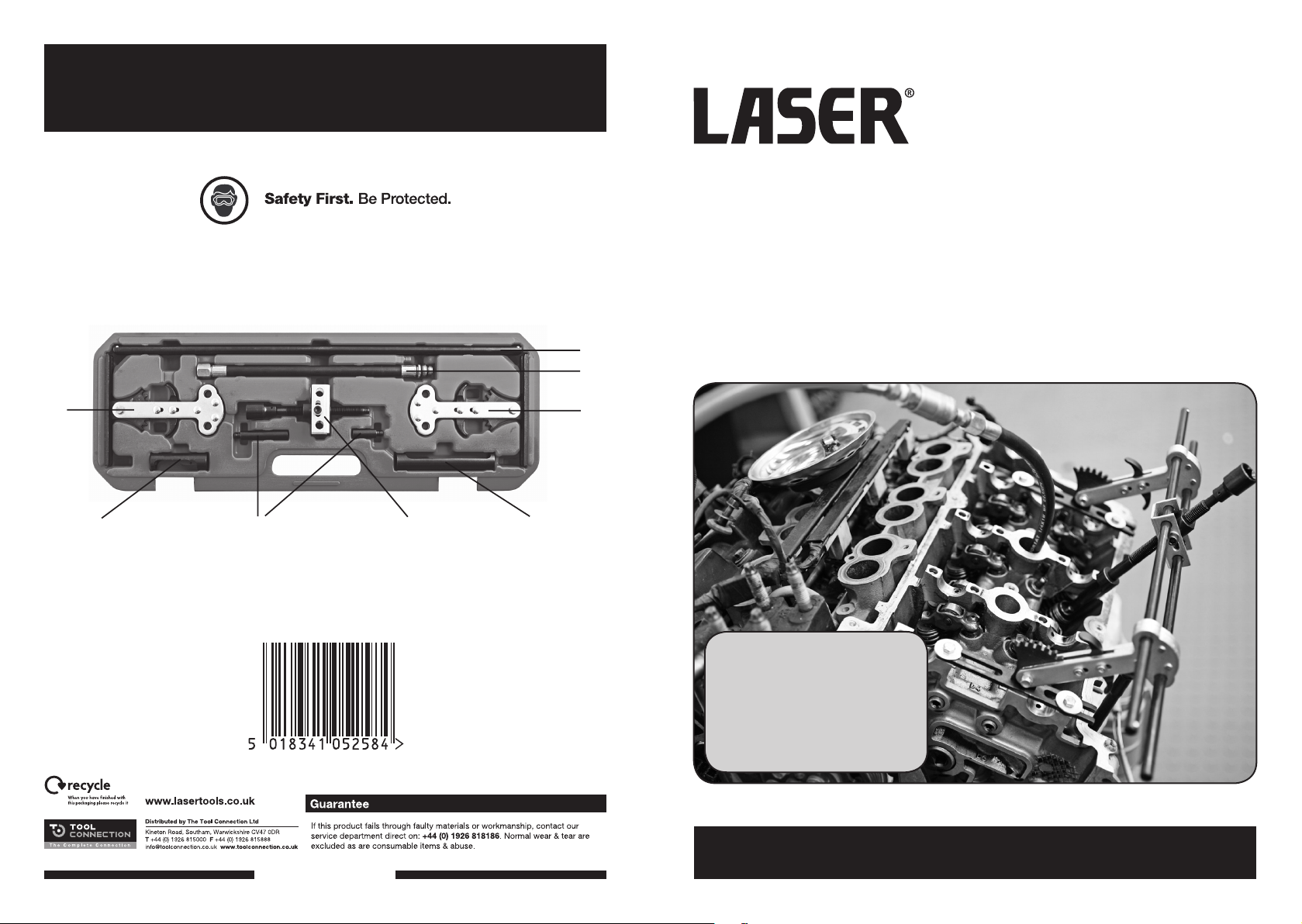

Contents:

A: Support bar x 2

B: Spark plug Air-line adaptor

C: Adjustable upright x 2

D: Compressor force screw assembly

E: Valve adaptor

F: Extension rods

www.lasertools.co.uk

www.lasertools.co.uk

Instructions

Instructions

Please refer to diagram on back cover

1. Remove camshaft. Sometimes both camshafts need to be removed to access

suitable mounting points for adjustable uprights (see 2).

2. Decide the most suitable mounting points for the two adjustable uprights (C) —

this may be the cam cover fixings, or the camshaft bearing cap mounting points,

for example. Secure one of the two adjustable uprights (C) to the cylinder head

using suitable fixings and washers (do not fully tighten fixings at this stage).

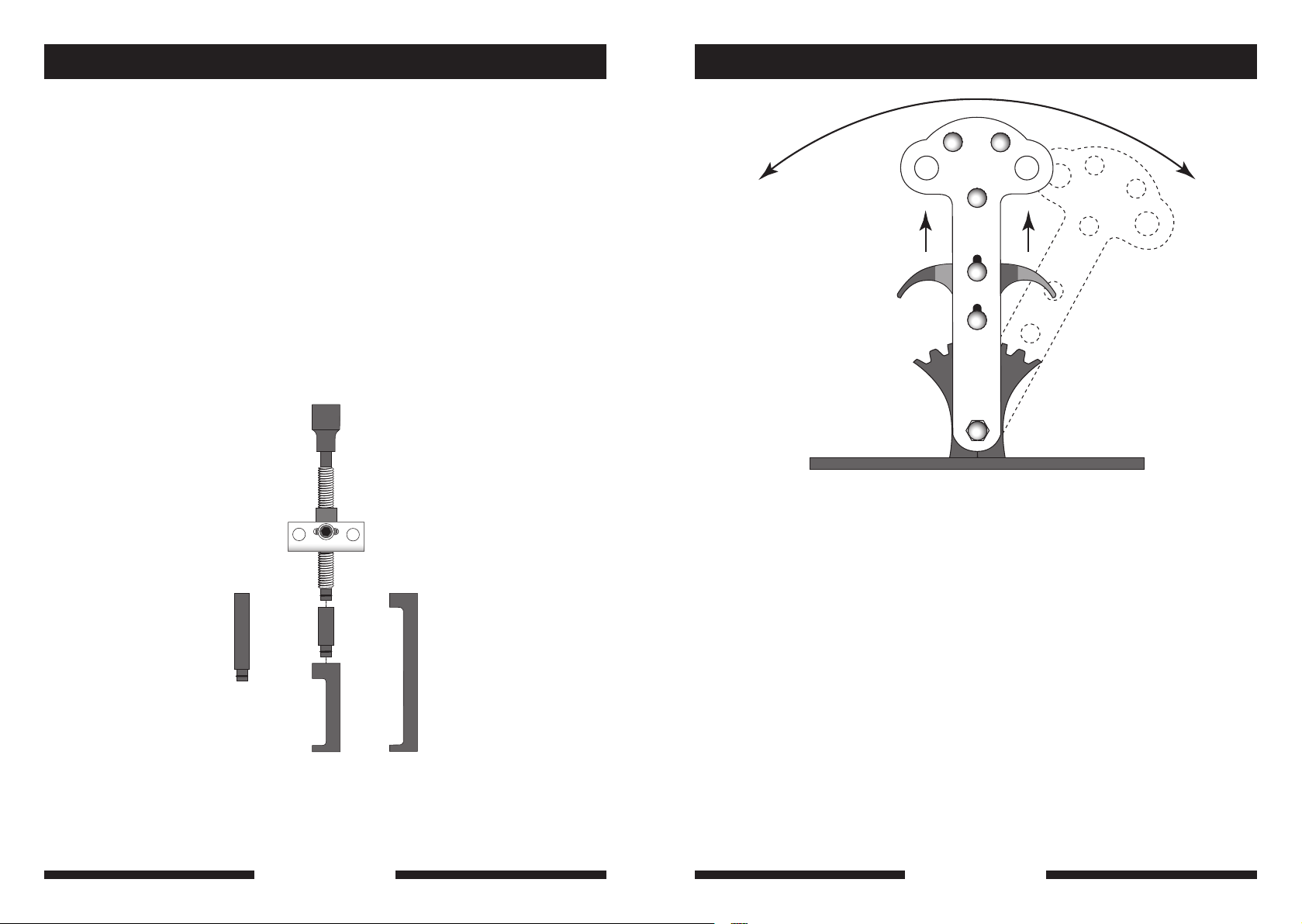

3. Locate the two support bars (A) through the adjustable upright.

4. Slide the compressor force screw assembly (D) along the two support bars until it

is above the valve spring to be removed.

PULL UP ON

FINGER GRIPS

TO ADJUST

ANGLE

5. Attach the second adjustable upright to the support bars and secure (do not fully

tighten fixings at this stage).

6. Choose either the short or long valve adaptor (E) and (if required) the extension

rods (F) (press-fit onto force screw) to enable the correct reach to the valve spring

retaining cap. (Refer to illustration.)

FORCE SCREW

ASSEMBLY

8. Screw force screw clockwise to take up any play against the top of the valve

spring retaining cap.

9. Once everything is lined up correctly tighten adjustable upright mounting bolts.

10. Remove the spark plugs from the engine.

11. Screw the spark plug air line adaptor (B) into the spark plug hole of the cylinder

concerned. Do not overtighten.

12. Connect the adaptor to an air supply (minimum 90psi). This will hold the valve

closed.

13. Tighten force screw using a 1/2”D ratchet or T-bar. The valve spring is then

compressed and the retaining collets can be removed.

EXTENSION

60mm

125mm

RODS

30mm

14. Release force screw by unscrewing; it can then be slid along the support bars to

VALVE

ADAPTORS

70mm

7. Ensure that the force screw is in the same axis as the valve by adjusting the

uprights and the force screw itself. The upright mounting position is adjusted by

gain access to the valve spring.

15. The valve spring can then be removed (and replaced if necessary) and new valve

stem seals can be fitted.

16. Re-compress the valve spring, insert the retaining collets and release tension on

force screw to finish.

17. Repeat instructions for other valves as necessary.

sliding the base plates on the fixings. The angle of the uprights is adjusted by

pulling up on the finger grips and moving the spring compressor assembly to

align. Release finger grips to lock position. (Refer to illustration.)

www.lasertools.co.uk

2 3

NOTE: Instructions are for guidance only.

Please refer to the manufacturer’s service manual.

www.lasertools.co.uk

Loading...

Loading...