Page 1

EXPLOSION-PROOF LED

3024XL, 3124XL SERIES

INSTALLATION, OPERATION AND MAINTENANCE DATA SHEET

IMPORTANT - Before installing, check the carton

label and fixture nameplate to be sure you have the

correct LED color and type of fixture. Read all

instructions before proceeding.

WARNING - Deactivate circuit before beginning

installation.

NOTE: All installations must comply with

applicable local and or National Electrical Code.

INSTALLATION:

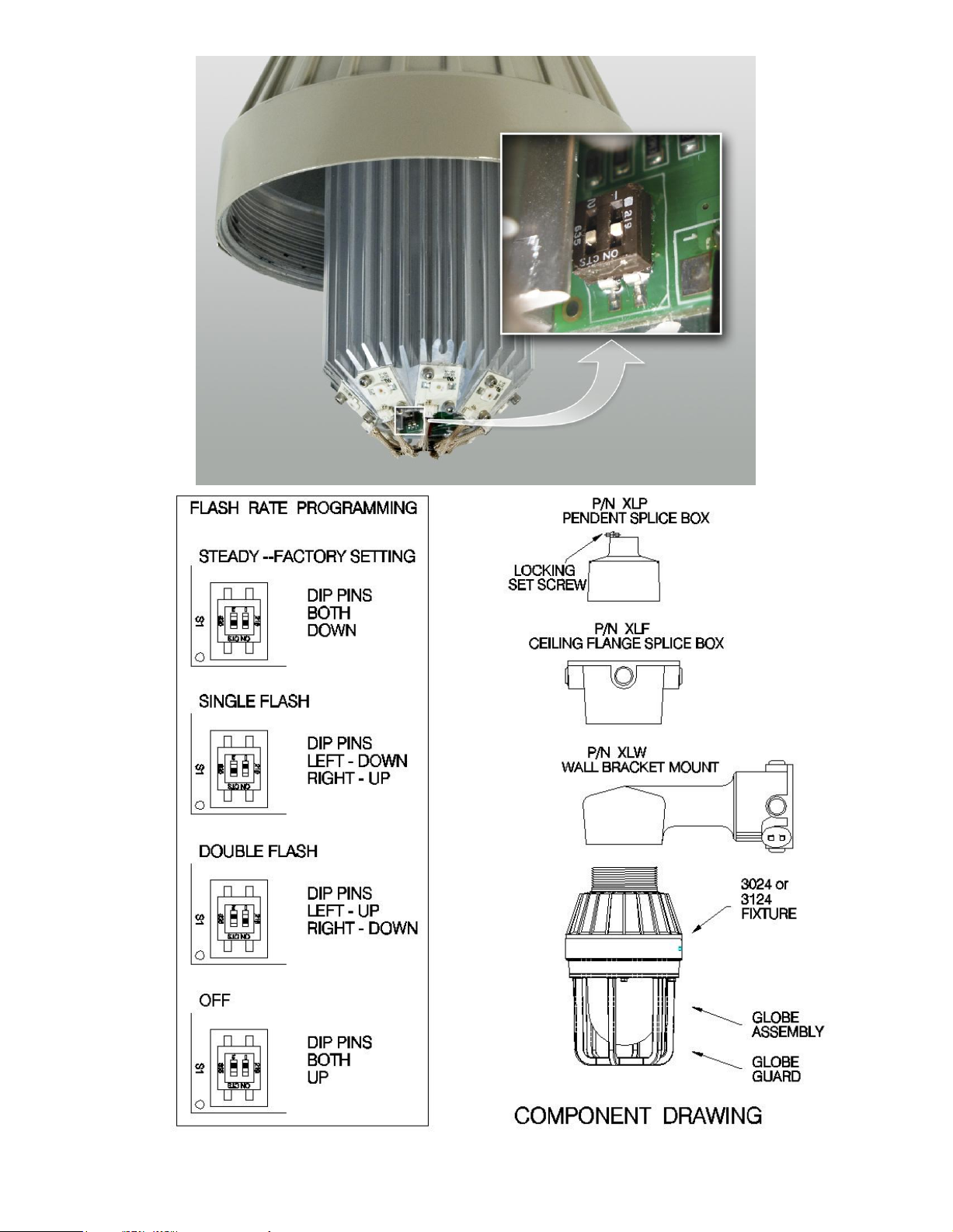

1. Using the component drawing shown here,

remove the splice box from the fixture (if attached).

2. Refer to the splice box mount instruction sheet

K1087 included with the splice box. Install the

pendent mount splice box to the conduit and secure

with locking set screw. Install the ceiling mount using

four (4) external mounting screws.

NOTE: Fixture splice box must be grounded.

3. Remove the terminal block from the splice box by

loosening the two (2) mounting screws.

4. Connect the ground wire to the green screw inside

the base of the splice box.

OPERATIONAL DATA

Operate this fixture at its rated voltage. See fixture

nameplate for this data.

CAUTION: Disconnect the supplying circuit

before opening or reprogramming this fixture.

REPROGRAM FLASH RATE

Loosen the set screw, unscrew and remove the globe

support assembly.

Locate the DIP switch on the LED power supply at

the top center of the LED heatsink. CAUTION: Use

care not to disturb the LED wire harness. Change

the DIP switch pin settings as per the diagram.

Inspect the mating threads to be sure they are clean

and well lubricated. Inspect the globe for scratches.

NOTE: If the globe is scratched or chipped, the

globe support assembly must be replaced.

Reinstall the globe assembly.

When reprogramming, be careful not to damage the

external threaded areas, since they maintain the

fixtures explosion-proof properties. The threads

should be lubricated periodically.

5. Connect the supply lines to the terminal block.

(NOTE: For DC voltage the terminal block is to be

wired “POS” (+) to the “LINE” terminal and “NEG” (-)

to the “COM” or “WHITE” terminal.)

6. Reinstall the terminal block in the splice box, and

securely tighten it in place.

7. Thread the fixture into the splice box and secure

with the set screw. Be sure that the mating threads

are clean and adequately lubricated.

8. Check the tightness of all set screws and all

threaded joints. Turn on the supplying circuit to test

the fixture.

Save the installation instructions for maintenance

personnel.

IS0516-01

06-04-2013

Check the tightness of all set screws and all threaded

joints. Turn on the supplying circuit to test the fixture.

MAINTENANCE DATA

To maintain maximum light output from this fixture, it

should be cleaned periodically per the following

suggestions.

The aluminum exterior of the fixture should be

cleaned only with a mild soap or cleaner, and should

be rinsed with water immediately. Alkaline or acidic

cleaners should never be used on aluminum.

The glass globe may be cleaned with any nonabrasive cleaner. The globe should be regularly

inspected for scratches and chips.

These periodic cleaning procedures are important in

preventing the accumulation of dust and dirt which

will impair the light output of the fixture.

Page 2

FLASH RATE PROGRAMMING SWITCH LOCATION

IS0516-01

06-04-2013

Page 3

IS0516-01

06-04-2013

Loading...

Loading...