USER MANUAL

MAGLINK LX

Rev. 9 – 04-2016

This page is left intentionally blank.

Maglink LX

S

UMMARY

User Manual | Summary

1 PREFACE ............................................................................................................................................................. 4

2 GENERAL WARNINGS ......................................................................................................................................... 4

3 INTRODUCTION .................................................................................................................................................. 5

4 GENERAL DESCRIPTION ...................................................................................................................................... 7

4.1

L

ABELLING AND TYPE DESIGNATION

4.2

D

ESCRIPTION

4.3

C

OMPATIBLE PROBES

5 INTENDED USE AND REASONABLY FORESEEABLE MISUSE .................................................................................. 9

6 POWER ON/OFF ................................................................................................................................................10

7 OPERATION .......................................................................................................................................................11

7.1

F

UNCTIONS

7.1.1 Tanks ........................................................................................................................................................... 13

7.1.2 Tank details ................................................................................................................................................. 14

7.1.3 Location....................................................................................................................................................... 22

7.1.4 List of ON/OFF sensors ................................................................................................................................ 23

7.1.5 Alarm Log .................................................................................................................................................... 24

7.1.6 INFO ............................................................................................................................................................ 25

8 MANUAL UPDATE PROCEDURE .........................................................................................................................27

9 PRINT INVENTORY .............................................................................................................................................28

......................................................................................................................................................... 7

.............................................................................................................................................. 8

......................................................................................................................................................... 12

............................................................................................................................ 7

10 SHIFT REPORT....................................................................................................................................................29

11 MAINTENANCE ..................................................................................................................................................30

12 SUPPORT ...........................................................................................................................................................31

13 SAFETY INSTRUCTIONS ......................................................................................................................................32

14 CERTIFICATION ..................................................................................................................................................33

15 NOTIFICATION ...................................................................................................................................................37

16 REVISIONS .........................................................................................................................................................38

Rev. 9, 04-2016

Page 3 of 40

Maglink LX

1 P

Start Italiana S.r.l. has made every effort possible so that this document is complete, accurate and updated.

With every revision of the console, the corresponding information is periodically added to the document.

Start Italiana S.r.l. reserves the right to make unannounced improvements and/or changes in the product

and/or associated programs. Start Italiana S.r.l. is not liable for damages of any kind, including those

resulting in the document, including typographical errors.

Making copies, citing quotes or other reproductions of all or part of this document is permitted only after

written consent of Start Italiana S.r.l.

Trade mark or name is protected by patents.

Copyright 2015© Start Italiana S.r.l. – All rights reserved

REFACE

«Manual_name»l | Preface

2 G

Before working on this equipment, please be certain to carefully read the instructions in this manual.

Configuration must be performed by properly trained personnel.

The manufacturer is not responsible for any operation performed which is not covered in this manual.

Any tampering with the equipment and software relieves the manufacturer of any responsibility in regards

to competent bodies.

In case of failure or defect, refer to an authorized service provider or manufacturer directly.

The manufacturer accepts no responsibility for any injury and/or damage to persons and/or property

and/or pets caused by failure to follow instructions relating to safety.

Qualified and trained staff has to know all safety requirements in this manual, in the user manual and in the

installation manual.

In case of doubt concerning the operation of the equipment, refer to an authorized service provider or

manufacturer directly.

ENERAL WARNINGS

IMPORTANT: It is compulsory to consult safety instructions before using the equipment

IMPORTANT: Improper use, not in accordance with the requirements described herein, may

compromise safety

Rev. 9, 04-2016

Page 4 of 40

Maglink LX

3 I

This manual has been prepared in accordance with IEC 82079-1 standards. “Preparation of instructions for

use - Structuring, content and presentation - Part 1: General principles and detailed requirements”and

according to the ATEX Directive 2014/34/EU concerning equipment and protective systems intended for

use in potentially explosive atmospheres.

The manual provides all necessary information on using a Maglink LX console.

The following table lists the symbols used in the document:

Symbol Description

The following table lists reference data of the manufacturer:

NTRODUCTION

ATTENTION: Important information and notes regarding operations and use

considerations

IMPORTANT: Danger to persons (including death), to property or to the

environment

User Manual | Introduction

Data Description

Name Manufacturer_name

Address

Address

Telephone Tel

Fax Fax

Website www

e-Mail eMail

ATTENTION: This manual must be used in conjunction with the following manuals:

In order to use the console as described below in this manual, you must have installed the

consoles as per Installation Manual and use the console as per the Configuration Manual

20813 Bovisio Masciago (MB)Address

ItaliaAddress

• Configuration Manual

• Installation Manual

Rev. 9, 04-2016

ATTENTION: This manual must be used in conjunction with safety instructions:

IMPORTANT: Console installation should be performed by qualified/trained personnel, as

shown in the Installation Manual, Configuration Manual and according to safety instructions

Page 5 of 40

Maglink LX

User Manual | Introduction

The Maglink LX console complies with the requirements of Directive 2012/19/EC on waste of electrical and

electronic equipment (WEEE) and hence displaying the according symbol:

IMPORTANT: The crossed out wheelie bin symbol indicates that the product, at the end of

its useful life, must be disposed of with household waste and must be brought to a

collection point for electrical and electronic equipment

ATTENTION: The units of measurement contained in this manual refer to a specific choice by

the user himself/herself. You can set the measurement units in a different way (see

Configuration Manual)

Rev. 9, 04-2016

Page 6 of 40

Maglink LX

User Manual | General description

4 G

ENERAL DESCRIPTION

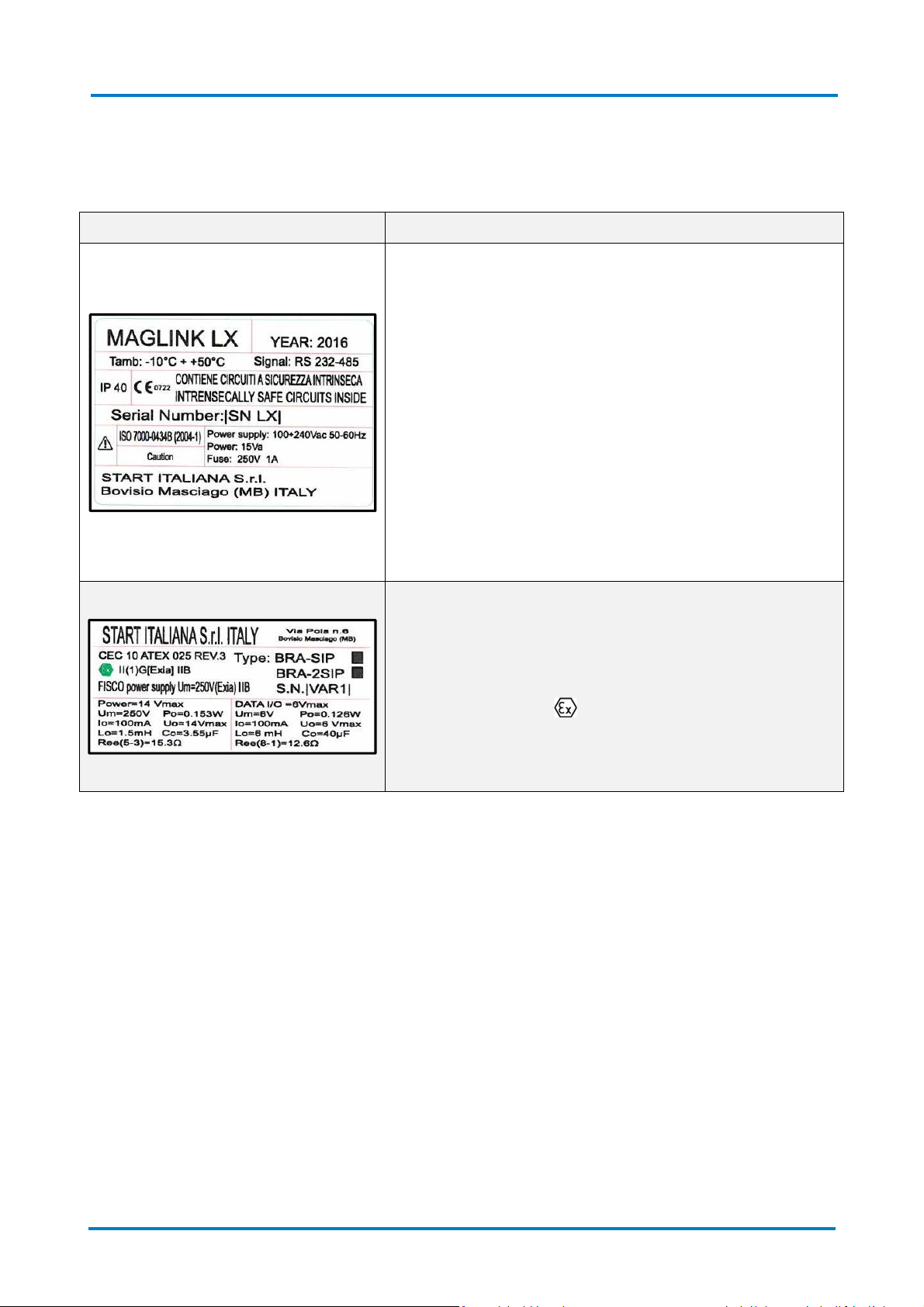

4.1 Labelling and type designation

The following table lists the labels placed on the equipment:

Labelling Description

The labelling on the outer container contains the following

data:

• Name and address of the manufacturer

• CE marking with the Notified Body

• Product Name

• The "Caution" symbol (0434B of 01/2004), according to

ISO 7000

• Serial number

• Year of production

• Power Supply(VAC and Hz)

• Power consumption (VA)

• Operating temperature (°C)

• Ingress protection (IP grade)

• Fuse rating

• Indication that inside there is intrinsically safe circuit

ATEX labelling on the outer container contains the following

data:

• Name and address of the manufacturer

• Equipment Type (BRA-SIP, or BRA-2SIP)

• ATEX Reference number of the certificate

• ATEX Marking: II (1) G [Exia] IIB FISCO power supply

UM=250 V [Exia] IIB

• Serial number

• Electrical data

4.2 Description

The console is a device for the monitoring of the level of probes and for signalling the relative tank alarms.

32 probes can be supported, 16 on-board (8 with the addition of a MagDirect ,Max 2 MagDirect), 32 DVD

(Fuel Quality Sensors, one for each tank), 4 on board relays, 6 inputs on board, and an external expansion

module that can carry up to 4 expansion cards. Each expansion card supports 8 relay outputs, 8 Digital

Inputs or 4-20mA. With a combination of these cards the system can support 32 relays and 0 inputs, 32

inputs and 0 relays, and combinations of both with modularity of 8.

The console can be interfaced with the FCC/POS on the station via either serial or Ethernet.

The console is equipped with a resistive type touch screen, so it is possible to use it with fingers (even with

gloves), special pens and likewise. It required to contact and apply a pressure to use it.

Rev. 9, 04-2016

Page 7 of 40

Maglink LX

User Manual | General description

The following table lists the principal technical characteristics of the console:

Characteristic Value

Power supply 100 ÷ 240 V~, 50÷60 Hz

Consumption 15 VA

Operating temperature (-10 ÷ +50) °C

Relative humidity (5 ÷ 95)%, non-condensing

Number of probes 32

Number of ON-OFF external sensors Up to 32

Number of ON-OFF internal sensors 6 (only with Dipswitch 2 on ON)

External relay outputs Up to 32

Internal relay outputs 4

Lower power of the relay output 0,5 A, 33 V~, or 2 A, 30 V DC

Output power for the probes

12 V DC, 100 mA per output per probe, connectors

MR3 MR4 (up to 8 probes per connector)

Serial communication of the probes RS485

Host communication (management) RS232

Printer communication and management software RS232

Integrated web server for configuration,

consultation, communication, and emails.

TCP/IP

GSM modem for SMS service 1 Optional

IFSF 1 Optional

Case Plastic

Protection IP40

Dimensions 265 x 190 x 95 mm

4.3 Compatible probes

The following table lists the probes compatible with the MAGLINK LX console:

Probe

XMT EXD 485

XMT SI 485

XMT RF (RF receiver required)

The following table lists the auxiliary equipment of the MAGLINK LX console:

Auxiliary equipment

Expansion cards, up to 32 relays and 0 inputs, up to 32 inputs and 0 relay, and various combinations in

modules of 8

Local printer

Rev. 9, 04-2016

Page 8 of 40

Maglink LX

5 I

The intended use for the MAGLINK LX console is only for that described in this manual.

The console is used for monitoring the level of the probes installed in the tanks.

The console must be installed in a safe area and includes an Intrinsic safety barrier, 2 channels (BRA-2SIP)

that serve to connect the XMT-SI-485 probes

The following table lists the characteristics of use of the intrinsically safe barrier contained in the console:

MAGLINK LX Features (barrier) Description

Group (area of use) II (Surface industries different from mines)

NTENDED USE AND REASONABLY FORESEEABLE MISUSE

User Manual | Power On/Power Off

Category and type of potentially explosive

atmosphere

Protection mode ia

Group of substances (gases, vapours or mists) IIB

The specifications of use for console security and for the Barrier are provided in this manual and on the

product label.

IMPORTANT: Safety instructions constitute an attachment to this manual and users must

acknowledge it before using the equipment

IMPORTANT: The Console should not be used in areas at risk of fire and explosion. The

probes of the XMT-SI-485 family are installed in risk of fire and explosion areas and must be

connected to the Barrier contained in the console itself.

The following table lists some reasonably foreseeable incorrect uses:

Element considered Incorrect use

(1) G

Resistive touch screen

USB and USB Port devices

Serial ports

Network cable

Rev. 9, 04-2016

Do not use for selection of options other than your

fingers and/or special accessories intended for

resistive touch screens

Do not use other USB devices than those formatted

as FAT 32

Do not connect the printer, PC, tablet, mobile phone

to the USB ports

Do not use serial ports other than for the printer

and PC with management programs that interface

with the protocols provided by Start Italiana S.r.l.

Do not use the other network cable to connect your

PC or the corporate network

Page 9 of 40

Maglink LX

6 P

The following table lists the steps necessary to switch on the console:

When switched on if the console is not configured it will emit an alarm when it does not communicate with

any tank. Press the red arrows up and down until you reach the page "ALARM LOG" and press the ACK

button to silence the alarm.

For any changes to be made to the console configuration, refer to the manual "Configuring the Console.”

The following table lists the steps necessary to switch off the console:

OWER

Step Description

1 Check that the power button is OFF (0)

2 Connect the power cable.

3 Connect the corporate network cable, if required

4 Press the power button ON (1)

ON/OFF

IMPORTANT: Only authorized/trained personnel following the installation inline with the

manufactures instructions can switch on the console. This operation must be in accordance

with the instructions of the Installation Manual and according to Safety Instructions.

User Manual | Power On/Power Off

Step Description

1 Press the INFO button at the top right of the screen

2 Press the "Off" button within the INFO page

3 Wait for the screen to turn black

4 Press the power OFF (0) button on the console

IMPORTANT: If the console is switched OFF simply removing power the SD card might be

damaged and the console might not restart. If this happen a new SD card is needed and the

image of the Operating System and application should be loaded, and at last the backup

restore in order to have the previous saved configuration

The Console needs to be shut down from info page before removing power for proper

operation.

Rev. 9, 04-2016

Page 10 of 40

Maglink LX

Information

Description

Red arrow on

Circular menu including: "Tanks

,” "Tank Details

,” "Location

,” "ALARM LOG"

Tokheim

Station name

Tanks

Page Title

INFO

Button to access system information/functions

Information

Description

Red arrow below

Circular menu including: "Tanks

,” "Tank Details

,” "Location

,” "ALARM LOG"

050 Page Number

192.168.1.209

IP address of the console

Current date and time (There may

be a message about the static/dynamic

2.3.3

– 2.3.0

Firmware, application and web versions

P 01/02

Tank number examined/total number of reservoirs

User Manual | Manual update

7 O

The application has an easy-to-use "circulate" menu, with which the user can browse through all the

available functions.

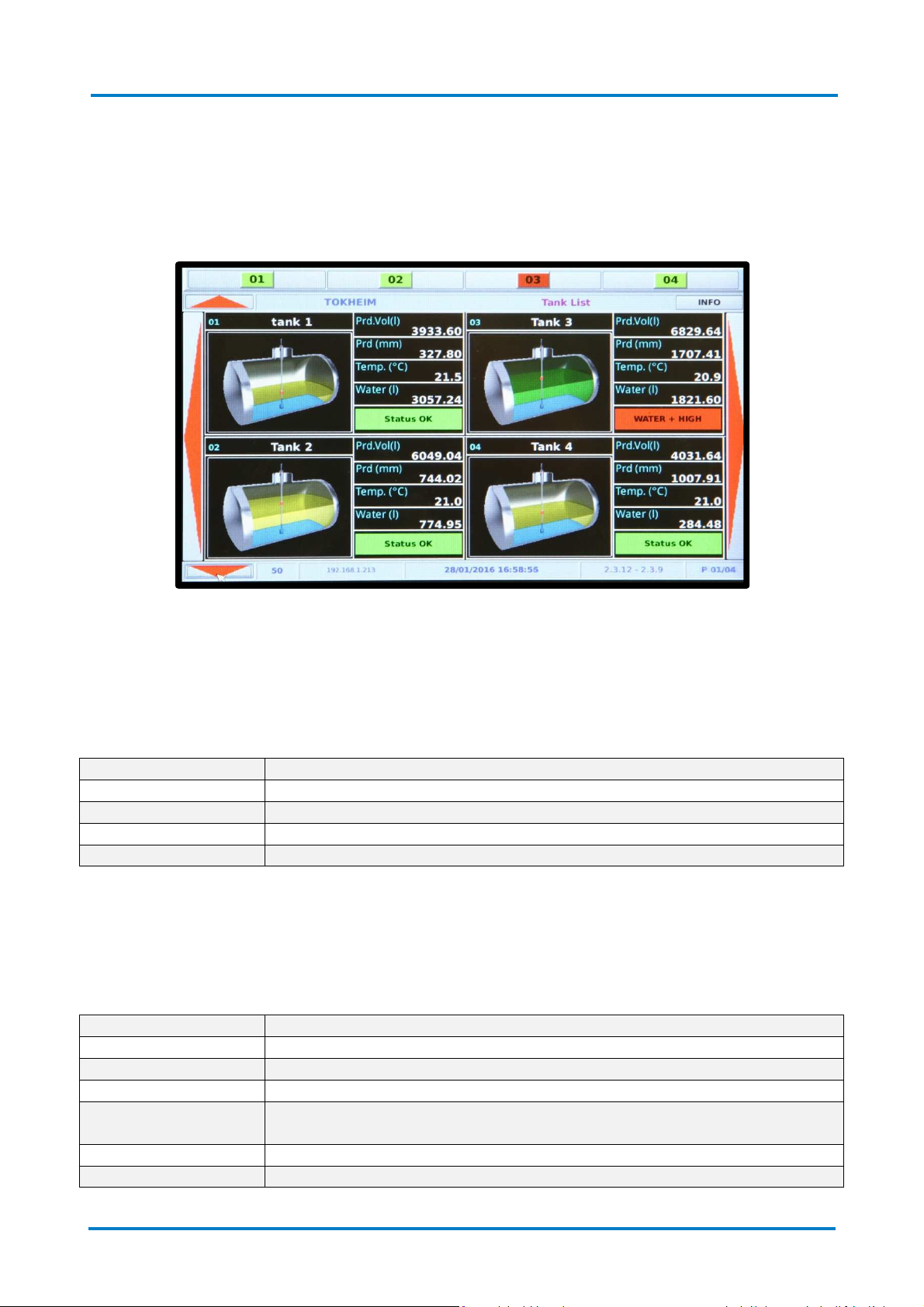

The following image shows the opening page of the console:

This page summarizes the main information relating to one or more tanks. You can view up to 4 tanks

simultaneously on the same page. If there are more than 4 tanks configured you can view the next one by

pressing the large red arrows in the left and right parts of the page.

The first line at the top of the page contains a list of tanks connected to the console: The icon colour of tank

number reflects the state of the reservoir.

The following table lists the data visible in the second row at the top of the page:

PERATION

In the central part of the page press the red right/left arrows to display the previous and/or subsequent

data of the tanks, in the case where more than 4 tanks are connected to console (The page allows

displaying 4 tanks at a time).

The following table lists the data visible in the lower row at the bottom of the page:

05/11/2015 11:44:23

Rev. 9, 04-2016

leakage/loss)

Page 11 of 40

Maglink LX

User Manual | Manual update

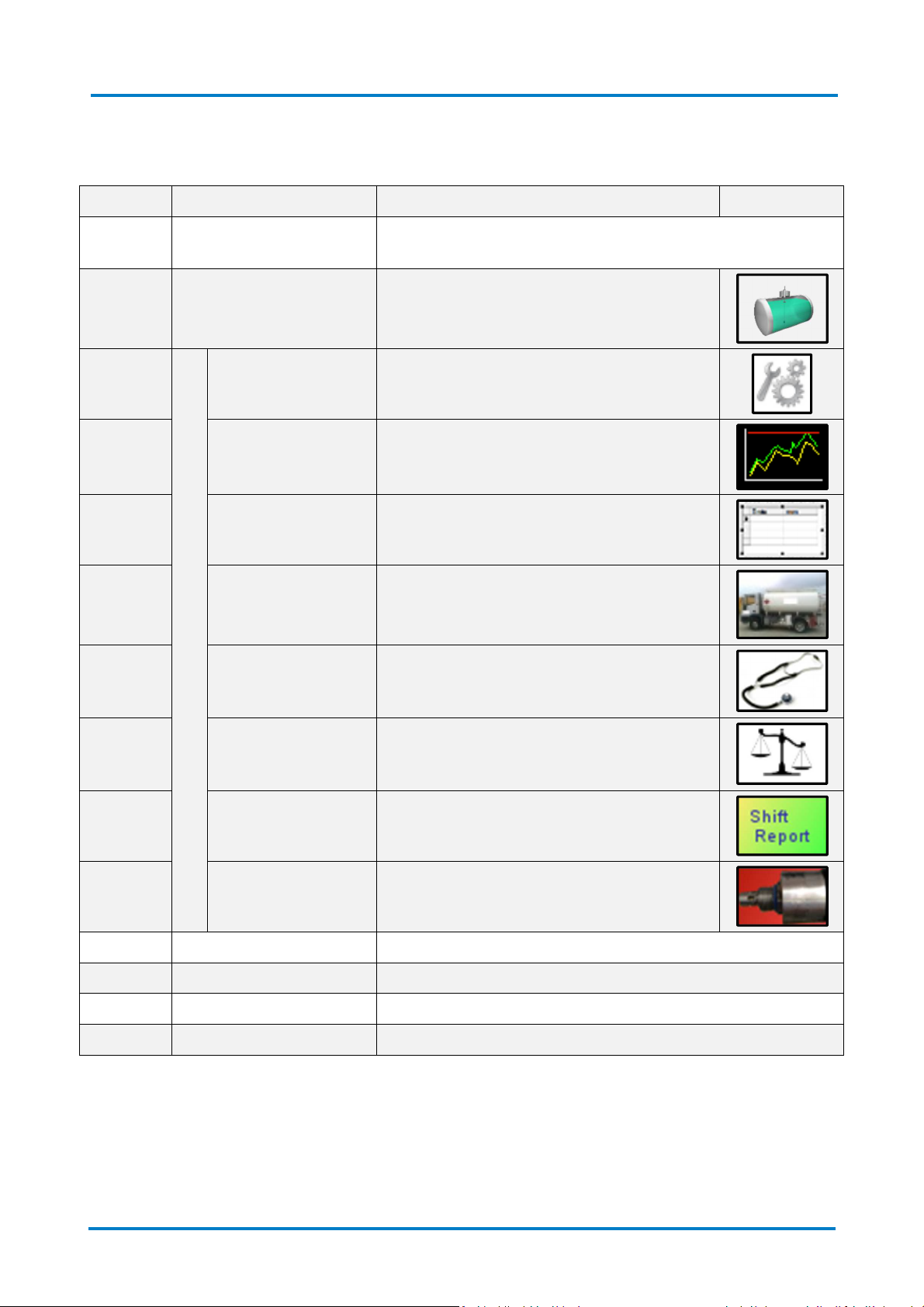

7.1 Functions

Using the up/down red arrows, you can access the functions of the console. The following table lists the

available functions:

Paragraph Function Description Icon

7.1.1 Tanks

7.1.2 Tank details

7.1.2.1

Tank Configuration Display Tank parameters

7.1.2.2 Historical chart

Display tanks connected to the console/Select tank to be

displayed

"Multi page" dedicated to a single tank with

the ability to view multiple screens

Display of trends over time for

levels/volumes/temperatures, etc.

7.1.2.3 Historical list Time display of tank levels in graph form

7.1.2.4 Delivery list Viewing the delivery list

7.1.2.5 Diagnostics Display diagnostic data

7.1.2.6 Reconciliation Display reconciliation data

7.1.2.7 Shift Report Display Shift Report

7.1.2.8 Product quality DVD View DVD data

7.1.3 Status Display tank level as a percentage for all connected tanks

7.1.4 List of ON/OFF sensors Display ON/OFF sensors connected to the tank

7.1.5 Alarm Log Display current and previous alarms

7.1.6 INFO System Information/Functions

Rev. 9, 04-2016

Page 12 of 40

Maglink LX

7.1.1 Tanks

The following image shows an example of the "Tank Page":

User Manual | Manual update

The following table lists the page elements:

Element Description

Tank graph Graphical representation of the level in the tank

The following data is displayed:

• Prd.Vol(l): Quantity of products in the tank displayed in [l]

• Prd (mm): Product level inside tank is displayed in [mm]

• Temp.(°C): Tank temperature displayed in [°C]

• Water (l): Quantity of water in the tank displayed in [l]

• Tank status (Internal alarm codes):

• OK STATUS (0)

• NO LINK (1, 8, 9, 11)

• HIGH (2)

• LOW (3)

• OUT OF RANGE (4)

Tank data

• PROBE (5)

• VERY HIGH (6)

• VERY LOW (7)

• WATER (10)

• WATER + HIGH (12)

• WATER + LOW (13)

• WATER + OUT OF RANGE (14)

• WATER + PROBE (15)

• WATER + VERY HIGH (16)

• WATER + VERY LOW (17)

• WATER + NO LINK (18, 19)

• DISABLED (30)

• NOT INITIALIZED (99)

Rev. 9, 04-2016

Page 13 of 40

Maglink LX

User Manual | Manual update

7.1.2 Tank details

The following image shows an example of the "Tank Details": (It is accessed by clicking on the graphic on

the page of this tank "Tank"):

The following table lists the page elements:

Element Description

Graphical representation of the level in the tank

The following data is displayed:

Image of the tank

• Name of the product in the tank

• Date and time of details

• Tank status

Product level graph

Graphical representation of the level in the tank, displayed in [l] and

alarm displayed in [mm]

The following data is displayed:

• Prd.H(mm): Product level displayed in [mm]

• Prd.Vol(l): Product volume displayed in [l]

• Ullage(l): Remaining product volume displayed in [l] referred

Table details

to the working capacity percentuage

• PrdVol15 (l): Compensated volume at 15° C displayed in [l]

• Temp.(°C): Product temperature displayed in [°C]

• Water (mm): Water level displayed in [mm]

• Water (l): Water level displayed in [l]

Rev. 9, 04-2016

Page 14 of 40

Maglink LX

User Manual | Manual update

7.1.2.1 Tank Details/Tank Configuration

The following image shows an example of the "Tank Configuration" (Accessed by clicking the icon on

the left):

The following table lists the page elements:

Element Description

The following parameters are displayed:

• Address probe

• Capacity (l): Capacity of tanks displayed in [l]

• Max Height (mm): Maximum height of tanks displayed in [mm]

• offset (mm): Difference between probe and dipstick displayed in

Tank details

[mm]

• Zero H2O (mm): Water offset displayed in [mm]

• Div. Vol. (l): Delivery volume detection below which nothing happens

(above, you have Delivery), displayed in [l]

• Leakage (l): Leakage volume detection below which nothing happens

(above, you have Leakage), displayed in [l]

Information Table Displays the information table in use [level (mm)/Volume (l)]

Rev. 9, 04-2016

Page 15 of 40

Maglink LX

User Manual | Manual update

7.1.2.2 Tank Detail/Historical chart

The following picture shows an example of the "Graph history" page (accessed by clicking the icon on

the left):

The page shows the trend of the tank level displayed in [mm] over a 24 hr period.

Legend (the lines are present only if the corresponding alarms are configured):

Colour Description

Blue line Water level

Higher Blue line Water alarm threshold

Lower red line VERY LOW product level threshold

Lower yellow line LOW product level threshold

Green Line Product level threshold

Higher yellow line HIGH product level threshold

Higher red line VERY HIGH product level threshold

Rev. 9, 04-2016

Page 16 of 40

Maglink LX

User Manual | Manual update

7.1.2.3 Tank Detail/Historical list

The following picture shows an example of the "Graph list" page (accessed by clicking the icon on the

left):

The following table lists the page elements, as a function of time:

Element Description

Prd (mm) Quantity of products in the tank displayed in [mm]

Prd (l) Quantity of products in the tank displayed in [l]

H2O (l) Quantity of water in the tank displayed in [l]

T (C) Product temperature dispalyed in [°C]

Tank state

• OK STATUS (0): everything OK

• NO LINK (1, 8, 9, 11): no communication

• HIGH (2): HIGH product level

• LOW (3): LOW product level

• OUT OF RANGE (4): A value that is not allowed (check tank table information)

• PROBE (5): generic problem on the probe

• VERY HIGH (6): VERY HIGH product level

• VERY LOW (7): VERY LOW product level

State

• WATER (10): Water level

• WATER + HIGH (12): HIGH water level + product level

• WATER + LOW (13): LOW Water level + product level

• WATER + OUT OF RANGE (14): Water level + a value that is not allowed (check

tank table information)

• WATER + PROBE (15): Water level + probe problem

• WATER + VERY HIGH (16): VERY HIGH Water level + product level

• WATER + VERY LOW (17): VERY LOW Water level + product level

• WATER + NO LINK (18, 19): Water level + no communication

• DISABLED (30): Probe disabled via Configuration

• NOT INITIALIZED (99): Probe not configured

Rev. 9, 04-2016

Page 17 of 40

Maglink LX

User Manual | Manual update

7.1.2.4 Tank detail/Delivery List/Losses

The following picture shows an example of the "Delivery list" page (accessed by clicking the icon on

the left):

White lines are related to Delivery, the red lines are related to losses.

The following table lists the page elements, as a function of data and time:

Element Description

Init. (l) Initial volume displayed in [l]

Final (l) Final volume displayed in [l]

Qty (l) Delivery (Amount delivered to the tank) displayed in [l]

Interval (min) Duration displayed in [min]

7.1.2.5 Tank details/Diagnostics

The following picture shows an example of the "Diagnostics" page (accessed by clicking the icon on

the left):

The data shown is for use by the support staff

Rev. 9, 04-2016

Page 18 of 40

Maglink LX

User Manual | Manual update

7.1.2.6 Tank details/Reconciliation

The following picture shows an example of the "Reconciliation" page (accessed by clicking the icon on

the left):

The following table lists the page elements:

Element Description

Time Reference time

Vol. Initial Initial time volume

Vol. Final Final time volume

Vol. Diff. Difference in volume from Start to End

Dispenser Volume dispensed by dispenser

Delta Vol Volume reconciliation value

GG +1 Selection of successive days

GG-1 Selection of previous days

The daily reconciliation will be available on reports in relation to the time programmed during the setup

phase.

Reconciliation is only available when the Console receives data from an FCC/POS supporting the

reconciliation process (dispenser sales)

Rev. 9, 04-2016

Page 19 of 40

Maglink LX

User Manual | Manual update

7.1.2.7 Tank Details/Shift Report

The following picture shows an example of the "Shift Report" page (accessed by clicking the icon on

the left):

The following table lists the page elements:

Element Description

ID Incremental shift number

Start Start of shift

End End of shift

Initial volume Opening shift volume

Final volume Closing shift volume

Delivery Volume of Delivery if present

Shift Difference in volume start-end

Rev. 9, 04-2016

Page 20 of 40

Maglink LX

User Manual | Manual update

7.1.2.8 Tank Details/DVD Details

The following picture shows an example of the "DVD Details" page (accessed by clicking the icon on

the left):

The following table lists the page elements:

Element Description

The following data is displayed:

• Tank: Tank number

Details in the first row

• DVD ID: DVD identifier

• Diagnosis: Support use only

• No.: Number of transmissions from emission

• Referral date and time of details

The following data is displayed:

• Density: Density of the product displayed in [g/ml]

• Viscosity: Viscosity of the product displayed in [cP]

• Dielectric: Product Dielectric

Table details

• Temperature: Product temperature displayed in [°C]

• Fuel ID/Biodiesel in Diesel: Product type

• Confidence index /% Biodiesel in Diesel: 100% compared

confidence value of the product in the tank of the product

with the theoretical value (Below the 50% confidence,we are

not able to recognize the product with certainty)

Detail in the last row Alphanumeric code for Start Italiana S.r.l. exclusive use

Rev. 9, 04-2016

Page 21 of 40

Maglink LX

User Manual | Manual update

7.1.3 Tank detail percentage

The following image shows an example of the "Status":

The number of the tank, the name of the tank, its state and the percentage filling of the tank are reported

on the page.

Rev. 9, 04-2016

Page 22 of 40

Maglink LX

7.1.4 List of ON/OFF sensors

The following image shows an example of the "List of ON/OFF sensors":

.

The following table lists the page elements:

User Manual | Manual update

Element Description

Sensor type:

Number

• 1 – Internal sensor (up to 6)

• 2 – Tri-state external sensor (optional)

• 3 – External expansion card from Start Italian Srl (optional)

Progressive number Progressive number on the type of sensor

Description

Sensor state

See description status of the sensor in the manual "Console

Configuration"

Sensor state description (NORMAL, NOT INSTALLED, NOT DEFINED,

CLOSED, OPEN)

Time Actual time

Rev. 9, 04-2016

Page 23 of 40

Maglink LX

Element

Description

Date

- Time

Date and time of alarm

Tank

Tank Number

Alarm

Tank status

Alarm type:

ACK Button to acknowledge all active alarms

7.1.5 Alarm Log

The following image shows an example of the "Alarm Log":

The following table lists the page elements:

User Manual | Manual update

Type

• ON (red): Active Alarm

• CLEAR (green): Resolved alarms

• ACK (yellow): The alarm is acknowledged

When each new alarm, the console emits an audible sound.

To acknowledge, the user has to open this page and press the ACK button.

The audio alarm is deactivated and the alarm is marked in yellow to signify acknowledged. If there is a relay

associated with the alarm relay, it will remain active as long as the alarm is present. The ACK button

acknowledges the audible alarm but does not change relay signalling.

Rev. 9, 04-2016

Page 24 of 40

Maglink LX

7.1.6 INFO

The following image shows an example of the page "INFO":

The following table lists the page elements at the left of the page:

User Manual | Manual update

Element Description

Version Console software version

Serial number Unique serial number of the console

IP address Unique IP address of the console

Protocol Type Communication protocol currently set

Rev. 9, 04-2016

Page 25 of 40

Maglink LX

Button

Description

Print inventory

Prints the current inventory report

Exporting the information log to a

USB device

s

(The button appears if a USB device

Download the latest

software from the USB device

(The button appears if a USB

Software update (Not present until

the upload from the USB is complete)

The

Restoring a

previous backup configuration

from the

USB device

s

(The button

Close

Close the INFO page

Power Off

Console power off

Restart

Restarts the console

application

Manual closure of the current Shift Reports and opening a new one (By pressing

Button to activate

static

Leakage control (Not present if the page "Reconciliation"

Button to activate Anti

-

theft control (Not present if the page "Reconciliation" is

The following table lists the page buttons:

User Manual | Manual update

Export Log

Download from USB

Update

To restore a previous

Backup

Close manual shift

report

Activate Static

Leakage Control

following EPA rules.

At least 2 hours is

needed to generate

the result.

The result is

generated only if a

leakage has been

detected and it is

written in the

Delivery/Leakage

page marked as red

line

Activate Anti-theft

Control.

After 10 minutes from

the activation waiting

for stabilization if

there is any loss the

console generate an

alarm

instantaneously, in

the same way done

for the Leakage

control, without

waiting the minimum

of 2 hours of elapsed

time

is connected)

device is connected

console is automatically restarted after the update.

appears if a USB device is connected The console is automatically restarted after

the update..

the button, the console displays the following message: "Closing shift reports and

opening the next one. Would you like to proceed?")

is active); Pressing the button will bring up the following window:

Enter the Serial Number of the console (6 digits) and press ENTER to confirm (Use

DEL to delete incorrect digits)

If Reconciliation is active the leakage is Dynamically activated whenever all the

nozzle are in “rest” position. If at least 2 hours elapse in this conditions then the

algorithm is activated, otherwise it will abort.

Dispenser and nozzle configuration is required for a proper operation.

active); Pressing the button will bring up the following window:

Enter the Serial Number of the console (6 digits) and press ENTER to confirm (Use

DEL to delete incorrect digits)

Remember to deactivate this functionality before starting to use the dispenser

otherwise it will trigger the alarm.

Rev. 9, 04-2016

Page 26 of 40

Maglink LX

User Manual | Manual update

8 M

ANUAL UPDATE PROCEDURE

The console can be periodically updated by downloading the latest version of the application files from the

site www.startitaliana.it (Section MagLink-LX, ZIP format).

The following table shows the necessary procedure steps for updating such data:

Step Description

Provide a USB device

1

ATTENTION: The USB device must be formatted to FAT32

2 Downloading the latest version of the application files for the START web site

3 Use a USB device with at least 50 MB of free space available

4 Connect the USB device to a PC

5 Create a folder on the USB device named "lx-update" (All in lower case)

6 Extract the ZIP file in the "lx-update" USB device

7 Connect the USB device to the console

8 Press the "INFO" button and access the relevant page

9

Wait until the "Download from USB" appears on the screen and then press it (The files on the

device are copied to the console)

10 Press the "Update" button to apply the update

11 The update process is completed with the reboot of the console

Rev. 9, 04-2016

Page 27 of 40

Maglink LX

9 P

The console can be connected to a Sprint serial printer through the RS232 serial port. Once connected, the

user can print the current inventory .

RINT INVENTORY

User Manual | Print inventory

The following table shows the necessary procedure steps for printing stock:

Step Description

1 Connect the Sprint printer to the console RS232 port using a CX cable

2 Press the "INFO" button and access the relevant page

3 Press the button "Print stock" and wait for printing

Via the console configuration you can turn on automatic printing of various events such as:

• Alarms

• Shift report

• Delivery

• Losses

• Reconciliation

Refer to the Configuration Manual.

Rev. 9, 04-2016

Page 28 of 40

Maglink LX

10 S

The console can produce a Shift Report.

The shift report can be manually triggered or it can be automatically configured. You can configure multiple

daily Shift reports.

The following table shows the necessary procedure steps for managing such Shift Reports:

HIFT REPORT

Step Description

1 Press the "INFO" button and access the relevant page

User Manual | Shift Report

2

You can access the page "Shift Report" and view the daily Shift Report data of, as per paragraph 7.1.2.7

"Tank Details/Shift Report.”

If you have configured the automated Shift reports by manually pressing Closure of Shift Reports from the

Info Page this closes the Shift Report in progress and opens the next one which will then be automatically

closed at the next scheduled date.

If a delivery is in progress, the value of the final volume of the Shift Report is equal to the volume in tanks

prior to commencement of Delivery.

Press the button "Close shift report" and confirm the subsequent message (The current Shift

Report is closed with a new shift automatically started)

Rev. 9, 04-2016

Page 29 of 40

Maglink LX

User Manual | Maintenance

11 M

Maintenance activities are defined and managed in accordance with EN 60079-17.

AINTENANCE

IMPORTANT: Maintenance must be carried out only by authorized personnel or by the

manufacturer

IMPORTANT: Maintenance of electrical connections must be performed only by personnel

trained and experienced (Refer to the installation manual of the console)

IMPORTANT: The opening of the console can compromise the level of safety of the

equipment, maintenance operations must only be performed by authorized personnel or by

the manufacturer

IMPORTANT: Changes to the console are prohibited unless authorized by the manufacturer

ATTENTION: Periodically check for cleanliness and integrity of the equipment and its

connections

ATTENTION: To clean the screen and the console use a monitor/screen/TV cleaning cloth

IMPORTANT: Do not use compressed air or liquid detergents to perform console and screen

cleaning

Rev. 9, 04-2016

Page 30 of 40

Maglink LX

12 S

If you need direct assistance from a Start Italiana S.r.l. technician the best solution is to connect the console

to the Internet .The console requires public IP address and port 80 opened. All data of interest to the

console can then be viewed directly by Start Italiana S.r.l. staff.

An alternative is to use third-party programs (Team Viewer 7 can be downloaded form the START Web Site

under the heading Assistance/Support) to allow a connection between the remote computer the console

must be connected to the computer to which Start Italiana S.r.l. will connect remotely.

In the case where Internet access is not possible the user must still provide Start Italiana S.r.l. with data

relating to the console for the execution of the debugging process.

The following table shows the necessary procedure steps for the provision of such data:

UPPORT

Step Description

Provide a USB device with at least 50 MB of free space available

User Manual | Support

1

2 Connect the USB device to a PC

3 Create a folder on the USB device named "lx-support" (All in lower case)

4 Connect the USB device to the console

5 Press the "INFO" button and access the relevant page

6

7

Wait until the "Export Log" appears on the screen and then press it (The files are copied to

your device in the console)

Perform a compression of the "lx-support" folder and send the ZIP file by e-mail to

assistenza@startitaliana.it

ATTENTION: The USB device must be formatted to FAT32

Rev. 9, 04-2016

Page 31 of 40

Maglink LX

13 S

Safety instructions are annexed to this document.

AFETY INSTRUCTIONS

User Manual | Safety directives

Rev. 9, 04-2016

Page 32 of 40

Maglink LX

14 C

ERTIFICATION

User Manual | Certification

Rev. 9, 04-2016

Page 33 of 40

Maglink LX

User Manual | Certification

Rev. 9, 04-2016

Page 34 of 40

Maglink LX

User Manual | Certification

Rev. 9, 04-2016

Page 35 of 40

Maglink LX

User Manual | Certification

Rev. 9, 04-2016

Page 36 of 40

Maglink LX

User Manual | Notification

15 N

OTIFICATION

Rev. 9, 04-2016

Page 37 of 40

Maglink LX

16 R

EVISIONS

The following table lists the revisions to the document:

User Manual |

Revisions

Revision No. Date Description

01 March 2014 Issue 1.0.0

02 February 2015 Added com ports inversion 2.0.0

03 March 2015 Addition of an application description section 2.0.0

04 April 2015 Addition of a certification and notifications section 2.1.x

05 April 2015

06 July 2015

Revision Date Description Verison_SW

08 January 2016 Revision with photos 2.2.x

09 April 2016 2.4

Addition of a new test report, audit certification and notifications

section

Addition of a manual update section, information on reconciliation,

shift reports, stock releases, support, program description

Firmware

Revision

2.1.x

2.2.x

Rev. 9, 04-2016

Page 38 of 40

Manufacturer_name

START ITALIANA S.r.l.

Via Pola 6

20813 Bovisio Masciago (MB)

Italia

Tel. +39 0362 1581465

Fax +39 0362 1581464

assistenza@startitaliana.it

www.startitaliana.it

Loading...

Loading...