Page 1

MA26 Meter &

MP-T1 Pulser

Component

Technical Manual

Document Ref 903158-001

Rev - 1

10/2001

Page 2

Document Ref 903158-001

MA26 MP-T1 Meter for Fuel Dispensers Component Technical Manual

This page is intentionally blank

Issue A

Page 3

Document Ref 903158-001 Page 1

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

REVISION RECORD

Date Revision Page Issue Reason

18/10/ 2001 1 A l l A Original Is s ue

Page 4

Page 2 Document Ref 903158-001

MA26 MP-T1 Meter for Fuel Dispensers Component Technical Manual

This page is intentionally blank

Issue A

Page 5

Document Ref 903158-001 Page 3

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

Issue A

CONTENTS

1. PURPOSE / DESCRIPTION ...........................................................................................6

1.1 MA26 Piston Meter ................................................................................................ 6

1.1.1 Purpose ...................................................................................................6

1.1.2 Description ............................................................................................. 6

1.1.3 Technical Specifications.........................................................................7

1.1.4 Approvals ............................................................................................... 7

1.1.5 Dimensions .............................................................................................8

1.1.6 Meter Operation ..................................................................................... 9

1.1.7 Adjustment ............................................................................................. 9

1.2 MP-T1 Pulser........................................................................................................10

1.2.1 System Description...............................................................................10

1.2.2 Functional Partition of the MP-T1 electronics..................................... 10

1.3 MA26 MP-T1 Sealing ..........................................................................................13

2. PARTS LIST....................................................................................................................16

2.1 MA 26 Meter ........................................................................................................16

2.2 MA 26 Collector ................................................................................................... 18

2.3 MA26 Bottom Cover ............................................................................................ 19

2.4 MP-T1 Pulser, Gears and Totaliser ....................................................................... 20

3 TROUBLE SHOOTING ................................................................................................22

3.1 Piston Meter Blocked ...........................................................................................22

3.2 Calibration Error ...................................................................................................23

3.3 External Leakage .................................................................................................. 23

Page 6

Page 4 Document Ref 903158-001

MA26 MP-T1 Meter for Fuel Dispensers Component Technical Manual

This page is intentionally blank

Issue A

Page 7

Document Ref 903158-001 Page 5

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

Issue A

CONTENTS

1. PURPOSE / DESCRIPTION ...........................................................................................6

1.1 MA26 Piston Meter ................................................................................................ 6

1.1.1 Purpose ................................................................................................... 6

1.1.2 Description ............................................................................................. 6

1.1.3 Technical specifications ......................................................................... 7

1.1.4 Approvals ............................................................................................... 7

1.1.5 Dimensions .............................................................................................8

1.1.6 Meter operation ......................................................................................9

1.1.7 Adjustment ............................................................................................. 9

1.2 MP-T1 Pulser........................................................................................................10

1.2.1 System description ...............................................................................10

1.2.2 Functional partition of the MP-T1 electronics .....................................10

1.3 MA26 MP-T1 Sealing ..........................................................................................13

Page 8

Page 6 Document Ref 903158-001

MA26 MP-T1 Meter for Fuel Dispensers Component Technical Manual

Issue A

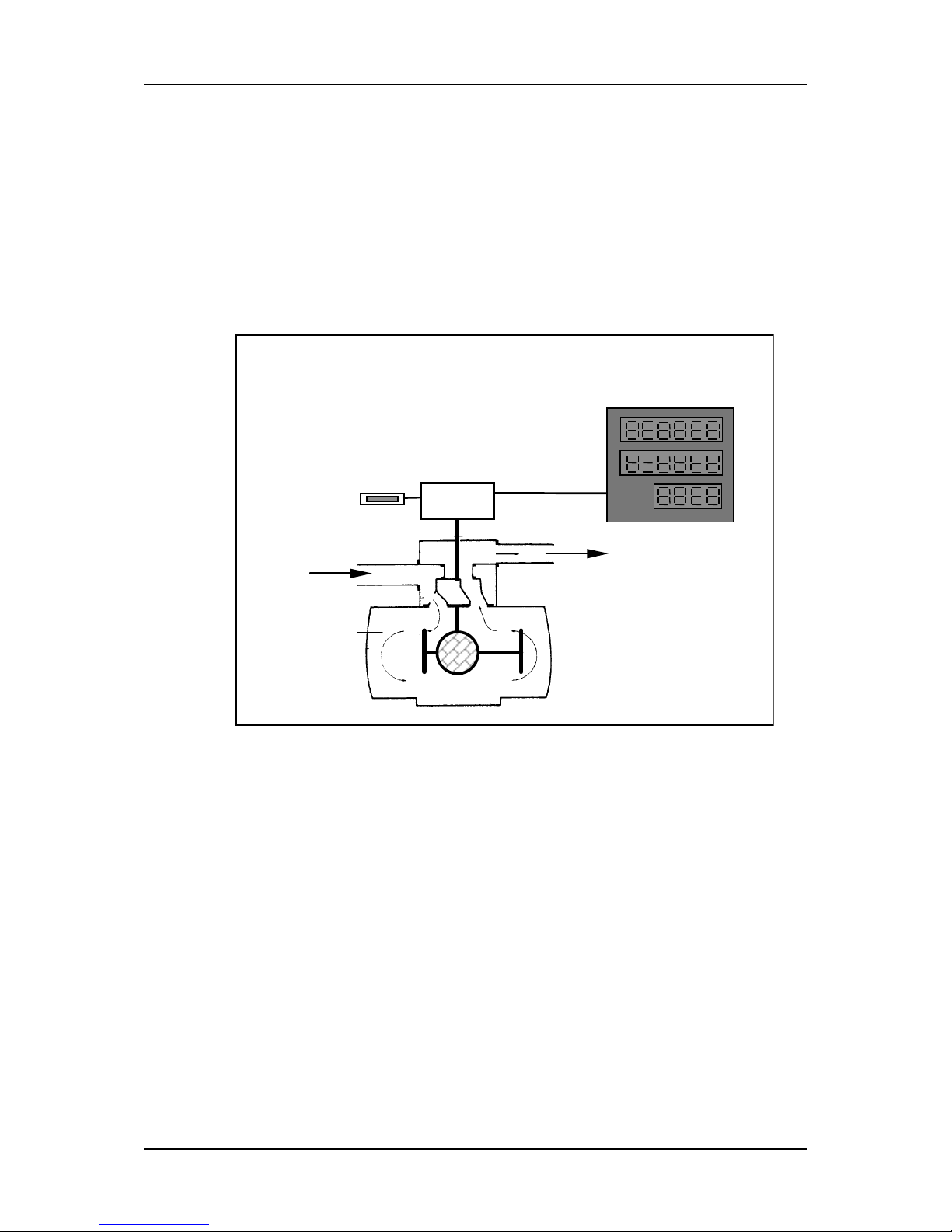

1 PURPOSE / DESCRIPTION

1.1 MA26 Piston Meter

1.1.1 PURPOSE

The MA26 meter has been designed to provide accurate measurement of

traditional fuels using a positive displacement system.

1.1.2 DESCRIPTION

The meter is made up of a body containing four sleeved cylinders which in turn

contain four pistons. These pistons move in connection with two transmission

rods. Rollers connected to a crankshaft move within the groove of these rods.

The alternative linear motion of the pistons therefore results in a rotary crankshaft

movement.

A valve is driven by the crankshaft, successively putting the cylinders in

communication with the meter inlet and outlet. The valve glides between a

slide plate integrated to the body and a gasket fixed to the outlet collector. The

slide plate has four holes, which are connected to the four cylinders. The link

between the gasket and the outlet collector is made via a Teflon diaphragm,

which acts as a seal between intake and exhaust.

The upper section of the crankshaft drives the indicating device.

Pulser

MP T1

Fuel

Entry

Calculator

Fuel

Exit

Meter MA 26

Totaliser

Page 9

Document Ref 903158-001 Page 7

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

Issue A

1.1.3 TECHNICAL SPECIFICATIONS

Characteristics UNITS VALUE

Displacement : Litre 0.700

Maximum flow-rate : l/mn 83

Minimum flow-rate : l/mn 5

Accuracy within the flow range : % ± 0.3

Maximum service pressure : bar 4

Maximum torque during delivery : Nm 4

Pressure drop without torque : bar 0.08 5 l/mn

0.12 40 l/mn

0.15 50 l/mn

0.26 80 l/mn

Adjusting device operating range : % ± 1.1

Environmental Conditions

Climate : marine, tropical, industrial and polar

Ambient temperature range : - 25°C to + 55°C.

Fuel temperature : - 25°C to + 55°C.

Atmosphere : In accordance with climate.

1.1.4 APPROVALS

Metrological

European Approval : 01.00 . 422.003.0 (21 June 2001)

The MA26 meter is a measurement transducer for use in a measuring instrument

for liquids other than water. As such it is tested and certified according to the

OIML (Organisation International de Metrology Legal) Recommendation R1 17.

The certificate is issued under number R117(1995)-NL-01.04 by the NMi (Dutch

national test institute).

Safety

The MA26 meter with the MP-T1 pulser is constructed for use in gasoline

dispensers in a zone 1 area. Therefore the pulser, as an electrical part, has been

approved by LCIE according the European Standard EN 50014 and EN 50018

with protection code EExdIIBT6 with certificate number DEMKO

00.E.128709X.

Page 10

Page 11

Document Ref 903158-001 Page 9

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

1.1.6 METER OPERATION

The fuel enters the meter via the intake orifice (5) and flows up to the valve (3),

where it applies pressure to the piston (7), while the piston (6) linked to the

former by the connecting rod (8) is in communication with the exhaust orifice

via the opening (4) of the rotary valve (3). Both perpendicular pistons that are

linked to the connecting rod (9) operate under the same conditions, offset by

90°.

Inside the connecting rods (8 and 9), two rolls (10) are mounted on the crankshaft

(2). The upper crankshaft pin drives the distribution valve (3) through a peg (1)

located on the crankshaft, transmitting the rotary movement to the indicating

device.

1.1.7 ADJUSTMENT

Capacity can be adjusted by varying the piston stroke. The device contains a

central cam (13) with four ramps, each one acting successively on the four

pistons. Travel can be adjusted by using a lever (11) to turn the cam around its

axle (12). The lever may be positioned firstly in relation to the position of the

cam, via a square section part (14). Its position on the notched part (15) may be

adjusted using the screw (16) which acts as a positioning pin.

The lever is designed in such a way that, whatever its position on the notched

part, the screw (16) is always hidden. It is protected by the sealing device (17).

The clearance needed for adjustment is obtained by the clearance between the

rollers and the connecting rod sliders.

Each notch on the notched part modifies the meter’s cylinder capacity by 0.1%

Access to the adjusting device is made impossible by a seal.

Issue A

Page 12

Page 10 Document Ref 903158-001

MA26 MP-T1 Meter for Fuel Dispensers Component Technical Manual

1.2 MP-T1 Pulser

1.2.1 SYSTEM DESCRIPTION

The MP-T1 pulser is part of the measurement transducer used in a fuel dispenser.

The task of this unit is to detect and to indicate when a volume of 1cl fuel has

left this unit. Below is a short description of the different parts of the

measurement transducer.

This device will be placed in series with the nozzle of a dispenser. It converts

the fuel flow into rotations of a shaft. One rotation of the MA26 volume meter

represents a fuel flow of 70cl.

The MP-T1 housing is placed on top of the volume meter. This housing contains

the MP-T1 electronics (placed on a support), 3 gear wheels and a magnetic

disc. The rotation of the volume meter shaft will be conveyed by the 3 gear

wheels to the magnetic disc. The speed ratio volume meter shaft:magnetic disc

= 1:3.5.

So one turn of the disc represents 20 cl.

The electronic outputs of the MP-T1 pulser, which contain “cl” pulses, will

drive the inputs of the calculator.

One or more pulsers, each with a 4 wire link, are connected to the calculator.

This link contains two pulse lines and two power lines to supply the pulser

1.2.2 FUNCTIONAL PARTITION OF THE MP-T1 ELECTRONICS

The MP-T1 electronics take care of the translation of the magnetic field changes

into proper “cl” pulses needed for the calculator. The MP-T1 electronics can be

divided into the following functional blocks. The functions of the different blocks

are described on the following pages. All digital functions of the MP-T1

electronics are integrated in an Asic.

-

T

backward flow

count

(centilitres)

cl=0

comparator

output

driver

timer

sequence

detector

digital

filter

cl=20+

backward

count

error

Asic parts

forward

count

hall effect sensor (fault detection)

magnetic disc

hall effect sensors (direction)

sensor defect

overflow

not equal

disable

pulse line

A and B

Issue A

Page 13

Document Ref 903158-001 Page 11

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

Magnetic disk

The disc contains one outer ring, divided into 20 north and 20 south polarised

magnetic parts and one inner ring divided into 10 north and 10 south polarised

magnetic parts. The disc will be driven by, as mentioned before, the volume

meter. A liquid flow in forward direction (this liquid has left the measurement

transducer) results in a counter-clockwise movement of the disc. If the liquid is

going backwards the disc will rotate clockwise.

The disc can have small movements in both directions, this will be caused by

vibrations of the MP-T1 pulser. These movements are called “oscillations of

the disc”. The oscillations will never result in centilitre pulses on the output of

the MP-T1 pulser.

Hall effect sensors (direction)

T wo sensors (sensor A and sensor B) are placed above the outer ring of the disc.

They are used to indicate the direction of the disc. Every transition on the

signal coming from sensor B represents a half centilitre.

Hall effect sensor (fault detection)

A third sensor (sensor C) is placed above the inner ring of the disc. Due to the

fact that this ring contains 10 north and 10 south polarised magnetic parts, the

output frequency of this sensor will be the half of the frequency coming from

the two other sensors. This difference in frequency makes it possible to

distinguish between normal operation, sensor defects or disc oscillations.

Digital filter

This part will remove glitches shorter then 8µs from the sensor signals.

Sequence detector

The sequence detector distinguishes the different movements of the disc by

evaluating the three sensor signals.

Backward flow count (centilitres)

When the disc turns clockwise the sequence detector generates backward count

pulses. The backward flow count buffer keeps up with the amount of backwards

count pulses. When the buffer reaches 20 cl (40 pulses) it will generate an

overflow message. If the disc turns counter-clockwise the sequence detector

generates forward count pulses. The backward flow count buffer will decrease

with the amount of forward count pulses until it reaches the 0 cl. At this point

the buffer will not decrease anymore and the switch will be closed so that the

timer receives forward count pulses on its trigger input.

Timer (400µs)

A pulse on the trigger input of the timer will start this one shot 400µs timer.

During this 400µs, the timer will activate the output driver for line A (or B).

Every half cl the timer alternates between line A and B. So, if there was a pulse

on output line A, a half cl later it will be followed by a pulse on output line B.

A pulse on output line B will be followed by a pulse on output line A, etc.

Issue A

Page 14

Page 12 Document Ref 903158-001

MA26 MP-T1 Meter for Fuel Dispensers Component Technical Manual

Output driver

The output driver is necessary to supply the current needed for the inputs of the

calculator. Furthermore it delays the low to high transition of the cl pulses on

the output lines A and B. This delay is to prevent cross talk between the two

pulse lines and interference on other lines.

Comparator

This block checks the input and output of the output driver during the 400µs

pulse. If the output line is high (idle state) while the input of the driver is activated,

it will send a “not equal” signal to the error block.

The inputs of the comparator used for monitoring lines A and B are provided

with a digital filter. This filter will remove glitches (smaller than 32µs) from

these two signals.

Error

The signals “overflow”, “sensor defect” and “not equal” are collected here.

When one or more signals are active, the error signal will be activated. This

signal can only be deactivated by switching off the MP T1 power. When the

error signal is activated, the output driver is disabled, so the output lines become

low (error indication of the MP-T1).

Issue A

Page 15

Document Ref 903158-001 Page 13

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

1.3 MA26 MP-T1 Sealing

1

2

3

4

Piston sealing

A sealing wire feeds through the head of a seal screw fitted in each piston end

cover. This seal wire also diverts upwards between two of the end covers to

feed through a seal screw securing the top housing to the meter body.

The seal wire is drawn taught and a seal fixed for stamp access above the

calibration quadrant.

Pulser sealing

A sealing wire feeds through holes in the bottom right hand corner of the pulser

casting and meter housing, then travels diagonally across the front of the pulser

to pass through either a hole in the meter mounting plate or the head of the front

meter mounting screw.

The seal wire is drawn taught and a seal fixed for stamp access in front of the

pulser.

Calibration sealing

A seal wire passes through holes in the calibration locking screw and is drawn

taught and a seal fixed.

Meter sealing

The meter is sealed into the dispenser by passing a seal wire through the heads

of two of the meter mounting screws.

The seal wire is drawn taught and a seal fixed for stamp access on the top of the

hydraulic stack.

Issue A

Page 16

Page 14 Document Ref 903158-001

MA26 MP-T1 Meter for Fuel Dispensers Component Technical Manual

This page is intentionally blank

Issue A

Page 17

Document Ref 903158-001 Page 15

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

CONTENTS

2. PARTS LIST....................................................................................................................16

2.1 MA 26 Meter ........................................................................................................16

2.2 MA 26 Collector ................................................................................................... 18

2.3 MA26 Bottom Cover ............................................................................................ 19

2.4 MP-T1 Pulser, Gears and Totaliser ....................................................................... 20

Issue A

Page 18

Page 16 Document Ref 903158-001

MA26 MP-T1 Meter for Fuel Dispensers Component Technical Manual

2. PARTS LIST

2.1 MA 26 Meter

Issue A

Page 19

Document Ref 903158-001 Page 17

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

Item Reference Désignation Description

901106 Mes ureur MA 26 as s em blé MA26 meter assembly

1 900015-010 Vi s M6-20 Screw M6-20

2 900050-009 Joint torique 94,5 x 3 O-ring 94,5 x 3

3 900050-010 Joint torique 104,2 x 3 O-ring 104 , 2 x 3

4 900050-011 Joint torique 110 x 3 O-ring 110 x 3

5 900053-002 Vi s torx M6-16 Torx s c re w M 6-16

6 900053-003 Vi s torx M6-20 Torx s c re w M 6-20

7 900101-004 Joint pl at Flat seal

8 900103-002 Circlips Circlips

9 901240 Corps équipé Equipped body

10 901246 Collec teur assembl é Collec t or as s em bly

11 901260 Vilebrequin Crankshaft

901264 Galet Roll

900008-005 Rondell e lai t on Bras s was her

900047-001 Anneau truarc Truarc ring

12 901265 Doigt d’ ent rainement Drive s t ud

13 901266 Tiroir Rotary valve

14 901267 Coulisseau Rod

15 901268 Pl at eau int erne Pi ston dis k

16 901269 Manc het te Piston seal

17 901270 Pl at eau ex t erne Tightening disk

18 901271 Em bas e assemblée Bottom cover ass em bly

19 901277 Couvercle Cover

Issue A

Page 20

Page 18 Document Ref 903158-001

MA26 MP-T1 Meter for Fuel Dispensers Component Technical Manual

2.2 MA 26 Collector

Item Reference Désignation Description

1 900053-001 Vis torx M 4-10 Torx s crew M4-10

2 901247 Collecteur bagué Collec t or wit h bearing

3 901249 Supp. m embrane assem blé (rodé) Counterval ve assem bly (lapped)

4 901251 Joint profil S vert Lipseal (green vi ton)

5 901252 Rondelle lai ton Bras s was her

6 901256 Ressort Spring

7 901257 Joint pl at Flat seal

Issue A

Page 21

Document Ref 903158-001 Page 19

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

2.3 MA26 Bottom Cover

Item Reference Désignation Description

1 900017-004 Vis CHc M8-50 i nox CHc st ainles s st eel screw M8 -50

2 900050-003 Joint torique 13, 6 x 2,7 O-ring 13.6 x 2.7

3 900101-005 Joint p l at F lat seal

4 901272 E m base Bot tom c over

5 901273 Came Adj ustmen t cam

6 901274 Levier de réglage Adjus tment lever

7 901275 V i s de plombage Seali ng screw

8 901276 Cage de pl om bage Seal housing

Issue A

Page 22

Page 20 Document Ref 903158-001

MA26 MP-T1 Meter for Fuel Dispensers Component Technical Manual

2.4 MP-T1 Pulser, Gears and Totaliser

6

Issue A

Item Reference Désigna tion Description

1 900643-001 V i s Fhc M 6 x 12 i nox Sc rew M6-12 s tainless st eel

2 901280 Pignon - vis d’entrai nem ent Endles s sc rew wheel

3 901281 Pignon axe intermédi aire Intermediat e s haft gear

4 901283 Pignon ent raîneur émetteur Puls er drive wheel

5 901284 Support t otalis at eur équipé Totaliser support as sembly

6 900843 Emetteur MP T1 avec câble MP-T1 pulser wit h c abl e

900743-002 Totalisateur mec ani que Mec hanical Totalis er

900043-001 E crou serrures pour tot al i s at eur Lock i ng nut for tot al i s er M 10x 1.00

Page 23

Document Ref 903158-001 Page 21

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

CONTENTS

3 TROUBLE SHOOTING ................................................................................................22

3.1 Piston Meter Blocked ...........................................................................................22

3.2 Calibration Error ...................................................................................................23

3.3 External Leakage .................................................................................................. 23

Issue A

Page 24

Page 22 Document Ref 903158-001

MA26 MP-T1 Meter for Fuel Dispensers Component Technical Manual

3 TROUBLE SHOOTING

3.1 Piston Meter Blocked

Meter inlet

pressure

OK?

NO

NO

YES

YES

Meter outlet

line open?

❍ Check the pump

❍ Check the nozzle

❍ Check the solenoid

valves

❍ Mechanism damaged

Issue A

Page 25

Document Ref 903158-001 Page 23

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

3.2 Calibration error

Positive display error / not enough liquid in the can:

❍

❍❍

❍ External leakage

Adjust the meter (see section 1.1.7)

Negative display error / Too much liquid in the can.

❍

❍❍

❍ Adjusting cam damage

If low flow error higher than max flow error over 0.5 %:

❍

❍❍

❍ Internal leakage through :

-piston seals

-diaphragm

-rotary valve

100.90

100.80

100.70

100.60

100.50

100.40

100.30

100.20

100.10

100%

99.90

99.80

99.70

99.60

99.50

99.40

99.30

99.20

99.10

3.3 External Leakage

Leakage : ❍...through the drive shaft: lip seal faulty

❍...under the collector : collector O-ring faulty

❍...under a cover: cover O-ring faulty

❍...through the adjustment axle: adjustment axle O-ring faulty

❍...under the bottom cover : bottom cover O-ring faulty

Issue A

Page 26

Page 24 Document Ref 903158-001

MA26 MP-T1 Meter for Fuel Dispensers Component Technical Manual

This page is intentionally blank

Issue A

Page 27

Document Ref 903158-001

Component Technical Manual MA26 MP-T1 Meter for Fuel Dispensers

This page is intentionally blank

Issue A

Page 28

Tokheim Europe & Africa Headquarters

ZAC Paris Nord 2

B.P. 40027 Tremblay-en-France

95912 Roissy C.D.G. Cedex

France

! +33 (0)1 49 90 77 00

" +33 (0)1 49 90 77 77

# marcom@tremblay.tokheim.com

Manufacturing

Unit 3, Baker Road

West Pitkerro Industrial Estate

Dundee DD5 3RT

Scotland

! +44 (0)1382 598000

" +44 (0)1382 598001

# service@tokheimuk.com

F

GB

SALES & SERVICE DIVISIONS - EUROPE

Austria

Tokheim

Eitzenberger Straße 4-6

A-2544 Leobersdorf

! +43 (0) 2256 606 0

" +43 (0) 2256 606 170

# office@leobersdorf.tokheim.com

Belgium

Tokheim

Everdongenlaan 31

2300 Turnhout

! +32 (0) 14 44 85 00

" +32 (0) 14 44 85 55

# saelen@turnhout.tokheim.com

Czech Republic

Tokheim

Pernerova 48

CZ-18602 Prague 8

! +420 2 248 90312

" +420 2 232 72 67

# pribrsky@prague.tokheim.com

Denmark & Scandinavia

Tokheim Scandinavia

Hejrevang 10

3450 Allerød

! +45 48 13 45 45

" +45 48 17 45 96

# service@alleroed.tokheim.com

France

Tokheim Services France

9 Avenue Galilée

92350 Le Plessis-Robinson

! +33 (0)1 41 36 13 00

" +33 (0)1 41 36 13 70

# parise@plessis.tokheim.com

Tokheim Sofitam Applications

ZAC Paris Nord 2

B.P. 40027 Tremblay-en-France

95912 Roissy C.D.G. Cedex

! +33 (0)1 49 90 77 00

" +33 (0)1 49 90 77 77

# accueil-tremblay@tremblay.tokheim.com

Germany

Tokheim GmbH

Lothstrasse 1a

D-80335 München

! +49 (0) 89 189 530

" +49 (0) 89 189 533 99

# service@muenchen.tokheim.com

Italy

Tokheim Sofitam Italia S.r.l.

S.P. 26 Km 10 800

14030 Scurzolengo (AT)

! +39 0141 2038200

" +39 0141 2038222

# info@asti.tokheim.com

Netherlands

Tokheim Netherlands B.V.

Touwslagerstraat 17

Postbus 4186

2980 GD Ridderkerk

! +31(0) 180 48 15 00

" +31(0) 180 48 15 55

# sales@ridderkerk.tokheim.com

Poland

Pol-Germann Tokheim Sp. z.o.o.

UL. Narwicka 1

PL-80-557 Gdansk

! +48 58 343 21 71

" +48 58 343 22 15

# plgerma@softel.gda.pl

Portugal

G.N.C.

Parque de Ciencia e Tecnologia

Edificio Tecnologia 1, N° 27

2780-920 Oeiras

Lisboa

! +351 214 220 420

" +351 214 214 226

Russia

Tokheim Russia & CIS

50, Office 603-605, Zemlyanoy Val St.

Moscow, 109544 GSP

! +7 095 916 6879

" +7 095 916 6878

# kolobov@dol.ru

Slovak Republic

Tokheim

Mlynske Nivy 70

SK-82015 Bratislava

! +421 2 58 27 02 15

" +421 2 52 41 41 23

# schroeder@berlin.tokheim.com

Spain

Koppens Iberica

Calle Imprenta 5

Poligono Industrial de Alcobendas

28100 Alcobendas (Madrid)

! +34 91 661 28 13

" +34 91 661 41 30

# urra@madrid.tokheim.com

Switzerland

Tokheim

Route du Crochet 7

Case Postale 50

1762 Givisiez

! +41 (0)26 460 51 11

" +41 (0)26 460 51 12

# user@givisiez.tokheim.com

United Kingdom

Tokheim

Adur Boatyard, Old Shoreham Road

Shoreham-By-Sea

West Sussex BN43 5TA

! +44 (0)1273 454831

" +44 (0)1273 464863

# sales@tokheimuk.com

AFRICA

Export Division

ZAC Paris Nord 2

B.P. 40027 Tremblay-en-France

95912 Roissy C.D.G. Cedex

France

! +33 (0)1 49 90 77 56

" +33 (0)1 49 90 77 93

# marcom@tremblay.tokheim.com

Cameroon

Socatam S.A.

BP 3941

Douala

! +237 40 57 86

" +237 40 57 88

# socatam.douala@camnet.cm

Morocco

Matam S.A

209 Bld Moulay Ismail

Route de Rabat

Casablanca

! +212 22 40 40 24

" +212 22 40 40 21

# matam@wanadoo.net.ma

Senegal

Cosetam S.A.

Quartier de Bel Air

Route des Hydrocarbures

BP 1237

Dakar

! +221 832 23 71

" +221 832 68 34

# cosetam@ns.arc.sn

South Africa

Tokheim South Africa Ltd

Stand 110, Precision Road

Kya Sand, Randburg

! +27 11 462 2105

" +27 11 462 1942

# tokheimsales@tokheim.co.za

Tunisia

Cottam SARL

116 Ave de l’Union du Maghreb Arabe

BP 117

La Soukra

2036 Tunis

! +216 175 95 50

" +216 175 95 30

# cottam@planet.tn

As Tokheim regularly improves its

products to ever better respond to

evolving market and regulatory requirements, it reserves the right to

change any of the specifications of

these products, and this without prior

notice.

B

A

B

CZ

F

F

I

MA

ZA

TN

DK

SK

CH

NL

P

GB

E

F

SN

D

PL

RUS

RFC

Loading...

Loading...