Tonghui Electronic TH9310 Series, TH9320 Series Operation Manual

◇1

TH9310/20 Series

AC/DC Withstanding Voltage/

Insulation Resistance Tester

Operation Manual

Tonghui Electronic Co.,Ltd.

www.tonghui.com.cn

◇2

Manual Printing History

The manual printing data and part number indicate its current edition. The

printing date changes when a new edition is printed. The manual part number

changes when extensive technical changes are incorporated.

TH9310/20 Series Operation Manual…………………………….2013.8

◇3

Content

Chapter 1 Setup ..................................................................................................................6

1.1 Unpacking .................................................................................................................................6

1.2 Precautions for Use .................................................................................................................6

1.3 Precautions for Moving............................................................................................................8

1.4 Checking Power Source and Fuse........................................................................................8

1.4.1 Toggle power line voltage ..........................................................................................................................8

1.4.2 Checking or replacing fuse........................................................................................................................8

1.5 Connecting the AC Power Cord.............................................................................................9

1.6 Grounding..................................................................................................................................9

1.7 Checking Operations .............................................................................................................10

1.8 Other Specifications...............................................................................................................11

Chapter 2 Precautions on Handling.............................................................................12

2.1 Prohibited Operations............................................................................................................12

2.2 Action When in Emergency ..................................................................................................13

2.3 Precautions on Testing..........................................................................................................13

2.4 Warning for Residual High Voltages ...................................................................................14

2.5 Dangerous States of Failed Tester......................................................................................15

2.6 To Ensure Long-Term Use without Failures ......................................................................15

2.7 Daily Checking........................................................................................................................16

Chapter 3 Part names and Functions..........................................................................17

3.1 Front Panel..............................................................................................................................17

3.1.1 POWER...................................................................................................................................................17

3.1.2 START and STOP ...................................................................................................................................17

3.1.3 Band and Model ......................................................................................................................................17

3.1.4 USB Interface ..........................................................................................................................................17

3.1.5 Indicator...................................................................................................................................................17

3.1.6 FUNCTION ..............................................................................................................................................18

3.1.7 HV ...........................................................................................................................................................18

3.1.8 Output voltage HIGH terminal (HV).........................................................................................................18

3.1.9 Test low terminal, test current return terminal (LOW/RET)......................................................................18

3.1.10 Move key ...............................................................................................................................................18

◇4

3.1.11 Shortcut key...........................................................................................................................................18

3.1.12 COPY key..............................................................................................................................................18

3.1.13 LCD screen ...........................................................................................................................................18

3.2 Instruction of rear panel.........................................................................................................18

3.2.1 Fan ..........................................................................................................................................................19

3.2.2 Test low terminal, test current return terminal (optional) .........................................................................19

3.2.3 High voltage output terminal (optional)....................................................................................................19

3.2.4 Power jack: with fuse holder, switchable line voltage mode....................................................................19

3.2.5 Protective earth terminal .........................................................................................................................19

3.2.6 Mark ........................................................................................................................................................19

3.2.7 RS232C serial interface ..........................................................................................................................20

3.2.8 USB serial communication interface .......................................................................................................20

3.2.9 HANDLER interface ................................................................................................................................20

3.2.10 SIGNAL interface...................................................................................................................................20

3.3 Description ..............................................................................................................................20

Chapter 4 Basic operation..............................................................................................26

4.1 Interface structure overview .................................................................................................26

4.2 Instruction of panel function interface and parameter ......................................................27

4.2.1 SETUP ....................................................................................................................................................28

4.2.2 TEST (Take AC for example)...................................................................................................................29

4.2.3 SYSTEM..................................................................................................................................................30

4.2.4 FILE.........................................................................................................................................................32

4.3 Test item interface and parameter setup............................................................................33

4.3.1 AC withstanding voltage test parameter setup:..................................................................................... 33

4.3.2 DC withstanding voltage test parameter setup :......................................................................................34

4.3.4 Open and short detection (OS) parameter setup:................................................................................. 36

4.4 Test function theory and instruction ....................................................................................37

4.4.1 Start up test .............................................................................................................................................38

4.4.2 Test delay ................................................................................................................................................38

4.4.3 Test voltage rise.......................................................................................................................................38

4.4.4 DC RAMP................................................................................................................................................38

4.4.5 High-voltage test......................................................................................................................................38

4.4.6 Voltage fall...............................................................................................................................................39

4.4.7 Ground wire current detection function ...................................................................................................39

4.4.8 Current over limit and arc detection (ARC) function................................................................................39

4.4.9 Fail judgment...........................................................................................................................................40

4.4.10 Deal with test results .............................................................................................................................41

4.4.11 STOP.....................................................................................................................................................41

◇5

4.4.12 OFFSET ................................................................................................................................................41

4.5 Structure and Use of HANDLER and SIGNAL Interface Circuit......................................42

4.5.1 Control interface theory ...........................................................................................................................42

4.5.2 Control interface instruction.....................................................................................................................43

4.6 Other interface and function .................................................................................................43

4.7 Serial port commands instruction ........................................................................................44

4.7.1 SCPI commands .....................................................................................................................................44

4.7.2 DISPlay Subsystem Commands .............................................................................................................44

4.7.3 FUNCtion Subsystem Commands ..........................................................................................................45

4.7.4 FETCh Subsystem Commands...............................................................................................................64

4.7.5 SYSTem Subsystem Commands ............................................................................................................65

4.7.6 Other Commands ....................................................................................................................................71

Chapter 5 Appendix .........................................................................................................72

5.1 Model and Specification of TH9320 series/TH9310 series ........................................72

◇6

Chapter 1 Setup

This chapter describes the procedures from unpacking to installation to

operation checking.

1.1 Unpacking

Upon receiving the product, confirm that the necessary accessories are included and

have not been damaged in transit. Should any damage or shortage be found, please

contact TongHui distributor/agent.

Items Quantity

TH9310/20 1

TH90003R withstanding-voltage test leadwires 1

TH90003B withstanding-voltage ground leadwires 1

2.5A(220V-240V)/5A(100-120V)Time-lag Fuse

2 of each

AC Power cord 1

Operation Manual 1

Tes t R e port 1

Servicing card 1

Accessories ordered by customers 1

1.2 Precautions for Use

Be sure to observe the following precautions when using the tester.

Do not use the tester in a flammable atmosphere.

To prevent explosion or fire, do not use the tester near alcohol, thinner, or other

combustible materials, or in an atmosphere containing such vapors.

Avoid locations where the tester is exposed to high temperatures or

direct sunlight.

Do not locate the tester near a heater or in areas subject to drastic temperature

changes.

Operating temperature range: 5 °C to +35 °C

Storage temperature range: -20 °C to +60 °C

◇7

Avoid humid environments.

Do not locate the tester in a high-humidity environment—near a boiler, humidifier or

water supply.

Operating humidity range: 20% to 80% RH (no dew condensation permitted)

Storage humidity range: 90%RH or less (no dew condensation permitted)

Condensation may occur even within the operating humidity range. In that case, do not

start using the tester until the location is completely dry.

Do not place the tester in a corrosive atmosphere.

Do not install the tester in a corrosive atmosphere or one containing sulfuric acid mist or

the like. This may cause corrosion of various conductors and imperfect contact with

connectors, leading to malfunction and failure, or in the worst case, a fire.

Do not locate the tester in a dusty environment.

Dirt and dust in the tester may cause electrical shock or fire.

Do not use the tester where ventilation is poor.

This tester features a forced-air cooling system. Provide sufficient space for the air inlet

on the lateral side and the air outlet on the rear side to allow air to flow.

Do not place the tester on a tilted surface or in a location subject to

vibrations.

If placed on a non-level surface or in a location subject to vibration, the tester may fall,

resulting in damage and injury.

Do not use the tester in locations affected by strong magnetic or

electric fields.

Operation in a location subject to magnetic or electric fields may cause the tester to

malfunction, resulting in electrical shock or fire.

Do not use the tester in locations near a sensitive measuring

instrument or receiver.

Operation in a location subject, may cause such equipment may be affected by noise

generated by the tester.

At a test voltage exceeding 3 kV, corona discharge may be generated to produce

substantial amounts of RF broadband emissions between grips on the test leadwire. To

minimize this effect, secure a sufficient distance between alligator clips. In addition, keep

the alligator clips and test leadwire away from the surfaces of conductors (particularly

sharp metal ends).

◇8

1.3 Precautions for Moving

When moving the tester to the installation site or otherwise transporting it, take the

following precautions:

Before moving the tester, turn off the power switch.

Transporting the tester with its POWER switch on can lead to electric shock and

damage.

When moving the tester, Disconnect all wires from it.

Moving the tester without disconnecting the cables may result in breakage of the wire or

injury due to the tester tipping over.

1.4 Checking Power Source and Fuse

1.4.1 Toggle power line voltage

!

WARNING:This instrument is designed to operate from the overvoltage category II.

Do not operate it from the overvoltage category III or IV.

Before turning on the power, make sure of the identifying fuse and the source voltage

agree with the input voltage on the rear panel.

Allowable voltage range:

110V:AC(99V to121V AC)

220V:AC(198V to 242V AC)

Allowable frequency range: 47 Hz to 63 Hz

!

WARNING: To prevent malfunctions, be sure to operate within the above voltage

range.

1.4.2 Checking or replacing fuse

!

WARNING To prevent electric shock, before checking or replacing the fuse, be sure to

turn off the POWER switch and unplug the AC power cord.

Make sure that the fuse used conforms to the instrument specifications, including shape,

rating, and characteristics. Using a fuse with different rating or short-circuiting, the fuse

holder will damage the instrument.

1. Turn off the POWER switch, and unplug the AC power cord.

◇9

2. On the rear panel, remove the fuse holder, by pushing it inward and unscrewing it

counterclockwise using a screwdriver.

3.The fuse holder has the feature of switching the power input range and it shall reveal

the POWER mark on the outer shell.

4. Check the fuse type and choose the fuse according to the following table. The fuse is

time lag fuse.

5. Reinstall the fuse holder.

Voltage range Frequency Fuse(Time-lag) Instrument series Rated Power

TH9320 400VA

110V 5A

TH9310 300VA

TH9320 400VA

220V

47-63Hz

2.5A

TH9310 300VA

1.5 Connecting the AC Power Cord

The power cord that is provided varies depending on the destination for the product at

the factory-shipment.

Do not use the AC power cord provided with the product as an AC power cord for

other instruments.

Connection procedure:

1. Confirm that the supply voltage is within the line voltage range of the tester.

2. Confirm the nominal value of the fuse and the line power are correctly selcected.

3. Confirm that the POWER switch on the tester is off.

4. Connect the AC power cord to the AC LINE connector on the rear panel.

5. Use the provided power code or power code that is selected by qualified personnel.

6. Plug in the AC power cord.

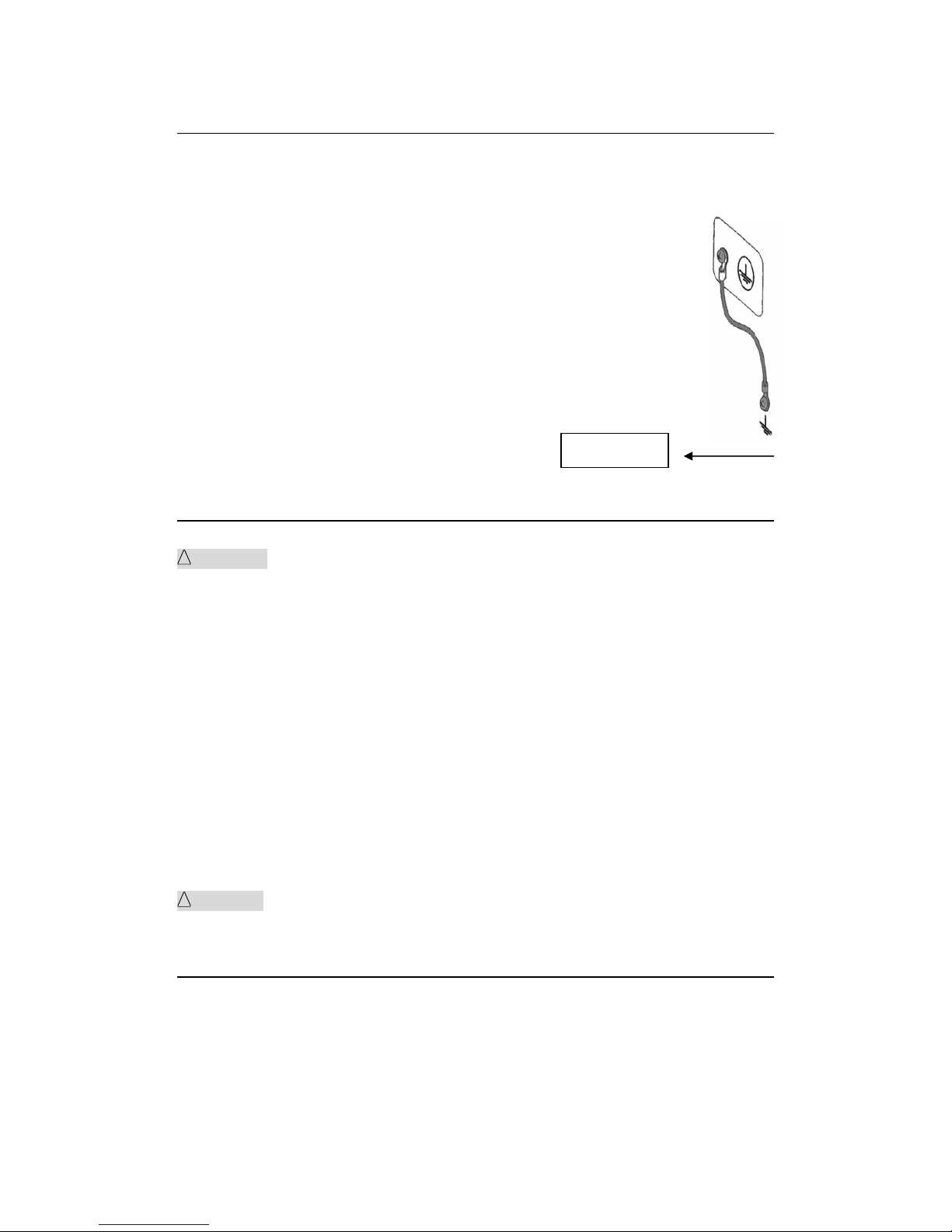

1.6 Grounding

!

WARNING: Be sure to connect the tester to an electrical ground (safety ground). If the

output to a conveyer or peripheral device that is connected to an earth ground or a

nearby commercial power line is short-circuited without grounding, the tester chassis is

charged to an excessively high voltage, resulting in extreme danger.

This tester is designed as a ClassⅡequipment (equipment protected against electric

shock with protective grounding in addition to basic insulation). Therefore, electric shock

◇10

may occur without proper grounding.

To ensure safety, be sure to ground the tester.

Choose either of the following two available methods of doing so:

1. Connect the AC power cord to a three-contact grounded electrical outlet.

2. Connect the protective conductor terminal on the rear panel to the earth

ground.

Have specialized engineers select, manufacture, and install cables.

To ensure secure connection, use proper tools.

1.7 Checking Operations

!

WARNING: Use the interlock jumper only to quickly cancel the protection status.

When using this tester in a cramped working space, make a box-like structure for the

DUT; when testing a complicated large-scale DUT, provide a cover or other means for

the DUT to prevent electric shock by cutting off the output when the cover is opened. It is

also recommended that an enclosure be provided around the operating area and that

output be cut off every time the door is opened.

Before turning on the power, confirm that the allowable voltage range indicated on the

power supply is the same as that indicated on the rear panel of the tester.

When the power is turned on, the tester lights all LEDs on the front panel and

self-diagnosis is started.

Before starting up the tester, confirm that all LEDs are on to ensure safety.

It is particularly dangerous to start a test when the DANGER lamp is broken.

Note that, in self-diagnosis, even when the DANGER lamp is lighting, no output or

voltage is being generated.

!

CAUTION: After turning off the POWER switch, wait several seconds before turning it

on. Turning the POWER switch on/off repeatedly with insufficient intervals may damage

the tester.

Earth

◇11

Checking procedure:

1. Confirm that the allowable voltage range indicated on the power supply is the same as

the input voltage range set by the fuse holder.

2. Confirm that the AC power cord is properly connected to the AC LINE connector on

the rear panel.

3. Plug in the AC power cord.

4. Turn on the POWER switch. Confirm that all LEDs on the front panel are lit. Following

the opening screen, display the ACW screen.

5. Following the opening screen, display the ACW screen and confirm that the tester is

kept in the READY status.

6.Turn on the POWER switch again.

Opening screen:

Tonghui

TH9320

HIPOT TESTER AC/DC/IR/OS

VERSION 1.0.6

2013.8.15

1.8 Other Specifications

1. Power: ≤500VA (TH9320/A/B)

≤400VA (TH9310/A/B)

2. Dimensions(W*H*D): 340mm*120mm*450mm;

3. Weight: approx. 15kg(TH9320/A/B); approx. 13kg(TH9310/A/B).

◇12

Chapter 2 Precautions on Handling

This chapter describes the precautions to be followed in the handling of this tester.

When using the tester, take utmost care to ensure safety.

!

WARNING :The tester derivers a 5 kV test voltage which can cause human injury or

death. When operating the tester, be extremely careful and observe the cautions,

warnings, and other instructions given in this chapter.

2.1 Prohibited Operations

Do not turn on/off the power repeatedly

After turning OFF the power switch, be sure to allow several seconds or more before turning it

ON again. Do not repeat turning ON/OFF the power switch rapidly. If you do this, the

protectors of the tester may not be able to render their protective functions properly. Do not

turn OFF the power switch when the tester is delivering its test voltage–you may do this only in

case of emergency.

Do not short the output to the earth ground

Pay attention so that the high test voltage line is not shorted to a nearby AC line or nearby

devices (such as conveyors) which are connected to an earth ground. If it is shorted, the tester

chassis can be charged up to the hazardous high voltage. Be sure to connect the protective

grounding terminal of the tester to an earth line. If this has been securely done, even when the

HIGH VOLTAGE terminal is shorted to the LOW terminal, the tester will not be damaged and

its chassis will not be charged up to the high voltage.

Be sure to use a dedicated tool when grounding the protective grounding terminal.

!

CAUTION: The term "AC line" here means the line on which the tester is operating. That is

the line to whose outlet the AC power cable of the tester is connected. It may be of a

commercial AC power line or of a private-generator AC power line.

Do not apply an External Voltage

Do not apply a voltage from any external device to the output terminals of the tester. The

◇13

analog voltmeter on the front panel cannot be used as stand-alone voltmeter. They may be

damaged if their output terminals are subject to an external voltage.

2.2 Action When in Emergency

In case of an emergency (such as electric shock hazard or burning of DUT), take the following

actions. You may do either (a) or (b) first. But be sure to do both.

1. Turn OFF the power switch of the tester.

2. Disconnect the AC power cord of the tester from the AC line receptacle.

2.3 Precautions on Testing

Wearing Insulation Gloves

When handling the tester, be sure to wear insulation gloves in order to protect yourself against

high voltages. If no insulation gloves are available on your market, please order Kikusui

distributor/agent for them.

Precautions for Pausing Tests

When changing test conditions, press the STOP switch once to take precautions. If you are not

going to resume the test soon or if you are leaving the Test area, be sure to turn-OFF the

POWER switch.

Items Charged Up to Dangerous High Voltages

When in test, the HV output, HV test leads, HV probes, DUT and output terminals and their

vicinities can be charged up to dangerous high voltages. Never touch them when in test.

!

WARNING: The vinyl sheaths of the alligator clips of the test leadwires which are supplied

accompanying the tester have no sufficient insulation for the high test voltages. Never touch

them when in test.

Matters to be Sure of After Turning-OFF Power

If you have to touch the DUT, test leadwires, probes, and/or output terminals and their

vicinities for re-connections or other reasons, be sure of the following two matters.

1. To confirm that the working condition is not in test mode.

2. The DANGER lamp has gone out.

Warnings for Remote Control

Be extremely careful when operating the tester in the remote control mode in which the

dangerous high test voltage is ON/OFF-controlled remotely. The operator cannot know the real

◇14

working condition of the instrument through the interface. Please pay special attention to

check the reliable connection of the remote control:

1. The “STOP” switch must be connected reliably. Press the “STOP” switch before changing

the DUT.

2. When testing in a working environment with a lot of people, remote control switch has the

“INTLOCK”switch and HV lamp. Disconnect the “INTLOCK” switch before changing the

DUT.

Provide means to assure that none can touch the DUT, test leadwires, probes, output

terminals and their vicinities when the test voltage is being delivered.

2.4 Warning for Residual High Voltages

!

WARNING: In DC withstanding voltage testing and insulation resistance testing, the test lead

wire, test probe, and DUT are charged to a high voltage. The tester is equipped with a

discharge circuit, but some time is nonetheless required to discharge them after the output is

cut off. There is a danger of electric shock during discharge. To avoid electric shock, take the

utmost care to ensure that the DUT, test lead wire, probe, and highly charged parts around the

output terminal are not touched. If it is necessary to touch them, be sure to confirm the

DANGER lamp has gone out.

As soon as the output is cut off, the tester’s discharge circuit starts forced discharging. Do not

disconnect the DUT during a test or prior to completion of discharging.

Under normal circumstances, it can be guaranteed that the test loop voltage is within the safe

voltage range when finishing discharging. When the capacitance of the DUT is too large or the

structure of the DUT is special, it may leads to incomplete discharge. In order to ensure

complete discharge, test method must be changed by technical personnel.

Discharge time:

Computational formula of discharge time: t = -ln(30 / U)×R×C

t: discharge time

30: discharge residue safty voltage 30V

U: test set voltage

R: discharge impedance of the DUT, the discharge impedance of the instrument is approx. 10k

C: capacitance of the DUT

In general, only DC high voltage test needs discharge and the length of the discharge time

varies according to the properties of the DUT.

If the test terminated normally, the voltage will drop to zero according to the voltage fall time. If

the test failed, discharge of the DUT is conducted by the transformer secondary

winding(resistance of approximately 10k). Approximately 0.05s are required for 1uF capacitor

with high voltage of 6000V to discharge to 30V. The fixed discharge time of the instrument is

◇15

0.2s, which ensures complete discharge of the device.

2.5 Dangerous States of Failed Tester

Typical possible dangerous states of the tester are as shown below and in which cases the

most dangerous situation that “the high test voltage remains delivered and the instrument

get out of control” may occur. When this situation has occurred,

1. Immediately turn OFF the power switch and disconnect the AC power cable from the AC

line receptacle.

2. Immediately keep far away from the instrument and confirm no risk of the test circuit by the

technical personnel; or keep the instrument still for more than one hour and confirm no

output voltage in the test terminal.

3. Remove the relevant connecting lines and send the instrument back to us for

maintenance.

!

WARNING: Keep away from the instrument after turning off the power and prevent other

people from approaching. Do not immediately disassemble the test circuit. Immediately call our

distributor or agent. High voltage may remain in the interior of the instrument. It is hazardous

for an unqualified person to attempt to troubleshoot any tester problem.

2.6 To Ensure Long-Term Use without Failures

The withstanding voltage-generating block of the tester is designed to release half the rated

amount of heat, in consideration of the size, weight, cost, and other factors of the tester. The

tester must therefore be used within the ranges specified below. If you deviate from these

ranges, the output block may be heated to excess, activating the internal protection circuit.

Should this happen, wait until the temperature returns to the normal level.

Output requirements for withstanding voltage testing

Ambient

temperature

Upper current Pause Time Output time

>12mA (TH9320/A/B)

>6mA (TH9310/A/B)

At least as long as the

output time

Maximum of 1

minute

AC

<8mA (TH9320/A/B)

<4m (TH9310/A/B)

Not necessary

Continuous output

possible

>6mA (TH9320/A)

>3mA (TH9310/A)

At least as long as the

output time

Maximum of 1

minute

T≤40℃

DC

<4mA (TH9320/A)

<2mA (TH9310/A)

At least as long as the

charging wait time

(WAIT TIME)

Continuous output

possible

Note: Test time <= Output time <= voltage rise time + test time + voltage fall time

◇16

2.7 Daily Checking

To avoid accidents, confirm at least the following before starting operation:

1. The input source complies with the standard and the tester power configuration is correct.

2. The tester is connected to an earth ground.

3. The coating of the high-voltage test lead wire is free from cracks, fissures, and breakage.

4. Without connecting the test lines, the instrument can finish the test successfully when

starting test by default.

5. The tester generates FAIL signal when the ends of the low-voltage test lead wire and

high-voltage test lead wire are short-circuited.

◇17

Chapter 3 Part names and Functions

This chapter describes the names and functions of components such as switches, displays,

and connectors on the front and rear panels.

3.1 Front Panel

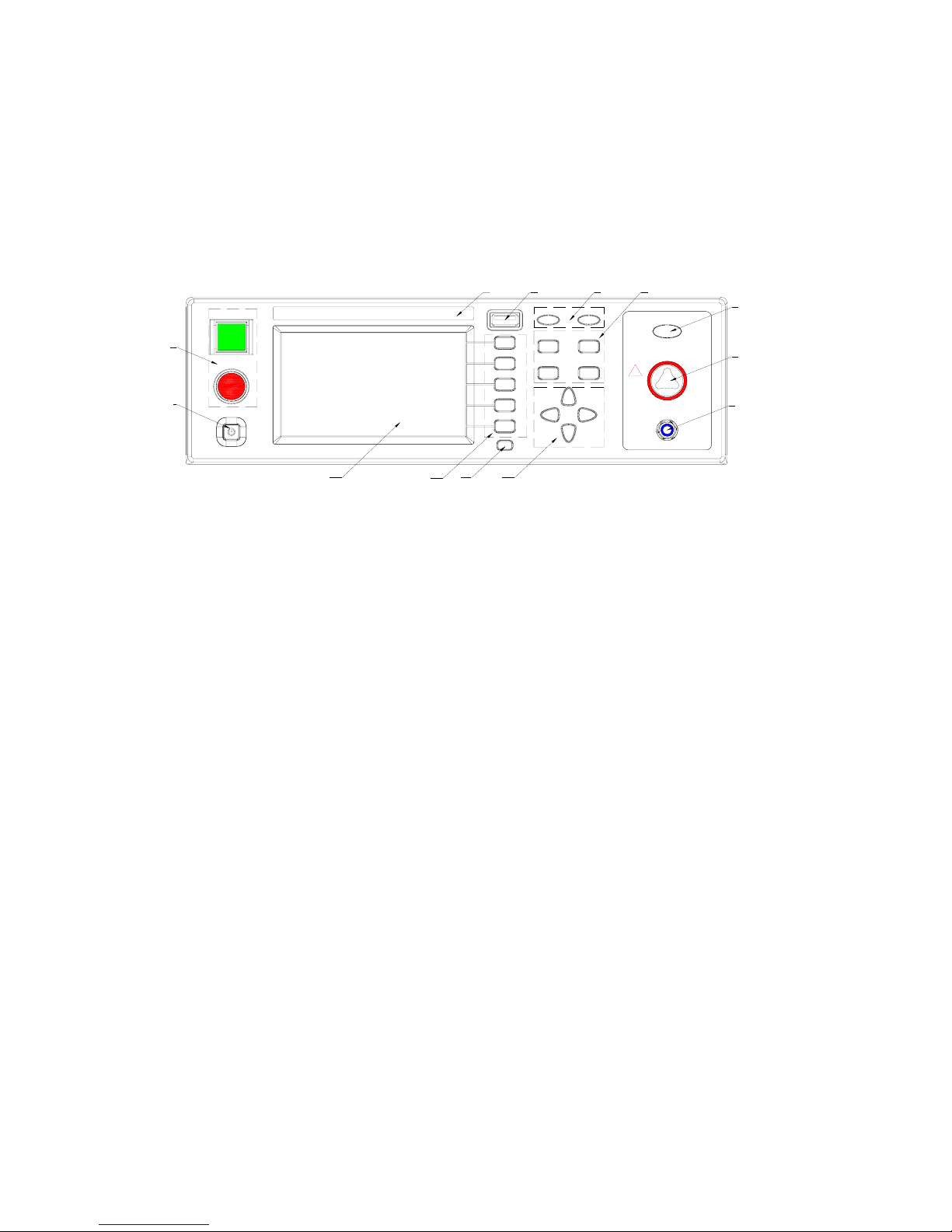

Figure 3-1 gives a brief description of the front panel for TH9310/20 series.

HV

RTN/LOW

OUTPUT

!

HIGH VOLT

MAX 5kV AC

START

STOP

POWER

FAIL PASS

SETUP

SYSTEM FILE

COPY

TEST

1

2

13

12

11

10

8

7

6

9

543

Figure 3-1

3.1.1 POWER

Power switch. Operators should check the power types and whether the test line

connections are normal.

3.1.2 START and STOP

START (square): Start up the instrument, once test starts, “TEST” will be displayed at the left

corner of the screen, TEST indicator lights.

STOP (circle): Stop key, used to cancel the test, or PASS, FAIL status.

3.1.3 Band and Model

Band and model.

3.1.4 USB Interface

Externally connect to USB storage.

3.1.5 Indicator

● FAIL

When the test data exceeds the set data in test, the instrument will lights in FAIL.

● PASS

When the test data does not exceed the set data after the test, the instrument will lights in

PASS.

◇18

When time function is off (TIMER OFF), there is no PASS judge. The test can be finished only

by pressing the ‘STOP’ key.

3.1.6 FUNCTION

Select mode, system and interface.

● TEST

Press the key and the corresponding key lights, the instrument is ready to test.

● SETUP

Press the key and the corresponding key lights, the instrument enters parameter setting;

● SYSTEM

Press the key and the corresponding key lights, the system setting interface will be displayed;

● FILE

Press the key and the corresponding key lights, the file operation interface will be displayed;

3.1.7 HV

DANGER!!It lights in test, indicating the test is underway.

3.1.8 Output voltage HIGH terminal (HV)

High voltage output of the high voltage test interface.

3.1.9 Test low terminal, test current return terminal (LOW/RET)

Voltage output terminal and current sampling terminal of the test.

3.1.10 Move key

It is used for moving cursor on the screen.

3.1.11 Shortcut key

F1-F5, corresponding with the function operation area on the right of the LCD.

3.1.12 COPY key

COPY key can copy the screen pictures to the USB storage. The USB starage should be

inserted into the USB jack on the front panel in advance.

3.1.13 LCD screen

480*272 TFT dot- matrix LCD screen, display setting and test interface, etc.

3.2 Instruction of rear panel

Figure 3-2 gives a brief description of the front panel for TH9310/20 series.

◇19

HV OUTPUT

110V/220V~50/60Hz

HANDLE RS-232C

SIGNAL

USB

RTN/LOW

WARNING:

FOR CONTINUED PROTECTION A GAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAM E TYPE AND RATING OF FUSE AS

SPECIFIED FOR THE LINE VOL TAGE BEING UTILIZED.

CAUTION:NO OPERATOR SERVICEABLE PARTS INSIDE

REFER SERVICING TO QUALIT IFIED PERSONNEL.

!

!

HIGH VOLTAGE

MAX:5kV AC

1 2 3 4 5

6789

10

Figure 3-2

3.2.1 Fan

Power amplifier circuit radiator.

3.2.2 Test low terminal, test current return terminal (optional)

Stand-by test low terminal of high voltage test interface.

3.2.3 High voltage output terminal (optional)

Stand-by high voltage output terminal of high voltage test interface.

3.2.4 Power jack: with fuse holder, switchable line voltage mode

Be used to input AC power. Please use the voltage within the specified input voltage range and

please use the attached power line with fuse. Change the fuse according to input power.

Please choose different installation position according to different input power type. Please pay

attention to the visible identification on the outer shell of the fuse holder when installing.

NOTE: The instrument supports 110 and 220 line voltage modes only. Other modes are

not connected in the interior of the instrument.

3.2.5 Protective earth terminal

Be used to connect instrument to ground.

NOTE: The three-pin power jack of the instrument can not guarantee reliable connection

to the ground. The protective earth terminal must be used to connect the instrument to

grounding bar.

3.2.6 Mark

This mark describes the serial number of the instrument.

◇20

3.2.7 RS232C serial interface

Serial communication, realize the communication with the computer.

3.2.8 USB serial communication interface

Realize the communication with the computer. Through this interface, the computer can control

the instrument by using the control instruction set.

3.2.9 HANDLER interface

Compared to PLC interface, the HANDLER interface has no INTERLOCK function in interface

signal. It is more convenient than PLC interface to use 9 core model D jack to output. It is

appropriate for the connection of general control circuit for multiple instruments.

TEST:Output synchronized-signal control when high voltage output is started.

START:Input the starting signal for starting high voltage output, corresponding to START

signal on the front panel.

RESET:Input the reset signal for stopping high voltage output, corresponding to STOP

signal on the front panel.

PASS :The output pass signal of the instrument, corresponding to PASS instruction on the

front panel.

FAIL:The output fail signal of the instrument, corresponding to FAIL instruction on the

front panel.

3.2.10 SIGNAL interface

It is the interface for online protection and interior 24V power output.

INTERLOCK:(COM(5) S+ -- (6) COM) valid in SHORT. It is the online locking signal of

the instrument, if off, starting output is not allowed.

DC 24V Power: (COM(1,2) 24V – (3,4) GND). It is used for requirement of indicator light

and other control power supply.

3.3 Description

TH9320 Provide 5kVAC/20mA withstanding voltage, 6kVDC/10mA withstanding voltage

and insulation resistance test.

TH9320A Provide 5kVAC/20mA withstanding voltage, 6kVDC/10mA withstanding voltage

test.

TH9320B Provide 5kVAC/20mA withstanding voltage test.

TH9310 Provide 5kVAC/10mA withstanding voltage, 6kVDC/5mA withstanding voltage and

insulation resistance test.

TH9310A Provide 5kVAC/10mA withstanding voltage, 6kVDC/5mA withstanding voltage

test.

TH9310B Provide 5kVAC/10mA withstanding voltage test.

◇21

The principle structure of the instrument: In high voltage module, there is a DA

standard, controllable forcing function generator, AB power amplifier, 40~600Hz high voltage

boost transformer and output voltage closed-loop control.

DA standard: ensure controllable output voltage amplitude.

Controllable forcing function generator: In AC output, set the operation in 50 or 60Hz,not

being limited by line voltage.

Linear power amplifier: low distortion of the voltage waveform with easy control and high

reliability.

40~600Hz high voltage boost transformer: to DC and insulation resistance test, the test

instrument uses 600Hz AC to form DC voltage to be the power, which can assure the DC

power ripple is far less than the formal withstanding voltage tester.

Output voltage closed-loop control: ensure small load regulation and reliable test data.

Software of the instrument: multiparameter continuous test and multiple upper

computer control function.

TH9310/20 series not only can perform the independent AC withstanding test, DC

withstanding voltage test, insulation resistance test, but also multi-item test via the setting of

test programme.

TH9310/20 series all allocate HANDLER, RS-232C and USB, thus the instrument can

adapt to the auto test system of different required safety and reliability.

Feature:

■ 4 test functions—AC withstanding voltage test, DC withstanding voltage test,

insulation resistance test, open and short detection.

TH9310, TH9320 provide AC/DC withstanding voltage test and insulation resistance test.

TH9310A, TH9320A provide AC/DC withstanding voltage test.

TH9310B, TH9320B provide AC withstanding voltage test.

All the instruments have the open and short detection function.

Once connected with load, the tester can perform different tests continually.

■ 2 different test power selection

In TH9320 series high voltage module, there is a AB power amplifier circuit and a 100VA

high voltage transformer, which can realize the output of 5kV/20mA (AC) and the output of

5kV/10mA (DC). The distortion of the waveform is less than 3%.

In TH9310 series high voltage module, there is a AB power amplifier circuit and a 50VA

high voltage transformer, which can realize the output of 5kV/10mA and the output of

5kV/5mA (DC). The distortion of the waveform is less than 3%.

If continuous current output is set, in order to guarantee the reliability of the instrument, the

maximum output time is 60 seconds when the output is more than 60% of the rated output

current. If the output is within 60%~40% of the rated output current, the continuous

working hours should be limited. If the output is less than 40% of the rated output current,

◇22

it can ensure continuous working.

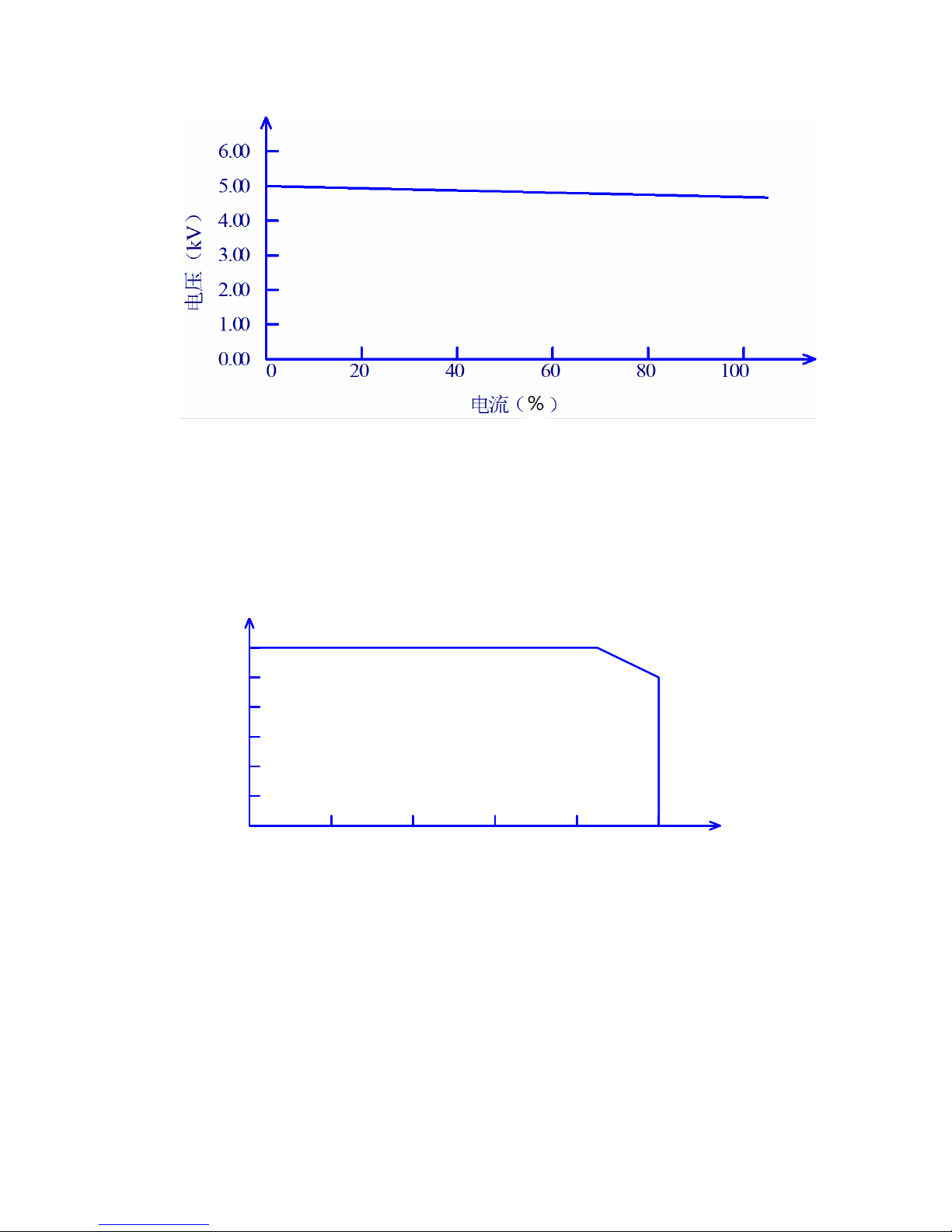

Figure 3-3 AC voltage load regulation

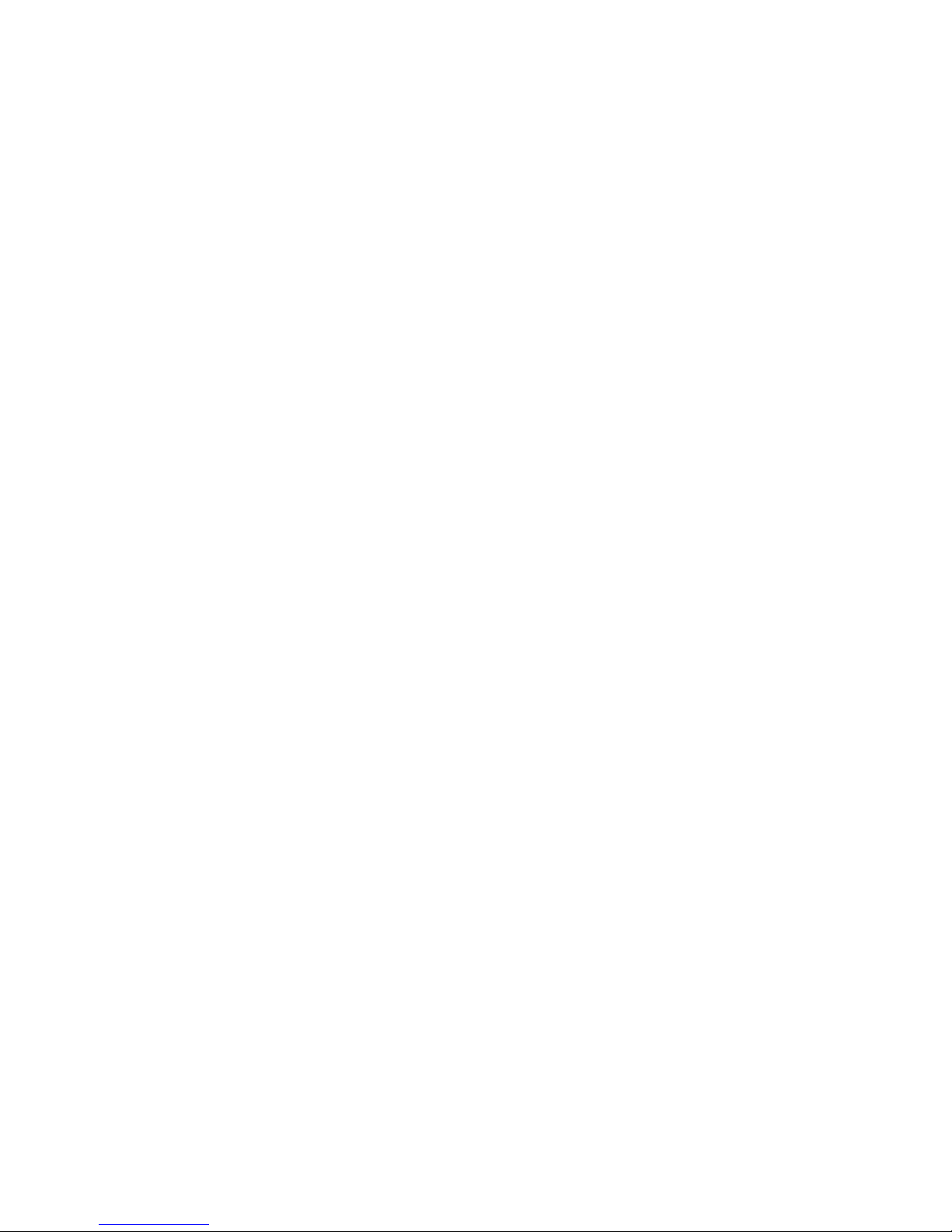

DC withstanding voltage test 5kV/10mA(TH9320/A)5kV/5mA(TH9310/A)

TH9310/20 series can provide DC withstanding voltage test of wide voltage range (Max.

output DC is 6kV). The automatic voltage regulation and voltage load regulation of

600Hz frequency hardware is less than 1%+10V.

0.0 0

1.0 0

2.0 0

3.0 0

4.0 0

5.0 0

电压(

kV

)

6.0 0

0246810

电流(

m

A

)

Figure 3-4 TH9320/A DC voltage output range

■ Insulation resistance test 0.050kV to 1.000kV(resolution of 1V)/0.1MΩ to 10.0GΩ

(Max. rated current of TH9320 is 10mA and max. rated current of TH9310 is 5mA)

◇23

Insulation resistance test range:

When the voltage is less than 500V: 0.1MΩ to 1GΩ with accuracy of ±[10% reading +5

digits].

When the voltage is greater than 500V: 0.1MΩ to 100MΩ with accuracy of [5% reading +5

digits], 100MΩ to 1GΩ with accuracy of [10% reading +5 digits].

■ Open and short detection: judge the reliability of the DUT before starting the high

voltage to ensure the accuracy and safety of high voltage test.

Open and short detection can judge the distribution impedance current of more than 100PF.

When the current is less than this value, the current acquisition circuit resolution of the

instrument can not distinguish the connection of open circuit and the test component

accurately.

■ RS-232C interface as the standard

Except power switch, key lock and execution (auto), other functions can be controlled

remotely. In DC withstanding voltage test, AC withstanding voltage test and insulation

resistance test, judge and time can be controlled remotely. The test result can also be read

via remote control. USB and RS-232C interface provides a stable and united standard test

interface for PC or other devices.

■ HANDLER and SIGNAL interfaces bring convenience for the connection and

control.

HANDLER interface can input START and STOP signals and output TEST, PA SS and

FAIL signals. Connecting with a footswitch, they can construct a foot-control device; while

connecting with simple test fixtures, they can realize safety interlock, air controls, test

indication, etc.

SIGNAL interface can input INTERLOCK signal and provide 24V, 1A power output. It is

convenient for control and connection.

■ USB interface for backup

Through the USB interface equipped by all testers, tester programmed test programmes

and customer’s measuring file can be saved to or recalled from an external U disk, which is

convenient to set, use and file a batch of testers.

■ Waiting time setup function

The instrument can set the test waiting time from 0.1s to 999.9s by a resolution of 0.1s. In

this period, the tester will output TEST control signals. They are used to control external

devices and ensure a reliable connection. After that high voltage measurement will be

enabled.

Loading...

Loading...