TOKO TK65015MTL, TK65015MBX Datasheet

V

V

V

G

T

FEATURES

■ 0.9 V Operation

■ Very Low Quiescent Current

■ Internal Bandgap Reference

■ High Efficiency

■ Low Output Ripple

■ Microprocessor Reset Output

■ Laser-Trimmed Output Voltage

■ Undervoltage Lockout

■ Regulation by Pulse Burst Modulation (PBM)

TK65015

STEP-UP VOLTAGE CONVERTER

WITH VOLTAGE MONITOR

APPLICATIONS

■ Battery Powered Systems

■ Cellular Telephones

■ Pagers

■ Personal Communications Equipment

■ Portable Instrumentation

■ Portable Consumer Equipment

■ Radio Control Systems

DESCRIPTION

The TK65015 Low Power Step-Up DC-DC converter is

designed for portable battery powered systems, capable of

operating from a single battery cell down to 0.9 V.

The output voltage is laser-trimmed to 3.0 V. An internal

detector monitors the output voltage and provides an

active-low microprocessor reset signal whenever the output voltage falls below an internally preset limit. An internal

undervoltage lockout circuit is utilized to prevent the inductor switch from remaining in the "ON" mode when the

battery voltage is too low to permit normal operation.

Special care has been taken to achieve high reliability

through the use of Oxide, Nitride passivation and an

additional polyimide coating. The TK65015 is available in a

very small plastic surface mount package. (SOT-23L)

Pulse burst modulation (PBM) is used to regulate the

voltage at the V

which an oscillator signal is gated or not gated to the switch

drive each period. The decision is made just before the start

of each cycle and is based on comparing the output voltage

to an internally-generated bandgap reference. The decision is latched, so the duty ratio is not modulated within a

cycle. The average duty ratio is effectively modulated by

pin at the IC. PBM is the process in

OUT

the "bursting" and skipping of pulses which can be seen at

the IND pin of the IC.

The TK65015 provides the power switch and the control

circuit for a boost converter. The converter takes a DC

input (typically a single battery cell) and boosts it up to 3

volts. This regulated 3 volt output is typically used to supply

power to a microprocessor-controlled system.

TK65015M

M15

1

IN

2 5

ND

3

IND

6

RESE

GND

V

4

O

BLOCK DIAGRAM

2

ORDERING INFORMATION

TK65015M

Tape/Reel Code

IN

TAPE/REEL CODE

BX : Bulk/Bag

TL : Tape Left

IND

3 4

V

REF

CONTROL

1

CIRCUIT

RC OSC.

2,5

GND

UVLO

O

RESET

6

February, 1996 TOKO, Inc. 2-2-96 Page 1

TK65015

V

ABSOLUTE MAXIMUM RATINGS

All pins except GND................................................... 6 V

Power Dissipation (Note1) ................................. 400 mW

Storage Temperature Range ................... -55 to +150 °C

ELECTRICAL CHARACTERISTICS

Over operating temperature range, unless otherwise specified.

VARIABLE PARAMETER TEST CONDITION MIN TYP MAX UNIT

Operating Temp. Range............................-10 to + 50 °C

Lead Soldering Temperature (10 s) ......................240 °C

Junction Temperature ...........................................150 °C

V

IN

V

UVL

I (VIN) Quiescent current into VIN pin V

I (V

ƒ

) Quiescent current into V

OUT

(OSC)

Supply Voltage range 0.90 1.60 V

Undervoltage lockout threshold TA = 25 °C .74 V

= 1.3 V 20 35 µA

IN

pin V

OUT

OUT

= V

OUT (REG)

+20 mV 22 34 µA

Internal oscillator frequency VIN = 0.9 V & VIN = 1.6 V 70 83 102 kHz

Temperature stability of oscillator VIN = 1.3 V 800 ppm/°C

D

(OSC)

V

OUT(REG)

∆V

OUT(LINE)

∆V

O (LOAD)

V

OUT(RST)

∆V

OUT(RST)VOUT(RST)

V

RST(HI)

V

RST(LO)

R

SW(ON)

I

I(Q)

I

O(MAX)

On-time duty ratio of oscillator VIN = 0.9V & V

Regulation threshold of V

Temperature stability of V

Line regulation of V

Load regulation of V

V

during reset transition 2.48 2.70 V

OUT

OUT

OUT(REG)

OUT(REG)

OUT(REG)

(Note 2) 0mA < IO < 4mA 0 mV

VIN = 0.9 V & V

VIN = 1.3 V 250 ppm/°C

V

= 0.9 V & VIN = 1.6 V -20 0 20 mV

IN

= 1.6 V 36 50 64 %

IN

= 1.6 V 2.85 3.00 3.10 V

IN

threshold hysteresis 45 mV

Logic High of RESET w/r/t V

OUT

300 kΩ Pullup -100 mV

Logic Low of RESET 300 kΩ Pullup 100 mV

On-resistance of switch, IND pin V

OUT

= V

OUT(REG)

0.5 ohms

Quiescent current of converter (Note 5) VI = 1.3 V, IO = 0mA 80 120 µA

Maximum IO for converter (Notes 3,5) VI ≥ 1.1 V, VO Regulated 4 mA

η Converter efficiency (Notes 4,5) VI = 1.3 V, IO = 4 mA 74 %

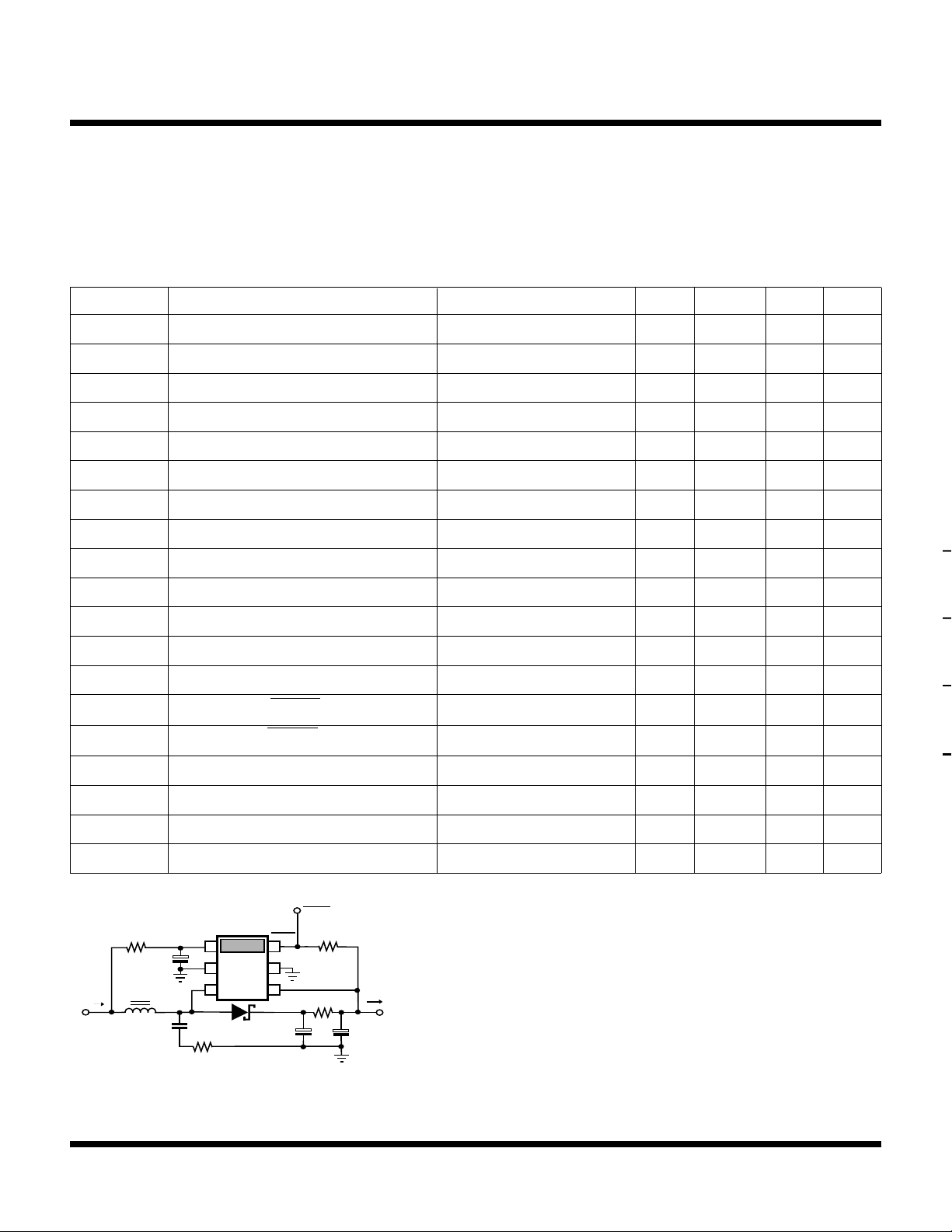

TEST CIRCUIT

1K

C

10 µF

L

= 95 µH

I

I

S

I

220 pF

V

IN

S

+

S

GND

S

IND

S

S

1K

1

2 5

3

D

RESET

6

GND

V

OUT

4

10 µF

RESET

ture, when heat conducting copper foil path is maximized on the printed circuit

board. When this is not possible, a derating factor of 1.6 mW/ °C must be used.

S

300 kΩ

15

S

+

C1

S

IO

V

+

10 µF

O

C2

S

S

Note 2: The output regulation threshold, V

be independent of the load. Regulation will occur provided that the load current is

within the capability of the converter, I

slightly with load due to the variation of the ripple voltage, whose magnitude is

OUT(REG)

O(MAX).

primarily determined by the inductor and the ESR of the output capacitors.

Note 3: Maximum load current depends on inductor value. With a 0.9 V or 1.0 V

supply voltage, 4 mA can be obtained with a smaller inductor value.

Note 4: Converter efficiency is a function of the diode forward voltage and

, is guaranteed-by-design to

The output voltage may fluctuate

inductor winding resistance. It may also depend in varying degree on the inductor

value and capacitor ESRs. By trading component size for better specifications,

Note 1: Derate at 0.8 mW/oC for operation above TA = 25 oC ambient tempera-

Inductor L: Toko A682AE-014=P3 or equivalent

Diode D: LL103A or equivalent

efficiency greater than 80% can be attained.

Note 5: Test performed using the test circuit below.

Page 2 2-2-96 February, 1996 TOKO, Inc.

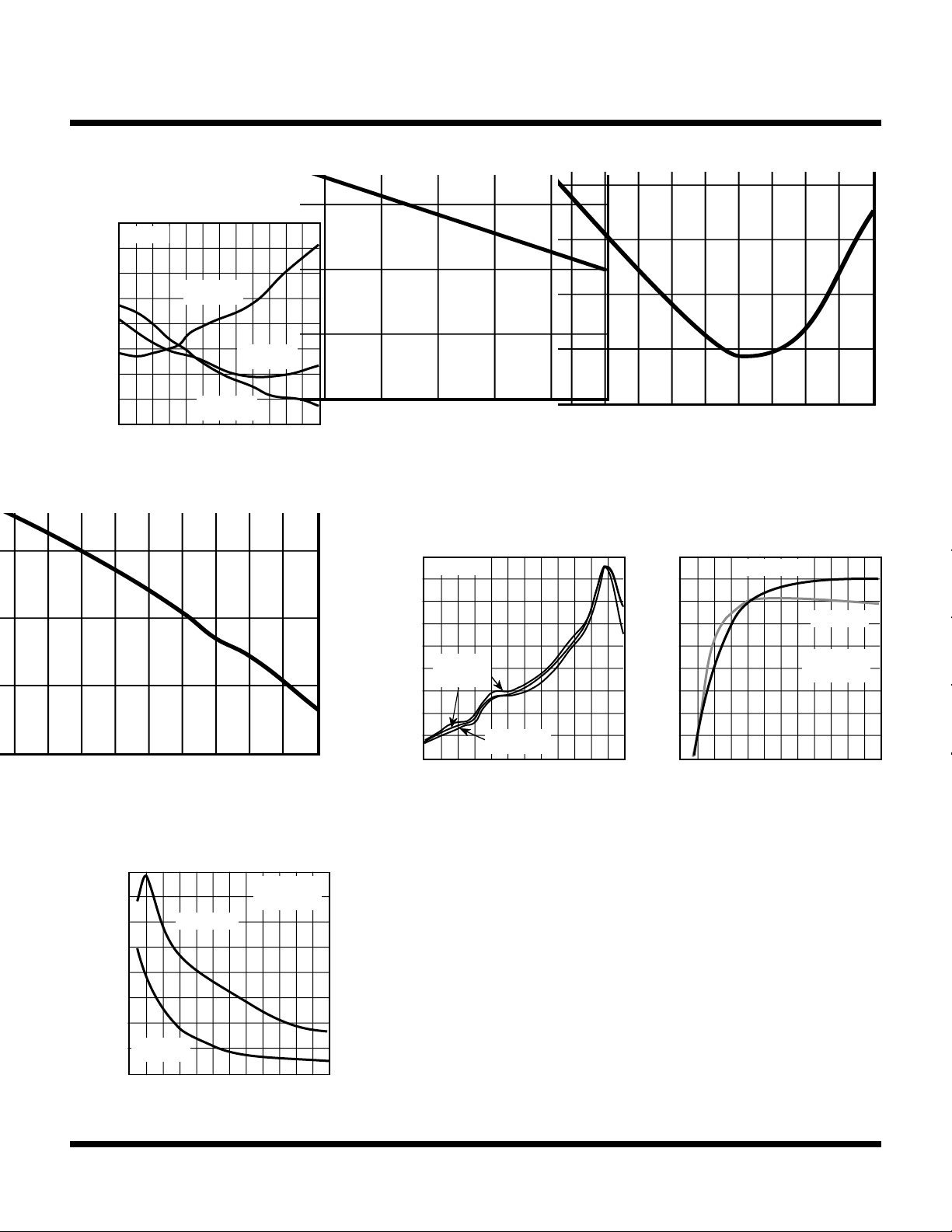

OSCILLATOR FREQUENCY vs.

-20040

80

T

)

8

6

884

280

0

22060

100

I

V

V

V

0

.0

-20040

80

T

)

2060100

5

5

5

5

5

5

I

5

5

5

5

V

V

080240

400

I

)

160

320

440

)

2

4

864

0

6

V

0

6

2

8

V

080240

400

I

)

160

320

440

4

642

0121086

V

V

0

4

= 1 mA

O

9

9

8

8

FREQUENCY (kHz)

8

7

TYPICAL PERFORMANCE CHARACTERISTICS

TEMPERATURE

= 0.9 V

IN

IN

= 1.6 V

IN

EMPERATURE (°C

= 1.3 V

1.5 2.5 3.5 4

UTPUT CURRENT (mA)

1

2.0 3.0

TEMPERATURE (°C)

TK65015

20 60 10

2

40 80

2

3

20 60 10

40 80

TEMPERATURE (°C)

MAXIMUM OUTPUT CURRENT vs.

1

1

INDUCTOR VALUE (µH)

= 1.3 V

IN

V

= 2.7 V

OUT

TA = 25 °C

OUTPUT VOLTAGE vs. TEMPERATURE

3.04

= 1 mA

O

3.03

3.02

3.01

3.00

2.99

2.98

OUTPUT VOLTAGE (V)

2.97

2.96

2.95

= 1.6 V

IN

= 1.3 V

IN

VIN = 0.9 V

EMPERATURE (°C

5

EFFICIENCY vs. INDUCTOR VALUE (µH

AT MAXIMUM OUTPUT CURRENT

8

8

8

7

7

6

EFFICIENCY (%)

6

5

5

= 1.3 V

IN

NDUCTOR VALUE (µH

= 0.9 V

IN

V

= 2.7 V

OUT

TA = 25 °C

Handling Molded Resin Packages

All plastic molded packages absorb some moisture from the air. If

moisture absorption occurs prior to soldering the device into the printed

circuit board, increased separation of the lead from the plastic molding

may occur, degrading the moisture barrier characteristics of the device.

This property of plastic molding compounds should not be overlooked,

paticularly in the case of very small packages, where the plastic is very

thin.

6

OUTPUT CURRENT (mA)

= 0.9 V

IN

In order to preserve the original moisture barrier properties of the package,

devices are stored and shipped in moisture proof bags, filled with dry air.

The bags should not be opened or damaged prior to the actual use of the

NDUCTOR VALUE (µH

7

devices. Once opened the devices should be stored in a low relative

humidity environment (40 to 65%) or in an enclosed environment with

desicant.

February, 1996 TOKO, Inc. 2-2-96 Page 3

Loading...

Loading...