TOKO TK65020MTL Datasheet

ADVANCED INFORMATION

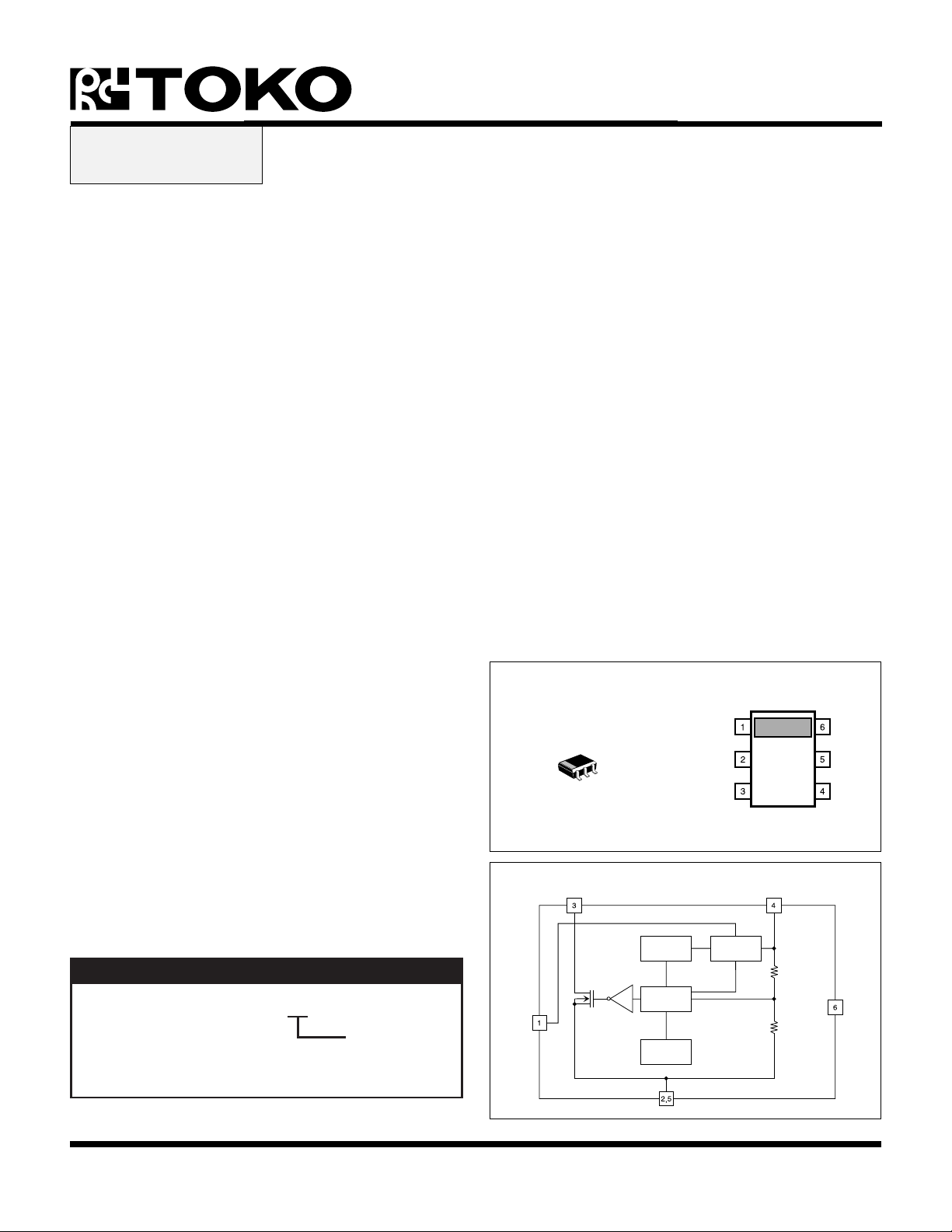

V

IN

GND

SW

NC

V

OUT

CONTROL

CIRCUIT

OSCILLATOR

Vref UVLO

20P

TK65020

ADVANCED

INFORMATION

FEATURES

■ Guaranteed 0.9 V Operation

■ Very Low Quiescent Current

■ Internal Bandgap Reference

■ High Efficiency MOS Switching

■ Low Output Ripple

■ Laser-Trimmed Output Voltage

■ Laser-Trimmed Oscillator

■ Undervoltage Lockout

■ Regulation by Pulse Burst Modulation (PBM)

DESCRIPTION

The TK65020 low power step-up DC-DC converter is

designed for portable battery-powered systems, capable

of operating from a single battery cell down to 0.9 V. The

TK65020 provides the power switch and the control circuit

for a boost converter. The converter takes a DC input and

boosts it up to a regulated 2.5 V output .

STEP-UP VOLTAGE CONVERTER

APPLICATIONS

■ Battery Powered Systems

■ Cellular Telephones

■ Pagers

■ Personal Communications Equipment

■ Portable Instrumentation

■ Portable Consumer Equipment

■ Radio Control Systems

taken to achieve reliability through the use of Oxide,

double Nitride passivation. The TK65020 is available in a

miniature 6-pin SOT-23L-6 surface mount package.

For other output levels, please refer to the TK651xx and

TK652xx Toko series of step-up converters.

The output voltage is laser-trimmed. An internal

Undervoltage Lockout (UVLO) circuit is utilized to prevent

TK65020

the inductor switch from remaining in the “on” mode when

the battery voltage is too low to permit normal operation.

V

IN

NC

Pulse Burst Modulation (PBM) is used to regulate the

voltage at the V

pin of the IC. PBM is the process in

OUT

which an oscillator signal is gated or not gated to the switch

drive each period. The decision is made just before the

GND

SW

GND

V

OUT

start of each cycle and is based on comparing the output

voltage to an internally-generated bandgap reference.

The decision is latched, so the duty ratio is not modulated

within a cycle. The average duty ratio is effectively

modulated by the “bursting” and skipping of pulses which

BLOCK DIAGRAM

can be seen at the SW pin of the IC. Special care has been

ORDERING INFORMATION

TK65020MTL

Tape/Reel Code

TAPE/REEL CODE

TL: Tape Left

January 1999 TOKO, Inc. Page 1

TK65020

ADVANCED INFORMATION

ABSOLUTE MAXIMUM RATINGS

All Pins Except SW and GND .................................... 6 V

SW Pin ....................................................................... 9 V

Power Dissipation (Note 1) ................................. 400 mA

Storage Temperature Range ................... -55 to +150 °C

Operating Temperature Range ...................-20 to +80 °C

Junction Temperature ...........................................150 °C

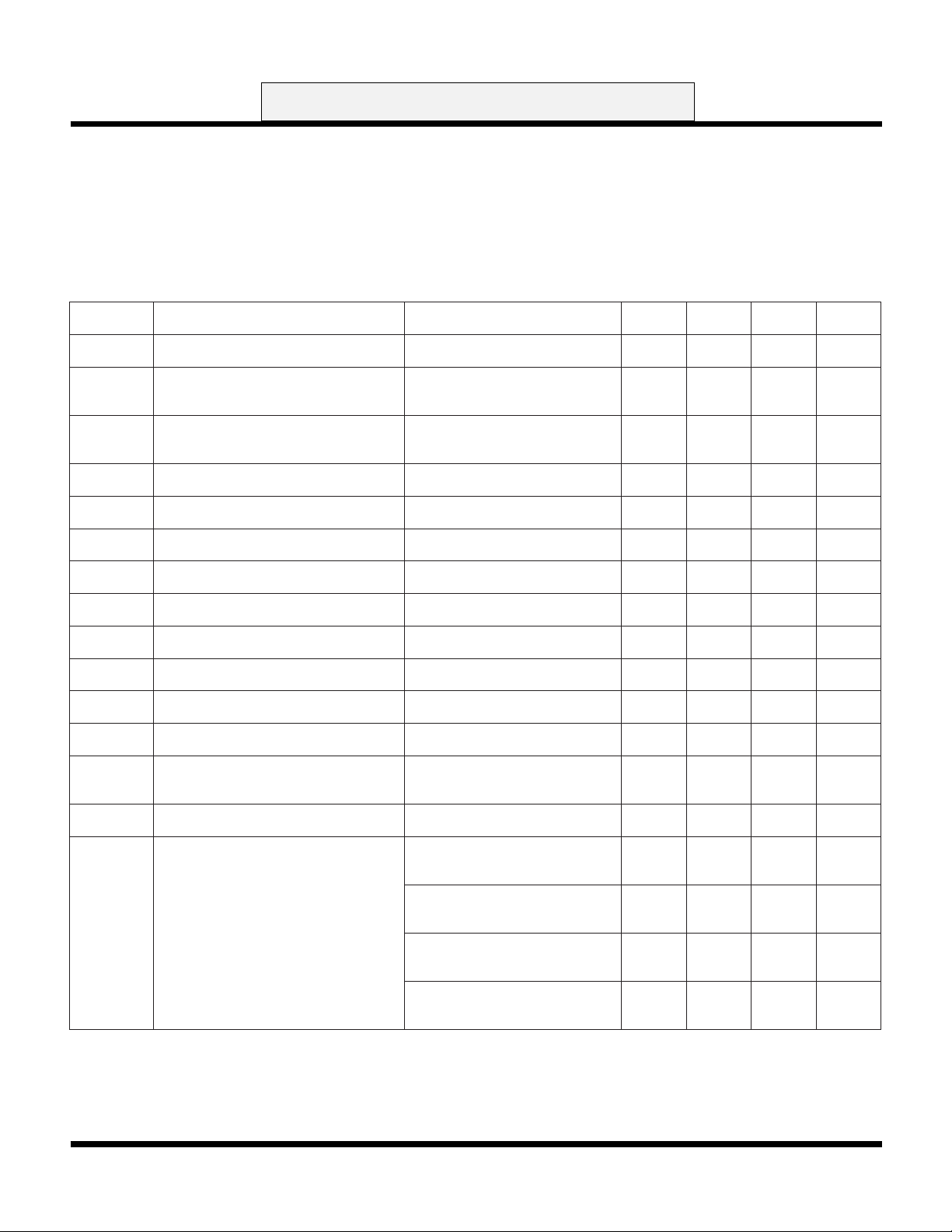

TK65020 ELECTRICAL CHARACTERISTICS

Over operating temperature range and supply voltage range, unless otherwise specified.

LOBMYSRETEMARAPSNOITIDNOCTSETNIMPYTXAMSTINU

V

NI

I

)Q(B

V(I

)VotnitnerruCtnecseiuQ

NI

)VotnitnerruCtnecseiuQ

V(I

TUO

f

CSO

∆f

/∆T

CSO

D

CSO

V

∆V

/∆T

TUO

∆V

∆V

R

)NO(WS

FFE)4,3setoN(ycneiciffEretrevnoC

egatloVylppuS09.006.1V

V

NI

)3etoN(tnerruCyrettaBdaoLoN

T

A

V

niP

NI

niPVNI,V3.1=I

TUO

ycneuqerFrotallicsOlanretnIV

rotallicsOfooitaRytuDemit-nOT

)GER(TUO

VfodlohserhTnoitalugeR

TUO

VfoytilibatSerutarepmeT

)DAOL(TUO

)ENIL(TUO

VfonoitalugeRdaoL

VfonoitalugeReniL

)GER(TUO

)GER(TUO

niPWSfoecnatsiser-nOT

NI

T

A

NI

rotallicsOfoytilibatSerutarepmeTV

NI

A

T

A

V

)GER(TUO

NI

V

NI

∆V

NI

≥ 4.20.1V

A

V

NI

,V3.1=I

TUO

C°52=

,V3.1=I

TUO

C°52=

TUO

,V3.1=I

TUO

,V3.1=

C°52=540555%

C°52=83.205.285.2V

,V3.1=I

TUO

,V3.1=I

TUO

V52.0=

,V3.1=I

TUO

,Am0=

,Am0=

1426Aµ

1102Aµ

Am0=2102Aµ

Am0=0738201zHk

gnippikSesluPoN

1.0C°/%

Am0=001Vm

Am4ot0=005Vm

02-03Vm

,Am6=

lioCFD3,Hµ59=L

67%

V

VLU

ImumixaM

I

)XAM(TUO

Note 1: Derate at 0.8 mW/oC for operation above TA = 25 oC ambient temperature, when heat conducting copper foil path is maximized on the printed

circuit board. When this is not possible, a derating factor of 1.6 mW/ °C must be used.

TUO

)4,2setoN(

egatloVtuokcoLegatlovrednUT

A

V

NI

T,V1.1=

)5etoN(,C°52=54.097.0V

A

,C°52=

lioCFD3,Hµ59=L

V

NI

retrevnoCrof

V

NI

T,V3.1=

A

,C°52=

lioCFD3,Hµ59=L

T,V1.1=

A

,C°52=

lioC37D,Hµ93=L

V

NI

T,V3.1=

A

,C°52=

lioC37D,Hµ93=L

50.8Am

90.51Am

8.91Am

0.83Am

Page 2 January 1999 TOKO, Inc.

ADVANCED INFORMATION

TK65020

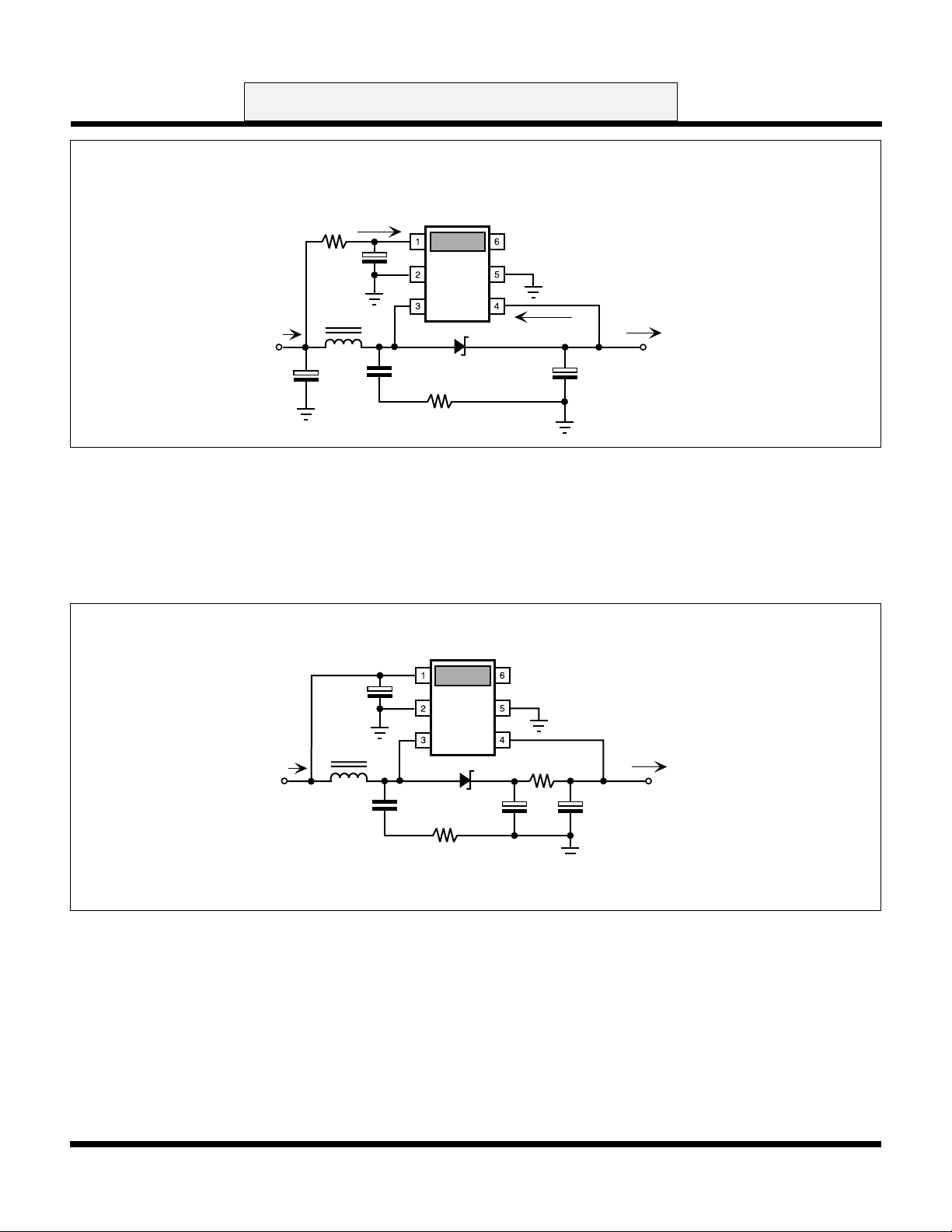

Inductor L: Toko A682AE-014 or equivalent

Diode D: LL103A or equivalent

Capacitors CN:CO:CB: Panasonic TE series,

ECS-TOJY106R

I

B

V

IN

BENCH TEST CIRCUIT

I(VIN)

V

R

N

1 K

C

10 µF

L = 95 µH

C

B

10 µF

IN

GND GND

N

C

S

220 pF

1 K

R

S

NC

V

OUTIND

D

I(V

)

OUT

Note 2: Maximum load current depends on

inductor value and input voltages.

Note 3: Output ripple depends on filter

capacitor values, ESRs and the

inductor value.

Note 4: When using specified Toko inductor

and Schottky diode with VF = 0.45 V

@ 100 mA.

Note 5: Regulation not guaranteed

I

OUT

V

OUT

C

O

10 µF

The Bench Test Circuit is used most of the time to measure the typical (typ.) values in the Electrical Characteristics

section, and make the Typical Performance graphs.

Note: In measuring the oscillator frequency and the Max I

on the bench, the converter was loaded until “no pulse

OUT

skipping” mode was achieved.

FINAL TEST CIRCUIT

V

IN

GND GND

N

C

S

220 pF

R

1 K

S

I

B

V

IN

Inductor L: Toko A682AE-014 or equivalent

Diode D: LL101

Capacitors CN:CU:CD: Panasonic TE series,

C

10 µF

L = 95 µF

ECS-TOJY106R

Above is the Final Test Circuit through which each of the production parts must pass. In this test circuit, the part is tested

against the specification limits in the data sheet (the min. and max. values in the Electrical Characteristics) at room

temperature, and is rejected if the tested values are outside the minimum (min.) and maximum (max.) values.

NC

V

OUTSW

I

R

OF

15

D

++

C

U

10 µF

10 µF

OUT

V

OUT

C

D

January 1999 TOKO, Inc. Page 3

TK65020

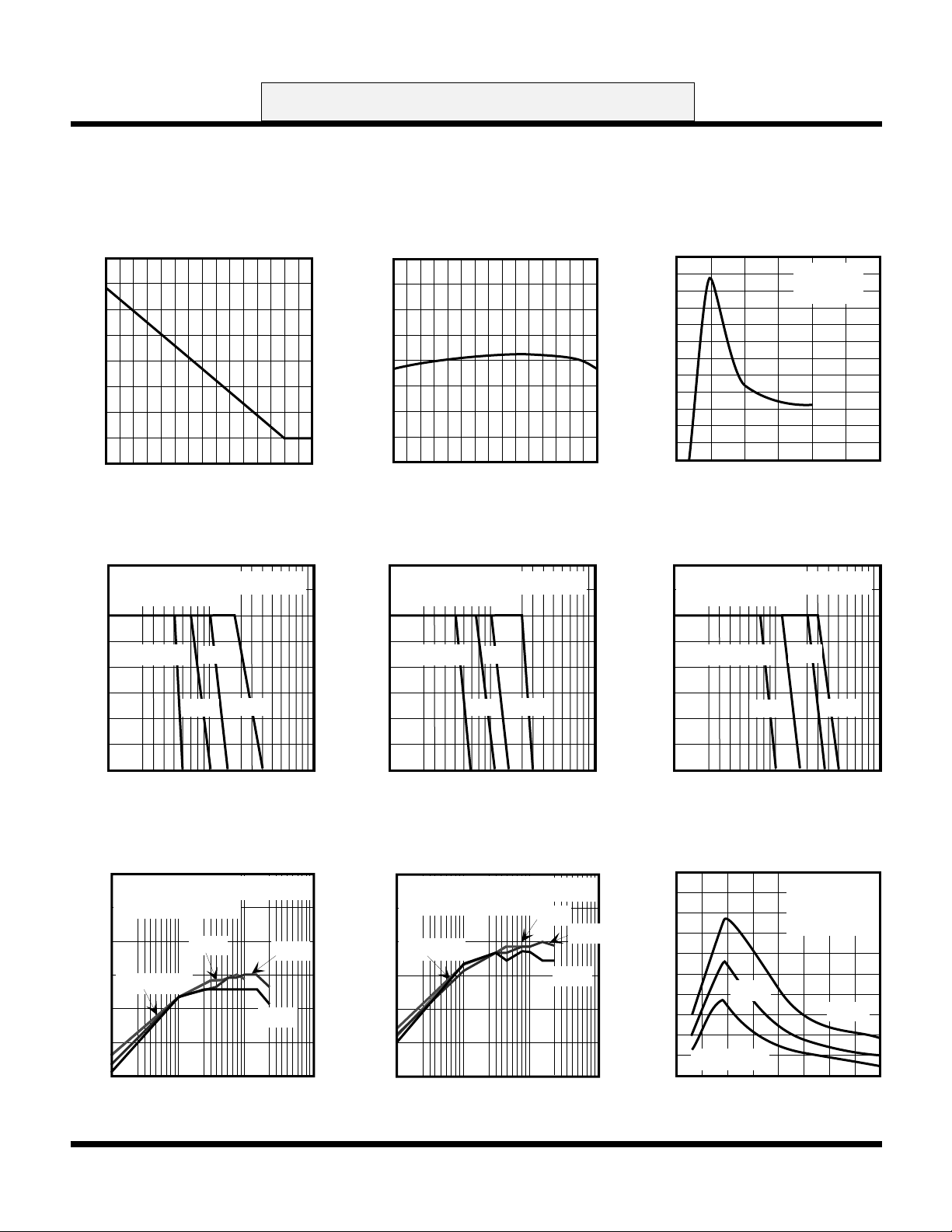

BATTERY CURRENT

VS.

INPUT VOLTAGE

120

0 .5 1 1.5 2 2.5 3

VIN (V)

I

B

(µA)

100

60

80

40

20

0

TA = 25 °C

NO LOAD

TK65020

ADVANCED INFORMATION

TYPICAL PERFORMANCE CHARACTERISTICS

OSCILLATOR FREQUENCY VS.

TEMPERATURE

95

90

(kHz)

85

OSC

f

80

75

-50 0 50 100

TEMPERATURE (°C)

OUTPUT VOLTAGE

2.6

L = 95 µH

TOKO P/N: A682AE-014

(3DF SERIES)

LOAD CURRENT

TA = 25 °C

2.5

(V)

OUT

V

2.4

2.3

V

IN

= 0.9 V

1.3 V

1.1 V

1.6 V

VS.

OUTPUT REGULATION VOLTAGE

TEMPERATURE

2.60

2.55

(V)

2.50

OUT(REG)

V

2.45

2.40

-50 0 50 100

TEMPERATURE (°C)

OUTPUT VOLTAGE

2.6

L = 100 µH

TOKO P/N: A636CY-101M

(D73 SERIES)

LOAD CURRENT

TA = 25 °C

2.5

(V)

OUT

V

2.4

2.3

V

IN

= 0.9 V

1.3 V

1.1 V 1.6 V

VS.

VS.

2.6

L = 39 µH

TOKO P/N: A636CY-390M

(D73 SERIES)

2.5

(V)

2.4

OUT

V

2.3

OUTPUT VOLTAGE

LOAD CURRENT

TA = 25 °C

V

IN

= 0.9 V

1.3 V

1.1 V 1.6 V

VS.

2.2

1 10 100

EFFICIENCY

90

L = 95 µF

Toko P/N: A682AE-014

(3DF SERIES) SMALL COIL

85

80

75

VIN = 0.9 V

EFF (%)

70

65

60

0.1 1 10 100

Page 4 January 1999 TOKO, Inc.

I

(mA)

OUT

VS.

LOAD CURRENT

TA = 25 °C

1.1 V

I

(mA)

OUT

1.3 V

1.6 V

2.2

1 10 100

I

(mA)

OUT

EFFICIENCY

90

L = 100 µF

Toko P/N: 636CY-101M

(D73 SERIES) LARGER COIL

85

80

V

= 0.9 V

IN

VS.

LOAD CURRENT

TA = 25 °C

1.1 V

75

EFF (%)

70

65

60

0.1 1 10 100

I

(mA)

OUT

1.3 V

1.6 V

2.2

1 10 100

I

(mA)

OUT

MAXIMUM OUTPUT CURRENT

INDUCTOR VALUE (µH)

50

NO PULSE

SKIPPING

40

(mA)

30

20

OUT(MAX)

I

1.1 V

MODE

TA = 25 °C

10

VIN = 0.9 V

0

0 40 80 120 160

INDUCTOR VALUE (µH)

VS.

1.3 V

ADVANCED INFORMATION

SINGLE-CELL APPLICATION

TK65020

The TK65020 is a boost converter control IC with the

power MOSFET switch built into the device. It operates

from a single battery cell and steps up the output voltage

to a regulated 2.5 V. The device operates at a fixed

nominal clock frequency of 83 kHz.

In its simplest form, a boost power converter using the

TK65020 requires only three external components: an

inductor, a diode, and a capacitor.

The analysis is easier to follow when referencing the

simple boost circuit below.

V

IN

GND GND

NC

V

OUTSW

V

+

OUT

FIGURE 1: SIMPLE BOOST CONVERTER

and Noise Considerations” section) can be determined if

needed or desired.

The TK65020 runs with a fixed oscillator frequency and it

regulates by applying or skipping pulses to the internal

power switch. This regulation method is called Pulse Burst

Modulation (PBM).

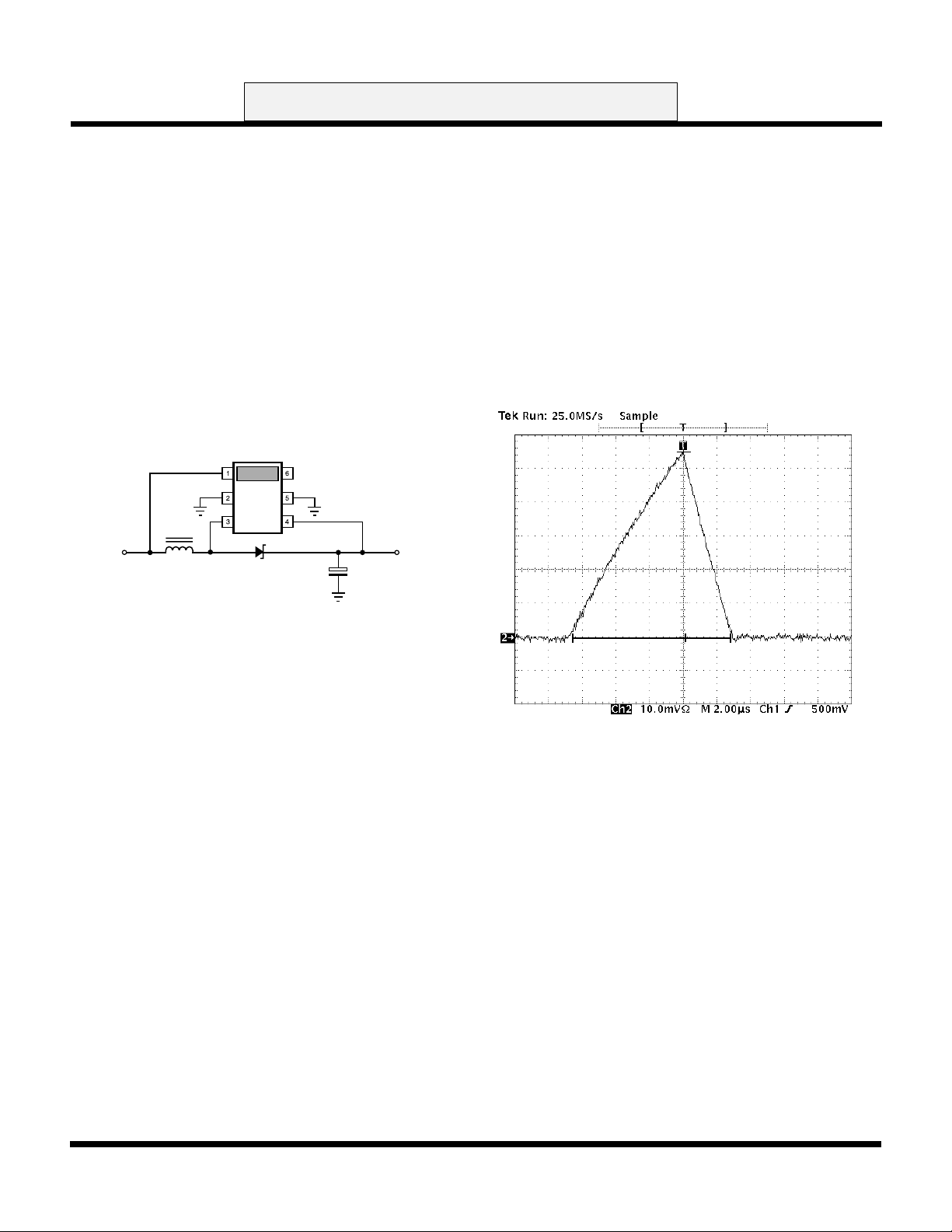

ANALYSIS OF SWITCHING CYCLE

I

PEAK

di/dt = VIN/ L

t (on)

di/dt = - (V

t (off)

+ Vf - VIN)/ L

OUT

t (deadtime)

THEORY OF OPERATION

The converter operates with one terminal of an inductor

connected to the DC input and the other terminal connected

to the switch pin of the IC. When the switch is turned on, the

inductor current ramps up. When the switch is turned off (or

“lets go” of the inductor), the voltage flies up as the inductor

seeks out a path for its current. A diode, also connected to

the switching node, provides a path of conduction for the

inductor current to the boost converter’s output capacitor.

The TK65020 monitors the voltage of the output capacitor

and has a 2.5 V threshold at which the converter switching

becomes deactivated. So the output capacitor charges up

to 2.5 V and regulates there, provided that no more current

is drawn from the output than the inductor can provide. The

primary task, then, in designing a boost converter with

the TK65020 is to determine the inductor value (and its

peak current rating to prevent inductor core saturation

problems) which will provide the amount of current

needed to guarantee that the output voltage will be

able to maintain regulation up to a specified maximum

load current. Secondary necessary tasks also include

choosing the diode and the output capacitor. Then the

snubber and filtering component values (consult the “Ripple

Above is the input or inductor current waveform over a

switching cycle.

From an oscillator standpoint, the switching cycle consists

of only an on-time and an off-time. But from an inductor

current standpoint, the switching cycle breaks down into

three important sections: on-time, off-time, and deadtime.

The on-time of the switch and the inductor current are

synonymous. During the on-time, the inductor current

increases. During the off-time, the inductor current

decreases as it flows into the output. When the inductor

current reaches zero, that marks the end of the inductor

current off-time. For the rest of the cycle, the inductor

current remains at zero. Since no energy is being either

stored or delivered, that remaining time is called “deadtime.”

This mode of the inductor current decaying to zero every

cycle is called “discontinuous mode.” In summary, energy

is stored in the inductor during on-time, delivered to the

output during off-time, and remains at zero during deadtime.

January 1999 TOKO, Inc. Page 5

Loading...

Loading...