Page 1

Tomos A3 1988 Workshop Manual

The following is a modified and English-only version of the A3 manual found at www.classiccycles.org

Please note that this version is NOT guaranteed to be a perfect reproduction of the original; if you have

any doubts as to what you are reading, please check the original to be sure.

CONTENTS

Technical Data ………………………………………………………………………………………………………………………………………..2

Nuts, Bolts, and Torque Specs …………………………………..…………………………………………………………………………..3

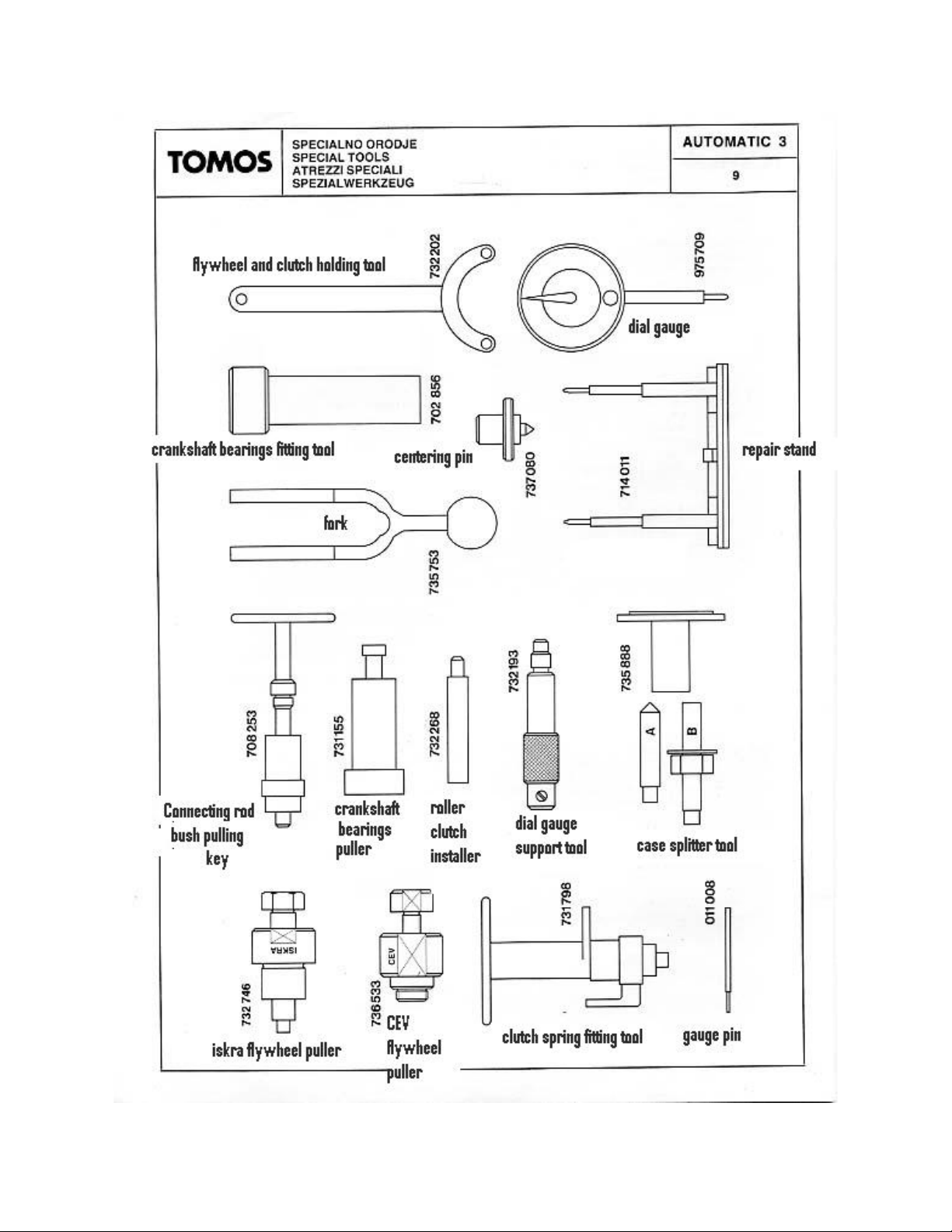

Special Tools……………………………………………………………………………………………………………………………………………3

Image..……………………………………………………………………………………………………….………………….….……….4

Engine Removal…………………………………………………………………………………………………….…………………………..……5

Engine Disassembly…………………………….……………………………………………………………….…………………………….…..8

Checking Engine Parts and Assemblies ………………………………………………………………………………………………..11

Checking, Dismantling, and Assembling of the Clutch ……………………………………………………….………………..13

Dismantling, Checking, and Assembling of the Countershaft ………………………….…………………………………..15

Checking Pedal Shaft and Transmission Chain .……………………………………………………………………………….……17

Carburetor Checking……………………………………………………………………..………………………………………………………18

Encarwi Image………………………………………………………..………………………………………………………………..18

Dellorto Image……………………………………………………………………………………………………………………….…19

Reassembling the Engine .……………………………….………………………………………………….……………………………….20

Adjusting the Contact Gap and Ignition Advance ……………………….……………………………………………………….23

Oil Pump……………………………………………………………………………………………………………………………………………….24

Magneto Settings and Electrical Equipment…………………………………….…………………………………………..……..25

Wiring Diagrams (COLOR!)

European without turn signals………………………………………………………………………………………………….26

European with turn signals……………………………………………………………………………………………………….27

U.S. without turn signals…………………………………………………………………………………………………………..28

U.S. with turn signals………………………………………………………………………………………………………….…….29

1

Page 2

Classic Cycles Technical Resources

TECHNICAL DATA

Engine

Single cylinder, two stroke, air cooled

Bore x stroke

38 x 43 mm (1.496 x 1.693 in)

Piston displacement

49 cm3 (2.990 in3)

Compression ratio

8.5 : 1

Engine output

0.75 -1.5 KW

Gear box

automatic 2-steps, with two centrifugal clutches

Ignition

Flywheel magneto

Ignition advance

1.8-2 mm B.T.D.C.

Contact breaker gap

0.35-0.45 mm (0.014-0.018 inches)

Spark plug gap

0.5 mm (0.020 inches)

Spark plug

NGK B6HS, Champion L86, Bosch W 4 AC

Fuel

Mixture of 86 octane gasoline and two stroke oil (2%, or 50:1)

Gearbox oil/ quantity

Valvomatic type A Suffix A – SAE 10W30 / 220 cm3

Front tire pressure

21 psi

Rear tire pressure

31 psi

Gearbox ratio (I)

17: 74, i = 4.3352

Gearbox ratio (II)

26: 64, i = 2.462

Main shaft

11: 71, i = 6.455

Secondary transmission

chain 90-93 rollers, i = 0.846 – 0.923

Crankshaft out-of-round deflection

max 0.01-0.02 mm

Magneto flywheel deflection

max aksialno 0.1mm

max radialno 0.3mm

Clutch drum axial play

0.1-0.3 mm

2

Page 3

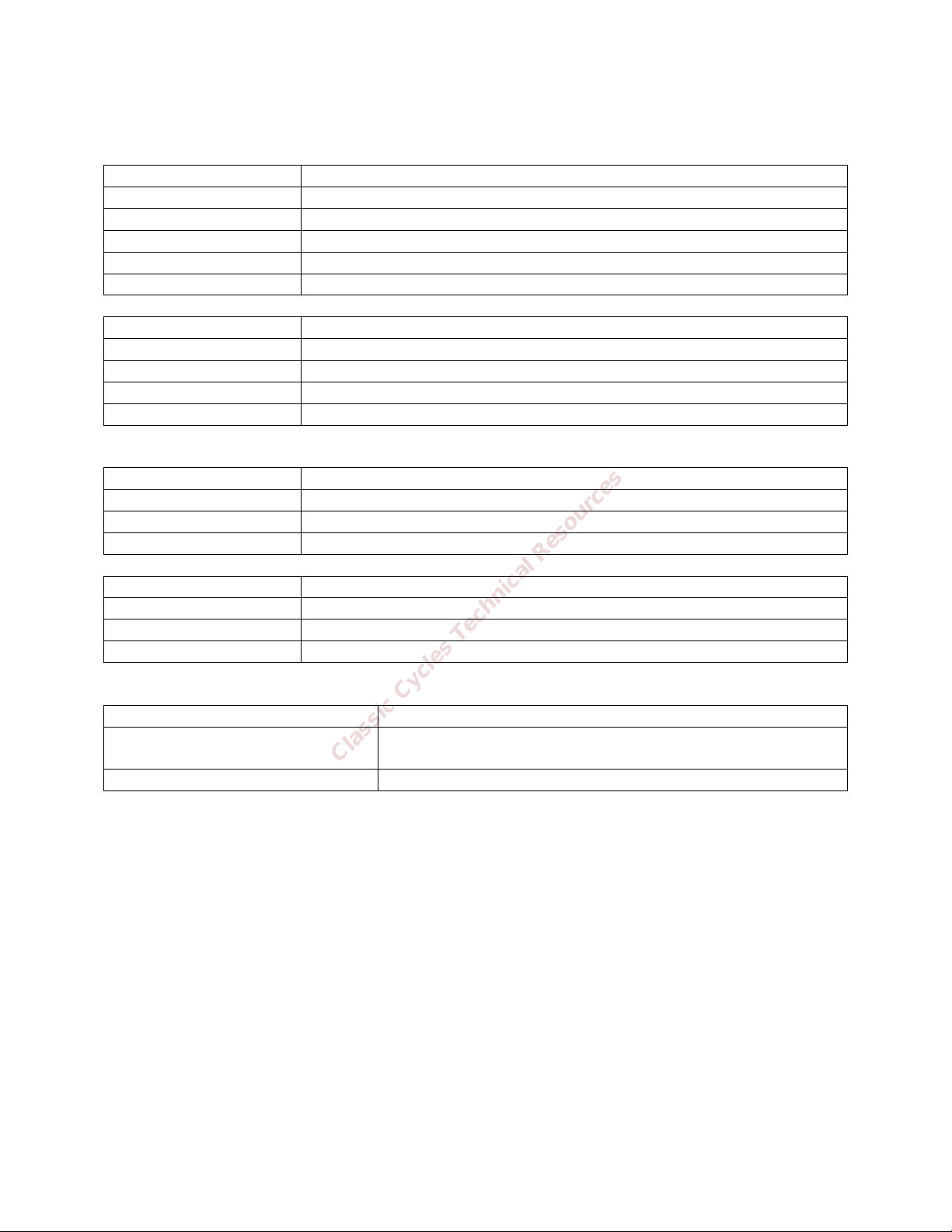

NUTS, BOLTS, AND TORQUE SPECIFICATIONS

Part

Thread

Torque

Spark plug

M14 x 1.25

18Nm

Cylinder cover

M7

12Nm

Flywheel

M10

30Nm

1st speed clutch

M10 x 1

25Nm

2nd speed driven gear

M14 x 1

80Nm

Mainshaft chain sprocket

M22

60Nm

Cylinder stud bolts

M7

15Nm

Crankcase

M6

10Nm

LH engine cover

M6

6Nm

RH engine cover

M6

7Nm

Engine-frame fastening screws

M8 x 1

25Nm

Swingarm fastening screw

M12 x 1.25

35Nm

Rear shock

M10

25Nm

Top fork lug

M12

35Nm

Front and rear wheel spindle

M11 x 1

32Nm

011.008

Gauge pin

702.856

Crankshaft bearings fitting tool

708.253

Connecting rod bush pulling key

714.011

Repair stand

731.155

Crankshaft bearings puller

731.798

Clutch spring fitting tool

732.193

Dial gauge support tool

732.202

Flywheel and clutch holding tool

732.268

Roller clutch installer

732.746

Iskra flywheel puller

735.753

Fork

735.888

Case splitter

736.533

CEV flywheel puller

737.080

Centering pin

975.709

Dial gauge

SPECIAL TOOLS

3

Page 4

Classic Cycles Technical Resources

4 5

Page 5

ENGINE REMOVAL

Drain the oil from the gearbox (fig 1)

With 11mm wrench, unscrew the nut and drive

out lever pin (fig 3)

Unscrew the footrest screw with 17mm wrench

(fig 2)

For pedal versions, refer to figures 3a and 4a

Remove the hub, cups and springs (fig 4)

Unscrew the three screws of LH and RH shield

each and detach shields from frame (fig 5)

Page 6

Classic Cycles Technical Resources

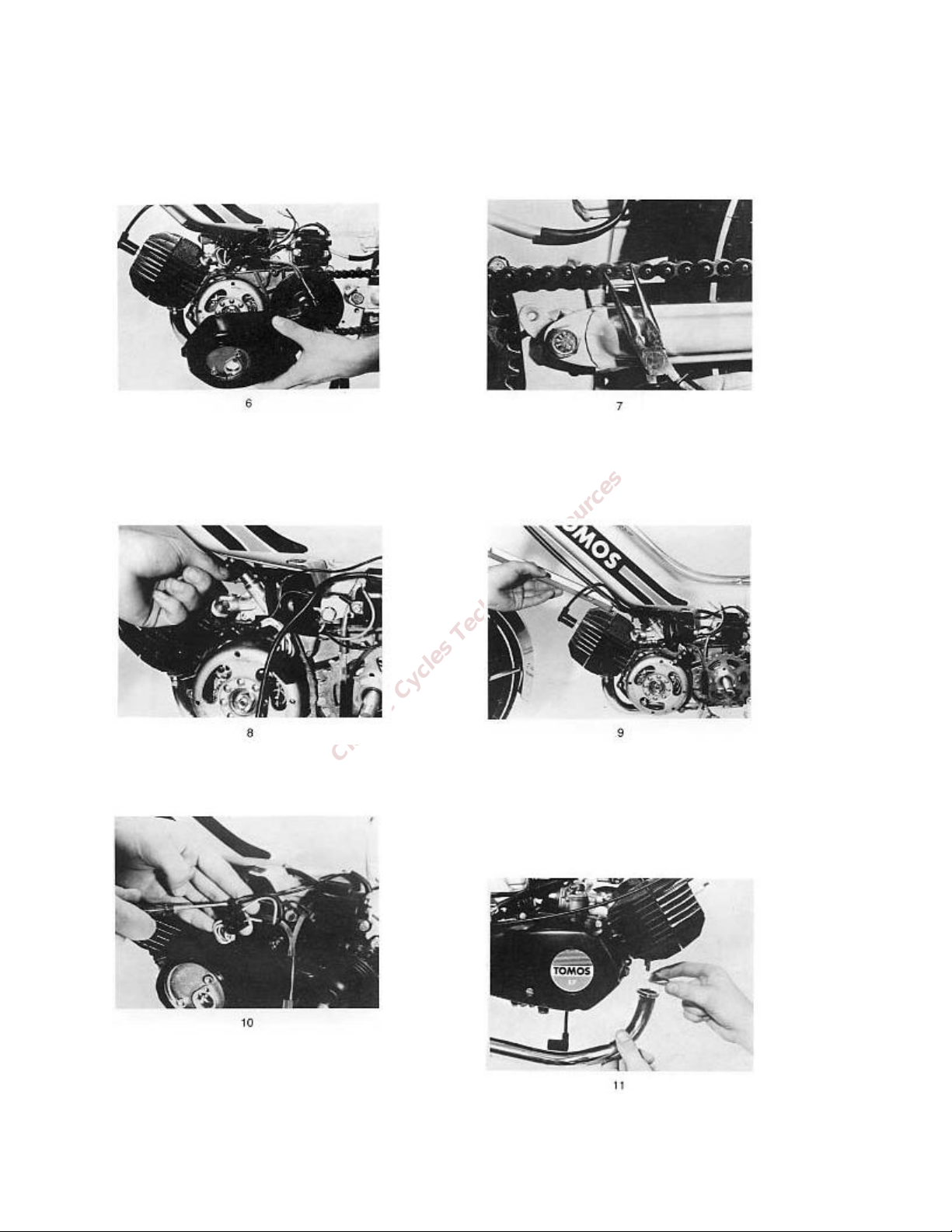

Unscrew three screws of magneto cover and

detach cover (fig 6)

For oil pump injection refer to chapter OIL PUMP

Remove the chain by removing master link (fig 7)

Unscrew the crown nut and extract control cable

along with throttle piston (fig 8)

Detach all electrical leads (fig 10)

Unscrew bottom screw on control cable cover and

release the spark plug cable (fig 9)

Remove fuel supply line. Remove the two exhaust

manifold bolts, the fixing screw, and remove the

exhaust silencer (fig 11)

6

Page 7

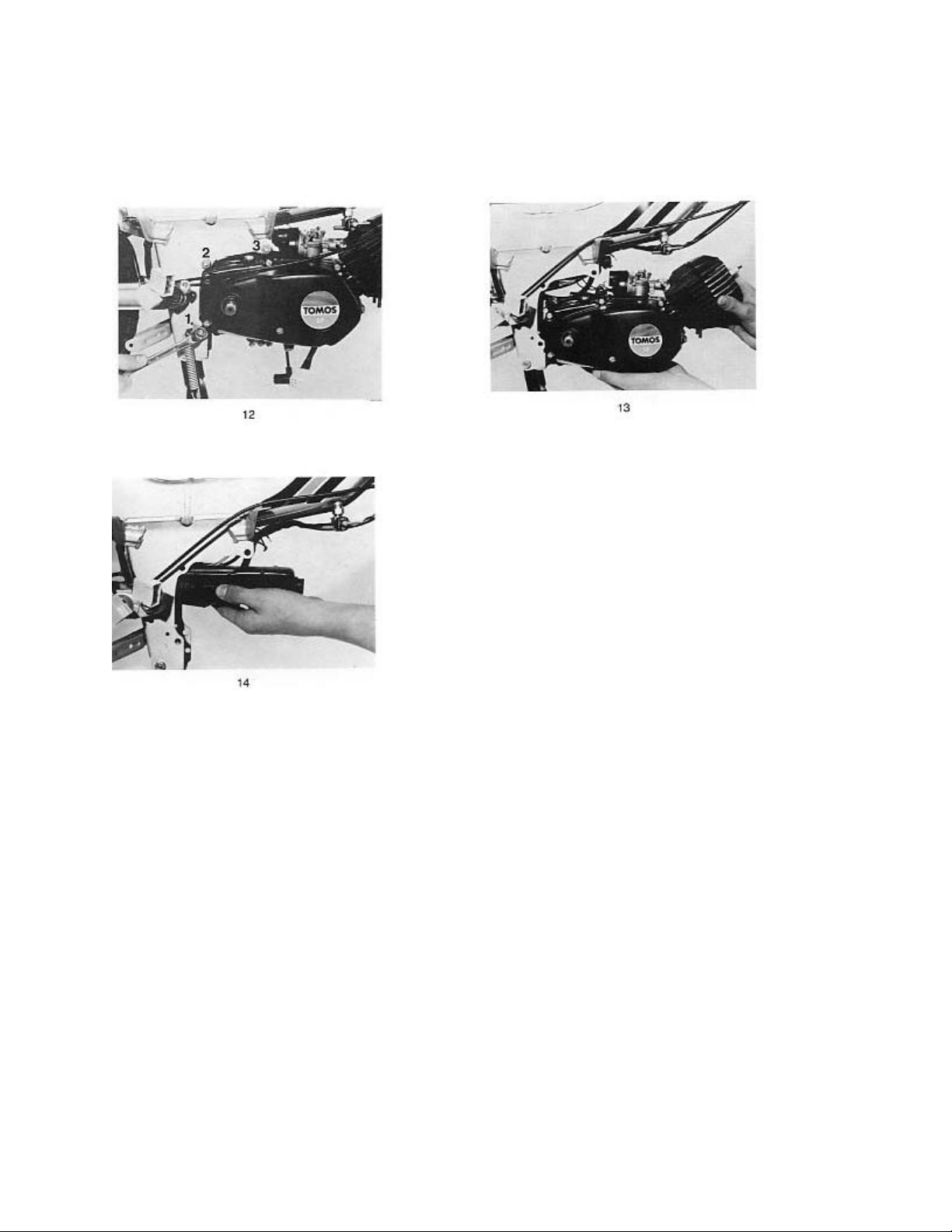

Unscrew all three engine screws with two 13mm

wrenches (fig 12)

Take the intake silencer out of the frame (fig 14)

Hold the engine by hand. Extract top screw (3) and

remove the engine out of the frame (fig 13)

7

Page 8

Classic Cycles Technical Resources

ENGINE DISASSEMBLY

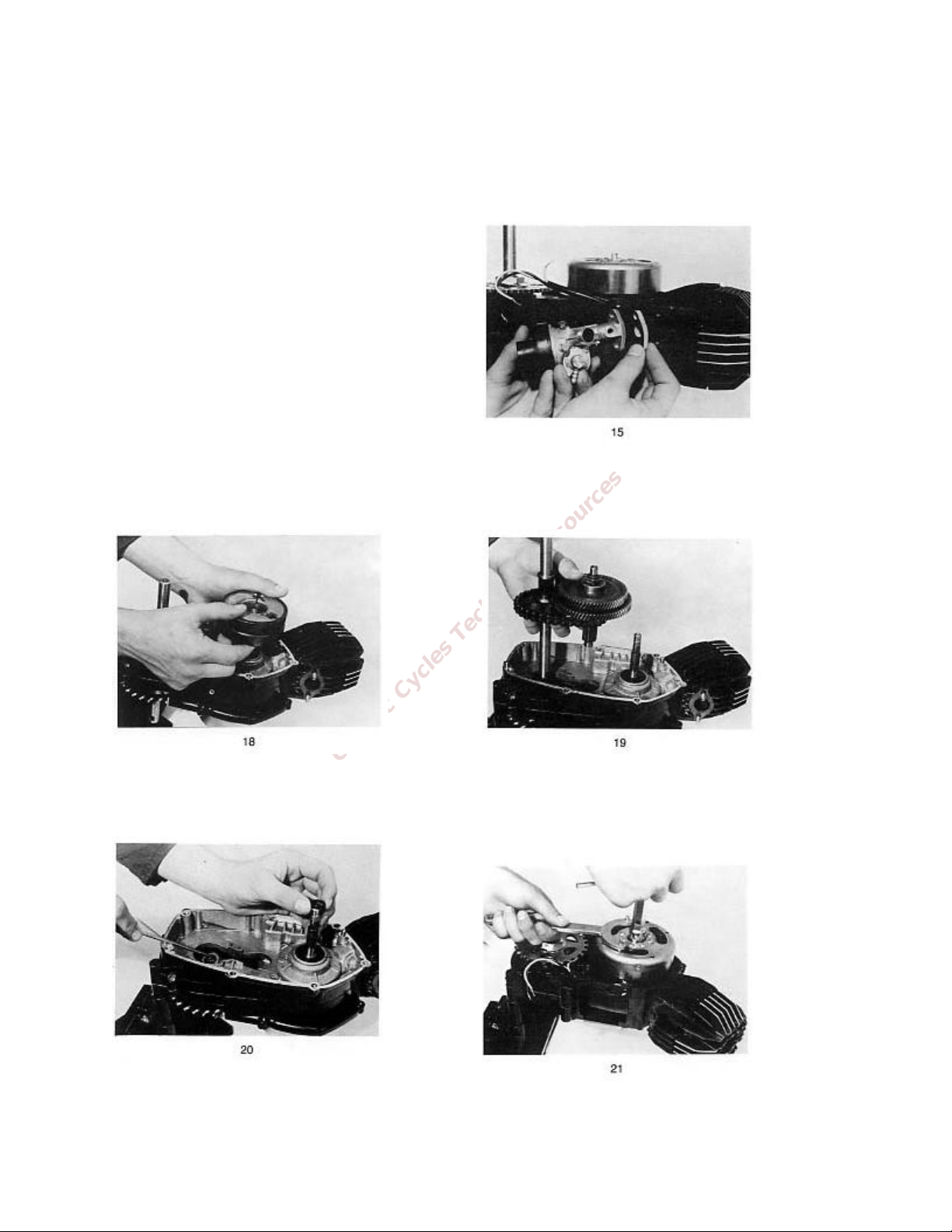

Rotate the engine placed on the stand so that the

Place the engine on the repair stand (special tool).

Remove the carburetor and spark plug (fig 15)

Detach clutch drum and sintered bush (fig 18)

Remove the standard washers on the crankshaft

and on the mainshaft (fig 20)

The pedal shaft and the countershaft are

connected by a starter chain, so both shafts will

have to be taken out together (fig 19)

flywheel magneto is on top. Using the flywheel

and clutch holding tool to hold the flywheel, use a

17mm socket to remove the flywheel nut (fig 21)

8

Page 9

The flywheel is removed with the flywheel puller,

a 19mm, and a 32mm wrench (fig 22)

Make a scriber mark across the bottom of the

stator plate and the crankcase in order to facilitate

the re-timing. Remove the 3 screws and lift the

stator assembly from the engine (fig 23)

Slacken the chain sprocket nut. Using the flywheel

and clutch holder tool and a 30mm wrench,

remove the sprocket nut (fig 24)

With pointed nose pliers, remove the gudgeon pin

spring circlips (fig 26)

Using an 11mm socket, unscrew the 4 cylinder

head nuts. Remove the washers, cylinder head,

cylinder, and base gasket (fig 25)

Press out the gudgeon pin and remove the piston

(fig 27)

9

Page 10

Classic Cycles Technical Resources

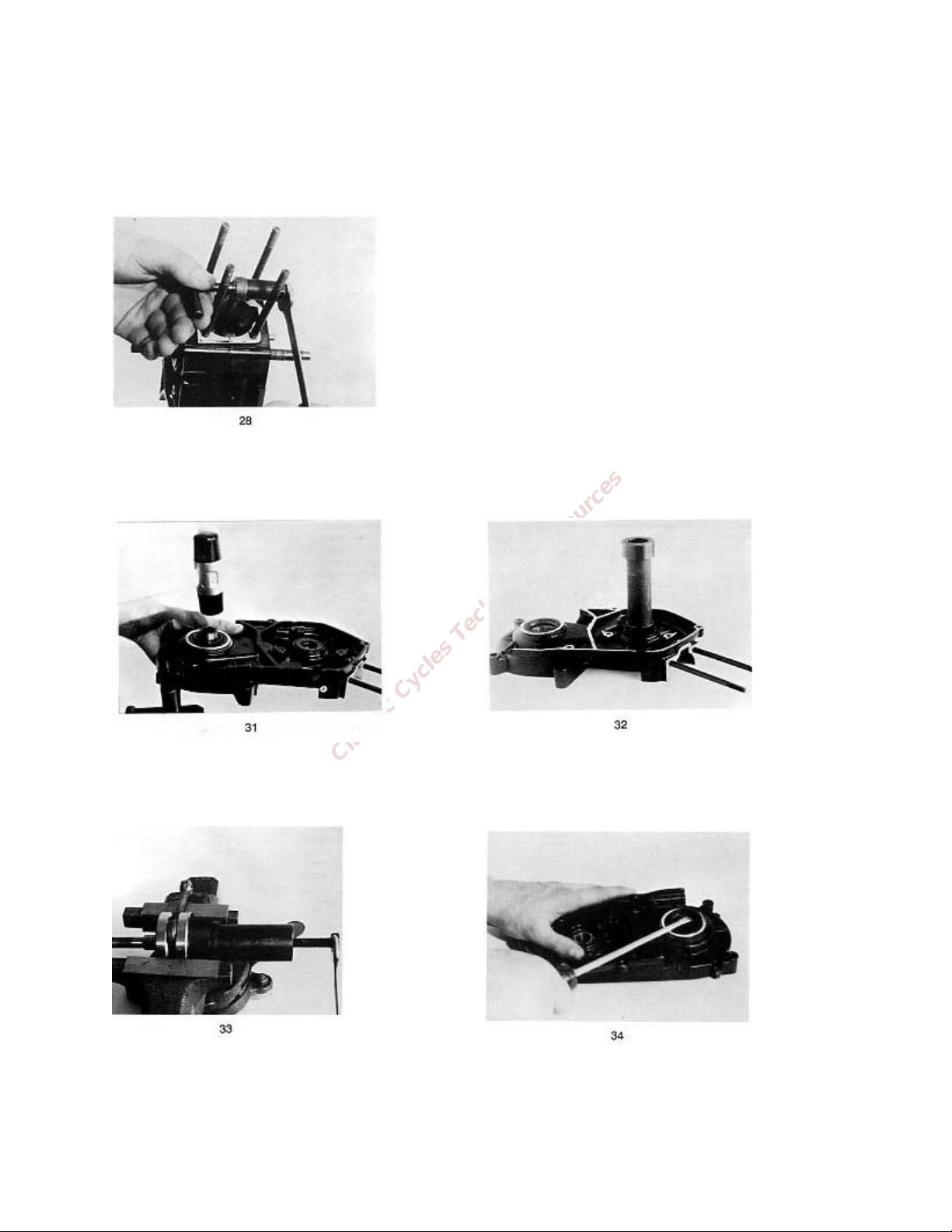

If the brass bushing in connecting rod needs to be

replaced, use the connecting rod bush pulling key,

and replace with a new one using same tool

(fig 28)

Upon installing the new bushing, drill two

lubrication holes according to the holes in the

connecting rod.

The bush as a spare part has inner diameter 9.80

+/- 0.1 mm and it is necessary to ream it out to

increase the inner diameter to 10mm.

Remove the crankshaft and gasket and knock out

the mainshaft (fig 31)

If the ball bearing remains on the crankshaft, use

the crankshaft bearings puller (fig 33)

In case the crankshaft ball bearing remains in the

RH crankcase, use the crankshaft bearings fitting

tool (fig 32)

The mainshaft sealing ring and ball bearing are

pressed out by using a suitable socket (fig 34)

10

Page 11

CHECKING ENGINE PARTS AND ASSEMBLIES

Figure 35

Figure 36

Check both crankcase halves for possible damages or distortions, particularly the joint surfaces, to avoid

later leaking of oil from the gearbox.

Check all bearings. If clearance is noticed, the bearings must be replaced.

Check the crankshaft between the center of a horizontal alignment tool and measure out-of-round on all

the points indicated in figure 35.

Permissible out-of-round should be within 0.01 mm at check pints 2 and 3 and 0.02 mm at check points

1 and 4. Check if the crankshaft conical part is damaged, inspect the thread on semiaxles and the

keyway.

Check piston surfaces for possible damages. With micrometer check piston diameter on points d1, d2,

d3 and d4 at right angles to gudgeon pin and compare the reading with the corresponding group on

piston and in the table (fig 36)

11

Page 12

Classic Cycles Technical Resources

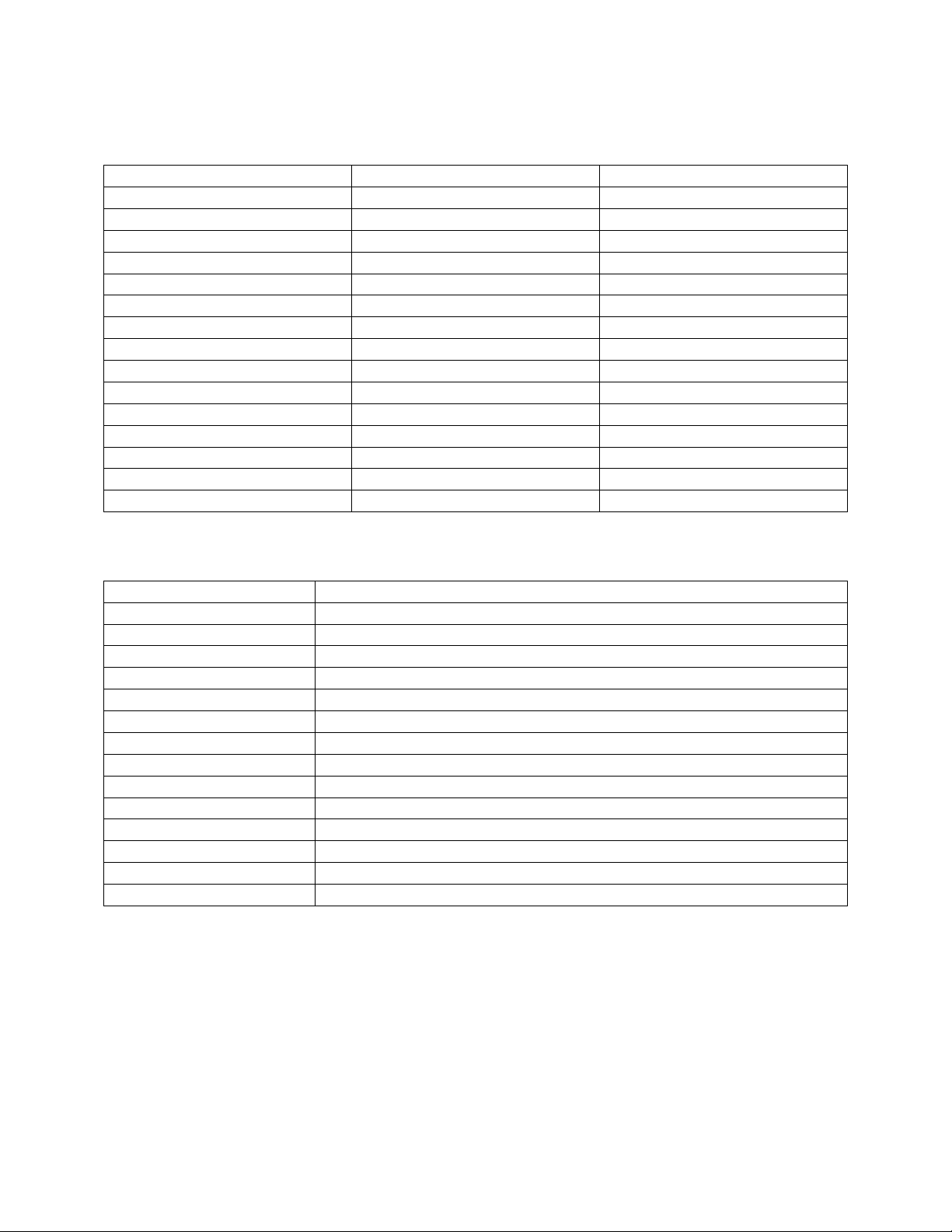

CYLINDER

D (mm, in)

A

B

38.01

+0.01

(1.4964

+0.0024

in)

38.02

+0.01

(1.4968

+0.0024

in)

D1

D2

D3

D4

A

37.95

+0.01

37.91

+0.01

37.87

+0.01

37.85

+0.01

B

37.96

+0.01

37.92

+0.01

37.88

+0.01

37.86

+0.01

D (mm, in)

A

B

38.51

+0.01

38.52

+0.01

D > D

max 0.012 mm

1

Ma x permissible bore taper: 0.006mm

PISTON

L = 50 mm

L= 52.5 mm

L = 55 mm

Piston I. oversize: Ø 38.50mm

The cylinder must be bored and honed as shown in the table:

OVERSIZE CYLINDER

12

Page 13

CHECKING, DISMANTLING, AND ASSEMBLING OF THE CLUTCH

Remove the circlip and separate the 1st and 2nd

Dismantle both clutches. The spring is removed

In this manner, brake strips are released, and all

Press pins out of shoes and check brake strips,

Fix the main pin of the clutch spring fitting tool

To assemble the 2nd speed clutch, turn the device

speed clutches (fig 37)

three shoes can be removed (fig 39)

with a screwdriver (fig 38)

spring inside of shoes and 2nd speed clutch gear. At

first, assemble the 1

st

speed clutch as reversed

order of dismantling. Particular care should be

taken of brake shoes; they must protect each

other from falling out (fig 40)

with the thinner part facing upwards. The spring

joint must be placed in the middle of one shoe.

With the lever of the device, insert the spring into

the shoes groove (fig 41)

over. The clutch hub with gear must be placed in

the way the gear is on the bottom and the gap

between the two shoes fits with the pin. The

manner of mounting the spring is the same as

mentioned before for the 1

st

speed clutch (fig 42)

13

Page 14

Classic Cycles Technical Resources

Dismantling of the needle clutch is necessary only in case of replacement. A new needle clutch is

pressed with special tool “roller clutch installer.” The needle clutch must be pushed with the signed side

towards the center of the clutch drum, or else it may operate in the reverse direction (fig 43)

14

Page 15

DISMANTLING, CHECKING, AND ASSEMBLING OF THE COUNTERSHAFT

Fix the countershaft into a vice and unscrew the

nut with a 19mm wrench (fig 44)

Remove the circlip at the shaft’s toothing (fig 46)

Remove the 2nd speed gear (fig 45)

Unfasten the wire spring and separate a small

chain sprocket with roller cage (fig 47)

Remove the 1

out (fig 48)

st

speed gear and shake the rollers

If troubles appear in the self-locking clutch,

consisting of rollers with 1

st

speed gear hub,

possible damage of the countershaft may be

repaired by grinding the bearing surface for

0.1mm at the most. When most rollers make small

hollows in the hub, the latter can be honed. If

hollows are rather large, the gear should be

replaced.

15

Page 16

Classic Cycles Technical Resources

Reassemble the countershaft in reverse order of

dismantling.

Put the chain sprocket in with cage so that the

Use of grease is not suggested because it may

impede the function of the self-locking clutch.

beginning of the wire spring is turned 90 degrees

left-ward from the spring nose (fig 49). Lock the

wire spring to riveted nose on the 1

st

speed gear

16

Page 17

CHECKING PEDAL SHAFT (kickstart) AND TRANSMISSION CHAIN

If it is necessary to replace the chain sprocket or claw collar on the pedal shaft or kick start, first rmove

the protective ring (fig 50/1) and the spring washer (fig 50/2). During assembly, take care that the

thinner part of the collar is mounted forward or else the brake spring will slide across the chain

sprocket. Check the chain for overtensioning or other damage. In case of damage, the needle bearings

in the main shaft should be replaced with a new complete main shaft (fig 51)

17

Page 18

Classic Cycles Technical Resources

CARBURETOR CHECKING

Dismantle the carburetor into component parts (fig 52 Encarwi or 52a Dellorto). Clean the parts with

carb cleaner and blow them out with compressed air. Check the parts. In case of wear throttle slide or

leakage of float, replace with a new one. When reassembling the carburetor, take care that the float

needle fits the float chamber cover. Slightly oil the air filter with light oil.

FIGURE 52 – ENCARWI CARBURETOR

18

Page 19

FIGURE 52a – DELLORTO CARBURETOR

19

Page 20

Classic Cycles Technical Resources

REASSEMBLING THE ENGINE

When reassembling the engine, replace all seals

With the crankshaft bearings fitting tool, press the

Insert the crankshaft into the LH half of the

Place the mainshaft and a washer on the

Join the right crankcase with the left one, acting as

With the crankshaft bearings fitting tool, insert

and gaskets. All parts of the engine should be

thoroughly cleaned and lightly oiled. All gaskets

should be given a light coat of grease to insure

better fit and seal.

crankcase using the splitter. Through the splitter,

screw the device on the crankshaft. With an 11mm

and a 24mm wrench, place the crankshaft in the

crankcase (fit 54)

crankshaft ball bearings into both crankcase halves

(fig 53)

mainshaft needle bearing. Insert the fork between

the two halves of the crankshaft (fig 55)

follows: (1) Press the two crankcases by hand and

then lightly tap them together with a mallet

(2) Insert the 6 screws in the inner holes and 2 in

the outer holes. Slowly tighten the screws (fig 56)

both crankshaft seal rings.

WARNING: The LH carter seal ring is facing

towards the connecting rod, while the RH side is

opposite.

20

Page 21

Check that the crankshaft turns freely. Insert pedal

shaft or kick shaft together with countershaft and

The claw collar brake spring must seat in the

chain (fig 57)

recess in the RH half of the crankcase. Place

washer 209.005 and bush 209.072 on the

crankshaft (fig 58)

Incorporate the clutch drum with mounted 2nd

speed clutch (fig 59)

Incorporate 1st speed clutch and protective

washer. With the flywheel and clutch holding tool,

lock the nut with a 19mm wrench. Torque to

25Nm. Clearance between shoes and clutch drum

rim is approx. 0.4 mm. Axial clearance of the clutch

drum is from 0.1 mm to 0.3 mm by means of

inserting the adjusting thrust washer of 0.3 mm or

0.5mm under the clutch (fig 61)

Handle the roller clutch carefully and if it is

necessary, turn the drum only counterclockwise

(direction of free rotation). Place the trust washer

under the clutch (fig 60)

21

Page 22

Classic Cycles Technical Resources

Before securing the nut with washer, it is

necessary to check the proper function of the

sprocket with the flywheel and clutch holding tool.

assembly. Firmly hold the 2

with the left hand and the clutch drum with the

right hand. When the clutch drum rotates

counterclockwise, both clutches idle. When it

rotates clockwise, the motion is transmitted to the

crankshaft (fig 62)

nd

speed driven gear

Fit the gasket and cover and tighten 7 screws with

torque of 10Nm (fig 63)

Make sure the piston rings are installed properly

by aligning them with the stationary pins mounted

in the ring grooves of the piston. Compress the

piston rings and mount oiled cylinder (fig 65)

Turn the engine on the stand 90 degrees. Clean

residue of crankcase gasket. Mount the piston so

that the arrow sign on the top of the piston is

facing the exhaust side of the cylinder (fig 64)

Mount the cylinder head, washers, and nuts.

Tighten them in an X pattern, torque to 12 Nm.

Turn the engine so that the magneto flywheel side

is on top. Install the stator base plate. If necessary,

slightly oil the felt inset piece of the base plate.

When mounting the magneto flywheel, take care

when positioning it. The groove on the flywheel

hub and the woodruff key on the crankshaft must

coincide. Fit the washer and nut, lock the flywheel

with the flywheel and clutch holding tool, and

tighten the nut to a torque of 30 Nm.

Place the distance bush, chain sprocket, and

protective washer on the main shaft and tighten

the nut with a 30 mm wrench. Lock the chain

22

Page 23

ADJUSTING THE CONTATCT GAP AND IGNITION ADVANCE

These two operations are interrelated and proceed as follows.

-Screw the dial gauge support tool and the dial gauge into the spark plug hole.

-By rotating the flywheel, put the piston at TDC and set the dial gauge to zero.

-The breaker points are fully open at TDC. Check and if necessary, reset the gap between 0.35 and 0.45

mm (fig 66)

-Rotate the flywheel in the clockwise direction until the breaker points connect. With a test light, buzzer

or Ohm meter, determine when a connection is made. The testing device must be connected to the

short circuit (black) wire and to the ground of the engine (fig 67)

-At the moment of connection of the points, the test battery light will glow brightly, the buzzer will

change the acoustic frequency, or the Ohm meter will show approximately zero Ohms. On the dial

gauge, read off the value in mm of the ignition advance which must be from 1.8 to 2 mm BTDC.

-In case of excessive advance, the stator base plate should be rotated in the direction of engine rotation

(see arrow on flywheel). In case of insufficient advance, turn the plate in the opposite direction.

23

Page 24

Classic Cycles Technical Resources

OIL PUMP

Note: When fitting the magneto cover on oil pump

cut off, which may lead to breakdown of the unit.

After assembly or repair of models with oil pump, you must keep to the following instructions

The pump is connected to the magneto nut on the

crankshaft by a special clutch (fig 68)

Pour approximately 1 liter gas mixture in the ratio

of 50:1 (2% oil) into the fuel tank and start the

engine. Let the engine run for about 5 minutes so

as to make the oil pump push oil into the engine.

Fill up the tank with regular gas.

Unscrew the bleed screw on the oil pump and wait

until oil from the tank under the seat flows to the

pump. The screw is then screwed on (fig 69)

Ensure that the oil level in the oil tank does not fall

under the marking MIN (fig 70). Pay special

attention to the routing of the oil lines to and from

the oil pump. If the outflow line is crimped, oil will

not reach the carburetor, causing engine damage.

models, make sure the oil pump seat axis lines up

with the crankshaft axis. Use the centering pin

attached to the magneto cover (fig 71) for this

purpose. When the center has been found, push

the cover by hand onto the crankcase (which is

made possible by the spring in the centering tool)

and fix the cover by screwing it down.

Major deviations from the center result in the

clutch damage, and this, in turn, causes the oil

pump drive stoppage. The lubrication of the

cylinder, piston, and crankshaft of this unit is thus

24

Page 25

MAGNETO SETTINGS AND ELECTRICAL EQUIPMENT

The voltage regulator should be checked when bulbs blow frequently. During the check, the engine

should be operating and the lights switched off-on, alternatively. The voltage should always read 12+/-

0.5 V. Before replacing the regulator, make sure the improper operation is not due to bad grounds.

The direction indicator relay should be checked within the wiring system. Previously check the bulbs

and direction indicators switch.

The STOP switch should be checked by a pilot bulb or OHM-meter. When replacing the switch, make

sure the new one is identical to the replaced one wince there are two types of STOP switches (those that

are switched on in neutral position, and those that are switched off in neutral position)

Electric wiring and combination switches are checked according to the wiring diagram. Check the

magneto components both within the wiring system and separately.

The flywheel should be checked by visual inspection for mechanical damage and proper cone fit. Check

deflection by help of the crankshaft. The maximum permissible axial deflection amounts to 0.1 mm and

radial deflection to 0.3 mm.

To check the capacitor it should be separated from other electrical components of the magneto. Check

the capacitor capacitance by means of a capacitance meter and the ability of the capacitor to retain an

electric charge.

NOTE: Caution is recommended in handling the non-insulated parts since there is a possibility of an

electric shock. The capacitor should, therefore, be discharged by connecting the two contacts.

Contact breaker: check the contacts and the cam nose for wear. Insert insulating mass between the two

breaker contacts and by an OHM-meter make sure the parts are electrically disconnected (there exists a

possibility of uncture on the bearing bush or fixing bolt insulation)

The ignition coil both external and internal can only be checked if a special mototester is available. The

checking procedure is laid down by the manufacturer of this device. If this is not available, a possible

fault can be established by replacing a truly good sample coil for the existing coil.

The lighting coil should be checked with engine in operation (2000-3000 RPM). To check the coil, use a

voltmeter and an approximate bulb of the same rated power (W) as the magneto.

25

Page 26

Classic Cycles Technical Resources

26

Page 27

27

Page 28

Classic Cycles Technical Resources

28

Page 29

29

Page 30

Classic Cycles Technical Resources

te

Yellow

Brown

Black

Brown

Whi

30

Page 31

MOTORCYCLE PARTS & ACCESSORIES

Tomos Motorcycle History & Technical Specifications

Motorcycle Parts & Accessories

Dirt Bike Parts & Accessories

Harley Davidson Parts & Accessories

Motorcycle Helmet Closeout Sale

Japanese Motorcycle Original Equipment Parts

Save On All Motorcycle Tires

Motorcycle Jacket Closeout Sale

High Visibility Motorcycle Safety Gear

Cycle Gear – Free Shipping

Women's Motorcycle Riding Gear

Free Shipping On All Motorcycles

Save Up To 80% On All Car Parts

Loading...

Loading...