TONAZZI COLIBRI’ 601 User Manual

3

COLIBRI’ 601

MACCHINA INTUBETTATRICE

QUADRI COMANDO E/O PANNELLI DI CONTROLLO

CLIENTE:

CUSTOMER:

TUBE FILLING MACHINE

COMMAND AND/OR CONTROL PANEL

BODY’N SCENTS INC.

MATRICOLA N°:

SERIAL N°:

502000019

3

Sede Amministrativa / Registered Administrative Office: Via Kennedy, 2/4 - 20023 CERRO M. (MI) ITALIA

Tel: (0331) 514356 - Fax (0331) 515671

COLIBRI’ 601

/

MACCHINA INTUBETTATRICE / TUBE FILLING MACHINE

QUADRI COMANDO E/O PANNELLI DI CONTROLLO / COMMAND AND/OR CONTROL PANEL

CLIENTE:

CUSTOMER:

MATRICOLA N°:

SERIAL N°:

Manuale redatto in conformità con la direttiva 98/37/CE.

Realizzato dal Dipartimento Documentale (Redazione/Grafica) della Marchesini S.p.A. in collaborazione con la

Direzione Tecnica Progettuale.

Traduzioni realizzate con la collaborazione della Agenzia Intracoop S.c.r.l., Società di Traduzioni operante in conformità

UNI EN 29002 (ISO 9002)

Manual drawn up in conformity with EEC directive 98/37/EC.

Created by the Marchesini S.p.A. Documentation Department (Editing/Graphic) in collaboration with the Technical

Design Department.

BODY’N SCENTS INC.

502000019

Translated in collaboration with Intracoop S.c.r.l., a translation company which operates in conformity with UNI EN

29002 (ISO 9002)

Codice Manuale: 502000019-1-1

Manual Code:

Ultima data di stampa: 15/04/03

Date of final print: Total N° of pages:

N° pagine totali: 17

USER MANUAL

Operating instructions and specifications . . . . . . . . . . . . . . . . . A-1

Machine Process Cycle . . . . . . . . . . . . . . . . . . . . . . A-1

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Description Of Controls . . . . . . . . . . . . . . . . . . . . . . . B-2

Program Structure . . . . . . . . . . . . . . . . . . . . . . . . B-3

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Selections . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Functional selectors . . . . . . . . . . . . . . . . . . . . . . . B-6

Key selector . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Parameters change . . . . . . . . . . . . . . . . . . . . . . . B-8

Semiautomatic adjustment . . . . . . . . . . . . . . . . . . . . . B-9

Operating size setting . . . . . . . . . . . . . . . . . . . . . . B-10

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Message Language Selection . . . . . . . . . . . . . . . . . . . . B-12

Size configuration . . . . . . . . . . . . . . . . . . . . . . . . B-13

Production data . . . . . . . . . . . . . . . . . . . . . . . . B-14

Resetting counters . . . . . . . . . . . . . . . . . . . . . . B-14

Machine states . . . . . . . . . . . . . . . . . . . . . . . . B-15

Service menu . . . . . . . . . . . . . . . . . . . . . . . . . B-16

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . B-17

Functional selectors Continued .... . . . . . . . . . . . . . . . . . . . C-1

Key selectors Continued .... . . . . . . . . . . . . . . . . . . . . . D-1

Parameters Change Continued .... . . . . . . . . . . . . . . . . . . . E-1

INDEX

PAGE 1

Marchesini Group

This page has been left deliberately blank

PAGE 2

Operating instructions and specifications

Machine Process Cycl e

A feed unit deposits a bottle in each bucket on the product chain conveyor.

The presence of the product enables pick-up of the carton and the leaflet.

The product and the leaflet are inserted in the carton by the pushers.

The cartons are then closed.

If there is no carton or no leaflet, the c ontent of the tray is r ejected.

USER MANUAL

PAGE A-1

PART A

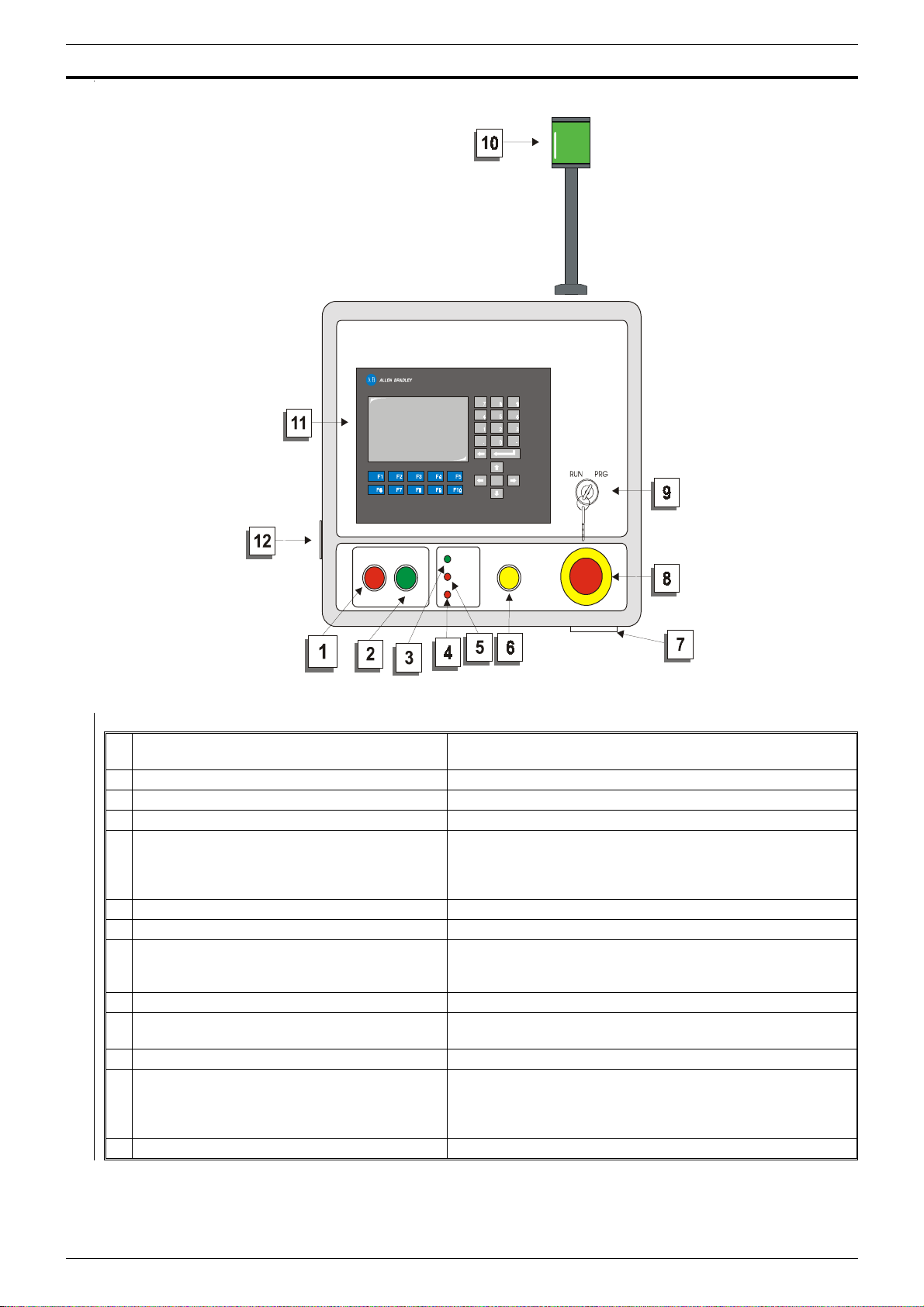

Control panel

Stop pushbutton

1

Start pushbutton

2

Power on led

3

CPU fault warning led When lit this indicates a P LC operating fault.

4

Communication error warning led

5

Reset pushbutton This acts as a safety device reset pushbutton

6

Acoustic alarm

7

Emergency stop pushbutton machine

8

Programming key

9

Machine automatic restart service/running

10

warning light

Display

11

Jack plug socket

12

Main switch

12

If pressed for longer than 3 seconds this pushbutton will

also perform a lamp test.

Fix: fault in the communication between display and PLC.

Data trasmission retry.

Flashing: display results disconnected.

Check the electrical connection.

In the event of an emergency press thi s pushbutton to

immediately stop all those motor s which might constitute

a danger for the operator.

When the remote control jack is plugged into this socket

the machine cannot be started from the main control

panel and the safety switches of the control circuit are

disenabled.

PAGE A-2

PARTE B Allen Bradley

Display

Description

The primary function of the control panel i s to facilitate the operator’s tasks by displaying machine status and

stoppage messages on the control panel display.

This approach has made it possible to dispense with a large number of warning lights and LED. The display

of status and stoppage messages enables rapid diagnosis of machine conditions and therefore more rapid

operator intervention.

The control panel also provides access to a series of menus for managing machi ne configuration, and other

functions.

The displays shown in the pages which follow are intended as examples only.

The processing program is tailored to customers’ individual requirements and as a consequence the displays on your

equipment might vary from those shown in the examples which follow.

Data interchange takes place over an All en Bradley DH+ protocol.

PAG. B-1

Allen Bradley PARTE B

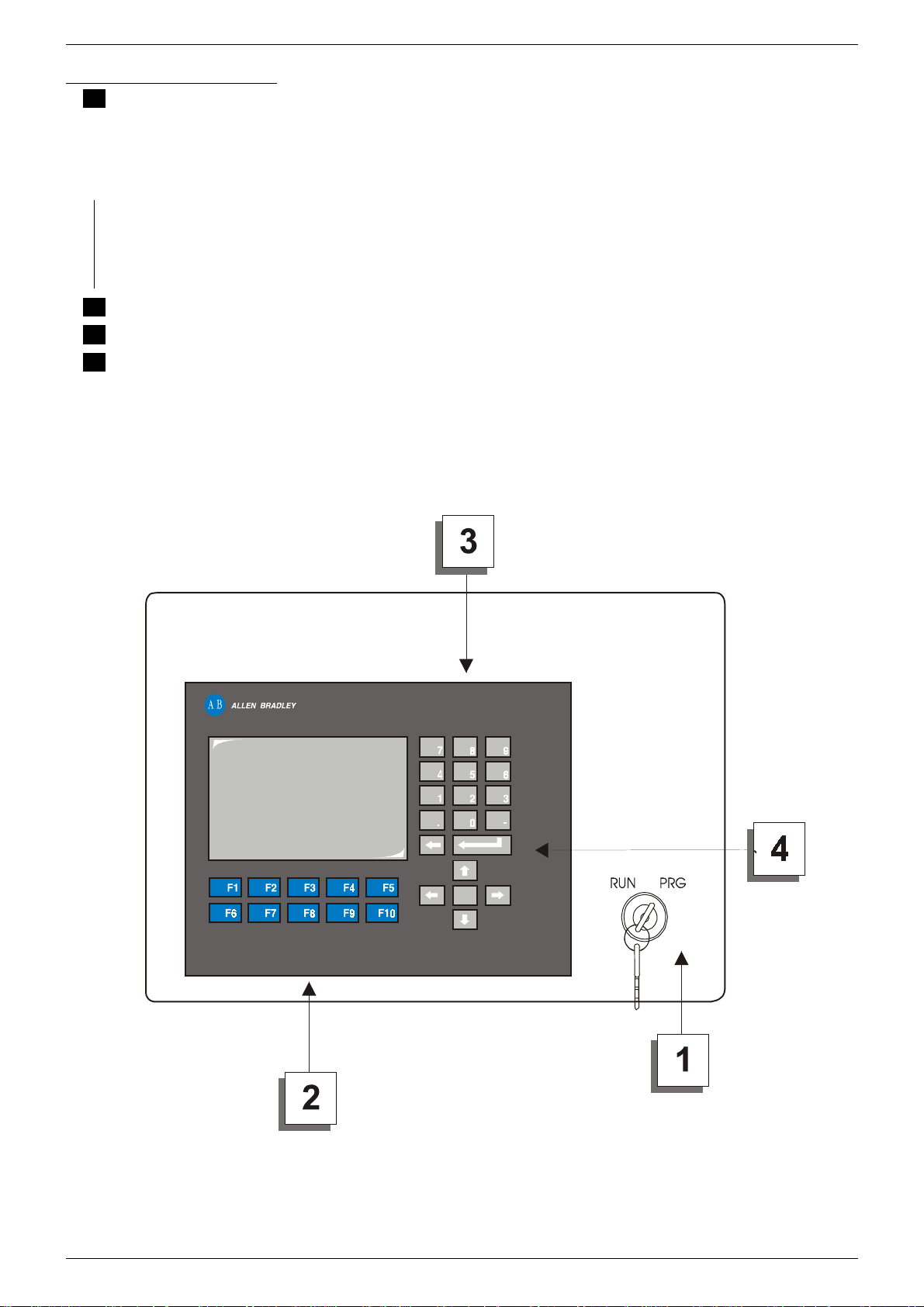

Description Of Controls

Programming key

1

All those functions which require insertion of the programming key will modify machine functioning. Turning the key

to the "PRG" position immediately stops the machine.

In order to prevent accidental or unauthorised use, do not leave the programming key inserted when not in use. The

programming key must only be used by authorised, qualified personnel.

To access programming functions (e.g. modifying parameters, other function), insert the programming key

and turn it to the "PRG" position.

When you turn the programming key to the "PRG" position, the message "Programming On" will be

displayed. In this position, the machi ne will remain stopped and wait for data entries from the control panel.

To restart the machine, turn the programming key to the "RUN" pos ition.

Function keys: allow access to s ub-menus and entry of machine func tions. (from F1 to F10)

2

Numeric keyboard

3

Confirm key (ENTER)

4

PAG. B-2

Loading...

Loading...