TOHATSU VC85BS, VC82ASE, VC72AS, VC52AS Quick Start Up Manual

MAIN

SWITCH

3

O

F

F

O

N

S

T

A

R

T

VC85BS•VC82ASE•

VC72AS•VC52AS

Quick Start Guide

1. BEFORE OPERATION

Gasoline Engine Oil

Countermeasuring when the monitor lamp is ON.

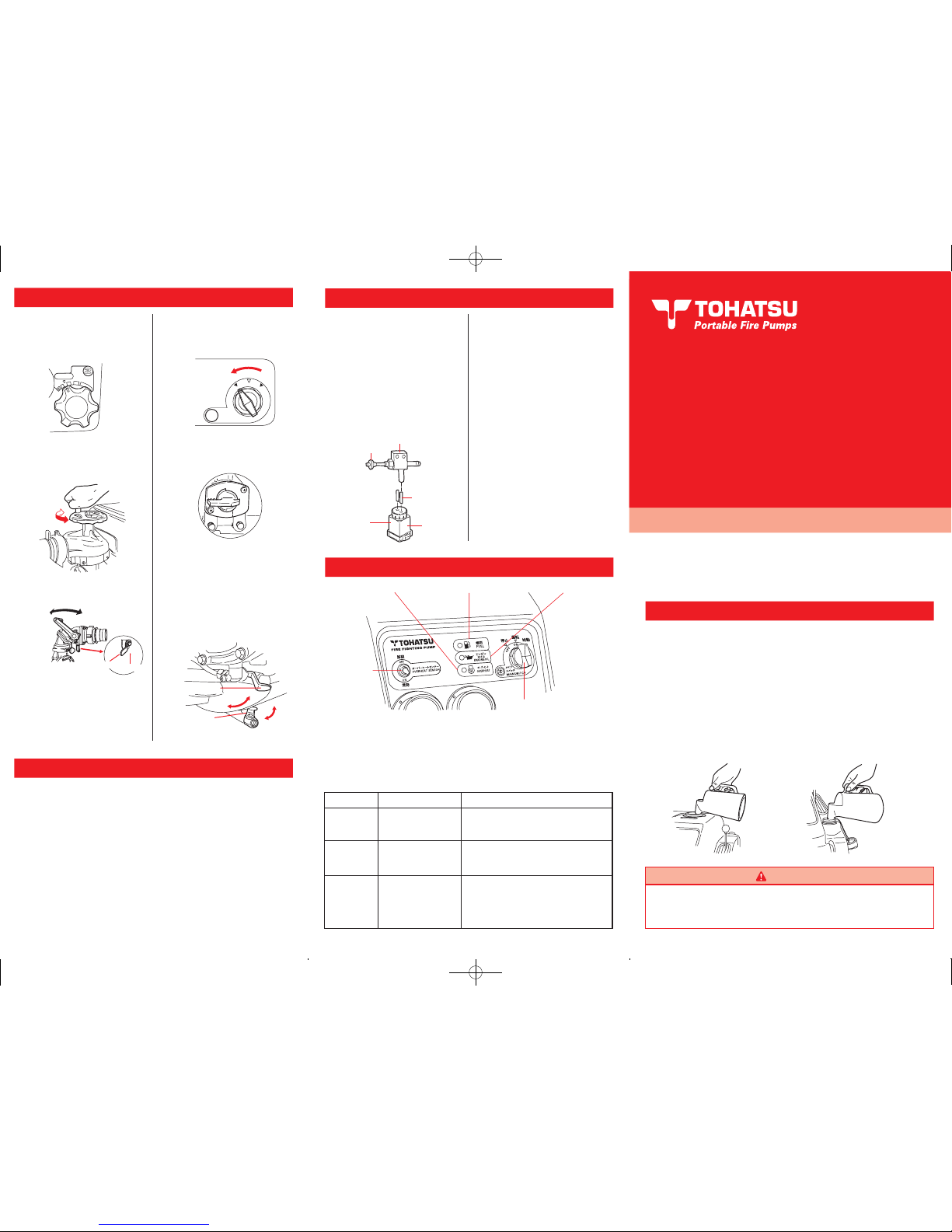

8. USE OF OK MONITOR

5. STOPPING

1 After stopping the

engine, close the fuel

cock.

2

Pull the knob of the

drain valve. (Fuel in the

float chamber will flow

out.)

3

Turn the main switch

to OFF position.

4

Close the fuel cock.

5

Open the drain cocks.

After checking all the

water has been

drained from the

pump, close the cocks

.

1 Battery initial charge

The battery mounted on the engine can be used immediately after filling

cells with electrolyte enclosed with battery (It is better to charge the

battery using the automatic battery charger after filling electrolyte). Do not

add distilled water because this is a sealed type battery. Please refer to the

INSTRUCTIONS on the battery.

2

Fuel & Engine oil

Fill gasoline (87 octane minimum at pump posted rating…91 based on the

research octane rating method) into the fuel tank. Fill two stroke engine oil

into the oil tank.

Maintenance after pumping seawater or foul water

After pumping seawater or foul water, flush fresh clean water

through the pump with the pump running to thoroughly clean

the inside.

And operate the vacuum pump for 5 seconds at low engine

speed in order to clean the vacuum pump

.

3

After all the fuel has

drained, release the

knob. (The drain valve

will return to the

closed position.)

4

Fuel from the drain pot

should be returned to

the fuel tank

.

Dispose of fuel if contaminated

with water, dirt or other

substances

.

7. Draining Fuel from the Carburetor

WARNING

Dry running of engine for over two minutes will cause seizure

of engine parts. Start suction of water immediately after

starting engine.

It is necessary to take a countermeasure if the lamp is on when turning the main

switch to the position of

“Operation”.

Monitor lamp

Fuel

Engine oil

Overheat

Level of fuel has

dropped below one

third of tank capacity

.

Supply fuel.

Supply 2 stroke engine oil.

Check the cause and remedy it. Turn the

overheat sensor switch to

“OFF” position

and start the engine. After co

nfirming the

lamp is off, return the switch to

“ON”

position.

(VC82ASE/72AS/52AS)

Oil level is below

quarter of oil tank

capacity.

Engine stops caused

by lack of cooling

water.

Lamp ON

Action required

1

Return the throttle

dial to low speed

position

.

2

Close the discharge

valve.

Open↔Close

CLOSE

OPEN

Standard Type

Discharge Valve

CLOSE OPEN

OPEN

Ball Cock Type

Discharge Valve (Option)

CLOSE

Be sure to read the instruction manual before operating

Tohatsu fire pump. Being familiar with all aspects of its

application will guarantee best performance.

The pot must

be emptied

each time.

Knob

Drain valv

e

Check the hose

is secured to the

drain pot.

Drain pot

6. PRECAUTIONS AFTER OPERATION

スロットル

THROTTLE

低圧

LOW

低圧

HIGH

始動

START給水SUCTION

ON

FUEL

O

O

C

C

For pump casing

For muffle

r

Printed in Japan No.004-22015-0

Overheat

Overheat

switch

Fuel

Engine oi

l

Main switc

h

QuickGuide_121022.indd 1 12.10.22 10:47:47 AM

WARNING

VC85BS / VC82ASE / VC72AS / VC52AS

1. BEFORE OPERATION

Gasoline Engine Oil

Countermeasuring when the monitor lamp is ON.

8. USE OF OK MONITOR

Fire Fighting Pumps

3

Governor case oil

4 Drain cock

1 Notes on installation

Before using fire pump check governor case oil

level. To check, remove oil gauge, oil level

should be between upper and lower line on the

gauge if necessary, add two stroke engine oil

into the oil gauge insert port.

Make sure the drain cock is closed.

5

Discharge valve

Make sure the discharge valve

is closed.

(1) Set the pump in a place that is flat near water source with

pump easily accessable to ease operation.

(2) Set suction hose rising slope toward pump to prevent

trapping of air.

(3) Connect suction hose and delivery hose to the pump

securely. Put end of suction hose in water source. The

suction hose must have a strainer and a basket.

4. WATER SUCTION AND DISCHARGE

3 Once water is visible in strainer cup

of vacuum pump, it is sign of suction

completed. Return the handle to

original position.

4 Open the discharge

valve.

2

Check water exiting from the vacuum

pump drain pipe. The pressure

gauge moves to the positive range.

5

Open the drain cocks.

After checking all the

water has been

drained from the

pump, close the cocks

.

1

After starting the engine,

lower the vacuum pump

handle to SUCTION side

.

5 Adjust the water

volume and pressure

controlling the

throttle dial

.

1

Open the fuel cock lever

by turning it

downward.

2 Set the throttle dial at

START

▼

SUCTION

position

.

3

Turn the main switch to

START position.

1 Battery initial charge

The battery mounted on the engine can be used immediately after filling

cells with electrolyte enclosed with battery (It is better to charge the

battery using the automatic battery charger after filling electrolyte). Do not

add distilled water because this is a sealed type battery. Please refer to the

INSTRUCTIONS on the battery.

2

Fuel & Engine oil

Fill gasoline (87 octane minimum at pump posted rating…91 based on the

research octane rating method) into the fuel tank. Fill two stroke engine oil

into the oil tank.

Maintenance after pumping seawater or foul water

After pumping seawater or foul water, flush fresh clean water

through the pump with the pump running to thoroughly clean

the inside.

And operate the vacuum pump for 5 seconds at low engine

speed in order to clean the vacuum pump

.

2. LOCATING PUMP

3. ENGINE START

WARNING

Dry running of engine for over two minutes will cause seizure

of engine parts. Start suction of water immediately after

starting engine.

Operation of vacuum pump should be completed within 30

seconds, or the pump may be damaged seriously. If no

vacuum is attained within 30 seconds, troubleshoot the

cause

.

WARNING

When delivery nozzle is not used, pumping plate must be

installed on delivery outlet to avoid engine overheating

caused by lack of cooling water.

It is necessary to take a countermeasure if the lamp is on when turning the main

switch to the position of “Operation”.

Monitor lamp

Fuel

Engine oi

l

Overheat

Level of fuel has

dropped below one

third of tank capacity

.

Supply fuel.

Supply 2 stroke engine oil.

Check the cause and remedy it. Turn the

overheat sensor switch to

“OFF” position

and start the engine. After co

nfirming the

lamp is off, return the switch to

“ON”

position.

(VC82ASE/72AS/52AS)

Oil level is below

quarter of oil tank

capacity.

Engine stops caused

by lack of cooling

water.

Lamp ON

Action required

CLOSE

OPEN

Standard Type

Discharge Valve

CLOSE OPEN

OPEN

Ball Cock Type

Discharge Valve (Option)

CLOSE

Discharge valve handle

(VC82ASE)

Fuel tank cap

Engine oil tank cap

Suction blank cap

Pump casing drain cock

Battery

If electric starter will

not work, use the recoil

starter.

Model

VC82ASE

VC72AS

VC52AS

Nozzle Dia. (mm)

19

21

22

Smallest dia.Largest dia. *

25

36

36

*The largest nozzle dia. in column is the maximum dia. at the 3m of the suction head.

MAIN

SWITCH

3

O

F

F

O

N

S

T

A

R

T

Be sure to read the instruction manual before operating

Tohatsu fire pump. Being familiar with all aspects of its

application will guarantee best performance.

The pot must

be emptied

each time.

drain pot.

Drain pot

(4) Water discharge is made by a branch pipe with nozzle

fitted. Recommended nozzle diameters are within the

range below.

6. PRECAUTIONS AFTER OPERATION

CLOSE

OPEN

スロットル

THROTTLE

低圧

LOW

低圧

HIGH

始動

START給水SUCTION

CLOSE

OPEN

Standard Type

Discharge Valv

e

ON

FUEL

燃料コック

F

U

E

L

O

F

F

FUELC OCK

CLOSED

OPEN

閉

開

O

O

C

C

For pump casing

For muffle

r

OPEN

CLOSE

Printed in Japan No.004-22015-0

Overheat

Overheat

switch

Fuel

Engine oi

l

Main switc

h

The part of rear cowl

formation is different than

one of

VC82ASE.

Vacuum pump handle

Fuel cock

Recoil starter

handle

Fuel drain po

t

Muffle

r

Carrying handle

s

Spark plug (#1)

Spark plug (#2)

Overheat switc

h

(VC82ASE/72AS/52AS

)

Floodlight projecto

r

and battery

charging socket

Monitor lamp

s

Main switch

Compoun

d

vacuum gauge

Compound

pressure gauge

Throttle dial

CLOSE

OPEN

Ball Cock Type

Discharge Valve (Option

)

QuickGuide_121022.indd 2 12.10.22 10:47:50 AM

Loading...

Loading...