Tohatsu VC52AS, VC72AS Owner's Manual

OW N E R’S

M A N U A L

VC52AS

VC72AS

PORTABLE

FIRE PUMP

No .0 03-120 5 4-3

Copyright © 2020 Tohatsu Corporation. All rights reserved. No part of this manual

may be reproduced or transmitted in any from or by any means without the express

written permission of Tohatsu Corporation.

APPLICATIONS

OF THIS FIRE PUMP

USAGE

TOHATSU fire pumps “VC52AS, VC72AS” are manufactured for use in firefighting

operations.

These portable fire pumps are intended only for firefighting activities in collaboration

with general public fire extinguishing equipment.

Using it for other applications is regarded as being used for improper purposes.

The manufacturer of these fire pumps bears no responsibility for any damages that may

result from modification of the fire pump without prior permission from the

manufacture, improper use of the fire pump, or use of the fire pump for applications

other than those stated above.

Note that the use of these fire pumps for applications other than those stated above

can result in personal injury or damage to the equipment.

Using the fire pump within the range of intended uses implies that the user should

follow the instructions provided by the manufacturer relevant to operation, servicing

and maintenance.

Intended people

All persons who operate, service or maintain the fire pump must read and understand

the following items:

・Owner’s manual

・Safety-related instructions on the pump and the other parts such as the battery.

・The other owner’s manuals, such as battery charger.

The portable f i r e pump should be operated by only persons who received training

as operators of fire engines along with each country’s (region’s) regulations.

The range of personal responsibility and supervision must be strictly defined by the

user.

If a person does not have adequate professional knowledge required for his/her

assignment, he/she must undergo relevant training or receive appropriate instructions

from an individual who is actually knowledgeable in operation of the fire pump.

A person who does not have enough knowledge is not permitted to operate the fire

pump.

When using the fire pump, conditions under which an explosion may occur are not

considered.

CAUTION

Keep this manual in a safe place for future reference.

Operators of this fire pump must always refer to all the relevant

manuals in order to avoid errors, personal injuries, and

equipment damage when operating the portable fire pump,

and to maintain faultless operation.

Arrange owner’s manual so that operators can refer to them

where they operate the fire pump.

INTRODUCTION

Thank you for purchasing the TOHATSU Fire Pump.

NOTE

This fire pump has passed a range of quality assurance standards.

Owner’s manual

The portable fire pump complies with relevant laws and regulations.

The manual includes a description for operation and maintenance. Before using this

fire pump, be sure to read and understand the manual thoroughly.

Engine operation

This manual also includes a description for operation and maintenance of the engine.

・The manual is an important item that goes with your portable fire

pump.

・This manual should accompany this fire pump if sold to another

person.

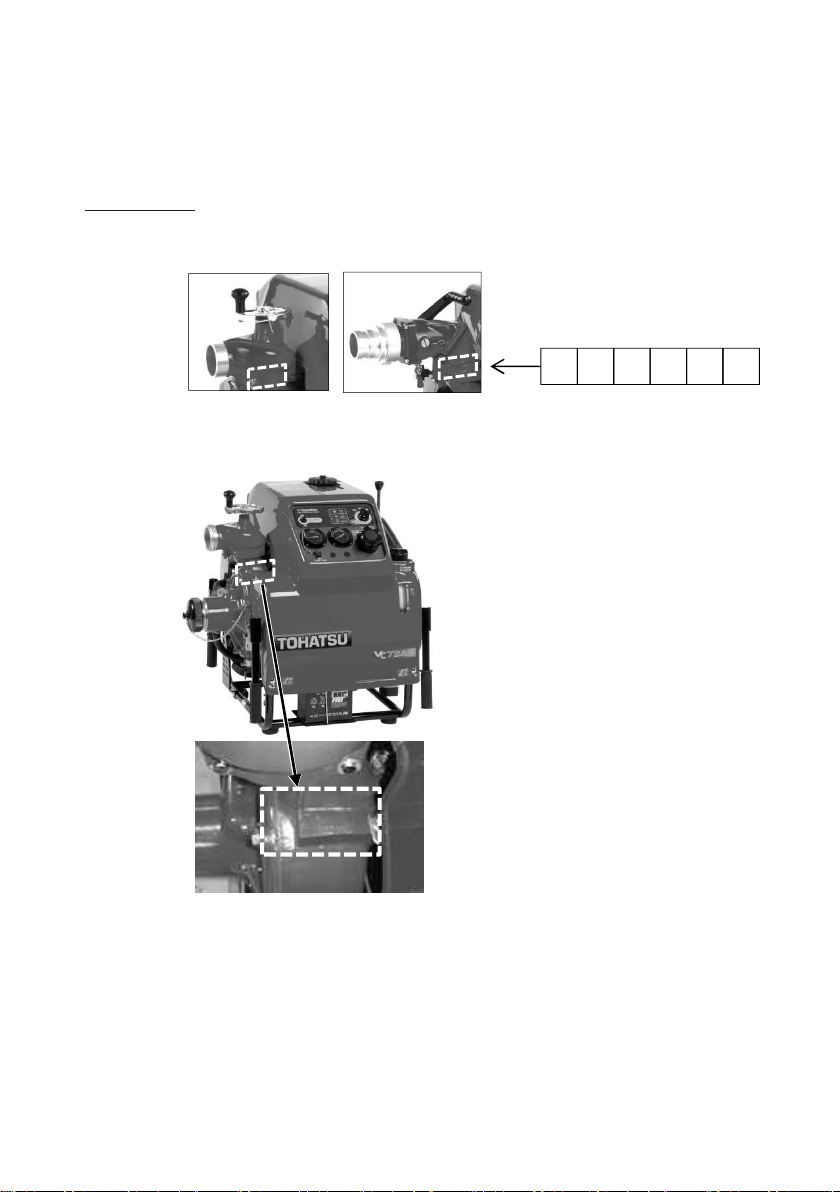

Before using this fire pump, write down the serial number in the following boxes. It will

be useful in the case of asking about servicing, repairs and genuine parts.

Serial Number

The pump serial number (identification number) is marked on the pump casing.

VC52AS

VC72AS

GENERAL SAFETY INFORMATION

CAUTION

Overview

Before operating the TOHATSU fire pump thoroughly

read this manual to understand the proper

operating procedures including “DANGER”,

“WARNING”, “CAUTION” and “NOTE”.

These notices are designed to bring attention to

very important information necessary to ensure

safe, trouble free operation.

Warning sign

Meaning

This sign is used for safety-related instructions in

this manual.

Be sure to follow all safety-related instructions,

otherwise, personal injury may occur.

Signal words

DANGER

・Failure to observe will result in severe personal injury or

death.

WARNING

・ Failure to observe could result in severe personal injury or

death.

・ Failure to observe could result in personal injury or property

damage.

・This instruction provides special information to facilitate the use or maintenance of

the pump or to clarify important points.

・For attaching position of the warning label, refer to the “CONTENT 3. LABELS”.

・Warning labels should be read clearly at any time.

If the display of the warning label becomes difficult to b e read, it was almost

come off, you must replace paste immediately.

Safety-related instructions and warning signs

Read and follow the safety-related instructions described in this manual and all

warning signs on the portable fire pump thoroughly.

Always keep the warning signs in a legible condition. If any warning sign becomes

illegible or detached, replace it immediately.

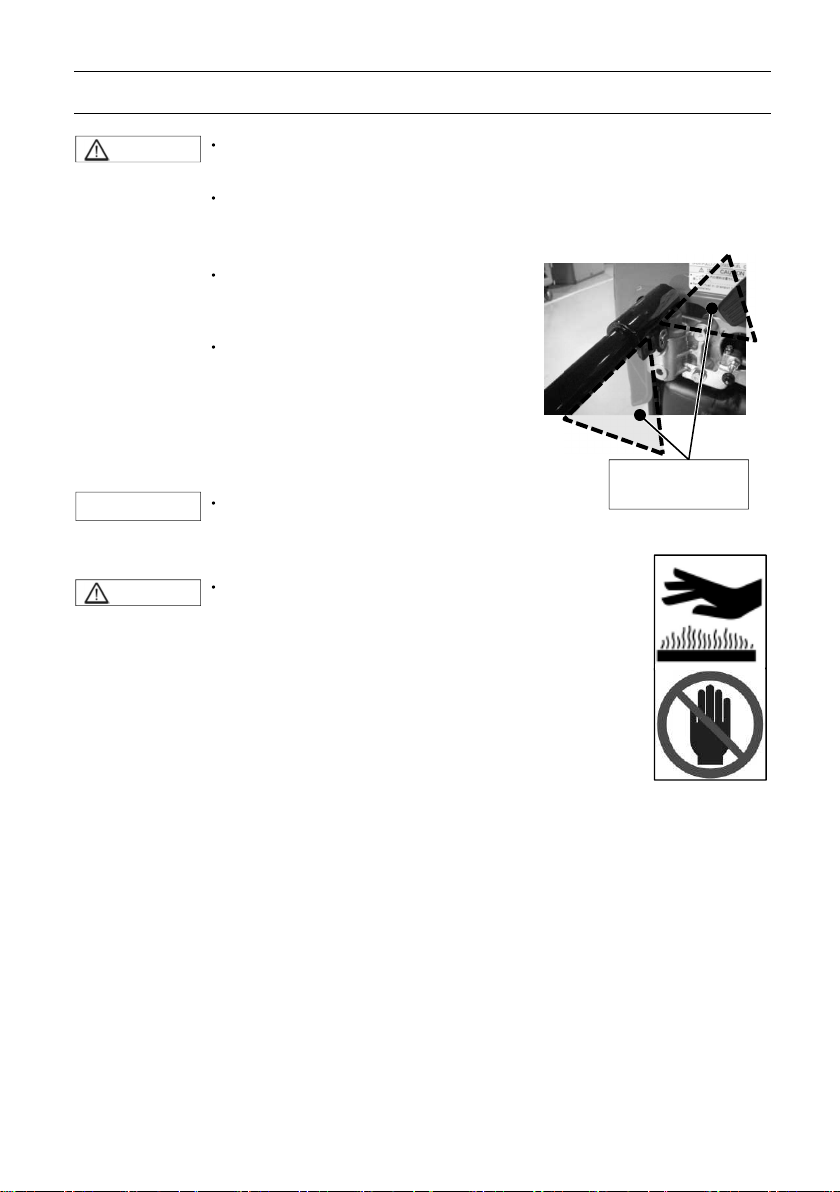

Transporting the portable fire pump

CAUTION

CAUTION

・ Retra cta ble ha ndl e is f olding

type.

・ Do not put hand or finger

between top of retractable handle

and bracket.

・ When transporting the portable

fire pump, assign one person per

handle.

・ Also, when you transport the

portable fire pump, it should be

transported holding the handle

firmly.

・ There is a risk of injury to the leg by

fall.

Durability of protection

When you purchase a new pump, it is placed in

packing box and protected.

Storage of pump after transportation

Keep the pump away from high humidity, and place

it on a horizontal plane.

Disposal of packing box

Dispose the packing box by following the

environmental laws.

Noise

・Wear proper hearing protection

during operation.

Exhaust gas

Fatal hazard from carbon monoxide (CO) poisoning

Exhaust gas emitted from the engine contains carbon monoxide (CO)

etc. that may seriously affect human health.

Do not operate the engine in a room, car, warehouse, tunnel or other

closed locations that have poor ventilation.

Safety devices

Before operating the portable fire pump, be sure to check that all

the safety devices have been installed in the appropriate positions.

Before removing the safety devices, turn the main switch off.

After protective devices (such as the muffler guard)

have been disassembled as part of servicing and

maintenance work, immediately install them back to

their original locations, making sure that they are in

safe and secure condition.

Check the portable fire pump visually and

functionally on a regular basis.

If you find any faulty device or equipment, remove

it immediately, and repair or replace it, if necessary.

Failure to do so may cause an accident.

After it has been repaired or replaced, make sure

that it functions correctly.

Protective clothing, Protective equipment

During fire extinguishing training or regular

firefighting services, wear normal protective

clothing and equipment to protect your body.

・Fireproof protective clothing

・Fireproof helmet

・Fireproof protective gloves

・Fireproof protective boots

Service, Maintenance

Servicing and maintenance of this fire pump must be carried out by

o n ly t h e persons who have professional knowledge, who are

familiar with the device, and who understand laws and regulations

regarding safety and accident prevention.

Before starting maintenance work, turn the main switch off to stop

the engine.

Disconnect the negative terminal of the battery.

Before starting maintenance work, securely place the portable fire

pump on the ground.

In the case of just after stopping the engine, do not touch the exhaust

pipe, the muffler and the other engine parts until these parts will be

cold enough. These parts could be very hot and will cause severe burns.

Electrical equipment

Only expert electricians or trained staff members

should handle electrical equipment.

When disconnecting the cable from the battery,

disconnect the negative (-) cable first.

When connecting the cable to the battery, be sure

to connect the positive (+) cable first. After that,

connect the negative (-) cable.

Do not place any metal on the top of or around the

battery. Doing so may cause a short circuit.

Use a fuse with the same specifications as the original

one when replacing it. Using a fuse that has a

greater capacity than the rated value may damage

the equipment.

Check the electrical equipment of the fire pump on

a regular basis.

Battery

Follow any safety-related instructions shown on the

battery.

The battery can generate flammable hydrogen gas

that may cause an explosion.

Do not charge the battery in closed location.

Do not smoke around the battery.

The battery electrolyte is caustic and may cause

personal injuries.

・ Always wear protective clothing.

・ Always wear protective gloves.

・ Always wear protective glasses.

・ Do not tilt the battery. Doing so may cause the

battery electrolyte to leak out from the vent hole.

Handling of fuel

Exercise care when handling fuel. Failure to do so

may cause fire.

Do not bring any flames near fuel. Stop the engine

before refueling. Do not smoke while refueling fuel.

Do not refill fuel in an enclosed room. Doing so may

cause an explosion caused by fuel fumes.

If fuel spills, wipe it with a cloth or other material,

and dispose of it according to relevant laws and

regulations.

Disposal

Dispose of disused batteries according to relevant

laws and regulations.

Genuine parts

When replacing parts for servicing and maintenance

of portable fire pumps, be sure to use only Tohatsu

genuine parts.

If genuine Tohatsu parts and accessories are not

used, it may adversely affect the functioning and

safety of the fire pump. Use genuine Tohatsu parts

only.

Tohatsu bears no responsibility for any personal

injuries or equipment damage that may result from

use of parts or accessories obtained from outside

sources.

Environmental protection measures

Dispose of oil, fuel, batteries, etc. according to

relevant environmental laws.

Do not dump waste into the ground, water, or

sewerage.

Store the fuel only in the specified container.

When disposing of parts, follow the correct disposal

procedure.

Water-prohibiting substance

Do not discharge water to water-prohibited

substance.

Use of water

Do not pump combustible liquids, chemical or

caustic liquids.

CONTENTS

1. SPECIFICATIONS……..……..….…...…..……….….……….…………..………1

2. OPERATION DEVICE……….….…..………………….…...…..…….…………5

3. LABELS……..….….……….………...…………...………...….…………….….……7

4. OPERATING PRECAUTIONS…………....…........………...……....…..…8

5. DESCRIPTION OF DEVICES……..…....……....….….….…..……….…..10

6. PREPARATION FOR OPERATION……………….…...………….…..…21

7. USE OF OPERATION PANEL…………..………...…..……………………26

8. STARTING THE ENGINE…..……….…...…….…….….…….....……....…29

9. PRIME AND DISCHARGE.……..……….….…………….……..….……..34

10. STOPPING THE ENGINE...……….………….…....…...…..…..….….…...41

11. MAINTENANCE AFTER OPERATION……..……..…..…..……..…...42

12. MAINTENANCE IN COLD CONDITION……...…...….………..….…49

13. USE OF ACCESSORY.……..….…..……………..….….…..….….….….…54

14. PERIODICAL INSPECTION…...……..…………..……........….….……..55

15. SERVICE AND MAINTENANCE….....................…......……...….…..58

16. TROUBLESHOOTING….………..….…..….….......……….….…......……69

17. APPENDIX….…..………..…………..…...…...…..……….……….….……...….83

18. TOOL AND STANDARD ACCESSORY……..…………….………..….84

19. WIRING DIAGRAM……………..……………...….…….….……..…….……..85

1. SPECIFICATION

S

Model

VC52AS

VC72AS

Description

Portable

pump

Engine

Manufacturer

TOHATSU CORPORATION

Model

2WT76AM

Type 2-stroke, water

-

cooled spark ignition engine

Bore ×Stroke

76 mm × 68 mm (2.99 in × 2.68 in)

Number of Cylinder

2

Piston displacement

617 cm

Authorized output

30kW (40.8PS)

Fuel type

Unleaded petrol RON91

Fuel tank capacity

18 L (4.76gal(US))

Fuel

consumption

9 L/h (2.38gal(US)/h)

13 L/h (3.

43

gal(US)/h)

Engine oil tank capacity

1.6 L (0.42gal(US))

Ignition

C.D.I.

Spark plug

NGK BPR7HS

-10

Starting system

Electric starter and Manual starter

Lubrication

Auto mixing

Fuel system

Carburetor

Battery

12V-16 Ah/5 h, 12V

-

18 Ah/10 h

Flooding bulb

12V-35W

3

1

1. SPECIFICATION

S

Model

VC52AS

VC72AS

Primer

Type Rotary

-

vane vacuum pump (Oil less type)

Max. suction height

Approx. 9 m (29.5 ft)

Pump

Type Single suction, single

stage, centrifugal pump

Number of delivery outlet

1

BSP thread 2

-

1/2” (male)

JIS fire thread (B

-

9912) 2

-

1/2” (male)

BSP thread

4”(male), 4

-

1/2" (

male)

JIS fire thread (B

-

9912), 3” (male), 3

-

1/2” (male)

1.45 m

3

/min at 0.5 MPa

1.43 m

3

/min at 0.7 MPa

1.15 m3/min at 0.7 MPa

1.02 m

3

/min at 1.0 MPa

Dimensions and weight

Length×Width×Height

700

× 620 × 730 mm (27.6 × 24.4 × 28.7 in)

Mass (Dry)

85 kg (187 lbs)

Engine

Crankcase, Cylinder, Cylinder head

Aluminum alloy

Crankshaft

Chromium

-

molybdenum steel

Connecting rod

Chromium

-

molybdenum

steel Piston

Aluminum alloy

Pump shaft

Chromium

-

molybdenum steel

Muffler

Steel Pump

Pump casing,

Impeller

Aluminum alloy

Shaft seal

Type Mechanical seal

Discharge port coupling

Suction port coupling

Pump performance

(Suction height: 3 m / 9.8 ft)

Materials

Pump cover

380 gal(US)/min at 75 psi

300 gal(US)/min at 100 psi

Aluminum alloy

375 gal(US)/min at 100 psi

265 gal(US)/min at 150 psi

2

1. SPECIFICATION

S

gal(

US)

/min

MPa

gal(US)/min

1.0

0

.9 0

.8 0

.7 0

.6 0

.5 0

.4 60

80

m3/min

0

.6 0

.7 0

.8 0

.9 1.0 1.1 1.2 1.3 1.4 1.5 400 350 300 250 200

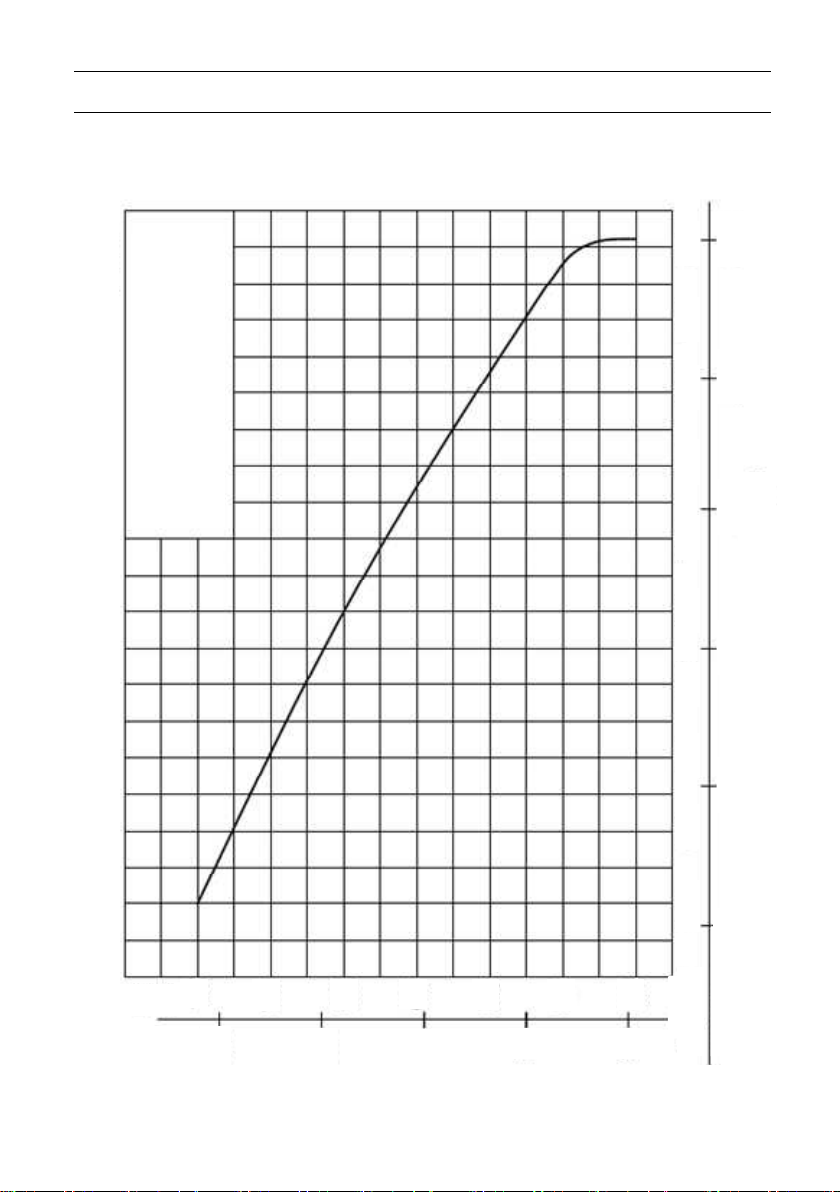

Performance Curve

VC52AS

Suction hose dia. :3’’

Suction hose length :6m

Suction hose height :3m

PERFORMANCE CURVE

psi

Discharge

140

120

100

Pressure

3

1. SPECIFICATION

S

MPa

m3/min

80 100 120 140

0

.8

0

.6

0

.8 0

.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 450 400 350 300 250

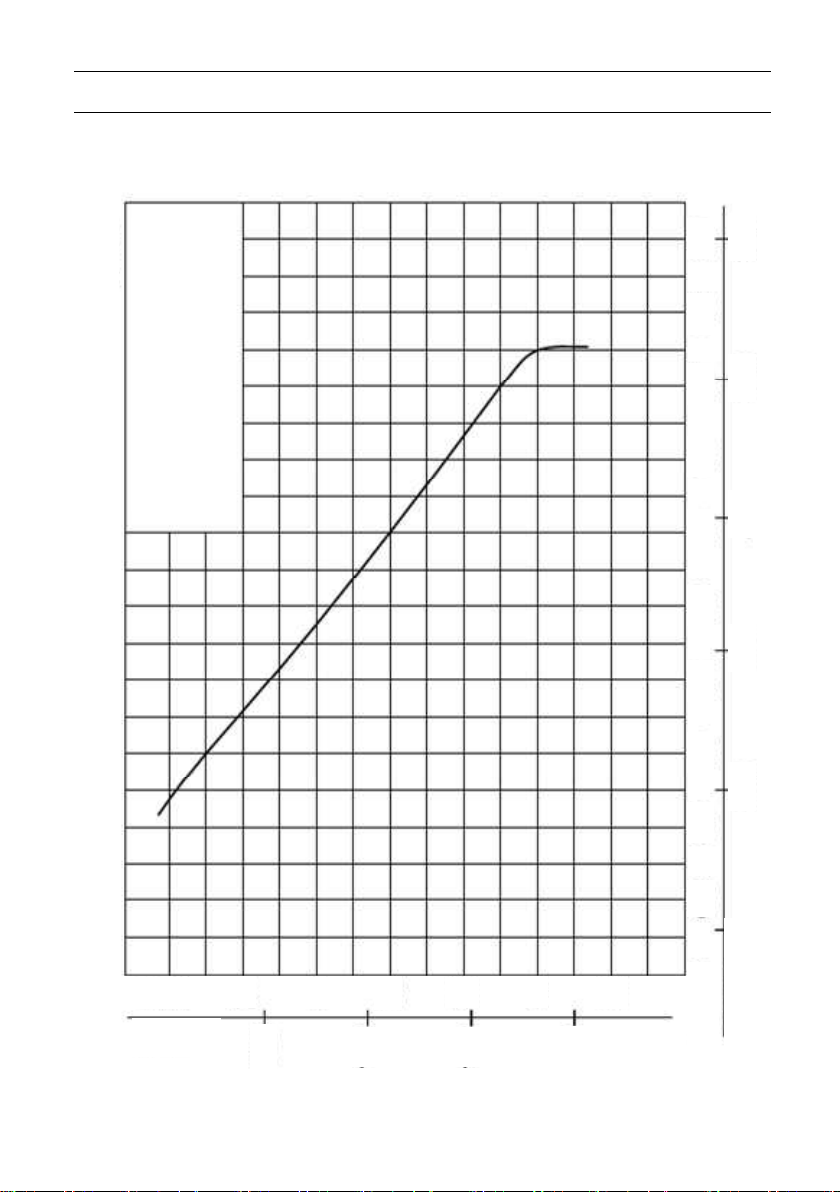

Performance Curve

VC72AS

PERFORMANCE CURVE

Suction hose dia. :3’’

Suction hose length :6m

Suction hose height :3m

psi

Discharge

1.0

0.9

0.7

Pressure

0.5

gal(US)/min

4

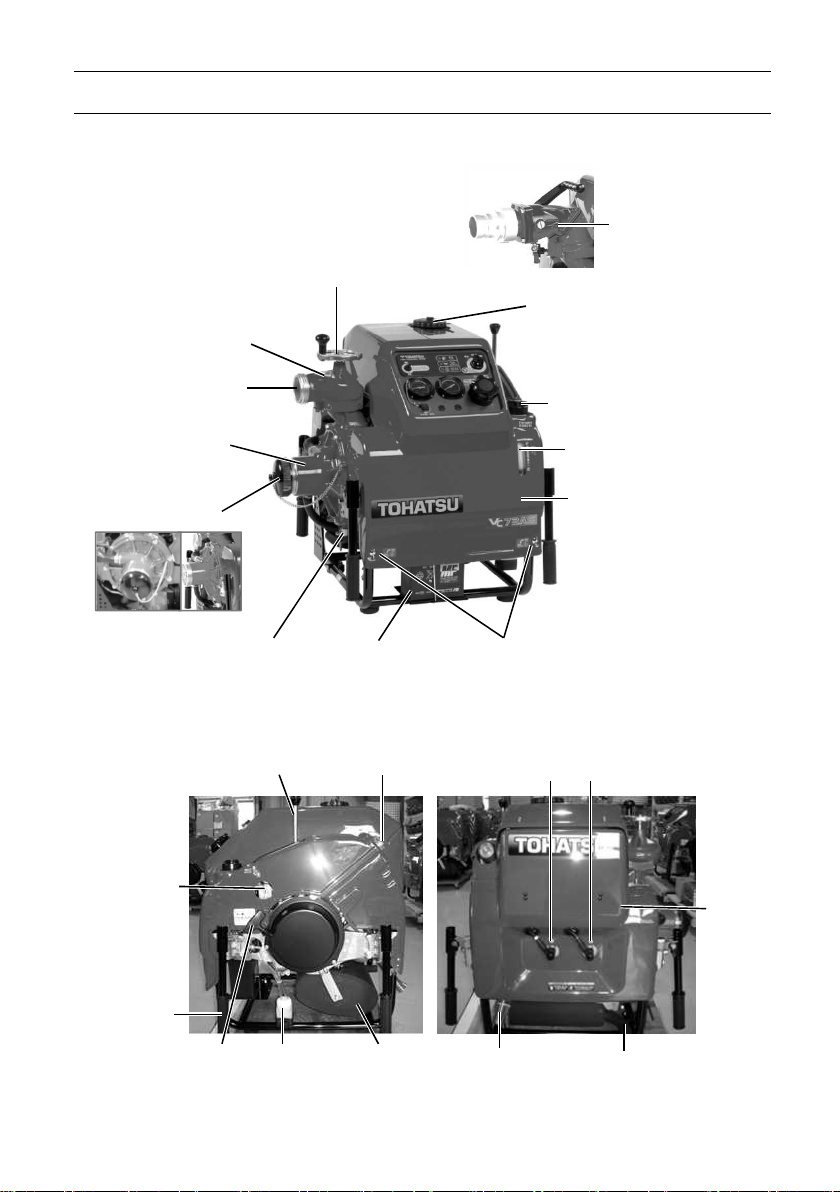

2. OPERATI

O

N DEVICE

Engine oil tank

Battery

Discharge valve

(Ball cock type)

Suction port

Suction hose

coupling (cap)

Carrying

Manual starter

Fuel drain pot

Muffler

Priming outlet

Exhaust pipe

Real

Discharge valve

Discharge port

Fuel cock

Handles(4)

handle

Discharge valve handle

Pump casing drain cock

Priming lever

Primer strainer

Fuel tank cap

Engine oil tank cap

Front cowl

Knob (wing screw)

Spark plug (#1)

Spark plug (#2)

cowl

5

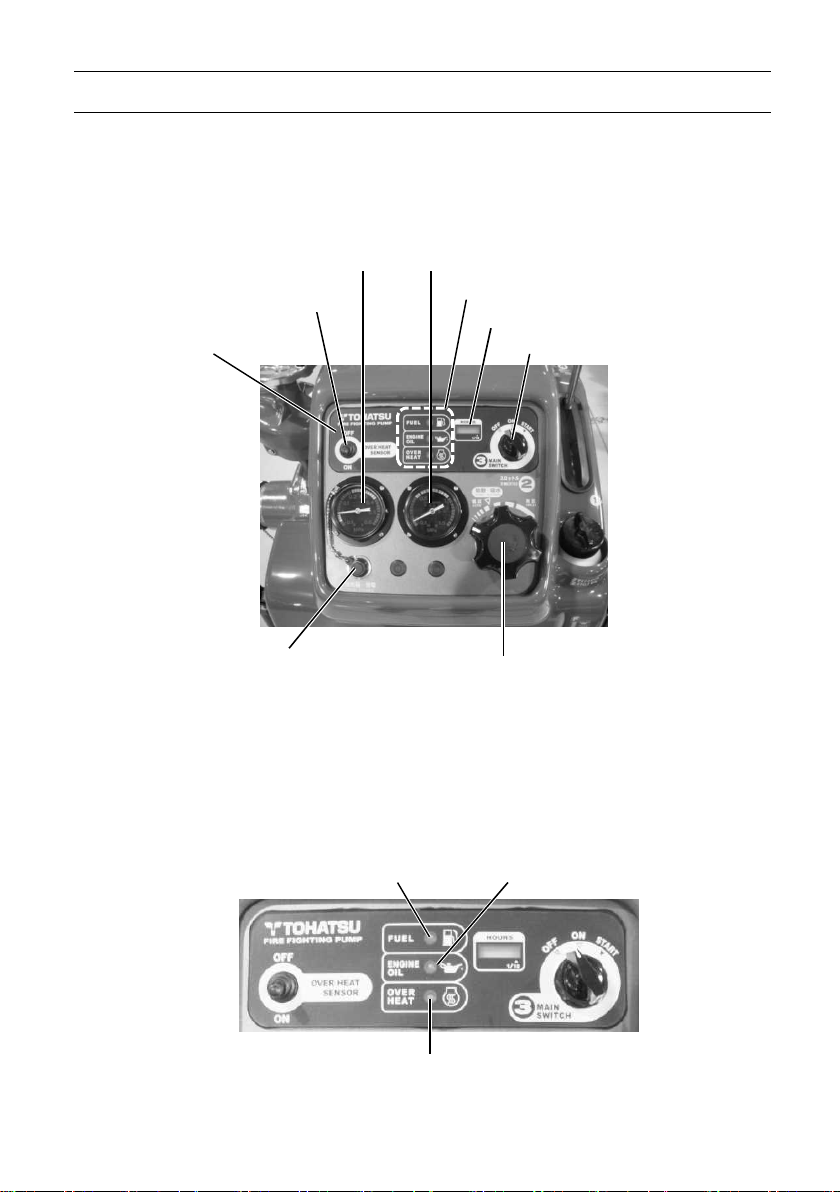

2. OPERATI

O

N DEVICE

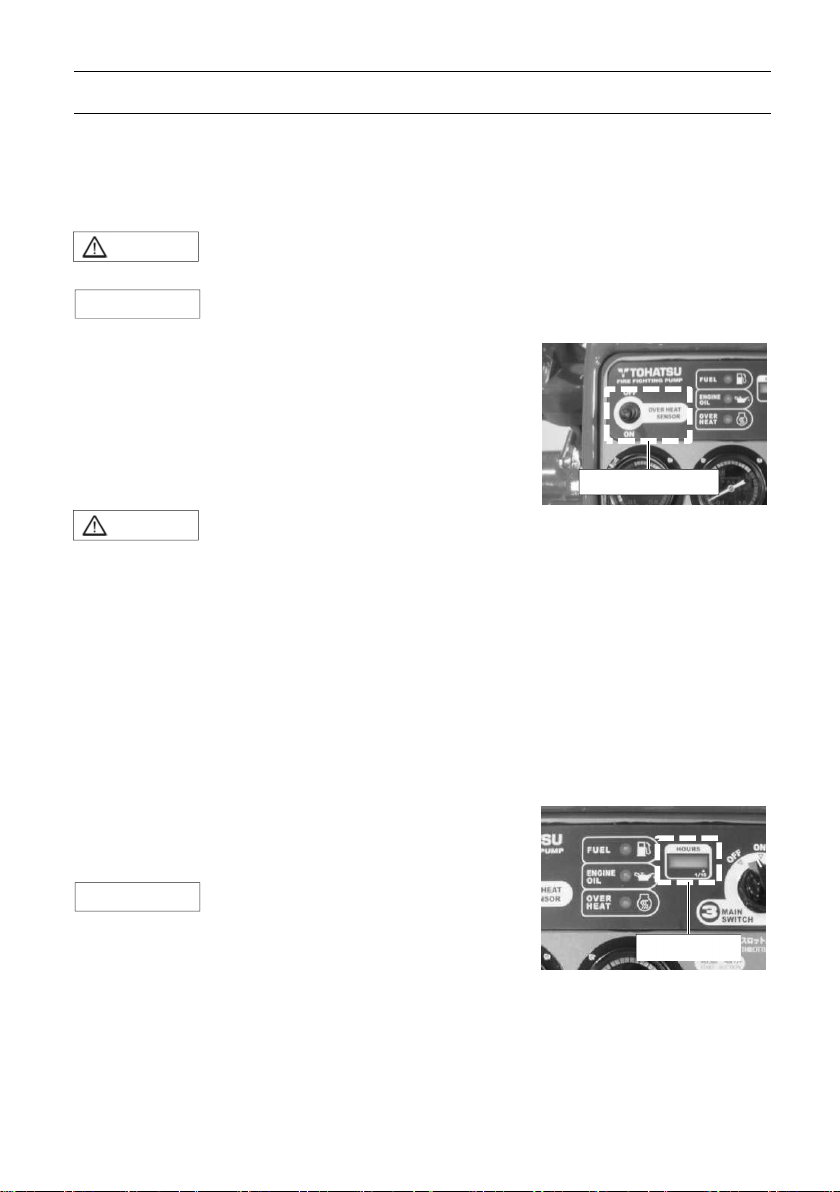

Monitor

lamps

Hour meter

Main switch

Control panel

Operation panel warning lamps

Pressure gauge for suction

Overheat switch

Operation panel

Floodlight projection and battery

charging socket

Fuel Engine oil

Pressure gauge for discharge

Throttle dial

Overheat

6

3. LABEL

(Pulley for Vacuum pump)

WARNING & CAUTION

On the fuel tank ~ Inside of the cowl

7

4.

OPERATING PRECAUTION

S

CAUTION

Installing pump

The fire pump must be installed on a level ground. Otherwise, an

accident may occur.

If the fire pump should be installed on uneven ground, it must be

secured.

NOTE

Place the pump as near as possible to water source, and water

suction height as low as possible.

When putting the portable fire pump down to the ground, put it

gently and horizontally.

In case of the inclined location or uneven ground, make sure that

water suction hose is located lower than suction port of the pump.

In case of the suction hose is put undulated, air can be left easily in

the hose, and possibly cause suction inability when the water

discharge valve is opened.

In case of the suction inability due to air remaining in the suction

hose, set the water discharge valve half-opened, and operate

vacuum pump until water is discharged continuously. (for 3 to 5

seconds from beginning of water discharge).

Be sure to install strainer and basket on the end of suction hose. If

the pump may suck sand or mud of the bottom of water source,

place sheet below the basket.

Strainer and basket of suction hose should be placed more than 300

mm (11.8 in) below water surface to prevent suck of air.

Discharge hose should be arranged not to be bent.

8

4.

OPERATING PRECAUTION

S

CAUTION

Do not put your

CAUTION

When installing the portable pump in the vehicle, place the

vehicle on a level place, and install the pump.

When installing the portable pump in the vehicle, make sure to

apply the brakes of the vehicle in order to stop the wheels. A

serious accident may occur if the vehicle moves.

Do not put your hands or fingers in

the retractable part when operating

the handle.

When transporting the portable fire

pump, assign one person per handle.

Also, when you transport the

portable fire pump, it should be

transported holding the handle

firmly.

NOTE

When lowering the portable fire pump

to the ground, lower it gently and

horizontally.

Do not touch the exhaust pipe and the muffler

while the engine is running, or for more than 10

minutes after the engine has been stopped.

These parts are very hot and will cause severe

burns.

hands or fingers

9

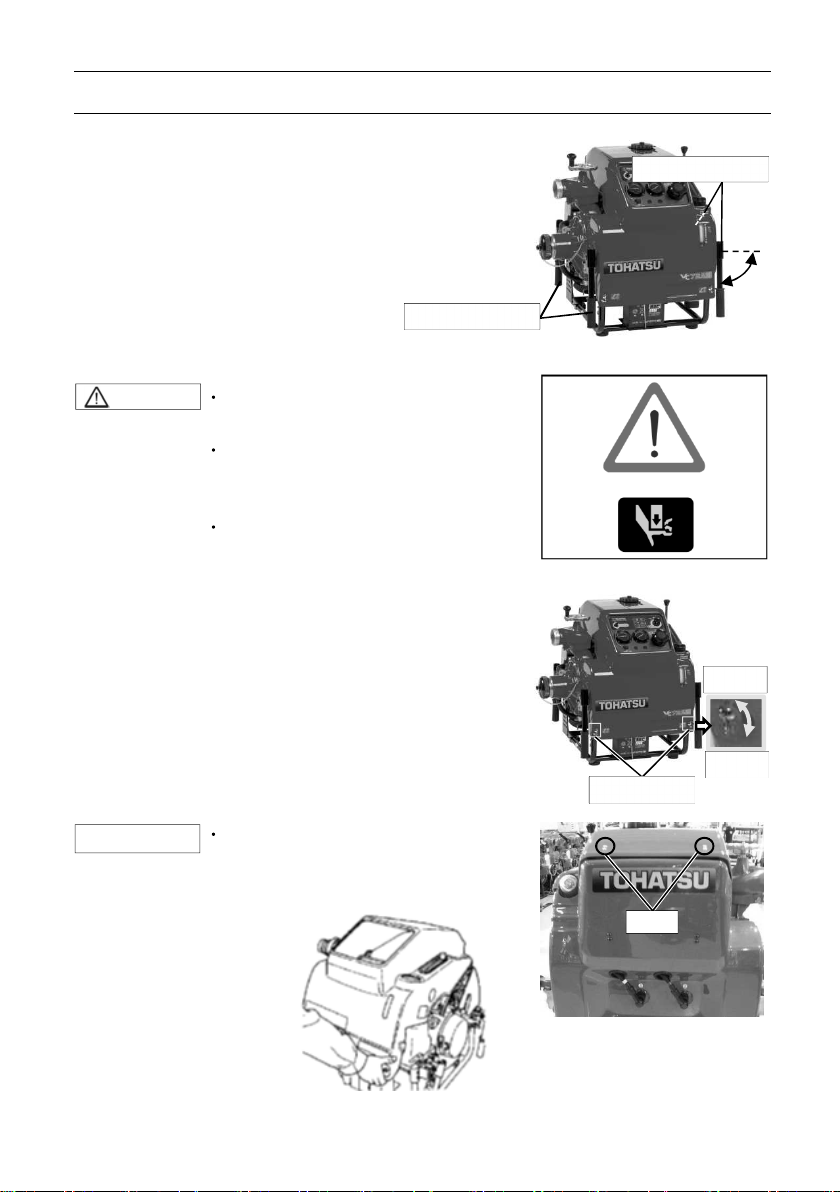

5. DESCRIPTION OF DEVICE

S

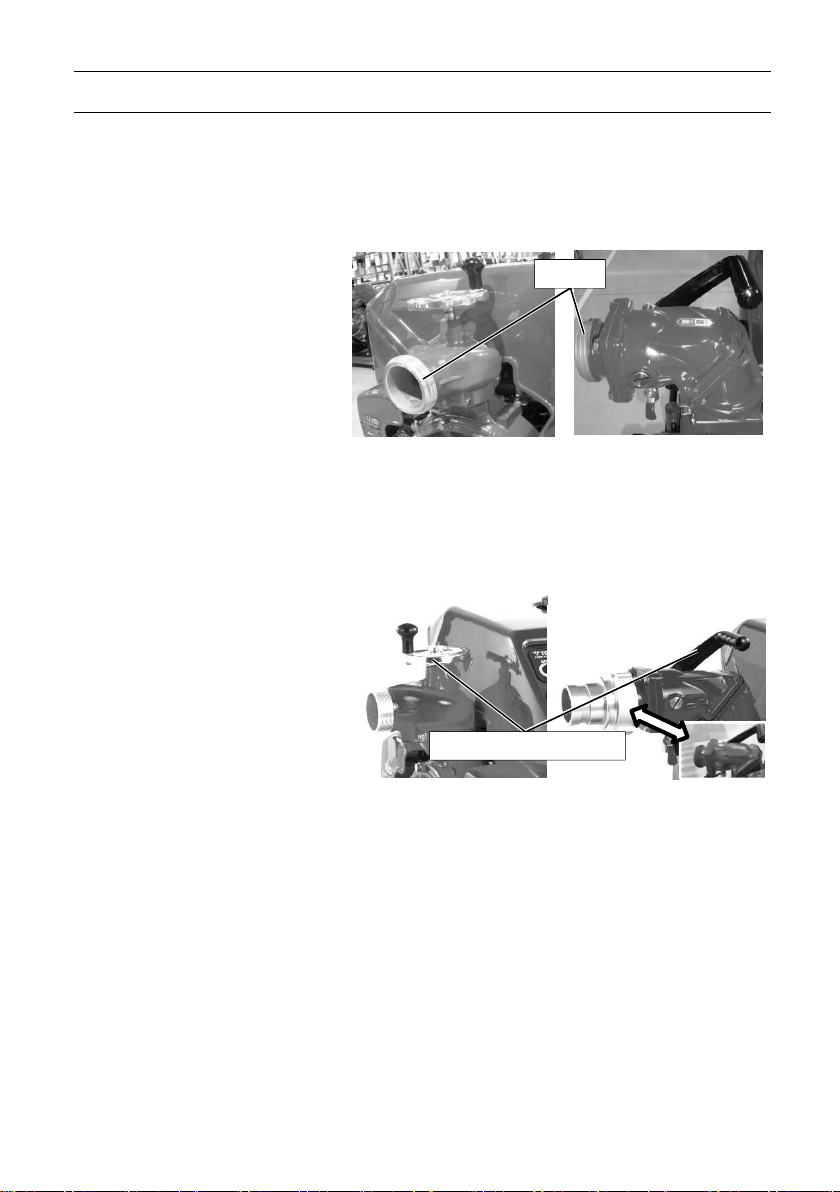

Carrying handle

Carrying handle

CAUTION

Wing screw

Open

Close

NOTE

Hook

Carrying handle

The fire pump is equipped with four carrying handles.

The handles can be folded manually, and opened by

rotating them by 90 degrees.

Personal injuries may occur when

opening or closing the handle.

Do not put your hands or fingers

into the retractable part when

operating the handle.

To prevent injuries, two persons

should work together when carrying

and placing the pump.

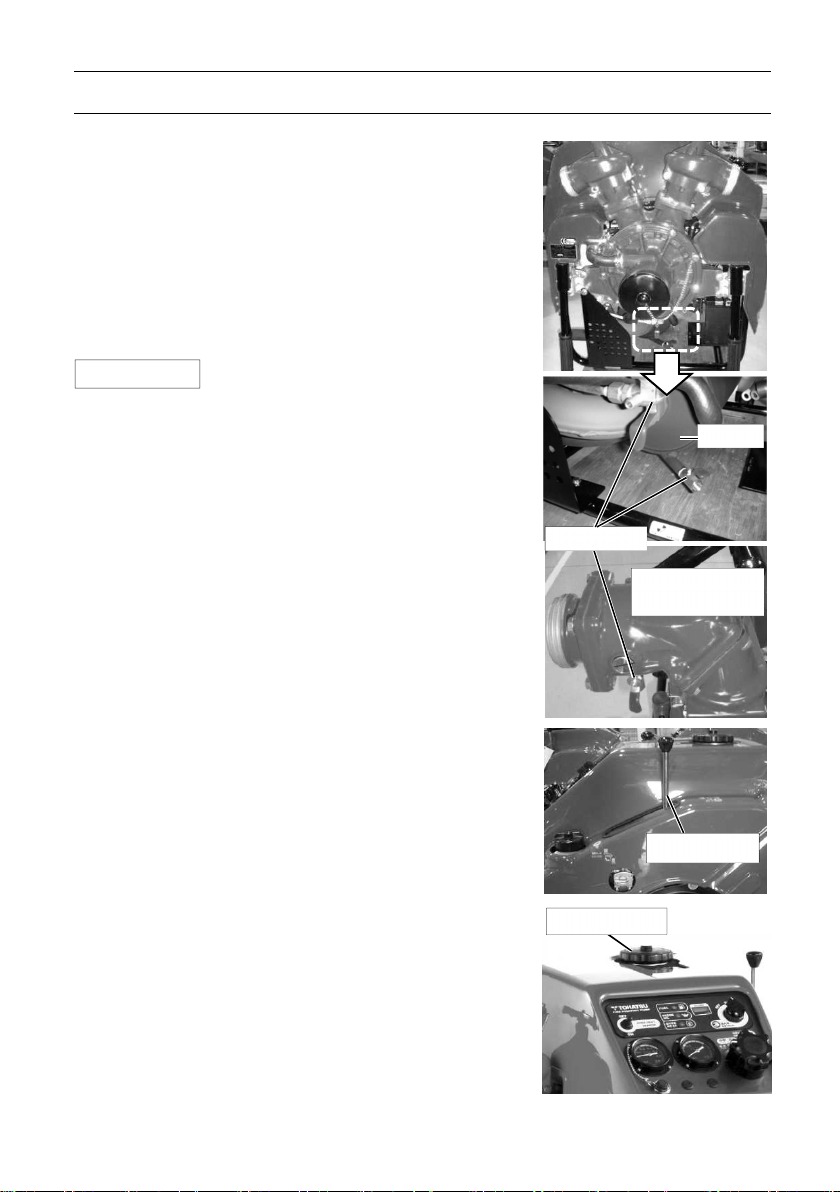

Opening the cowl

Front cowl

When you remove the front cowl, turn the 2 wing screws

at the front cowl and release the lock on each screw.

Release the 2 hooks up at the back side of the pump.

Lift the front cowl toward upper side.

When removing the cowl, do not use

excessive force with care to avoid

damaging the hook, cowl or other

parts.

10

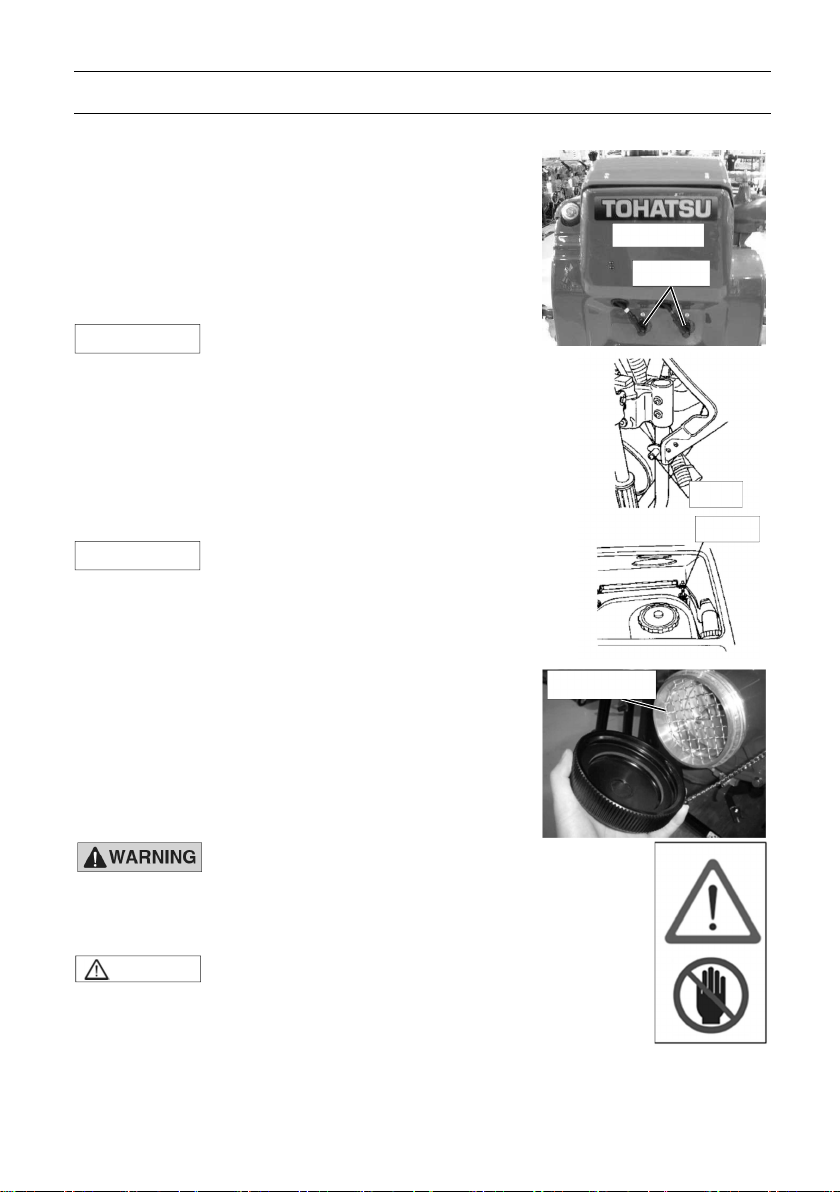

5.

DESCRIPTION OF DEVICE

S

Rear cowl

Plug cap

Pin Hook

Suction port

CAUTION

Rear cowl

・ When you remove the rear cowl, detach the two plug

caps from the spark plugs.

・ Pull open the cowl at around the support pin.

・ Remove the plug caps through the holes in the cowl.

・ Lift the rear cowl toward upper side.

NOTE

Assembling the cowl

Assembling order is in reverse order of the opening.

The hooks (at 2 locations on the cowl) must be aligned

to sockets of the grommet before insert firmly.

・ Remove the front cowl first, and the

real cowl second.

NOTE

Suction port

The diameter of the thread for the fire pump is

BSP thread 4” (male), 4-1/2” (male)

JIS fire thread (B-9912), 3” (male), 3-1/2” (male)

・ Assemble the rear cowl first, and the

front cowl second.

・ When the pump is running, do not

put your finger Into the suction port,

you may be seriously injured by the

rotating inducer.

・ If the pump runs without a strainer,

gravel may enter the pump,

resulting in significantly reduced

water discharge capacity.

11

5. DESCRIPTION OF DEVICE

S

Screw down discharge

Ball valve discharge

Thread

Screw down discharge

Ball valve discharge

Discharge valve handle

Discharge port

The diameter of the thread for the fire pump is

BSP thread 2-1/2” (male)

JIS fire thread (B-9912) 2-1/2” (male)

Discharge valve

Use the discharge valve handle for opening and closing the discharge valve.

Valve (Single outlet)

valve (Single outlet)

Valve (Single outlet)

valve (Single outlet)

12

5. DESCRIPTION OF

DEVICE

S

Drain valve

Muffler

Ball cock

Priming

lever Fuel tank cap

Drain valve

Use the drain valves to drain water.

Drain valves;

- at the pump case

- at the muffler

- at the ball cock discharge valves (Only for ball cock

discharge valve type)

NOTE

Priming lever

Use for suctioning water.

After starting the engine, pull down the priming lever to

suction water.

After priming has been completed, return the priming

lever to its original position.

Fuel tank

Refill appropriate amount of gasoline to the fuel tank.

Close the fuel tank cap all the time except refuel.

・ Close all the valves when operating

the fire pump. If the valve is opened,

water cannot be suctioned.

Discharge valve

13

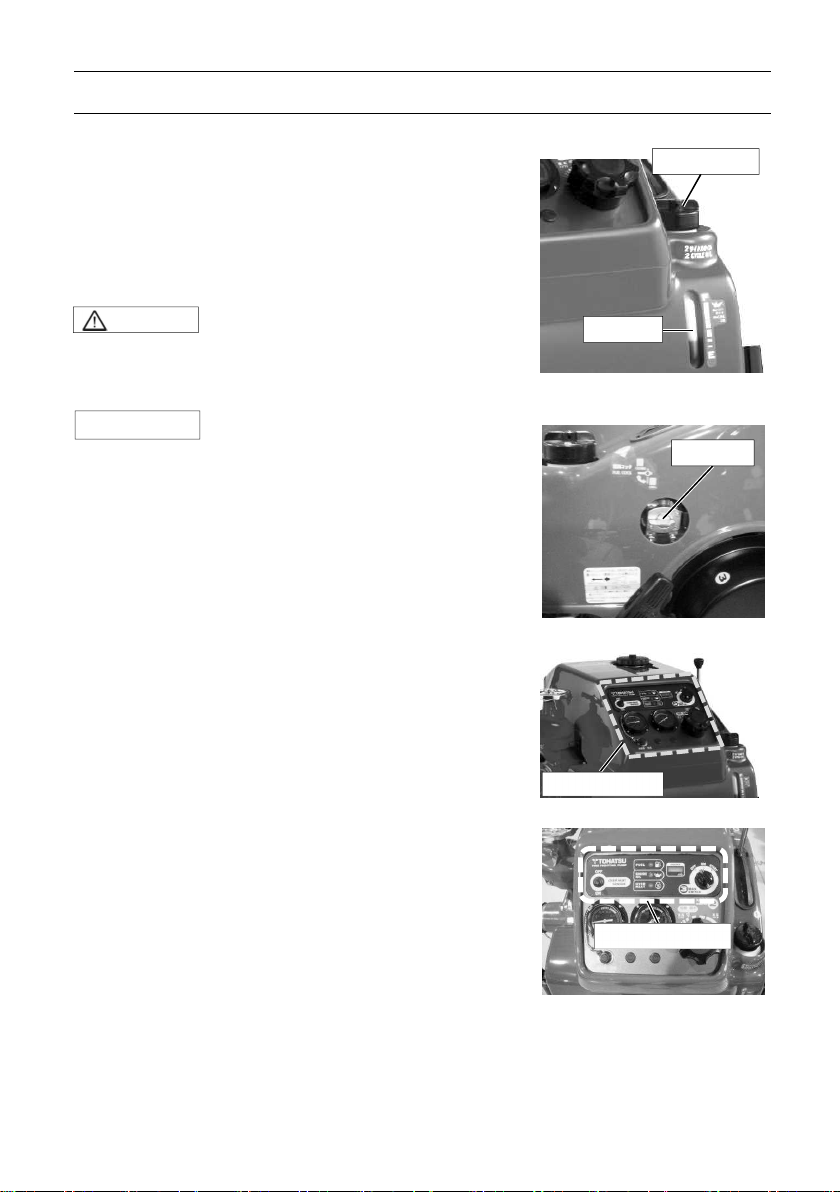

5. DESCRIPTION OF DEVICE

S

Control panel

Operation panel

CAUTION

Oil tank cap

Oil tank

Fuel valve

Engine oil tank

Refill appropriate amount of oil to the oil tank.

Close the Oil tank cap all the time except filling.

The oil tank has an oil level sensor.

The warning buzzer sounds, if the engine oil is not

enough filled.

・ If you run the pump despite of the

warning buzzer sounds, the engine

could have damages and/or be

stuck.

NOTE

Fuel valve

Full open or close completely.

Control panel

The control panel is equipped with all the necessary

operating and control instruments as follows.

Operation panel

The operation panel is equipped with

・ Fill the 2-stroke engine oil until the oil

level warning buzzer does not sound.

・ Main switch

・ Warning lamp : Fuel, Oil, Over heat

・ Hour meter

・ Over-heat switch

14

5.

DESCRIPTION OF DEVICE

S

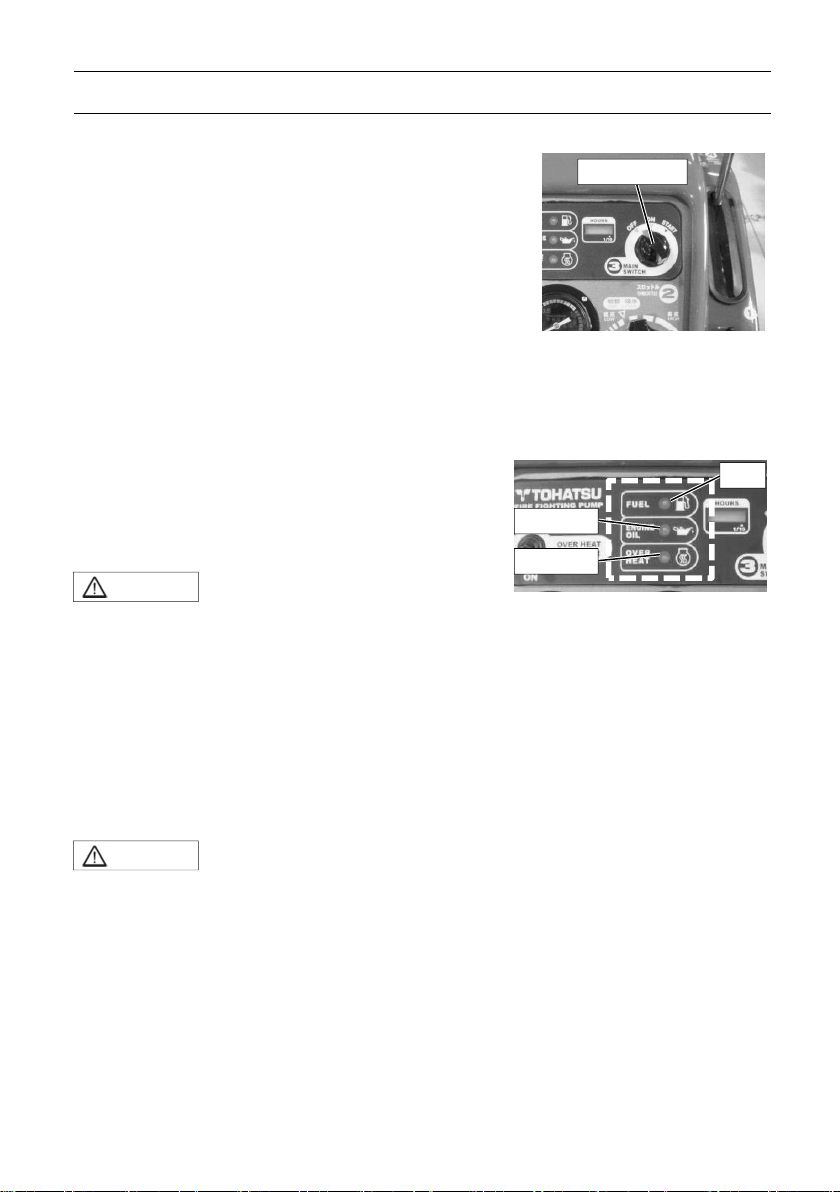

Main switch

Fuel Engine oil

Overheat

Main switch (Stop switch)

Turn the Main switch to run or to stop the pump.

Description Function

OFF To stop the pump

ON Running position

START To start the pump running

Warning lamp and Warning buzzer

Turning the start switch “ON” position, if there is no problem in the engine to start,

the warning lamps and buzzer are off. If there some problems in the pump, the

monitor lamps light on when you turn the start switch on. The warning lamps and the

buzzer indicate the following information:

Warning lamp: Fuel, Engine oil, Overheat

Warning buzzer alarms: Engine oil

CAUTION

-Low fuel level warning

If the fuel level goes down below approximately 1/3 of the fuel tank, monitor lamp

lights up.

・ If they do not, remove the cause

by following the content ”16

troubleshooting” section.

-Low engine oil warning

If the engine oil level goes down below approximately 1/3 of the engine oil tank,

warning lamp lights up and the warning buzzer sound.

CAUTION

・ Refill the engine oil immediately. Even if the warning lamp lights

up and the buzzer sound, the engine will not stop soon.

However, refill the engine oil immediately to avoid the engine

stuck risk.

15

5.

DESCRIPTION OF DEVICE

S

Overheat switch

Hour meter

NOTE

-Overheat warning

If the engine overheat caused by lack of cooling water, etc. then the overheat lamp

lights.

CAUTION

NOTE

Overheat switch

The overheat sensor switch should be always set in “ON”

position to avoid a malfunction or destruction of the

engine by overheating.

CAUTION

In the case of the switch “ON”, the engine will stop, the lamp turns on and buzzer

sound when the overheat sensor works.

In the case of the switch “OFF”, the engine will not stop, the lamp turns on and buzzer

also sound when the overheat sensor works.

The engine can be started if the switch is at “OFF” position.

Hour meter

The hour meter indicates the accumulated operation

time of the fire pump.

・ The engine may be damaged. Do not restart the engine soon after

stopped running.

・ In the case of the overheat sensor switch is set in “ON” position, the

engine stops automatically when an overheated is detected.

・ Restarting without treating with the cause of overheating may

cause the engine condition become worse or be damaged.

In particular, with regard to trouble that occurs in the suction

line, cooling line, fuel line and engine itself, remove the cause

and then restart the engine.

・ Make sure that the warning lamp and the buzzer have turned off.

・ Use it to check the running time.

・ The meter continues counting as long

as main switch is “ON”

16

5.

DESCRIPTION OF DEVICE

S

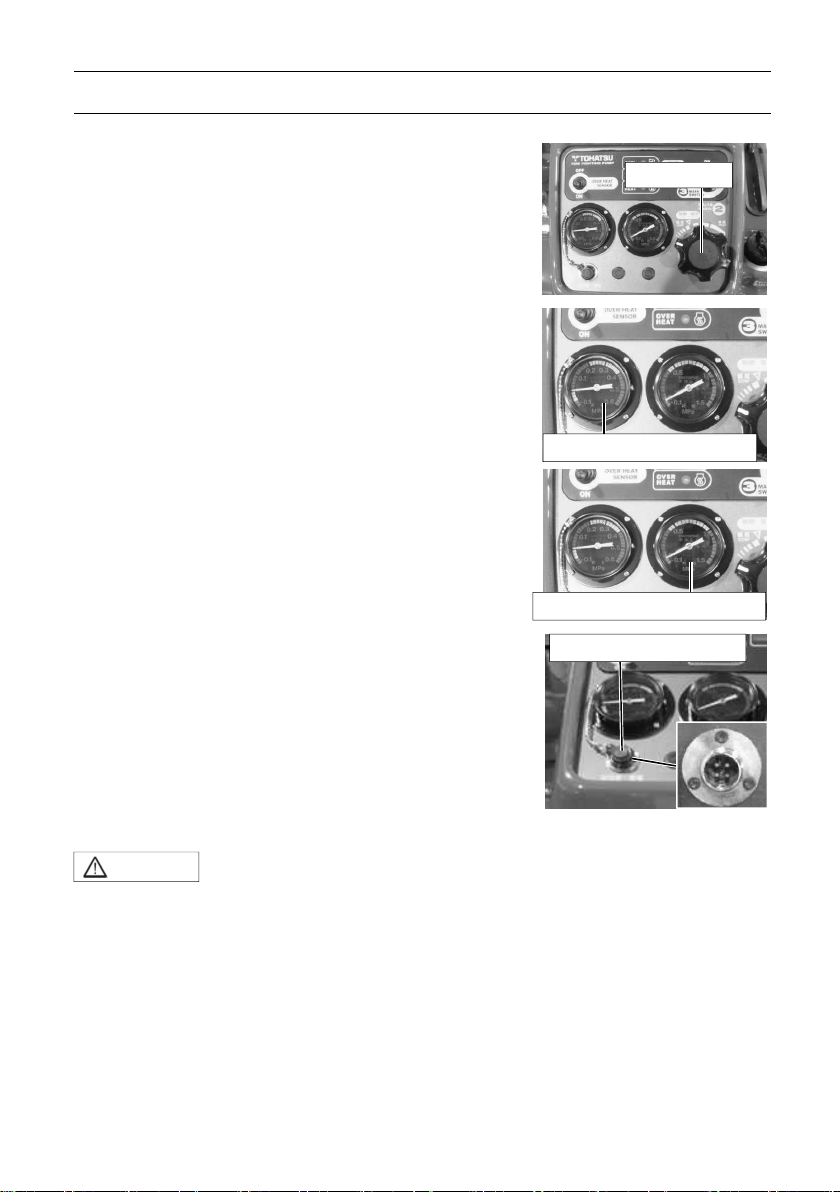

Throttle dial

Pressure gauge for suction

Pressure gauge for discharge

Battery charger socket

Throttle dial

Use the Throttle dial to control discharge pressure.

Pressure gauge for suction

The pressure gauge for suction indicates the actual

operating pressure.

Pressure gauge for discharge

The pressure gauge for discharge indicates the actual

operating pressure.

Battery charger socket

Connect the battery charger plug to the socket when

charging the battery of the pump.

<Specifications of accessory socket>

・ Voltage: DC12V

・ Max. allowable current: 5A

CAUTION

・ Before charging a battery, turn the main switch OFF.

・ When starting operation, make sure to remove the battery

charger before turning the main switch ON.

・ The socket is for a battery and a floodlight.

・ Do not connect a cigarette lighter to the socket, because it is not

a heat-resistant object.

17

Loading...

Loading...