Tomco DE89RB100-US, HP-200, HP-500, DE89RB- 1000, HP-1000 Operation & Maintenance Manual

...

CARBON DIOXIDE

DRY ICE PELLETIZER

OPERATION &

MAINTENANCE

MANUAL

ii

CARBON DIOXIDE

DRY ICE PELLETIZER

OPERATION & MAINTENANCE MANUAL

Copyright © 1998 by TOMCO2 EQUIPMENT COMPANY

All rights reserved. No part of this document

may be reproduced by any means without

the written permission of TOMCO

Revision 8– Add Ice behind piston problem to page 5.4

EQUIPMENT COMPANY.

2

January 14, 2003

TOMCO2 EQUIPMENT COMPANY

3340 Rosebud Road

Loganville, Georgia 30052 USA

Telephone

(770) 979-8000 • Toll Free in the U.S. (800) 832-4262

Fax

(770) 985-9179

Parts & Service Fax

(770) 979-2514

E-Mail

tomco@tomcoequipment.com

Internet

http://www.tomcoequipment.com

iii

iv

TABLE OF CONTENTS

Section 1 - Introduction ................................................................................... 1.0

Tomco2 Equipment Company Carbon Dioxide Dry Ice Pelletizers ......................... 1.1

Understanding Carbon Dioxide .............................................................................. 1.2

Learning More About Carbon Dioxide .................................................................... 1.5

Specifications ........................................................................................................ 1.7

Section 2 - Carbon Dioxide Safety .................................................................. 2.0

General Safety Considerations .............................................................................. 2.1

Rescue .................................................................................................................. 2.2

Inhalation First Aid ................................................................................................. 2.2

Exposure First Aid ................................................................................................. 2.2

Section 3 - Installation ..................................................................................... 3.0

Section 4 - Operation & Maintenance ............................................................. 4.0

Manual Operation ................................................................................................. 4.1

Automatic Operation .............................................................................................. 4.2

Maintenance .......................................................................................................... 4.4

Section 5 - Troubleshooting ............................................................................ 5.0

Section 6 - Repair & Adjustments ................................................................... 6.0

Section 7 - Appendix ........................................................................................ 7.0

Glossary ................................................................................................................ 7.1

References ............................................................................................................ 7.2

Warranty ................................................................................................................ 7.3

Replacement Parts & Ordering Information ........................................................... 7.4

Cus t omer Questionnaire ........................................................................................ 7.16

Drawings

v

vi

SECTION

1

INTRODUCTION

1.0

INTRODUCTION

TOMCO2 EQUIPMENT COMPANY CARBON DIOXIDE DRY

ICE PELLETIZERS

Tomco2 has been a CO2 equipment specialist for over thirty years. Tomco2 manufactures Urethane Insulated CO

CO

ISO Containers, CO2 Particle Filters, CO2 Vaporizers, CO2 Pumps, CO2 Clean-

2

ing Systems, and CO

Tomco

offers a 24-hours a day, 365 days a year, Parts and Service Department. The

2

Water Treatment Systems.

2

Storage Units, Vacuum Insulated CO2 Storage Units,

2

telephone number is 800-832-4262 (toll free in the U.S.) or 770-979-8 000.

Our dry ice pelletizers are available in models capable of producing from 100

hour to 3000 lbs/hour of dry ice pellets. These units are made of the highest quality

lbs/

materials and workmanship.

Thank you for purchasing our CO

dry ice pelletizers, and if we can be of service to

2

you, please contact us.

1.1

INTRODUCTION

UNDERSTANDING CARBON DIOXIDE

Carbon dioxide is a chemical compound formed by combining one atom of carbon

with two atoms of oxygen, and is expressed by the molecular formula CO

. Carbon

2

dioxide can exist in any one or all three states of matter: solid, liquid, and/or vapor;

depending on conditions of temperature and pressure.

Under normal atmospheric conditions, carbon dioxide exists as a colorless, odorless

gas which is about 1.5 times heavier than air. Carbon dioxide will not burn or

support combustion and will not sustain life.

When confined within a suitable pressure vessel, carbon dioxide can exist in any of

three states of matter depending on conditions of temperature and pressure. The

point at which all three states may exist in equilibrium is -69.9

o

F (-56.6 oC) and 60.4

psig (4.2 bar). This is called the triple point. At temperatures and pressures

lower than the triple point, carbon dioxide may be either a solid or a vapor, again

depending on conditions. Dry ice (solid carbon dioxide), at a temperature of -109.3

o

F (-78.5 oC) at atmospheric pressure, sublimes (transforms directly from solid into

vapor without the formation of a liquid).

o

The critical point of carbon dioxide is 87.9

At temperatures and pressures greater than 87.9

F (31.1 oC) and 1070.6 psig (73.8 bar).

o

F (31.1 oC) and 1070.6 psig (73.8

bar), carbon dioxide cannot exist as a liquid. At pressures and temperatures greater

than the critical point, carbon dioxide exist s onl y as a supercritical fluid.

At temperatures and pressures above the triple point and below the critical point,

carbon dioxide liquid with overlying vapor may exist in equilibrium within a closed

vessel. Within this range, there is a definite relationship between te mperature,

pressure, and density.

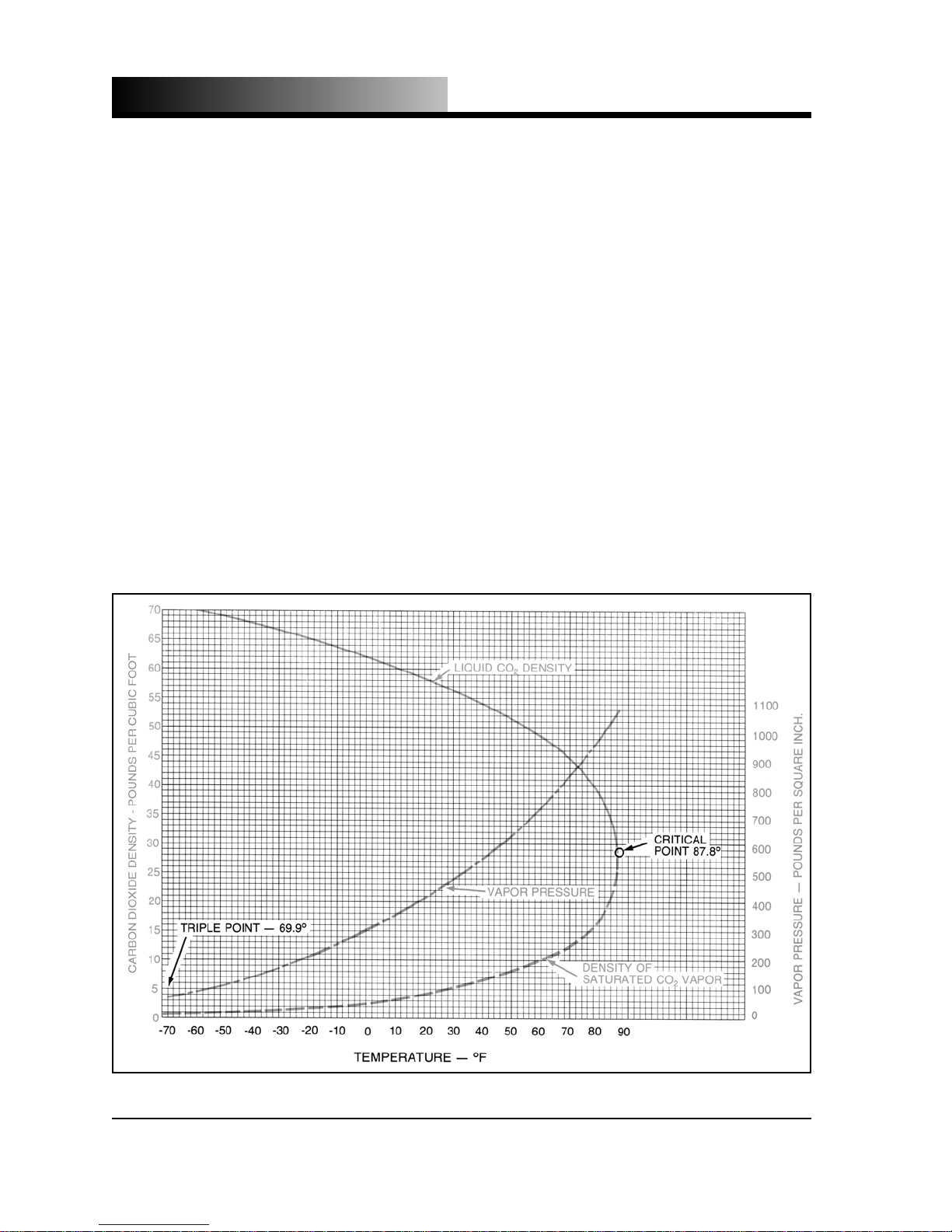

By following the vapor pressure curve in Figure 1.1 on page 1.3, it becomes obvious

o

that if you desire to store liquid carbon dioxide at 70

F (21.1 oC), the pressure vessel

would have to be bui lt to withs t and pressures of around 840 psig (57.9 bar). By

1.2

INTRODUCTION

following the liquid dens ity curve, one finds that the liquid becomes less dense as the

temperature increases and at 70

per cubic foot (754 kg/m

3

).

By comparing the pressure and liquid density at 70

bar) and 47.6 pounds per cubic foot (764 kg/m

o

F (-17.8 oC) [291.1 psig (20.1 bar) and 63.65 pounds per cubic foot (1022 kg/m3)],

0

it is obvious that relatively large quantities of carbon dioxide liquid can be stored in

relatively small, thin walled pressure vessels; hence low-pressure bulk storage of

CO

.

2

The term "low-pressure" is used in the industry to describe the storage of carbon

dioxide at low temperatures below ambient, usually around 0

relative term and should not be taken literally, as the pressures involved range up to

approximately 350 psig (24.1 bar).

o

F (21.1 oC), the liquid density is around 47 pounds

o

F (21.1 oC) [837.8 psig (57.8

3

)] with the pressure and density at

o

F (-17.8 oC). It is a

Fig. 1.1 - Carbon Dioxide Density & Vapor Pressure Curves

1.3

INTRODUCTION

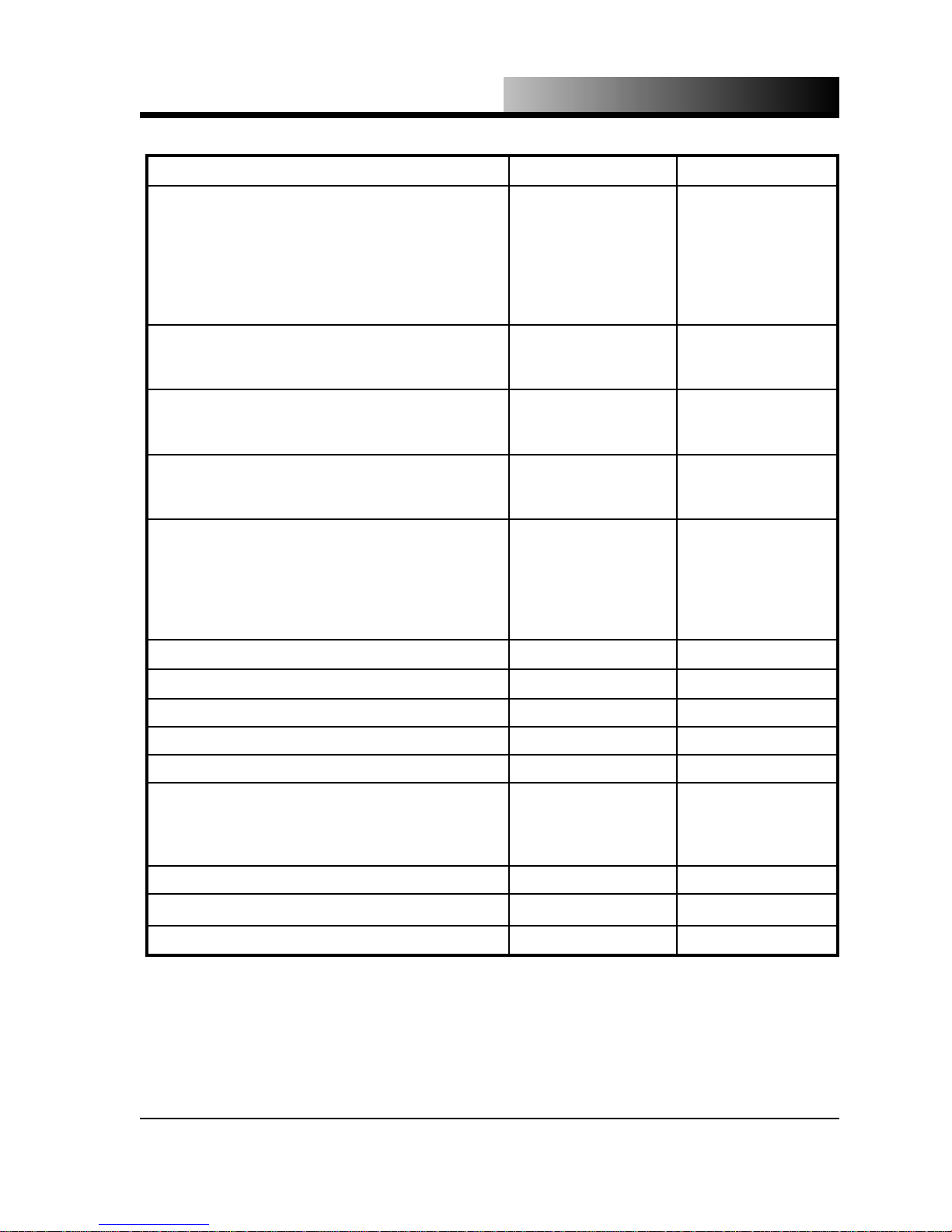

Molecular Weight 44.01 lb/lb-mol 44.01 kg/kg-mol

Vapor Pressure

at 70 °F (21.1 °C)

at 32 °F (0 °C)

at 2 °F (-16.7 °C)

at -20 °F (-28.9 °C)

at -69.9 °F (-56.6 °C)

at -109.3 °F (-78.5 °C)

Density of the gas

at 70 °F (21.1 °C)

at 32 °F (0 °C)

Specific gravity of the gas

at 70 °F (21.1 °C)

at 32 °F (0 °C)

Specific volume of the gas

at 70 °F (21.1 °C)

at 32 °F (0 °C)

Density of liquid, saturated

at 70 °F (21.1 °C)

at 32 °F (0 °C)

at 2 °F (-16.7 °C)

at -20 °F (-28.9 °C)

at -69.9 °F (-56.6 °C)

838 psig

491 psig

302 psig

200 psig

60.4 psig

0 psig

0.1144 lb/ft

0.1234 lb/ft

1.522

1.524

8.741 ft

8.104 ft

47.6 lb/ft

58.0 lb/ft

63.3 lb/ft

66.8 lb/ft

73.5 lb/ft

3

3

/lb

/lb

3

3

3

3

3

57.79 bar

33.86 bar

20.83 bar

13.79 bar

4.17 bar

0 kPa

3

3

1.833 kg/m

1.977 kg/m

3

3

1.522

1.524

0.5457 m

0.5059 m

764 kg/m

931 kg/m

1016 kg/m

1072 kg/m

1179 kg/m

3

/kg

3

/kg

3

3

3

3

3

Sublimation temperature (1 atm) -109.3 °F -78.5 °C

Critical temperature 87.9 °F 31.1 °C

Critical pressure 1070.6 psig 73.81 bar, abs

Critical density 29.2 lb/ft

3

468 kg/m3

Triple point -69.9 °F at 60.4 psig -56.6 °C at 4.16 bar

Latent heat of vaporization

at 32 °F (0 °C)

at 2 °F (-16.7 °C)

at -20 °F (-28.9 °C)

100.8 Btu/lb

119.0 Btu/lb

129.6 Btu/lb

234.5 kJ/kg

276.8 kJ/kg

301.4 kJ/kg

Latent heat of fusion at -69.9 °F (-56.6 °C) 85.6 Btu/lb 199 kJ/kg

Density of liquid at 2 °F (-16.7 °C) 63.3 lb/ft

3

1015.9 kg/m3

Latent heat of sublimation at -109.3 °F (-78.5 °C) 245.5 Btu/lb 571.0 kJ/kg

Table 1.1 - Physical Constants of Carbon Dioxide

1.4

INTRODUCTION

LEARNING MORE ABOUT CARBON DIOXIDE

An important part of maintaining a carbon dioxide dry ice pelletizer is understanding

the properties of CO

. Therefore, maintenance and service of your pelletizer should

2

be performed only by a qualified carbon dioxide equipment technician.

To start or increase your knowledge of carbon dioxide, we recommend that you begin with the pamphlets and literature from the CGA (Compressed Gas Association).

The CGA has a number of pamphlets and videos on CO

and CO2 equipment.

2

We recommend:

G-6 Carbon Dioxide

G-6.1 Standard for Low Pressure Carbon Dioxide Systems at Consumer S ites

G-6.4 Safe Transfer of Low Pressure Liquefied Carbon Dioxide in Cargo Tanks,

Tank Cars and Portable Containers

AV-7 Characteristics and Safe Handling of Carbon Dioxide

The CGA has other publications, vi deos, etc. that pertain to the CO

and CO2 equip-

2

ment. Contact the CGA for a list of available publications at:

Compressed Gas Association

1725 Jefferson Davis Hwy.

Suite 1004

Arlington, VA 22202-4102 USA

Phone: (703) 412-0900

1.5

CARBON DIOXIDE DRY ICE PELLETIZER

INTRODUCTION

SPECIFICATIONS

METHOD OF OPERATION: The dry ice Pelletizer consists of a system for

injecting liquid CO

into a compression cylinder. The process of reducing the

2

pressure on the liquid from approximately 300 psi (20.68 bar), below the Triple

Point, to atmospheric pressure causes about 40% of the carbon dioxide to

change to a solid. The remaining carbon dioxide changes to a vapor and is

vented from the machine. Finally, the solid is hydraulically extruded through

a die to form dry-ice pellets. These pellets can range in size from 0.114” (2.9

mm) to 3/4” (19.05 mm) diameter. The LB-450 disk press has an extra step

that takes the extruded pellets and forms them into a disk 4” (101.6 mm) in

diameter by 1/2” (12.7 m m) thick.

HYDRAULIC SYSTEM:

• High oil temperature automatic shut-off (greater than 150 ºF (65.5 ºC))

• Low oil level automatic shut-off

• High pressure relief valve (see Tabl e 1.2 on page 1.7 for actual setting of

each model

ELECTRICAL: Available to meet electrical requirements worldwide

(Capacities may vary due to frequency variation.)

FEATURES:

• U.S.D.A (United States Department of Agriculture) approved

• Automatic (unattended) operat ion

1.6

INTRODUCTION

High

Capacity

LB-450

1500

HP-1000 DE89RB-

1000

57 3/4”

(146.7cm)

46"

(116.8 cm)

50"

(127.0 cm)

46"

(116.8 cm)

46"

(116.8 cm)

128 7/8”

(327.3cm)

78"

(198.0 cm)

118"

(300 cm)

117"

(297.2 cm)

117"

(297.2 cm)

93”

79"

81"

84"

81"

8000 lbs

(236.2cm)

2500 lbs

(201 cm)

5018 lbs

(206.0 cm)

4000 lbs

(213.4 cm)

3700 lbs

(206.0 cm)

(3636 kg)

40 seconds

per cylinder

(1136 kg)

(2280 kg)

(1818 kg)

(1682 kg)

per disc

8 seconds

per cylin-

40 seconds

55 seconds

per cylinder

55 seconds

per cylinder

2

der

50 hp

(37.3 kW)

15 HP

(11.2 kW)

25 HP

(18.6 Kw)

25 HP

(18.6 kW)

20 HP

(15 kW)

ters)

(832.7 li-

220 gallons

(455 liters)

120 gallons

(455 liters)

120 gallons

(455 liters)

120 gallons

(455 liters)

120 gallons

4000psi

(276 bar)

(152 bar)

2200 psig

3000 psig

(206.8 bar)

3000 psig

(206.8 bar)

3000 psig

(206.8 bar)

HP-500 DE89RB-

46"

46"

500

117"

(116.8 cm)

117"

(116.8 cm)

HP-200 DE89RB-

MODEL DE89RB-

40"

40"

100-US

WIDTH

40"

(101.6 cm)

40"

(101.6 cm)

LENGTH

84"

(297.2 cm)

81"

(297.2 cm)

60"

(101.6 cm)

60"

(101.6 cm)

HEIGHT

3200 lbs

(213.4 cm)

2770 lbs

(206.0 cm)

945 lbs

(152.4 cm)

945 lbs

(152.4 cm)

APPROX.

(1455 kg)

55 seconds

(1256 kg)

55 seconds

(429 kg)

43 seconds

(429 kg)

25 seconds

WEIGHT

CYCLE TIME

per cylinder

per cylinder

per cylinder

1 2 1 1 2 2 2 3

per cylinder

CYLINDERS

NUMBER OF

25 HP

(18.6 kW)

15 HP

(11.2 kW)

7.5 HP

(5.6 kW)

7.5 HP

(5.6 kW)

MOTOR

(455 liters)

120 gallons

(455 liters)

120 gallons

35 gallons

(133 liters)

35 gallons

(133 liters)

HYDRAULIC

OIL CAPACITY

3000 psig

(206.8 bar)

3000 psig

(206.8 bar)

Table 1.2 - Dry Ice Pelletizer Dimensional Data

(186 bar)

2700 psig

(186 bar)

2700 psig

RELIEF

PRESSURE

HYDRAULIC

1.7

SECTION

2

CARBON DIOXIDE

SAFETY

2.0

CARBON DIOXIDE SAFETY

The text in this section has been adapted from CGA (Compressed Gas Association)

publication CGA G-6 – 1984: Carbon Dioxide

.

GENERAL SAFETY CONSIDERATIONS

Gaseous carbon dioxide is an asphyxiant. Concentrations of 10% or more ca n produce unconsciousness or death. Lower concentrations may cause headache, sweating, rapid breathing, increased heart rate, shortness of breath, dizziness, mental depression, visual disturbances, and shaking. The seriousness of the latter manifestations is dependent on the concentration of carbon dioxide and the length of time the

individual is exposed.

Carbon dioxide is an odorless gas and should be treated as a material with poor

warning properties. It is denser than air, and high concentrations can persist in open

pits, tanks, or low depressions on the terrain. Before entering such an area, carbon

dioxide monitoring should be carried o ut and the area cleared by forced venti l ati on,

or a self-contained, supplied air respirator should be worn.

Appropriate warning signs shoul d be affixed outside of those areas where high concentrations of carbon dioxide gas can accumulate. An example is shown below:

CAUTION - CARBON DIOXIDE GAS

Ventilate the area before entering.

A high CO

gas concentration

2

may occur in this area

and may cause suffocation.

2.1

CARBON DIOXIDE SAFETY

RESCUE

Do not attempt to remove the individual without utilizing proper rescue equipment or

you may also become a casualty. If the exposed person is unconscious, obtain assistance and put into effect the established emergency procedures.

INHALATION FIRST AID

Inhalation of gaseous carbon dioxide can adversely affect body function. Skin, eye,

or mouth contact with dry ice (solid carbon dioxide) or compressed carbon dioxide

can cause adverse effects.

If a person has inhaled large amounts of carbon dioxide and is exhibiting adverse effects, move the exposed individual to fresh air at once. If breathing has stopped, perform artificial respiration. Keep the affected person warm and at rest. Get professional medical attention immediately.

EXTERNAL EXPOSURE FIRST AID

Skin or mouth contact with dry ice or with vapor or liquid carbon dioxide discharged

from a container may result in frostbite, causing skin lesions or more serious injury

from deep freezing of the tissues.

If dry ice or compre ssed CO

the exposure immediately. If frostbite has occurred, obtain professional medical attention immediately. Do not rub the area. Do not apply heat warmer than 107 °F

(41.7 °C).

Eye contact with dry ice or compressed CO

Frostbite of the eye structure may also occur.

If dry ice or CO

vapor or liquid comes in contact with the eyes, stop the exposure

2

and obtain professional medical attention immediately.

vapor comes in contact with the skin or mouth, stop

2

should be considered as a corneal burn.

2

2.2

SECTION

3

INSTALLATION

3.0

INSTALLATION

INSTALLATION

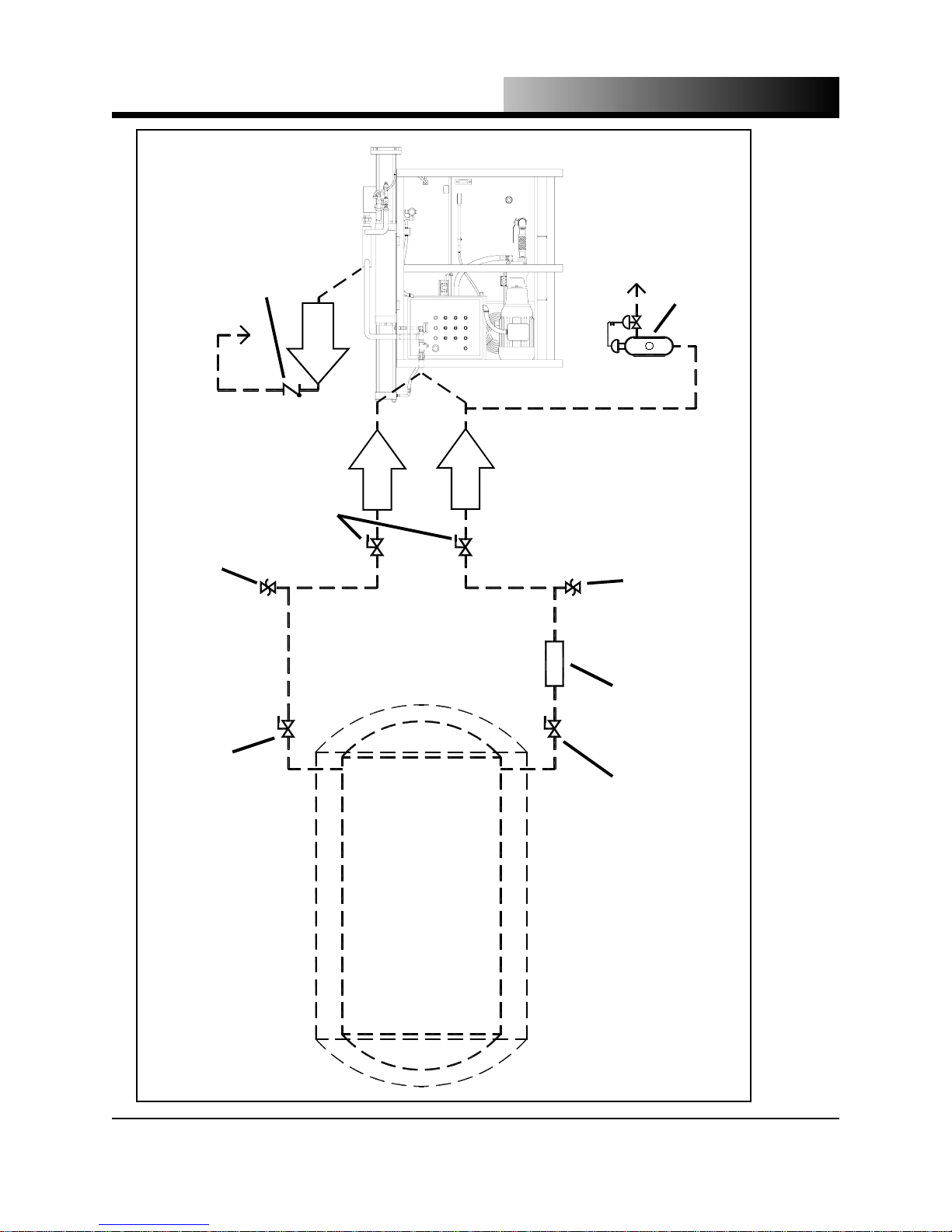

Following is the standard installation procedure for a Tomco2 Equipment Co. carbon

dioxide dry ice pelletizer. Note: This should be performed by a qualified carbon

dioxide equipment technician only. Refer to Figure 3.1 on page 3.3.

Note: A liquid CO

quired for satisfactory performa nce. Contact Tomco

pressure will be lower than 250 psig (17.23 bar). Contact Tomco

liquid CO

Dew point will be above –60°F (-51.1°C).

2

supply pressure of 250 to 300 psig (17.23 to 20.68 bar) is re-

2

Equipment Co. if liquid CO2

2

Equipment Co. if

2

1. Install an insulate d connecting line between the liquid process isolation valve on

the carbon dioxide storage unit and the 1” FNPT (1/2” on 100lb and 200lb machines) (1 1/2” on high capacity machines) connection on the rear of the pelletizer. We recommend that you use pre-insulated (2 1/2” (63.5 mm) urethane) 1

1/8” (1 5/8” on high capacity) Type K copper. However, 1” NPT (1 1/2” on high

capacity) schedule 80 seamless pipe can be substituted. Include in this line a core

type liquid CO

filter. We recommend a Sporlan Valve Co. model C-1449G for

2

1 1/8” copper or a Sporlan Valve Co. model C-1448P for 1” NPT pipe. Each of

these filters uses a single Sporlan Valve Co. core model RC-4864. (Filters are

available from Tomco

25’ (7.62 m). Tomco

Parts and Service.) This line should be no longer tha n

2

recommends the use of an automatic va por purge devic e

2

on any pelletizer that has more than 25’ (7.62m) of liquid supply piping. Contact Tomco

Equipment Co. if the installation will require more than

2

25’ (7.62m) of liquid supply pipi ng. The above is for a single machine opera tion.

If several machines are connected to the same liquid line, consider using sizes

larger than mentioned above.

Using an undersized liquid line will result in decreased production.

2. Install a connecting line between the vapor process isolation valve on the carbon

dioxide storage unit and the 1/4” FNPT connection on the rear of the pelletizer.

The construction material of this line is not critical and is up to the installer’s discretion, but it must be approved for at least 350 psig (24.1 bar).

3.1

INSTALLATION

Note: If isolation valves are included in the connecting lines (steps 1 & 2),

you must install a safety relief valve between the optional isolation valve and

the liquid or vapor process isol ation valves at the storage unit in the event

that carbon dioxide becomes trapped between the two valves.

TRAPPING CARBON DIOXIDE IN A PIPE WITHOUT A SAFETY RELIEF VALVE CAN RESULT IN

A RUPTURE OF THE PIPE CAUSING SERIOUS

INJURY OR DEATH!

DANGER

3. Install a low-pressure check valve (no greater than 5 psi cracking pressure) on the

exhaust port of each heat exchanger and vent to the outdoors using either a flexible hose or suitable piping. Tomco

valves and piping if needed. Slope piping at least 1/4” per foot (20mm per me ter)

away from the pelletizer and include a downturn in the piping to prevent moisture

from entering the pelletizer.

Note: Forced air ventilation is not a sufficient means of removing carbon

dioxide vapor. The exhaust ports must be vented to the outdoors.

Parts and Service can supply the check

2

CARBON DIOXIDE IS AN ASPHYXIANT AND

WHEN RELEASED IN HIGH CONCENTRATIONS

AND IN CONFINED AREAS CAN CAUSE SUFFOCATION AND DEATH! CO2 VAPOR IS HEAVIER

THAN AIR AND WILL ACCUMULATE IN LOW AR-

DANGER

4. Fill the hydraulic fluid reservoir to the top of the sight glass with a good quality

hydraulic fluid (R ando HD68 or equal) with a fluid viscosity of 150-300 SUS

EAS OR DEPRESSIONS.

(ISO 32-68) @ 100 ºF (37.7 ºC).

3.2

INSTALLATION

Note: U.S.D.A. appr oved equipment must use a food grade hydraulic fluid

with similar properties (Citgo Clarion FG ISO 68 or equal).

5. Install conduit s uitable for four wires between the top right side of the control

panel (above the transformer) and the rear outer panel. Use wires that are the

same size or larger than the largest gauge wires in the control panel. Use clamp

type conduit bulkhead fittings with anti-chafe bushings.

6. Install three wires and a protective earth wire (see included electrical drawing for

wire size) from an appropriate power source through the conduit, leaving enough

wire inside the control panel to reach the top of the disconnect switch. Attach

the green protective earth ground wire to the ground terminal. Ground the pelletizer before use because static electricity can build up on the pelletizer under certain conditions.

Be sure that the power source is

WARNING:

turned off.

7. Strip the proper amount (as recommended by the ferrule manufacturer) of insulation from the wires and secure ferrules on the bare ends. Place ends in the terminals at the top of the disconnect switch (DIS-1) and tighten securely. Close the

control panel and be sure the disconnect switch (DIS-1) is off.

8. Turn on the power at the power source. Turn on the disconnect switch (DIS-1) at

the control panel and press the START button. Observe the rotation of the electric motor. If the motor rotates in the same direction as the reference arrow on

the motor, the electrical connections are correct.

9. If the motor rotates in the wrong direction, press the STOP button. Turn off the

disconnect switch (DIS-1) at the control panel and disconnect the power source.

Open the control panel and swap any two leads at the top of the disconnect

switch (DIS-1). Be sure to tight en the terminal connections securely.

3.3

INSTALLATION

VENT TO ATMOSPHERE

LOW-PRESSURE

CHECK VALVE

OPTIONAL

VENT TO

OUTDOORS

AND TURN DOWN

2

EXHAUST

CONNECT FROM

HEAT EXCHANGER

2

CONNECT TO

CONNECT TO

1/4” FNPT

1” FNPT

100LB and 200LB

use 1/2” FNPT High Capacity

use 1 1/2” FNPT

2

2

(P.N. 17001-CA)

OPTIONAL AUTOMATIC

VAPOR PURGE DEVICE

AVAILABLE FROM TOMCO

SAFETY RELIEF VALVE

SET AT 450 psig (31 bar)

NOT BY TOMCO

OPTIONAL ISOLATION

VALVES AT PELLETIZER

CONNECTIONS

NOT BY TOMCO

(REQUIRED IF OPTIONAL

(REQUIRED IF OPTIONAL

ISOLATION VALVE USED)

SAFETY RELIEF VALVE

2

FILTER

LIQUID CO

ISOLATION VALVE USED)

SET AT 450 psig (31 bar)

NOT BY TOMCO

(OPTIONAL)

VALVE & PIPING

Figure 3.1 - Typical Pelletizer recommended installation

VAPOR SUPPLY ISOLATION

MAXIMUM OAL 25’ (7.62 m)

LIQUID SUPPLY ISOLATION

CARBON DIOXIDE

STORAGE UNIT

VALVE & INSULATED PIPING,

3.4

SECTION

4

OPERATION

&

MAINTENANCE

4.0

OPERATION & MAINTENANCE

MANUAL OPERATION – SWITCH / PUSHBUTTON

CONTROLS

Note: Manual operation is not satisfactory for production purposes and should only

be used to check the pelleti z er for proper operation. For pelletizers that have two

cylinders, do not operate both cylinders manually at the same time.

1. Turn on electrical power to the control panel.

2. Be sure the EMERGENCY STOP button is pulled out.

3. Turn the MAN/AUTO switch to the MAN (manual) position.

4. If the pelletizer has two cylinders, place the A/B/A&B switch to the desired cylinder, either A or B. Do not operate both cylinders manually at the same time.

5. Place the corresponding injection switch (A INJ or B INJ) to OFF.

6. Be certain that the compression cylinder is completely retracted and inject liquid

into the compression cylinder by holding the injection switch (A INJ or B

CO

2

INJ) in MAN (manual) position for 20 - 30 seconds, and then release the switch.

Note: The injection switch will not lock in the MAN (manual) position and

must be held for the duration of the liquid CO

injection

2

DO NOT INJECT LIQUID CARBON DIOXIDE INTO

THE CYLINDER UNLESS THE CYLINDER IS COMPLETELY RETRACTED. DOING SO WILL RESULT

IN CARBON DIOXIDE BEING INJECTED BEHIND

THE PISTON AND WILL RESULT IN DAMAGE TO

WARNING

7. Extrude dry ice through the extrusion die by holding the corresponding cylinder

switch (A CYL or B CYL) in EXT (extend) position until the cylinder fully extends, and then release the switch.

THE COMPRESSION CYLINDER, PISTON AND ROD.

4.1

OPERATION & MAINTENANCE

8. Hold the corresponding cylinder switch (A CYL or B CYL) in RET (retract) po-

sition until the cylinder fully retracts, and then release the switch.

9. To continue manual operation, repeat Steps 6 - 8.

AUTOMATIC OPERATION – SWITCH / PUSHBUTTON

CONTROLS

1. Turn on electrical power to the control panel.

2. Be sure the EMERGENCY STOP button is pulled out.

3. Depending on the length of liqui d supply lines from the carbon dioxide st orage

unit, it may be a long time before the machine starts making ice. Use the following procedure to get liquid to the machine and reduce the required start-up time.

NOTE: This procedure is not necessary on high capacity pelletizers. To start this

type of machine, simply press the start button. On all other types of pellet izers

manufactured by Tomco

starting automatic operation.

To pre-charge the pelletizer, turn the MAN/AUTO switch to the MAN

(manual) position. Place the corresponding injection switch (A INJ or B INJ)

to OFF. Be certain that the compression cylinder is completely retracted and in-

, it may be necessary to pre-charge the pelletizer before

2

ject liquid CO

(A INJ or B INJ) in MAN (manual) position until vapor begins to flow through

the extrusion die, and then release the switch. If the pelletizer has two cylinders and both will be used for automatic operation, repeat this process for the

other cylinder.

into the compression cylinder by holding the injection switch

2

DO NOT INJECT LIQUID CARBON DIOXIDE INTO

THE CYLINDER UNLESS THE CYLINDER IS COMPLETELY RETRACTED. DOING SO WILL RESULT

IN CARBON DIOXIDE BEING INJECTED BEHIND

THE PISTON AND WILL RESULT IN DAMAGE TO

WARNING

THE COMPRESSION CYLINDER, PISTON AND ROD.

4.2

Loading...

Loading...