Page 1

Quantium

110 & 210

Installation Manual

Document Ref 947571-001

Rev - 2

03/2011

Page 2

Quantium 110 & 210 Installation Manual

Great care has been taken in the preparation of this manual however T okheim

shall not be liable for any misunderstanding, errors and/or loss or defect

arising from the use of this manual.

Tokheim shall not be liable for damage to the product, nor for personal or

third party injury, caused by incorrect use of the product or by attempts to

maintain or to repair the product by parties other than those fully trained by

Tokheim or by its accredited third party representatives.

Please contact your nearest service department, at the relevant address printed

on the back cover of this manual, should any aspect of this manual be unclear.

© Copyright by T okheim. All intellectual rights arising fr om, accruing to,and

residing in this manual belong to Tokheim. No part of this document may be

repr oduced in any form without the expr ess written permission of Tokheim.

Tokheim reserves the right to apply changes to this document and the

equipment without further notice.

Document Ref 947571-001 Rev 2

Page 3

Quantium 110 & 210 Installation Manual Revision Record

REVISION RECORD

Date Revision Pa ge Rea son

30/06/ 2010 1 All Original Is s ue

03/03/2011 2 3-2 Dimension c han ge

2 3-3 Remove Q110 dimensions drawi ng (di m s from cl adding)

2 3-6 Remove Q210 dimensions drawi ng (di m s from cl adding)

Document Ref 947571-001 Rev 2 1

Page 4

Revision Record Quantium 110 & 210 Installation Manual

This page is intentionally blank

2 Document Ref 947571-001 Rev 2

Page 5

Quantium 110 & 210 Installation Manual Contents

CONTENTS

1 INTRODUCTION......................................................................................................... 1-2

1.1 How To Use This Manual ................................................................................... 1-2

1.2 Product Scope ..................................................................................................... 1-2

1.3 Authorised Technicians....................................................................................... 1-3

1.4 Contact Information ............................................................................................ 1-3

1.5 Health & Safety .................................................................................................. 1-3

1.5.1 Safety Checklist.................................................................................. 1-3

1.5.2 Duties of the Employees..................................................................... 1-3

1.5.3 Hazards ............................................................................................... 1-4

1.5.4 Warning Signs .................................................................................... 1-5

1.5.5 Personal Protective Equipment (PPE) ................................................ 1-6

1.6 Standards & Certificates ..................................................................................... 1-7

1.6.1 Dispenser Marking for the ATEX Directive....................................... 1-7

1.6.2 Special Conditions for Safe Use......................................................... 1-8

1.7 MID Dispensers .................................................................................................. 1-8

2 SITE PREPARATION.................................................................................................. 2-2

2.1 General................................................................................................................ 2-2

2.1.1 Zoning Diagrams ................................................................................ 2-2

2.2 Q110 and Q210 Hose and Pump Configurations................................................ 2-5

2.3 Hydraulic Connections ....................................................................................... 2-7

2.3.1 TQP Connections ............................................................................... 2-7

2.3.2 PAS V3 Connections .......................................................................... 2-8

2.3.3 Submerged Connections ....................................................................2-11

2.3.4 Q210 SDS Connections .................................................................... 2-12

2.3.5 Vapour Recovery Connections ......................................................... 2-12

2.4 Electrical Connections ...................................................................................... 2-16

3 DRAWINGS................................................................................................................... 3-2

3.1 Q110 Dispenser................................................................................................... 3-2

3.1.1 Q110 Dispenser Dimensions .............................................................. 3-2

3.1.2 Q110 Ground Plans ............................................................................ 3-3

3.1.3 Q110 Retention Tray Assembly.......................................................... 3-4

3.1.4 Q110 Ground Fixing........................................................................... 3-4

3.2 Q210 Dispenser................................................................................................... 3-5

3.2.1 Q210 Dispenser Dimensions .............................................................. 3-5

3.2.2 Q210 Ground Plans ............................................................................ 3-6

3.2.3 Q210 Retention Tray Assembly ......................................................... 3-7

3.2.4 Q210 Ground Fixing .......................................................................... 3-7

3.3 Q210 SDS Dispenser .......................................................................................... 3-8

3.3.1 Q210 SDS Dimensions ....................................................................... 3-8

3.3.2 Q210 SDS Ground Plan ..................................................................... 3-9

4 PACKAGING & HANDLING..................................................................................... 4-2

4.1 Shipping Documentation .................................................................................... 4-2

4.2 Packaging ............................................................................................................ 4-2

4.2.1 Unpacking .......................................................................................... 4-2

4.3 Inventory Inspection ........................................................................................... 4-2

4.3.1 Checking List ..................................................................................... 4-3

(CONT.)

Document Ref 947571-001 Rev 2 3

Page 6

Contents Quantium 110 & 210 Installation Manual

4 PACKAGING & HANDLING/

4.4 Dispenser Weights .............................................................................................. 4-3

4.4.1 Q110 Dispenser Weights .................................................................... 4-3

4.4.2 Q210 Dispenser Weights .................................................................... 4-3

4.5 Handling.............................................................................................................. 4-3

4.6 Access the Hydraulic Area.................................................................................. 4-4

4.7 Access the Calculator Head ................................................................................ 4-4

4.8 Access the Junction Box ..................................................................................... 4-5

4.8.1 Bernstein Junction Box ...................................................................... 4-5

5 INSTALLATION........................................................................................................... 5-2

5.1 General................................................................................................................ 5-2

5.2 Identification of Side A....................................................................................... 5-2

5.3 Lifting ................................................................................................................. 5-3

5.4 Placement............................................................................................................ 5-3

5.4.1 By Forklift .......................................................................................... 5-4

5.4.2 Fixing to Ground ................................................................................ 5-6

5.4.3 Earthing .............................................................................................. 5-7

5.5 Hydraulic Connections ....................................................................................... 5-8

5.5.1 Pipework - Suction Dispensers with Internal Filter ........................... 5-8

5.5.2 Pipework - Suction Dispensers with External Filter ........................ 5-10

5.5.3 Pipework - Submerged Dispensers................................................... 5-12

5.6 Electrical Connections ...................................................................................... 5-12

5.6.1 Direct wiring into Terminal Rail - WWC......................................... 5-13

5.6.2 Junction Box Wiring......................................................................... 5-16

5.6.3 Communications Wiring (WWC Head only) ................................... 5-19

5.6.4 OPT Communications option ........................................................... 5-24

6 COMMISSIONING ...................................................................................................... 6-2

6.1 Test and programming the Dispenser ................................................................. 6-2

6.1.1 Program the Dispenser ....................................................................... 6-2

6.1.2 Dispenser Functions ........................................................................... 6-2

6.1.3 Test the Dispenser .............................................................................. 6-2

6.2 Calibration of the Dispenser ............................................................................... 6-3

6.2.1 Mechanical Calibration of the Meter ................................................. 6-3

6.2.2 Electronic Calibration of the MPE Pulser .......................................... 6-4

6.2.3 Temperature Compensation Function ................................................ 6-6

6.3 Final Checks ....................................................................................................... 6-7

6.4 Handing over to the Station Manager ................................................................. 6-7

4 Document Ref 947571-001 Rev 2

Page 7

Quantium 110 & 210 Installation Manual Introduction

CONTENTS

1 INTRODUCTION......................................................................................................... 1-2

1.1 How To Use This Manual ................................................................................... 1-2

1.2 Product Scope ..................................................................................................... 1-2

1.3 Authorised Technicians....................................................................................... 1-3

1.4 Contact Information ............................................................................................ 1-3

1.5 Health & Safety .................................................................................................. 1-3

1.5.1 Safety Checklist.................................................................................. 1-3

1.5.2 Duties of the Employees..................................................................... 1-3

1.5.3 Hazards ............................................................................................... 1-4

1.5.4 Warning Signs .................................................................................... 1-5

1.5.5 Personal Protective Equipment (PPE) ................................................ 1-6

1.6 Standards & Certificates ..................................................................................... 1-7

1.6.1 Dispenser Marking for the ATEX Directive....................................... 1-7

1.6.2 Special Conditions for Safe Use......................................................... 1-8

1.7 MID Dispensers .................................................................................................. 1-8

Document Ref 947571-001 Rev 2 Page 1-1

Page 8

Introduction Quantium 110 & 210 Installation Manual

1 INTRODUCTION

1.1 How To Use This Manual

It is recommended that all relevant persons familiarise themselves with the contents of

this manual prior to carrying out any operations or procedures.

This manual is divided into sections which are described as follows: -

Section 1 - Introduction

This section contains information on how to use the manual, the scope of equipment

covered, recommendations on qualified technicians and contact information. It also

includes relevant health and safety information required for the safe installation and

commissioning of the product.

Section 2 - Site Preparation

This section details the procedures to be carried out in preparation for receipt of equipment

at site and the necessary actions prior to installation.

Section 3 - Drawings

All necessary drawings required for reference during the installation and commissioning,

are listed and contained in this section.

Section 4 - Packaging and Handling

This section provides instructions for unpacking and safe handling of the equipment.

Section 5 - Installation

The instructions for the correct installation of the equipment are contained within this

section.

Section 6 - Commissioning

This section highlights the actions and checks, to be carried out, in preparation for the

commissioning activity and the procedures required from commissioning of the equipment

to handover.

1.2 Product Scope

The equipment and models covered by the contents of this manual are: -

The Quantium 110 & 210 range of fuel dispensers, with the exception of the LPG versions.

For information on Quantium LPG dispensers refer to the relevant LPG manual as provided

by T okheim.

All dispensers in the Quantium 110 & 210 ranges use the same standard sub-assemblies

and offer a wide range of configurations and includes provision for options such as vapour

recovery etc.

Page 1-2 Document Ref 947571-001 Rev 2

Page 9

Quantium 110 & 210 Installation Manual Introduction

1.3 Authorised T echnicians

Only qualified technicians familiar with the contents of this manual should carry out the

procedures contained herein.

WARNING : ANY ATTEMPTS TO CARRY OUT THE PROCEDURES OF THIS

MANUAL, BY UNQUALIFIED OR UNAUTHORISED PERSONS, MAY RESULT

IN SERIOUS INJURY OR LOSS OF LIFE.

NOTE : THIS MANUAL IS NOT INTENDED TO REPLACE THE SERVICES OF

A FULLY QUALIFIED TECHNICIAN.

1.4 Contact Information

For information relating to the contents of this manual please contact: T echnical Author

Tokheim UK Ltd.

Dundee, Scotland

author@dundee.tokheim.com

For technical assistance please contact the appropriate service division listed on the back

cover of this manual.

1.5 Health & Safety

1.5.1 SAFETY CHECKLIST

•It is obligatory that this checklist be fully complied with during all work at the

petrol station, particularly construction or repair work.

•It is the duty of the contractor to ensure that all workers employed by him obey

each and all of the relevant laws, directives and other regulations.

Areas where special caution is required

•The insides of tanks, tubes, dome shafts, filling shafts, change over shafts, vessels

and dispensers.

•All areas in which fuel vapour that is heavier than air can accumulate, e.g. fuel

separator, draining shafts, low located rooms, cellars, excavations, pipe trenches

etc.

•The areas around the outlets of tank ventilation pipes, especially during the

filling phase.

•All areas near dispensers, tanker lorries and other vehicles while they are being

tanked up, and particularly when there is a lack of wind.

•A radius of 1.0 metres around petrol carrying pipes, as well as pipes that are not

vapour free.

•Silt traps.

1.5.2 DUTIES OF THE EMPLOYEES

•To ensure optimal accident prevention in our company, in addition to general

rules applying to worker’s protection, it is necessary to take into account all the

national protection of workers legislation and to actively support all measures

which enhance safety standards.

Document Ref 947571-001 Rev 2 Page 1-3

Page 10

Introduction Quantium 110 & 210 Installation Manual

•It is an employee’s duty to follow all company directives regarding the prevention

of accidents, unless such directives can be proved to be unfounded.

•Employees should not follow any instructions that go against safety standards.

•Employees are only permitted to use equipment for its original purpose, and

this is defined by the company alone.

•If an employee detects equipment that is deficient in terms of safety, he shall

eliminate this deficiency immediately . If such safety rectification is not part of

his defined area of activities, or if his knowledge is insufficient to carry out

such work he must immediately inform his superior about the detected safety

deficiency.

This equally applies to:

1) Work Materials which have not been correctly packed or correctly marked in

order to meet safety requirements.

2) Work Methods or work processes which have not been correctly coordinated

or controlled in order to meet safety requirements.

3) Where dangerous activities are carried out by several persons, the need for

a permanent faultless communication between them in order to avoid dangerous

events shall require the appointing of one person in order to carry out overall

supervision.

1.5.3 HAZARDS

Prior to starting work, the dispenser must be isolated (i.e. entirely disconnected

from the mains supply) and the mains supply switch locked in the OFF position.

The submerged pump (if applicable) and control signals from the dispenser

must also be isolated. This is done to provide safety for the technician. As a

further precaution, switch off the mains supply in the service station shop and

place a clear notice on the switch to avoid it being turned on again inadvertently .

WARNING : THE CONNECTION AND DISCONNECTION OF

ELECTRICAL CONNECTIONS MAY ONLY BE CARRIED OUT BY

QUALIFIED PERSONNEL AUTHORISED FOR SUCH ACTIVITIES.

WORK IN DANGEROUS AREAS MUST BE MADE SAFE BY

OBSERVING ALL THE NATIONAL SAFETY REQUIREMENTS IN

FORCE.

It is not permitted to put a fuel dispenser into operation before an authorised

official has inspected it and released it. This depends upon the national

regulations in force.

Dismantled packaging and cladding must be stored in such a way as to avoid

damage to components or injuries to persons. Covers that can be opened, such

as the calculator housing, should be handled with care. Ensure that the retaining

catch is placed in the correct position to prevent the cover falling onto the head

of the service engineer or other persons in the area.

At unattended service stations, every end-user should be able to read the User

Instructions. They should be visible on a notice board or integrated into the DIT

and should be sufficiently well lit so that they can be read at night.

Page 1-4 Document Ref 947571-001 Rev 2

Page 11

Quantium 110 & 210 Installation Manual Introduction

At unattended service stations break away couplings must always be used to

reduce the danger caused by a motorist driving off with the nozzle still in the

tank.

1.5.4 WARNING SIGNS

The following warning signs are fitted as standard, on the dispenser, however

they may vary according to individual country requirements or customer

specifications.

SIGN

MEANING POSITION

Do not use mobile

phones

No naked flames

Visible from both

sides of dispenser

Visible from both

sides of dispenser

Do not spill fuel on the

ground

Smoking forbidden

Visible from both

sides of dispenser

Visible from both

sides of dispenser

Stop vehicle engine Visible from both

sides of dispenser

Trucks only

At Diesel high speed

dispensers near the

nozzle boots

Do not drive away with

nozzle in tank

Visible from both

sides of dispenser

Next to User Instructions

near the nozzle boot

Document Ref 947571-001 Rev 2 Page 1-5

Page 12

Introduction Quantium 110 & 210 Installation Manual

1.5.5 PERSONAL PROTECTIVE EQUIPMENT (PPE)

PROTECTIVE CLOTHING

The following clothing should be worn at all times during installation and

maintenance procedures:-

•Protective helmet.

•Protective shoes (conductive).

•Protective gloves and/or protective hand cream.

•Anti static clothing.

•Eye protection.

SAFETY EQUIPMENT FOR WORKING IN HAZARDOUS AREAS

The following safety equipment is required for working in hazardous areas:-

•Only spark free tools are permitted for work on dispensers.

•Work on bearings is only permitted using the standard workshop tools authorised

for this kind of work.

•The use of all electrical tools is strictly prohibited.

•Only the use of explosion protected work lights is permitted.

•The use of telecommunications equipment in hazardous areas is strictly

prohibited.

SAFETY INSTRUCTIONS

The following safety instructions must be adhered to during installation and

maintenance procedures:-

•Inhalation of petrol vapour must be avoided. Suitable precautions must be

taken and where necessary respirators used.

•Avoid direct contact of fuel with the skin.

•Use suitable protective clothing, protective gloves and/or protective hand cream.

•Avoid fuel spills.

•No smoking, no naked flames are permitted.

•Long hair and ties can get caught in moving parts. Hair must be suitably covered.

Page 1-6 Document Ref 947571-001 Rev 2

Page 13

Quantium 110 & 210 Installation Manual Introduction

1.6 Standards & Certificates

This dispenser is constructed in conformity with the requirements of all the applicable

European Directives (Machinery 2006/42//EC; EMC 89/336/EEC; ATEX 94/9/EC).

The components used within the dispenser, including connection facilities, are selected in

accordance with the European Standard EN BS 60079-0 (Electrical Apparatus for explosive

gas atmospheres), and the supplementary Standards listed therein.

Diesel dispensers do not create an explosive hazard, but due to the probability of these

being in close proximity to gasoline dispensers, the same construction rules are applicable.

The dispenser is certified by SIRA as suitable for use in Potentially Explosive Atmospheres

Directive 94/9/EC, and marked to be in accordance with the European Dispenser

Construction Standard EN 13617-1.

This dispenser is also certified to OIML International Recommendations R1 17 and R1 18.

Certificate Numbers R117/1995-NL-01.04 & 08.

The production and end test is controlled through the Quality Assurance systems within

the Tokheim Manufacturing Centres, and has received Quality Assurance Notification

from a Notified Body.

No modification to the dispenser may be performed without express permission from

Tokheim and must always use original components or Tokheim retrofit kits. Failure to

comply with the above will invalidate product conformance with the relevant European

Directives and Tokheim will no longer accept product liability.

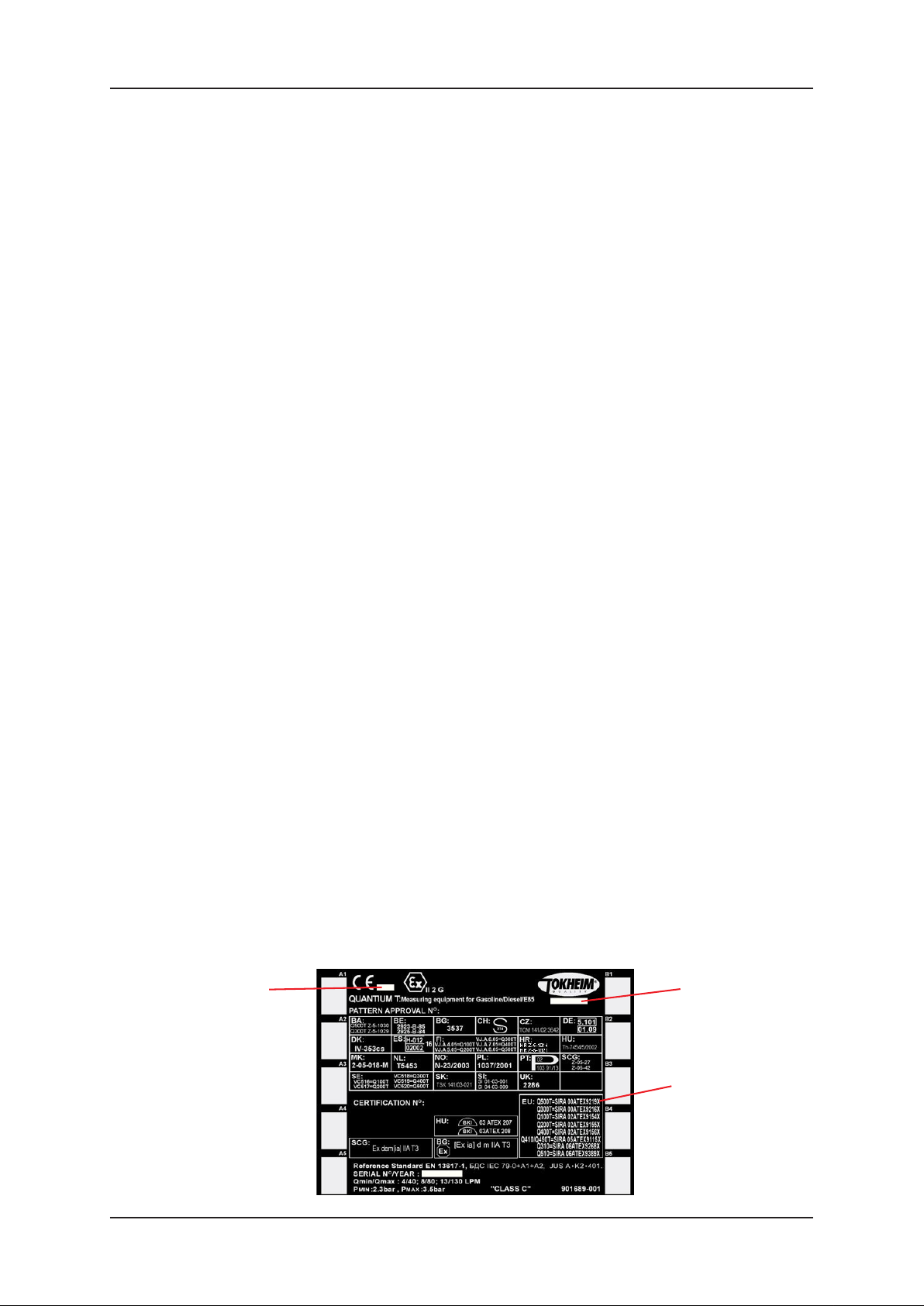

1.6.1 DISPENSER MARKING FOR THE ATEX DIRECTIVE

The dispenser is labelled by Tokheim in accordance with the requirements of

the ATEX Directive. This labelling includes:-

•The CE mark (CE conformity)

•The specific explosion protection mark, together with the mark indicating the

equipment group and category; and, relating to equipment group II, the letter

“G” (concerning explosive atmospheres caused by gases and vapours)

•The “Tokheim” name or logo and manufacturing location

•The dispenser type and serial number including the year of production

Labels can either be plastic stickers or metal plates and may vary according to

national requirements. A typical example of a label follows:-

0518 SIRA

or

0081 LCIE

DUNDEE

or

GRENTHEVILLE

“X” CONDITIONS refer to section 1.6.2

Document Ref 947571-001 Rev 2 Page 1-7

Page 14

Introduction Quantium 110 & 210 Installation Manual

1.6.2 SPECIAL CONDITIONS FOR SAFE USE

Certain models include Special Conditions for Safe Use which must be observed

prior to putting the dispensers into operation. Failure to do so will invalidate

the ATEX certification of the dispenser. These models can be identified by an

X at the end of the certificate number as shown on the dispenser typeplate.

The Special Conditions for Safe Use are identified in the ATEX EC TypeExamination Certificates and are repeated below:-

•Where a dispenser is supplied without hoses and/or nozzles, they shall be fitted

in accordance with:

-Hoses : EN1360 or EN13483

- Nozzles: EN13012

•When used for ethanol (blend) dispensing, the fuel specification must be less

than or equal to 85% ethanol, with minimum water content.

•The metering pumps and dispensers are designed for use in open air. Where a

metering pump or dispenser is positioned within a building, incorporated into

an enclosure, or integrated into a larger piece of equipment, additional measures

shall be taken to ensure that the zoning diagrams illustrated in the schedule

drawings are not compromised.

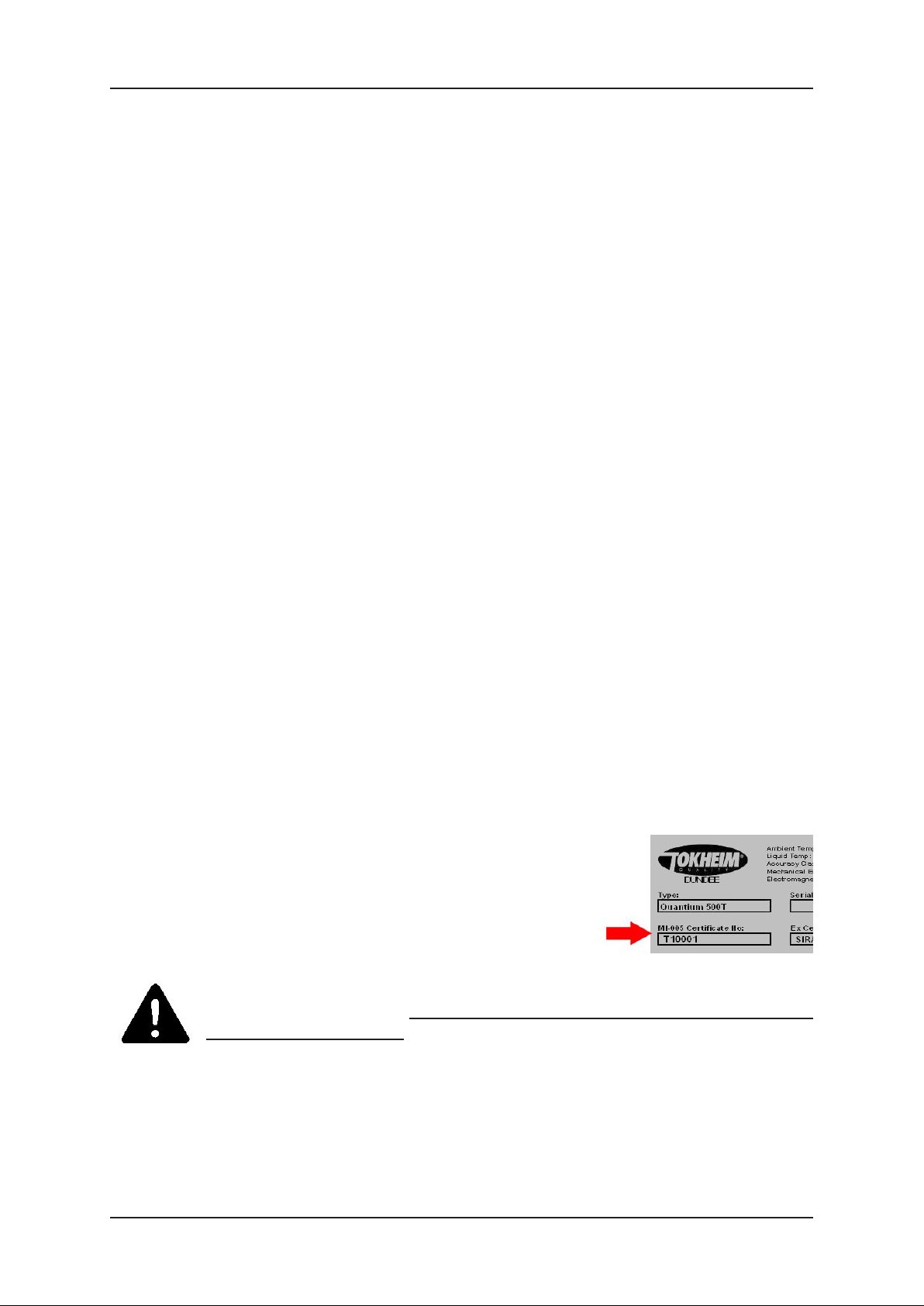

1.7 MID Dispensers

From mid 2007, T okheim dispensers may be shipped from European factories in accordance

with the Metrological Instruments Directive (MID). Such dispensers are calibrated and

the relevant seals stamped in the factory so that the dispensers are fit for trade immediately

upon installation without the need for a local W eights and Measures inspector to put them

into use.

The dispenser is shipped with its own “MID datasheet” which documents the serial numbers

of the prime components fitted in the dispenser. This datasheet must remain with the

dispenser. Similarly dispensers are shipped with a Declaration of Conformance to the

MID. This document must not be lost as it is an essential document to allow the continued

use of the dispenser.

MID dispensers can be identified by the typeplate which

contains a reference to the MID certificate number as

shown:-

CHECKING THE SEALS

It is the responsibility of the Installer to check that all required seals are present and

correct prior to putting the dispenser into use. This includes seals on the pumping unit,

meter, pulser and calculator.

broken during installation.

Under no circumstances must any seals be disturbed or

METER CALIBRA TION

A calibration check should be performed during Commissioning (refer to section 6).

If a seal is damaged or missing, or if the calibration is outwith legal tolerances or in the

unlikely event that any repair is required to a pumping unit, meter, pulser or calculator

during installation, the factory MID verification is invalidated and a local National

verification will need to be performed before the dispenser can be used.

Page 1-8 Document Ref 947571-001 Rev 2

Page 15

Quantium 110 & 210 Installation Manual Site Preparation

CONTENTS

2 SITE PREPARATION.................................................................................................. 2-2

2.1 General................................................................................................................ 2-2

2.1.1 Zoning Diagrams ................................................................................ 2-2

2.2 Q110 and Q210 Hose and Pump Configurations................................................ 2-5

2.3 Hydraulic Connections ....................................................................................... 2-7

2.3.1 TQP Connections ............................................................................... 2-7

2.3.2 PAS V3 Connections .......................................................................... 2-8

2.3.3 Submerged Connections ....................................................................2-11

2.3.4 Q210 SDS Connections .................................................................... 2-12

2.3.5 Vapour Recovery Connections ......................................................... 2-12

2.4 Electrical Connections ...................................................................................... 2-16

Document Ref 947571-001 Rev 2 Page 2-1

Page 16

Site Preparation Quantium 110 & 210 Installation Manual

2 SITE PREP ARATION

2.1 General

Tokheim dispensers must only be installed on a level island or forecourt surface.

The ground plan will depend on the model ordered. See drawings in Section 3. Refer to

separate LPG Dispenser Manuals for information on LPG dispenser classifications.

VENTILATION

There are no vapour traps in the structure of the dispenser. The hydraulic cabinet is

ventilated via the hydraulic doors. Note : The hydraulic doors must not be blocked

during installation.

VAPOUR BARRIERS

Hazardous areas, as defined in this manual, are applicable only when the dispenser is

located in open air. The control of the hazardous areas in and around the fuel dispenser is

by the use of Vapour Barriers. No specific precautions are taken to reduce the Zone 1

classification of the internal hydraulic housing of the dispenser.

2.1.1 ZONING DIAGRAMS

Quantium 110 and 210 dispensers comply with the requirements of the ATEX

Directive 94/9/EC by conforming to PrEN13617-1.

The classification of vapour barriers are indicated in the following diagrams.

The zone classifications shown are always the highest applicable to that location

within the dispenser. The zone drawings respect the zones created by the use of

vapour recovery systems. No fuel pipes pass through any vapour barrier except

dispensers with Mechanical Registers where a drive shaft passes through the

airgap. Cables glands and blanking plugs used in the vapour barriers are certified

to an equivalent protection rating.

Page 2-2 Document Ref 947571-001 Rev 2

Page 17

Quantium 110 & 210 Installation Manual Site Preparation

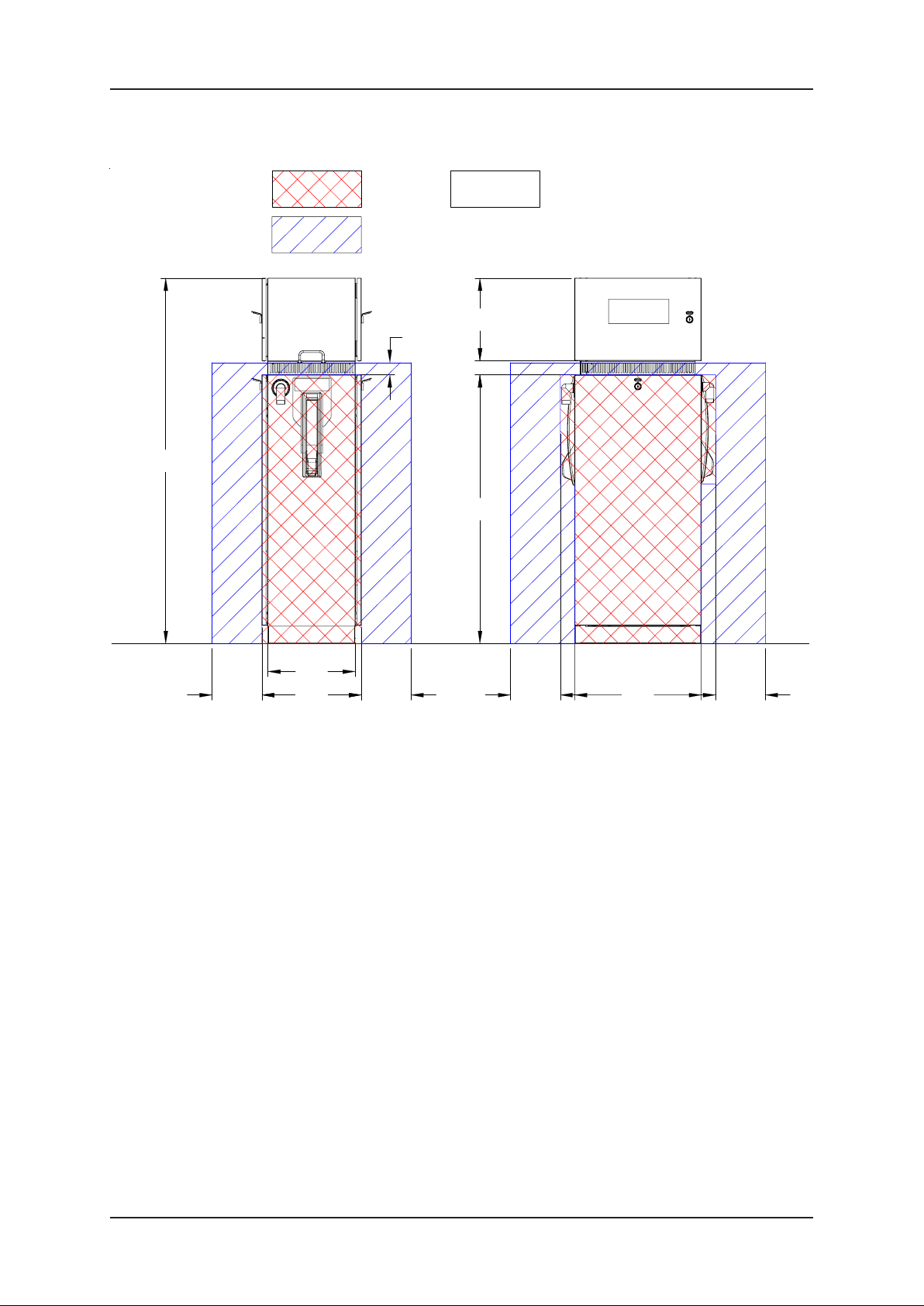

Q110 DISPENSER

1471

Zone

2

Zone 1

Zone 1

Zone 2

Zone

2

50

328.5

62

1080

Non-hazardous zone

Calc Head

Zone

2

Hydraulic

housing

Zone 1

Zone

2

Island Level

350

200 200

200 200

509427

Note:- On this dr awing all zone 2 areas are external of the dispenser.

Zone 1 is internal in the dispenser.

Document Ref 947571-001 Rev 2 Page 2-3

Page 18

Site Preparation Quantium 110 & 210 Installation Manual

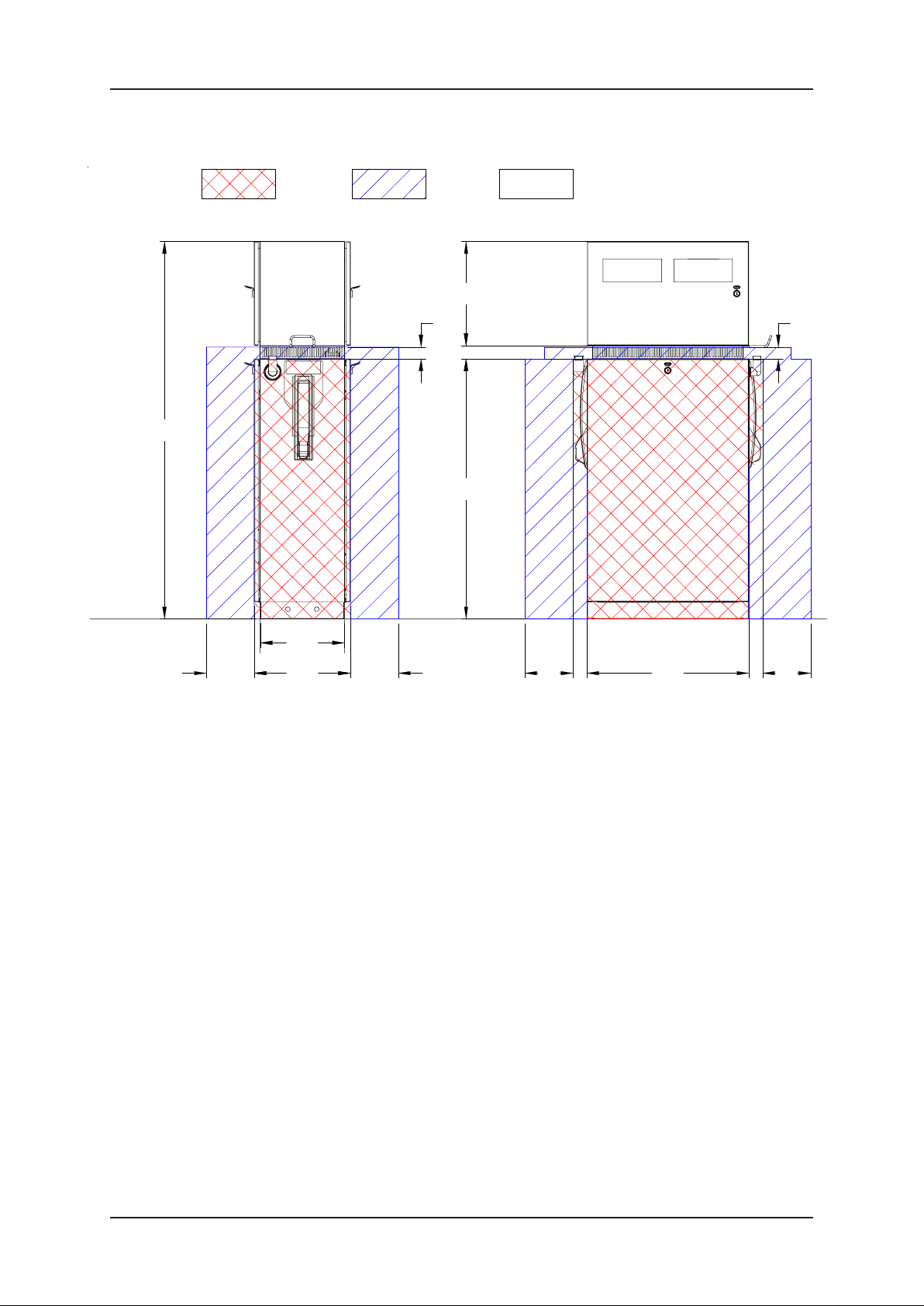

Q210 DISPENSER

1570.5

Island Level

Zone

2

Zone 1

Zone 1

350

Zone

2

50

432

56.5

1080

Zone

2

Non-hazardous zoneZone 2

Calc Head

Zone 1

Hydraulic

housing

50

Zone

2

200 200

Note:- On this drawing all zone 2 areas are external of the dispenser.

Zone 1 is internal in the dispenser.

673427

200200

Page 2-4 Document Ref 947571-001 Rev 2

Page 19

Quantium 110 & 210 Installation Manual Site Preparation

g

g

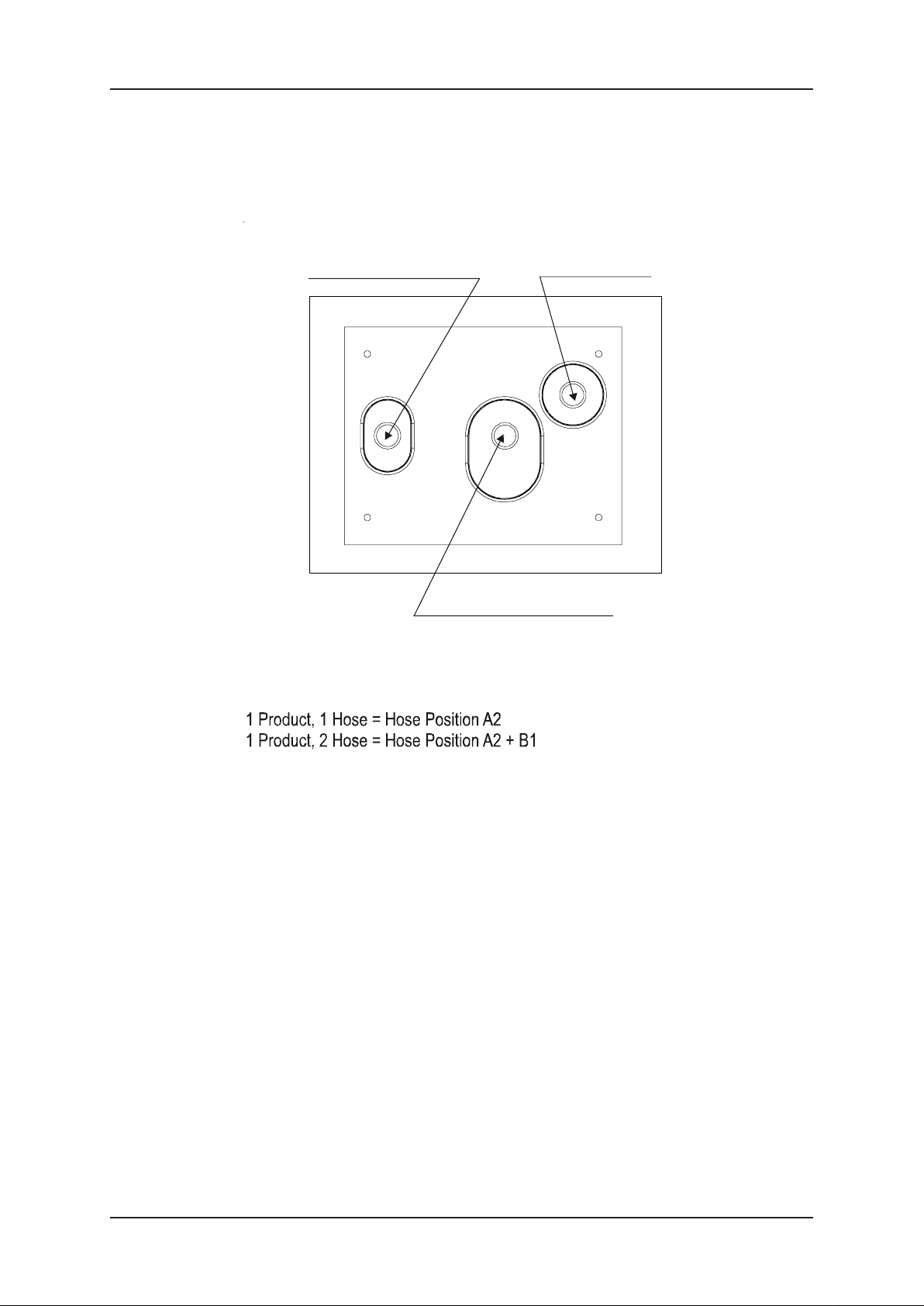

2.2 Q110 and Q210 Hose and Pump Configurations

The diagram below shows the possible functioning positions of the Q110 dispenser.

Vapour recovery (default)

or

Suction pipe for P AS V3

Electrical supply

Side B

B1

B2

A1

Hose outlet positions

Any Product + 1 Hose =

Any Product + 2 Hose =

A2

Side A

Product pipe only for TQP

TQP Low Pow e r 40 o r 40/80 or 80

P ASV3 High Power 130

Submer

ed 40 or 40/80 or 80 or 130

PASV3 High Power 40 or 80, Shared 130

Submer

ed 40 or 40 /80 or 80 or 13 0

Document Ref 947571-001 Rev 2 Page 2-5

Page 20

Site Preparation Quantium 110 & 210 Installation Manual

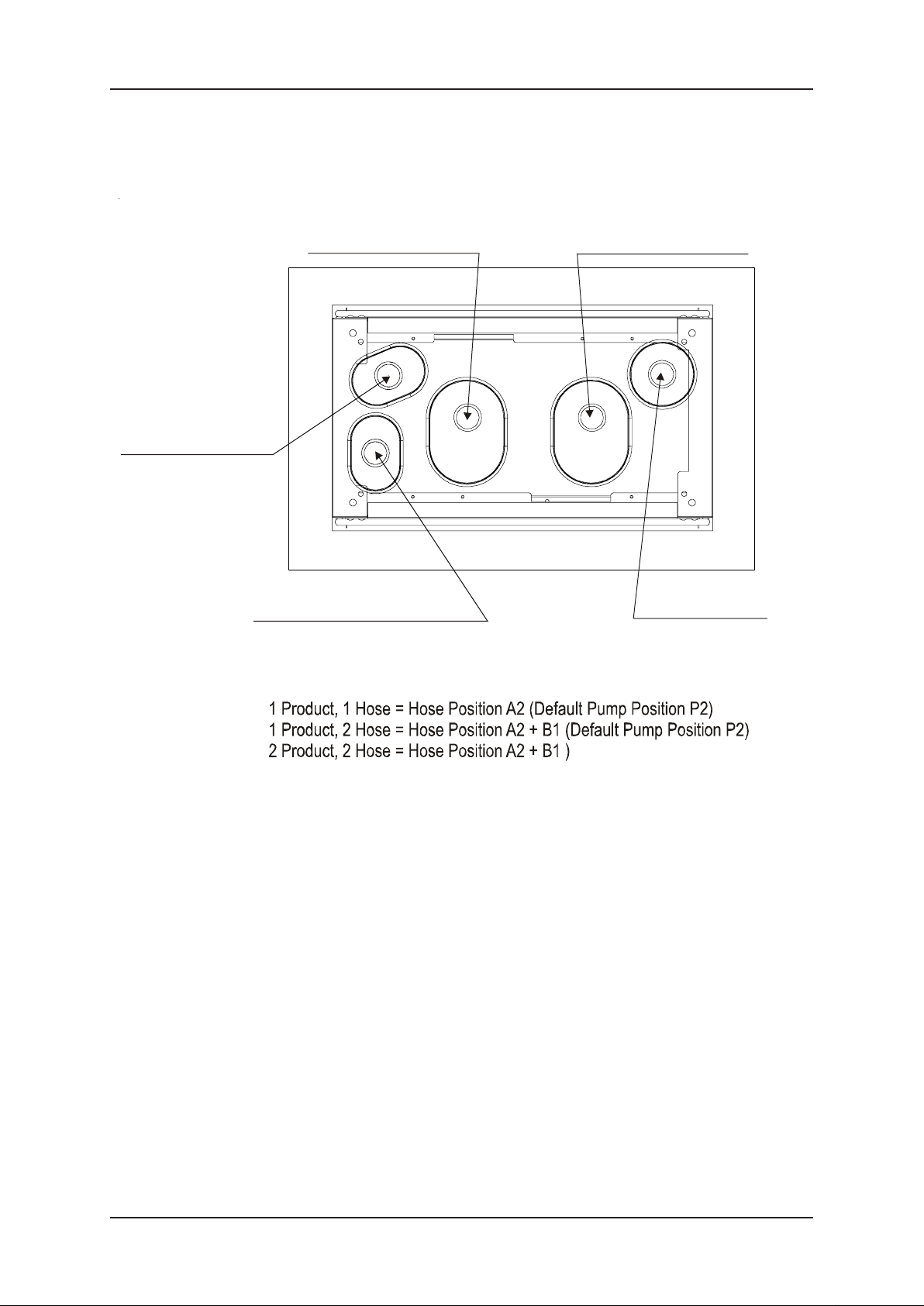

g

g

The diagram below shows the possible functioning positions of the Q210 dispenser.

Vapour Recovery

product 1 (only if return

line to product) or

Satellite connection

product 1

Vapour Recovery (Default) or

Satallite connection product 2

Product pipe 1 with TQP

or

Suction pipe for P AS V3

B1

A1

P1

Product pipe 2 with TQP

or

Satellite produ c t 2

Side B

B2

P2

A2

Side A

Electrical Supply

Hose outlet positions

Any Product + 1 Hose =

Any Product + 2 Hose =

TQP Low Power 40 or 40/80 or 80

PASV3 High Power 130

Submer

ed 40 or 40/80 or 80 or 130

PASV3 High Power 40 or 80 or Shared 130

Submer

ed 40 or 40/80 or 80 or 130

Page 2-6 Document Ref 947571-001 Rev 2

Page 21

Quantium 110 & 210 Installation Manual Site Preparation

2.3 Hydraulic Connections

The suction pipes are accessible from either side of the Dispenser. Different types of

hydraulic connection are available depending on the dispenser configuration.

Please note : If the inlet riser pipe has a female connection, an adaptor must be used

(1.5” or 2”).

If an adaptor is used, the dimensions shown will need to be reduced (maximum 36mm).

2.3.1 TQP CONNECTIONS

Q110 Dispenser with TQP (Standard configuration)

Riser VR pipe height (Std)

40

Vapour

Recovery

pipe

55.5

Ø1.5"

NEW DRA WINGS REQUIRED

Electrical Supply

Suction pipe

Ø1"

End threaded (VR pipe)

Riser knee height

(Ø40/49)

Dimensions shown from the bottom of base

Suction pipes

Q210 Dispenser with TQP (Standard configuration)

70 Min - 90 Max

Riser pipe height

55.5

70 Min - 90 Max

NEW DRA WINGS REQUIRED

Suction pipes

Ø1.5"

Riser VR pipe height (Std)

40

Electrical supply

Vapour

recovery

pipes

Document Ref 947571-001 Rev 2 Page 2-7

Ø1"

End threaded (VR pipe)

Suction pipes

Riser knee height

(Ø40/49)

Dimension shown from the bottom of chassis.

Riser pipe height

Page 22

Site Preparation Quantium 110 & 210 Installation Manual

Q210 Dispenser with TQP & Satellite Connection

201

Riser flange connection height

Satellite connection - Product 2

Accessible from Side A

Satellite connection - Product 1

Accessible from Side B

Product 1

NEW DRA WINGS REQUIRED

Suction pipes

Product 2

Electrical supply

55.5

Suction pipe

Ø1.5"

Riser knee height

(Ø40/49)

Dimension shown from the bottom of chassis.

70 Min - 90 Max

Riser pipe height

2.3.2 PAS V3 CONNECTIONS

Q110 & Q210 Dispensers with PAS V3 (Standard configuration)

Riser filter height

201

Product 2

Side A

Suction pipe

Electrical supply

Dimensions shown from the bottom of the base

Page 2-8 Document Ref 947571-001 Rev 2

Page 23

Quantium 110 & 210 Installation Manual Site Preparation

Q110 & Q210 Dispensers with PAS V3 & Satellite Connection

Riser flange connection height

201

Satellite connection

Accessible from Side A

Riser filter height

201

Dimensions shown from the bottom of the base

PAS V3 Standard Suction & Submerged Hydraulic Connection

(without flexible coupling)

78

M10

Side A

Suction pipe

Product 2

Electrical supply

Filter Level

82

201

Driptray

height

70

Island Level

Document Ref 947571-001 Rev 2 Page 2-9

Page 24

Site Preparation Quantium 110 & 210 Installation Manual

PAS V3 Suction Connection - Flexible Coupling to 1.5” O-Ring

Compression Flange

Ø50

Flexible coupling to 1.5"

O-ring compression

flange

O-ring seal level

101

max

70

Driptray

height

78

Island Level

PAS V3 Suction Connection - Flexible Coupling to 1.5” Female Thread

Rc 1.5"

Ø38

Option - Flexible coupling to

1.5" female thread

O-ring seal level

70

Driptray

height

78

Island Level

Page 2-10 Document Ref 947571-001 Rev 2

Page 25

Quantium 110 & 210 Installation Manual Site Preparation

2.3.3 SUBMERGED CONNECTIONS

Standard Submerged Connection

Riser nut coupling height

NEW DRA WINGS REQUIRED

133

Riser shear valve height

Filter Level

117

201

Ø1.5"

(40/49)

Dimensions shown from the bottom of the base

Submerged Connection with Nefit Adaptor & Tokheim Shear Valve

End threaded

Adapter NEFIT

Pipe 903583

Driptray

70

height

Island Level

117

Document Ref 947571-001 Rev 2 Page 2-11

Page 26

Site Preparation Quantium 110 & 210 Installation Manual

2.3.4 Q210 SDS CONNECTIONS

With Breakaway & Cradle Without Breakaway or Cradle

Riser height from base

Riser height from base

201

201

117

Breakaway

2.3.5 VAPOUR RECOVERY CONNECTIONS

Standard VR Connection

Connection

flange level

For M8 screw

Island level

40

Page 2-12 Document Ref 947571-001 Rev 2

78

Page 27

Quantium 110 & 210 Installation Manual Site Preparation

VR Connection with Risbridger Shear Valve Option

Insulation Sleeve

Flange 1" 78mm

M10 Nut

Risbridger Shear Valve

900758-003

Gasket

901320-001

900011-004

Nipple

U Clamp

NOTE : All threads must be

sealed using Loctite 577

901859

901772

906069

903184

G1" VR Pipe

with male thread

900015-022

901596

Underside of dispenser

17

97.5

Terminate VR pipe

99mm below dispenser

M10x45 Bolt

Flange on Dispenser

VR Flexi

Driptray

height

70

99

IMPORTANT

Assembly below the shear point

must be secured to the ground

frame (NOT dispenser frame)

SPECIAL INFORMATION RELATING TO HIGH BLEND ETHANOL

FUELS (HBEF) & VAPOUR RETURN (VR) RETURN LINES

Following extensive explosion safety tests with HBEF by PTB, Tokheim

recommends all pipework back to the vapour space of the HBEF storage tank

should be protected by special flame arresters.

The vapour return line to the underground storage tank should be protected in

the event of a vehicle collision with a dispenser and also for maintenance

operations. The flame arrester(s) in the dispenser VR pump do not meet this

requirement.

An additional flame arrester must be positioned under the dispenser and must

be protected from potential damage during a vehicle collision so it remains

connected to the vapour return line to the tank in the event that the dispenser is

knocked off the island.

Note : This flame arrester is a r equirement of the installation, not a r equirement

of the dispenser.

If the Stage II VR return lines are routed back to the HBEF tank then the VR

return line from the dispenser vapour recovery system should protect the tank

by including a flame arrester.

Document Ref 947571-001 Rev 2 Page 2-13

Page 28

Site Preparation Quantium 110 & 210 Installation Manual

The correct type of flame arrester must be carefully selected:-

•Deflagration or detonation arrester dependent upon its position relative to the

anticipated end of line

•Inline type (unless it can be guaranteed to be at the end of line during maintenance

or after a vehicle collision)

•End of line types will need to be suitable for use with burning alcohol

•Arrester must be suitable for the correct Gas Group:-

- Ethanol blends 60% to 90% require Gas Group IIA Arresters

- Ethanol blends >90% require Gas Group IIB1 Arresters

•Arrester must be manufactured from materials suitable for use with ethanol and

bio-ethanol blended fuels

Tokheim offer two kits for use with Quantium dispensers to fullfil these

requirements, both kits using the inline deflagration flame arrester certified for

use with Gas Group IIB1 thus suitable for all percentage ethanol blends. The

kit must be installed in close proximity to the underside of the dispenser in

accordance with the drawings in this section.

Insulation Sleeve

Gasket

Flange 1" 78mm

M10 Nut

Nipple

•The standard kit includes an intentionally weak section above the arrester to

ensure that the device remains on the underground vapour pipe following a

vehicle collision

•The alternative kit includes a certified shear valve (with poppets) above the

arrester which additionally ensures that the line back to the tank is closed

following a vehicle collision

VR Connection with Shear Point & Flame Arrester for Ethanol

Kit 1 - Tokheim Part No 943143-001

900758-003

901859

901320-001

900011-004

901772

900015-022

901596

Underside of dispenser

M10x45 Bolt

Flange on Dispenser

VR Flexi

Driptray

height

70

Shear Valve

3

G1"- G

" Nipple

4

(Under Clamp)

Flame Arrester

U Clamp

NOTE : All threads must be

sealed using Loctite 577

904587

900416

943050-001

903184

with male thread

G1" VR Pipe

70

Terminate VR Pipe

70mm below dispenser

943143-001 Rev 1

86

IMPORTANT

Assembly below the shear point

must be secured to the ground

frame (NOT dispenser frame)

Page 2-14 Document Ref 947571-001 Rev 2

Page 29

Quantium 110 & 210 Installation Manual Site Preparation

VR Connection with Risbridger Shear Valve & Flame Arrester for Ethanol

Kit 2 - Tokheim Part No 943143-002

Insulation Sleeve

900758-003

Gasket

Flange 1" 78mm

M10 Nut

901320-001

900011-004

Nipple

Risbridger Shear Valve

U Clamp

3

G1"- G

" Nipple

4

(Under Clamp)

Flame Arrester

943050-001

NOTE : All threads must be

sealed using Loctite 577

901859

901772

906069

903184

900416

G1" VR Pipe

with male thread

900015-022

M10x45 Bolt

901596

VR Flexi

Driptray

height

Underside of dispenser

17

152.5

Terminate VR pipe

154mm below dispenser

943143-002 Rev 1

IMPORTANT

Assembly below the shear point

must be secured to the ground

frame (NOT dispenser frame)

70

154

Document Ref 947571-001 Rev 2 Page 2-15

Page 30

Site Preparation Quantium 110 & 210 Installation Manual

2.4 Electrical Connections

The electrical connection to be established between the kiosk and the dispenser exists in

different configurations. The mains connection (power from the mains supply panel to

the dispenser) and the data connection (link between forecourt controller and calculator)

are customer, country and configuration specific. The number of cores and the cross

section of the cable will be specified, as will the cable construction (armoured or Explosion

proof) and guidance troughs, channels or cable trunks have to be carried out in accordance

with national technical regulations.

Page 2-16 Document Ref 947571-001 Rev 2

Page 31

Quantium 110 & 210 Installation Manual Drawings

CONTENTS

3 DRAWINGS................................................................................................................... 3-2

3.1 Q110 Dispenser................................................................................................... 3-2

3.1.1 Q110 Dispenser Dimensions .............................................................. 3-2

3.1.2 Q110 Ground Plans ............................................................................ 3-3

3.1.3 Q110 Retention Tray Assembly.......................................................... 3-4

3.1.4 Q110 Ground Fixing........................................................................... 3-4

3.2 Q210 Dispenser................................................................................................... 3-5

3.2.1 Q210 Dispenser Dimensions .............................................................. 3-5

3.2.2 Q210 Ground Plans ............................................................................ 3-6

3.2.3 Q210 Retention Tray Assembly ......................................................... 3-7

3.2.4 Q210 Ground Fixing .......................................................................... 3-7

3.3 Q210 SDS Dispenser .......................................................................................... 3-8

3.3.1 Q210 SDS Dimensions ....................................................................... 3-8

3.3.2 Q210 SDS Ground Plan ..................................................................... 3-9

Document Ref 947571-001 Rev 2 Page 3-1

Page 32

Drawings Quantium 110 & 210 Installation Manual

3 DRAWINGS

3.1 Q110 Dispenser

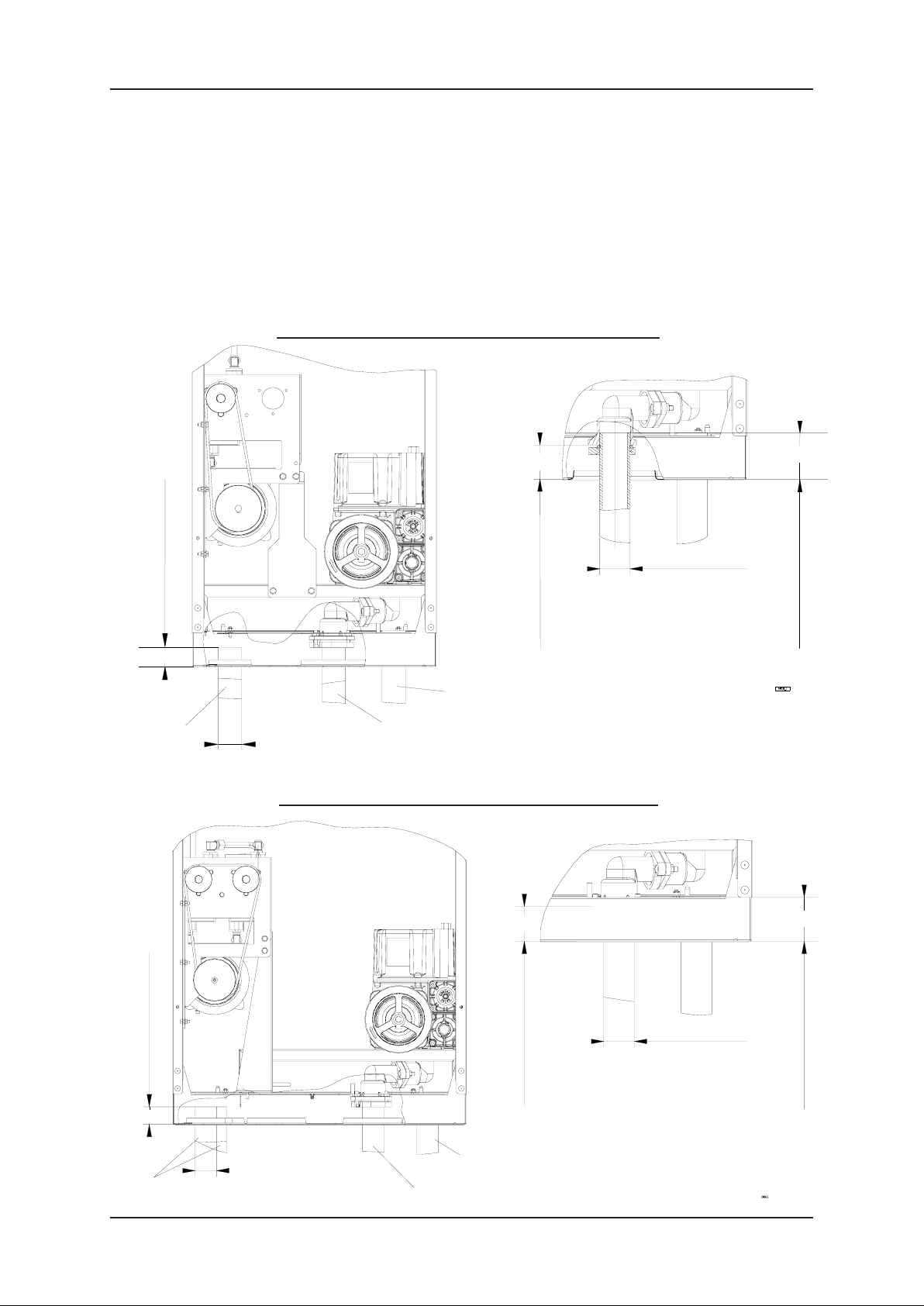

3.1.1 Q110 DISPENSER DIMENSIONS

Display

1471

1339

1137

1080

Product2

Side A

506

509

(Base)

(Cladding)

Side A is the side where t he pulley is (if TQP config).

Nozzle

825

Hose Hook

1132

Sprng Mast

2123

Island level

(Base)

(Cladding)

Side A

Side B

350

427

Side B is the side where the air vent outlet is.

For option "Display one side only", display is on side 'A'.

With single hose models, the hose is always on the right hand side when facing side A.

Outlet elbows are oriented upwards for springmast and oriented downwards for hose hook.

Page 3-2 Document Ref 947571-001 Rev 2

Page 33

Quantium 110 & 210 Installation Manual Drawings

3.1.2 Q110 GROUND PLAN

Product pipe only for TQM

Vapour recovery or Suction

Side B

Electrical supply

pipe for PAS V3

350

325

250

25

175

Side - Product outlet

(product 2) ( Std)

Bolting holes

Side A

88

212.6

428.5

465.5

506

Dimensions shown are from bottom of base.

40.5

Document Ref 947571-001 Rev 2 Page 3-3

Page 34

Drawings Quantium 110 & 210 Installation Manual

3.1.3 Q110 RETENTION TRAY ASSEMBLY

903944

3.1.4 Q110 GROUND FIXING

Leak plate option

Leak plate

(904188)

Washer Pl M10

(900008-014)

SECTION A-A

SCALE 1:1

Page 3-4 Document Ref 947571-001 Rev 2

Page 35

Quantium 110 & 210 Installation Manual Drawings

g

g)

g)

g

g

3.2 Q210 Dispenser

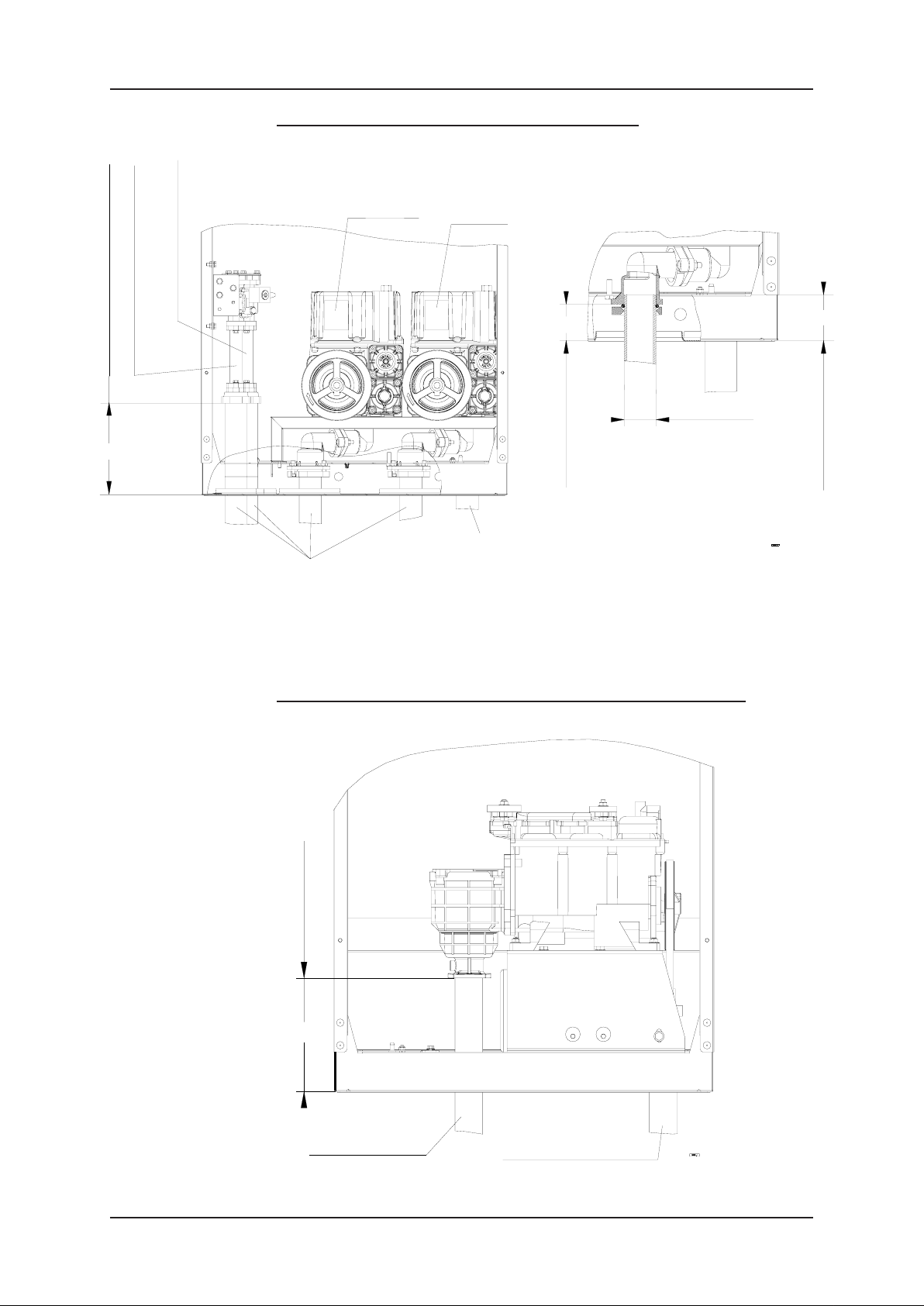

3.2.1 Q210 DISPENSER DIMENSIONS

1032

Rigid mast

2410

Display

1570

1439

1137

1082

Side A

Product 1

(Base)

673

Nozzle

825

Product 2

(Cladding)

Springmast

2223

Hose Hook

1133

Side A

Island level

(Base)

(Cladding)

NOTES:Side A is the side wh ere t he pulleys are (if TQP config).

When facin

Side A the pump pul ley is on the right hand side (if PASV3 co nf i

When facing Side A, filter brackets are on th e right hand side (if submerged confi

For option "Dis play one side only" dis plays are on side A

Product outlet always on side 2 for single product

Outlet elbows are oriented upwards for sprin

For retainin

hose option, the standard one is wit h th e hook otherwise ot her options are eithe r

mast and orient ed downwards for ho s e hook

spring or rigid mast.

Side B

350670

427

Document Ref 947571-001 Rev 2 Page 3-5

Page 36

Drawings Quantium 110 & 210 Installation Manual

3.2.2 Q210 GROUND PLAN

Bolting holes

Vapour recovery product 1 (only

if return line per product) or

Satellite connection product 1

Vapour recovery (default)

or Satellite connection

product 2

249

112

Product pipe 1 with TQP

or Suction pipes for

PASV3

Side B

Side A

432

572

595

635

670

Dimensions shown are from base of chassis

Product pipe 2 with TQP

or Satellite product 2

212

Electr ic al su pp ly

35

88

25

175

252

325

350

Side-Product outlet(product2)(std)

Page 3-6 Document Ref 947571-001 Rev 2

Page 37

Quantium 110 & 210 Installation Manual Drawings

3.2.3 Q210 RETENTION TRAY ASSEMBLY

903930

3.2.4 Q210 GROUND FIXING

Base of the dispenser

Washer Pl M10

(900008-014)

Leak plate

(903567)

Leak plate option

Apply SILICON sealant all around the leak plate before placing the dispenser.

Ensure the seal between the leak plate and dispenser is complete to avoid water

ingress.

Document Ref 947571-001 Rev 2 Page 3-7

Page 38

Drawings Quantium 110 & 210 Installation Manual

3.3 Q210 SDS Dispenser

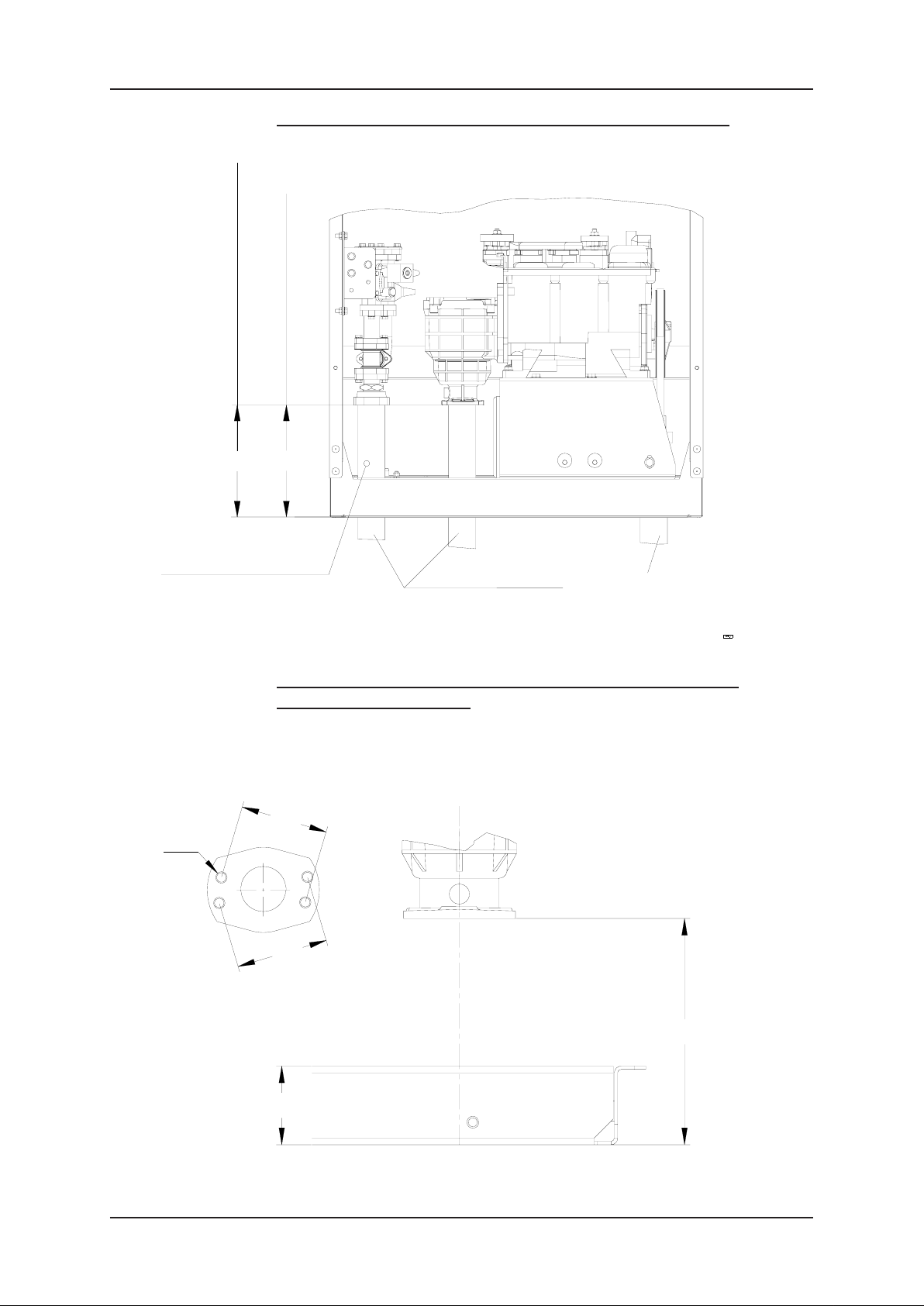

3.3.1 Q210 SDS DIMENSIONS

Stripped do wn satellite with breakaway and cradle

Lockheight

Overall height

1085

Cradle height

106

Stripped down satellite without breakaway or cradle

Nozzle height

1038.5

830

Side B

Side B

Cradle

250 245

x 250

366

Hoseoutlet

1030.5

SideA

Cladding

Lock position

Overall height

1086

Side A

250

Embedding Plate

1038.5

Nozzleheight

830

SideB

Side B

250

365.9

Hose outlet

1030.5

Page 3-8 Document Ref 947571-001 Rev 2

Page 39

Quantium 110 & 210 Installation Manual Drawings

3.3.2 Q210 SDS GROUND PLAN

Top view

Electrical supply

Suction pipe

68

225

250

Nozzle side

125

225

250

Dimensions taken from the base

42

12

125

42

12

Base of the satellite

182

Hose outlet side

Document Ref 947571-001 Rev 2 Page 3-9

Page 40

Drawings Quantium 110 & 210 Installation Manual

This page is intentionally blank

Page 3-10 Document Ref 947571-001 Rev 2

Page 41

Quantium 110 & 210 Installation Manual Packaging & Handling

CONTENTS

4 PACKAGING & HANDLING..................................................................................... 4-2

4.1 Shipping Documentation .................................................................................... 4-2

4.2 Packaging............................................................................................................ 4-2

4.2.1 Unpacking .......................................................................................... 4-2

4.3 Inventory Inspection ........................................................................................... 4-2

4.3.1 Checking List ..................................................................................... 4-3

4.4 Dispenser Weights .............................................................................................. 4-3

4.4.1 Q110 Dispenser Weights .................................................................... 4-3

4.4.2 Q210 Dispenser Weights .................................................................... 4-3

4.5 Handling.............................................................................................................. 4-3

4.6 Access the Hydraulic Area.................................................................................. 4-4

4.7 Access the Calculator Head ................................................................................ 4-4

4.8 Access the Junction Box..................................................................................... 4-5

4.8.1 Bernstein Junction Box ...................................................................... 4-5

Document Ref 947571-001 Rev 2 Page 4-1

Page 42

Packaging & Handling Quantium 110 & 210 Installation Manual

4 PACKAGING & HANDLING

4.1 Shipping Documentation

The following documents will accompany every delivery:-

•Shipping List

•Packing/Checking List

•CE Sticker

•Certificate of Conformity

The Serial Number on the dispenser should be identical to the Serial Number on the

Shipping List, CE sticker and Certificate of Conformity . Please inform Tokheim UK Ltd

before unpacking if there are any discrepancies in the notation.

4.2 Packaging

The type of packing depends on the destination of the goods. All products containing a

frame are fixed on a pallet by means of screws and by the use of beams or blocks screwed

onto the frame.

The goods are protected from moisture and scratching by bubble wrap and polystyrene

corner blocks and a standard carton is used for packing. Where the use of a forklift truck

or pallet truck is necessary, special arrangements make this possible through the use of

pallets, beams, dispenser beam bridges or blocks.

All separate components belonging to the same delivery are packed together.

4.2.1 UNPACKING

When the dispensers arrive at the installation site, the unpacked units should be

inspected for possible shipping damage. If damage is evident, it must be reported

to the carrier. Shipping damage is not covered under the Tokheim warranty

policy.

After checking the equipment, the dispenser may be unwrapped. Cladding is

packed in such a way that paint, screening and stickers are protected. T ake care

when unwrapping so that these elements are not damaged.

After unwrapping, the dispensers must be checked for any faults or damage.

Any faults or damage found must be reported to the Installation Supervisor

immediately.

Make sure that all packing materials are removed from the service station. It is

recommended that you discuss this with the station’s supervisor.

4.3 Inventory Inspection

After unpacking and prior to installation, the delivered equipment should be inspected to

ensure that all the required materials are on hand, and the dispensers have all the ordered

options and markings. If discrepancies in dispenser options and markings are evident,

contact Tokheim France.

Page 4-2 Document Ref 947571-001 Rev 2

Page 43

Quantium 110 & 210 Installation Manual Packaging & Handling

4.3.1 CHECKING LIST

Proper installation of today’s sophisticated electronic dispensing systems is

essential to ensure trouble-free performance. Therefore, T okheim has established

inspection and check-out procedures to be followed to ensure correct equipment

installation.

All products within a package are listed on the Checking List. Follow the

procedure on the Checking List to ensure all required components have been

delivered then return the completed Checking List to the Quality Dept., T okheim,

Grentheville, France.

4.4 Dispenser Weights

The following weights are approximate and will vary according to options fitted.

4.4.1 Q110 DISPENSER WEIGHTS

•One Hose Dispenser : 120kg

4.4.2 Q210 DISPENSER WEIGHTS

•Two Hose Dispenser : 190kg

4.5 Handling

The recommended procedure for safe handling of the dispenser is by use of a forklift

under the pallet.

The installer must supply all handling equipment and ensure safe working practice at all

times.

Document Ref 947571-001 Rev 2 Page 4-3

Page 44

Packaging & Handling Quantium 110 & 210 Installation Manual

4.6 Access the Hydraulic Area

The following instructions detail the procedure to be followed for the removal of the

hydraulic access panel(s) to allow safe access to the dispenser hydraulics.

INSTRUCTIONS

1) Locate the key for the hydraulic access panel.

2) Unlock the hydraulic access panel.

3) Carefully lift out the panel.

Note - the panel is still attached by a retaining cord, earth and/

or electrical cables.

4) Disconnect the retaining cord, earth and/or electrical cables from

the panel door.

5) Lift up the panel to release from the drive pins in the base and

remove the hydraulic access panel completely.

6) Repeat for opposite side of dispenser as required.

7) Place the hydraulic access panel(s) in a safe position.

8) To re-fit the hydraulic access panels, follow the instructions in

reverse.

4.7 Access the Calculator Head

The following instructions detail the procedure to be

followed for the safe access to the calculator head.

INSTRUCTIONS

1) Locate the key for the calculator head door.

2) Unlock the calculator head door on the relevant side of the

dispenser and carefully open it.

Note : the door is still attached by electrical and/or earth cables.

3) Secure the calculator head door in the open position.

4) Repeat for opposite side of dispenser as required.

5) To close and lock the calculator head door, follow

the instructions in reverse.

Note : ensure the electrical and/or earth cables

remain inside when closing the calculator head

door.

Page 4-4 Document Ref 947571-001 Rev 2

Page 45

Quantium 110 & 210 Installation Manual Packaging & Handling

4.8 Access the Junction Box

4.8.1 BERNSTEIN JUNCTION BOX

The following instructions detail the procedure to be followed to allow safe

access to the junction box connections.

INSTRUCTIONS

1) Follow the instructions given to access the hydraulic

area.

2) Locate the Junction Box in the hydraulic area.

3) Using a screwdriver, loosen and remove the four

screws on the junction box cover and remove

completely.

4) Refer to the wiring diagrams in section 5.

5) To re-fit the junction box cover , follow the instructions

in reverse.

Document Ref 947571-001 Rev 2 Page 4-5

Page 46

Packaging & Handling Quantium 110 & 210 Installation Manual

This page is intentionally blank

Page 4-6 Document Ref 947571-001 Rev 2

Page 47

Quantium 110 & 210 Installation Manual Installation

CONTENTS

5 INSTALLATION........................................................................................................... 5-2

5.1 General................................................................................................................ 5-2

5.2 Identification of Side A....................................................................................... 5-2

5.3 Lifting ................................................................................................................. 5-3

5.4 Placement............................................................................................................ 5-3

5.4.1 By Forklift .......................................................................................... 5-4

5.4.2 Fixing to Ground ................................................................................ 5-6

5.4.3 Earthing .............................................................................................. 5-7

5.5 Hydraulic Connections ....................................................................................... 5-8

5.5.1 Pipework - Suction Dispensers with Internal Filter ........................... 5-8

5.5.2 Pipework - Suction Dispensers with External Filter ........................ 5-10

5.5.3 Pipework - Submerged Dispensers................................................... 5-12

5.6 Electrical Connections ...................................................................................... 5-12

5.6.1 Direct wiring into Terminal Rail - WWC......................................... 5-13

5.6.2 Junction Box Wiring......................................................................... 5-16

5.6.3 Communications Wiring (WWC Head only) ................................... 5-19

5.6.4 OPT Communications option ........................................................... 5-24

Document Ref 947571-001 Rev 2 Page 5-1

Page 48

Installation Quantium 110 & 210 Installation Manual

5 INSTALLATION

5.1 General

Before the dispenser can be installed, the Safety Instructions as described in Section 1.5

and the Installation Instructions in this section must be carefully read.

Follow unpacking instructions in Section 4.2.1.

After unwrapping and before installation, the dispensers must be checked for any faults or

damage. Any faults or damage found must be reported to the Installation Supervisor

immediately.

NOTE: IF USING SUBMERGED PUMPS, THE CONTROL MUST BE

COMPLETELY ISOLATED DURING ALL PHASES OF INSTALLATION.

The following checks need to be made before starting the installation :-

•Check that the electric cabling and the piping arrangements have been made in accordance

with the Installation drawings in section 3.

•Check that the leakage plates have been produced in accordance with the Installation

drawing. Any differences or defects should be reported to the Installation Supervisor

immediately. The function of the leakage plate is to drain leakages to the outside of the

dispenser where they act as a warning to the station attendant.

•Check that all flame arresters are correctly installed according to the drawings.

5.2 Identification of Side A

The different sides of the dispenser referred to in this manual are described as follows:-

•Side A of the dispenser has the pulleys and inlet connections (visible upon removal of

hydraulic doors). All single hose models have the hose on the right hand side when facing

side A.

Side A

Page 5-2 Document Ref 947571-001 Rev 2

Page 49

Quantium 110 & 210 Installation Manual Installation

•Side B of the dispenser has the electrical supply (visible upon removal of hydraulic doors).

All single hose models have the hose on the left side when facing side B.

Side B

5.3 Lifting

The responsibility for carrying out the procedures described

in this manual lies with the persons lifting and placing the

dispenser.

Lifting equipment can be

The installer must supply all lifting equipment and ensure

safe working practice at all times.

Quantium 110 & 210 dispensers can be lifted by forklift

truck under the pallet.

5.4 Placement

hazardous, and must be

rated to lift the weight of

the dispenser. Equipment

could fall and cause

severe injury or death.

St and clear from the

dispenser when lifting and

lowering.

Before placement on the island can take place, the following

procedures must be carried out:-

•Check that the electric cabling and piping arrangements have been made in accordance

with the Installation drawing

• Check the pipes have been flushed before connecting the hydraulic components (if

necessary, contact the tank installer)

•Removal of stop plugs on fuel and vapour recovery pipes

•Preparation of mounting frame

•Fitting of seals for cable, fuel and vapour recovery pipe access

•Sealing of non-used holes

IMPORTANT - Make sure Side A of the dispenser is positioned onto the island per

customer specifications. See Section 5.2 for locating Side A.

Document Ref 947571-001 Rev 2 Page 5-3

Page 50

Installation Quantium 110 & 210 Installation Manual

5.4.1 BY FORKLIFT

1) Lift the dispenser using a forklift truck under the pallet. Position the dispenser

close to the dispenser island. Ensure side A with the inlet connections is correctly

positioned - refer to section 5.2 for the identification of side A.

2) Remove the hydraulic doors. Unbolt the pallet from the base of the dispenser.

IMPORT ANT - Wher e supplied, the leak plate must be placed in the ground PRIOR

to positioning the dispenser . Once placed, the leak plate must be sealed to the ground

frame and to the dispenser using a suitable sealant.

Page 5-4 Document Ref 947571-001 Rev 2

Page 51

Quantium 110 & 210 Installation Manual Installation

3) Where supplied, place the leak plate onto fixing studs provided on the island

prior to positioning the dispenser ensuring the riser pipes and cables pass through

the correct holes in the leak plate.

Carefully lift the dispenser and position on the leak plate.

Leak Plate

4) IMPORTANT:Secure the dispenser to the ground as described in section 5.4.2.

Placement complete.

Document Ref 947571-001 Rev 2 Page 5-5

Page 52

Installation Quantium 110 & 210 Installation Manual

5.4.2 FIXING TO GROUND

The following information relates to a typical Tokheim dispenser, unmodified

by the user, with no additional advertisement boards, canopies or items added

to the dispenser. Any such modifications may affect the stability and have

warranty/liability consequences.

IMPORTANT:- Tokheim dispensers must be secured to the ground using

all 4 mounting positions provided in the driptray - refer to the gr oundplan

drawings in section 3 for mounting hole positions.

TYPICAL FIXING INTO CONCRETE (NO GROUNDFRAME)

M12 ANCHOR BOLT FOR

CONCRETE high tensile

WASHER

min thickness = 2mm

min dia = 25mm

Underside of

dispenser driptray

Min depth into

concrete = 100mm

100

TYPICAL FIXING INTO TOKHEIM GROUNDFRAME

WASHER

min thickness 2mm

min dia 25mm

Underside of

dispenser driptray

Tokheim groundframe

M10 BOLT high tensile

Nut insert

TYPICAL FIXING INTO THIRD PARTY GROUNDFRAME / SUMP

FRAME

M12 BOLT high tensile

Alternative to nut & washer :Welded nut on groundframe

with min. 5 captured threads

Underside of

dispenser driptray

Steel groundframe/

sump frame

WASHERS

min thickness = 2mm

min dia = 25mm

M12 NUT

Page 5-6 Document Ref 947571-001 Rev 2

Page 53

Quantium 110 & 210 Installation Manual Installation

5.4.3 EARTHING

Earthing requirements are dictated by local National regulations and must always

be observed.

Tokheim recommends the following guidelines as a minimum requirement:-

2

•6mm

•10mm

earth conductor(s) back to main site earth (up to 85m cable run)

2

earth conductor(s) back to main site earth (85 to 150m cable run)

The primary earth connection point for Quantium dispensers is the M2000T

Junction Box provided for installation cable connections. Threaded inserts or

studs (M8) are also provided in the base frame as an additional external

connection facility for an earthing or equipotential bonding conductor.

Earthing requirements are dependent upon the number of earth conductors

provided (one per power cable) and the types of cable used. For example,

where steel wire armour cables or MICC are used in conjunction with the

appropriate termination glands, no supplementary specific earth cable is likely

to be required. Where simple PVC covered cables are used, Tokheim

recommends an additional earth core is connected to the point provided on the

dispenser base frame.

IMPORTANT : It is the responsibility of the Installer to supply the earth

wire and ensure the dispenser is safely earthed.

The photograph below is an typical example of an earth connection point on a

Q210 dispenser (exact location and/or fixture may differ between dispenser

ranges):-

Document Ref 947571-001 Rev 2 Page 5-7

Page 54

Installation Quantium 110 & 210 Installation Manual

5.5 Hydraulic Connections

Connect all hydraulic and electric junctions according to the specifications as described

in this section and indicated on the drawings in Section 3.

Flow rates achieved are dependent upon the type of submerged pumping system used and

other site-specific conditions.

Note : The maximum pressure must not exceed 3.5 bar.

5.5.1 PIPEWORK - SUCTION DISPENSERS WITH INTERNAL FILTER

Connections to the fuel supply pipes and the vapour return lines are accessible

from side A of the dispenser (see section 5.2 for identification of sides).

TQP PUMPS WITH INTERNAL FILTER

Screw HFHS M8x25

Screw HFHS M8x30

O-Ring OD49, 00x6.00

Terminal Earth Clamp

O-Ring OD37, 47x5.33

Junction Flange

Flexi Pipe EPZ

Flange

Threaded Flange

M8 Self Lo ck Nut

Page 5-8 Document Ref 947571-001 Rev 2

Page 55

Quantium 110 & 210 Installation Manual Installation

1) Place the terminal earth clamp over the supply riser

pipe and tighten.

Add the threaded flange and O-ring OD49.

2) Place the elbow of the flexi pipe through

the hole of the flange. Connect to the

threaded flange resting on the supply

riser pipe using 3 M8x30 screws.

3) Tighten the screws on the terminal earth clamp and the

2 flanges.

4) Place the elbow of the flexi pipe through the

hole of the junction flange, then add the Oring OD37. Bend the flexi pipe until the

junction flange mates with the pump inlet.

5) Tighten the screws from the junction flange to the

pump inlet.

6) Repeat steps 1 to 5 for each hydraulic position as

required.

Document Ref 947571-001 Rev 2 Page 5-9

Page 56

Installation Quantium 110 & 210 Installation Manual

5.5.2 PIPEWORK - SUCTION DISPENSERS WITH EXTERNAL FILTER

Connections to the fuel supply pipes and the vapour return lines are accessible

from side A of the dispenser (see section 5.2 for identification of sides).

The dispenser is positioned with the filter box positioned above the relevant

fuel supply risers. If required, adapters should be fitted to the supply pipes.

The flexible connection (rigid for pressurised systems) should then be fitted

between the fuel supply risers and the filter box.

P AS V3 PUMPS WITH EXTERNAL FILTER BOX ONL Y

1) Remove the protective covers on the fuel supply riser pipe and on the filter

box.

WARNING : BEWARE OF FUEL SPILLAGE.

2) Cut the rubber manchet to suit the riser pipe diameter

and fit over the pipe to cover the hole in the driptray .

3) Apply a sealant compound to the fuel supply riser

and to the inside of the flexible coupling.

4) Fit the flexible coupling to the fuel supply riser pipe.

Note : Hand tighten only at this point

5) Insert the top hat filter (provided in the installation

kit) into the flexible coupling.

6) Manoeuvre the flexible coupling into the correct

position, ready for securing to the filter box.

7) Insert the gasket between the filter box and the flange

on the flexible coupling.

8) Fit the flange to the filter box using the two screws

provided in the installation kit.

Note : Hand tighten only at this point.

Page 5-10 Document Ref 947571-001 Rev 2

Page 57

Quantium 110 & 210 Installation Manual Installation

9) Use a large adjustable spanner to tighten and secure

the flexible connection to the fuel supply riser pipe.

10) Using a 15mm spanner or socket, tighten the two

screws on the flange.

11) Repeat steps 1 to 10 for each hydraulic position as

required.

Document Ref 947571-001 Rev 2 Page 5-11

Page 58

Installation Quantium 110 & 210 Installation Manual

5.5.3 PIPEWORK - SUBMERGED DISPENSERS

The Installer is responsible for supplying the riser

pipe to the heights given in section 2.4 and all

pipework and connections below the filter box

connection.

EXTERNAL FILTER BOX ONLY

1) The dispenser must be positioned directly above the

riser pipes and carefully lowered into position.

2) Remove the protective covers on the fuel supply riser pipe and on the filter

box.

WARNING : BEWARE OF FUEL SPILLAGE.

3) Connect the fuel supply pipe to the filter box or optional flange (where fitted).

4) Repeat for each hydraulic position as required.

5.6 Electrical Connections

During installation, the main switch must be switched off - ensure the main switch cannot

be switched on inadvertently.

The installation of the cables must be carried out carefully to ensure the Eex-norm is

enforced (insertion of cables via glands).

The electrical connections are compatible with all European installation practices and

typical country specific cable types. The following information is the Tokheim

recommended installation, however where differences exist in the standards relating to

installation according to country specific legislation, the local/national standards must be

employed. Electrical connections are made by either :-

•Direct wiring into a terminal rail in a WWC (refer to section 5.6.1):-

- Single Phase Suction

- Three Phase Suction

- Submerged

•Wired into a junction box in hydraulic area (refer to section 5.6.3):-

- Single Phase Suction

- Three Phase Suction

- Submerged

- Split Power option - Three Phase Suction

- Split Power option - Single Phase Suction

- Split Power option - Submerged

Page 5-12 Document Ref 947571-001 Rev 2

Page 59

Quantium 110 & 210 Installation Manual Installation

CABLING

The type of cabling used will differ by country according to local and/or national laws and

regulations. The drawings in this section show the minimum number of cores required in

cables and the minimum core cross sectional area. Cables with more than the minimum

can be used provided that the cables are suitable for use with the cable gland sizes fitted.

Individual cables can be combined provided that the minimum number of conductors

remains.

The maximum number of forecourt cables required will be :-

•One power cable for motor power supply

•One power cable for calculator and lighting supply

•One cable for dispenser communications

•One cable per side for OPTimum communications (optional Q210 only)

•One cable per submerged pump control signals (where applicable)

ELECTRONICS & LIGHTING PROTECTION

Tokheim recommends the use of a 2 pole thermal-magnetic device for protection of the

metering pump electronics. A fuse must NOT be used in the neutral conductor . Thermalmagnetic breakers or fuses must be capable of extinguishing a fault current of at least

4000A. Pump lighting and lighting switched remotely are optional.

MOTOR WIRING

The number of motors per dispenser will vary according to different models and options.

Always connect to the furthest left terminal first. Jumper sizes and positions vary according

to the number of motors connected.