Tomberlin 2010 E-Merge Maintenance Manual

TOMBERLIN®CONSUMERDISCLAIMER

Tomberlin®reservestherighttochangethesuggestionsgainedinthisconsumersupportsite.Itis

intendedprimarilyforeducationalpurposesonly.Someexperiencedconsumersprefertodothe

maintenanceandservicethemselves,forthe"DoItYourself"owners,Tomberlinstronglyencourages

interactionwithyourlocaldealerfirstandtoneverattemptaprocedureyouareunfamiliarwithsafely

performing.Anelectricvehiclehasasignificantvoltagethatcanresultinshock,fireandinjuryifnot

performedbyaprofessional.Damagetothevehiclecanalsooccur.Someproceduresrequirespecific

torquesettingsthatwhennotfollowedcanresultindangerous,possiblylifethreateningsituations.

Manyerrorswillnotsurfaceimmediately.Theinformationhereinhasgenerallyproventoenhancethe

lifecycle,safetyandoverallownershipexperiencewhenproperlyfollowed.Tomberlinassumesno

liabilityforthecontentprovidedinthisconsumereducationalsectionanditispossiblethatanerror

withregardtospelling,grammar,nomenclature,andtranslationispresent.Notethattheinformation

providedshouldbetreatedaslivedocumentsmeaningtheyarealwaysinastateofrefinement,

correctionandimprovement.Checkbackoftenandifprinted,checkbackpriortoreliancetoassurethey

remaincurrent.Neverattempttomanipulatethevehicletoexceedthespeedasrequiredby

regulations.ThehighestspeedrangeforTomberlin®E‐Merge™PTV'sandLSV'sarefactorysetat15‐19

mphasaPTVor22‐25mphasanLSV.Consumersshouldalwaysexerciseprudentcommonsense

measures,usepropersafetygearwithtoolsdesignedspecificallyforthetask.Alwaysutilizeinsulated

toolsaroundelectricalconnections.Neverexceedyourcomfortlevelandwhenindoubt,stopandcall

yourlocaldealer.TomberlinAuthorizedDealersarealwaysyourbestresource.Ifyounoticeanerroror

haveanideathatwillimproveoureffortshere,pleaseemailyourideatoinfo@tomberlin.net.

2

INTRODUCTION

This Maintenance Manual is compiled by TOMBERLIN Company for dealers authorized by

the Company and their technicians. The Manual is only for the maintenance and repair of

electric vehicles of E-MERGE series.

TOMBERLIN reserves the rights to revise the specifications and design from time to time

and the electric vehicles and other products. are subject to improvement that may influence

the maintenance procedure with no notice, nor obligation to alternate devices sold

previously.

Before starting any service on the electric vehicle, read the Manual carefully and note the

difference of the following symbols:

This indicates Note! Alarm! Watch your safety!

WARNING The symbol indicates a danger may occur, calling the attentions of

the driver, passenger, by stander or inspection and maintenance

personnel.

CAUTION It describes some special precautions to avoid vehicle damage.

3

Chapter 1 Overview

Safety Precautions................................................................................................................................1-1

Preparation for Emergency ............................................................................................................1-1

Safe Use of Lubricating Oil.............................................................................................................1-1

Safe Use of Battery........................................................................................................................1-1

Protection of Vehicle Safety...........................................................................................................1-2

Electrical Safety During Maintenance.............................................................................................1-2

Use the Designated Lifting Jack.....................................................................................................1-5

Use Appropriate Tools...........................................................................................................................1-6

Special Tools..................................................................................................................................1-6

Instrumentation for Electric Control System...................................................................................1-6

Cautions................................................................................................................................................1-6

Washing and Cleaning...................................................................................................................1-6

Keep Tidy.......................................................................................................................................1-6

Tightening Torque...........................................................................................................................1-7

Parts Replacement .........................................................................................................................1-7

Washer, Grease Fitting and O-ring.................................................................................................1-7

Bearing and Oil Seal ......................................................................................................................1-7

Recommendations on Disassembly and Assembly........................................................................1-7

Chapter 2 Regular Inspection and Adjustment

Regular Maintenance ............................................................................................................................2-1

Periodic Lubrication Plan.......................................................................................................................2-2

Braking System..................................................................................................................................2-4

Braking Inspection.............................................................................................................................2-4

Inspection of Parking Brake...............................................................................................................2-5

Inspection of Brake Drum and Brake Shoe ........................................................................................2-6

Inspection of the Accelerator Pedal ...................................................................................................2-9

Inspection of the Steering System.....................................................................................................2-9

Inspection of the Steering Linkage...................................................................................................2-10

Inspection of Stub Axle....................................................................................................................2-11

Inspection of the Front Wheel Alignment.........................................................................................2-11

Install for the Adjustment of Toe-in:.................................................................................................2-12

Inspection of Tires and Wheel Rim..................................................................................................2-12

Inspection of the Front Wheel Bearing.............................................................................................2-13

Inspection of the Rear Axle Bearing ................................................................................................2-13

Inspection of the Shock Damper......................................................................................................2-14

Inspection of the Seat Belt...............................................................................................................2-14

Chapter 3 Canopy

Removal of the Canopy.........................................................................................................................3-1

Remove..........................................................................................................................................3-1

Install..............................................................................................................................................3-1

4

Removal of Canopy Rods......................................................................................................................3-1

Remove..........................................................................................................................................3-1

Install..............................................................................................................................................3-2

Removal of the Pillar.............................................................................................................................3-2

Remove..........................................................................................................................................3-2

Install..............................................................................................................................................3-3

Chapter 4 Body

Removal of the Front Bumper ...............................................................................................................4-1

Remove..........................................................................................................................................4-1

Removal of the Rear Tray................................................................................................................4-1

Remove..........................................................................................................................................4-1

Removal of the Rear Bumper.........................................................................................................4-1

Remove..........................................................................................................................................4-1

Install..............................................................................................................................................4-1

Removal of the Seat Cushion................................................................................................................4-2

Remove..........................................................................................................................................4-2

Install..............................................................................................................................................4-3

Removal of Front Cover ........................................................................................................................4-4

Remove..........................................................................................................................................4-4

Install..............................................................................................................................................4-4

Removal of the Dashboard....................................................................................................................4-4

Remove..........................................................................................................................................4-4

Install..............................................................................................................................................4-5

Removal of the Rear Cover...................................................................................................................4-6

Remove..........................................................................................................................................4-6

Install..............................................................................................................................................4-6

Rear cover.............................................................................................................................................4-9

Chapter 5 Front Axle

Front axle ..............................................................................................................................................5-1

Removal of the Front Axle.....................................................................................................................5-2

Remove .............................................................................................................................................5-2

Inspect...............................................................................................................................................5-6

Install .................................................................................................................................................5-7

Chapter 6 Driving Axle

Driving axle............................................................................................................................................6-1

Removal of the Driving Axle..................................................................................................................6-2

Remove..........................................................................................................................................6-2

Inspect and test..............................................................................................................................6-5

Install..............................................................................................................................................6-6

Gearbox.................................................................................................................................................6-8

Removal of the Differential Gear...........................................................................................................6-9

Remove..........................................................................................................................................6-9

5

Inspection.....................................................................................................................................6-11

Install............................................................................................................................................6-12

Chapter 7 Brake System

Brake System........................................................................................................................................7-1

Brake Pedal...........................................................................................................................................7-2

Parking brake handle ............................................................................................................................7-3

Accelerator pedal ..................................................................................................................................7-4

Chapter 8 Steering System

Steering System....................................................................................................................................8-1

Removal of the Steering System....................................................................................................8-2

Removal of the Steering Gear........................................................................................................8-3

Disassembly of the Steering Gear..................................................................................................8-4

Install..............................................................................................................................................8-7

Chapter 9 Electric Component

Key switch removal........................................................................................................................9-1

Key switch installation....................................................................................................................9-1

Removal of forward/reverse gear switch........................................................................................9-1

Installation of forward/reverse gear switch.....................................................................................9-2

Battery discharge meter removal ...................................................................................................9-2

Battery discharge meter installation...............................................................................................9-3

Horn removal..................................................................................................................................9-3

Horn installation .............................................................................................................................9-3

Combination switch removal ..........................................................................................................9-4

Combination switch installation......................................................................................................9-4

Controller removal..........................................................................................................................9-5

Controller installation......................................................................................................................9-6

Charger receptacle removal...........................................................................................................9-7

Charger receptacle installation.......................................................................................................9-7

Battery removal..............................................................................................................................9-7

Battery installation..........................................................................................................................9-8

DC converter removal ....................................................................................................................9-8

DC converter installation................................................................................................................9-8

Removal of DC changeover contactor and diode assembly...........................................................9-9

Installation of DC changeover contactor and diode assembly......................................................9-10

Motor removal..............................................................................................................................9-10

Motor installation..........................................................................................................................9-12

Removal of bulb of headlight and front turn signal light................................................................9-12

Headlight installation....................................................................................................................9-13

Tail light removal..........................................................................................................................9-13

6

Tail light installation......................................................................................................................9-14

High mount stop lamp removal.....................................................................................................9-14

High mount stop lamp disassembly..............................................................................................9-14

High mount stop lamp installation ................................................................................................9-14

Wiper removal..............................................................................................................................9-15

Chapter 10 Troubleshooting

Troubleshooting Instructions Part 1.....................................................................................................10-1

Check procedures........................................................................................................................10-3

Index for check procedures..........................................................................................................10-3

Check Procedure 1-- Battery/ voltage check................................................................................10-4

Check Procedure 2--Accelerator signal voltage...........................................................................10-4

Check Procedure 3-- Motor voltage at A1 and A2........................................................................10-4

Check Procedure 4 - TOW/RUN switch .......................................................................................10-5

Check Procedure 5—Battery voltage...........................................................................................10-5

Check Procedure 6—Circuit check for key switch and accelerator pedal switch..........................10-5

Check Procedure 7--Controller signal

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

10-7

Check Procedure 7A—Pin 1

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

10-7

Check Procedure 7B—Pin 4 and 5

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

10-8

Check Procedure 7C—Pin 7

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

10-9

Check Procedure 7

D

—Pin 6

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

10-9

Check Procedure 7E—Pin 3

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

10-9

Check Procedure 8 – voltage at the red wire jack of charger rec

eptacle....................................

10-10

Check Procedure 9—Motor speed sensor .................................................................................10-10

Check Procedure 10—forward/reverse gear switch................................................................... 10-11

Check Procedure 11—Reverse buzzer...................................................................................... 10-11

Check Procedure 12 -- Battery discharge meter........................................................................10-12

Check Procedure 13-- High mount stop lamp ............................................................................10-12

Check Procedure 14 - wiper.......................................................................................................10-13

Check Procedure 15—flashing light...........................................................................................10-13

Troubleshooting Instructions Part 2............................................................................................10-14

CHAPTER 11 BATTERY AND CHARGER

Battery.................................................................................................................................................11-1

Overview......................................................................................................................................11-1

Common misconceptions about battery.......................................................................................11-2

Battery replacement.....................................................................................................................11-3

Battery maintenance ....................................................................................................................11-4

Preventative maintenance............................................................................................................11-4

Self discharge .............................................................................................................................. 11-5

Electrolyte liquid level................................................................................................................... 11-5

Mineral content............................................................................................................................. 11-6

Vibration damage.........................................................................................................................11-6

7

Battery charging...........................................................................................................................11-6

Deep discharge............................................................................................................................ 11-7

Premature excessive discharge...................................................................................................11-7

AC power supply line....................................................................................................................11-7

Alternating use of vehicles ........................................................................................................... 11-7

Electric vehicle and charger numbering ....................................................................................... 11-8

Battery troubleshooting diagram .................................................................................................. 11-9

Inspection and test of the battery ...............................................................................................11-10

Inspection and test of the battery charger..................................................................................11-10

Charging voltage inspection....................................................................................................... 11-10

Inspection with hydrometer ........................................................................................................11-10

Procedures for inspection with hydrometer................................................................................ 11-11

Calibration of hydrometer........................................................................................................... 11-11

Hydrometer inspection result presentation................................................................................. 11-11

Discharge test............................................................................................................................11-12

Procedures for discharge test .................................................................................................... 11-13

Discharge test result presentation..............................................................................................11-13

Battery troubleshooting example................................................................................................11-14

Battery storage...........................................................................................................................11-15

Battery charge

r …

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

11-16

Overview....................................................................................................................................11-16

Conditions to be noted before charging...................................................................................... 11-16

Get to know the charger............................................................................................................. 11-17

Removal of the charger.............................................................................................................. 11-18

Maintenance of the battery charger............................................................................................ 11-19

Troubleshooting ......................................................................................................................... 11-19

Diode test procedure.................................................................................................................. 11-20

Procedures for component replacement .................................................................................... 11-20

Charger trouble-shooting procedure...........................................................................................11-20

On-board charger …

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

1

1-23

Operatin

g Instructions…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

1

1-23

Maintenance instructions …

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

1

1-24

Specifications…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

1

1-24

Inst

allation Instructions…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

1

1-25

Chapter 12 Electric Motor

Overview .............................................................................................................................................12-1

Exterior inspection of the electric motor ..............................................................................................12-1

Check Procedure 1-internal short circuit...........................................................................................12-1

Check Procedure 2-disconnection of armature circuit.......................................................................12-1

Check Procedure 3-open excitation circuit........................................................................................12-2

Removal of the electric motor..............................................................................................................12-3

Inspection and test of the motor element ............................................................................................12-4

Inspection of the armature............................................................................................................12-4

Armature earth test.......................................................................................................................12-4

8

Inspection of the excitation winding..............................................................................................12-5

Motor element..............................................................................................................................12-5

Bearing inspection........................................................................................................................12-6

Removal of the bearing................................................................................................................12-6

Mounting of the bearing................................................................................................................12-6

Inspection of the speed sensor magnet........................................................................................12-6

Removal of the speed sensor magnet..........................................................................................12-7

Mounting of the speed sensor magnet.........................................................................................12-7

Readjustment of the electric motor...............................................................................................12-7

Specifications for the electric motor.....................................................................................................12-8

Assembly of the electric motor ............................................................................................................12-9

Mounting of the electric motor...........................................................................................................12-11

Speed sensor of the electric motor....................................................................................................12-14

Inspection of the speed sensor of the electric motor..................................................................12-14

Removal of the speed sensor.....................................................................................................12-14

Mounting of the speed sensor of electric motor..........................................................................12-14

Overview

MERGE 1-1

Chapter 1

Safety Precautions

WARNING

During the maintenance of these vehicles, the following safety precautions can be taken to prevent

serious accidents.

Preparation for an Emergency

To prevent a potential in jury or fire hazard, the following

simple articles should be prepared. For example:

• First-aid kit

• Fire extinguisher

• Emergency phone

Safe Use of Lubricating Oil

While refilling or replacing oil, do not smoke and keep

away from fire.

Any spilled grease should cleaned on a regular basis

and be handled properly.

Safe Use of Battery

Before maintenance, the battery acid should be sealed.

The battery can give off explosive gases. The battery

should be kept away from the ignition source. The liquid

level of electrolyte should be inspected with the use of

flashlight.

Do not measure and test the voltage after connecting the

battery wire. A voltmeter or hydrometer should be used

for taking this measurement.

Do not connect the wire with the negative electrode first.

Connect it at last.

Do not charge the battery while it is refrigerated. The

battery should be unfrozen before it is charged.

To prevent the production of explosive hydrogen gas, the

Overview

MERGE 1-2

Chapter 1

battery should be placed in an area with good ventilation

while charging.

The electrolyte of the battery contains sulfuric acid,

which is toxic and highly corrosive and should be

prevented from being spilled onto the skins, eyes and

clothes. In the event that electrolytes are spilled into

eyes, water should be used to clean the eyes for 15

minutes and effective medical treatment should be

taken.

WARNING

During the maintenance of these vehicles, the following

safety precautions can be adopted to prevent serious

accidents.

Vehicle Safety During Maintenance

• The parking brake should be applied.

• Blocks should be placed in front of the front tires.

• No one should be allowed to stand in front of or

behind the vehicle being serviced.

Electrical Safety During Maintenance

DANGER

• Battery contains explosive gas! Smoking is strictly

prohibited. Sparks and open flames should be kept

away from the electric vehicle and the working area.

The place where the battery is charged should be a

space where it is kept in good ventilation. While

maintaining or working beside the battery, the

operator should wear a full face mask and rubber

gloves.

• Batteries are toxic and contain acid fluid that may

cause serious burns if the fluid should contact the

skin. Anti-acid measures:

Overview

MERGE 1-3

Chapter 1

• Exterior: Flush the area where acid is spilled with

water, and visit the doctor immediately.

• Oral medication: Drink a large quantity of milk or

water before taking milk of magnesia or vegetable

oil. Visit the doctor immediately.

• Eyes: If battery acid should contact your eyes, you

should flush your eyes with water for 15 minutes

and immediately contact your doctor.

WARNING

• The electric vehicle can only be repaired or

maintained by technician with adequate training.

Even the personnel who are in charge of simple

repair or maintenance are required to have the

knowledge or experience in relation to electrical and

mechanical maintenance.

• Please follow the procedures contained in this

Manual, and note all the “DANGER”, “WARNING”

AND “NOTICE” marks contained in this Manual and

attached to the electric vehicle.

• Misuse of electric vehicles or inappropriate

maintenance may result in the performance

degradation of the vehicle or serious personal injury.

• Any refit or alteration of the electric vehicle that may

affect its stability or maneuverability or any speed

increase beyond the maximum speed specified in

the manufacturer’s specifications may result in

death and serious personal injury.

• Refer to the user’s manual for the corresponding

positions labeled on the electric vehicle of all

“WARNING” marks and ensure that they are in

place and easily visible.

• During the maintenance of electric vehicle, please

wear the safety goggles or effective eye-shields.

While maintaining or working beside the battery, the

operator should wear full face mask and rubber

gloves. During the maintenance of electric vehicle, it

is strictly prohibited to wear loose clothes or earrings,

watches, necklace and bracelets, etc.

Overview

MERGE 1-4

Chapter 1

• Moveable elements! It is strictly prohibited to

maintain the electric vehicle while it is in operation.

• Hot! It is strictly prohibited to maintain a hot motor.

Any violation of this warning may result in serious

burns.

• While working beside the battery or electrical

element, the operator should use insulated tools

with special care to avoid short circuit of the

component or wiring.

• Before servicing the electric vehicle, please turn the

key switch to the OFF position and take the key out.

Turn FWD/REV switch to NEUTRAL position and

chock the wheels with blocks.

Overview

MERGE 1-5

Chapter 1

• To avoid unintentional start-up of the electric

vehicle, please turn the Tow/Run switch to the

TOW position before disconnecting or

connecting the battery.

• After disconnection of the battery, please wait for 90

seconds to allow for the discharge of the capacitor

in the controller.

NOTICE:

After removing or replacing the wire, please arrange

and fix the wiring and wiring harness. Inappropriate

arrangement of the wiring and wiring harness may

result in the malfunction of the vehicle, property

damage and/or personal injury and death.

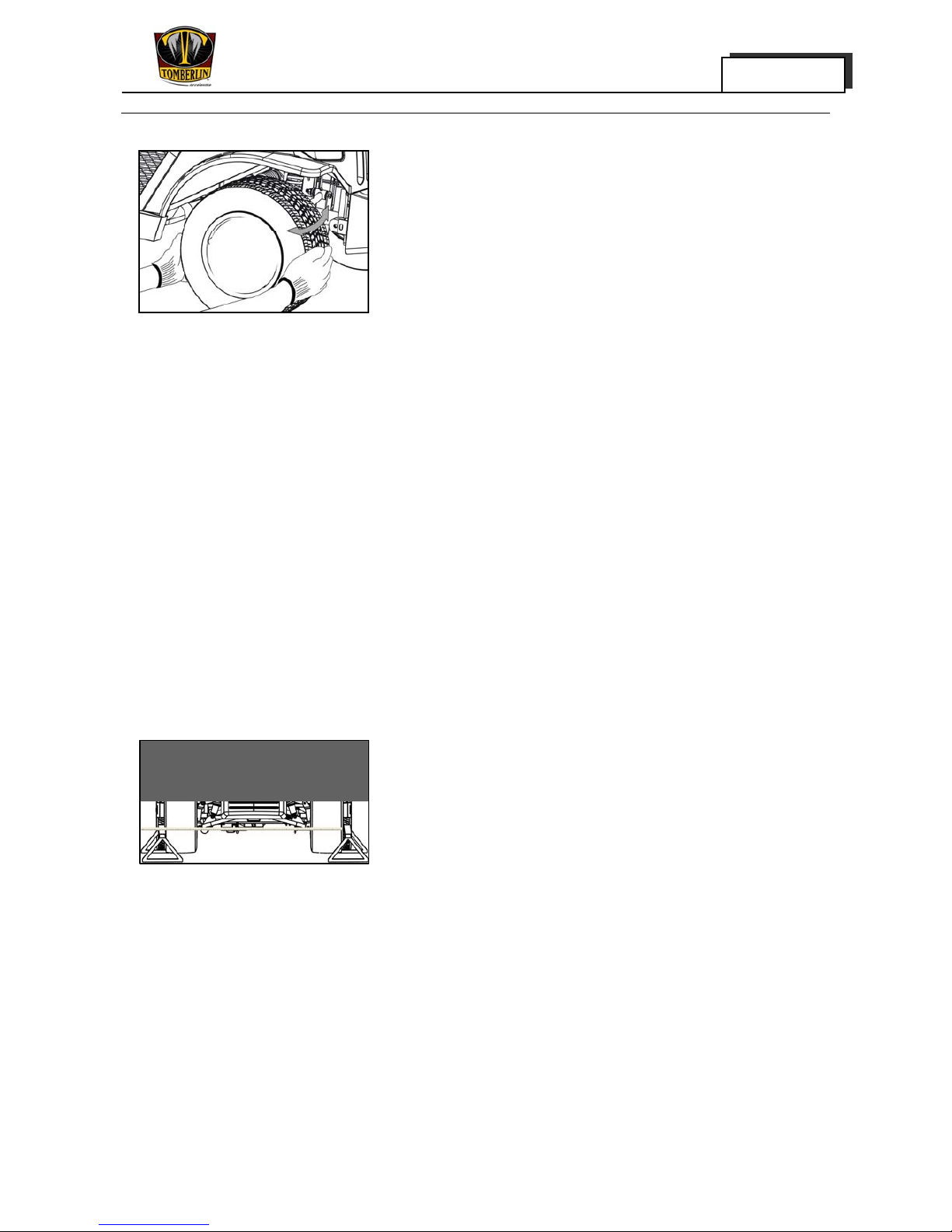

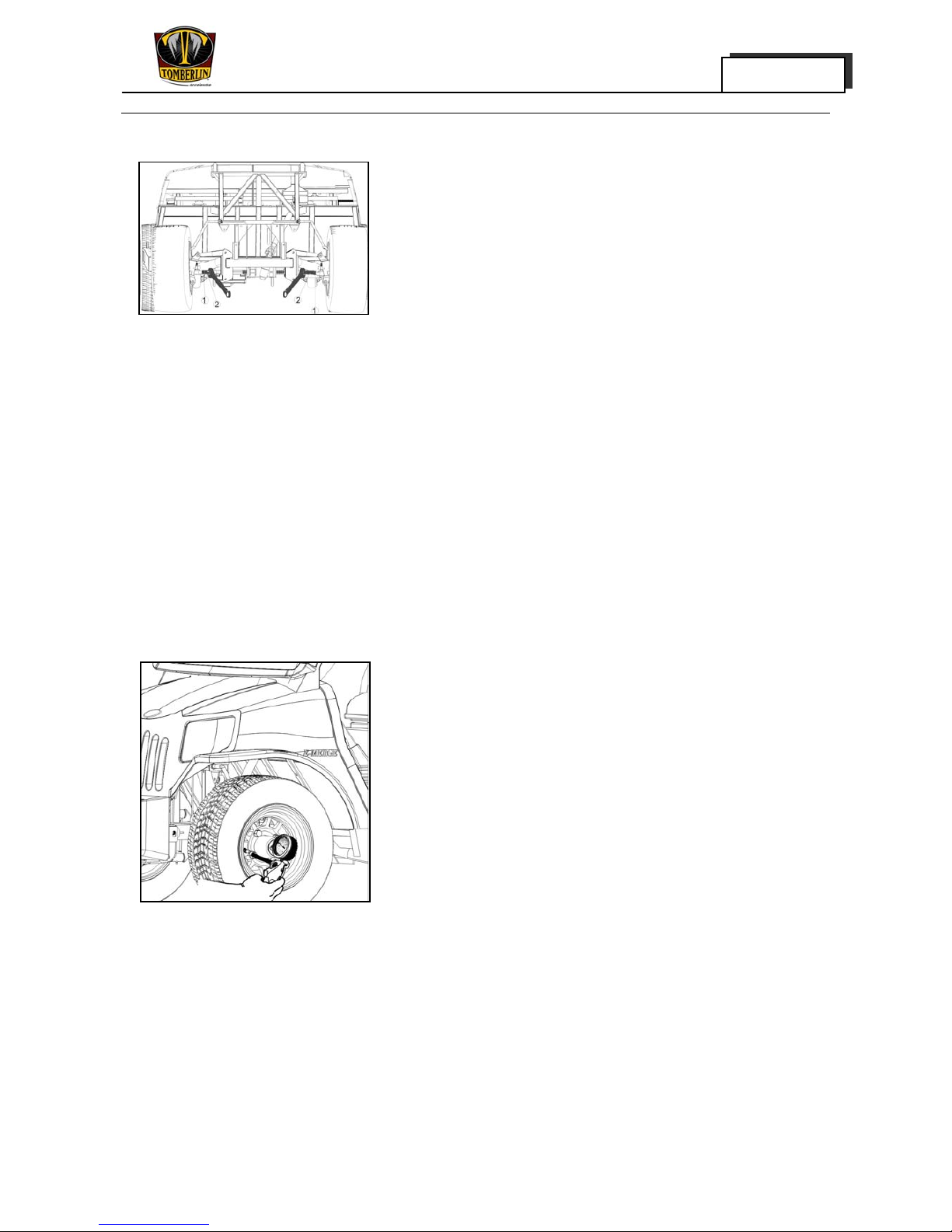

Use the Designated Lifting Jack

Front: put the lifting jack below the pivot to support it.

Rear: Use the portion of crossed frames.

Caution:

In the case that the lifting jack is placed behind the

vehicle, the lifting jack should be prevented from

touching the back tower bar.

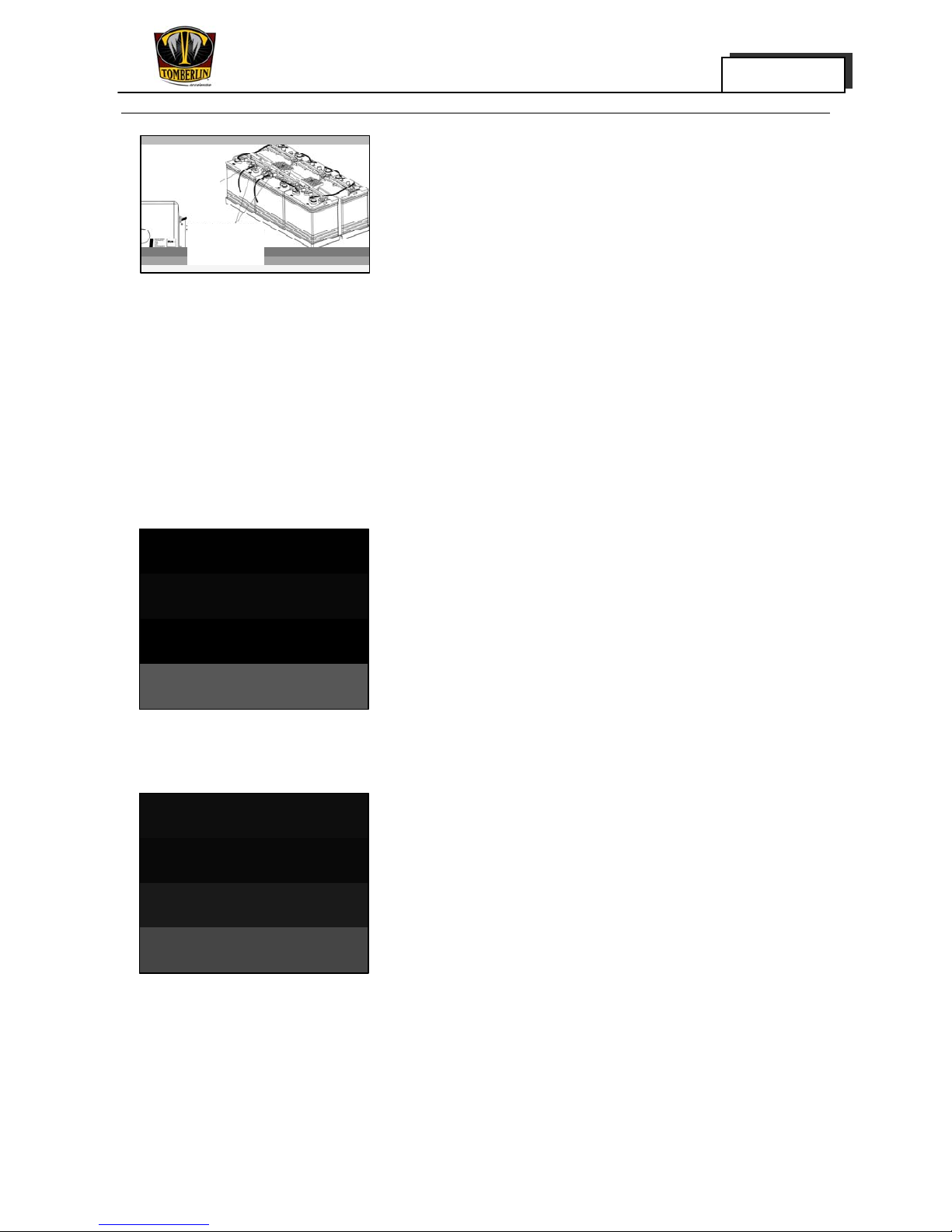

First, remove the

positive electrode

cable

Disconnect the

storage battery

cable here

Overview

MERGE 1-6

Chapter 1

Use Appropriate Tools

To prevent the components and the vehicle from damage,

appropriate tools must be used.

Special Tools

The use of appropriate special tools is necessary for the

improvement of vehicles, accurate adjustment and

assembly. The use of appropriate special tools can

prevent damage resulting from the use of inappropriate

tools.

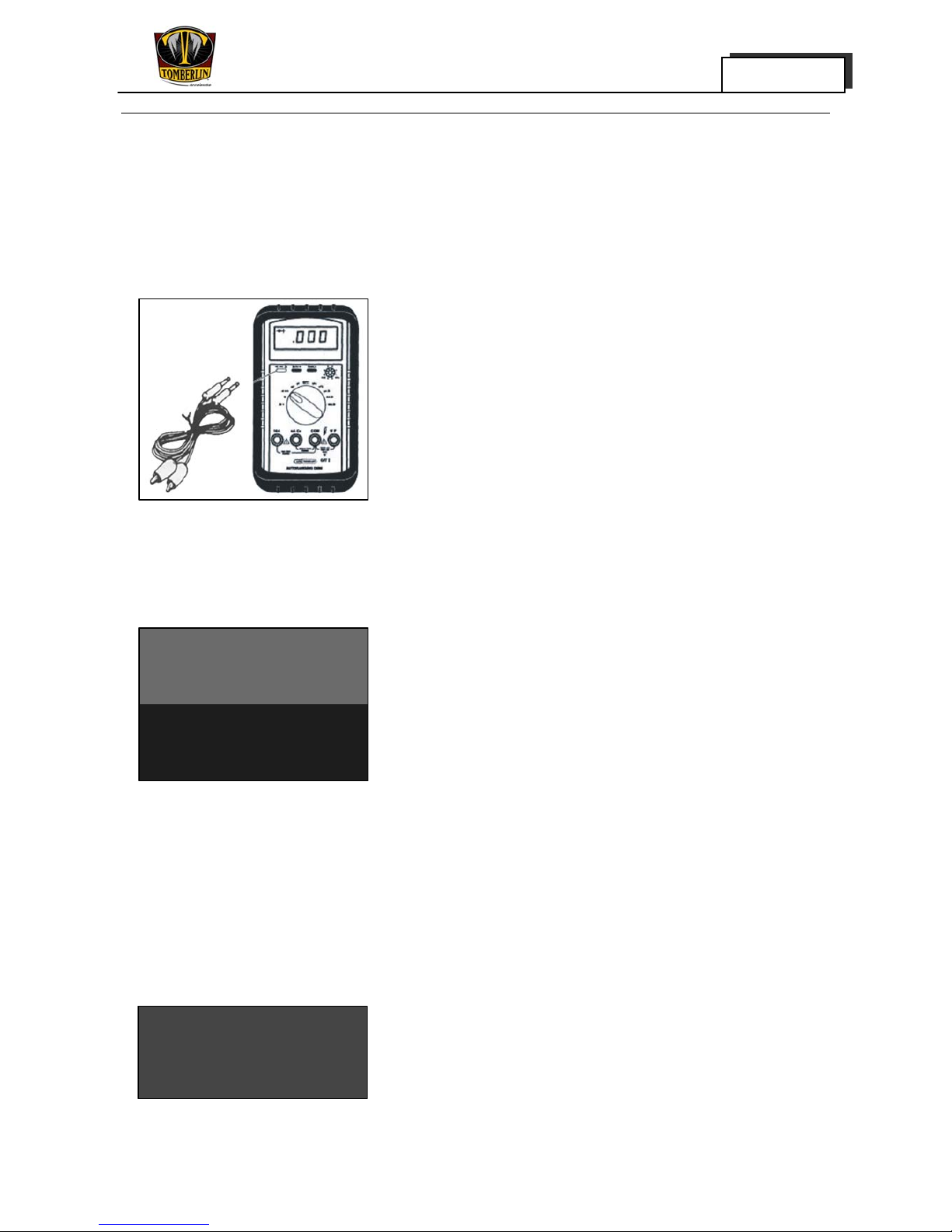

Instrumentation for Electric Control System

1. Pocket detector

This device is of vital importance to the inspection of

the electrical control system.

2. Hydrometer

This instrument is designed to measure the precise

specific grayte. of the electrolyte.

Cautions

Washing and Cleaning

Before the maintenance, thoroughly clean the body and

exterior of the components. During the cleaning, care

should be taken to protect electrical components such as

the relay and controller.

Keep Tidy

To ensure that vital parts are not misplaced, put them in a

secure location away from disarray.

Overview

MERGE 1-7

Chapter 1

Tightening Torque

Tighten the bolts, nuts or screws pursuant to the

instructions on the torque in each chapter.

Parts Replacement

We recommend that you use E-MERGE original parts for

all replaceable parts. Use the oil or grease

recommended by TOMBERLIN during the assembly,

inspection and repair.

Washer, Grease Fitting and O-ring

During the inspection and repair of vehicles, all the

washers, grease fittings and O-rings removed should be

cleaned up before being mounted.

Bearing and Oil Seal

During the mounting of bearing and oil seals on which

the manufacturer’s mark and number are present, the

mark and number should face outwards for easy

identification. All the bearing and oil seals, once removed,

must be replaced with new ones. To apply th e oil seal,

cover a thin layer of light lithium grease over the oil seal.

While mounting the bearing, the lubricants should be

fully applied.

Recommendations on Disassembly and Assembly

Follow the following recommendations to remove and

mount the parts:

• Whenever the parts are disassembled, they must be

cleaned and air dried.

• Apply the lubricant oil over the surface of the parts that

are to be mounted.

• After the mounting of all parts in place, verify that all

movable parts are in normal operation.

Original

Regular Inspection and Adjustment

MERGE 2-1

Chapter 2

Regular Maintenance

Normal maintenance is of paramount importance to the optimal performance and safe operation of

vehicles.

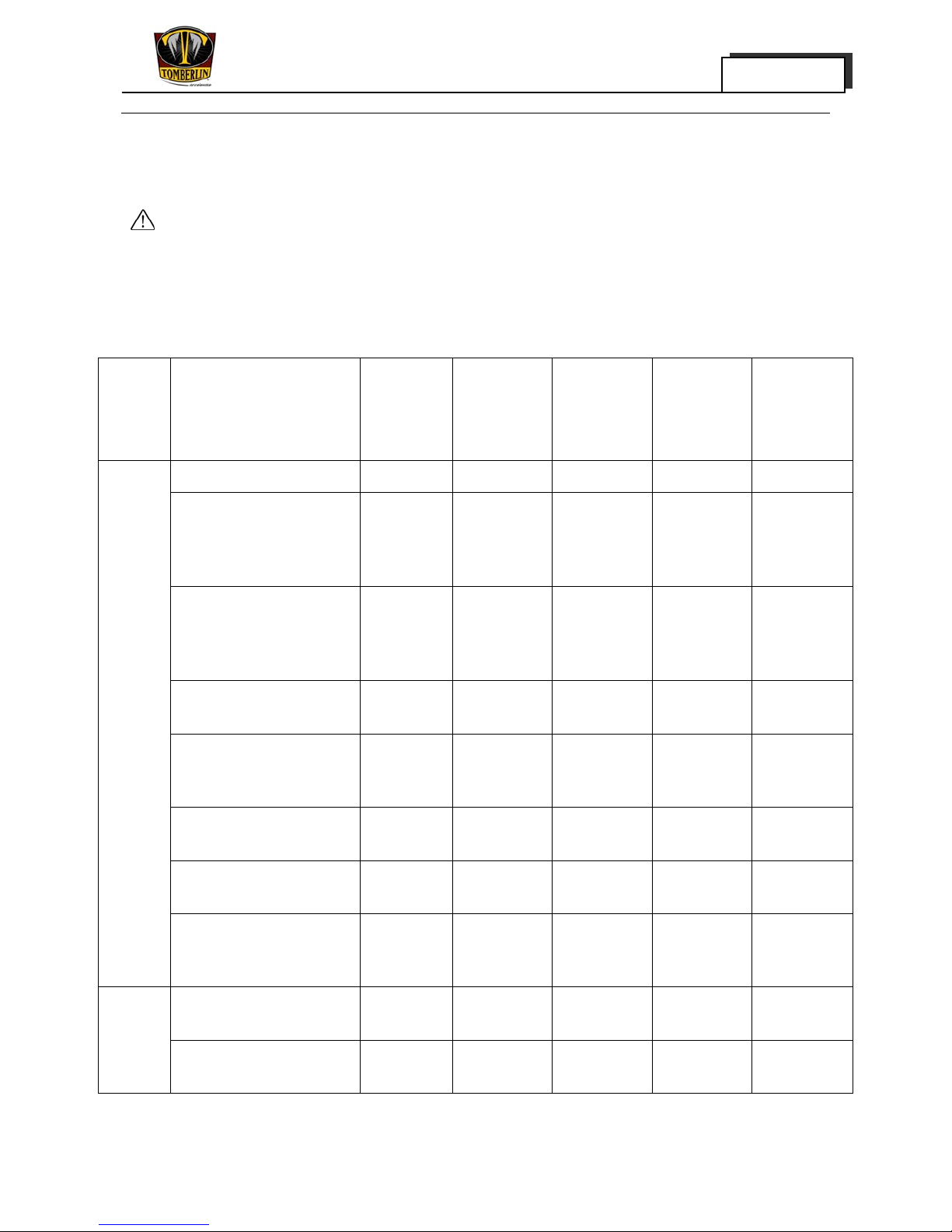

B WARNING

Unless otherwise required, the master switch must be turned off and the parking brake must be

applied during the maintenance.

C–Check CA-Check and Adjustment R-Replacement S-Service CL-Cleaning and Lubricating

L-Lubricating

Remarks

Before

operation

3100 miles

5000

kilometers

(Semiannuall

y)

6200 mile

10000

kilometers

(Annually)

12400 miles

20000

kilometers

(Every two

years)

18600 miles

30000

kilometers

(Every three

years)

Charging

S S S S S

Clean the top of the

battery and inspect the

retaining screws and

terminals for tightness.

S S S S S

Inspect the brake pedal

for free travel and make

adjustments when

necessary.

C CA CA CA CA

Inspect the operation of

the steering wheel

C C C C C

Inspect the tire pressure

and the tire recession

and tread for damage

C CA CA CA CA

Inspect the body and

chassis for damage

C C C C C

Inspect all the bolts, nuts

and screws for tightness

C C C C C

Inspectio

n before

operatio

n

Inspect the reverse

buzzer for normal

operation

C C C C C

Inspect the level of the

electrolyte

C C C C

Monthly

inspectio

n

Inspect all the connecting

lines

C C C C

Regular Inspection and Adjustment

MERGE 2-2

Chapter 2

Clean/Lubricate the pedal

control area

L L L L

Inspect all the insulated

wires for rupture or

dirtiness

C C C C

Semian

nual

inspecti

on

Inspect the shock

damper for oil leakage

and damage of spring

C C C C

Conduct discharging test

S S S

Use terminal protective

agent

S S S

Inspect the brake shoes

for tightness and the rear

axle bearing for normal

operation

C C C

Inspect the steering

knuckle bushing for

normal operation/Adjust

front wheel alignment

CA CA CA

Inspect the nuts of the

wheel for tightness and

the front-wheel bearing

for normal operation

C C C

Replace the lubricating

oil in the gear box

R

Annual

inspecti

on

Inspect the parking pedal

for free travel and make

adjustments when

necessary.

CA CA CA

Inspect the rear axle

bearing and replace it if

abrasion is identified

R

Inspectio

n every

three

years

Inspect for oil leakage,

and adjust the gear box

when necessary

CA

Regular Inspection and Adjustment

MERGE 2-3

Chapter 2

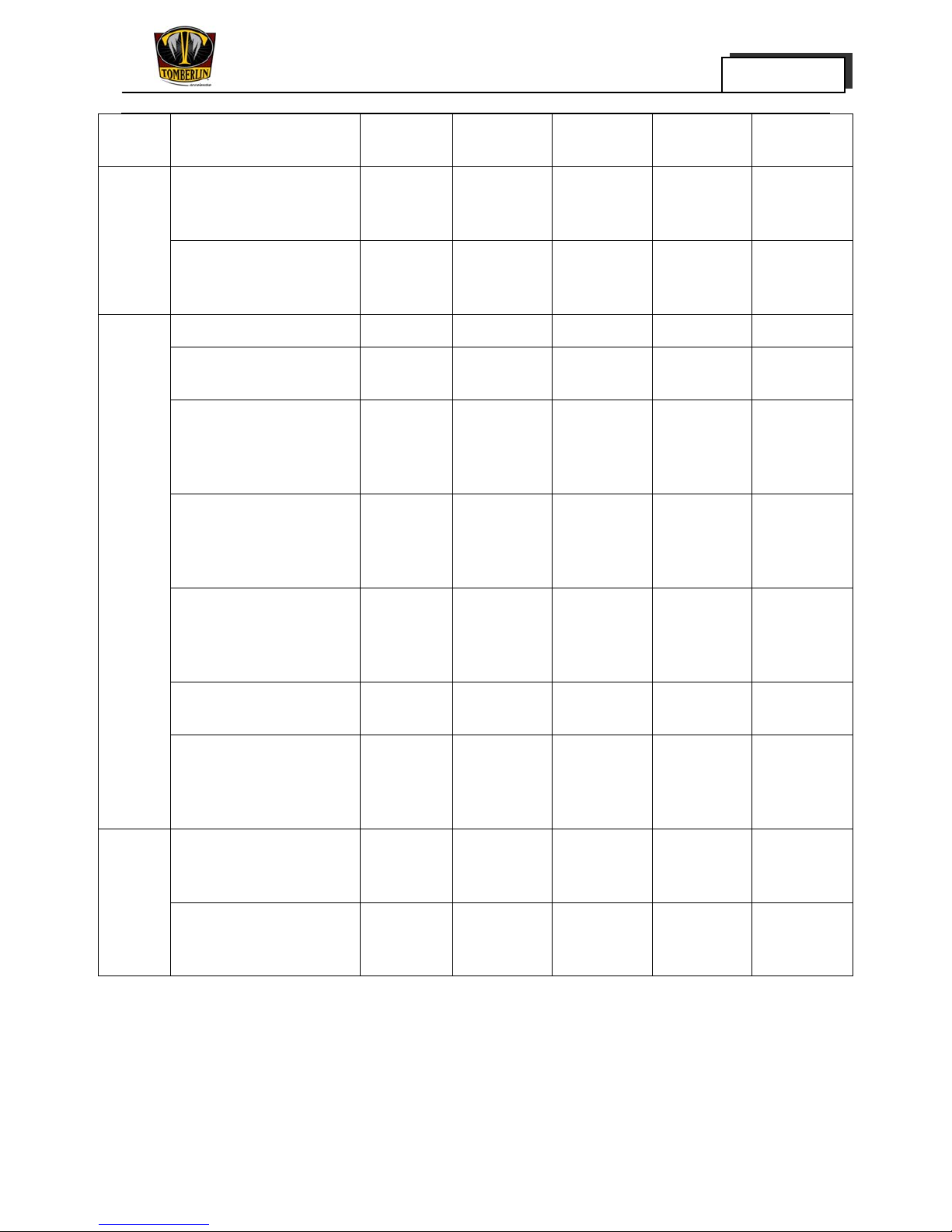

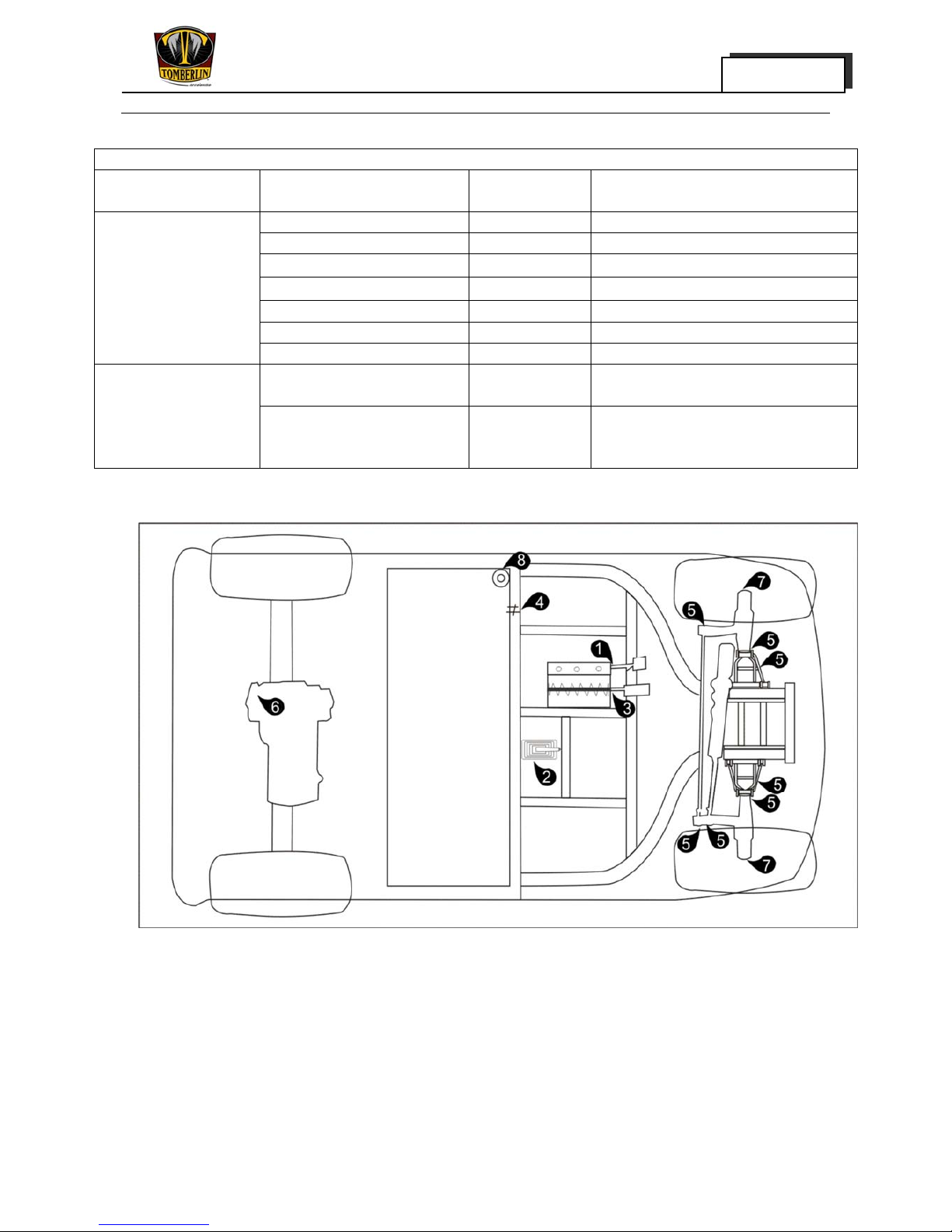

Periodic Lubrication Plan

Periodic lubrication plan

Normal intervals Maintenance

Lubricated

points

Recommend lubricating oil

Brake pedal shaft 1 3# Lithium based grease

Parking brake 2 3# Lithium based grease

Accelerator pivot bar foot 3 3# Lithium based grease

Charger receptacle 4 NYE760G

Front suspension 5 3# Lithium based grease

Front stub axle 7 Lithium based grease

The user or trained

technician applies the

lubricating oil once a

quarter (every 50

working hours)

Braking grease cup 8 DOT3 (3000)brake oil

Inspect the driving axle/oiled

cork position.

6

32.8 ounce(1.1 liter),37OZ

lubricating oil (GL - 5)

The trained

technician applies the

lubricating oil once a

year (every 100

working hours)

Inspect the front-wheel

bearing (Remount when

necessary).

7 3# Lithium based grease

Regular Inspection and Adjustment

MERGE 2-4

Chapter 2

Braking System

Main Brake Inspection

1. Remove:

· Anti-slip pedal

· Protective cover plate

Care should be taken to avoid scraping the body.

2. Inspect:

· Brake master cylinder ①

· Brake Oil Pipeline ②

· Tee joint ③

· Front wheel brake caliper ④

Oil leakage →if any, replacement is required

· Front wheel brake shoe

Standard thickness

7.0 mm (0.28 in)

Maximum wear value of thickness:

2.5 mm (0.1 in)

· Brake disc

Standard thickness:

4.0 mm (0.16 in)

Maximum thickness wear value:

1.0 mm (0.04 in)

Damaged/defective one is to be replaced

Regular Inspection and Adjustment

MERGE 2-5

Chapter 2

3. Measure:

· Free play of the brake pedal

Push against the pedal by hand (slightly) and measure

the distance it travels before the pressure is lost.

Defects are to be replaced.

Free Travel of the brake pedal

13mm(0.512 in)

Inspection of Parking Brake

1. Turn the key switch to "OFF" position and take out the

key.

2. Remove the protecting jacket of brake handle.

1. Inspect:

· Parking brake ratchet①

· Ratchet brake②

Worn or damaged ones are to be replaced.

2. Measure:

· Free travel

15mm (0.591in)

In case of non-compliance with the standard,

adjustment is to be made.

Regular Inspection and Adjustment

MERGE 2-6

Chapter 2

Procedures for the Adjustment of Free Travel

· Loosen the locknut ④

· Adjust the free travel via adjusting nut ③

· Tighten the locknut

· Re-inspect the free travel

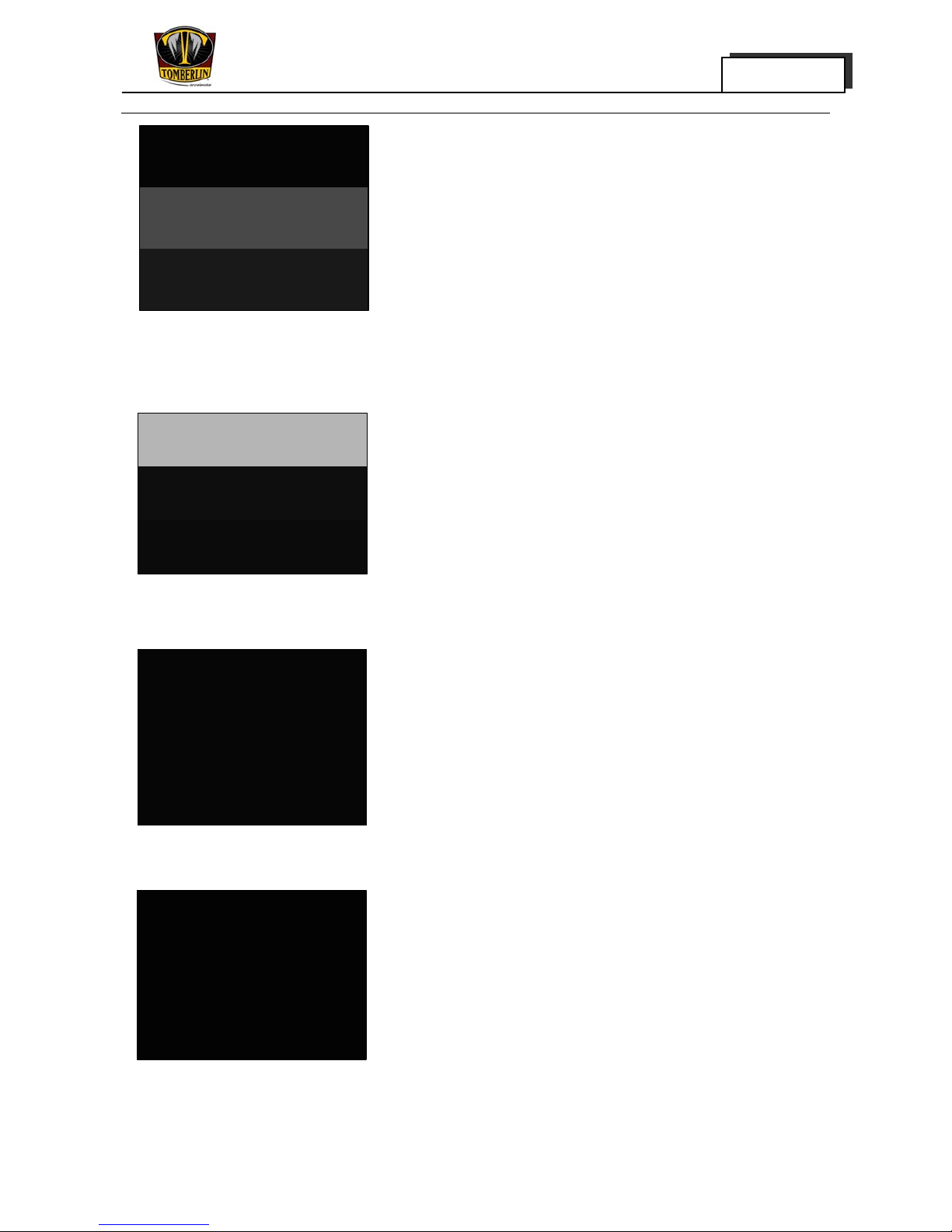

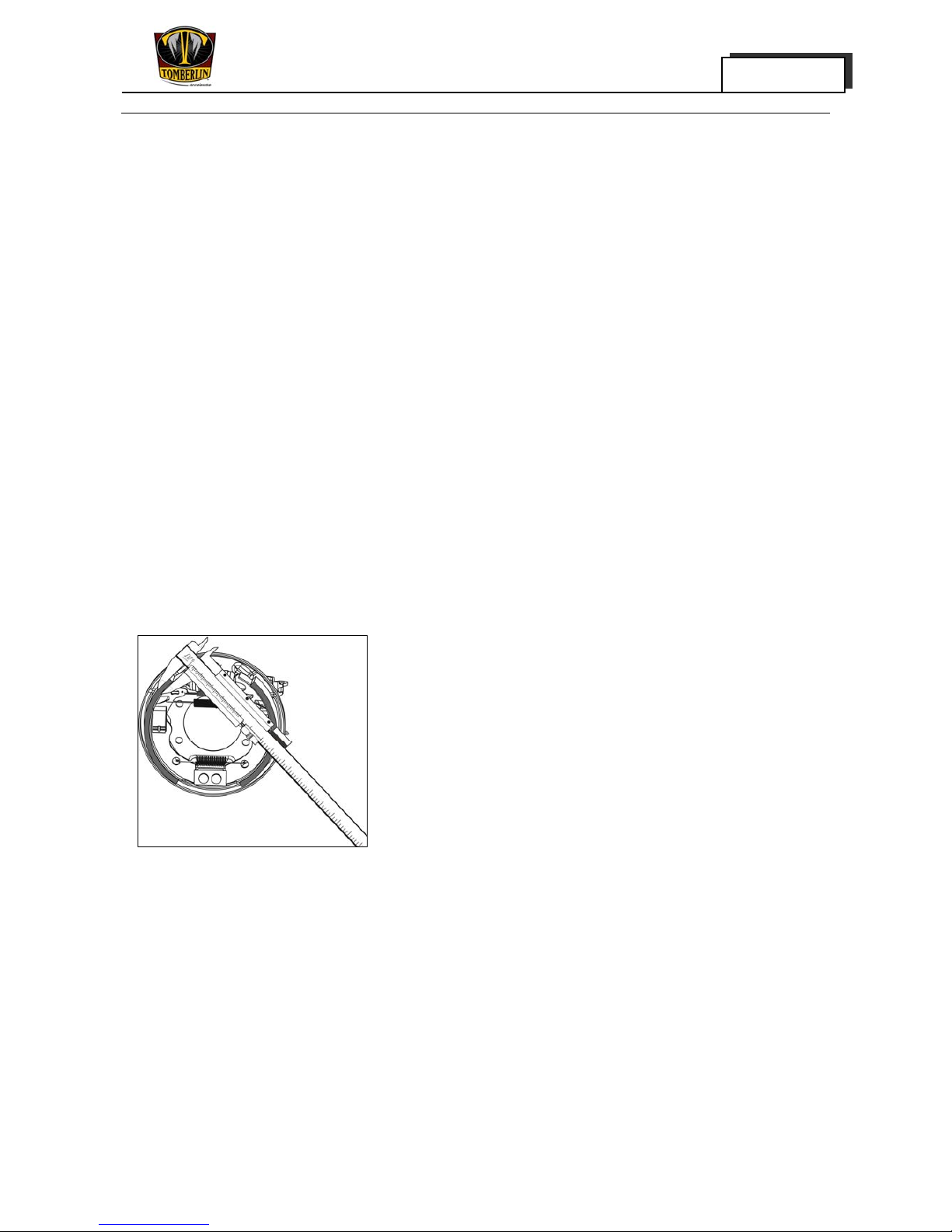

Inspection of Brake Drum and Brake Shoe

1. Turn the key switch to the "OFF" position and take

out the key.

2. Wedge the blocks onto the front lower part of the

front tires. Lift the rear body with the lifting jack.

3. Remove the rear tire lug nuts and then the rear

wheels.

4. Loosen the brake drum and knock slightly on the

drum with mallet.

5. Inspect:

· Internal surface of the brake drum

Oil → fully clean until no oil is found

Scrape → Rub lightly with the abrasive cloth

· Brake wheel cylinder

Where the upstream assembly is in normal working

condition, step on the brake pedal. In case the brake

wheel cylinder cannot open the brake shoe or oil

leakage is found, the brake wheel cylinder is to be

replaced with a new one.

Regular Inspection and Adjustment

MERGE 2-7

Chapter 2

6. Measure

In case the inside diameter of the drum does not

meet the specification, it will be replaced with a new

one.

Standard inside diameter:

180mm(7.2 in)

Maximum wearing value of the inside diameter:

1.5mm(0.06 in)

7. Inspect:

· Surface of shoe block

Oil → Replace the old one or fully clean until no oil is

found

Scrape → Rub lightly with the abrasive cloth

8. Measure the thickness of the shoe plate, and replace

the shoe plate that does not meet the specifications

or in case brake shoe block is too old.

Standard thickness:

7.0 mm (0.16in)

Maximum thickness wearing value:

1.75mm (0.07in)

Regular Inspection and Adjustment

MERGE 2-8

Chapter 2

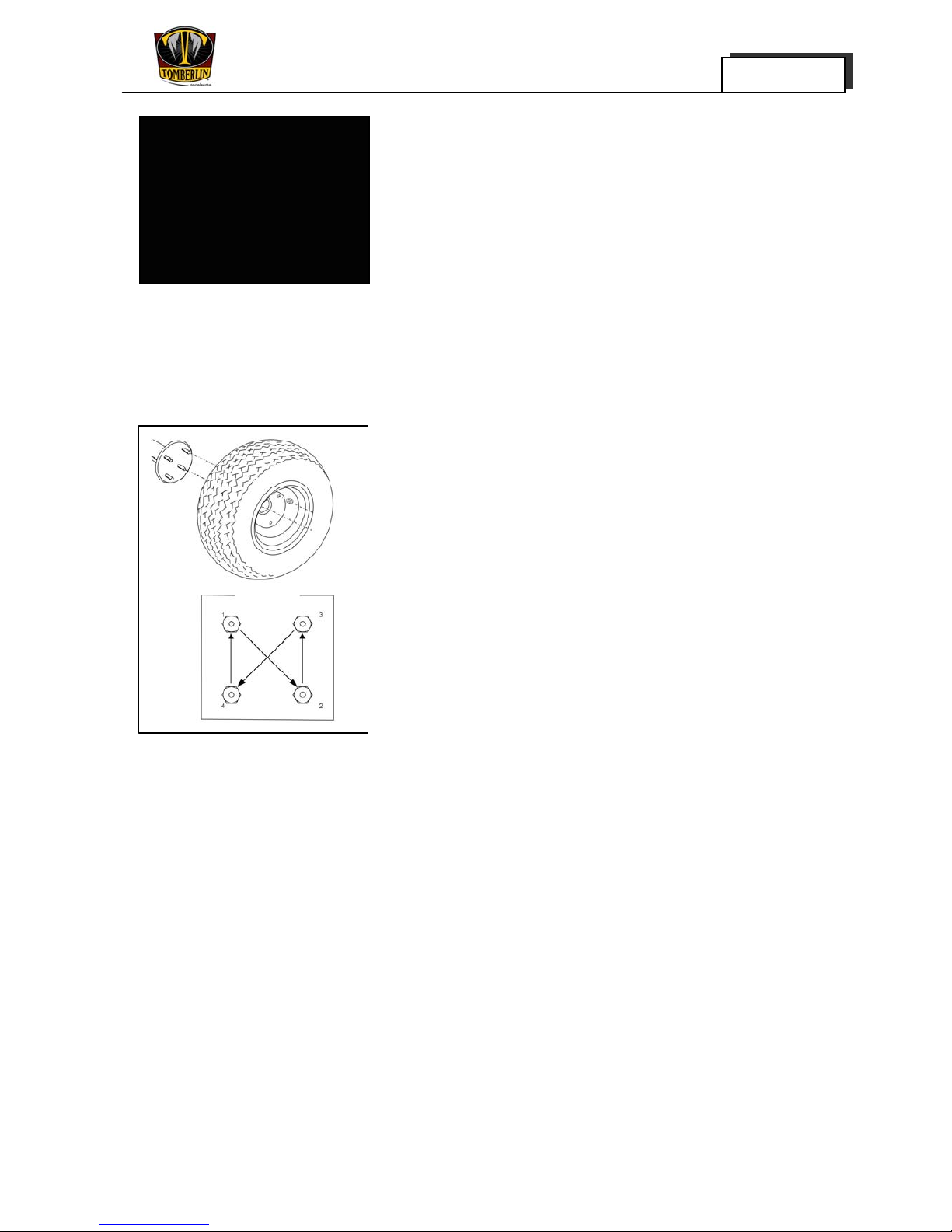

9. Install

· Brake drum

· Rear wheel

WARNING:

Verify that there is no oil or water on the surface of

the brake drum and shoe block.

10. Install:

Wheel nuts

Tightening torque to

90N·m (66.4ft·1b)

NOTICE:

First, screw on the wheel nuts by hand, and then

tighten the nuts diagonally.

11. Upon the completion of the installation, step on the

brake pedal about 10 times to adjust the clearance

between the shoe plate and the drum.

Regular Inspection and Adjustment

MERGE 2-9

Chapter 2

Inspection of the Accelerator Pedal

1. Inspect:

Operating condition of the pedal

In case of unsmooth operation, the pivot should be

lubricated.

2. Inspect:

Lateral free travel of the pedal

4mm (0.158 in)

Step on the pedal and replace the pivot in case the

free play is too loose.

Limit value to the free pedal travel:

95mm (3.74in), measured at the top of the pedal

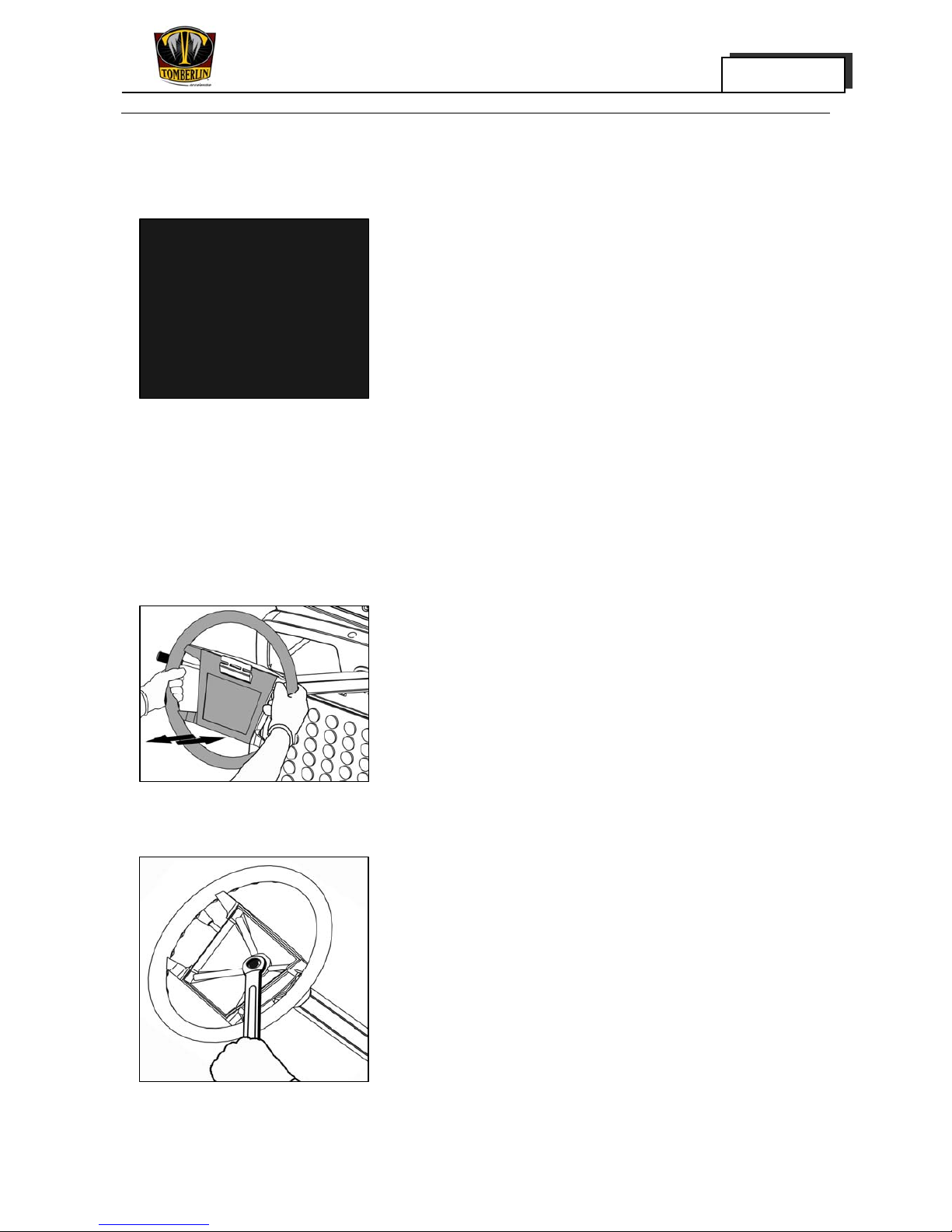

Inspection of the Steering System

State of the Steering Wheel in Steering Operation

1.Inspect:

Steering clearance

Push and pull or turn the steering wheel. In case of

over-looseness, the steering wheel or cross-pin type

joint bolts should be tightened.

Limit value to steering clearance of steering wheel:

5°(arc length:15.27mm)

2.Tighten:

Nuts (of steering wheel)

Tightening torque to

Regular Inspection and Adjustment

MERGE 2-10

Chapter 2

50N·m (36.9ft·1b)

And tighten:

Bolts (of universal joint)

Upper fixing bolt

Lower fixing bolt

Tightening torque to

22N·m (16.2ft·1b)

3.Re-inspect:

· Steering clearance

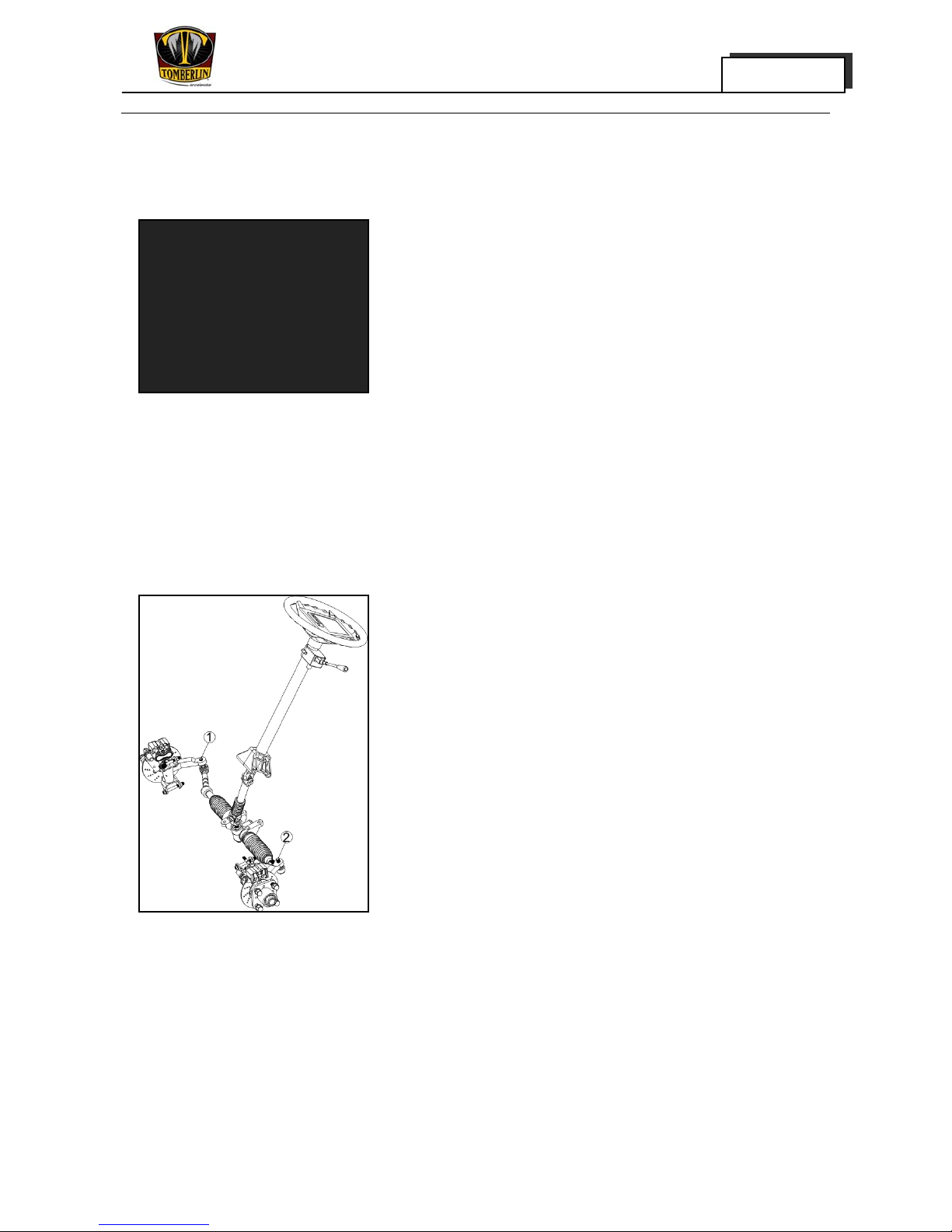

Inspection of the Steering Linkage

Removal of Tie Rod Ball Joint

2. Inspect:

Ball joints in the following conditions:

· Unsteady operation

· Over-loose free operation

· Bending or scrape

· Damage of dust boot

Refer to Chapter 8 "Steering System"

NOTICE:

In case of any of the above conditions, replace with

a new ball joint.

3. Install:

Steering Gearbox ball joint.

Regular Inspection and Adjustment

MERGE 2-11

Chapter 2

Inspection of Stub Axle

· Free gap of kingpin bolt, spacer and bushing

a. Park the vehicle on flat surface and apply

parking brake

b. Jack up the front wheels of vehicle

c. Move the wheels lightly

In case the free clearance is too large, the bushing is to

be replaced or the bearing clearance is to be adjusted.

Inspection of the Front Wheel Alignment

Toe-in

1. Park the vehicle on flat surface.

2. Push the vehicle straightly ahead for about 20 steps

to stabilize the suspension.

NOTICE:

Do not pull back the vehicle or step on the brake

pedal, as it will leads to changing of toe-in.

3. Measure:

· Toe-in

Empty:5~8mm (0.20~0.32in)

Full load:0-3mm (0in-0.118in)

In case of non-compliance with standard specified,

adjustment is to be made

Regular Inspection and Adjustment

MERGE 2-12

Chapter 2

Procedures for the Adjustment of Toe-in:

· Park the vehicle on the flat surface and apply

parking brake.

Loosen the locknut(1) on the ends of the tie rod

Turn the steering tie rod to adjust the toe-in

increase→ rotate the steering tie rod so that the

length between two ball joints increases

Decrease→ rotate the steering tie rod so that the

length between two ball joints decreases (toe-in

decrease)

·

Tighten the locknut on the drag link ball joints.:

· Tightening torque to

40N·m (29.5ft·1b)

Inspection of Tires and Wheel Rim

1. Measure:

· Air pressure

In case of non-compliance with the standard,

adjustment is to be made

Tire pressure:(front and rear tires)

200-220kPa

Inspect:

· Tire surface

In case of any abrasion, damage, scrape or inset, the

tire is to be replaced.

· Wheel rim

In case of any damage or deformation, the rim is to be

replaced rather than go through the motions of

inspecting the wheel rim.

2. Measure:

Regular Inspection and Adjustment

MERGE 2-13

Chapter 2

· Wheel tread thickness

In case of non-compliance with the standard,

replacement is to be made

Maximum wearing value of wheel tread thickness

(front and rear tires) 4.0mm(0.16in)

Inspection of the Front Wheel Bearing

1. Wedge blocks onto the rear lower part of the rear

wheels and lift the front body with lifting jack.

2. Move front wheels by hand. Move the front wheel

with the Main Shaft being touched. In case the

clearance is too large, replace the bearing.

Inspection of the Rear Axle Bearing

1. Wedge blocks on the front lower part of the front

wheels, and loosen the rear wheel bolts.

2. Lift the rear body with the lifting jack.

3. Remove:

· Rear wheels

Brake drum

4. Slowly rotate by hand the half shaft of rear axle.

In case of unsmooth or unsteady rotation, the bearing

is to be replaced.

5. Lightly swing the half shaft of the rear axle. In case

that the free gap is too large, the bearing is to be

replaced.

NOTICE:

We do not recommend the replacement of bearing

and bearing sleeve as an individual part. During

Regular Inspection and Adjustment

MERGE 2-14

Chapter 2

the operation, the quality of fit between half shaft

and bearing or bearing sleeve may deteriorate. In

this case, we usually recommend the replacement of

a new rear axle half shaft assembly.

Inspection of the Shock Damper

1. Inspect:

· For oil leakage

In case of oil leakage, the shock damper is to be

replaced

· Spring

In case of decay, scrape or damage, the shock

damper is to be replaced

Mounting bolts of front shock damper:

Tightening torque

63N·m (46.5ft·1b)

Mounting bolts of the rear shock damper:

Tightening torque

63N·m (46.5ft·1b)

Loading...

Loading...