Tonghui TH2816B Operation Manual

OPERATION MANUAL

TH2816B

Precision LCR Meter

2

Contents

Chapter 1 Overview.......................................................................................................................5

1.1 Product introduction....................................................................................................5

1.2 Operation conditions...................................................................................................6

1.2.1 Power requirements...................................................................................................6

1.2.2 Operation environment..............................................................................................6

1.2.3 Warm-up time............................................................................................................6

1.2.4 Notes for usage..........................................................................................................6

1.3 Dimension and weight...................................................................................................7

1.4 Safety Summary............................................................................................................7

1.5 Electromagnetic compatibility......................................................................................7

Chapter 2 Basic Specifications..................................................................................................8

2.1 Measurement Functions................................................................................................8

2.1.1 Measurement Parameters..........................................................................................8

2.1.2 Combinations of Measurement Parameters...............................................................8

2.1.3 Equivalent Circuit.....................................................................................................8

2.1.4 Ranging.....................................................................................................................9

2.1.5 Trigger.......................................................................................................................9

2.1.6 Delay Time..............................................................................................................10

2.1.7 Measurement Terminals..........................................................................................10

2.1.8 Measurement Speed................................................................................................10

2.1.9 Averaging................................................................................................................10

2.1.10 Basic Accuracy........................................................................................................10

2.2 Test Signal...................................................................................................................10

2.2.1 Test Signal Frequency.............................................................................................10

2.2.2 Test signal level.......................................................................................................10

2.2.3 Output impedance ...................................................................................................11

2.2.4 Test Signal Level Monitor.......................................................................................11

2.2.5 Display Range.........................................................................................................11

2.3 Functions.....................................................................................................................11

2.3.1 Correction Functions...............................................................................................11

2.3.2 Comparator function ...............................................................................................11

2.3.3 Measurement results display...................................................................................12

2.3.4 File Function ...........................................................................................................12

2.3.5 Other Function ........................................................................................................12

2.3.6.1 Ranging mode.........................................................................................................12

2.3.6.2 Contrast adjustment.................................................................................................12

2.3.6.3 Beep ........................................................................................................................12

2.3.6.4 Comparator alarm....................................................................................................12

2.3.6.5 Key lock function....................................................................................................12

2.3.6.6 Password .................................................................................................................13

2.3.7 Interface Function ...................................................................................................13

2.3.7.1 IEEE488 interface...................................................................................................13

2.3.7.2 RS232C interface....................................................................................................13

2.3.7.3 HANDLER interface...............................................................................................13

Chapter 3 Panel and Display Introduction ......................................................................................14

3.1 A Tour of the Front Panel............................................................................................14

3.2 A Tour of the Rear Panel.............................................................................................15

3.3 Display Area Definition..............................................................................................16

3.4 MENU keys and Display Page....................................................................................16

3.5 Summary of Pages.......................................................................................................17

Chapter 4 Operation.....................................................................................................................19

4.1 Basic operation............................................................................................................19

4.2 Welcome Page.............................................................................................................20

4.3 Detailed Operation......................................................................................................21

4.3.1 MeasDisplay Page...................................................................................................21

4.3.1.1 Measurement Function............................................................................................22

3

4.3.1.2 Test Frequency ........................................................................................................23

4.3.1.3 Oscillator Level.......................................................................................................24

4.3.1.4 Measurement Range................................................................................................25

4.3.1.5 Measurement Speed................................................................................................26

4.3.1.6 Short Correction......................................................................................................26

4.3.1.7 Open Correction......................................................................................................27

4.3.1.8 File Management.....................................................................................................27

4.3.1.9 Useful Tools ............................................................................................................29

4.3.2 Bin Number Display Page.......................................................................................30

4.3.2.1 Comparator Function ON/OFF...............................................................................31

4.3.2.2 Auxiliary Bin ON/OFF ...........................................................................................31

4.3.2.3 File Management.....................................................................................................32

4.3.2.4 Useful Tools ............................................................................................................32

4.3.3 Meas Setup Page.....................................................................................................33

4.3.3.1 Trigger Mode...........................................................................................................35

4.3.3.2 Output Signal impedance........................................................................................36

4.3.3.3 Delay Time (DELAY )............................................................................................36

4.3.3.4 Averaging Rate (AVG)............................................................................................36

4.3.3.5 Signal Level Monitor ON/OFF...............................................................................36

4.3.3.6 Deviation Measurement Function...........................................................................37

4.3.3.7 File Management.....................................................................................................38

4.3.3.8 Useful Tools............................................................................................................38

4.3.4 Limit Table ..............................................................................................................38

4.3.4.1 Nominal Value for tolerance mode..........................................................................39

4.3.4.2 Swap Parameter Function........................................................................................40

4.3.4.3 Comparator Function's Limit Mode........................................................................40

4.3.4.4 Comparator Function ON/OFF...............................................................................40

4.3.4.5 Auxiliary bin ON/OFF............................................................................................40

4.3.4.6 Low/High Limit Value ............................................................................................40

4.3.4.7 File Management (File)...........................................................................................41

4.3.4.8 Useful Tools............................................................................................................41

4.3.5 System Configuration Page .....................................................................................41

4.3.5.1 LCD Contrast Function...........................................................................................42

4.3.5.2 Information Beeper Function ON/OFF...................................................................43

4.3.5.3 Comparator Alarm Function ON/OFF ....................................................................43

4.3.5.4 Password Function..................................................................................................43

4.3.5.5 Bus Mode Function.................................................................................................44

4.3.5.6 GPIB address...........................................................................................................44

4.3.5.7 AutoFetch mode ON/OFF.......................................................................................44

Chapter 5 Remote Control ..............................................................................................................45

5.1 RS232C Interface Introduction ...................................................................................45

5.1.1 RS232C Connection................................................................................................45

5.1.2 Communication with a Computer...........................................................................46

5.1.3 Communication with a DC Bias Current Source....................................................49

5.2 GPIB Interface Introduction........................................................................................50

5.2.1 GPIB Connection....................................................................................................50

5.2.2 GPIB Interface Capabilities Functions....................................................................53

5.2.3 GPIB Addressing.....................................................................................................53

5.2.4 GPIB Bus Function.................................................................................................53

5.3 Data Format.................................................................................................................53

5.3.1 Format 1..................................................................................................................54

5.3.2 Format 2..................................................................................................................55

Chapter 6 Command Reference......................................................................................................56

6.1 Notation Conventions and Definitions........................................................................56

6.2 Command Structure.....................................................................................................56

6.3 Command Abbreviations.............................................................................................58

6.4 Suffix Units and suffix Multipliers .............................................................................58

4

6.5 Command Reference...................................................................................................59

6.5.1 DISPlay Subsystem.................................................................................................60

6.5.2 FREQuency Subsystem...........................................................................................61

6.5.3 VOLTage Subsystem...............................................................................................62

6.5.4 FUNCtion Subsystem..............................................................................................63

6.5.5 APERture Subsystem..............................................................................................66

6.5.6 TRIGger Subsystem................................................................................................67

6.5.7 FETCh? Subsystem.................................................................................................68

6.5.8 ABORt Subsystem..................................................................................................69

6.5.9 CORRection Subsystem..........................................................................................69

6.5.10 COMParator Subsystem..........................................................................................71

6.5.11 Mass MEMory Subsystem......................................................................................76

6.5.12 Common Commands...............................................................................................77

6.5.13 Error and Warning Messages...................................................................................78

Chapter 7 Handler Interface.........................................................................................................79

7.1 Basic Information........................................................................................................79

7.2 Handler Interface Operation........................................................................................79

7.2.1 Signal line definition...............................................................................................79

7.2.1.1 Signal Line Used for Comparator Function............................................................79

7.2.1.2 Signal Line Used for List Sweep Comparator Function.........................................83

7.3 Electrical Characteristics.............................................................................................87

7.3.1 DC Isolated Outputs................................................................................................ 87

7.3.2 DC Isolated Input....................................................................................................89

7.4 Setting Up the Handler Interface Board ......................................................................89

7.5 Operation.....................................................................................................................91

7.5.1 Setting Procedure For Comparator Function...........................................................91

7.5.2 Setting Procedure For List Sweep Comparator function.........................................91

5

Chapter 1 Overview

Thank you for choosing our product. The contents of the shipment should be as listed in

the packing list. If the contents are incomplete, if there is mechanical damage or defect, or

if the instrument does not pass the power-on self tests, please notify our company.

1.1 Product introduction

TH2816B is a precision LCR meter with high accuracy, good stability, and wide

measurement range. Controlled by a 16 bits MPU, TH2816B can be used for

evaluating LCR components, materials and semiconductor devices over a wide range

of frequencies (50 Hz to 200 kHz) and test signal levels (0.01 V to 2.00 V, with 0.01 V

resolution ). With its powerful function, excellent performance, perspicuous LCD

display and easy menu operation, TH2816B is suitable for high speed measurement

need on product line and high accuracy and stability measurement need in laboratory.

By using the Handler interface, IEEE488 interface (optional), and RS232C interface,

TH2816B can easily be used for automatic test system and computer remote control.

The instrument provides variable test conditions, typical conditions are as follows:

z Test signal frequency

37 typical frequency points available from 50 Hz to 200 kHz.

z Test signal level

Programmable signal level from 0.01 V to 2.00 V in 0.01 V resolution.

z Measurement speed

Fast, Medium and Slow measurement speed can be selected. Using the

averaging rate (from 1 to 255 programmable) function, you can get more stable

measurement results.

z Constant signal source output impedance

30 Ω or 100Ω selectable

z Bias current

TH2816B can control the external bias current source (for example TH1773) for

bias current list sweep measurement.

z Correction function

The OPEN, SHORT correction for correcting the stray admittance, the residual

impedance, and the other errors can be performed. The correction function has

two kinds of correction methods. In one method the open and short correction

can be performed at all of the frequency points, and in the other method the open,

short correction can be performed at the frequency points you specify.

z Test signal level monitor

The actual signal level may be different with the setup signal level. The level

monitor function allows you to monitor the actual voltage level across the device

under test or the actual current level though the device under test.

TH2816B provides 3 types of display results and 2 kinds of comparison methods

z Direct readout: The actual measurement results are displayed.

Absolute deviation (ΔABS): The difference between the measured value of

the DUT and a previously stored reference value

are displayed.

Percent deviation (Δ%): The difference between the measured value of the

DUT and a previously stored reference value are

displayed as a percentage of the reference value.

6

z Absolute deviation or percent deviation can be set as comparison limits.

TH2816B can output comparison results for sorting components into a maximum

of 10 bins. (BIN1 to BIN 9 and OUT). Also, devices whose primary parameter is

within limits, but whose secondary parameter measurement result is not within

limits, can be sorted into an AUXiliary BIN.

TH2816B provides several communication interfaces which make it easy to output

the measurement results to other equipments (for example computers), or build an

automatic test system.

z RS232C interface: RS232C interface make it easy to communicate with other

equipments. You can set the measurement functions and input the parameters

through the RS232C interface instead of front panel keyboard.

The RS232C interface can also be used as the control interface for the external

bias current source.

z IEEE488 interface (optional): The IEEE488 interface is an optional interface on

the TH2816B and can be used to build an automatic test system to completely

characterize new components and materials, and to fully automate production

line testing.

z HANDLER interface(optional): By using the handler interface, the TH2816B can

easily be combined with a component handler, and a system controller to fully

automate component testing, sorting, and quality control data processing.

TH2816B’s file function can save the setup parameters, limit parameters and list

sweep parameters as a file in the internal nonvolatile memory, and the No. 0 file will

be automatically reloaded when TH2816B is powered on.

1.2 Operation conditions

1.2.1 Power requirements

TH2816B requires the following power source:

Voltage: 198 to 242 Vac

Frequency: 47 to 66 Hz

Power: 50 VA maximum

1.2.2 Operation environment

TH2816B must be operated under within the following environment conditions.

Temperature:0℃ to 40℃

Humidity: less then 90% RH

1.2.3 Warm-up time

Allow TH2816B to warm up a minimum of 20 minutes before starting tests.

1.2.4 Notes for usage

z Please do not operate the instrument in the places where is vibrative, dusty,

under direct sunlight, or where there is corrosive air.

z Although the instrument has been specially designed for reducing the noise

cased by ac power, a place with low noise is still recommended. If this cannot be

arranged, please make sure to use power filter for the instrument.

z Please store the instrument in the place where temperature is between 5℃ and

40℃, humidity is less then 85% RH. If the instrument will not be put in use for a

time, please have it properly packed with its original box or a similar box for

storing.

z TH2816B has the cooling fan on the rear panel and cooling holes on both sides.

High temperature inside will decrease the measurement accuracy, so sufficient

space must be kept around the TH2816B to avoid obstructing the air flow of the

7

cooling fans.

z Don’t frequently turn on and off the instrument, doing so will lead to the loss of

the calibrated data and the data saved by users.

1.3 Dimension and weight

Dimensions: 350(W) by 110(H) by 340(D) (mm)

Weight: Approximately 4 kg

1.4 Safety Summary

The following general safety precautions must be observed during all phases of

operation, service, and repair of this instrument.

Ground the Instrument

To avoid electric shock hazard, the instrument chassis and cabinet must be

connected to a safety earth ground by the supplied power cable with earth blade.

DO NOT Operate In an Explosive Atmosphere

Do not operate the instrument in the presence of flammable gasses or fumes.

Operation of any electrical instrument in such an environment constitutes a definite

safety hazard.

Keep Away From Live Circuits

Operating personnel must not remove instrument covers. Component replacement

and internal adjustments must be made by quailed maintenance personnel. Do not

replace components with the power cable connected. Under certain conditions,

dangerous voltages may exist even with the power cable removed. To avoid injuries,

always disconnect power and discharge circuits before touching them.

DO NOT Service or Adjust Alone

Do not attempt internal service or adjustment unless another person, capable of

rendering first aid and resuscitation, is present.

DO NOT Substitute Parts or Modify Instrument

Because of the danger of introducing additional hazards, do not install substitute

parts or perform unauthorized modifications to the instrument. Return the instrument

to our Sales and Service Office for service and repair to ensure that safety features

are maintained.

1.5 Electromagnetic compatibility

This product has been designed and tested to the requirements of the

Electromagnetic Compatibility (EMC) Directive. To use a properly shielded cable or

shielded coaxial cable to connect each of the ports to their respective controllers,

peripherals, equipments or devices may ensure to meet the requirements.

8

Chapter 2 Basic Specifications

2.1 Measurement Functions

2.1.1 Measurement Parameters

L: Inductance

C: Capacitance

R: Resistance

|Z|: Absolute value of impedance

X: Reactance

B: Susceptance

G: Conductance

D: Dissipation factor

θ: Phase angle

Q: Quality factor

2.1.2 Combinations of Measurement Parameters

Suffix “s” means series; suffix “p” means parallel.

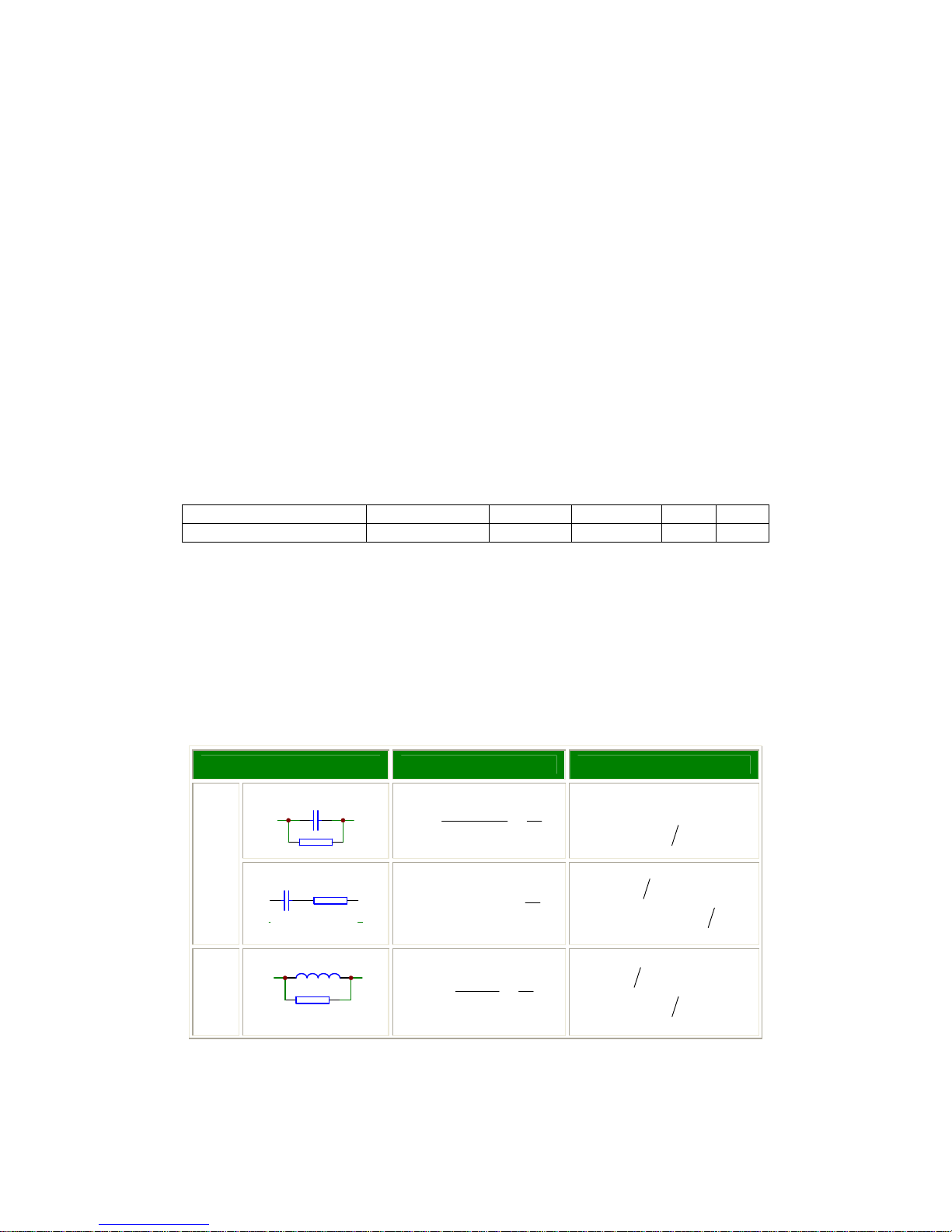

2.1.3 Equivalent Circuit

The actual capacitor, resistor and inductor are not the ideal capacitor, resistor and

inductor. Normally, a component has the characteristics of the resistor and the

reactor at the same time. The actual component is composed of an ideal resistor and

reactor (ideal inductor or capacitor) in series or parallel equivalent circuits.

The values in the two different equivalent circuits can be converted to each other

using the following formulas in Table 2-1. The values are different due to the quality

factor Q (or the dissipation factor D).

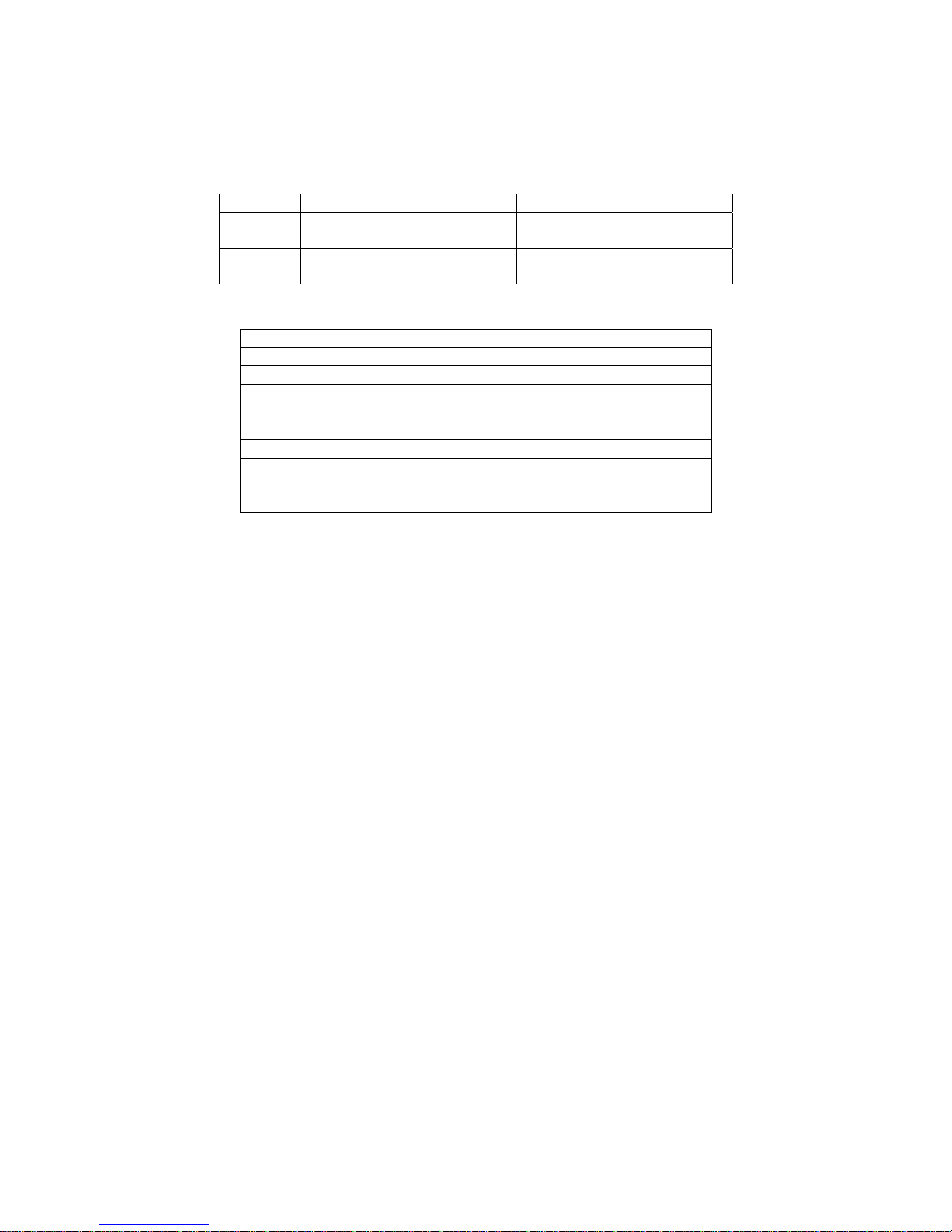

Table 2-1 Parallel and Series Circuit Mode

Circuit Mode Dissipation Factor Conversion

Cp

QRfC

D

Pp

1

2

1

==

π

)1(

)1(

22

2

DDRR

CDC

PS

PS

+=

+=

C

Cs

Rs

Q

CfRD

SS

1

2 ==

π

22

2

)1(

)1(1

DDRR

CDC

SP

SP

+=

+=

L

Lp

Rp

QR

fL

D

P

P

1

2

==

π

)1(

)1(1

22

2

DDRR

LDL

PS

PS

+=

+=

Main parameters Z L C R G

Secondary parameters θ(deg), θ(rad) Q,Rs,Rp D, Rs, Rp X B

9

Lp Rp

QfL

R

D

S

S

1

2

==

π

22

2

)1(

)1(

DDRR

LDL

SP

SP

+=

+=

L: Inductor C: Capacitor f: Frequency

R: Resistor D: Dissipation factor Q: Quality factor

Suffix s: Series Suffix p: Parallel

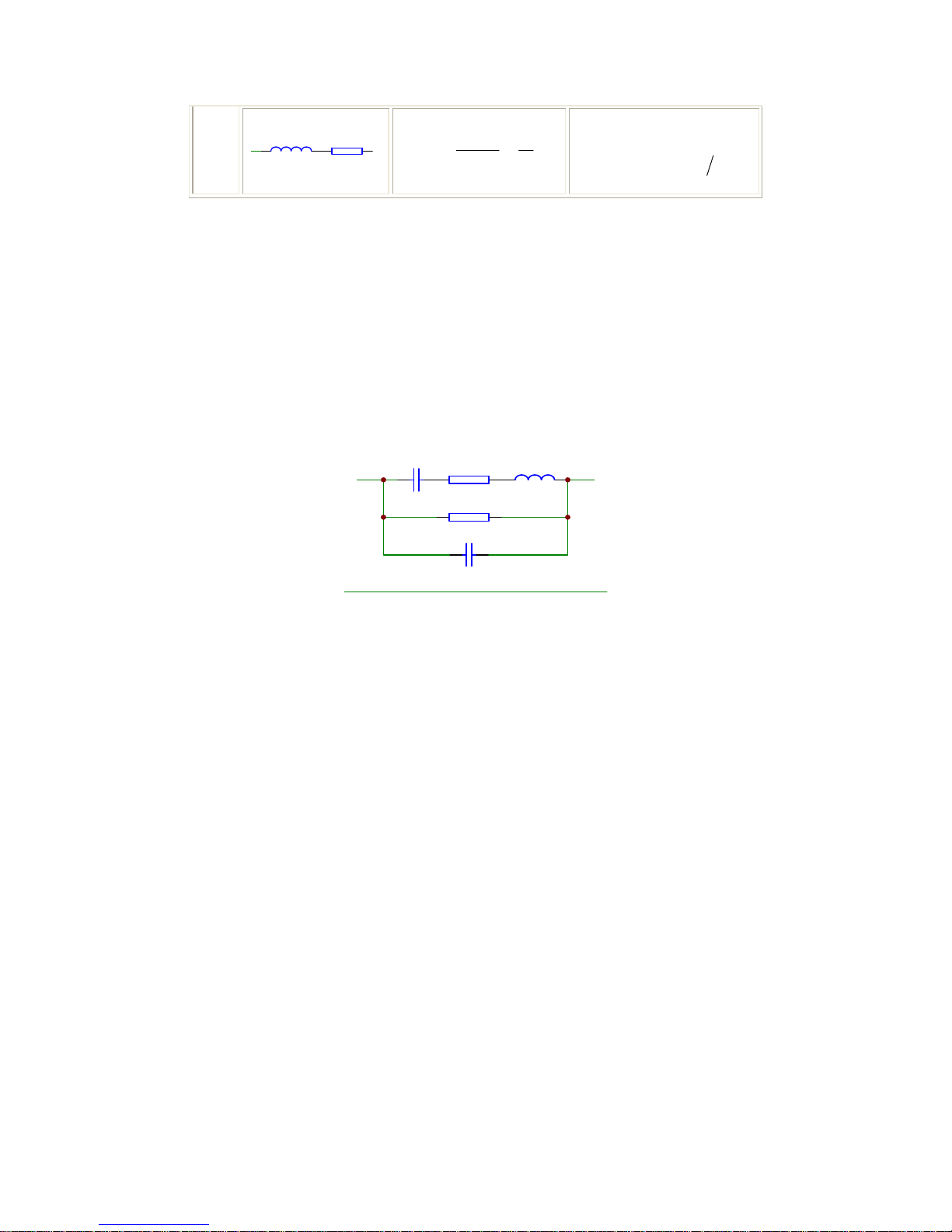

The following description gives some practical guidelines for selecting the

capacitance measurement circuit mode.

a) We can select the circuit mode according to the variation of D at two different

frequencies. If the dissipation factor of a capacitor increases with the increase of

the test frequency, series circuit mode should be selected. If the dissipation factor

decreases with the increase of the test frequency, parallel circuit should be used.

For inductor, the situation is just in the opposite side. In fact, D is impossible in

direct ratio with the test frequency. From Figure 2-1, we can find that Rp and Rs

exist at the same time. If Rs is more significant than Rp, series mode is selected;

If Rp is more significant than Rs, parallel mode is more suitable.

Cs

Rp

Cx

Rs Lo

Figure 2-1. Equivalent circuit of an actual capacitor

Where,

Cx: ideal capacitor

Rx: resistance of the leads

Lo: inductance of the leads

Rp: insulation resistance across the capacitor

Co: stray capacitor across the capacitor.

For a given frequency F, Cs and Cp can be calculated.

b) When there is no proper information available, please make decision according to

following rules:

For low impedance component(such as large capacitor or small inductor),

the series equivalent circuit mode should be used.

For high impedance component(such as small capacitor or large inductor),

the parallel equivalent circuit mode is the appropriate choice.

If a capacitor is used as a filter capacitor, series circuit mode is the best

choice.

If a capacitor is used in a LC oscillator then parallel circuit mode can be

selected.

2.1.4 Ranging

Auto and Manual (Hold/Up/Down), total 9 ranges.

2.1.5 Trigger

TH2816B has four trigger modes: INTernal, EXTernal, MANual, and BUS. Except for

BUS trigger mode these trigger modes can be set on the front panel. The BUS trigger

mode is used when TH2816B is controlled via GPIB.

Internal: When the trigger mode is set to INTernal trigger mode, TH2816B

continuously repeats measurements.

10

External: When the trigger mode is set to EXTernal, TH2816B performs a single

measurement every time a low-to-high transition TTL level signal is applied

to the Handler interface on the rear panel.

BUS: When the trigger mode is set to BUS trigger mode, TH2816B performs a

single measurement every time the *TRG common command is sent to

TH2816B via GPIB. The BUS trigger mode cannot be set on the front panel.

Send the TRIGger:SOURce BUS command via GPIB or RS232C to set the

trigger mode to the BUS trigger mode.

Manual: When the trigger mode is set to MANual trigger mode, TH2816B performs a

single measurement every time when TRIGGER key on the front panel is

pressed.

2.1.6 Delay Time

Programmable delay from the trigger command to the start of the measurement, 0 to

60.000 s in 1 ms steps.

2.1.7 Measurement Terminals

Four terminals:

HD (H

CUR

): High current

HS (H

POT

): High potential

LS (L

POT

): Low potential

LD (L

CUR

): Low current

2.1.8 Measurement Speed

TH2816B’s measurement speed is determined by Integration time, measurement

result display time, averaging rate and delay time.

FAST: about 25 meas/sec, maximum 30 meas/sec.

MED: about 10 meas/sec.

SLOW: about 1.5 meas/sec.

2.1.9 Averaging

1 to 255, programmable

2.1.10 Basic Accuracy

0.05%

2.2 Test Signal

2.2.1 Test Signal Frequency

Total 37 typical frequency points available from 50Hz to 200kHz:

50Hz、60Hz、80Hz、100Hz、120Hz、150Hz、200Hz、250Hz、300Hz、400Hz、

500Hz、600Hz、800Hz、1kHz、1.2kHz、1.5kHz、2kHz、2.5kHz、3kHz、4kHz、

5kHz、6kHz、8kHz、10kHz、12kHz、15kHz、20kHz、25kHz、30kHz、40kHz、50kHz、

60kHz、80kHz、100kHz、120kHz、150kHz、200kHz

Frequency Accuracy: 0.02%

2.2.2 Test signal level

0.01 V to 2.00 V, 0.01 V resolution

Level accuracy: ±(10%×setup value+2 mV)

11

2.2.3 Output impedance

30Ω±5% (default), 100Ω±5%

2.2.4 Test Signal Level Monitor

Mode Range Monitor Accuracy

Voltage

10 mV

rms

– 2.00 V

rms

0.01 mV

rms

–10 mV

rms

±(3% of reading+0.5mV)

±(12% of reading+0.1mV)

Current

100μA

rms

– 66mA

rms

0.001μA

rms

– 100 μA

rms

±(3% of reading+5μA)

±(12% of reading+1μA)

2.2.5 Display Range

Parameter Range

L 0.01 nH to 9999.99 H

C 0.00001 pF to 999.999 mF

R, X, Z 0.01 mΩ to 99.9999 MΩ

B, G 0.01 nS to 999.999 S

D 0.00001 to 9.99999

Q 0.01 to 99999.9

θ Deg -179.999° to 179.999°

Rad -3.14159 to 3.14159

% -99.999% to 999.999%

2.3 Functions

2.3.1 Correction Functions

Open correction

Eliminates measurement errors due to parasitic stray admittance (C, G) of the

test fixture. Three frequency points or sweep frequency Open correction is

available.

Short correction

Eliminates measurement errors due to parasitic residual impedances (L, R) of

the test fixture. Three frequency points or sweep frequency Short correction is

available.

Load correction

Improves the measurement accuracy by using a device which value is accurately

known (a working standard) as a reference. Three frequency points load

correction is available.

2.3.2 Comparator function

10-bin sorting for the primary measurement parameter, and IN/ OUT decision output

for the secondary measurement parameter.

BIN1 to BIN9: Both primary and secondary measurement parameters are within

limits.

OUT BIN: Primary parameter is not within limits. Or primary parameter is within

limits, secondary parameter is not within limits, and AUX bin is off.

AUX BIN: Primary parameter is within limits, but whose secondary parameter

measurement result is not within limits.

If the secondary parameter limits are not set, TH2816B will not compare the

secondary parameter.

z Sorting Modes

Absolute deviation mode: absolute deviations are compared with bin limits.

Percent deviation mode: percent deviations are compared with bin limits.

z Bin Count

Each bin has a bin counter, counts from 0 to 999999.

12

z Display pages

BinNo. Disp page and Bin Count page

More detail information is outputted through the Handler interface:

PHI: Primary measurement parameter is high.

PLO: Primary measurement parameter is low.

SREJ: Secondary measurement parameter is rejected.

2.3.3 Measurement results display

z Measurement results can be displayed in large characters or normal characters.

z Measurement results display mode

1) Direct readout: The actual measurement values are displayed.

2) ΔABS: The difference between the measured value of the DUT and a

previously stored reference value are displayed

3) Δ%: The difference between the measured value of the DUT and a

previously stored reference value are displayed as a percentage of the

reference value.

z Primary and secondary parameters are displayed with 6 digits resolution.

z Fixed decimal point function is used to display the measurement data using a

fixed point display format. This function can also be used to change the number

of digits displayed.

2.3.4 File Function

Control settings, comparator high and low limits etc. can be stored and retrieved as a

file in the non-volatile memory. Users don’t have to set the parameters for the

instrument every time. A maximum of 12 sets of instrument control settings can be

stored in the internal non-volatile memory.

TH2816B will reload the No. 0 file every time when the instrument is turned on. So

users can save the control settings in file No. 0 for convenience.

2.3.5 Other Function

2.3.6.1 Ranging mode

When the measurement range is set to AUTO, TH2816B automatically selects the

appropriate range according to the DUT's impedance, test frequency, and oscillator

level.

When the measurement range is set to the HOLD mode, the impedance range is

fixed at the current range setting, and the impedance range name is displayed in the

RANGE field.

2.3.6.2 Contrast adjustment

Contrast function allows you to adjust the LCD’s contrast value from 1 to 31.

2.3.6.3 Beep

You can turn on or turn off the internal beep.

2.3.6.4 Comparator alarm

You can select a comparator alarm status from IN, OUT, AUX and OFF.

2.3.6.5 Key lock function

TH2816B has keyboard lock-out capability that disables all front panel operation

except for softkey KEY. This is useful when you don't want the control settings changed.

13

2.3.6.6 Password

If the password function is set to ON, you are required to input the correct password

in order to turn on the TH2816B, or unlock the keyboard.

Password is composed of the digits 0 to 9.

Factory default password: 2816

2.3.7 Interface Function

2.3.7.1 IEEE488 interface

IEEE488 interface is also called as GPIB interface, and equal to IEC625 interface

(only with different connector). The programming language is SCPI. All commands

and data are transmitted using ASCII codes over the bus.

Interface Functions:SH1, AH1, T5, L4, SR1, RL1, DC1, DT1, C0, E1

Compatible with IEEE-488.1 and 488.2

2.3.7.2 RS232C interface

Baud rate: fixed 9600 bps

Signal logical level: ±8V

Maximum transmission distance: 15 m

The programming language is SCPI. All commands and data are transmitted using

ASCII codes over the bus.

2.3.7.3 HANDLER interface

TH2816B can receive the Trigger signal and output the comparison results and list

sweep comparison results through the HANDLER interface.

Synchronous signal IDX and EOM can be outputted.

The output signals are logical low active and opto-isolated.

TH2816B’s outputs have pull-up resistors on the handler interface board. External

source is used as the default power supply.

14

Chapter 3 Panel and Display Introduction

This chapter provides information including a tour of the front panel and display area

definition, which will help you to quickly learn how to operate the TH2816B. For more

information, please refer to chapter 4.

3.1 A Tour of the Front Panel

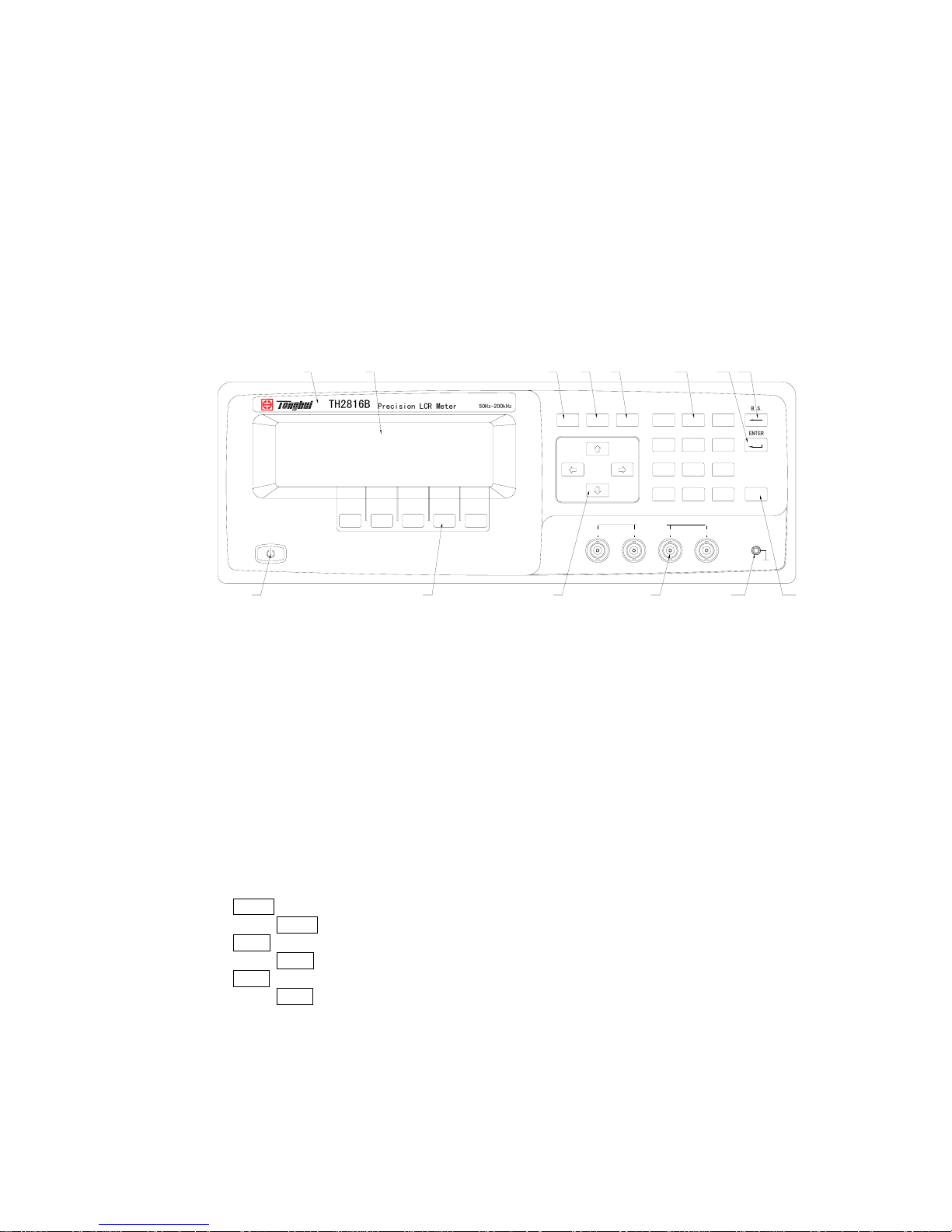

Figure 3-1 shows the brief description of key on the TH2816B’s front panel.

SYSTEMSETUPDISPLAY

B.S

.

ENTER

TRIGGER

HCURHPOTLPOTLCUR

UNKNOWN

789

456

123

0

.

-

PQRS TUV WXYZ

GHI JKL MNO

ABC DEF

Cp:206.335

D :0.00012

50Hz-200kHz

Precision LCR Meter

TH2816B

1

2

3 5 6 7 11

8 9 10

12 13

4 14

Figure 3-1. Front panel overview

1) Brand and Model

The registered brand of our company and model of the instrument are printed.

2) Power on/off

Power on/off switch. In the “ON” position all operating voltages are applied to the

instrument. In the “OFF” position NO operating voltages are applied to the

instrument.

3) LCD

240×64 dot-matrix Liquid Crystal Display (LCD) displays measurement results,

test conditions, etc.

4) SOFTKEYs

The five keys’ functions are not fixed, they have different functions in different

menus. Five softkeys are used to select control and parameter functions. Current

function of each softkey is displayed in the softkey area at the bottom of LCD.

5)

HOME menu key

Press HOME menu key to enter the Meas Display page.

6) PREV menu key

Press PREV menu key to enter the Previous page.

7) NEXT menu key

Press NEXT menu key to enter the Next page.

8) Cursor keys

The CURSOR arrow keys are used to move the field select cursor from field to

field on the LCD display page. When the cursor is moved to a field the field

changes to an inverse video image of the original field.

9) Unknown terminals

These are the UNKNOWN Terminals used to connect a four-terminal pair test

15

fixture or test leads for measuring the device under test.

HD(H

CUR

): High current drive

HS(H

POT

): High potential sense

LS(L

POT

): Low potential sense

LD(L

CUR

): Low current drive

10) Frame terminal

This is the FRAME Terminal which is tied to the instrument's chassis and which

can be used for measurements that require guarding.

11) Number keys

The NUMBER keys are composed of the digits 0 to 9 , a period . , a minus sign

- , number keys are used to enter numeric data into the TH2816B.

12) ENTER key

ENTER terminates numeric input data and enters the displayed value in the input

window.

13)

B.S. key

BACKSPACE key deletes one last character of the input value.

14) TRIGGER key

This is the TRIGGER key used to manually trigger the TH2816B when it is set to

the Manual Trigger mode.

3.2 A Tour of the Rear Panel

Figure 3-2 gives a brief description of the TH2816B's rear panel.

INPUT

F1A

FUS

E

RS-23

2

IEEE-48

8

HANDLER

123

456

Figure 3-2. Rear panel overview

1) HANDLER Interface Connector(Optional)

This is the HANDLER interface connector used when operation with a

component handler to fully automate component testing, sorting, and quality

control data processing.

2) IEEE488 Interface Connector (Optional)

This is the IEEE488 interface connector used when operating on the General

Purpose Interface Bus.

3) RS232C Interface Connector

This is the RS232C interface connector used when operating on the serial

interface.

4) LINE Input Receptacle

16

AC power cord receptacle.

5) Fuse Holder

Fuse holder for TH2816B line fuse, 220Vac, 1A.

6) Name Plate

Name Plate is used to provide the information of date, model, lot number and

manufacturer etc.

3.3 Display Area Definition

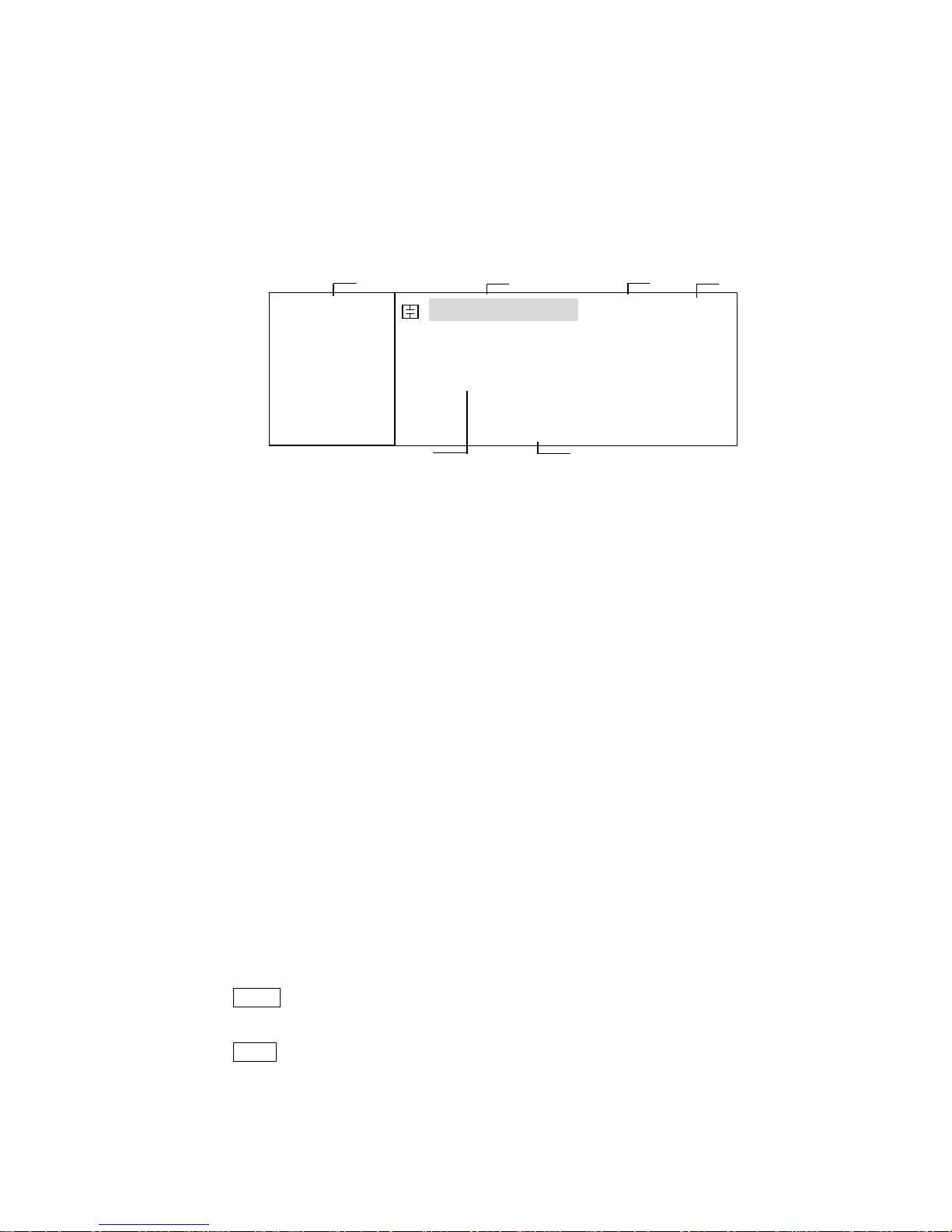

The display area on the LCD is divided into the areas show in Figure 3-3.

Figure 3-3. Display Area Definition

1) Display Page Area

This is the display page area. This area identifies the current display page.

2) Measurement Conditions area

This area is where measurement conditions are displayed.

3) File Menu Field

When the cursor is set on the File field, common file functions which are not

displayed on the display pages (for example, LOAD/Save function) are made

available.

4) Tools Menu Field

Some special controls which cannot be set on a display page's fields are made

available.

5) Measurement Date Area

This area is where measurement results are displayed.

6) Softkey Area

The bottom line is reserved for softkey labels. The softkeys displayed correspond

to the field at the cursor's position on the LCD.

3.4 MENU keys and Display Page

TH2816B has total file display pages:

MeasDisplay

BinNo. Disp

MeasSetup

LimitSetup

SystemConfig

TH2816B has three MENU keys which are used to switch the LCD display page.

1) HOME MENU key

This MENU key always switch to MeasDisplay page.

2) PREV MENU key

This MENU key can switch to the previous page sequentially.

FUN: Cp-D

F:1.00000k

LEV:1.000V

RANGE: AUTO

SPEED: SLOW

SHORT: OFF

OPEN : ON

< MeasDisplay> File Tools

Cp :217.324nF

D :0.00012

SYST LIMIT SETUP BinNo LCR

2 1 3 4

6

5

17

3) NEXT MENU key

This MENU key can switch to the next page sequentially.

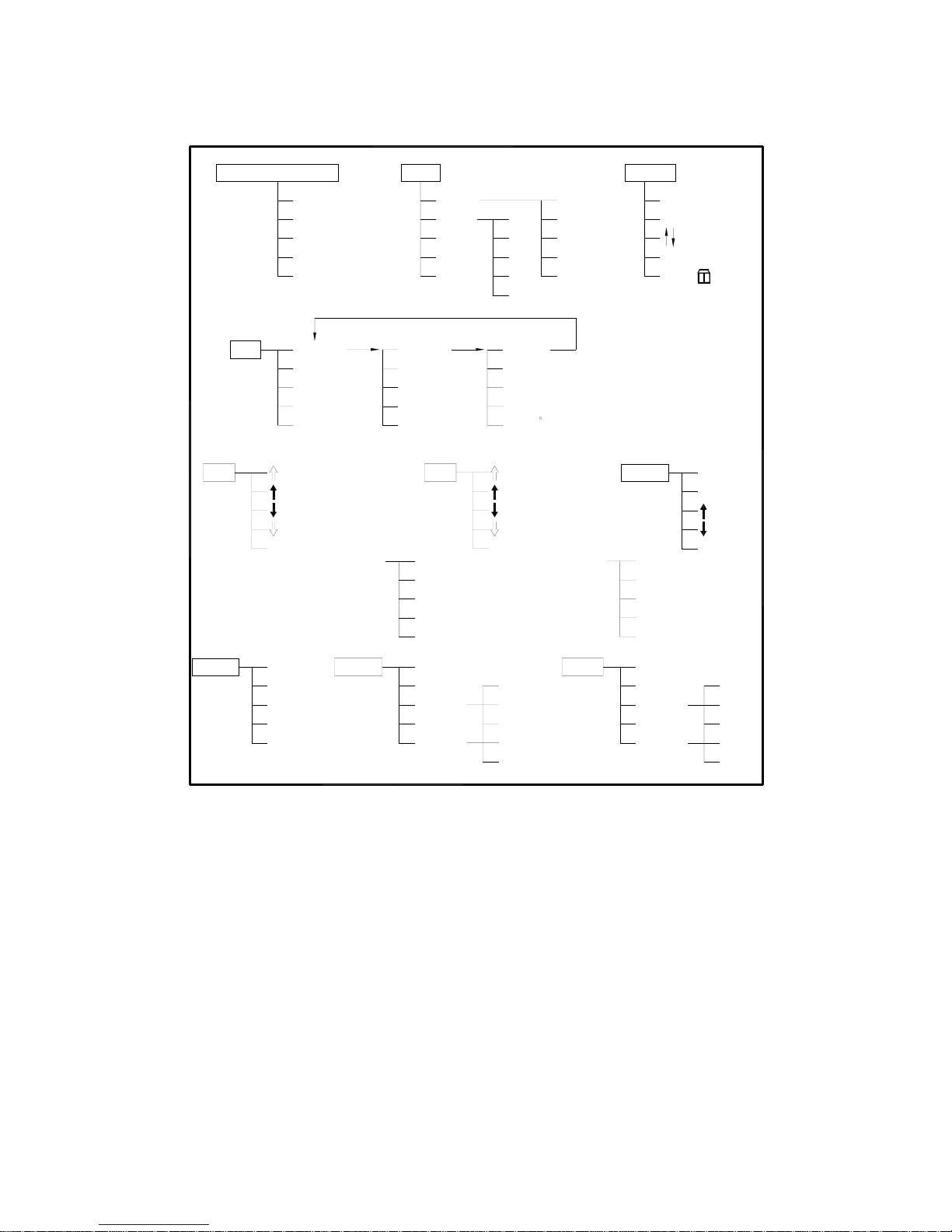

3.5 Summary of Pages

MeasDisplay

This display page provides the measurement result information, and some

control settings are entered from this page. TH2816B measures the DUT from

this page, and displays the measurement results in large or normal size

characters. This display page is the default display page when TH2816B is

turned on.

BinNo. Disp

This display page provides the bin sorting result information, the measurement

results, and comparator function on/off settings. The TH2816B measures the

DUT from this page. The bin number is displayed in large characters, and the

measurement results are displayed in normal size characters.

Meas Setup

This display page provides all of the measurement control settings. TH2816B

can not perform a measurement from this page, and the measurement result can

not be displayed on this page. When you want to measure the DUT using the

control settings on this page, use one of the display pages from DISPLAY menu

key.

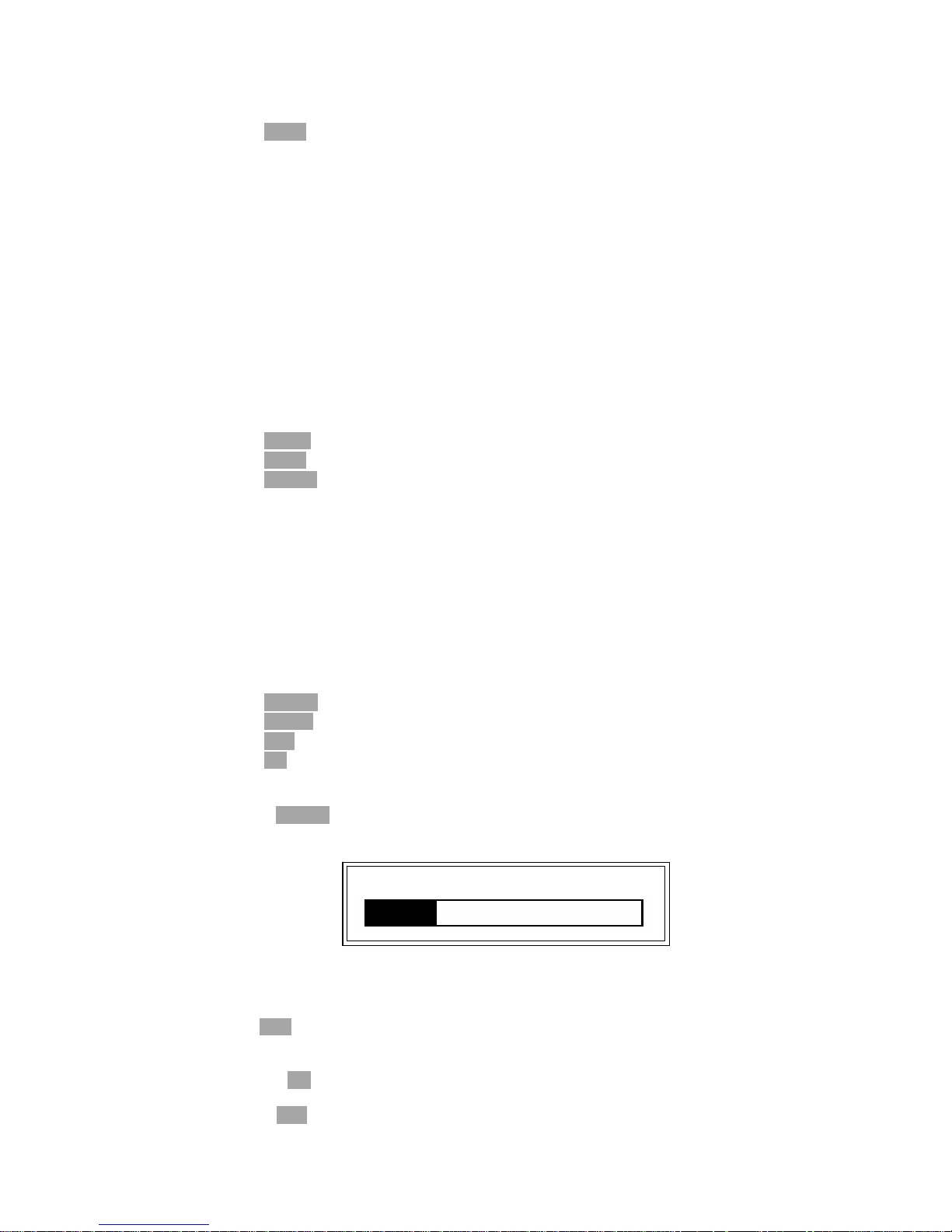

MeasDisplay SystemConfig LimitTable MeasSetup

BinNo.Disp

MeasDisplay

BinNo.Disp

MeasSetup LimitTable

SystemConfig

FUN: Cp-D

F: 1.00000k

LEV:1.000V

RANGE: A UT O

SPEED: LOW

SHORT: OFF

OPEN : ON

< MeasDisplay> File Tools

Cp :217.324nF

D :0.00012

SYST LIMIT SETUP Bi n N o LCR

FUN: Cp-D

F: 1.00000k

LEV:1.000V

RANGE: AUTO

SPEED : LOW

SHORT: O FF

OPEN : ON

<BinNo. Disp> File Tools

COMP: ON AUX: ON

BIN : AUX

Cp : 217.324nF D : 0.00012

SYST LIMIT SETUP Bi n N o LCR

18

Limit Table

This display page provides the limit table settings for bin sorting. TH2816B

doesn't perform measurement from this page. To see the comparison results,

either the BinNo. Disp page or the Bin Count page should be used.

System Config

This display page provides the system information and control settings, such as

LCD contrast adjustment, PASSWORD, and GPIB ADDRESS etc.

FUN: Cp-D

F: 1.00000k

LEV:1.000V

RANGE: AUTO

SPEED: LOW

CABLE: 0m

< Meas Setup> File Tools

TRIG : INT DEV_A:OFF

INT_R : 30Ω REF_A:0.00000pF

DELAY: 0ms DEV_B:OFF

Vm/Im : OFF REF_B:0.00000

SYST LIMIT SETUP Bi n N o LCR

NOMINAL:

0.00000pF

FUNC:Cp-D

MODE:±TOL

COMP: OFF

AUX : OFF

IN ALARM

< Meas Setup> File Tools

[BIN] [ LOW ] [ HIGH ]

1

2

3

2nd

SYST LIMIT SETUP Bi n N o LCR

CONTRAST

INFO BEEP

CMP ALARM

PASSWORD

BUS MODE

GPIB ADDR

AUTO FETCH

< System Config>

Selcet Item From

Left Column_

SYST LIMIT SETUP Bi n N o LCR

19

Chapter 4 Operation

4.1 Basic operation

TH2816B's basic operation is described in the following paragraphs.

Display the desired display page using the MENU keys and the softkeys. (Refer

to Figure 3-1.)

Move the CURSOR to the field to be used using the CURSOR keys. The cursor

will be an inverse video marker, and the field is an area at which you can set the

CURSOR. (Refer to Figure 4-1.)

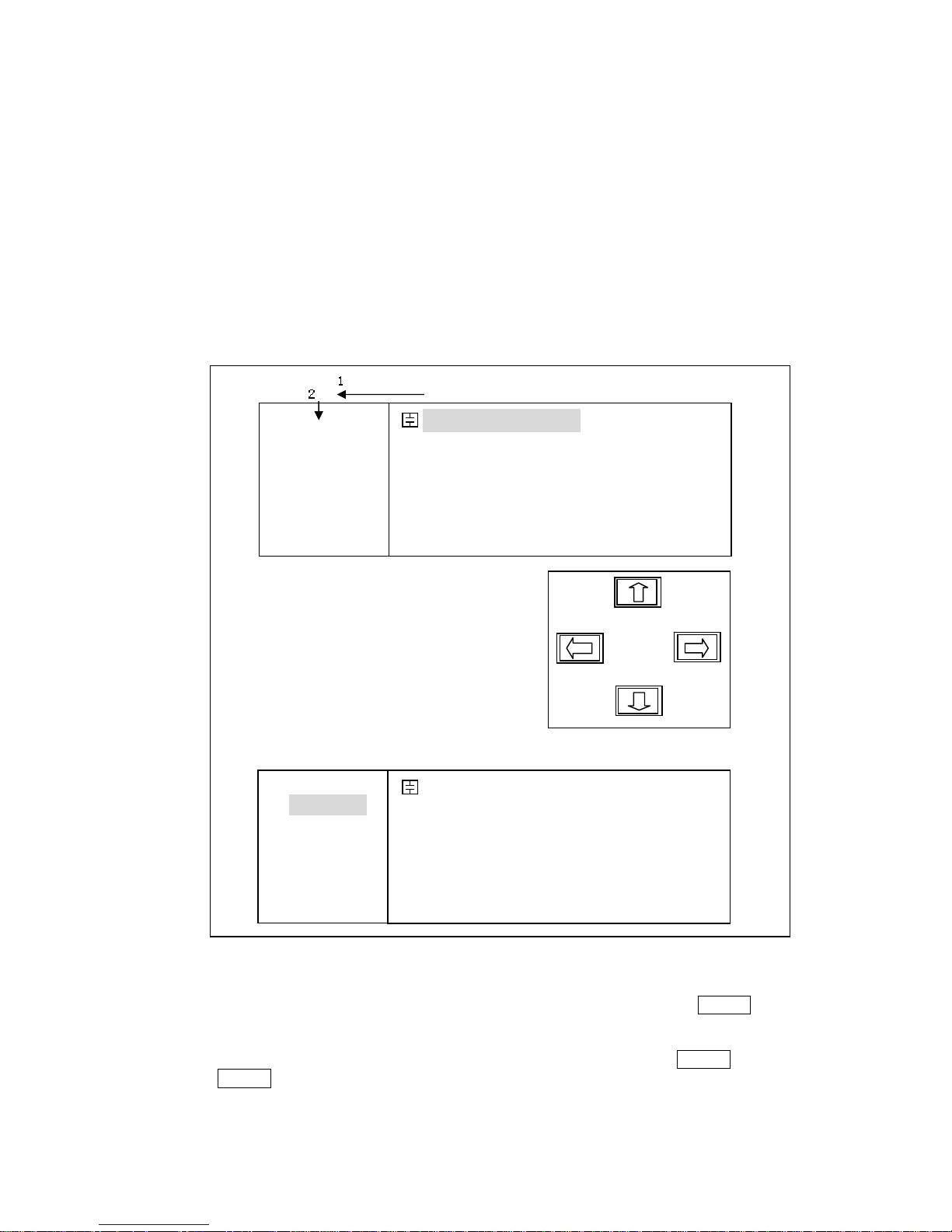

Figure 4-1. CURSOR Keys and Field Operation Example

The softkeys corresponding to the field pointed to by the CURSOR will be

displayed. Select and press a softkey. The numeric entry keys and ENTER are

used to enter numeric data. (Refer to Figure 4-2.)

When one of the numeric entry keys is pressed, the softkeys will change to the

available unit softkeys. You can use these unit softkeys instead of ENTER. When

ENTER is used, the numeric data is entered with Hz, V, or A as the default unit

depending on the cursor field selected, for example, the test frequency's unit will be

Hz, etc.

FUN: Cp-D

F: 1.00000k

LEV:1.000V

RANGE: A UT O

SPEED: LOW

SHORT: OFF

OPEN : ON

< MeasDisplay> File Tools

Cp :217.324nF

D :0.00012

SYST LIMIT SETUP Bi n N o LCR

FUN: Cp-D

F: 1.00000k

LEV:1.000V

RANGE: A UT O

SPEED: LOW

SHORT: OFF

OPEN : ON

< MeasDisplay> File Tools

Cp :217.324nF

D :0.00012

ª(--) (-) (+) ©(++)

1

2

20

<MeasDispaly>

SPEED: SLOW

OPEN: ON

SHORT: OFF

Cp-D

RANGE: AUTO

LEV: 1.000V

FRQ: 1.0kHz

FUN: Cp-D

Cs-Rs

Cp:206.335nF

D :0.00012

Cp-RpsCs-D

File

NEXT

Tools

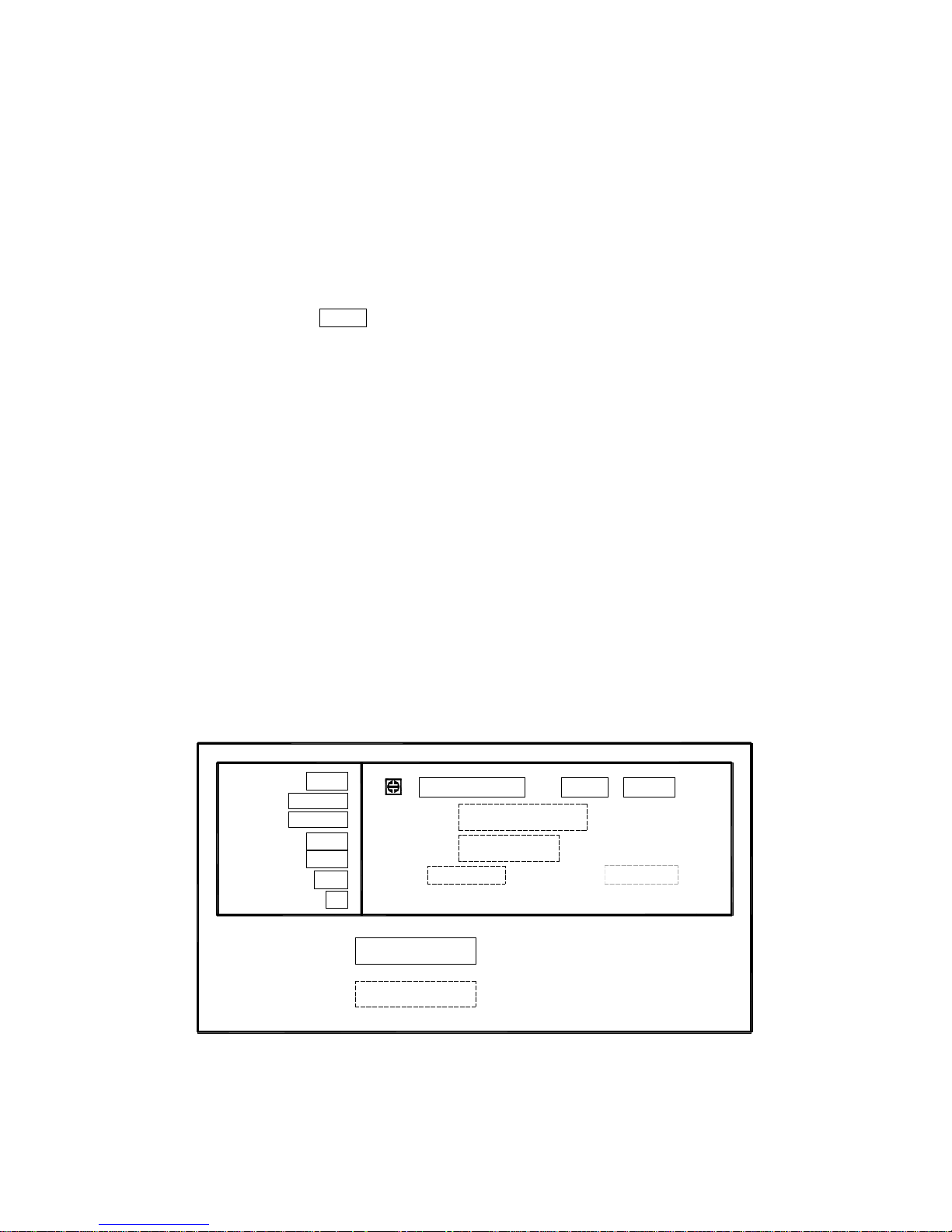

Figure 4-2. Softkey Selection Example

4.2 Welcome Page

Press the power switch to turn on TH2816B, the welcome page will display as shown

in Figure 4-3. The name of the instrument with its version will also be displayed. If

password function is ON, you must input the correct password to start the instrument.

If you input a wrong password for three times, the instrument will be locked. You must

turn off the power and then turn on the power again in order to try another password.

(Refer to Figure 4-4)

Figure 4-3. Welcome Page

Figure 4-4. Input the Password

Note: TH2816B’s factory default password is “2816”.

21

4.3 Detailed Operation

This Chapter provides information about the function of each page.

MeasDisplay

BinNo. Disp

MeasSetup

LimitSetup

SystemConfig

This Chapter describes the functions on each page in the order of the preceding list.

4.3.1 MeasDisplay Page

When you press HOME, the MeasDisplay page will be displayed. On this page, the

measurement results are displayed in large characters, and the following

measurement controls can be set from this page. (The field in parenthesis is used to

set the control function.)

Measurement Function (FUN)

Test Frequency (FRQ)

Oscillator Level (LEV)

Measurement Range (RANGE)

Measurement Speed (SPEED)

Short Correction (SHORT)

Open Correction (OPEN)

File Management (File)

Useful Tools (Tools)

There are ten fields on this page: <MeasDisplay>, FUN, FRE, LEV, RANGE, SPEED,

SHORT, OPEN, File and Tools. Each control function is described in the following

paragraphs.

This page also provides the oscillator level voltage/current monitor value information

in monitor areas on the displayed page. These conditions can be set from the Meas

Setup page.

The available fields and the softkeys which correspond to the fields on this page are

shown in Figure 4-5 and Figure 4-6 respectively.

Vm:999.1mV

<MeasDisplay>

Cp:206.335nF

D :0.00012

SHORT: OFF

OPEN: ON

SPEED: SLOW

RANGE: AUTO

LEV: 1.000V

FRQ: 1.0kHz

FUN: Cp-D

Im:1.364mA

BinNo

Tools

: Field

: Monitor

COUNTSWEEP

File

LCR

Figure 4-5. Available Fields on the MeasDisplay Page

22

Ls-Q

Ls-Rs

Lp-Q

Lp-Rp

NEXT

File

Cs-Rs

(TH2816A)

Cs-D

Cp-D

SLOW

FAST

(--)

(++)

Cp-Rp

[NUMERIC ENTRY]

SPEED

MED

FRQ

(-)

(+)

SHORT

NEXT

LCR

BinNo.

COUNT

SWEEP

<MeasDisplay>

FUN

ESC ESC

RANGE

Tools

G-B

(++)

(--)

ZZ-

R-X

[NUMERIC ENTRY]

Hz

ON

ShSWP

ShCLR

OFF

ESC

kHz

LEV

(-)

(+)

OPEN

θ

θ

r

NEXT

OK

ESC

LOAD

SAVE

ESC

mV

ON

OFF

OpSWP

OpCLR

ESC

V

AUTO

(+)

(-)

HOLD

FIX B

FIX A

KEY

Figure 4-6. Available Softkeys on the MeasDisplay Page

4.3.1.1 Measurement Function

TH2816B measures two components of the complex impedance (parameters) at the

same time in a measurement cycle. The measurement parameters are listed as

follows.

Primary Parameters

|Z| (absolute value of impedance)

L (inductance)

C (capacitance)

R (resistance)

Secondary Parameters

D (dissipation factor)

Q (quality factor)

Rs (equivalent series resistance)

23

Rp (equivalent parallel resistance)

X (reactance)

Θ (phase angle)

The primary parameter measurement result is located on the upper line as two large

character lines on this page, and the secondary parameter measurement result is

located on the lower line as two large character lines on this page.

The combinations of primary and secondary parameters, including the equivalent

parallel and serial combinations, are listed in Table 4-1.

Table 4-1. Measurement Function

Primary

Parameter

Serial Mode Parallel Mode

Z

Z-Θr

Z-Θ°

C

Cs-D

Cs-Rs

Cp-D

Cp-Rp

L

Ls-Q

Ls-Rs

Lp-Q

Lp-Rp

R R-X

Front Panel Operation for Setting the Measurement Function

Perform the following steps to set the measurement function.

1) Use the CURSOR arrow keys to move the cursor to the FUN field. The following

softkeys will be displayed.

Cp-D

Cp-Rp

Cs-D

Cs-Rs

NEXT

2) Select and press a softkey to set the measurement function. If the softkey you

want is not displayed, press NEXT to display the following set of softkeys.

Ls-Q

Ls-Rs

Lp-Q

Lp-Rp

NEXT

3) Select and press a softkey to set the measurement function. If the softkey you

want is not displayed, press NEXT to display the following set of softkeys.

Z-Θ°

Z-Θr

R-X

NEXT

4) Select and press a softkey to set the measurement function. When NEXT is

pressed, the softkeys shown in step 1 will be displayed. Retry steps 1 through 4 if

you missed the function you were looking for.

4.3.1.2 Test Frequency

TH2816B operates from 50 Hz to 200 kHz with 37 typical frequency points which can

be selected through softkeys, or set through numeric entry keys.

Front Panel Operation for Setting the Test Frequency

Perform the following steps to set the test frequency.

24

1) Move the CURSOR to the FRQ field. The following softkeys will be displayed.

⇓(--)

This softkey is the coarse frequency decrement softkey which is used to

decrease the test frequency to the next sequentially lower tenth value after

50 Hz. The frequency points set using this softkey are as follows.

50 Hz 100 Hz 1.0 kHz 10 kHz 100 kHz 200 kHz

↓(-)

This softkey is the fine frequency decrement softkey used to decrease the

test frequency to the next sequentially lower frequency point. The sequential

frequency points which can be set using this softkey are as follows.

50Hz 60Hz 80Hz 100Hz 120Hz 150Hz 200Hz 250Hz

300Hz 400Hz 500Hz 600Hz 800Hz 1kHz 1.2kHz 1.5kHz

2kHz 2.5kHz 3kHz 4kHz 5kHz 6kHz 8kHz 10kz

12kHz 15kHz 20kHz 25kHz 30kHz 40kHz 50kHz 60kHz

80kHz 100kHz 120kHz 150kHz 200kHz

If the input frequency is not the one supported by TH2816B, the TH2816B

will automatically modify to the frequency point which is the nearest higher

point.

↑(+)

This softkey is the fine frequency increment softkey used to increase the

current test frequency to the next sequentially higher frequency point. The

frequency points set using this softkey are the same values as set using

↓(-).

⇑(++)

This softkey is the coarse frequency increment softkey used to increment

the test frequency to the next sequentially higher tenfold value after 50 Hz.

The frequency points set using this softkey are the same as the frequency

points set using ⇓(--).

4.3.1.3 Oscillator Level

TH2816B’s oscillator level can be set as the effective value (RMS value) of a sine

wave of the test frequency from TH2816B's internal oscillator. The oscillator level can

be set from 0 V

rms

to 2.00 V

rms

with a 0.01 V

rms

resolution. The output impedance can

be selected either 30Ω or 100Ω.

Note: The set value of the oscillator voltage level is the value set when the

measurement contacts (UNKNOWN Terminals) are opened.

Front Panel Operation for Setting the Oscillator Level

There are two ways to set the oscillator level. One is to use the softkeys, and the

other is to use the use the numeric entry keys.

Perform the following steps to set the oscillator level.

1) Move the cursor to the LEV field. The following softkeys will be displayed.

⇓(--)

This softkey is the coarse level decrement softkey which is used to decrease

the test signal level by a 0.1 V

rms

step.

↓(-)

This softkey is the fine level decrement softkey which is used to decrease

the test signal level by a 0.01 V

rms

step.

↑(+)

This softkey is the fine level increment softkey which is used to increase the

test signal level by a 0.01 V

rms

step.

25

⇑(++)

This softkey is the coarse level increment softkey which is used to increase

the test signal level by a 0.01 V

rms

step.

2) Select and set the oscillator level using either the softkeys or the numeric entry

keys. When the oscillator level is entered using the numeric entry keys, the

softkey labels are changed to the available units labels (mV, V), and you can use

these softkeys to enter the units and enter the data instead of ENTER. When

ENTER is used, the numeric data is entered with V as the default unit.

4.3.1.4 Measurement Range

TH2816B has nine measurement ranges: 10Ω, 30Ω,100Ω, 300Ω, 1 kΩ, 3 kΩ, 10

kΩ, 30 kΩ, and 100 kΩ. The measurement range is selected according to the DUT's

impedance even if measurement parameter is capacitance or inductance. Table 4-2

shows the effective measuring range for each measurement range while in the

impedance mode (|Z|, R, X).

Table 4-2. Measurement Range for Each Range

RANGE MEASUREMENT RANGE

10 Ω 0 Ω to 10 Ω

30 Ω 10 Ω to 100 Ω

100 Ω 100 Ω to 316 Ω

300 Ω 316 Ω to 1 kΩ

1 kΩ 1 kΩ to 3.16 kΩ

3 kΩ 3.16 kΩ to 10 kΩ

10 kΩ 10 kΩ to 31.6 kΩ

30 kΩ 31.6 kΩ to 100 kΩ

100 kΩ More than 100 kΩ

When the measurement range is set manually, the optimum measurement range

should be selected by matching the DUT's impedance to the measurement range

shown in Table 4-2. When the measurement range is set to AUTO, the optimum

measurement range is automatically selected according to the impedance of each

DUT.

Note: The measurement range is limited by the test frequency setting, when the

oscillator level is equal to 2 V or less than 2 V. When the measurement

range and the test frequency are set under the above conditions, the test

frequency must be set first, and then the measurement range. If you set the

measurement range first and then frequency, the resulting measurement

range may not be the one you wanted to set.

Front Panel Operation for Setting the Measurement Range

Perform the following procedure to set the measurement range.

1) Move the cursor to the RANGE field using the CURSOR keys. The following

softkeys will be displayed.

↓(-)

This softkey is used to decrease the measurement range in the HOLD (fixed

range) mode.

↑(+)

This softkey is used to increase the measurement range in the HOLD (fixed

range) mode.

HOLD

This softkey is used to change the measurement range from the AUTO

mode to the HOLD mode. When the measurement range is set to the HOLD

mode, the impedance range is fixed at the current range setting, and the

26

impedance range is displayed in the RANGE field.

AUTO

This softkey is used to set the measurement range to AUTO.

2) Use the softkeys to set the measurement range.

4.3.1.5 Measurement Speed

TH2816B's measurement speed is determined by the following conditions.

Integration Time (A/D conversion)

Averaging Rate (number of measurement averaged)

Delay Time (time delay between the trigger and the start of the

measurement)

Measurement result's display time.

Generally, a slow measurement speed will result in more stable and accurate

measurement results. SLOW, MED, and FAST measurement speed can be set.

Front Panel Operation for Setting the Measurement Speed

Perform the following steps to set the measurement speed.

1) Move the cursor to the SPEED field. The following softkeys will be displayed.

FAST

MED

SLOW

2) Use the preceding softkeys to select and set the measurement speed.

4.3.1.6 Short Correction

TH2816B's SHORT correction capability corrects for the residual impedance (R, X) in

serial with the device under test.

Front Panel Operation for the Short Correction

There are two procedures: SHORT correction at all frequency points, and SHORT

correction at the current test frequency point.

Perform the following steps to execute SHORT correction.

1) Move the cursor to the SHORT field. The following softkeys will be displayed.

ShSWP

ShCLR

OFF

ON

2) Connect the test fixture to the UNKNOWN Terminals, and short the measurement

contacts together.

3) Press ShSWP. TH2816B will measure the short impedance (inductance and

resistance) at all frequency points. Figure 4-7 shows the short correction

information.

Figure 4-7. Short Correction Information

During the SHORT correction measurement cycle, the following softkey is

available.

ESC

This softkey is used to stop the short correction data measurement. The

previous SHORT correction data is still stored.

4) Press ON to perform SHORT correction calculations on subsequent

measurements.

5) Press OFF to halt SHORT correction calculations on subsequent measurements.

Shorting 1kHz

27

4.3.1.7 Open Correction

TH2816B's OPEN correction capability corrects errors due to the stray admittance (G,

B) in parallel with the device under test.

Front Panel Operation for the Open Correction

There are two procedures: OPEN correction at all frequency points, and OPEN

correction at the current test frequency point.

Perform the following steps to execute OPEN correction.

1) Move the cursor to the OPEN field. The following softkeys will be displayed.

OpSWP

OpCLR

OFF

ON

2) Connect the test fixture to the UNKNOWN Terminals without connecting the

device under test.

3) Press OpSWP. TH2816B will measure the open admittance (capacitance, and

inductance) at all frequency points. Figure 4-8 shows the open correction

information.

Figure 4-8. Open Correction Information

During the OPEN correction measurement cycle, the following softkey is

available.

ESC

This softkey is used to stop the OPEN correction data measurement. The

previous OPEN correction data is still stored.

4) Press ON to perform OPEN correction calculations on subsequent

measurements.

5) Press OFF to halt OPEN correction calculations on subsequent measurements.

4.3.1.8 File Management

TH2816B uses the internal non-volatile memory for storing and retrieving a maximum

of 12 sets of instrument control settings. The following data will be stored in

non-volatile memory as one file.

Control settings on the Meas Setup page.

Measurement Function

Test Frequency

Oscillator Level

Measurement Range

Measurement Speed

Trigger Mode

Output Impedance

Delay Time

Averaging Rate

Deviation Measurement A/B(ΔABS/Δ%/off)

Deviation Measurement AB Reference Value

Control settings on the Limit Table page.

Nominal Value

Measurement Function (Swap Parameter)

Limit Mode for the Primary Parameter

Comparator Function on/off

Opening 1kHz

28

Auxiliary Bin on/off

Alarm on/off

Low/High Limits for Each Bin

Display page format

When TH2816B is turned on, TH2816B's auto load function will load the control

settings stored in file number 0. If there are no control settings stored in file number 0,

the power-on default settings will be used.

The following items are stored in internal nonvolatile memory without using the

LOAD/SAVE function.

Control settings on the User Correction page.

OPEN, SHORT, LOAD correction on/ff

OPEN, SHORT correction data for all test frequencies.

OPEN, SHORT, LOAD correction data at FREQ1, FREQ2, and FREQ3.

(OPEN correction data at each frequency, SHORT correction data at

each frequency, and LOAD correction reference data and actual data at

each frequency.)

Control settings on the System Config page.

Contrast of LCD

Information Beeper on/off

Comparator Alarm on/off

Password

Bus Mode

GPIB address

AutoFetch on/off

Perform the following steps to save the control settings to the internal non-volatile

memory.

1) Select and set all control settings on the MeasDisplay page.

2) Move the cursor to the File field.

3) Press SAVE. The message “Enter save number” will be displayed in the

message window.

4) Press ESC to cancel the number input operation.

5) Enter a save number from 0 to 11 using the numeric entry keys and press

ENTER. The message “Enter File Name” will be displayed in the message

window.

6) Press ESC to cancel the file name input operation.

7) Enter a file name using the numeric entry keys and ENTER to save the current

control settings. Numeric digits and characters can be inputted as a file name.

Perform the following steps to load the control settings from the internal non-volatile

memory.

1) Move the cursor to the File field.

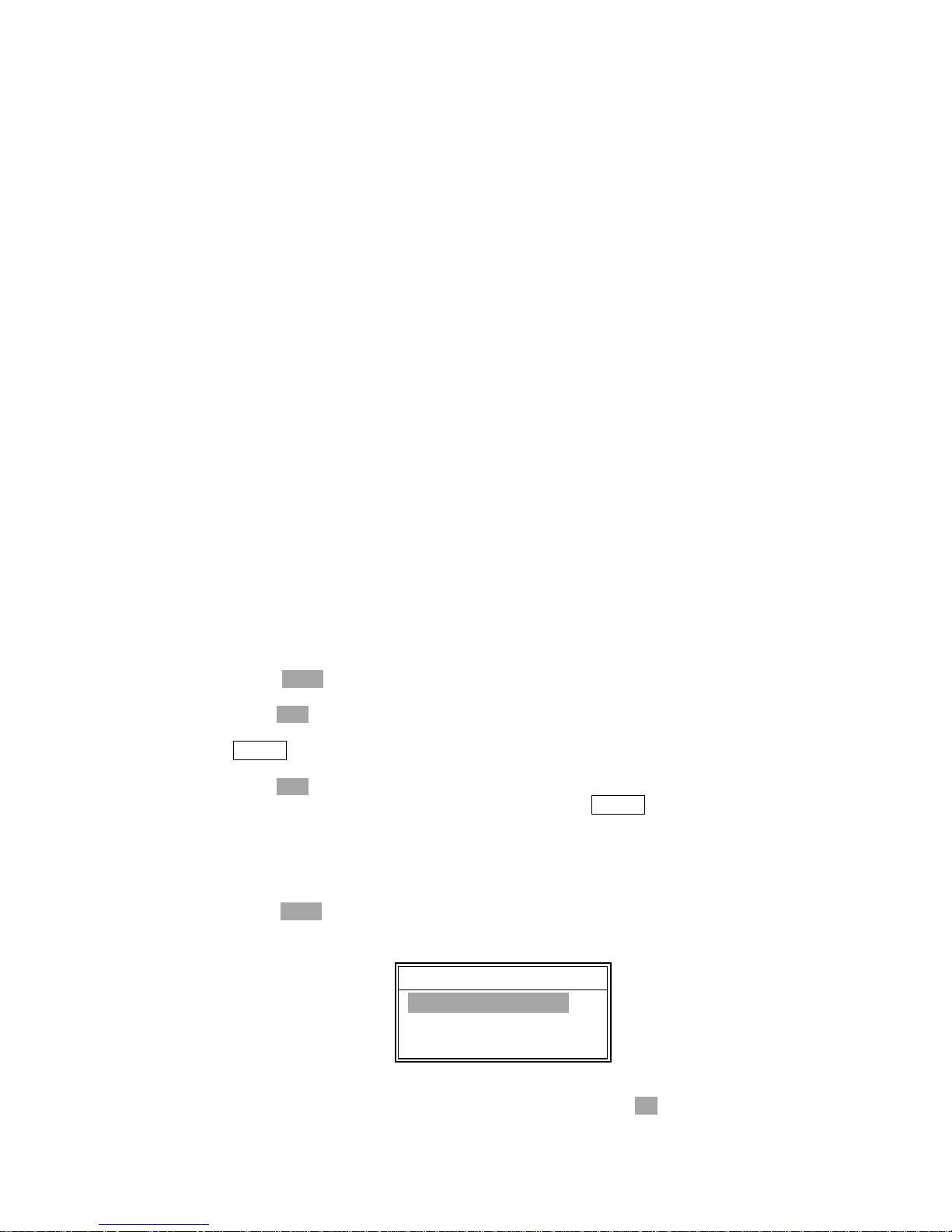

2) Press LOAD. The message of available file(s) will be listed in the message

window as shown in Figure 4-9.

Figure 4-9. Available Files Message Window

3) Use the up and down cursor keys to select a file and press OK to load the file.

Load File:No.1

CBB13-325J

<Unnamed>

*TH2816B*

Loading...

Loading...