Page 1

WWC T1

Calculator

Set Up & Maintenance

Manual

Document Ref 905675-001

Rev - 2

01/2006

Page 2

WWC T1 Set Up & Maintenance Manual

Great care has been taken in the preparation of this manual however T okheim

shall not be liable for any misunderstanding, errors and/or loss or defect

arising from the use of this manual.

Tokheim shall not be liable for damage to the product, nor for personal or

third party injury, caused by incorrect use of the product or by attempts to

maintain or to repair the product by parties other than those fully trained by

Tokheim or by its accredited third party representatives.

Please contact your nearest service department, at the relevant address

printed on the back cover of this manual, should any aspect of this manual

be unclear.

© Copyright by Tokheim. All intellectual rights arising from, accruing

to,and residing in this manual belong to Tokheim. No part of this

document may be reproduced in any form without the express written

permission of Tokheim.

Tokheim reserves the right to apply changes to this document and the

equipment without further notice.

Issue A

Document Ref 905675-001 Rev 2

Page 3

WWC T1 Set Up & Maintenance Manual Revision Record

REVISI ON RECORD

Date Revision Page Issue Reason

01/07/2004 1 All A Original Issue

19/01/2006 2 3 to 6 B Main Contents revised

19/01/2006 2 2-16,2-17 B Updated Func tionalities

19/01/ 2006 2 2-21 to 2-23 B New info added (Input Type, Mast er PIN Code, Gallon

Type, Cent Overshoot Hide, 4 position product indicator,

Heavy Lei); repagination

19/01/ 2006 2 3-1 B Sec tion 3 Contents revised

19/01/2006 2 3-6,3-7 B Headings changed

19/01/ 2006 2 5-1 B Sec tion 5 Contents revised

19/01/2006 2 5-4 to 5-16 B New info added (Cent Overs hoot Hide, 4 pos ition

product indicator, Heavy Lei); repagination

19/01/ 2006 2 6-1 B Sec tion 6 Contents revised

19/01/ 2006 2 6-8,6-9 B New info added (Heavy Lei)

19/01/2006 2 6-15 to 6-42 B New info added (Cent Overshoot Hide, 4 position

product indicator); repagination

19/01/ 2006 2 7-1 B Sec tion 7 Contents revised

19/01/2006 2 7-3 B New information added (Vapour Mes menu)

19/01/2006 2 7-7,7-8 A New pages inserted, new information added (Tokheim

protocol

19/01/2006 2 11-4 B New info added (max time no flow)

19/01/2006 2 12-2,12-3 B New options added to POM

Document Ref 905675-001 Rev 2 1

Page 4

Revision Record WWC T1 Set Up & Maintenance Manual

This page is intentionally blank

Issue A

2 Document Ref 905675-001 Rev 2

Page 5

WWC T1 Set Up & Maintenance Manual Contents

CONTENTS

1 INTRODUCTION......................................................................................................... 1-2

1.1 How to Use this Manual ..................................................................................... 1-2

1.2 Product Scope ..................................................................................................... 1-3

1.3 Authorised Technicians....................................................................................... 1-3

1.4 Contact Information ............................................................................................ 1-3

1.5 Health & Safety .................................................................................................. 1-3

1.5.1 Safety Checklist.................................................................................. 1-3

1.5.2 Duties of the Employees..................................................................... 1-4

1.5.3 Hazards ............................................................................................... 1-4

1.5.4 Warning Signs .................................................................................... 1-5

1.5.5 Personal Protective Equipment (PPE) ................................................ 1-6

1.6 Nomenclature ...................................................................................................... 1-7

2 PRODUCT INFORMATION....................................................................................... 2-2

2.1 System Description ............................................................................................. 2-2

2.1.1 Operating Principles ........................................................................... 2-2

2.2 Main Components of the WWC ......................................................................... 2-2

2.2.1 External Power Supply ....................................................................... 2-3

2.2.2 Mainboard .......................................................................................... 2-3

2.2.3 I/O Board (version 3++) ..................................................................... 2-4

2.2.4 Transaction Displays .......................................................................... 2-4

2.2.5 User Access Devices (UAK/UAM).................................................... 2-4

2.3 Different Configurations ..................................................................................... 2-4

2.3.1 Standard dispensers with up to four single products.......................... 2-5

2.3.2 Low-end dispensers : single product or twin configuration, super

high speed, single-sided (Fleet).......................................................... 2-5

2.3.3 Vapour Recovery Controller Board (VRC) ........................................ 2-6

2.3.4 Option Controller Board (OCB) ......................................................... 2-6

2.3.5 Hydraulic Option Modules (HOM) .................................................... 2-6

2.3.6 I/O Extension Board (IEB) ................................................................. 2-6

2.4 Product Option Matrix (POM)............................................................................ 2-6

2.5 Functionality ....................................................................................................... 2-6

2.5.1 Functionalities per hose...................................................................... 2-7

2.5.2 Functionalities per side .................................................................... 2-10

2.5.3 Functionalities per dispenser ............................................................ 2-16

2.5.4 Weights & Measures related Functionality ...................................... 2-21

Issue B

3 LPG SET UP .................................................................................................................. 3-2

3.1 LPG Functionality............................................................................................... 3-2

3.1.1 LPG Pulse Menu ................................................................................ 3-2

3.1.2 LPG Nozzle Flag Menu ...................................................................... 3-2

3.1.3 LPG Delay Timer Menu ..................................................................... 3-3

3.1.4 LPG Motor Off Timer Menu.............................................................. 3-3

3.2 LPG Hydraulic Functions ................................................................................... 3-4

3.2.1 Valves ................................................................................................. 3-4

3.2.2 Hydraulic Schematic .......................................................................... 3-5

3.3 Timing Diagrams ................................................................................................ 3-6

3.3.1 Timing with Nozzle Switch & Motor Off Delay

≠≠

≠ 0 ......................... 3-6

≠≠

3.3.2 Timing with Nozzle Switch & Motor Off Delay = 0 ......................... 3-6

(CONT.)

Document Ref 905675-001 Rev 2 3

Page 6

Contents WWC T1 Set Up & Maintenance Manual

3 LPG SET UP /

3.3.3 Timing with Deadmans Button only & Motor Off Delay

3.3.4 Timing with Deadmans Button only & Motor Off Delay = 0 ............ 3-7

4 SERVICE KEYPAD...................................................................................................... 4-2

4.1 User Access Keypad (UAK) ............................................................................... 4-2

4.2 Infra Red (IR) Remote Control Keypad.............................................................. 4-4

4.3 Internal Configuration Keypad ........................................................................... 4-4

5 SET UP MODE.............................................................................................................. 5-2

5.1 General ................................................................................................................ 5-2

5.2 Start Ups ............................................................................................................. 5-2

5.2.1 Cold Start............................................................................................ 5-2

5.2.2 Warm Start.......................................................................................... 5-3

5.2.3 Service Start ....................................................................................... 5-3

5.3 Initial Set Up Menu............................................................................................. 5-3

5.3.1 Set up Function Overview .................................................................. 5-4

5.3.2 Set Up Menu....................................................................................... 5-5

5.4 AFM Set Up Menu ........................................................................................... 5-10

5.4.1 No Address Conflict ......................................................................... 5-10

5.4.2 Address Conflict ............................................................................... 5-14

5.4.3 AFM Addresses ................................................................................ 5-16

≠≠

≠ 0 ............ 3-7

≠≠

6 MAINTENANCE MODE............................................................................................. 6-2

6.1 General ................................................................................................................ 6-2

6.2 Maintenance Function Overview ........................................................................ 6-2

6.3 Access the Maintenance Functions..................................................................... 6-4

6.4 Exit Maintenance Mode...................................................................................... 6-5

6.5 Diagnostic Information (Error Log) ................................................................... 6-6

6.5.1 Kernel versions > 01.07 ..................................................................... 6-6

6.5.2 Kernel versions <= 01.07 ................................................................... 6-7

6.6 Leak Tests ........................................................................................................... 6-8

6.7 Country Code, Euro and Application Set Up...................................................... 6-8

6.8 LPG Functionality............................................................................................. 6-10

6.9 Thermal Protection Reset .................................................................................. 6-11

6.9.1 Kernel versions > 01.07 ....................................................................6-11

6.9.2 Kernel versions <= 01.07 ..................................................................6-11

6.10 Leak Detection Functionality............................................................................ 6-12

6.10.1 Vapour Leak Detection (France only) .............................................. 6-12

6.10.2 Flow Protection Reset (AFM Leak Detection) ................................ 6-12

6.10.3 Esso Leak Detection......................................................................... 6-13

6.11 Fraud Detection Functionality .......................................................................... 6-13

6.12 Combined Hose Pre-selection and Display Timeout ........................................ 6-14

6.13 Electro-Mechanical Totaliser Mode (EMT) Functionality ............................... 6-14

6.14 Cent Overshoot Hide Functionality .................................................................. 6-15

6.15 Q500T1 Four Position Product Indicator ......................................................... 6-15

6.16 Stop/Off Switch ................................................................................................ 6-16

6.17 Fuel Leak Detection.......................................................................................... 6-16

6.17.1 Set Up PIN Code (Fuel Leak Detection only).................................. 6-17

6.18 Blend Ratio ....................................................................................................... 6-17

6.19 Local Preset Values ........................................................................................... 6-18

Issue B

(CONT.)

4 Document Ref 905675-001 Rev 2

Page 7

WWC T1 Set Up & Maintenance Manual Contents

6 MAINTENANCE MODE /

6.20 Node Address .................................................................................................... 6-18

6.21 Test Delivery..................................................................................................... 6-19

6.22 Emergency Manual Pumping Device (EMPD)................................................. 6-21

6.23 Product Relation ............................................................................................... 6-21

6.23.1 Product Name by Character Input .................................................... 6-22

6.23.2 Product Name from Pick List ........................................................... 6-23

6.24 Vapour Recovery............................................................................................... 6-24

6.24.1 Kernel versions <= 0.???.................................................................. 6-24

6.25 Vapour Delay .................................................................................................... 6-25

6.26 Pump Motor Delay (Submerged/Remote pumps only)..................................... 6-25

6.27 Optional Preset Valve........................................................................................ 6-26

6.28 Valve Reponse Value ........................................................................................ 6-26

6.29 AFM Menu ....................................................................................................... 6-27

6.29.1 AFM change menu ........................................................................... 6-27

6.29.2 AFM Read-only menu ...................................................................... 6-27

6.30 Product Position................................................................................................ 6-29

6.31 Option Selection ............................................................................................... 6-30

6.31.1 IEB (I/O Extension Board) Options ................................................. 6-30

6.31.2 OCB (Option Controller Board) Options ......................................... 6-31

6.32 Nozzle Sensor Definition.................................................................................. 6-37

6.32.1 Kernel version >= 03.08................................................................... 6-37

6.32.2 Kernel version >= 03.03................................................................... 6-37

6.32.3 Kernel version >= 02.12................................................................... 6-40

6.32.4 Kernel version < 02.12 ..................................................................... 6-42

Issue B

7 APPLICATION MODE................................................................................................ 7-2

7.1 All Applications .................................................................................................. 7-2

7.2 EPS...................................................................................................................... 7-3

7.3 IFSF..................................................................................................................... 7-4

7.4 ZSR ..................................................................................................................... 7-5

7.5 Dunclare .............................................................................................................. 7-6

7.6 Tokheim .............................................................................................................. 7-7

8 PIN CODES ................................................................................................................... 8-2

8.1 First PIN code ..................................................................................................... 8-2

8.2 Change PIN code ................................................................................................ 8-3

9 TOTALS ......................................................................................................................... 9-2

9.1 Reading the Totals (Amount, Volume & Number of Deliveries) ....................... 9-2

10 UNIT PRICES ............................................................................................................. 10-2

10.1 Set/Change Unit Prices ..................................................................................... 10-2

11 INSPECTION FUNCTIONS ......................................................................................11-2

11.1 Inspection Function Overview ...........................................................................11-2

11.2 General...............................................................................................................11-3

11.3 Delivery Mode ...................................................................................................11-3

11.4 Traffic Lights .....................................................................................................11-3

11.5 Idle Display Control...........................................................................................11-3

11.6 Satellite Control .................................................................................................11-3

(CONT.)

Document Ref 905675-001 Rev 2 5

Page 8

Contents WWC T1 Set Up & Maintenance Manual

11 INSPECTION FUNCTIONS /

11.7 Release Management .........................................................................................11-4

11.8 Maximum Time for a Filling .............................................................................11-4

11.9 Time Between Two Fillings ...............................................................................11-4

11.10 Maximum Time of No Flow ..............................................................................11-4

11.11 Maximum Time a Filling can be Suspended .....................................................11-5

11.12 Timer for Display TImeout................................................................................11-5

11.13 Delivery Fraud Timer.........................................................................................11-5

11.14 Software Versions ..............................................................................................11-5

11.15 Pulser Hide.........................................................................................................11-8

11.16 Preset Totalisers .................................................................................................11-8

12 APPENDIX .................................................................................................................. 12-2

12.1 Appendix A - Product Option Matrix ............................................................... 12-2

12.2 Appendix B - Country Codes............................................................................ 12-4

12.3 Appendix C - Error Codes ................................................................................ 12-6

12.3.1 Startup Error Situations.................................................................... 12-6

12.3.2 Displaying Error Messages .............................................................. 12-6

12.3.3 Diagnostic Database ......................................................................... 12-7

12.4 Appendix D - Jumper Positions ...................................................................... 12-10

12.4.1 Mainboard ...................................................................................... 12-10

12.4.2 VRC Board ......................................................................................12-11

12.4.3 User Access Module ....................................................................... 12-12

12.4.4 OCB Board ..................................................................................... 12-13

12.4.5 I/O Extension Board (IEB)............................................................. 12-14

12.4.6 Hydraulic Option Module (HOM) ................................................. 12-14

12.4.7 Axial Flow Meter Measurement Solution (AFM) ......................... 12-14

12.5 Appendix E - General Purpose Inputs ............................................................ 12-15

12.6 Appendix F- IEB General Purpose Outputs.................................................... 12-16

6 Document Ref 905675-001 Rev 2

Issue B

Page 9

WWC T1 Set Up & Maintenance Manual Introduction

CONTENTS

1 INTRODUCTION........................................................................................................ 1-2

1.1 How to Use this Manual ......................................................................................1-2

1.2 Product Scope ......................................................................................................1-3

1.3 Authorised Technicians ........................................................................................1-3

1.4 Contact Information .............................................................................................1-3

1.5 Health & Safety ...................................................................................................1-3

1.5.1 Safety Checklist ...................................................................................1-3

1.5.2 Duties of the Employees......................................................................1-4

1.5.3 Hazards................................................................................................1-4

1.5.4 Warning Signs ......................................................................................1-5

1.5.5 Personal Protective Equipment (PPE) ................................................1-6

1.6 Nomenclature .......................................................................................................1-7

Issue A

Document Ref 905675-001 Rev 2 Page 1-1

Page 10

Introduction WWC T1 Set Up & Maintenance Manual

1 INTRODUCTION

1.1 How to Use this Manual

It is recommended that all relevant persons familiarise themselves with the contents of this

manual prior to carrying out any operations or procedures.

This manual is divided into sections which are described as follows: -

Section 1 - Introduction

This section contains information on how to use the manual, the scope of equipment covered,

recommendations on qualified technicians and contact information. It also includes relevant

health and safety information and certification relating to the product.

Section 2 - Product Information

This section contains the system description and operating principles of the WWC T1

Calculator. It also describes the main components, their configurations and functions

including the service keypads.

Section 3 - LPG Specification

All additional information relating to LPG options is contained in this section.

Section 4 - Service Keypad

This section describes the functions of the various keypads.

Section 5 - Set Up Modes

This section provides instructions for cold start, warm start and service start of the product.

Section 6 - Maintenance Mode

All aspects relating to the maintenance of the equipment are covered in this section.

Section 7 - Application Mode

This section contains information on the EPS, IFSF and ZSR Application Modes.

Section 8 - PIN Code

This section contains information on how to change the PIN code.

Section 9 - Totals

Instructions on how to read totals is contained in this section.

Section 10 - Unit Prices

This section contains information on setting and changing the Unit Prices.

Section 11 - Inspection Functions

All information relating to the Inspection Function is contained in this section.

Section 12 Appendices

This section contains the appendices.

Page 1-2 Document Ref 905675-001 Rev 2

Issue A

Page 11

WWC T1 Set Up & Maintenance Manual Introduction

1.2 Product Scope

This manual is designed to cover the Quantium T range of dispensers including LPG. As

functionality is equivalent to the Coca 1.1 functionality , reference is frequently made to the

existing Coca Manuals.

1.3 Authorised Technicians

Only qualified technicians familiar with the contents of this manual should carry out the

procedures contained herein.

WARNING : ANY ATTEMPTS TO CARRY OUT THE PROCEDURES OF THIS

MANUAL, BY UNQUALIFIED OR UNAUTHORISED PERSONS, MAY

RESULT IN SERIOUS INJURY OR LOSS OF LIFE.

Note : This manual is not intended to replace the services of a fully qualified

technician.

1.4 Contact Information

For information relating to the contents of this manual please contact: T echnical Author

Tokheim UK Ltd.

Dundee, Scotland

For technical assistance please contact the appropriate service division listed on the back

cover of this manual.

1.5 Health & Safety

1.5.1 SAFETY CHECKLIST

•It is obligatory that this checklist be fully complied with during all work at the

petrol station, particularly construction or repair work.

•It is the duty of the contractor to ensure that all workers employed by him obey

each and all of the relevant laws, directives and other regulations.

Areas where special caution is required

•The insides of tanks, tubes, dome shafts, filling shafts, change over shafts, vessels

and dispensers.

•All areas in which fuel vapour that is heavier than air can accumulate, e.g. fuel

separator, draining shafts, low located rooms, cellars, excavations, pipe trenches

etc.

Issue A

•The areas around the outlets of tank ventilation pipes, especially during the filling

phase.

•All areas near dispensers, tanker lorries and other vehicles while they are being

tanked up, and particularly when there is a lack of wind.

•A radius of 1.0 metres around petrol carrying pipes, as well as pipes that are not

vapour free.

•Silt traps.

Document Ref 905675-001 Rev 2 Page 1-3

Page 12

Introduction WWC T1 Set Up & Maintenance Manual

1.5.2 DUTIES OF THE EMPLOYEES

•To ensure optimal accident prevention in our company, in addition to general

rules applying to worker’s protection, it is necessary to take into account all the

national protection of workers legislation and to actively support all measures

which enhance safety standards.

•It is an employee’s duty to follow all company directives regarding the prevention

of accidents, unless such directives can be proved to be unfounded.

•Employees should not follow any instructions that go against safety standards.

•Employees are only permitted to use equipment for its original purpose, and this

is defined by the company alone.

•If an employee detects equipment that is deficient in terms of safety, he shall

eliminate this deficiency immediately . If such safety rectification is not part of

his defined area of activities, or if his knowledge is insufficient to carry out such

work he must immediately inform his superior about the detected safety

deficiency.

This equally applies to:

1) Work Materials which have not been correctly packed or correctly marked in

order to meet safety requirements.

2) Work Methods or work processes which have not been correctly coordinated

or controlled in order to meet safety requirements.

3) Where dangerous activities are carried out by several persons, the need

for a permanent faultless communication between them in order to avoid

dangerous events shall require the appointing of one person in order to carry out

overall supervision.

1.5.3 HAZARDS

Prior to starting work, the dispenser must be isolated (i.e. entirely disconnected

from the mains supply) and the mains supply switch locked in the OFF position.

The submerged pump (if applicable) and control signals from the dispenser must

also be isolated. This is done to provide safety for the technician. As a further

precaution, switch off the mains supply in the service station shop and place a

clear notice on the switch to avoid it being turned on again inadvertently.

WARNING : THE CONNECTION AND DISCONNECTION OF

ELECTRICAL CONNECTIONS MAY ONLY BE CARRIED OUT BY

QUALIFIED PERSONNEL AUTHORISED FOR SUCH ACTIVITIES.

WORK IN DANGEROUS AREAS MUST BE MADE SAFE BY

OBSERVING ALL THE NATIONAL SAFETY REQUIREMENTS IN

FORCE.

It is not permitted to put a fuel dispenser into operation before an authorised

official has inspected it and released it. This depends upon the national regulations

in force.

Issue A

Dismantled packaging and cladding must be stored in such a way as to avoid

damage to components or injuries to persons. Covers that can be opened, such

as the calculator housing, should be handled with care. Ensure that the retaining

catch is placed in the correct position to prevent the cover falling onto the head

of the service engineer or other persons in the area.

Page 1-4 Document Ref 905675-001 Rev 2

Page 13

WWC T1 Set Up & Maintenance Manual Introduction

At unattended service stations, every end-user should be able to read the User

Instructions. They should be visible on a notice board or integrated into the DIT

and should be sufficiently well lit so that they can be read at night.

At unattended service stations break away couplings must always be used to

reduce the danger caused by a motorist driving off with the nozzle still in the

tank.

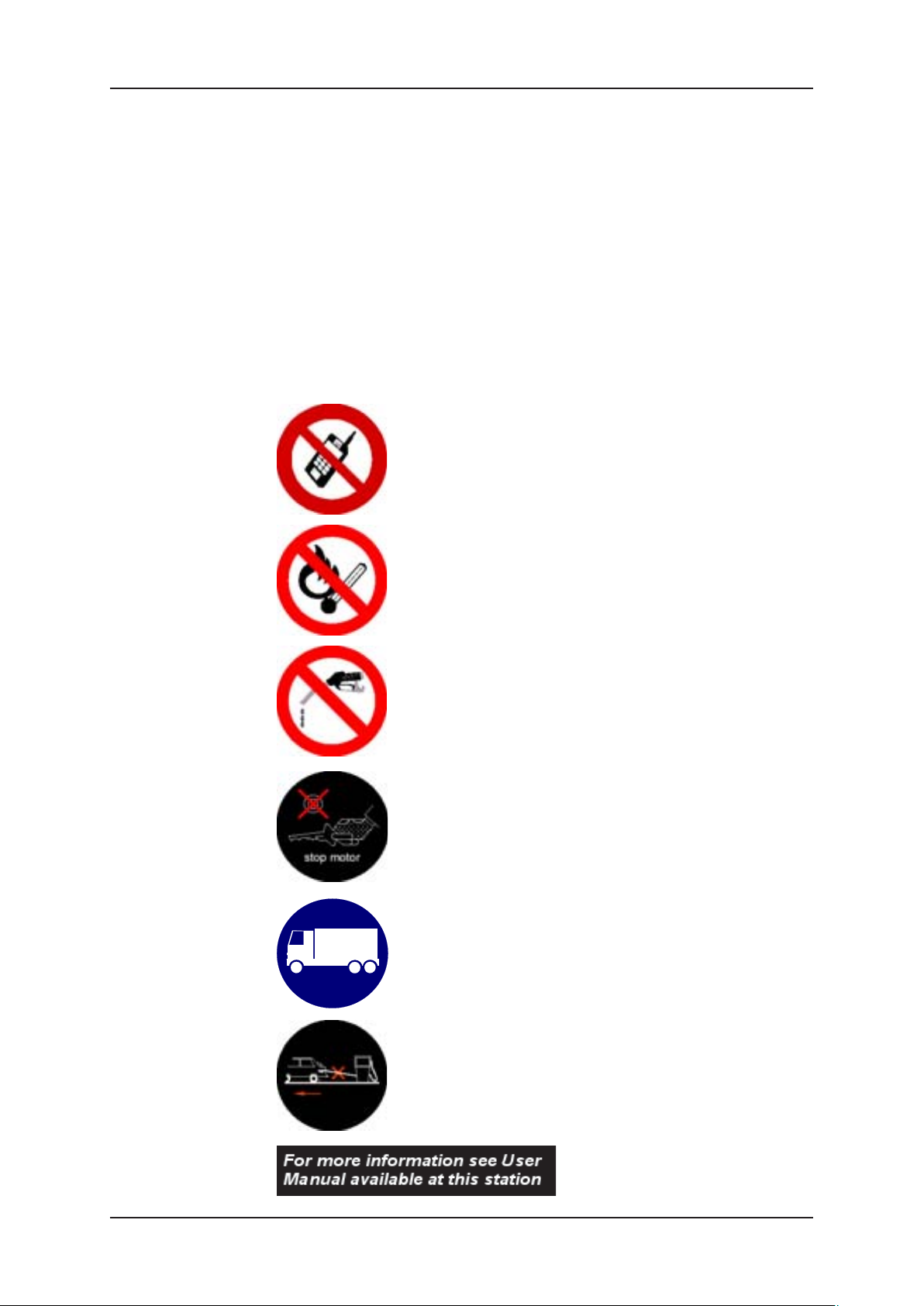

1.5.4 WARNING SIGNS

The following warning signs are fitted as standard, on the dispenser, however

they may vary according to individual country requirements or customer

specifications.

SIGN

MEANING POSITION

Do not use mobile

phones

Naked flames and

smoking forbidden

Do not spill fuel on the

ground

Stop vehicle engine

Visible from both

sides of dispenser

Visible from both

sides of dispenser

Visible from both

sides of dispenser

Visible from both

sides of dispenser

Issue A

At Diesel high speed

Trucks only

dispensers near the

nozzle boots

Do not drive away with

nozzle in tank

Visible from both

sides of dispenser

Next to User

Instructions near the

nozzle boot

Document Ref 905675-001 Rev 2 Page 1-5

Page 14

Introduction WWC T1 Set Up & Maintenance Manual

1.5.5 PERSONAL PROTECTIVE EQUIPMENT (PPE)

PROTECTIVE CLOTHING

The following clothing should be worn at all times during installation and

maintenance procedures:-

•Protective helmet.

•Protective shoes (conductive).

•Protective gloves and/or protective hand cream.

•Anti static clothing.

•Eye protection.

SAFETY EQUIPMENT FOR WORKING IN HAZARDOUS AREAS

The following safety equipment is required for working in hazardous areas:-

•Only spark free tools are permitted for work on dispensers.

•Work on bearings is only permitted using the standard workshop tools authorised

for this kind of work.

•The use of all electrical tools is strictly prohibited.

•Only the use of explosion protected work lights is permitted.

•The use of telecommunications equipment in hazardous areas is strictly prohibited.

SAFETY INSTRUCTIONS

The following safety instructions must be adhered to during installation and

maintenance procedures:-

•Inhalation of petrol vapour must be avoided. Suitable precautions must be taken

and where necessary respirators used.

•Avoid direct contact of fuel with the skin.

•Use suitable protective clothing, protective gloves and/or protective hand cream.

•Avoid fuel spills.

•No smoking, no naked flames are permitted.

•Long hair and ties can get caught in moving parts. Hair must be suitably covered.

Page 1-6 Document Ref 905675-001 Rev 2

Issue A

Page 15

WWC T1 Set Up & Maintenance Manual Introduction

1.6 Nomenclature

The various abbreviations used in thie manual are described as follows:CoCa Today’s Common Calculator and base of the WWC

CSD-F Common Sales Display - Ferranti

CSD-L Common Sales Display - LCD

Dipnet Dispenser inter-peripheral network

ELU Energy Limiting Unit (i.e.Nozzle Bus Intrinsically Safe Barrier)

EMPD Emergency Manual Pumping Device

EMT Electro-Mechanical T otalizer

HCM Hydraulic Control Module

HOM Hydraulic Option Module

HSC Hall Sensor Controller

HVU High V oltage Unit

IEB I/O Extension Board

IFSF International Forecourt Standard Forum

IOB I/O Board

IRM Infra Red Module

LON Local Operating Network

MB251 Mainboard 80251

MP1 Magnetic Pulser 1

NBB Nozzle Bus Board (integrated in Main Board v3 and later)

OCB Option Controller Board

ODU Optional Display Board

OPB Option Peripheral Board

OPU Optional Peripheral Unit

PCB Printed Circuit Board

POS Point of Sale

SCG Self Calibrating Gas

SPI Serial Peripheral Interface

UA K User Access Keypad

Issue A

UAM User Access Module

UPD Unit Price Display

VFM V apour Flow Module

VRC V apour Recovery Controller

WWC W orld Wide Calculator

Document Ref 905675-001 Rev 2 Page 1-7

Page 16

Introduction WWC T1 Set Up & Maintenance Manual

This page is intentionally blank

Issue A

Page 1-8 Document Ref 905675-001 Rev 2

Page 17

WWC T1 Set Up & Maintenance Manual Product Information

CONTENTS

2 PRODUCT INFORMATION .................................................................................... 2-2

2.1 System Description ..............................................................................................2-2

2.1.1 Operating Principles.............................................................................2-2

2.2 Main Components of the WWC ..........................................................................2-2

2.2.1 External Power Supply ........................................................................2-3

2.2.2 Mainboard............................................................................................2-3

2.2.3 I/O Board (version 3++)......................................................................2-4

2.2.4 Transaction Displays............................................................................2-4

2.2.5 User Access Devices (UAK/UAM) ...................................................2-4

2.3 Different Configurations ......................................................................................2-4

2.3.1 Standard dispensers with up to four single products............................2-5

2.3.2 Low-end dispensers : single product or twin configuration, super high

speed, single-sided (Fleet)....................................................................2-5

2.3.3 Vapour Recovery Controller Board (VRC).........................................2-6

2.3.4 Option Controller Board (OCB) ..........................................................2-6

2.3.5 Hydraulic Option Modules (HOM)......................................................2-6

2.3.6 I/O Extension Board (IEB)..................................................................2-6

2.4 Product Option Matrix (POM).............................................................................2-6

2.5 Functionality .........................................................................................................2-6

2.5.1 Functionalities per hose........................................................................2-7

2.5.2 Functionalities per side.......................................................................2-10

2.5.3 Functionalities per dispenser ..............................................................2-16

2.5.4 Weights & Measures related Functionality........................................2-21

Issue A

Document Ref 905675-001 Rev 2 Page 2-1

Page 18

Product Information WWC T1 Set Up & Maintenance Manual

2 PRODUCT INFORMATION

2.1 System Description

The WWC (World Wide Calculator) is a ‘measuring system’ built to conform to the

international recommendations specified in the document OIML R1 17 Edition 1995.

The WWC is also a peripheral within the different Tokheim filling station systems. As

such, the WWC software and hardware can be configured without modifying the

characteristics of the measuring system.

The WWC is based on the CoCa (Today’s Common Calculator). The hardware has been

re-designed to keep up with technological advances and to allow more flexibility in the

extended scope but the main controlling parts are structured in the same way as the CoCa.

The software is similar to the CoCa software with adaptations to the new hardware and

updated functionality on the kernel side to ensure the re-use of all application parts, with

only minor changes. For further details, refer to the separate documentation, WWC System

Functional Description.

2.1.1 OPERA TING PRINCIPLES

The WWC T1 Calculator has been built around a central microprocessor which

controls several other microcontrollers for the input and output devices e.g.

counters, indicators, peripherals etc.

For each road side (right and left) of the metering pump/dispenser, the double

pulse signals from one or more pulsers, mounted at mechanical volume meters,

are checked and the information is counted and displayed on the corresponding

transaction indicator unit.

One calculator can simultaneously control two deliveries - one at each side of

the dispenser. The data is checked through several hardware and software

security systems.

Connection to a filling station control system (self-service arrangement) is possible

through data communication. The calculator can also function as a standalone

unit whereby information is transmitted to the WWC via a remote control unit.

For further information on hardware components, general description of a delivery ,

data security and technical characteristics, refer to the separate documentation,

WWC System Functional Description.

2.2 Main Components of the WWC

The WWC consists of a number of modules which can be combined depending on the type

of the calculator and the number of products and options used. The main components

are:-

•External Power Supply (refer to see section 2.2.1)

•Mainboard (refer to section 2.2.2)

•I/O Board (refer to section 2.2.3)

•Transactions Displays (refer to section 2.2.4)

•User Access Devices (refer to section 2.2.5)

Page 2-2 Document Ref 905675-001 Rev 2

Issue A

Page 19

WWC T1 Set Up & Maintenance Manual Product Information

y

y

y

p

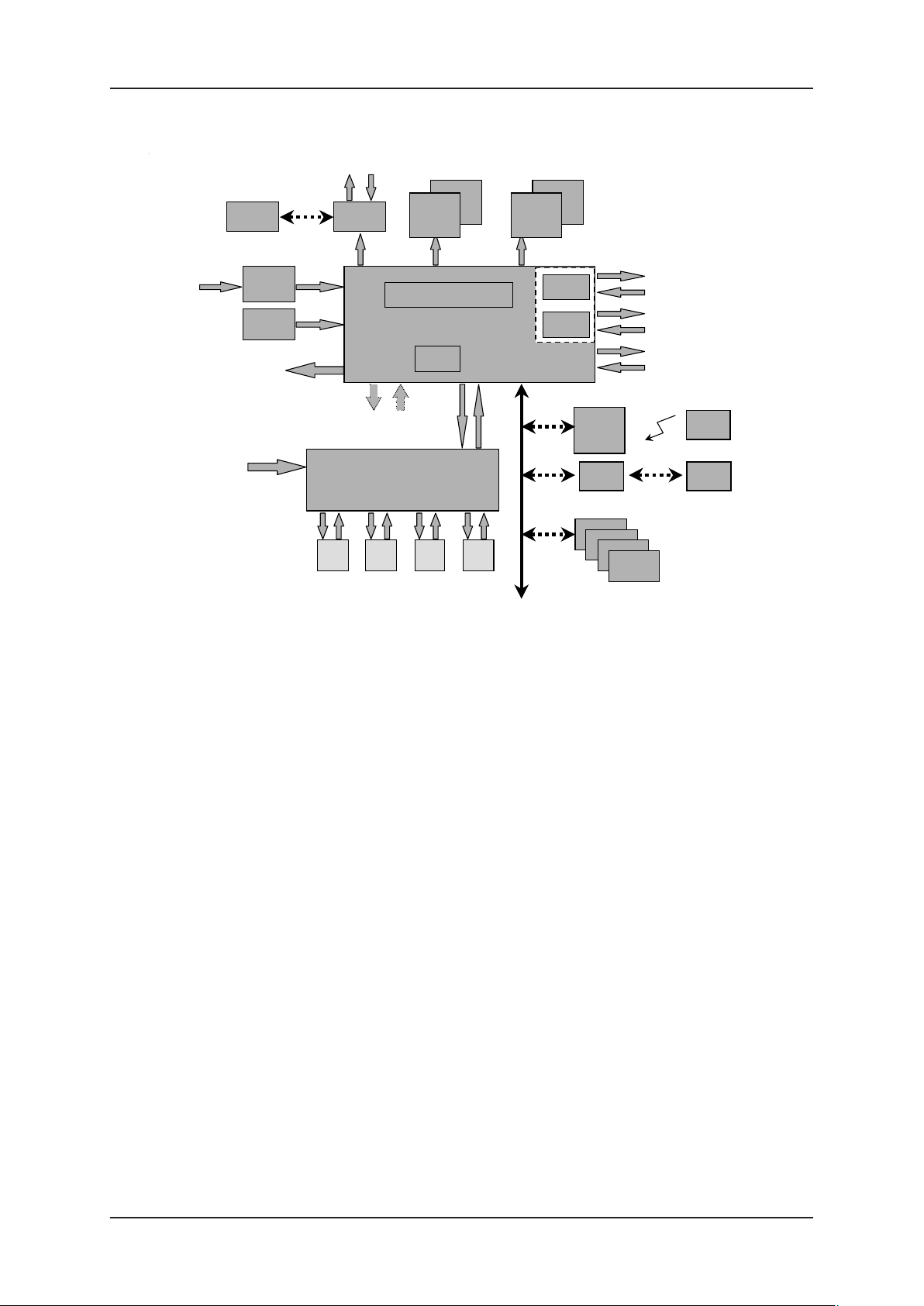

ARCHITECTURAL OVERVIEW

Mains

Dispenser light,

Electr totaliser

Dispenser I/O

Valves, motors and sensors

UAK

VRC

HVU

1

Battery

Low End H

(Single/Twin)

H1 H2 H3

H

(pulsers, valves, motors)

CSD-L

CSD-F

Calculator Module

2

Mainboard MB251

HCM

draulic

I/O Board

3

draulic Units

Displa

4

H4

s

CSD-L

CSD-F

Dipnet

COM

IEB

Interfaces

I/O extensions

Nozzle Bus

Interface

Communication

UAM/

5

UAK

OCB

tional Peripherals:

O

HOM

Hydraulic Option Modules

IRM

OPU

OPB

ODU

UPD

Product Indication

Others

Issue A

Fig. 1 Calculator Block Diagram

2.2.1 EXTERNAL POWER SUPPLY

The external power supply contains the following components:-

•A power distribution unit High Voltage Unit (HVU) including transformer

•A rechargeable back-up battery

2.2.2 MAINBOARD

The mainboard (version 3++) includes the calculator module and the Hydraulic

Controller Module (HCM):-

•The calculator module is able to manage two deliveries independently (one on

each road side); control the deliveries; maintain the volume and amount counters;

control the transaction displays and hydraulic units; and communicate with the

self-service device.

•The HCM is responsible for supporting the hydraulic interface by checking the

volume pulser devices; counting and checking the two incoming line volume

pulses; controlling the motor and valves and updating the electro-mechanical

totalisers.

The mainboard provides all the interfaces required to drive the ‘low-end’ hydraulics

without the need for an I/O board - single product and twin functionality (two

motors, two pulsers, four valves).

Document Ref 905675-001 Rev 2 Page 2-3

Page 20

Product Information WWC T1 Set Up & Maintenance Manual

Since the release of Version 3 of the mainboard, the NBB board has been

eliminated and the serial nozzle bus is directly controlled by the mainboard.

T wo optional modules can be directly connected to the mainboard (piggy-back):-

•The COM (Communications adapter) is used to interface the hardware to the

various self-service devices.

•The IEB (I/O Extension Board) is used to connect the peripherals often used in

Single/T win configurations e.g. preset keypad, simple set up and configuration

keypad.

2.2.3 I/O BOARD (VERSION 3++)

The I/O Board is a level converter and control signal distributor for one to four

single product hydraulic units.

2.2.4 TRANSACTION DISPLA YS

The transaction displays indicate the transactions on each side of the dispenser

showing the volume, amount and fuel price of the actual delivery. For each

side, it is possible to add a ‘slave’ display. Two different types of display are

available:-

•CSD-L : Liquid Crystal Display device

•CSD-F : Electromechanical Display device (Ferranti)

2.2.5 USER ACCESS DEVICES (UAK/UAM)

User Access Devices are used to set the basic set up and configuration for the

calculator and optional devices via an integrated keypad module for service

engineers (UAK) or via an infra-red remote control unit (UAM/IRM). It is

possible to get a readout of totals, errors and service parameters. Either the

UAK (also used for VRC configuration and calibration) or the UAM/IRM can

be used but both devices cannot be used in parallel.

2.3 Different Configurations

With the main components, the following configurations are possible:-

•Standard dispensers with up to four single products (refer to section 2.3.1)

•Low end dispensers: single product or twin configuration, super high speed single-sided

(Fleet) (refer to section 2.3.2)

In addition to the above configurations, the following options can be added via the Dipnet:-

•Vapour Recovery Controller Board (refer to section 2.3.3)

Issue A

•Option Controller Board (refer to section 2.3.4)

•Hydraulic Option Modules (refer to section 2.3.5)

•I/O Extension Board (refer to section 2.3.6)

Page 2-4 Document Ref 905675-001 Rev 2

Page 21

WWC T1 Set Up & Maintenance Manual Product Information

y

y

y

p

y

(

)

play

y

p

p

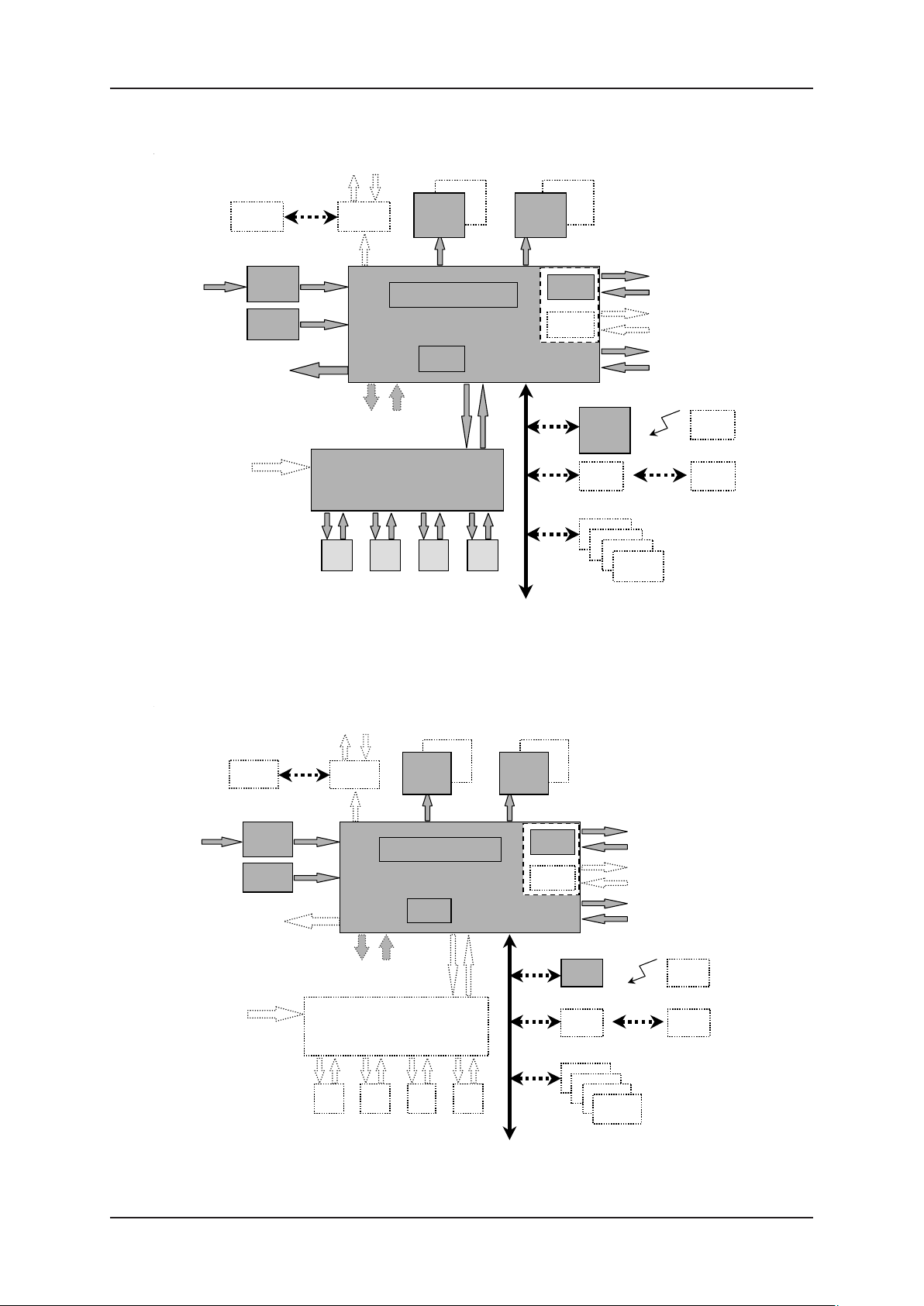

2.3.1 ST ANDARD DISPENSERS WITH UP TO FOUR SINGLE PRODUCTS

Mains

Dispenser light,

Electr totaliser

Dispenser I/O

Valves, motors and sensors

UAK

VRC

HVU

1

Battery

Low End H

(Single/Twin)

H1 H2 H3

H

(pulsers, valves, motors)

CSD-L

CSD-F

Calculator Module

2

Mainboard MB251

HCM

draulic

I/O Board

3

draulic Units

Displa

4

H4

s

CSD-L

CSD-F

Dipnet

Communication

COM

IEB

Interfaces

I/O extensions

Nozzle Bus

Interface

UAM/

5

UAK

OCB

tional Peripherals:

O

HOM

Hydraulic Option Modules

IRM

OPU

OPB

ODU

UPD

Product Indication

Others

Issue A

2.3.2 LOW-END DISPENSERS : SINGLE PRODUCT OR TWIN

Mains

Dispenser light,

Electr totaliser

Dispenser I/O

Fig. 2 Standard Dispenser Block Diagram

CONFIGURA TION, SUPER HIGH SPEED, SINGLE-SIDED (FLEET)

Valves, motors and sensors

UAM

HVU

Battery

VRC

1

Low End H

Single/Twin

H1 H2 H3

H

draulic Units

(pulsers, valves, motors)

CSD-L

CSD-F

Calculator Module

2

Mainboard MB251

HCM

draulic

I/O Board

3

H4

Dis

4

s

CSD-L

CSD-F

Di

COM

IEB

net

UAM

OCB

O

Hydraulic Option Modules

Communication

Interfaces

I/O extensions

Nozzle Bus

Interface

5

tional Peripherals:

HOM

IRM

OPB

UPD

Product Indication

Others

OPU

ODU

Fig. 3 Low End Dispensers Block Diagram

Document Ref 905675-001 Rev 2 Page 2-5

Page 22

Product Information WWC T1 Set Up & Maintenance Manual

2.3.3 VAPOUR RECOVERY CONTROLLER BOARD (VRC)

The VRC is an independent module which communicates with the calculator

module. After the VRC is initialised at each delivery start, it performs the open

or closed loop vapour recovery process by controlling its own motors and valves.

2.3.4 OPTION CONTROLLER BOARD (OCB)

The Option Module provides an interface to optional modules such as:-

•Unit Price Displays (UPD)

•Product Indicators

•Traffic Lights

•OPU/ODU (as replacement of the above)

•Preset Keypads

2.3.5 HYDRAULIC OPTION MODULES (HOM)

Up to four Hydraulic Option Modules can be connected to the mainboard via the

Dipnet to operate in a similar way to the HCM. The HOMs are designed to

provide the interface to optional hydraulic units eg. Super High Speed, Satellite,

Blender or to extend the number of products to a maximum of five.

Like the HCM, the HOM is responsible for supporting the optional hydraulic

interface by checking the volume pulser devices, counting and checking the two

incoming line volume pulses and by controlling the motor(s) and valves.

2.3.6 I/O EXTENSION BOARD (IEB)

The I/O Extension Board is designed to connect peripherals often used in lowend configurations (single/twin). The IEB is a piggy-back board attached to the

mainboard and is easy to assemble. The IEB is able to interface to:-

•A preset keypad (same functionality as connected to OCB)

•A simple configuration keypad (dispenser configuration only, no VRC). This

keypad is kept inside the calculator head.

•Four spare additional outputs

2.4 Product Option Matrix (POM)

The product option matrix defines the options of WWC available for each application. For

release status, please check the Software Status Overview. Refer to Appendix A for the

POM.

Note: Not all country specific W&M options are listed (e.g. low-level detection Italy,

display reset methodology for UK etc.)

Issue A

2.5 Functionality

Refer to the POM in Appendix A for supported functions per application.

Page 2-6 Document Ref 905675-001 Rev 2

Page 23

WWC T1 Set Up & Maintenance Manual Product Information

2.5.1 FUNCTIONALITIES PER HOSE

40 (45) litres per minute - Petrol or Diesel

Standard speed flow rate is achieved using one pump and one meter.

40 (45) litres per minute for two filling positions - Petrol or Diesel

Standard speed flow rate is achieved using one pump and two meters.

80 (90) litres per minute - Diesel only

High speed flow rate is achieved using one pump and one meter.

Note : 90 litres per minute for UK only.

130 litres per minute - Diesel only

V ery high speed flow rate is achieved using one pump and two meters in parallel.

150 litres per minute - Diesel only

Super high speed flow rate is achieved with two pumps and two meters in parallel.

40/80 litres per minute (Push Button selection) with one nozzle - Diesel

only

The standard flow rate is 40 litres per minute. A push button is available to

enable the selection of a higher flow rate of 80 litres per minute for trucks. A

double valve system in the hydraulic unit is required.

40/130 litres per minute or 40/80 litres per minute with two nozzles Diesel only

The first nozzle dispenses the standard flow rate of 40 litres per minute. If the

second nozzle is used then the higher flow rate for trucks is given. A special

valve system in the hydraulic unit is required.

Satellite Connection

This function enables the connection of a slave or satellite dispenser to a master

dispenser. The satellite dispenser has a maximum configuration of a display,

calculator lighting, satellite button and nozzle switch.

Submerged Standard

A timer can be activated via the Maintenance menu to enable this function. The

submerged pump starts running when the nozzle is lifted then, after approximately

three seconds, the valve in the dispenser is opened.

Issue A

Submerged Mouvex

Similar functionality to Submerged Standard with an additional switch for the

Mouvex air separator which is managed by the calculator.

Blender

Blending mixes two fuel grades in a certain ratio to give a third grade blend with

another octane. This is preferable under some fuel taxation systems, for example,

in Scandinavia.

Document Ref 905675-001 Rev 2 Page 2-7

Page 24

Product Information WWC T1 Set Up & Maintenance Manual

The choice is made by push button selection with product indication.

There are two principles:-

• 2 grades in, 3 grades out, 2 hoses

•2 grades in, 3 grades out, 1 hose

Refer to section 6.18 for programming information.

Combined Hose

The Combined Hose option allows two or more products to be delivered through

one common hose. Each product has its own hydraulic block (pump/meter)

which controls the valves and routes the fuel to the associated combined hose.

The choice is made by push button selection with product indication. In special

cases, for example Tatsuno application, the last product used is pre-selected by

default when the nozzle is next lifted.

Refer to section 6.14 for programming information.

Electronic Controlled Vapour Recovery (VRC)

T o support VRC, volume information is routed to a VRC main controller which

controls the motor and valves of the VRC system. The VRC system is available

as an open loop or self-calibrated loop system.

Vapour Leak Detection

A specific leak detection method is required for France in conjunction with vapour

recovery. After the nozzle is replaced, the calculator keeps the pump motor

running to check for leakages. The length of time for the pump motor to run and

the amount of volume to be detected for a leak is fixed and cannot be changed.

If detected, the leak error is forwarded to the system. If the same error is found

three times then the applicable product will be blocked. The calculator keeps

track of the leak status per product.

Parameter:

-hose expansion volume : 5 cl for 40 l/min

10 cl for 80 l/min

40 cl for 130 l/min

-hose expansion time : 1 second

-leak volume : 2 cl

-leak time : 2 seconds

Refer to section 6.10.1 for programming information.

Esso Leak Detection

This function is designed for use at unmanned service stations with IFSF

application. After the nozzle is replaced, the calculator keeps the pump motor

running to check for leakages. The length of time for the pump motor to run and

the amount of volume to be detected for a leak is entered via this menu.

Page 2-8 Document Ref 905675-001 Rev 2

Issue A

Page 25

WWC T1 Set Up & Maintenance Manual Product Information

If detected, the leak error is forwarded to the system and will immediately block

the complete dispenser. The calculator keeps track of the leak status.

Parameter:

-hose expansion volume : 5 cl for 40 l/min

10 cl for 80 l/min

40 cl for 130 l/min

-hose expansion time : 1 second

-leak volume : 2 to 8 cl

-leak time : 2 seconds

Refer to section 6.10.3 for programming information.

Fuel Leak Detection

At the start of each delivery, a leak test is started via a request from the kiosk.

Up to three attempts are made to verify the leak. If the leak is verified, the

results of the leak tests are forwarded to the kiosk via special messages.

Parameter:

- volume (v) : 0 to 45 cl default = 0

-time (t) : 0 to 20 second(s) default = 0

Refer to section 6.17 for programming information.

Axial Flow Meter (AFM) Leak Detection (kernel >= 3.02)

This function can identify a potential AFM spindle lock situation which could

result in a leakage of approximately 1.2 to 1.5 gallons per minute.

The assumption is made that “an AFM leak situation occurs when the ‘no flow’

timeout occurs n times in a sequence AND the total reported volume is 0”.

Normally , during a delivery , the “no flow” timer is restarted each time a volume

update is done. When the timer expires i.e. no flow during the “no flow” period

(default = 1 minute within a range of 0 to 9:59 minutes), the delivery will be

stopped and the motor and valves switched off without indicating an error .

To be able to detect an AFM spindle lock situation when the “no flow” timer

has expired, the corresponding volume is checked:-

•If volume > 0 : no change in the behaviour, reset the leak sequence counter of

the associated hose (product/side)

Issue A

•If volume = 0 : increment the leak sequence counter of the associated hose

(product/side)

If the counter exceeds the predefined (not user adjustable) limit of three (3)

then an error will be logged and reported. The associated hose will be blocked

until a manual release action is performed. Lifting the nozzle of a blocked hose

will display the error again but it will not log another error.

Document Ref 905675-001 Rev 2 Page 2-9

Page 26

Product Information WWC T1 Set Up & Maintenance Manual

If the nozzle is replaced with volume = 0 before the time out expires, the leak

sequence counter is neither incremented nor reset i.e. this will not increase the

volume lost if it is a real leak.

If an error is detected, all motors and valves will be switched off and the error

will be logged and displayed with the standard error format:-

Error

HC p s

65

p : product

s : side (R/L)

Note : If HOMs are used, HC may be displayed as H1 to H4.

Error Reset Menu

Within the Maintenance menu, the sub-menu AFM-Leak (FLPROT - Flow

Protection menu) needs to be added to display the status of each installed product

per side. For standard dispensers this is related to the hose and for SHS/Satellite

dispensers, it is related to the product.

ON : Hose is activated and ready for use

OFF : Hose is blocked due to leak error (or manually set to OFF)

Note : It is not possible to cover all leak situations and a certain amount of

volume may still be lost.

Fraud Detection

This function is designed to prevent uncontrolled fuel flow by the detection and

control of such situations as far as possible using a limited scope of detection

methods and actions.

Additional sensors on the Nozzle Bus enable the meters/pulsers to detect any

rotations and the calculator will switch off all transactions (where possible) and

log the unexpected flow events. This functionality requires the use of specific

hardware i.e. sensors using the Hall Sensor Controller (HSC).

This function is not available in all installations due to the maximum limit of 32

sensors on the sensor bus. Only existing piston meters will be supported; AFM

will not be supported.

2.5.2 FUNCTIONALITIES PER SIDE

REMOTE PRESET VALVES

Preset valves are controlled remotely by the Pump Controller.

LOCAL PRESET VALVES

There are two methods available to control the Local Preset valves depending

on the hardware used:-

•Push buttons

•Keypad

Issue A

Page 2-10 Document Ref 905675-001 Rev 2

Page 27

WWC T1 Set Up & Maintenance Manual Product Information

Push Button Methods

- Push buttons connected to the sensor bus or direct connections

- Push buttons connected to the IEB

Up to four buttons (three amount or volume and one reset button) are available

and can be connected to the sensor bus, direct connections or via IEB at each

filling position. In combination with preset valves, it is possible to fill up with the

fixed preset amount or volume.

preset code button 1 button 2 button 3 button 4 Ty pe

clear Value_1 Value_2 Value_3

1 Y 100 500 1000 Amount

2 Y 500 1000 5000 Amount

3 Y 1000 5000 10000 Amount

4 Y 200 500 1000 Amount

5Y 1510VOLUME

6 Y 11050VOLUME

7 Y 1000 2000 5000 Amount

8 Y 5000 10000 50000 Amount

9 Y 2000 5000 10000 Amount

10 Y 5000 10000 20000 Amount

11 Y 10 50 100 Amount

12 Y 500 1000 1500 Amount

13 Y 100 500 2000 Amount

Issue A

The parameters used for local preset push buttons are as follows:-

- Y = function supported N = function not supported

- Value_1, Value_2 and Value_3

Each time a button is pressed, the amount or volume is increased by the

corresponding value. The volume is always defined in litres. The amount needs

to be updated using the comma position as defined by the specified country (for

further information, refer to Appendix B).

Example 1

If Value_1 = 500 and Spain is selected (Country code 0034), each push of the

button increases the amount by 500 Ptas because the “comma position” of the

amount display is 0 (refer to Appendix B).

→ (0034 SPAIN 0 / 2 / 1)

Example 2

If Value_1 = 500 and The Netherlands is selected (Country code 0031), each

push of the button increases the amount by 5,00 Dfl. since the “comma position”

of the amount display is 2 (refer to Appendix A).

→ ( 0031 NETHERLANDS 2 / 2 / 3)

Note: To select the push button functionality via the IEB, the jumper W300

on the IEB must be closed (refer to Appendix D for Jumper Positions).

Document Ref 905675-001 Rev 2 Page 2-11

Page 28

Product Information WWC T1 Set Up & Maintenance Manual

Keypad Methods

- Keypad connected to the IEB

- Keypad connected to the OCB

123

456

789

CASH

When Local Preset is connected using a keypad method, a 4x4 keypad is available

at each filling position to allow the entry of a preset amount or preset volume.

With the keypad layout as shown, volumes and/or amounts can be entered in

decimals.

Note: Please check the appropriate Product Releases Notes for the

supported functionality of the “Credit” and “Cash” button.

Car Detection

0

,

preset

clear

CREDIT

preset

amount

preset

volume

A special device (i.e. inductive coil) detects if there is a car present at the filling

position and transmits this information via a potential free contact to the calculator.

This will enable the calculator and inform the site controller when the car is

leaving.

Continuous Filling Button for Satellite

Depending on the application, this button must be pressed before or within three

seconds of the replacement of the nozzle of the master or satellite dispenser.

This keeps the pump in ‘released’ mode for the “maximum time a filling can be

suspended” period. T o continue the filling at the satellite dispenser , the valves in

the pipework are switched via the nozzle contact. The calculator then continues

the transaction started at the master dispenser. The push button is located adjacent

to the nozzle boot on the dispenser. Refer to Satellite Nozzle Control Menu

per dispenser side for further information.

Product Indication on the Display at start of the filling

When the nozzle is lifted, the associated product light is illuminated briefly (M3000

application only).

Idle Display Control Menu

This menu determines which information is displayed when the dispenser is idle.

The following selections can be made:-

Issue A

Page 2-12 Document Ref 905675-001 Rev 2

Page 29

WWC T1 Set Up & Maintenance Manual Product Information

0 displays last delivery

1 filling is cashed and the volume and amount display show “0”

2 filling is cashed and all displays show “0”

3 to 9 reserved for future implementations

Satellite Nozzle Control Menu

A high speed diesel dispenser can have a satellite nozzle on each side. At each

nozzle, a filling can be started and the following selections can be made:-

0 satellite function disabled

3 at the master or satellite nozzle

4 at the master or satellite nozzle - once the filling is continued at

the satellite nozzle, it is not possible to continue again using the

master nozzle.

This selection is required by W&M in France to prevent fraud.

5 to 9 reserved for future implementations

Release Management Menu

T o release a dispenser for the next filling, the following selections can be made:-

0 release only via the forecourt controller system - no manual release

possible

1 release can be via the forecourt controller system and IR remote

control:-

• push button 9 to release right/side A

• push button 7 to release left/side B

2 release via the forecourt controller system and button on the

dispenser

3 to 9 reserved for future implementations

Maximum Time for a Filling Menu

This is the maximum time the pump motor can be active. It starts when the

nozzle is lifted from the nozzle boot.

Parameters:-

•function is disabled 0000

•max. time 5959 (= 59 minutes and 59 seconds)

•default value 1500 (certain applications may overrule this e.g.

Dunclare default value = 1000)

Issue A

Maximum Time for a Filling to be Suspended Menu

Within the set time period, a filling has to be started (released via payment

terminal) or continued at a satellite dispenser. When this time has elapsed, the

filling is assumed to be finished and the dispenser will have to be released again

before a new filling can be started.

Document Ref 905675-001 Rev 2 Page 2-13

Page 30

Product Information WWC T1 Set Up & Maintenance Manual

Parameters:-

•function is disabled 0000

•max. time 0959 (= 9 minutes and 59 seconds)

•default value 0100 (certain applications may overrule this)

Time Between Two Fillings Menu (Inter delivery time out)

This is the minimum time to elapse between two successive fillings.

Parameters:-

•function is disabled 0000

•max. time 0959 (= 9 minutes and 59 seconds)

•default value disabled 0000 (certain applications may overrule this

e.g. Dunclare : fixed at 5 seconds)

Maximum Time of No Flow Menu

This is the maximum period allowed between powering the pump motor and the

detection of fuel flow. If no flow is detected, the pump motor switches off.

Parameters:-

•deliveries are disabled 0000

•max. time 0959 (= 9 minutes and 59 seconds)

•default value 0100 (certain applications may overrule this)

Delivery Mode

The calculator must totalise the amount, volume and number of fillings according

to the delivery mode selected. The delivery mode is set as follows:-

•Standalone 0

•Console cash 1

Product Position

This defines the position of the Electromechanical Totalisers (EMT), the Unit

Price Displays (UPD) and the Product Lights per product and per side. It is not

possible to select another UPD position for product 1 other than the appropriate

EMT.

For programming information, refer to section 6.xx

•Product 1 to 5 - position 1

- position 2

- position 3

- position 4

- position 5

Issue A

Note: This menu has been removed from the Option Controller Board (OCB)

menu because the EMTs are not controlled via the OCB. The UPD and

Product Lights are controlled via the OCB.

Page 2-14 Document Ref 905675-001 Rev 2

Page 31

WWC T1 Set Up & Maintenance Manual Product Information

Note: The request to program EMT positions for left-hand dispensers

(PMR297) means that the EMT connector must always be used for 4/5

products on the Optional Peripheral Board (OPB).

OCB Functionality

When an OCB board is connected, the following functions can be selected:-

•Lights (Traf fic Lights, Indication Lights)

Two coloured lights (red and green) indicate the state of the dispenser.

off disabled (default)

1 application dependent

(please check the appropriate documentation for support)

2 default kernel function

IDLE - Green is on

FILLING - Red is on

•Product Lights (Product Indication)

Between two and five lamps light a coloured glass through the front plate of the

calculator housing. Each light corresponds to one of the product stickers located

on the front plate. During a filling, the appropriate light will be on or flashing and

the other lights will be switched off.

off disabled (default)

1 application dependent

(please check the appropriate documentation for support)

2 default kernel function

IDLE - all lights on

FILLING - only the light for the selected product is on

•Unit Price Displays (UPD)

Additional Unit Price Displays show unit prices for all available products:-

off disabled (default)

1 application dependent

please check the appropriate documentation for support)

2 default kernel functionality

IDLE - all unit prices shown

FILLING - only the unit price of the selected product shown

•LCD Display

Additional user displays are not yet supported

off disabled (default)

Issue A

•V olume and Amount Pulses

To support outdated interfaces for Outdoor Payment Terminals (OPT), the

calculator provides two channel pulse outputs each for the actual delivered volume

and amount.

Document Ref 905675-001 Rev 2 Page 2-15

Page 32

Product Information WWC T1 Set Up & Maintenance Manual

- volume unit (number of cl/pulse) 1 to 10 (default = 1)

- volume period (value * 0.25 ms) 5 to 40 (default = 5)

- amount unit (number of units/pulse currency unit)

1 to 10 (default = 1)

- amount period (value * 0.1 ms) 10 to 99 (default = 10)

•Fleet Functionality

In addition to the volume and amount pulses, the “Fleet Functionality” is added

for outdated interfaces to certain controllers.

An OCB output (OUT_SPARE) is reserved to indicate a request for release

and an input (OPT_INPUT) is reserved for the “controller” to release the

dispenser. This requires a special release sequence:-

- calculator will set OUT_SPARE if a nozzle is lifted

- the filling can only start if the controller sets the OPT_INPUT

- the controller can interrupt or stop the filling when resetting the

OPT_INPUT

This release functionality is activated via the RELEAS submenu in the OCB

menu.

For the applicable input and output refer to the OCB definitions in the Appendix.

2.5.3 FUNCTIONALITIES PER DISPENSER

Common Set-Up Codes

The common set-up codes have been defined for the new dispenser range in the

following table.

Refer to the hydraulic flow diagrams for a symbolic drawing regarding supported

hydraulic configurations.

Note : there is also a fleet version of WWC available (volume only display).

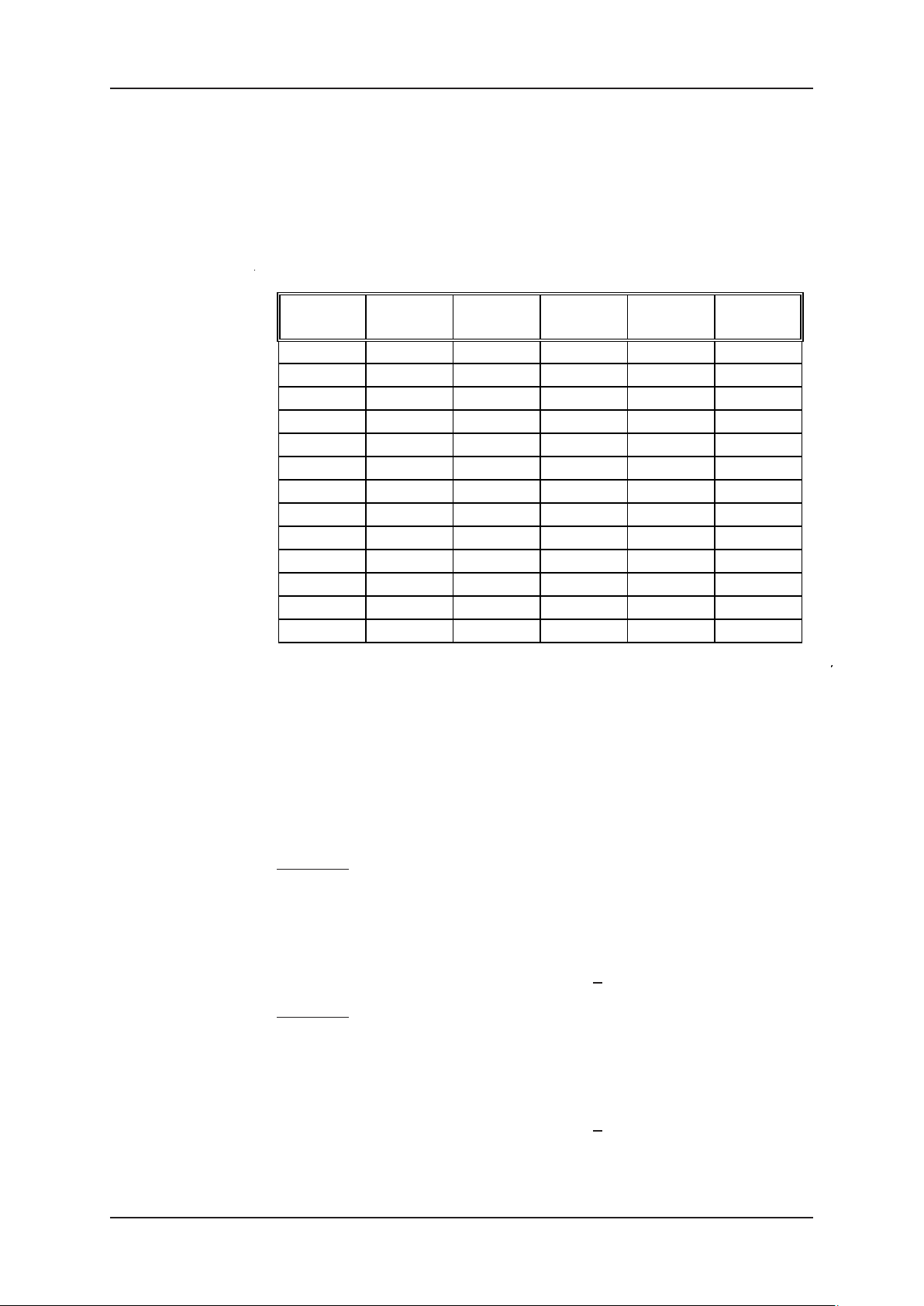

Kernel

Version

all 50 Double

01.07 51 Double 4

02.00 51 Single

>

>

01.09 52 Double

01.09 53 Double

>

03.11 53 Double 1 mot or 1 130 l/min/ SAT 900238

>

01.09

>

>

01.09 55 Double

Hydr

Set up No

Sided

Additional

Description

No of

Products

Flow Rates/Product s Drawing No

5 40/80 l/min button per s i de

130 l/m i n SAT and 3x40 l/min per

side

130l/m i n SAT (SHS on M ai nboard)

1

SHS with 1 product on bot h sides ; 9235110580

4

130 l/m i n/SA T and 3x40 l / m i n per

side

80 l/m i n SAT and 3x40 l/min per

4

side

160 l/m i n/SA T154 Double

1

130 l/m i n/SA T and 1x40 l / m i n

9235110557

900236

9235110???

9235110619

900246

900237

9235110581

900238

9235110582

900239

9235110583

900240

Issue B

Page 2-16 Document Ref 905675-001 Rev 2

Page 33

WWC T1 Set Up & Maintenance Manual Product Information

Kernel

Version

>

01.09

Hydr

Setup No

56 Asymmetric

Sided

Additional

Description

No of

Products

5 right

Flow Rat es/Products Drawing No

130 l/min/SA T and 4x40 l/min

(right);

9235110584

4 left 4 x 40 l/mi n (left) 900241

01.09

>

01.09 58

>

>

01.10 60 Double LPG

>

02.15 61 LPG low-end Extended func tionalit y 901335

57 Asymmetric

Double

Twin

4 right 4 x 40 l/min (right); 9235110585

5 left 130 l/ m in/S AT and 4x40 l/min (l eft) 900242

Product 1 and 3 x 40 l/min (ri ght); 9235110586

4

Product 2 and 3 x 40l/min (l eft) 900243

LPG and 4 x 40 l/ m in per side 9235110618

5

900245

SHS wi th different product s on

>

03.12 62 Double 4

both sides

906015

130 l/min/SA T and 3 x 40 l/min

03.16 63 Double

>

Different

products on

both sides

80 l/min/SA T and 3x40 l/min per

4

side

906377

Different

> 03.16 64 Double

products on

1 160 l/min/SA T 906378

both sides

Different

03.16 65 Double

>

products on

1 130 l/min/SA T and 1 x 40 l/min 906379

both sides

01.09 70 Double Blender

>

3 products in, 5 products out (2

hoses/side);

9235110591

2 blend products 1in + 2in / 1in +

3in

>

01.09 71 Doubl e Blender 3 products in, 4 products out ; 9235110612

1 blend product 1 i n + 2 in

>

01.09 72 Doubl e Blender 3 products in, 4 products out ; 9235110610

1 blend product 1 i n + 2 in

01.09 73 Doubl e Blender 4 products in, 5 products out ; 9235110614

>

1 blend product 1 i n + 2 in

Issue B

01.09 74 Doubl e Fak e Blender 3 products i n, 4 products out 9235110611

>

>

01.09 75 Doubl e Blender 3 products in, 4 products out ; 9235110609

1 blend product 1 i n + 2 in

3 products in / 3 products out on

>

01.09 76 Double Blender

one hose, and 40l/min per side

9235110613

(in=out)

02.00 77 Double Blender ????????? 9235110???

>

900244

03.19 80 Double

>

Oil M ix 3 Oil M ix + 2 x 40l /mi n per side

906927

906928

03.07 90 Doubl e Comb Hose 4

>

Document Ref 905675-001 Rev 2 Page 2-17

2 com bined hose products on firs t

hose

905148

Page 34

Product Information WWC T1 Set Up & Maintenance Manual

Backlight for LCD

The backlight is standard with LCD displays.

Switch Dispenser Lighting

If defined in the application, the switch for the dispenser or calculator lighting is

via a command from the forecourt controller system.

Electronic Totaliser

The totals of amount, volume and number of fillings per nozzle are stored in the

calculator for single, blended and high speed configurations. T otals and subtotals

are also available per delivery mode (two modes). This information is permanent

and cannot be erased or changed unless a “cold start” or “service start” is

performed which would erase all the data in order to prevent data corruption.

Voice Synthesizer

The calculator controls the voice synthesizer in order to output the required

sentence (only the French language is supported). This principle will enable

other languages to be stored.

Remote Reset - Thermal Overload (Pump Motors)

When the thermal protection of the motor is tripped during three sequential fillings,

the motor cannot be switched on again by the calculator without user intervention.

Reset can be done via the service keypad, hardwired input (General Purpose

Input, depending on the selected application) or by switching the power on/off.

When the thermal protection trips before the third sequential time, the motor is

automatically started after the two corresponding nozzles have been replaced

and lifted again.

Note : Applications using kernel version 01.xx will block the motor each

time the thermal protection is tripped.

Note : When testing the Thermal Protection, it may be necessary to increase

the “Maximum time of no flow” to prevent the motor from being switched

off by the calculator.

Refer to section 6.9 for programming information.

Uploading Totals

This function enables the upload of the totals from the calculator to the system.

When the calculator is configured to be used in system mode but is switched

temporarily to standalone mode, the standalone totals are downloaded to the

Point of Sale (POS).

Issue A

Country Code Menu

The country code is predefined and can only be set during a cold start. Refer to

Appendix B for the table of implemented country codes and related variables.

Refer to section 6.7 for programming information.

Page 2-18 Document Ref 905675-001 Rev 2

Page 35

WWC T1 Set Up & Maintenance Manual Product Information

Node Address Menu

This function is required for multi drop communication links (e.g. IFSF) to select

the address of the calculator on the network.

Refer to section 6.20 for programming information.

Test Delivery Menu

This module monitors volume and flow in the following ways:-

•total flow and total volume

•volume of each meter

•flow of each meter

Refer to section 6.21 for programming information.

Product Name

This function displays a name for a product when setting or changing unit prices

or reading totals. This can be done character by character or from a pick list.

Refer to section 6.23 for programming information.