Tokyo Keiso M-900 series Technical Guidance

■ OUTLINE

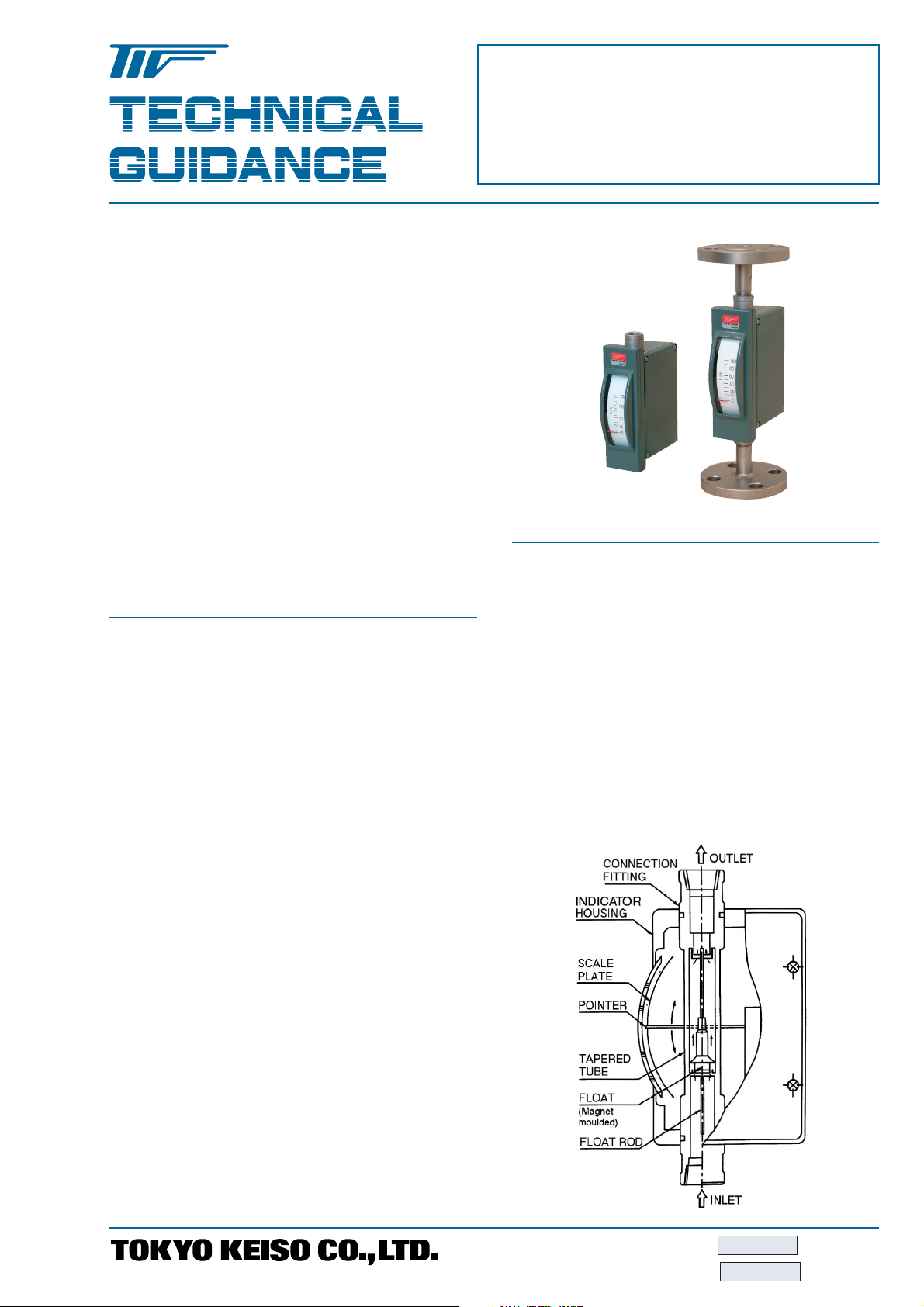

M-900 series MICRO FLOWMETER is a metal tube

variable area flowmeter for small flow measurement.

All metallic construction covers even high temperature

and high pressure applications.

Thanks to compact design, M-900 is suitable for

assembling onto various devices. It also covers small

sized industrial processes.

M-900 series MICRO FLOWMETER has been used

for nuclear power plants for long time and HPGSL

certified version is also available.

In addition to local indication, various versions including

pneumatic, electric and alarm output types are ready

to meet your requirements of remote monitoring and

control.

■ FEATURES

1. Compact design

Small and light design offers easy installation onto

panels as well as process pipings.

2. High sensitivity

The pivot bearing and light weight pointer enable

to follow float movement swiftly.

3. Suitable for corrosive and opaque fluids

Anti-corrosive materials such as titanium and

MA276 are available to meet your specifications.

For assembling onto devices, test plants and general

industrial processes

M-900 Series

MICRO FLOWMETER

■ OPERATING PRINCIPLE

The flow path has a tapered part. A float in which a

magnet is moulded is located in the tapered tube. The

fluid is introduced from the bottom end of flowmeter

and goes through the tube upward.

Because of the differential pressure produced by the

float and tapered tube, the float is pushed upward and

stops at a position where the weight of float and the

differential pressure balance. Thus, the position of float

corresponds to the flow rate. The moulded magnet in

the float attracts the pointer, and the pointer indicates

the flow rate on the scale plate.

The inside of the tube and indication mechanism are

totally isolated by magnetic coupling.

4. Easy reading of scale and pointer

The long pointer and wide linearized scale plate

make your reading easier.

5. Supporting devices

Various supporting devices to meet your requirements

are available such as flow control needle valve,

strainer and constant flow valve.

TG-F285-2E JAN. 2007K

TG-F285-8E MAY. 2014K

M-900 Series MICRO FLOWMETER

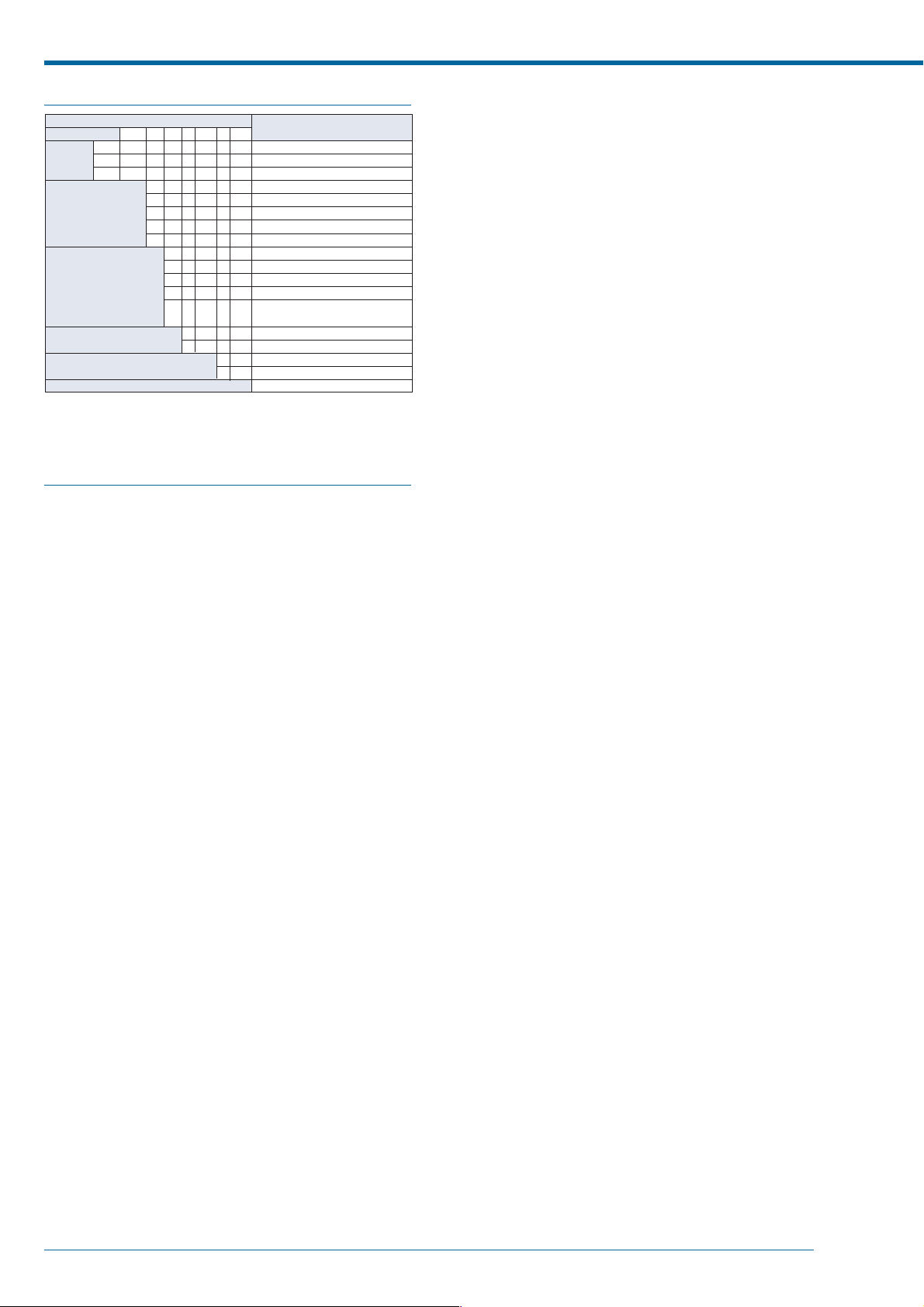

■ MODEL CODE

MODEL CODE

M–9

Construction

Function

Flow direction

Additional function 1

Additional function 2

Special

*1 Flameproof type is applied only for electric transmission type EP-M-92첸.

*2 Intrinsically safe type is applied only for alarm output type IS-M-95첸.

*3 Liquid damper can be provided on the flowmeters with Bottom side

EP–

IS –

and Bottom rear

→Top rear connections only.

–

–

Dust-proof and weatherproof

Flameproof *

0

1

2

5

6

1

2

3

4

5

–

D

–

DU

Intrinsically safe *

Local indication

Pneumatic transmission

Electric transmission

Alarm output with reed switch

Alarm output with photo electric switch

Bottom to Top

Bottom to Top side

Bottom side to Top side

Bottom side to Top

Bottom rear to Top rear (only available for local indicator type)

With liquid damper *

With gas damper

–

Needle valve at outlet

VU

–

Needle valve at inlet

VL

/Z

Contents

1

2

3

→첸

■ ADITIONAL FUNCTION

1. Liquid damper Model M-9첸첸-D

A damper mechanism is required for gas and steam

measurement especially at low pressure service to

prevent float hunting.

The damper installed at the bottom of flowmeter

ensures the accuracy and durability of flowmeter.

The damping mechanism works to reduce the

abrupt movement of float utilizing the resistance

generated between oil in the damper and damping

element connected to float rod.

The damper is recommended also for the liquid

service having a pulsation flow.

is applicable because of the ingress into the piston

and cylinder which might lead to the malfunctioning

of the flowmeter.

3. Needle valve M-9첸첸-V첸

A needle valve used for flow rate control is

recommended at the downstream of flowmeter to

avoid hunting for gas measurement.

On the other hand, for liquid measurement the

pulsation may be eased by the valve located

upstream.

4. Magnet strainer. See clause "Accessories" at the

following page.

The iron particles contained in fluids may cause

the malfunctioning of flowmeter due to the attracted

irons on the moulded magnet in the float. The

particles can be eliminated with the magnet strainer

at the inlet of the flowmeter. For this purpose

dedicated strainer with 100 mesh (optionally 200

mesh) is available.

5. Purge set. See clause "Accessories" at the

following page.

Purge set of M-900 micro flowmeter and constant

flow valve keeps constant flow rate even supply

pressure or down stream pressure is fluctuated.

2. Gas damper Model M-9첸첸-DU

The gas damper which requires no damper liquid

is available for gas measurement. A mechanical

damper consists of a cylinder and a piston

connected with float rod. This type needs no space

for damping mechanism at the bottom of flowmeter.

Therefore, this damper is applied for any direction

type of flowmeters which result in the flexibility of

piping design. Furthermore unnecessary re-filling

of damper liquid improves the maintenability.

The gas damper is effective for the low pressure

gas services which cause hunting of indication and

for the services which does not permit damping

liquids. It is highly recommended to have gas

damper for the services less than 0.3MPa pressure

and without needle valve at the downstream.

However, this type is applicable only for dry gas

services and not applicable for liquids nor

condensable vapors. Neither chlorine gas which is

synthesized easily with other chemicals nor gases

containing foreign materials like rust, dust and oil

2TOKYO KEISO CO., LTD. TG-F285-8E

■ ACCESSORIES

NEEDLE VALVES

Needle valve for flow adjustment. It will be assembled onto flowmeter

● STANDARD SPECIFICATION

Nominal size Rc3/8

Fluid pressure Max. 3 MPa

Fluid temperature –15 to +150°C

Material SUS316/PTFE

High pressure versions are available on request.

Consult factory for details

M-900 Series MICRO FLOWMETER

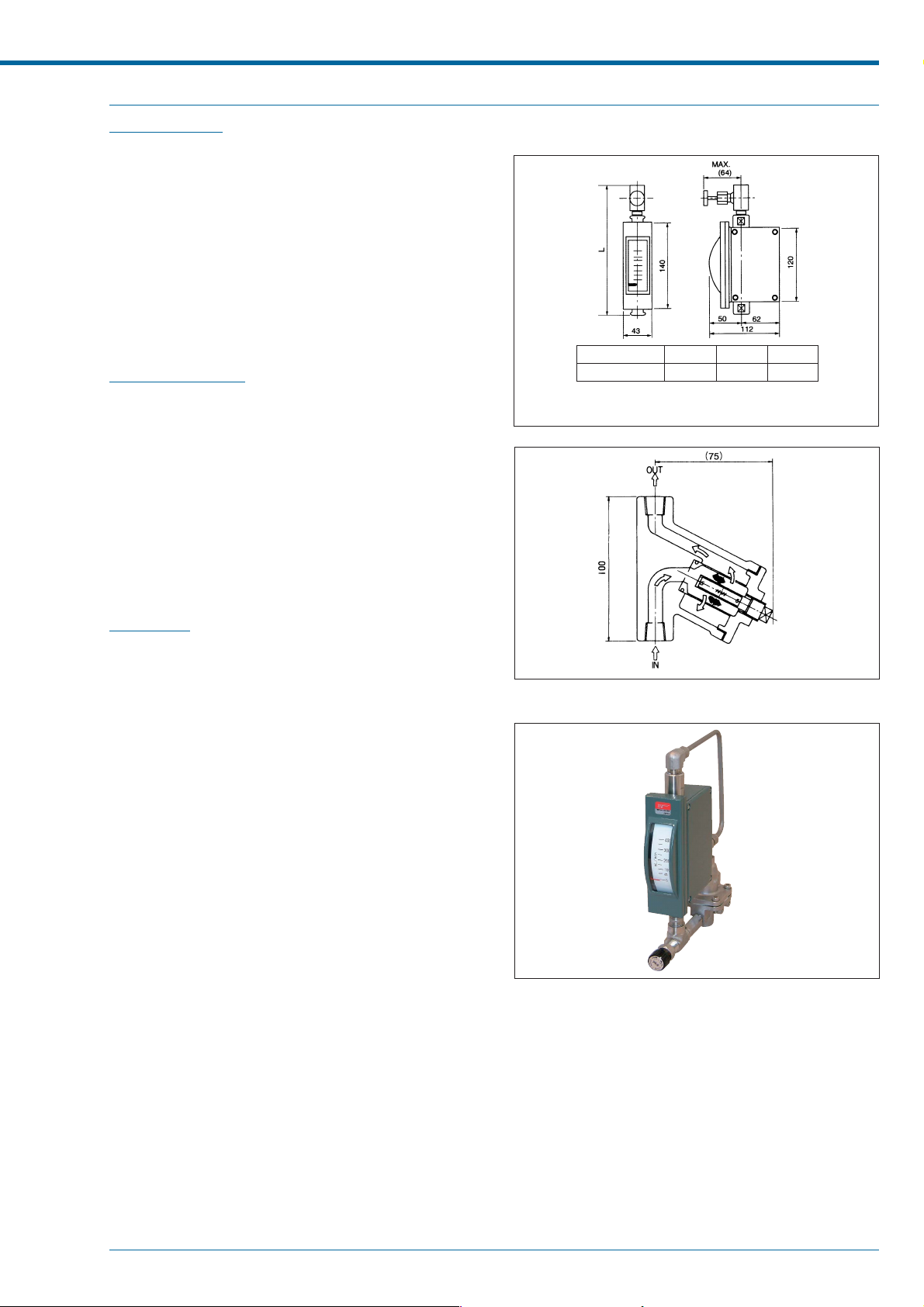

● External dimension of M-901-V (With valve)

Standard type

MAGNET STRAINER

A magnet strainer will be assembled into the flowmeter before deliv-

ery on request.

● STANDARD SPECIFICATION

Nominal size 1/4”, 3/8”, 1/2”

Fluid pressure Max. 1.5MPa

Fluid temperature Max. 200°C

Filter Std. 100 mesh

(200 mesh as option)

Material SUS304, SUS316

PURGE SET

Separate TECHNICAL GUIDANCE of "C" Series is available on re-

quest for this version.

Thread size

L (mm

* Screw socket (s) provided for Rc1/4 and Rc 1/2.

* "L" length of the flowmeter with gas damper is

extended by 40mm at downstream.

Rc1/4

)

245

Rc3/8

225

● External dimension of MAGNET STRAINER

Rc1/2

275

● CM-21-900 TYPE PURGE SET

TOKYO KEISO CO., LTD. 3TG-F285-8E

Loading...

Loading...