Page 1

Page 2

Tomos

Mopeds

Owners

Workshop

Manual

Pete

Shoemark

Models

covered

A3K. 49cc. Introduced

November

1982

A3M. 49

cc.

Introduced

August

1984

A3MS. 49cc. Introduced

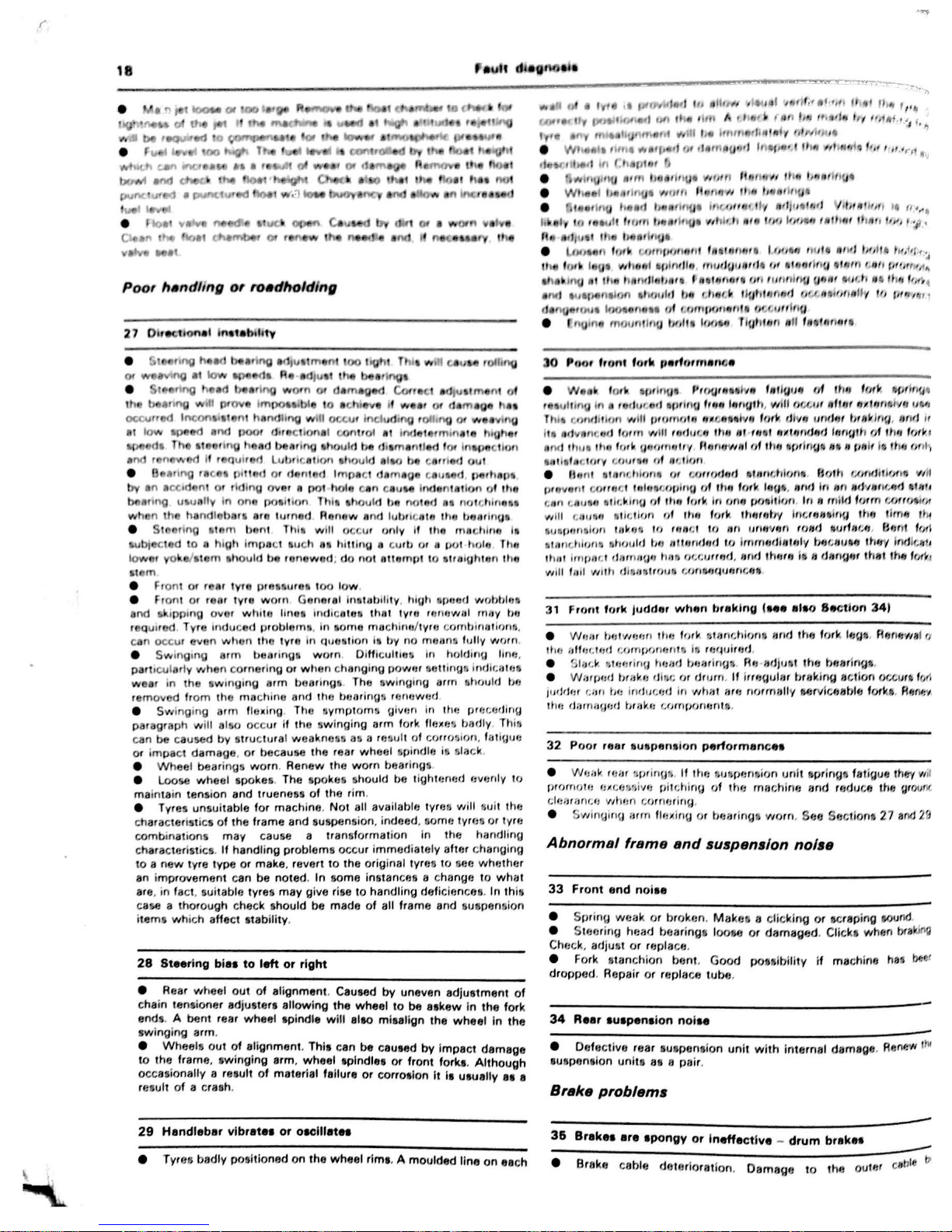

July

1984

A3ML.

49cc. Introduced

July

1984

ISBN 1 85010

062

4

© Haynes Publishing Group

1984

All rights

rnerwd

. No

put

of this

book

may

be

reproduced

or

transmitted

in

any

form

or

by

any

means, electronic

or

mechanical. i

ncluding

photocopying,

recording

or

by

any information

sto..-ge

or

retriewil

system

, wi

thout

permission

in

writing

from

the

copyr

ight

holder

.

Printed

in

England

HAYNES PUBLISHING GROUP

SPARKFORD

YEOVIL

SOMERSET BA22 7JJ ENGLAND

HAYNES PUBLICATIONS

INC

861 LAWRENCE

DRIVE

NEWBURY

PARK

CALIFORNIA

91320 USA

Britlall lib••rv Ce1el09uinv in

Publicelion

D•t•

St.o..mA P

ete

Tomas

lnO!l<'ds

owners

WOO.shoP manual,

I M

ope<l

s - ll1aln

1en

• nce and repaii - Tomos moued

1. nu.

529 2e· 12 T

l45

3 T6

ISBN

1-85010--062~

Page 3

Our thanks are

due

to

Dwek

International

Limited

. the

UK

importer and di

stributor

of

the

Tomos

range. and in

particular

to

Stewart

C Bronstein

of

the

above

company

who

arranged the

loan

of

the machine used in

the

woritshop

project. provided

the

technical

information on

the

models

covered

by

the

manual

and checked the

About this manual

conten

ts

of

the

manual

for

technical

accuracy.

The

Avon

Rubber

Company

supplied information

on

tyre careanc

fitting

. and

NGK

Spark

Plugs

(UK)

Ltd

provided

informat

ion

on

plug

maint

enance a

nd

electrode

conditions

.

Page 4

Contents

Page

Acknowledgements

2

About

this

manual

2

Introduction

to

the Tomos mopeds

6

Model

dimensions

and

weights

6

Ordering spare parts 7

Safety

first

I 8

Tools and

working

facilities 9

Choosing and

fitting

accessories

12

Fault diagnosis

14

Routine maintenance

21

Chapter 1 Engine and transmission

26

Chapter 2 Fuel system and lubrication

49

Chapter 3

Ignition

system

54

Chapter 4 Frame and suspension

59

Chapter 5

Wheels

, brakes and tyres

68

Chapter 6 Electrical system

75

Wiring

diagrams

79

Conversion

factors

81

Index

82

Page 5

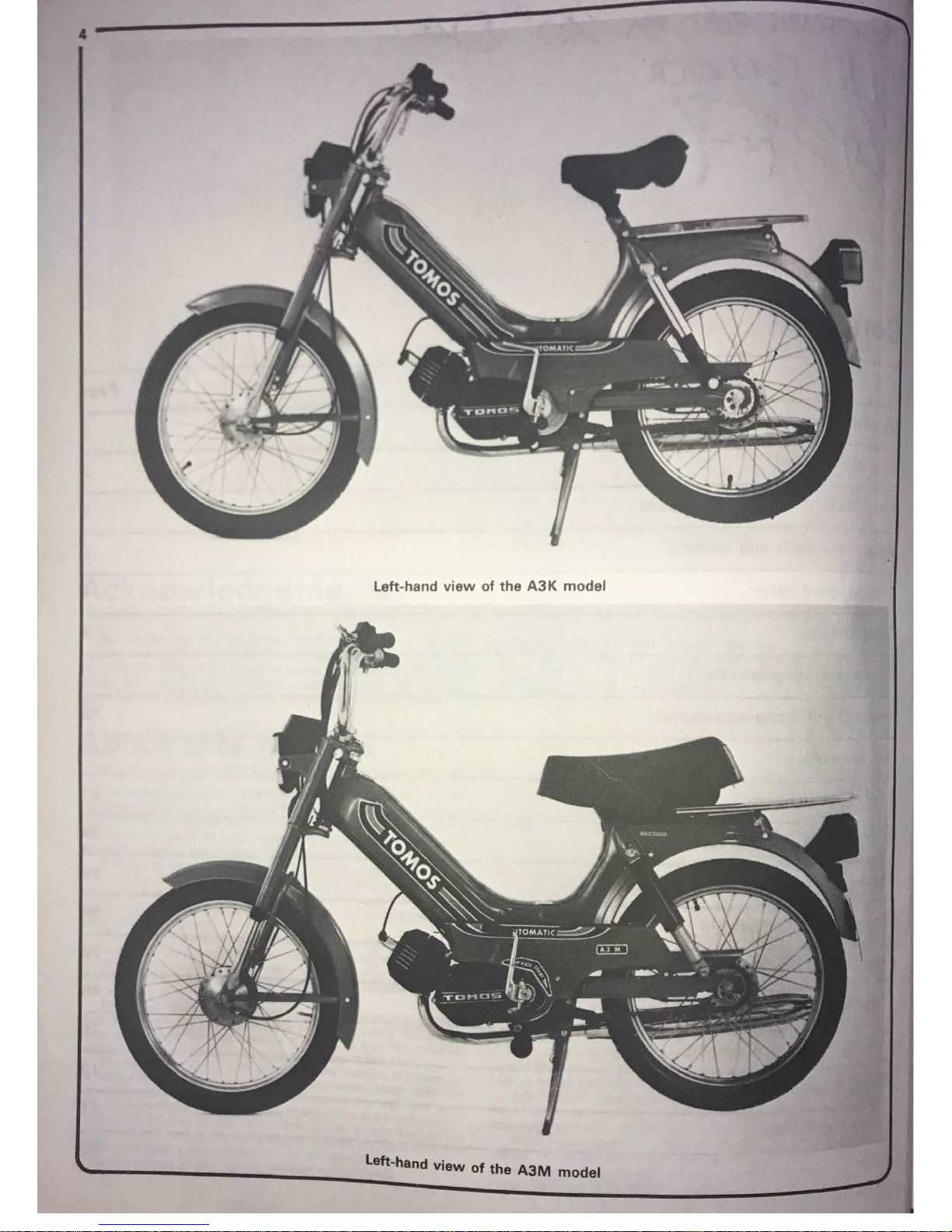

Left-hand

view

of

the

A3K

model

Left-hand

view

of

the

A3M

model

Page 6

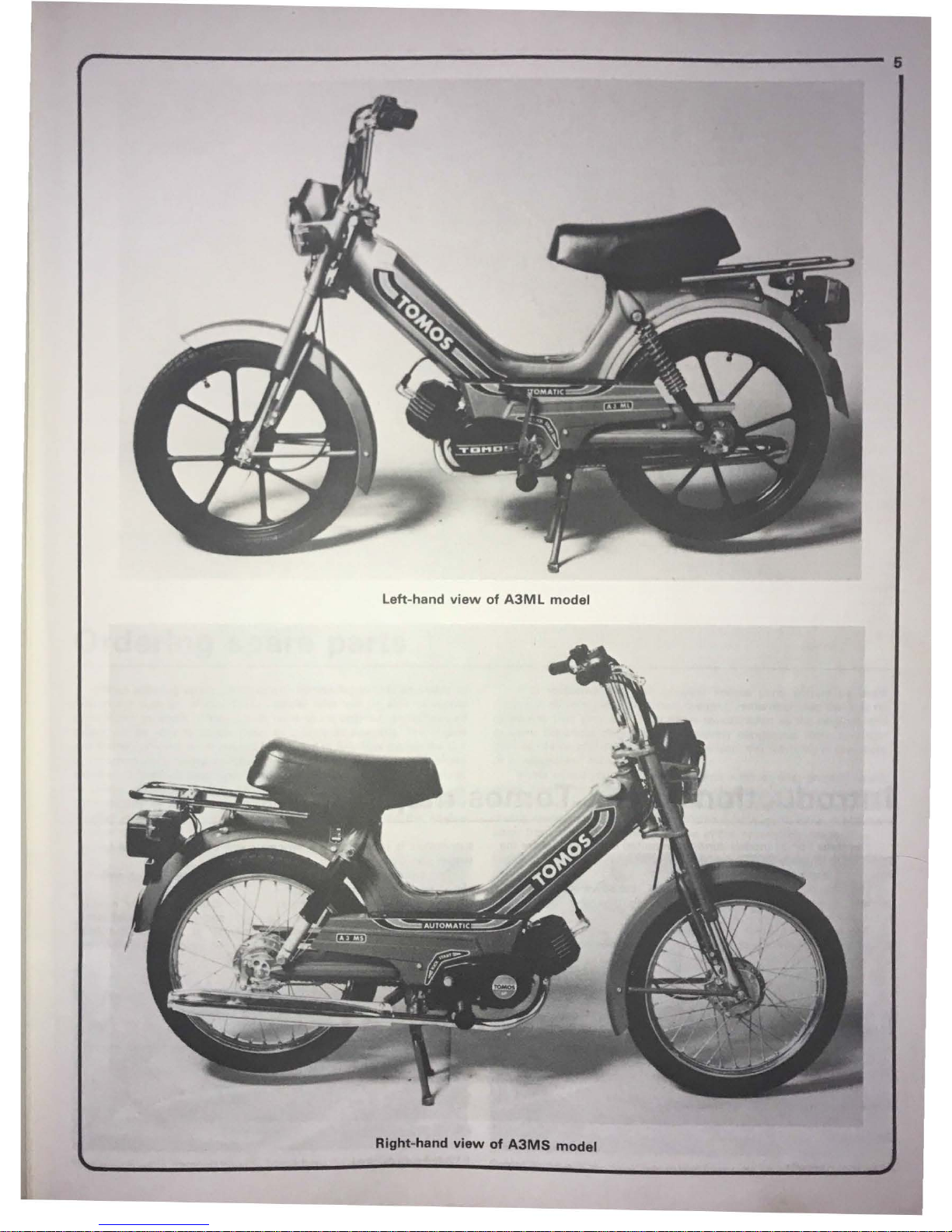

~-------------------------------------------------------------·

Left-hand

view

of

A3ML

model

Right-hand

view

of

A3MS

model

Page 7

Introduction

to

the

Tomos mopeds

The three

Tomos

models currently imported

into

the

UK

share the

same basic chassis and engin

e/

transmission unit.

with

variations in

equipment and accessory

fitments

.

The base

model

of

the range is the

A3K. It

is powered

by

a single-

cylin

der air-cooled

two

-stroke engine driving through a

two

-speed

auto

mat

ic transmission.

The engine/transmission unit is mounted

in

a semi-monocoque

spine frame. fabricated from steel pressings and incorporating the fuel

tank. Fro

nt

suspension is

by

undamped telescop

ic

forks,

whilst

rear

suspension is provided

by a swinging

arm

controlled by coil-spring

suspension

unit

s.

Front and rear

wheels

are

of

the

wire

-spoked type with c

hromium

·

plated steel

rims and

tubed

tyr

es. If·

The

A3MS

Is largely

similar, but

Is distinguished

by

8

~

eel

contained turn signal system, a larger seat and a plated

tubu~

ar

1

5

has

luggage rack. The

A3ML

model Is similar

to

the MS.

1

~

b

lack

redesigned rear suspensi

on

units

with

e>Cposed

springs

and

ma

cast alloy wheels.

_IVl_o

__

d_e_l_d_im

__

e_n_s_io_n_s

__

a_n_d

__

-w_e_i~g~h_t_s

______________

__

Overall

length

.................................................................................... .

1

640

mm

(64

.6 in)

Wheelbase

.......

...

....

...

..................

................

.............................

....

...... .

1080

mm

(42.6 in)

Dry

weight

.....

....

........................

....................

...

.............

...

.................

. .

44

kg

(97

lbs)

Carrying

capacity

.......

...

...................

...

..........

......

........

....................

.. .

1 12.6 kg

(248

lbs)

Page 8

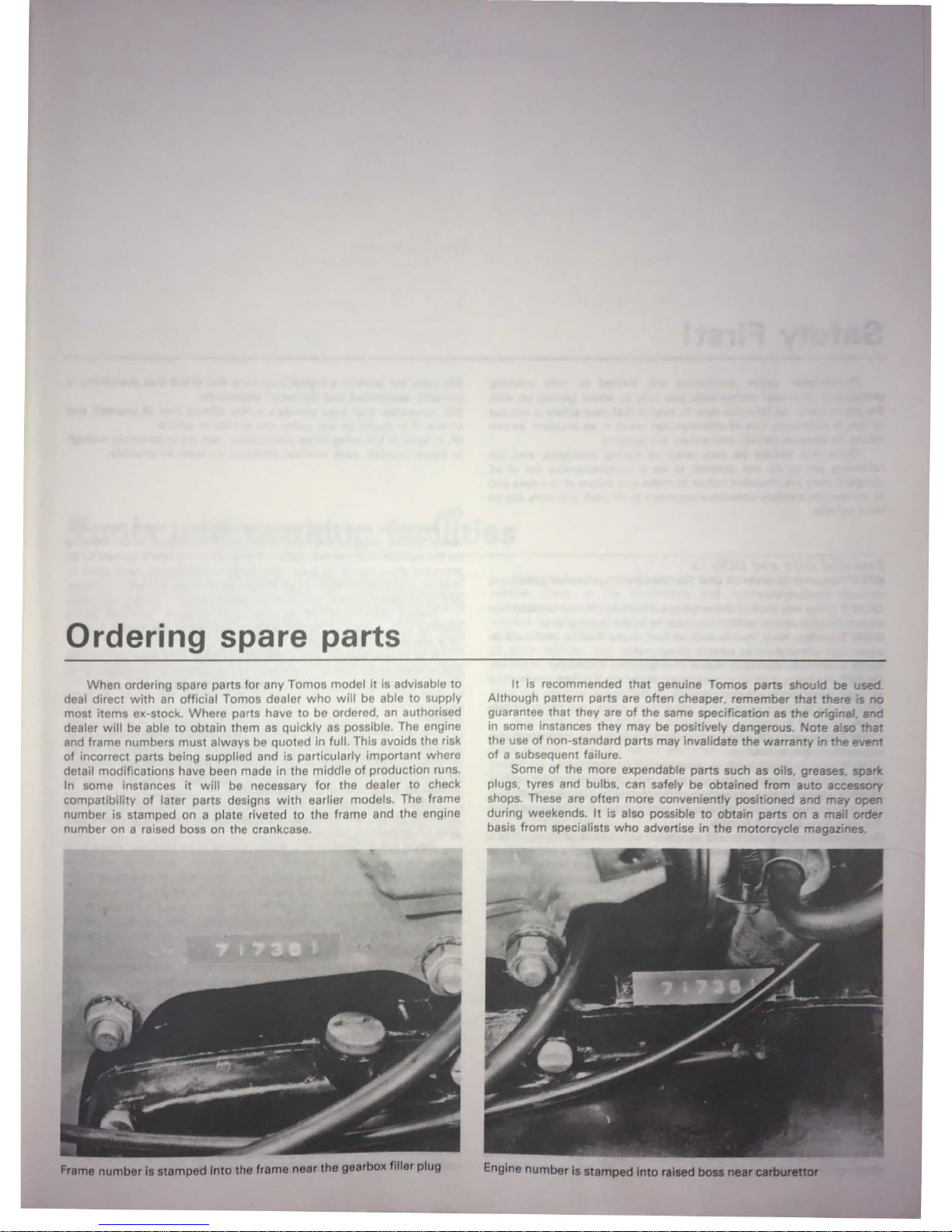

Ordering spare parts

When ordering spare parts for

any

Tomos model

it

is advisable to

deal direct

with

an official Tomos dealer

who

will be able to supply

most items ex-stock. Where parts have to be ordered, an authorised

dealer

will

be able to obtain them

as

quickly

as

possible. The engine

and frame numbers must always be quoted in full. This avoids the risk

of

incorrect parts being supplied and is particularly important where

detail modifications have been made in the middle

of

production runs.

In some instances

it

will be necessary for the dealer to check

compatibility

of

later parts designs

with

earlier models. The frame

number is stamped

on

a plate riveted to the frame and the engine

number on a raised boss on the crankcase

Freme number la

stamped

Into

the

frame

near

the

gearbox filler plug

It

is recommended

that

genuine Tomos parts should

be

used

Although pattern parts are often cheaper, remember

that

there is no

guarantee that they are

of

the same specification as the orig·nal, and

in some instances they

may

be positively dangerous

Note

also

that

the use

of

non-standard parts

may

invalidate the warranty

in

the

event

of

a subsequent failure.

Some

of

the more expendable parts such as oils, greases, spark

plugs, tyres and bulbs, can safely be obtained from auto accessory

shops. These are often more conveniently positioned and may apen

during weekends.

It

is also possible

to

obtain parts

on a mail

order

basis from specialists

who

advertise in the

moto

rcycle magazines.

Page 9

,,

.

Safety First I

r.

, I " .. ' " '

"'''

" "

fl

«I

I h -

"".

" ' " l

lltlll

t 11

ltl

•• ,,,

Wt

l 1~.t11u

"'" 1111 '"''

" ' 1 11111hu••ll•

lh "''" m..

lo "'"'"

'

untt

lll\)

11

11 with

Ill

11 h

It'

ll11l\ll

11

11

1111.tt

l

htt

1

111111

h i

110111

111111

V•l•ll

anl• II( 11

11•

)1 11111

111

11•1..

n\Ott\ Ill • 1

11

1 I\ tlf

11

11

11111111

1

1111 '"""

"

h1

nll

'" ,

ltfn11

1 n• 1

n11

f

fltf\tl

"' \>! lo t\,tl t f!flti

ftl

nl

tt1

n11f11ly

Ill I

111111111

1

1\"'" "'"

"'"

\

II

i;11

""

wny• 111 h 1

1\

1lt1l l 1 c lt

ft

1111

1

n11tl

tll•r

''

""'~'"'

II

'

"""

'' ,,,, "'''

Ill

Ct1t1d ,

,,

It•

fl

I '

'"'

llfltlu

1111h

1t1

ll

•t tll

nil

(111

1

II

••

m Ill

lt

11n11.tntl

1 lllho

tt

h i

'"

"~"

yt111

nw111t1

11

1

11

111

rl•

~ •

n111

f

hl !

Hit

,Jul U

II

11,.

lnl\

I

1llllh

ft)\111

lljlf

llt1n1

h l

ol

nit Wtlt

l\

y11111rttty11

111

1111

I 1\111

""l\11

I

f,

t,ttmtf1tl UOs

""''

OON

' 1 s

DON 'T

1'11<1111

111

" ' 11

1111

11

1111

11111

11

v•H• "'" """'

11 ''"'', ""'"" r1

11ll

l1 l11111lv

h l 1

1\

'0ttt

'' ,.1,t11111

\'

Oii

DON'T ll••l!lt

n11v

"""

or

111

11

ri1111l

1111 "-'""'

"'

'"

""'

""

'" wlt

l11

1" 1

111111

•~•

'"

'" 111

1111 tl\11

1 It I•

~

11ll

t.

l

t111llv

,

u11I

ltl nvoltl

1111111

111

11

Y''"

DON'T

~111h111

1

tml1•

llq11lct

111

11

h

"

~

1111

11

hrnlo.•

t

rt.oltl

111

11111lh11111•i l1y

n

ou

th

O•

nllt1w thttm h i 10

111nl11

1111

yo111

~t.,1

11

DON'T """'"

l

11n

ko 11111

1111

t111~t

It

Is lr1

j11il111111

1t1

l11

1nl

1h

DON'T

;illuw ""Y 81)

1it

u

ll

ur

1110:111ri

to 1111110111 1i11

11111 fl

11u• wltJ•J II

1111

ltA11Jht 11w

11v

holu10 '

u11111011c

8llfJ~

11

11

II

DON'T U

IM!

111

lltt l

11y

11J11

11110111

01 uthc1

tu11I

~

whir h

111rty 1111a11rl1,n11!lu

111ju1y

DON'T

11t1otnp

t tu illt

11

heovv c

u111pu11

1111t wh

ich

11 11

1y IJu b11y1111t1 yo"'

"IJ"llllltv

yot 11ul11

t1111

o

DON'T

1u

' h to

ll11l

1h n

lob

, 01

t11k

11

u11votlllutl t1hu

11

c11111

DON 'T o

ll

uw hllrltun

or

01111110111 111

ur

n1uu11d

1111 u1111tt1111uuct

v11hl

clo.

DON'T

lr1fh1tw

o tyro tu

11

IJ'Oll&uro

obuvo thu rocu

111111

011do

tl

111uxl111u111

.

Aoort hum o

vo11110

11t1l

ny 1hu cnrcnso

1111d

whuol rlrn, In uxtromo

cu11u

11

tho tv•

11

moy lllow o

rr

lorclllly,

DO 0

11

t1u

ru thot th u

n111

chl

110

11 11upp

urt

od

11o

cur o

ly

ut ull tlrnu11. Th

l8

1

11

u

i-..

lnllv

lmpo

1tont

when

tho mnchlnu

11

bluckud

up

tu old whool

or

I

11>.

111

111

ovol,

DO Ink@

1110 when

11ttom1>tlng

to 1lockon o 11tubbu1n

nut

01

bolt.

It

11

ueno111lly

l>otte• to

J)ull

0

11

11 llP!lt1t101, ruthor thon pu11

h, so

lhot

If

11llJ)

1J•Uil

OC

011

you

foll

owoy

hum

tho

rr1ochl1111

rothor

thon

on

to

It.

DO

w

o11

1 ovo 01otootlon when u1l

ng

powor toul

11

such

oa

drill i t1ndor

berr

h

ytlnd111

etc. ' '

DO

u110

11

b111t

lor c1

110n

1 on yu

u1

h1111d1 p1l

or to undortoklng dirty Jobi

It will 01oto t your 1kln lrom lnluotl

on

01 wnll

0

11

moklng

tho

dirt

entlor

to 10

111

ovw 1tftn1wo1d1:

but

m11k

o

11

uro

yuur

horidt1

r n't I f

11

ll1motv

11

o o t

DO

kl!iip

l

ooH

clothing lcuff1, tlo otol

1111d

long holr woll out f

th

of

muvl

11u

rnochonlool uorta.

0

0

way

DO romovo

rl11y

8, w1l1twotch oto,

bol

oro working

011

the

v .

hi 1.

01111o

clollv

thn

oloc

t1l

col 1y1tnm.

0

c o -

DO

kMp vour

work oroo tidy - It

lt1

only t

oo

0111y

to

loll

ov

1

1 1

loll

1v1110

orou11d

.

0

11rt

c

111

DO

ntcor

c18o ooutlo

11.wl11111 cum111oul11y 01Jrlr1•

-•• for r

1 i: "

cm1ov11

or

l11111t1llntl

on.

1111ur

·o tht1t

tho

t111111lo11

I"

n11pll

11d

011d 101

0111

11

d

In

11

00

1111oll

otl

monn

or,

u11lny

11ultoblo toul11

which procludo

tht1

POlll!lblll

of

tho

"ruing o8unnlnu vlolontly. ty

DO

yot

110111001111

to ohook 11orludl

oollv thnt

1111

In

woll, whon workln

11luno

011

tho vehhJllJ

, g

U()

1

llll'(

•J

'll

w•H

~

IJI

11

1•11111,

111

ti•J'

fll'lll',lj

lirl•I r,ll

lJ•)-

lll"J

YIV

, ,11,,

1

,

1ly 11

t1d•H11t1l11d

11

11•1

rl

ul1111r1•1•

I 1tfl'ltWttr•Jt

fl

f,

00

trlflllfllllltfl 111

111

y11

111

V•llil•,lt1'

«i

lilfftily

lflf1J•,l1t 111

111

I~

I

n

l'

N>;.-1

oll1•1t•

II

111

tl•

111li1

•Jll

tttly

Jl'I

Ill, lj•1I lll

JIJl,l/iJ

ll,1

i,tl~'At.

"''

If

'. 1

11

•

rJ'"

' ,,, l

11

ll•

1wl11u

1li•

111

•1

tJ1111,1

1111l•1

r111

,

vou "'"

1111

19,

1

1

,

.,._.~

" ' l

11j11111

yt1111••1l

l ... ,

.,.,, 111<1tll•

,nl l

llf•Jril

l•m

""

f$/i')

f}

.H

V,.,.,•

I+

,

,~,

r 1"'

lt•1

1111

1111

l1•

JJ 111

1111

1l

11J1m 11 11

11 11•11111

1 (

1,1•Jtjl1lln.,

) I•

h#J

"i

~"''l';

~

N•JV'

JI

rlJ•

lll~•t

,

111

l111v11

1111y

~lrt

d

•11

111

1~•1d

fl

llm

'I

1'

tf'IUnd ,

rf~

l

l'/

" r

•HI

11

111 V•J

ltl,,l1J 11

111 11111

rlt1

~

d1J•

H1

11111 •Jtld

lfl'lllj

11

'f)1Jf1o1,j>WJ

11

(;

•1l•11,1rlt.

11I r1l1•11I

1,l11.ul1, l

1y

rw•i 1n1,1:1l

c;1nfT1•

,,11•

•

/)f)Uf'.UN

.J

u '11i/

·"1

't

•1v•1

11

tiv 1111111•

, •1l•i•.

1rl1

,lrv 1

111111

11p

In y11

1Jr

ll•>

dy und.,, t'Arlb'

l/J'

~,-1~

1,1

111 i(j11lt11 lf<

Jll•

ll

Vflf/')11

1, Wlil

1,

h

ltl

!l

1,1Jnf1

n,,tJ

§f);Ji;,t

l•

nlrji

(

i;

l',l

f,+,.

/\l

w11y•1 tflr1r,•1n11111, 1

1111

1 IJ<1ll•JJ

Y 1

1:

irth

(

f,Jrt)Ur\11

)

Ufl

.& !.'!'/•

W•11l-,l1111

•)

II

!Illy

JJltl

I •11 I h•1 fu•

JI

fiYIJl•;m,

1,t

nd

rltrtfjr

rl~

~r/J

I

ill

'I

1t1 " l

11J1 •111t1lt111 01

•1~lt111JNI

II I /

11

1r,11

1111111

111

tl•

1d 110:

11

o

f111;

!Jl!tlnyul1hor

of

a typt

.vJ'.lM.1.-.

~1

1111

11

rt11

tf •ilt

11,1

tl1

,al llrcrri

Ir;

~•iJJI

l1111 11

Jy In th.,

ij!H391'

or

w0ft1):;-,;,

I'

1

t

h111111 N•1v

•11

try tu •111ln

11u

l11

t. '' f

u•1

I m 111.,ctr1

c1I

11,,1

vA

Nl'

K

Fumus

Co

rt11

ln l•rnH

1t1

:m1 h1

1Jhl

y toirl

r.

!lnrJ c

11n quicklv

cau~

uw rt>"

..<;;.,

11

ur10 1111t1 •1v

•m d•J!lth If lntwl•J

rl

10

any

m1tont.

P1Jtr

ol lg1v.krtl

¥"7

//

c1Jrn1J

n 1

1110 thlr1 r.1

1t•111

ury, 0

11

rJ

o th•J V

!lfJOIJr§ from

~ruin

yA-

1i:,

ac

11

0 trlchlo1oothyl•1n"

/\11

v d rol

nlno

or po uring

of

well

vCila

r

./~

uhouhJ

h•1

tlo

no

In

11

W!lll von tll1

J11

id

aroa

.

Whori uolnlJ c

l11a11ln1J

flu

ldlJ and w l

v6ntl

,

rlJad

tM

im!l1.o~J

curi1lullv. Novirr u

110

motorioln from unmarlu.td

co

ntain11r1

-

rhl:Y

r-~

I

ylvo o

ff

pol11unou1i v11puur11.

G'

Novor run

tho

unglno

of a mot

or

vehiclB In

an

encio~

Jf)Y.);

•

111 II

gurnyo. E•

h11u111

fum

o11 contain carbon

m

~

,,,t

"TJ:

otctrom•Jlv

pol1011ou11; If

you

nood

to

run

the

engine

. alw

av10<J

to';:

opo

n olr or ot loo1 t

havo tho roar

of the vehicle out

.;d'l

tnlJ

W(J('r

f/

~

If

vou

aro

fortunato ono

ugh

to

have the u

te

of

an

I

~~~

novor

drain

or pour

petr

ol, and n

ever run

the

engine

.

wniJe

~

.-r.J

11 t1tandlng

ovor

It;

tho

fumo1.

boin

g h

11avier than

air, will

CJ1(Y/.f

In

the

pit

with

po111lblv lethal r111

ult1.

Mains

electrfclty

.,,

..

¢

Whon

u1l

ng

11n

olectrlc

power too

l, ln..,ection

li

ght

:c;ott~

work

s from

tho

m11ln

1. 11lway1 ensure

that

the

app

liance

trfY

e

aJtt,.d

c

onnect11d

to

Ill

plug

and

that. wher11

nece15ary. it is

~oot

and

141

'

(groundodl. Do not u10 1uch

applian

ces

In

damp condiflonJ .

"

-wi

~~

b

·

~ ~

·

ewor11

of creating a 1p

11rk

or applvl

ng

e11

ce11ive

heat

in

fuol or fuol

vap

our.

Ignition

HT

voltage .

parU

iJ

A

1111vore

el11ctrlc shock can

r111ult from

tou

ching

~rt.a·~

(lllllli<i9

tho

Ignition 1y11om, 1u

ch

111 th11

HT

lead

s.

when

the

eng~!

;,,wJa:P'

or bolng c

rankod

, p

ortlcul11rly

If components are

damP or

ed

1

M !ff

1

•

do

foctl

v11. Whore ""

oloctronlc Ignition 1y!ltem 1•

fitt

'

vo

lt8gt

11 much

hlgh11r

ond could

prove

fatal.

Page 10

Tools

and

working

facilities

The first pri

ority

when

undert3king maintenance

or

repa

ir

work

of

any sort

on a motorcycle

is

to

have a clean. dry,

well

-lit

work

ing area.

Wo

rk carried

out

in

peace and

quiet

in

the

well

-ordered atmosph e

re

of

a good

workshop

will

give

more

satisfac

tion

and much

better

results

than can usually

be

achieved in

poor

working

conditions. A good

workshop

must

have a clean

flat

workbench

or

a solidly constructed

table

of convenient

working

height

. The

workb

ench

or

table sho

uld

be

equipped wi

th

a vice

which

has a jaw

openi

ng

of

at

least 4 in (

100

mm). A set

of

jaw

covers

should

be

made

from

soft

metal such as

aluminium

alloy

or

copper. or

from

wood

. These covers will minim

ise

the

marking

or

damaging

of

soft

or

delicate

components

whi

ch

may

be

clamped in

the

vice. Some clean, dry, storage space

will

be required

for

tools, lubricants and

dismantled components. It

will

be

necessary

during a major

overhaul

to

lay

out

engine/gearbox components

for

examination and

to

keep

them

where

they

will

remain undisturbed

for

as long as is necessary.

To

this

end

it

is recommended

that

a supply

of

metal

or

plastic containers

of

suitable size is collected. A supply

of

clean.

lint

-free, rags

for

cleaning purposes and some newspapers,

other

rags,

or

paper

towels

for

mopping

up

spillages should also be

ke

pt. If

working

on

a hard concrete

floor

note

that

both

the

floor

and

one's knees can

be

protected

from

oil spillages and

wear

by

cutting

open a large cardboard

box

and spreading

it

flat

on

the

floo

r under the

machine

or

workbench. This

also

helps

to

provide some

warmth

in

wi

nter

and

to

prevent

the

loss

of

nuts

, washers, and

other

tiny

components

which

have a tendency

to

disappear

when

dropped on

anything

other

than a perfectly

clean,

flat

, surface.

Unfortunately, such

working

conditions

are

not

always available

to

the home mechanic.

When

working

in

poor

conditions

it

is essential

to

take extra ti

me

and care

to

ensure

that

the

components

being

worked

on are

kept

scrupulously clean

and

to

ensure

that

no

components

or

tools are lost

or

damaged.

A

selection

of

good

tools

is a fundamental requirement

for

anyone

cont

e

mplating

the maintenance and repair

of a motor

vehicle. For

the

own

er

who

does

not

possess

any, their

purchase

will

prove a

considerable expense,

offsetting

some

of

the

savings made by

doing

-

it

-yourself.

However

, provided

that

the

tools

purchased are

of

good

quality,

they

will

last

for

many

years and prove an extremely

worthwhile

investment

.

To help

the

average

owner

to

decide

which

tools

are

neede~

to

carry

out

the

various tasks

detailed

in

this

manual,

we

have compiled

three lists

of

tools under

the

following

headings:

Maintenance

and

minor

repair, Repair

and

overhaul, and Specialized. The

newcomer

to

practical mechanics shou ld start

off

with

the simpler

jobs

around the

vehicle. Then, as his confidence and experience

grow

. he can

undertake more

difficult

tasks, buying extra tools as and

when they are

needed.

In

this

way

, a

Maintenanca

and minor

repair

tool

kit can be

built-up

into

a Repair

and

overhaul

tool

kit

over a considerable period

of

time

without

any

major

cash outlays. The experienced

home

me

chanic

will

have a

too

l kit good e

nough

for

most

repa

ir

and overhaul

procedures and

will

add

tools

from the

specialized category

when

he

feels the expense is justified

by

the

amount

of

use these

tools

will

be

put to.

It

is

obv

iously

not

possible

to

cover

the

subject

of

tools

fully

here.

For those

who

wish

to

learn more

about

tools and

their

use

the

re is a

book

ent

itl

ed

How

to

Choose

and

Use

Car Tools availabl e

from

the

publis

hers

of

this

manual.

Although

, as

its

title

implies,

this

publi

cation

is directed at car

owners. the

information

given is equally applicable

to

mo

torcycle owners.

It

also provides

an

introduction

to

basic

workshop

practice

whi

ch

will

be

of

int

erest

to a home

mechanic worki

ng

on

any

type

of

motor

vehicle.

As

a general rule.

it

is

bett

er

to

buy

the

more

expensive, good

quality

tool

s. Given reasonable use,

such

tools

will

last

for

a very long

time

, whereas

the

cheaper,

poor

quality,

item

will

wear

out

faster and

need

to

be renewed

more

often, thus

nullifying

the

orig

inal saving.

There

is

also

the

risk

of a poor

quality

tool

breaking

while

in use.

causing

personal injury

or

expensive damage

to the

component

being

worked

on.

It

should be

noted, however, that

many

car

accessory

shops and

the

large

department

stores sell

tools

of

reasonable quality

at

competitive

prices. The best example

of

this

is found

with socket

sets,

where

a mediu

m-priced

socket set wi

ll

be

quite

adequate for the

home owner

and

yet

prove less expensi

ve

than a selecti

on

of

individual

sockets and accessories.

This

is because individual pieces are usually

only available

from

expensive,

top

quality

. ranges and

whilst they are

undeniably good, it should be remembered

that

they

are intended

for

professional use.

The basis

of

any

toolk

it is a

set

of

spanners.

While

open-ended

spanners w i

th

the

ir

slim

jaws.

are useful

for worki

ng

on

awkwa

rdly-

positioned

nuts, ring

spanners have advantages

in

that

they

grip the

nut

far

more

positively. There is less risk

of

the

spanner slippi

ng

off the

nut

and

damaging it,

for

this

reason alone ring spanners are

to

be

~referred

.

Ideally,

the

home

mechanic

should acquire a set

of

each.

but

if

expense rules this

out

a set

of combination

spanners (open-ended

at

one end and

with a ring

of

the

same

size at

the other) will provide a

good

compromise. Another

item

which

is

so

useful

it

should be

Page 11

10

Tools

and

wortting

facilities

considered an essential

requ

irement

f~

an

~e

mecha

c is a set

of

soc;ket soanners

These

a

re

ava~able

m _a van

ety

of

d

ri

e size

It

Is

ecommended

th

at

the

f-i

nch

dm

<e

type

is

purchased to

beg

m

th

as

1

linough bul er and

mor

e e

x:pe

nsive than the !

-inc

h

type

,

the

larger

:i

ze

rs far

moie

common and will accept. a greater variety

of

torque

wrenchel

e~en:sion

pi

eces a

od

soclt

et size

s. The

socket

set

should

compnlloC

sockets of sizes

between 8 and

24

~m

.

a re ersible ratch

et

d

. an extension bar

of

about 10 i

nch

es m length. a spark plug

mre. _

_.

I I

'.

0

socket wi

th

a rubber inse

rt

. a

•ou a un

versa

JOm

t. ther

attachments

can

be

added

to

the set

at

a l

ater

date

.

Maintenance

and

minor

repair

tool

kit

Sf!f

of

spannf!

rS

8 -

24

mm

Sf!t

of

sockets

and

attachments

Spark

plug

spanner wi

th

rubber insert

-

10

. 1 2. or

14

mm

as appropn'ate

Adjustab

le spanner

c-spanner/pin

spanner

Toroue wrench (

same

size dri

ve

as

sockets

}

Set

of

scre

wdrivttrs (flat

blade}

Set of scrtt

wdrivttrs

(c

ross-head}

Se

t of

All

en lceys 4 -

10

mm

Im

pact scre

wdr

iver

and

bits

B

all pein hammttr - 2

lb

Hacksaw (junior}

Self-l

ocki

ng plittrs -

Mole gri

ps

or vice grips

Pliers - c

ombination

Pliers - nttedle nose

Wirt! brush (

small

}

S

oft-br

istlttd brush

Tyre

pum

p

Tyre

prtt

ss

ure gaugtt

Tyre

tread

depth

gauge

O

il

can

F

in

e emery

cloth

Funn

el (medium

size)

Drip

tr

ay

Set of feeler gauges

Strobe timi

ng light

Continuity tester

(dry

battery

and

bulb)

Solderi

ng iron

and

solder

Wi

re

stripper

or

craft

knife

PVC insulating tape

As

sortment

of

split

pins. nut

s.

bolts. and washers

Repair

and

overhaul

toolkit

The tools in this list are virtually essential for anyone undertaking

major repairs

to

a motorcycle and are additional

to

the tools listed

above. Concerning

Tone

driver

bits. Tone screw

s are enc

ount

ered on

some of the more modern machines where their use is res

tri

cted

to

fastening certain components inside the engine/gearbox

unit. It

is

therefore recommended

that

if

Tone

bits cannot be borr

owed

from

a

local

dealer. they are purchased individually as

the

need arises. They

are not in regular use

in

the

motor trade and

will therefore on

ly

be

:t\1!>;1-,.h

ln

:n

..,_

....

....

: ... 1

:-• •--

• - •

Will!

brush fla

rge

J

Soft ·re

brush

(similar to thos

e used for

cleaning

sued

e

shoes}

S

hee

r of

pla

te glass

Hac

ksaw

(/11rgtt}

Valve

grinding tool

Valve g

rind

ing compound (coarse a

nd fine}

St

ud

extract

or

set

(E-Z

out}

Specialized

tools

Th

is

is

not

a list

of

the

tools

mode

by

the ma chine's manufactu

rer

to

carry o

ut

a specific task on a

limit

ed range

of

models. Occasional

references are

ma

de

to such tools in the text

of

this manual ond. In

general. an alternative met

hod

of carrying o

ut

the task w

itho

ut

tho

manufacturer's t

oo

l is given where possible. Tho tools me

nti

oned In

th

is list are those

whi

ch ero

not

used regularly and are oxpenslvo to

buy

in view of their infrequ e

nt use. Wh

ere this

is

the case it may

be

possible

to

hire or bor

row

the tools

against a deposit from a local

dea ler

or

tool hire shop. An alternative is for a group of friends

or

a

motor

cycle club to join in the purchase.

Piston ri

ng

comp

ressor

U111versal

beari

ng pull

er

Cylinder bore h

oning attachment (for

elecrric

drill)

M

icror

net

er

set

Vernier calipers

Dial gauge set

Cylinder

co

mpression gau

ge

Vacuum

gauge set

Mulrimeter

Dw

ell merer/racho

met

er

Care

and

maintenance

of

tools

Whatever the quali

ty

of the tools

pur

chased, they

will

last much

longer if cared for.

Th

is means in practice ensuring

that a too

l Is used

for its

in

tended purpose:

for

example screwdrivers should

not

be used

as

a substitut

e for a centre

pun

ch.

or

as

chisels. Always remove dirt or

grease and any metal partic

les but

remember

that a light

film

of oil will

preve

nt rusting if the tool

s are infrequently used. The common tools

can be kept together in a large box

or

tray

but the mo

re

delicate. and

more expensive,

items

shou ld be stored separately where they

cann

ot

be damaged. When a

tool

is damaged or

worn

out

, be sure to renew

it

immediately.

It

is false eco

nomy

to continue

to use a

worn

spanner

or

scre

wdr

iver

whi

ch may sl

ip

and cause expensive damage to the

component be

ing wo

rked on.

Fastening

systems

Fastener

s.

basica

lly

, are

nut

s, bol

ts

and screws used

to

hold two

or

more p

art

s together. There are a

few thi

ngs

to

keep in mind when

working

with

fasteners.

Almost

all

of

them

use a locking

device of

som

e type;

eithe

r a lock was

her

. lock

nut

, locking

tab

or thread

adhesive. All

th

readed fasteners should be clean. straight. have

un

dama

ged threads and

undama

ged co rners on the hexagon h

ead

Page 12

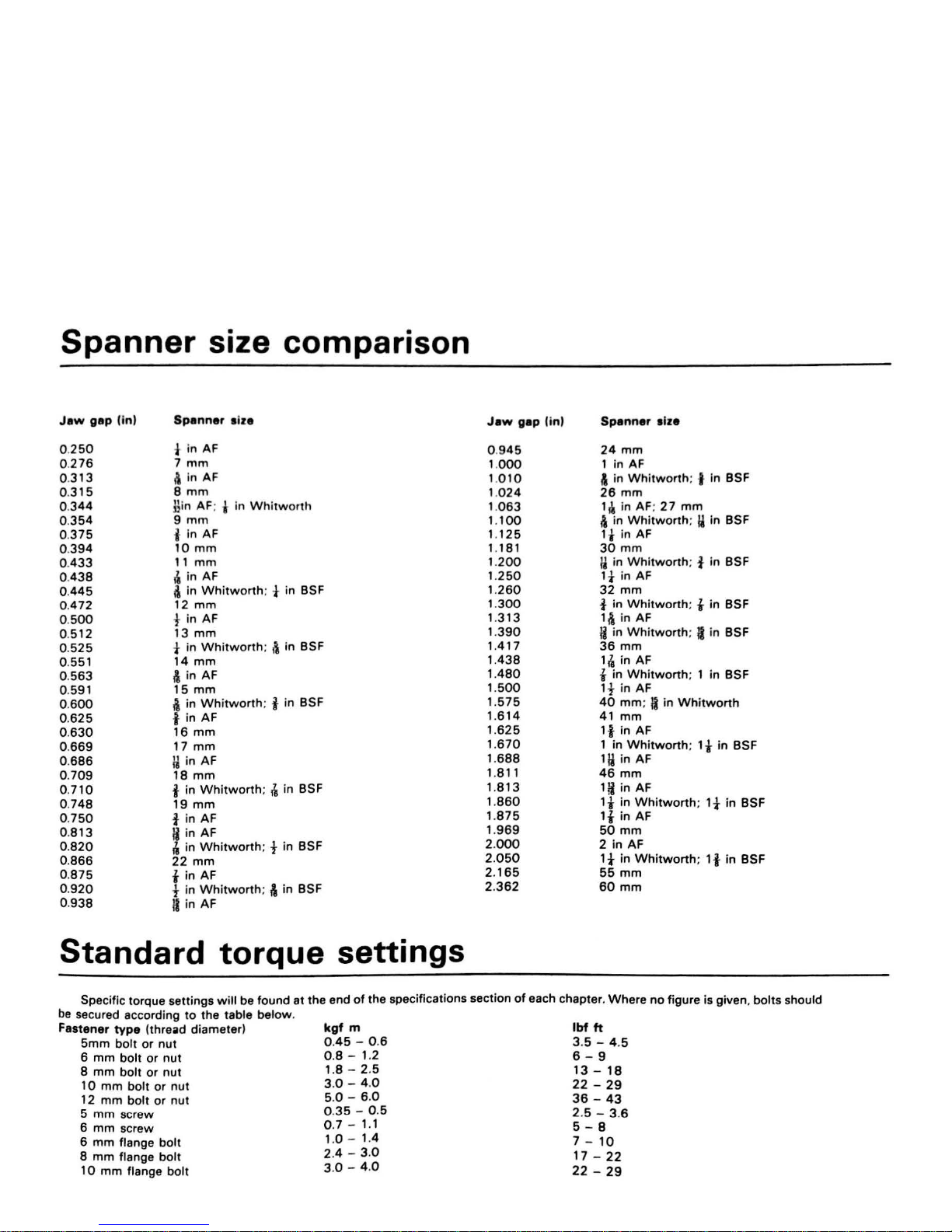

Spanner

size comparison

Jew

gap

(in)

0.

250

0.

276

0.

313

0.

315

0.

344

0.

354

0.

375

0.

394

0.

433

0.

438

0.

445

0.

472

0.

500

0.

512

0.

525

0.551

0.

563

0.591

0.

600

0.625

0.

630

0.

669

0.

686

0.

709

0.

710

0.

748

0.

750

0.

813

0.

820

0.

866

0.

875

0.

920

0.

938

Spenner

eize

t in AF

7

mm

i\

in

AF

8

mm

}lin

AF; t in

Whitworth

9

mm

i In AF

10

mm

11

mm

4

in

AF

.\

in

Whitworth

; t in BSF

12

mm

tin

AF

13

mm

t in

Whitworth

:

t\

in BSF

14

mm

i\

in AF

15

mm

i in

Whitworth

: i in BSF

i in AF

16

mm

17

mm

ij

in AF

18

mm

i

in

Whitworth

: 4 in BSF

i9

mm

tin

AF

Ii in AF

4 in

Whitworth

; t

in

BSF

22

mm

tin

AF

t in

Whitworth

; i\ in BSF

II

in AF

Standard

torque

settings

Jaw

gap

(in)

0.

945

1.

000

1.

010

1.

024

1.

063

1.100

1.

125

1 .181

1.

200

1.250

i .

260

1.

300

i .

3i3

i .

390

1.

417

1.

438

i .

480

1.

500

i .

575

i .

6i4

i .

625

1.670

1.688

i .8

ii

i .

813

i .

860

1.875

i .

969

2.

000

2.

050

2.i65

2.

362

Spanner

elze

24

mm

1 in AF

A in

Whitworth

; i In BSF

26

mm

1~

in AF;

27

mm

A in

Whitworth

;

ij

in BSF

1-f

in

AF

30

mm

ij

in

Whitworth

; t

in

BSF

lt

in AF

32

mm

t in

Whitworth

; i in BSF

11\

in

AF

Ji

in Whi

tworth

;

II

in BSF

36

mm

i4 in AF

t in

Whitworth

; i in BSF

1t

in AF

40

mm

: Ii

in

Whitworth

4i

mm

it

in AF

i in

Whitworth; it

in

BSF

1ij in AF

46

mm

i!j

in

AF

it

in

Whitworth; if

in

BSF

it

in

AF

50

mm

2 in AF

ii

in

Whitworth; ii

in

BSF

55

mm

60

mm

Specific torque settings

will

be found at

the

end

of

the specifications section

of

each chapter. Where

no

figure is given.

bolts

should

be

secured according

to

the

table

below

.

Fastener

type

(thread diameter)

5mm

bolt

or

nut

6

mm

bolt

or

nut

8

mm

bolt

or

nut

10

mm

bolt

or

nut

12

mm

bolt

or

nut

5

mm

screw

6

mm

screw

6

mm

flange

bolt

8

mm

flange

bolt

1 0

mm

flange

bolt

kgf

m

0.

45

- 0.6

0.8

- 1.2

1.8 -2.5

3.0 - 4.0

5.0

- 6.0

0

.3

5 - 0.5

0.7

-

i.

i

i .0 - i .4

2.4 - 3.0

3.0

- 4.0

lbf

ft

3.5 -

4.5

6 - 9

i3 -i0

22 -29

36 -43

2.5 - 3.6

5 - 8

7 -

io

i7 -22

22

-

29

Page 13

r

,~

Choosing and fitting accessories

The range

of

accessories available

to

the

modern

motorcyclist

is

almost as varied and

bewildering

11

the

range

of

motorcycles

. This

Sectio

n is intended

to

help

the

owner

in

choosing

the

correct

equlpment for his needs

and

to

avoid some

of

the

mistakes

made

by

many riders

when

adding accessories

to

their

machines. It

will be

evident that

the

Section can

only

cover the subject

in

the

most

general

terms and so

It

is

recommended that

the

owner

. havi

ng

decided

that

he wants

to

fit.

for

example. a luggage rack

or

carrier. seeks t

he

adv

ice

of several local deelers end

the

owners

of

similar

machin

es. This

will

gi

ve

a good idea

of

what

makes

of

carrier are easily available . a

nd

at

what price. Talking

to

other

owners

will

give

some

insight

into

the

drawbacks or

good

points

of

any one make. A

walk

round

the

motorcycles

in

car

parks

or

outside a dealer

will

often

reveal the same

sort

of

information.

The first priority

when

choosing accessories is

to

assess exactly

what

one needs.

It is, for example, pointless

to

buy a large

heavy-duty

carrier

which

is designed

to

take

the

weight

of

fully laden panniers and

topbox when all you need

is

a place

to

strap

on

a set

of

waterproofs

and a lunchbox when

going

to

work.

Many

accessory manufacturers

have ranges

of

equipment

to

cater for the individual needs

of

different

riders and

this

point

should

be

borne

in

mind

when

looking

through

a

dealer's catalogues. Having decided exactly

what

is

required and the

use

to

which

the accessories are

going

to

be

put.

the

owner

will

need

a

few

hints

on

what

to

look

for

when

making

the

final choice. To

this

encl

the Section

is

now

sub-divided

to

cover

the

more

popular

accessories

fitted. Note

that

it

is

in

no

way

a customizing

guide, but

merely seeks

to

outline

the

practical considerations

to

be taken

into

account

when

adding aftermarket equipment

to a motorcy

cle.

Fairings

and

windscreens

A fairing

is

possibly

the

single.

most

expensive, aftermarket

item

to

be fitted

to

any motorcycle and, therefore, requires

the

most

thought before purchase. Fairings can be divided

into

two

main

groups: front fork mounted handlebar fairings and

winds

creens, and

frame mounted fairings.

The first group, the

front

fork

mounted fairings, are

becoming

far

more popular than was once the case, as they offer several advantages

over

the

second group. Front fork mounted fairings generally are much

easier and quicker

t?

fit,

involve less modification

to

the motorcycle,

do

not

as a rule restrict the steering lock,

permit a wider

selection

of

handlebar styles

to

be used, and

offer

adequate protection

for

much

less money than the frame mounted type. They are also

lighter

can be

swapped easily

~etween

different motorcycles, and are availa0ble

in

a

much greater variety

of

styles. Their main disadvantages are

that

they

do

not

offer

as much weather protection .as

the

frame

mounted

types,

rarely offer any storage space, and,

1f

poorly fitted

or

naturally

incompatible, can have an adverse effect

on

the stability

of

the

motorcycle.

The second group,

the

frame mounted fairings, are secured

so

rigidly

to

the

main

frame

of

the

motorcycle that they can offer

8

substantial

amount

of

protection

to

motorcycle and rider

in

the

event

of

a crash. They

~ffer

a.lmost

comp~ete

protectlo~

from

the

weather

and,

if

double-skinned

in

construction, can provide a great deal

of

useful storage space. The

'?~ling

of. peace, quiet and complete

relaxation encountered

when

riding behind a good full fairing has

to

be

experienced

to

be believed. For this reason full fairings are considered

essential

by

most

to

·

11

uring motorcyclists and by many people

who

ride

: year

roun~

.

The main. disadvantages

of

this type are that fitting can

ake a

long

time. often

involving removal

or

modification

of

standard

motor

cycle components, they restrict the steering

lo.ck

and they can

add

up

to

about

40

lb

to

the weight

of

the machine They do

not

usually affect the stability

of

the machine

to

any great

e~ent

once the

front tyre pressure and suspension have been adi·usted t

f

. o compensate

or

the

e~tra

w?1ght, but can be affected

by

sidewinds.

The.

f1~st

thing

to

look

!?r

when

purchasing a fairing is the quality

of

the fittings. A

good

famng

will

have strong, substantial brackets

c.onstructed from heavy-gauge tubing; the brackets must be shaped

to

fit the frame

or

forks evenly so that the minimum

of

stress is imposed

on the assembly

when

it

is bolted

down

. The brackets should

be

properly painted

or

finished - a nylon coating being the favourite

of

the

better manufacturers - the nuts and

bolts

provided should

be

of

the

same thread a

nd

size standard as

is

used

on

the

motorcycle and

be

properly plated. Look also

for

shakeproof locking nuts or locking

washers

to

ensure

that

everything remains securely tightened down.

The fairing shell

is

generally made from one

of

two

materials:

fibreglass

or

ABS

plastic. Both have their advantages

and

disadvantages,

but

the

main

consideration

for

the owner is that

fibreglass

is

much easier

to

repair

in

the

event

of

damage occurring

to

the fairing.

Whiche

ver material

is

used, check that

it

is properly

finished inside as

well

as out,

that

the

edges are protected by

beading

and that

the

fairing shell

is

insulated from vibration by the

use

of

rubber

grommets

at

all

mounting

points

. Also be careful

to

check

that

the windscreen is retained

by

plastic

bolts

which

will

snap

on

impact

so that

the

windscreen

will

break

away

and

not

cause personal i

njury

in

the event

of

an

accident.

Having purchased your fairing

or

windscreen, read the

manufac

-

tur

er's

fitting

instructions very carefully and check that you

have

all

the

necessary brackets and

fittings

. Ensure

that

the

mounting brackets

are

located correctly and

bolted

down

securely.

Note

that

some

manufac

-

turers use hose clamps

to

retain

the

mounting brackets;

these

should

be

dis

carded as

they

are convenient

to

use

but

not

strong

enough

for

the task. Stronger clamps should

be

substituted; car

exhaust

pipe

clamps

of

suitable size

would

be

a good alternative.

Ensure

that

the

front

forks can turn

through

the

full steering lock available wit

hou

t

fouling

the

fairing.

With

many

types

of

frame-mounted fairing the

handlebars

will

have

to

be

altered

or

a different type fitted

and

the

steering lock

will

be restricted

by

stops provided

with

the

fittings

.

A

l~

check

that

the

fairing does

not

foul

the

front

wheel

or

mudguard

.

in

any steering position

under

full

fork

compression. Re-route

anv

cabl~s

.

brake pipes

or

electri~I

wiring

which

may

snag

on

the fairin.g

and

ta

~

great

care

to

protect

all electrical connections, using insulating tape.

the

manufacturer's instructions are

followed

carefully

at

every

stage

"

1

.

0

be

h t

hydrau

1c

serious problems should

be

encountered. Remem r t . 8 d

and

pipes

that

have been

dis

connected

must

be

carefully .re-

t1ghten

e

the

hydraulic system purged

of

air

bubbles

by

bleeding.

k.

a

Two

things

will

become immediately apparent when .

ta

~n~he

motorcycle

on

the

road

for

the

first

time

with

a fairing - the

ftrs~

/:;nd

tendency

to

underestimate

the

road speed because

of

the

lack

.1 ne

pressure

on

the

body. This

must

be very carefully watched unti

~ng

has

grown

accustomed

to

riding behind

the

fairing. The

second 1 t>ut

is the alarming increase

in

engine noise

which

is an

u~fortu

nate

and

in

evitable by-product

of

fitting

any

type

of

fairing

or w1.

ndscreen.ases

is

caused

by

normal engine noise being reflected. and in

some

c

amplified,

by

the

flat

surface

of

the

fairing.

Page 14

Choosing

and

fitting

accessori•

13

Luggage racks

or

carriers

Carriers are possibly

the

commonest item

to

be

fitted

to

modem

motorcycles. They vary enonnousty

in

size. carrying capacity, and

durability.

When

selecting a carrier. always loolt for one which Is made

specifically

for

your machine and

which

is

bolted

on

with

as

few

separate brackets as poasible. The universal-type carrier,

with

it.a

man

of

brackets and adaptor pieces.

will

generally prove

too

weak

to

be

of

any real use. A good carrier should

bolt

to

the main frame . generally

using the

two

suspension

unit

top

mountings and a mudguaro

mounting

bolt

as attachment points. and have

its

luggage platform as

low

and

as

far forward as possible

to

minimise the effect

of

any load

on

the machine's stability. Look for good

quality

, heavy gauge tubing.

good

welding and good finish. Also ensure that the carrier does

not

prevent opening

of

the seat. sidepanels

or

tail compartment. as

appropriate. When using

a carrier.

be

very careful

not

to

overload it.

Excessive

weight

placed so high and so far

to

the rear

of

any

motorcycle

will

have an advenie effect

on

the machine·s steering and

stability.

Luggage

Motorcycle luggage can

be

grouped under

two

headings: soft and

hard. Both types are available

in

many

sizes and styles and have

advantages and disadvantages

in

use.

Soft luggage is

now

becoming very popular because

of

its lower

cost and its

versatility.

Whether

in

the

form

of

tankbags, panniers.

or

strap-on bags. soft luggage requires in general no brackets and no

modification

to

the motorcycle. Equipment can be swapped easily

from one motorcycle

to

another and can be

fitted

and removed in

seconds.

Awkwardly

shaped loads can easily be carried. The disadvan-

tages

of

soft luggage are

that

the contents cannot be secure against

the

casual

thief

. very

little

protection

is afforded in the event

of

a crash.

and

waterproofing is generally

poor

. Also.

In

the case

of

panniers.

carrying capacity is restricted

to

approximately 1 O lb. although this

amount

will

vary considerably depending on the manufacturer·s

recommendation.

When

purchasing soft luggage. look for good quality

material. generally vinyl

or

nylon,

with

strong. well-stitched

attachment points.

It

is always useful

to

have separate pockets.

especially

on tank bags,

for

items

which

will

be needed on the journey.

When purchasing a tank

bag, look

for

one which has a separate.

well-

padded, base. This

will

protect

the tank·s paintwork and permit easy

access

to

the

filler

cap

at

petrol stations.

Hard

luggage is confined

to

two

types: panniers, and top boxes

or

tail trunks.

Most

hard luggage manufacturers produce matching sets

of

these items.

the

basis

of

which

is generally

that

manufacturer's own

heavy-duty

luggage rack. Variations on this theme occur in the form

of

separate frames for the

better

quality panniers. fixed

or

quicklydetachable luggage, and in size and carrying capacity. Hard luggage

offers a reasonable degree

of

security against

theft

and good

protection against

weather

and accident damage. Carrying capacity is

greater than

that

of

soft

luggage, around 1 5 -

20

lb

in the case

of

panniers, although top boxes should never

be

loaded

as

much as their

apparent capacity

might

imply

. A

top

box should

only

be used for

lightweight items. because one

that

is heavily laden can have a serious

effect on the

stability

of

the

machine. When purchasing hard luggage

look

for the same good points as mentioned

under

fairings and

windscreens.

ie

good

quality

mounting

brackets and

fittings

, and

well-

finished fibreglass

or

ABS

plastic cases. Again as

with

fairings, always

purchase luggage made specifically

for

your motorcycle, using as

few

separate brackets as possible,

to

ensure

that

everything remains

securely bolted

in

place.

When

fitting

hard luggage. be careful

to

check

that the rear suspension and brake operation

will

not

be impaired in

any

way and remember

that

many pannier

kits

require re-siting

of

the

indicators. Remember

also

that

a non-standard exhaust system may

make fitting

extremely difficult.

Handlebars

The occupation

of

fitting

alternative types

of

handlebar is

extremely popular

with

modern motorcyclists,

whose

motives

may

vary

from the purely practical. wishing

to

improve the

comfort

of

their

machines.

to

the purely aesthetic, where form Is

more

important than

function. Whatever the reason, there are several considerations

to

be

borne in

mind

when changing

the

handlebars

of

your machine.

If

fitting

lower bars check carefully

that

the

switches and cables

do

not

foul the

Petrol

tank

on full lock and

that

the surplus length

of

cable. brake pipe,

and

electrical

wiring

are smoothly and

tidily

disposed of. Avoid

tight

kinks In cable or brak.e pipes which

will

produce

stiff

cont1ols

or

the

pnimature and disastrous failure

of

an

overstrened

component.

If

necessary. remove the petrol tank and re-route the cable from the

engln gearbox

unit

upwaros. ensuri

ng

smooth gentle curves are

produced.

In

extreme cases.

it

will

be

neceuary

to

purchase a shorter

brake pipe

to

overcome this problem.

In

the c11e

of

higher handlebars

than standard

it

will

almost certainly be

necesury

to

purchase

extended cables and brake pipes. Fortunately.

many

standard

motorcy

-

cles

have a custom version which

will

be equipped

with

higher

handlebars and . therefore. factory-

built

extended components

will

be

available from your local dealer.

It

Is

not

usually necessary

to

extend

electrical

wiring

, as switch clusters may be used on several different

motorcycles. some being custom

versions. This point should be borne

in

mind however

when

fitting extremely high

or

wide handlebars.

When fitting different

types

of

handlebar. ensure that the

mounting

clamps are correctly tightened

to

the manufacturer

's

speci -

fications and

that

cables and

wiring

.

111

previously mentioned. have

smooth easy runs and

do

not

snag

on

any part

of

the

motorcycle

throughout the full steering lock. Ensure that the fluid level

In

the

front

brake master cylinder remains level

to

avoid any chance

of

air

entering

the

hy

draulic system. Also check

that

the

cabl111

are adjusted correctly

and that all handlebar controls operate correctly and can

be

easily

reached when riding.

Electrical equipment

The vast range

of

electrical equipment available

to

motorcyclists

is

so large and so diverse that

only the

most

general outline

can

be

given

here. Electrical accessories very from electric ignition

kits

fitted

to

replace contact breaker points.

to

additional lighting

at

the

front

and

rear. more

powerful horns. various instruments and gauges. clocks.

anti-theft systems. heated clothing.

CB

radios, radio-cassette players.

and intercom systems.

to

name

but a few

of

the more

popular

items

of

equipment.

As

will

be evident. it

would

require a separate manual

to

cover

this

subject alone and

this

section is therefore restricted

to

outlining a few

basic rules which m·Jst be borne

in

mind

when

fitting

electrical

equipment. The first consideration is

whether

your

machine's electrical

system has enough reserve capacity

to

cope

with

the

added

demand

of

the accessories you wish

to

fit

. The motorcycle·s manufacturer

or

importer should be able

to

furnish

this

sort

of

information

and

may

also

be

able

to

offer advice on uprating

the

electrical system. Failing this.

a good dealer

or

the accessory manufacturer may be able

to

help.

In

some cases. more powerful generator components

may

be

available.

perhaps from another

motorcycle

in

the

manufacturer's range. The

second consideration is the

legal requirements

in

force

in

your area.

The

local police may be prepared

to

help

with

this

point

. In the

UK

for

example. there are strict regulations governing the position and use

of

auxiliary riding lamps and

fog

lamps.

When

fitting

electrical equipment always disconnect

the

battery

first

to

prevent the risk

of

a short-circuit, and

be

careful

to

ensure

that

all connections are properly made and

that

they are

waterproof

.

Remember

that

many

electrical accessories are designed primarily

for

use in cars and

that

they cannot easily withstand the ellposure

to

vibration and

to

the

weather. Delicate components

must

be rubber-

mounted

to

insulate them from vibration, and sealed carefully

to

prevent the entry

of

rainwater and dirt. Be careful

to

follow

exactly the

accessory manufacturer's instructions

in

conjunction

with

the

wiring

diagram

at

the

back

of

this manual.

Accessories - general

Accessories

fitted

to

your motorcycle

will

rapidly deteriorate

if

not

cared

for

. Regular washing and polishing

will

maintain

the

finish and

will

provide an

opportunity

to

check

that

all mounting

bolts

and nuts

are securely fastened. Any signs

of

chafing

or

wear

should

be

watched

for. and the cause cured as soon as possible before serious damage

occurs.

As a general rule.

do

not

expect the re-sale value

of

your

motorcycle

to

increase

by

an amount proportional

to

the amount

of

money and effort

put

into

fitting

accessories.

It

is

usually the case

that

an

absolutely standard motorcycle

will

sell more easily

at a better

price

than one

t~at

has been modified.

If

you are

in

the habit

of

exchanging

your

~ach1.ne

for

another

at

frequent intervals. this

factor

should

be

borne

'"

mind

to

avoid loss

of

money.

Page 15

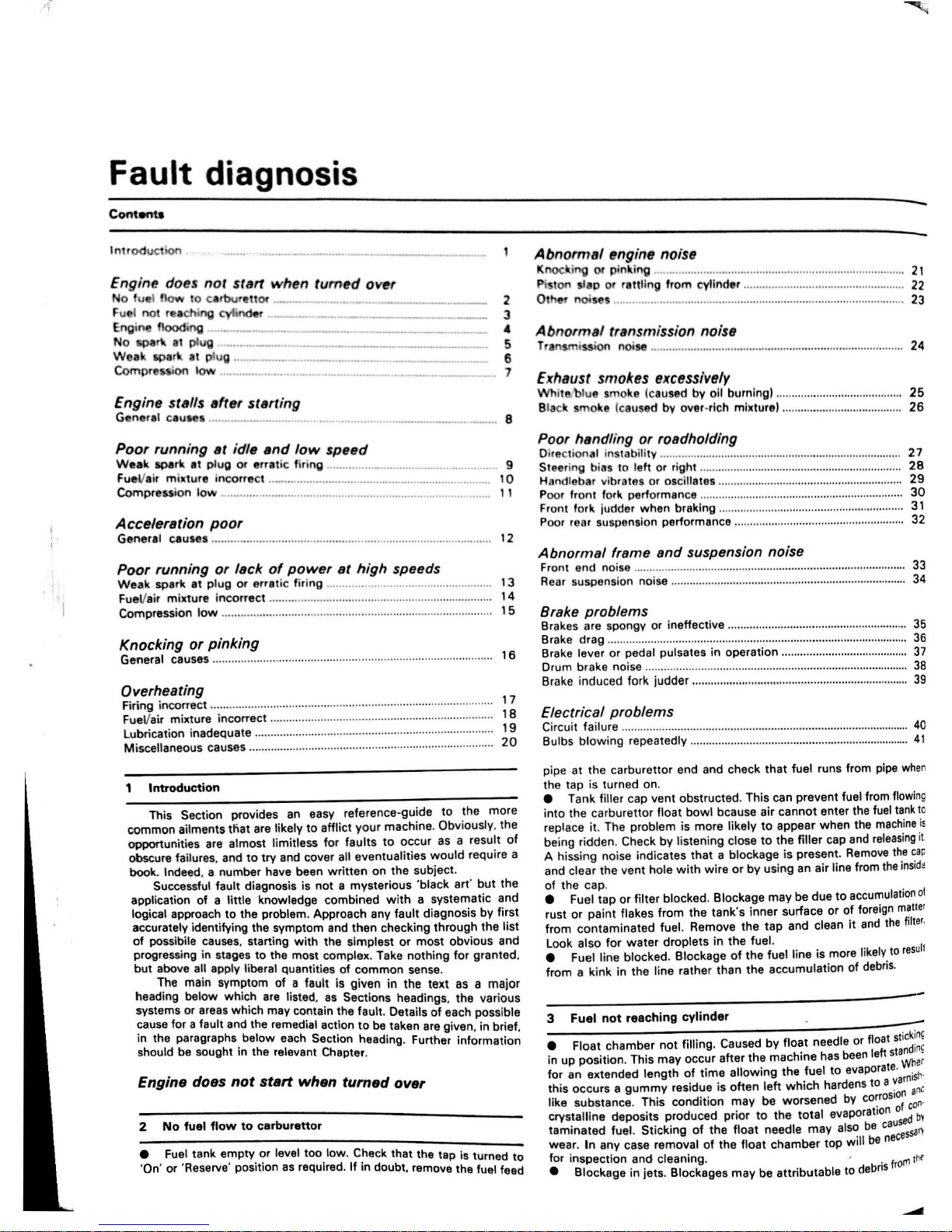

Fault diagnosis

In

t 1

oduet

lon

Engine does

not

start

when

tumed

over

No

hJel

flow

to

c&rt>u

et10f

Fuel

not

ra.ching

cy11~r

_

··-------

Eng

ine

flooding

-----~-------

No

spa!1( at

plug

------····-

W

eak

5011'\

at plug. -····--

·-··-·--------

Compression

low

.......

·····-···---

·--·

_____

--·--

Engine stalls afrer starting

2

3

•

5

6

7

General causes ....

..

.. . ..........

.

. ...

-····--

·---···--···-·-·····

8

Poor

running

at

idle

and

low

speed

Weak

spark

at

plug

or

errat

ic

flri

ng

.... .

....

-··········-····················. 9

Fue air m

hc

ture

incorrect ........

........

.................................... -............ 1 O

Compr

ession

low

........

..................................................................... ....... 1 1

Acceleration

poor

General causes ................................................ ..... ....................

.......

........ 12

Poor

running

or

lack

of

power

at

high

speeds

Weak

spark

at

plug

or

erratic

firing ..........

........................................

...

13

FueVair

mixture

incorrect ...............................

...

.....................................

14

Compre.ssion

low

...... ...

.. . ..

... .... . .

.. ... ... .................

....

.. ..

.. ..

.. ........

...

.........

...

. 1 5

Knocking

or

pinking

General causes .................. ......

....................... ........

...

..........

...

...

.............

..

1 6

Overheating

F

iri

ng

incorrect ............................................................... · ·

··

·· ....

····

··

..

·· ·

.. ····

FueVair mixture incorrect ...................................................................... .

lubrication

inadequate ..........................................................................

..

Miscellaneous causes ............................................................................. .

1

Introduction

17

18

19

20

This Section provides an easy reference-guide

to

the more

common ailments

tliat

are likely

to

afflict

your

machine. Obviously, the

opportunities are almost limitless for

faults

to

occur

as a result

of

obscure failures. and

to

try

and cover all eventualities

would

require a

book. Indeed. a number have been

written

on

the

subject.

Successful fault diagnosis

is

not

a mysterious 'black art"

but

the

application

of a little

knowledge combined

with

a systematic and

logical approach

to

the problem . Approach any fault diagnosis

by

first

accurately identifying

the

symptom and then checking through

the

list

of

possibile causes, starting

with

the simplest

or

most

obvious and

progressing in stages

to

the

most complex. Take nothing

for

granted,

but

above all apply liberal quantities

of

common sense.

The main symptom

of

a fault

is

given in the

text

as a majo

r

heading below which are listed, as Sections headings,

the

various

systems or areas which may contain the fault. Details

of

each possible

cause for a fault and the remedial action

to

be taken are given, in brief,

in the paragraphs below each Section heading . Further information

should be sought in the relevant Chapter.

Engine does

not

start when turned over

2

No

fuel

flow

to

carburettor

• Fuel tank

empty

or level too

low

. Check

that

the tap Is turned

to

·

on·

or

'Reserve' position

as

required.

If

In doubt. remove the fuel feed

Abnormal

engine noise

Knocking

01

pinli.lng ................................................................................

21

Piston slap

01

rattling

from