TOHATSU TLDI 40, TLDI 50 Service Manual

SERVICE MANUAL

OIL

WASH

OILLEVEL

B

Chapter 1 Specifications

1. Specifications Table ......................................................................1-3

2. Outline Dimensions .......................................................................1-4

3. Background on TLDI......................................................................1-6

1

1-2

1-3

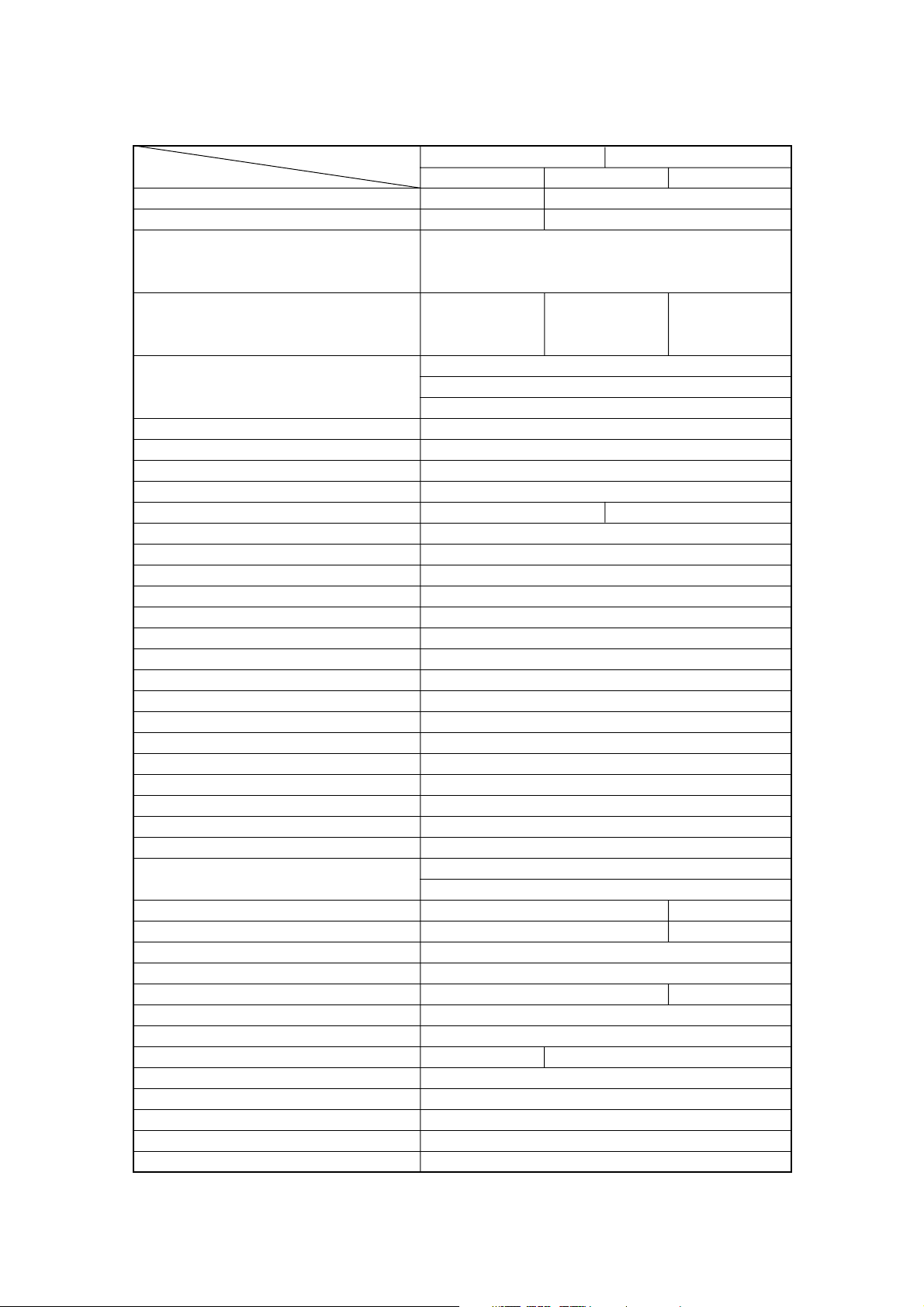

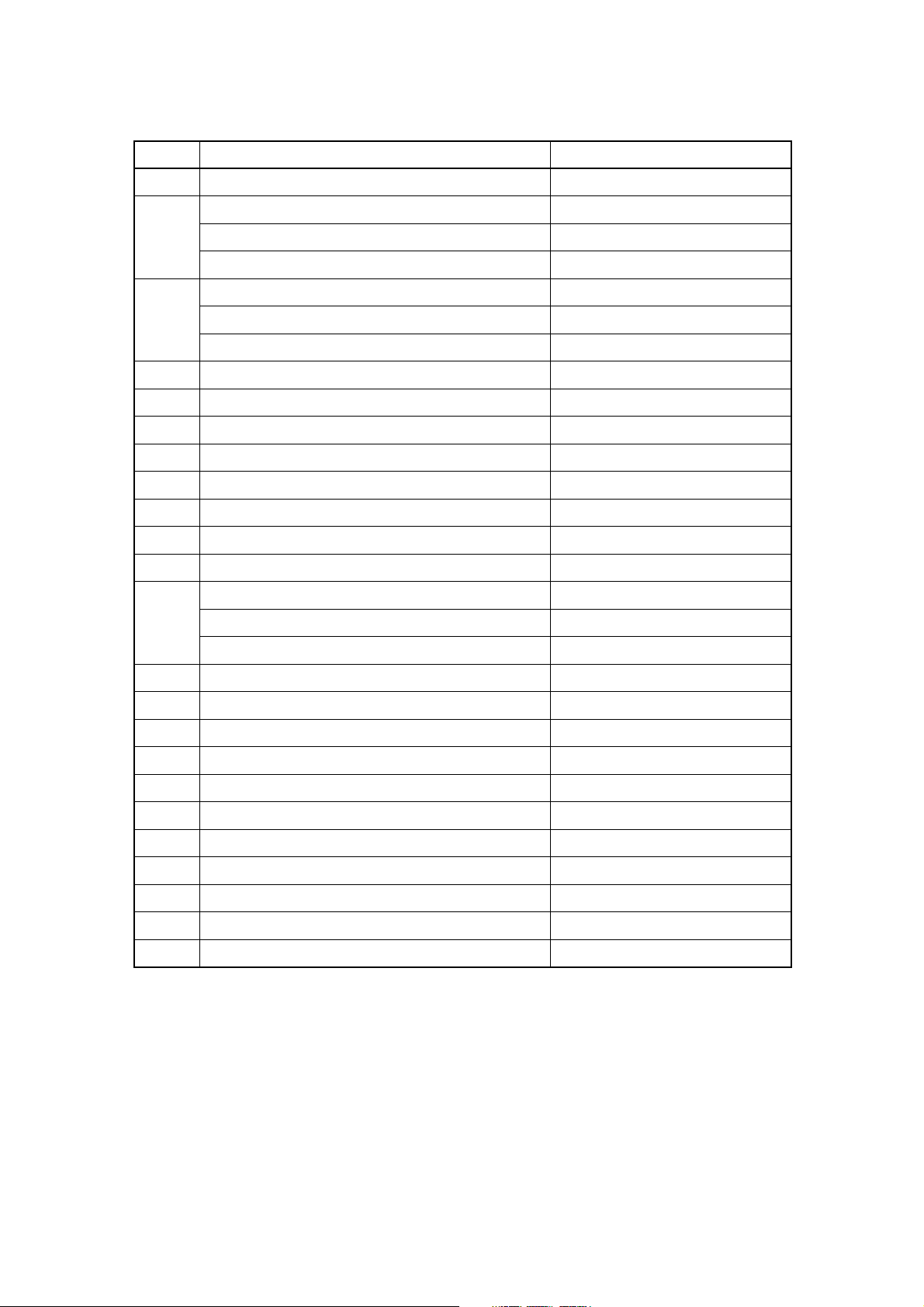

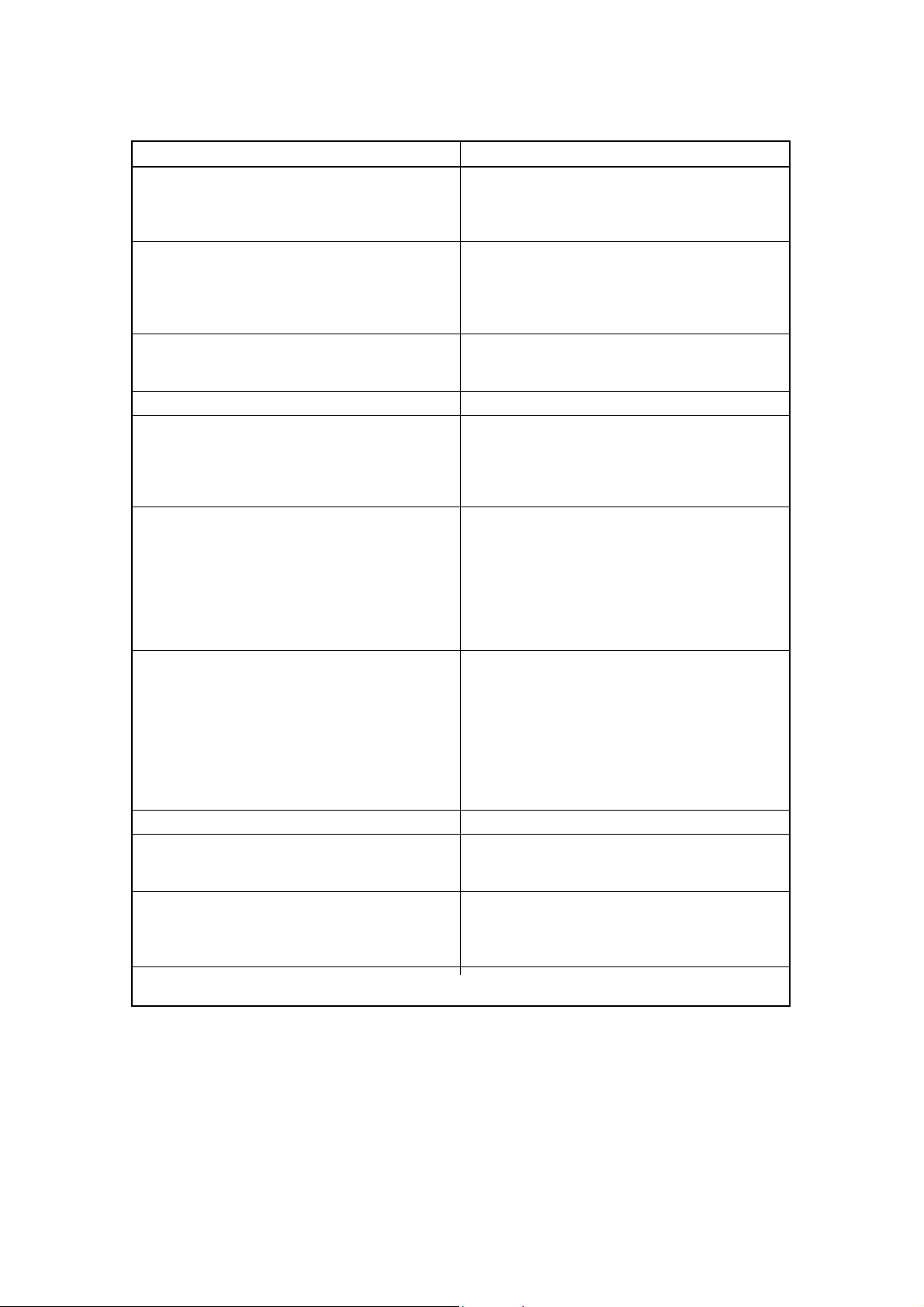

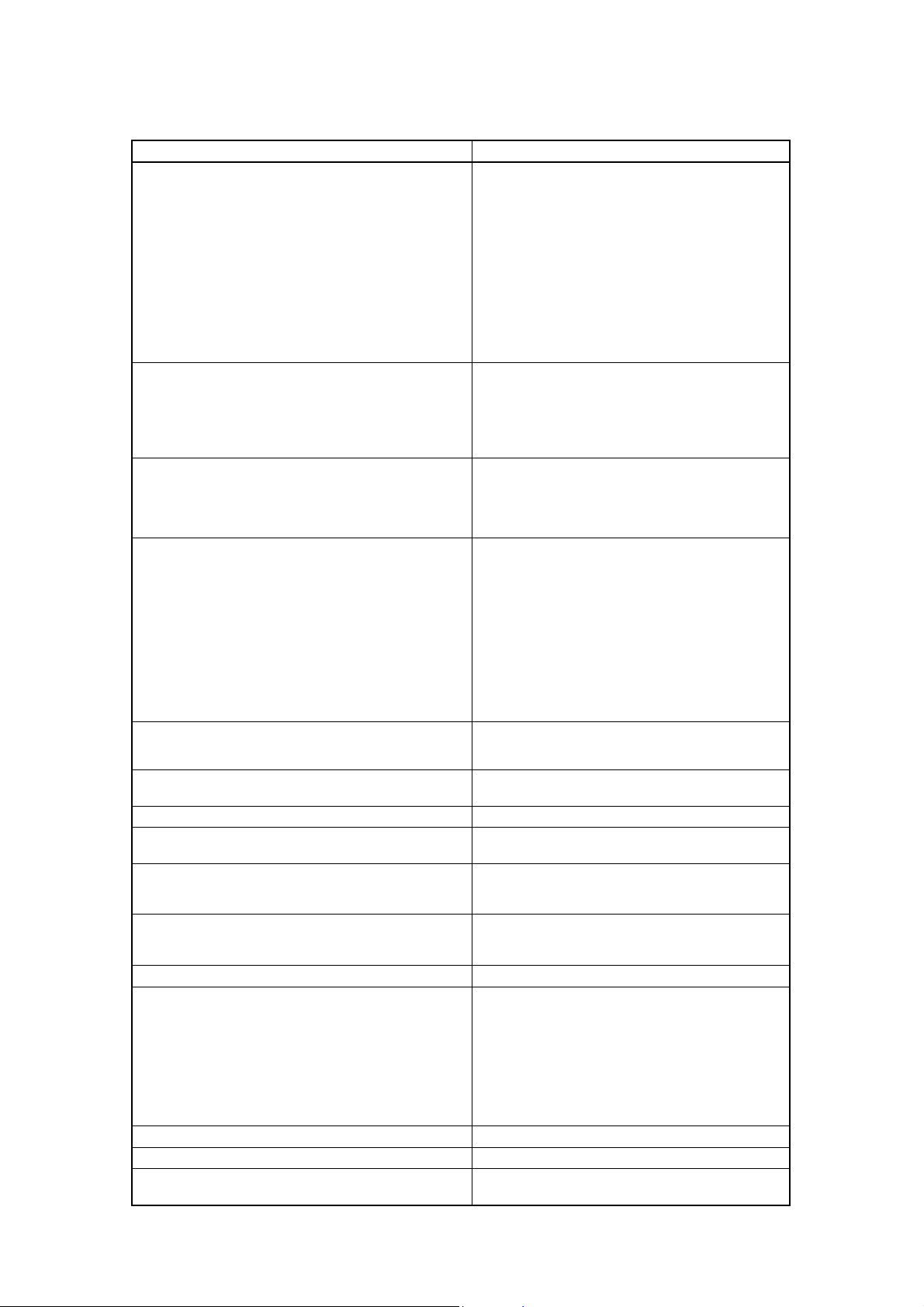

1. Specifications Table

MODEL

40A 50A

Item

EPTO EFTO EFO

Overall length (approx.) 630 mm (24.8 in) 1120 mm (44.1 in)

Overall width (approx.) 345 mm (13.6 in) 384 mm (15.1 in)

Transom (S) 1227 mm (48.3 in)

Overall height

Transom (L) 1354 mm (53.3 in)

(approx.)

Transom (UL) 1481 mm (58.3 in)

Transom (S) 95.5 kg (211 lb) 98.5 kg (217 lb) 88.5 kg (195 lb)

Weight

Transom (L) 96.5 kg (213 lb) 99.5 kg (219 lb) 89.5 kg (197 lb)

(approx.)

Transom (UL) 99.0 kg (218 lb) 102.0 kg (225 lb) 92.0 kg (203 lb)

Transom (S) 403 mm (15.9 in)

Transom length

Transom (L) 530 mm (20.9 in)

(outboard)

Transom (UL) 657 mm (25.9 in)

Engine type 3-cylinder inline

Piston displacement 697ml (42.5 cu.in)

Bore & stroke 68 mm (2.68 in) x 64 mm (2.52 in)

No. of cylinders 3

Maximum output 29.4 kW 36.8 kW

Full-throttle range 5150~5850 rpm

Trolling 700 rpm

Idling 700 rpm

Full-throttle fuel consumption (approx.) 17 L/Hr (4.5 US gal/Hr)

Starting system Electric starter motor

Intake system Reed valve

Scavenging system 5-port loop

Exhaust system Through hub

Lubrication system Auto-mixing

Cooling system Forced water-cooling

Water temp. control Thermostat

Ignition system L-CDI

Ignition timing control Electronically advanced

Firing order 1-2-3

Sparkplug Champion RC10ECC

Alternator 12V 280W

Battery

12V 100AH

12V 120AH (0°C or low)

Trim angle 8°~24° 4°~24°

Trim angle settings 5 6

Maximum tilt-up angle 75°

Transom board thickness 31~70 mm (1.22 ~ 2.76 in)

Maximum steering angle 70° 80°

Gear shift Dog clutch (F-N-R)

Gear ratio 1.85 : 1 (13 : 24)

Throttle control Remote-control Tiller handle

Fuel tank 25L (6.60 US gal)

Oil tank 2L (2.1 US qt)

Fuel Unleaded regular gasoline

Engine oil Genuine engine oil or TC-W, 2-stroke marine outboard oil*

Gear oil Genuine gear oil (500 ml) or API GL5, SAE #80

*: Only those products that have been approved.

1-4

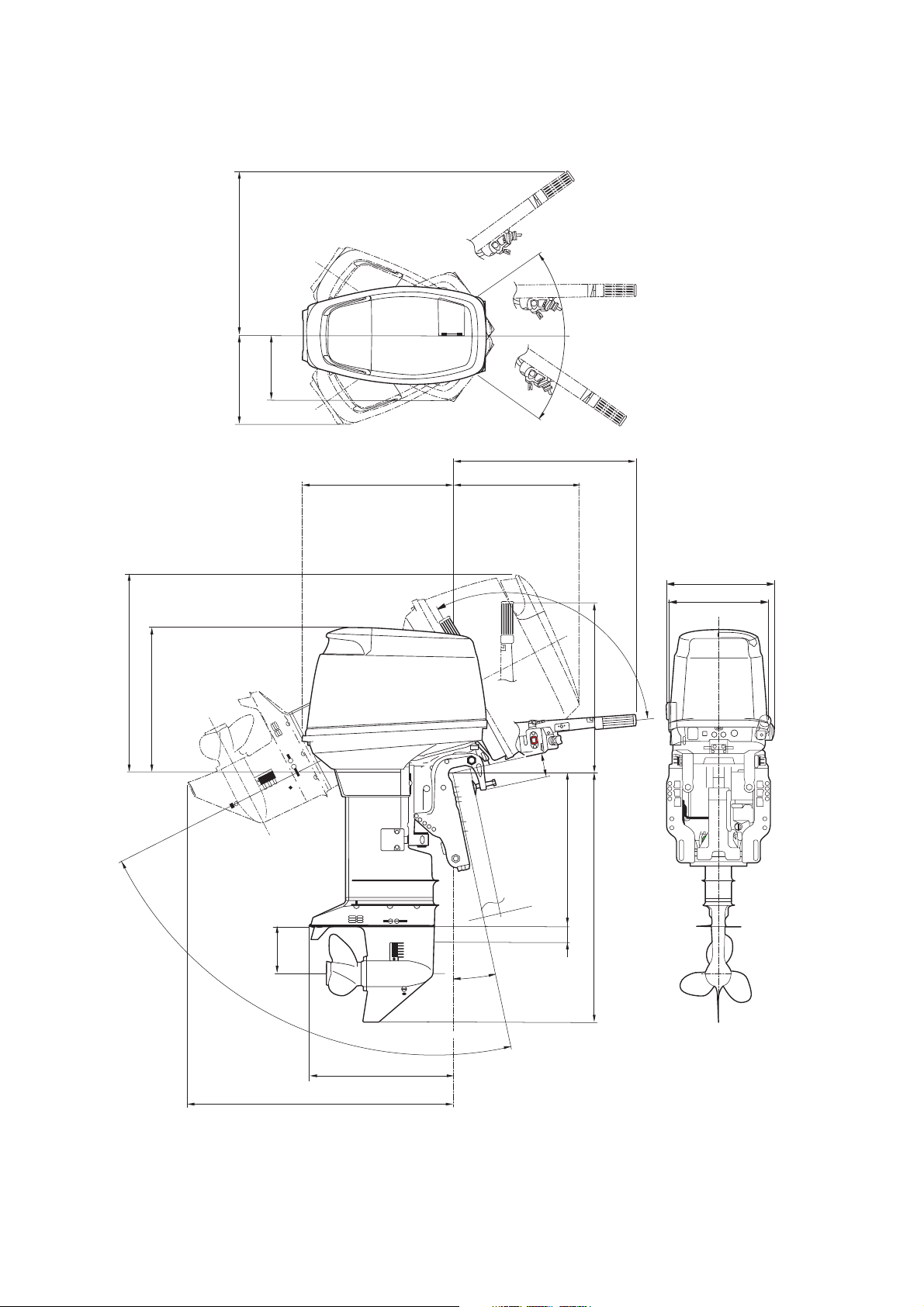

2. Outline Dimensions

M 1

M 2

P

N

O

S

G

HI

Q

D

F

C

B

J

Y

R

U

L

K

T

A

E

S

1-5

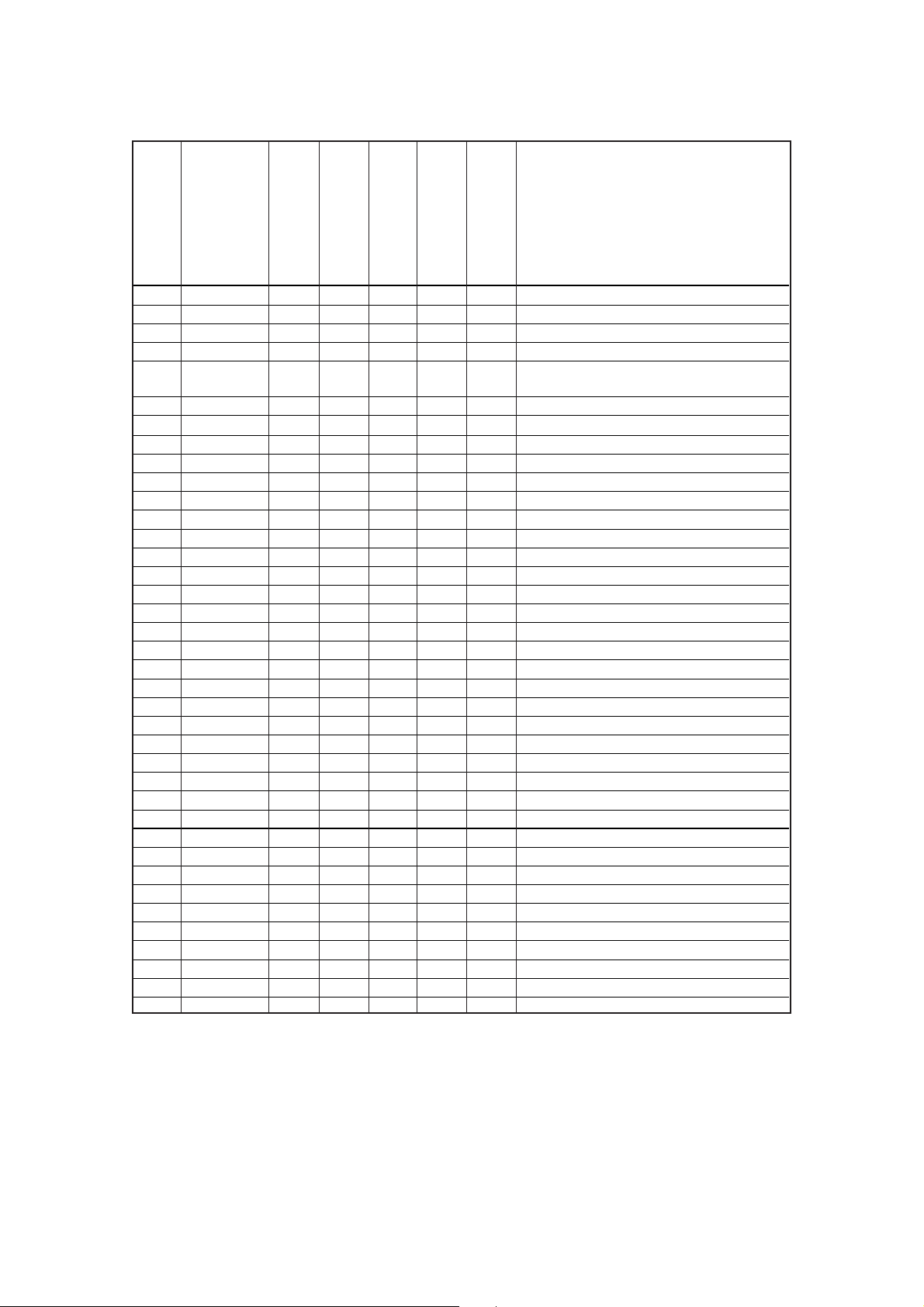

External Dimensions

Item Remarks

A 499 mm (19.6 in)

Transom (S) 728 mm (28.7 in)

B Transom (L) 855 mm (33.7 in)

Transom (UL) 982 mm (38.7 in)

Transom (S) 403 mm (15.9 in)

C Transom (L) 530 mm (20.9 in)

Transom (UL) 657 mm (25.9 in)

D 568 mm (22.4 in) Models EFTO, EFO

E 680 mm (26.8 in)

F 85 mm (3.3 in)

G 623 mm (24.5 in) Models EFTO, EFO

H 520 mm (20.5 in)

I 440 mm (17.3 in)

J 30-75 mm (1.2~3.0 in)

K 490 mm (19.3 in)

Transom (S) 800 mm (31.5 in)

L Transom (L) 910 mm (35.8 in)

Transom (UL) 1025 mm (40.4 in)

M1 384 mm (15.1 in) Models EFTO, EFO

M2 345 mm (13.6 in) Model EPTO

N 310 mm (12.2 in)

O 235 mm (9.3 in)

P 565 mm (22.2 in) Models EFTO, EFO

Q 120deg. Models EFTO, EFO

R 12deg.

S 35deg.

T 75deg.

U 161 mm (6.3 in)

Y 54 mm (2.1 in)

3. Background on TLDI

The abbreviation TLDI stands for Two-stroke Low-pressure Direct Injection and

is the name Tohatsu applies to direct fuel-injection system engines.

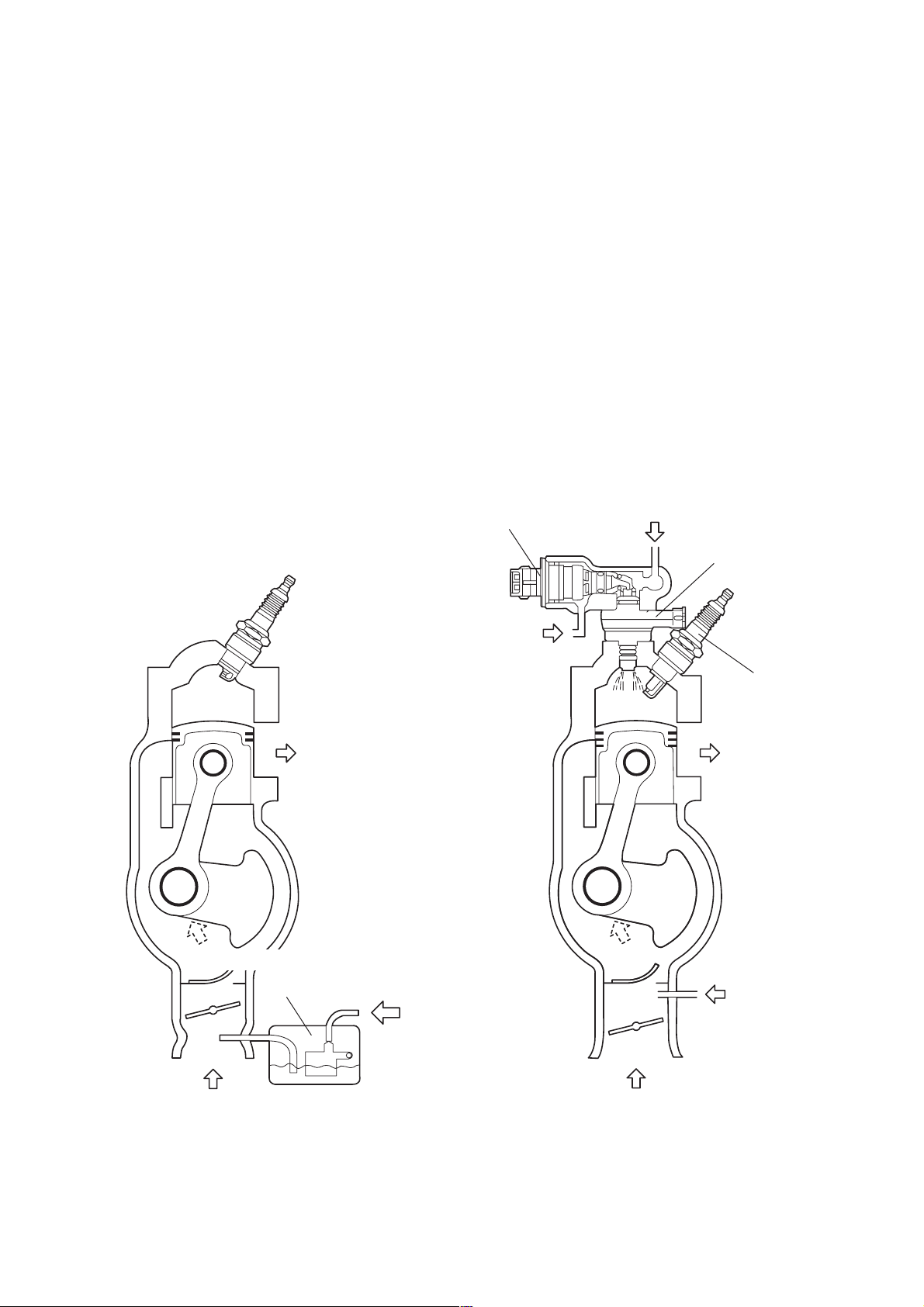

1. Two-Stroke Low-Pressure Direct Injection (TLDI)

TLDI is the name Tohatsu uses for two-stroke engines that utilize the air-assisted, low-pressure direct

injection system.

The air-assisted, low-pressure direct injection system has been combined with the L-CDI or (Long-arc

duration CDI ignition system and Engine Control Unit (ECU), which performs precision control of fuel

mixture, injection timing and ignition timing to maximize combustion efficiency in the TLDI-50 engine.

The result is better fuel economy, smaller size and greater power in a two-stroke engine.

2. Air-Assisted Low-Pressure Direct Injection

With TLDI, the air-assisted, low-pressure direct injection process involves using an air compressor to

pressurize the fuel supplied by the fuel pump to in order to propel or inject it directly into combustion

chambers in the form of a finely atomized mixture to achieve maximum combustion efficiency.

CARBURETOR TLDI

Compressed air

Pressurized fuel

ExhaustExhaust

Oil

Air

AirAir

Gasoline + Oil

Atomized fuel mixture

r

q

e

w

1-6

q Fuel injector

w Air injector

e Spark plug

r Carburetor

1-7

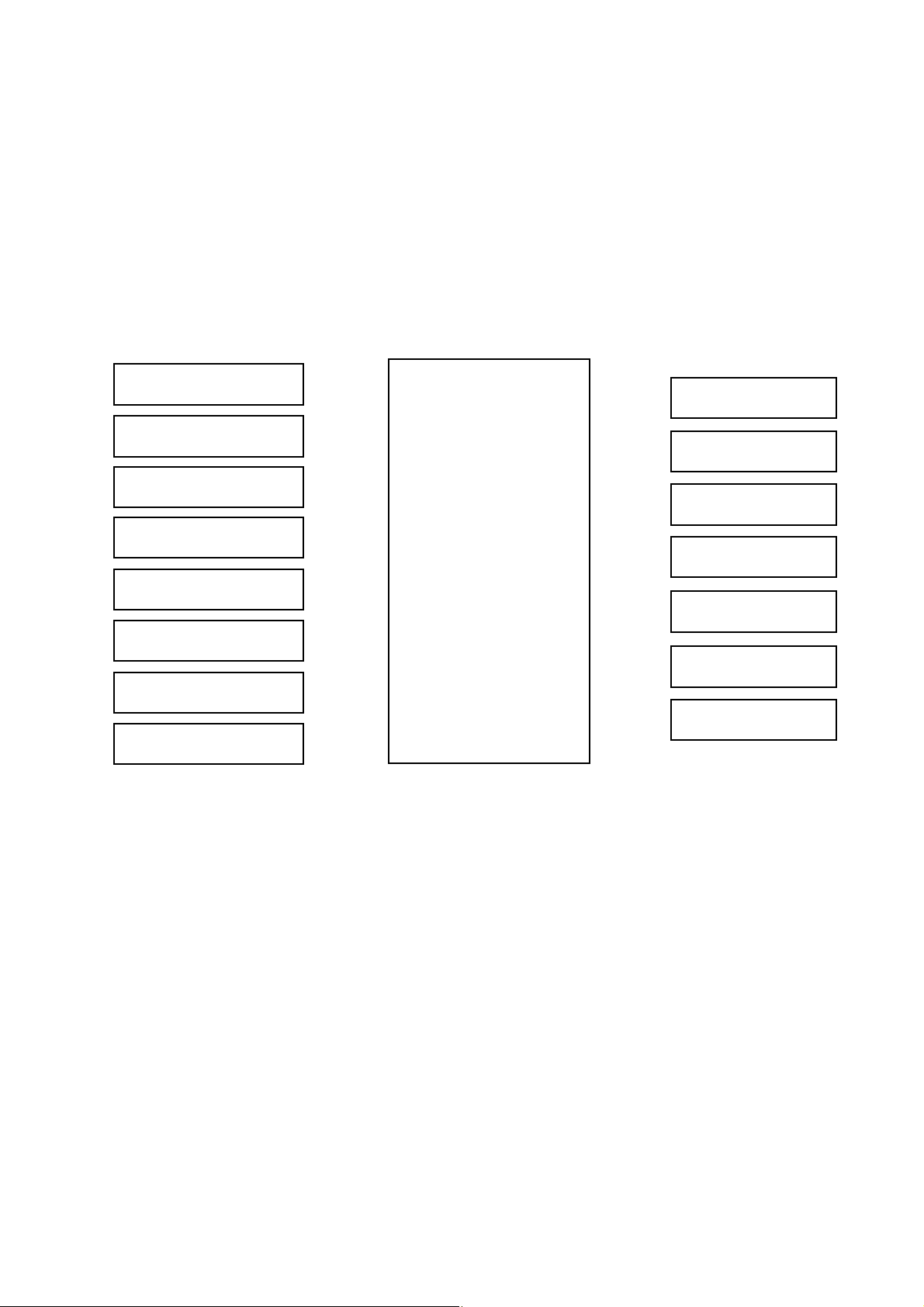

3. ECU Control

With TLDI, a network of connected sensors enables the Engine Control Unit (ECU) to precisely

regulates fuel mixture injection rate and ignition timing. The ECU also uses a stratified fuel feed process

to provide lean combustion in the low-speed range, while utilizing more homogenized change to ensure

the fuel mixture is distributed uniformly throughout the combustion chamber when operating in the high-

speed range to ensure maximum combustion efficiency.

L-CDI charge coil

Crank-position sensor

(CPS)

Throttle-position sensor

(TPS)

Water-temperature sensor

(WTS)

Oil level sensor

Battery

Key switch

Stop switch

#1, #2 & #3

Fuel injectors

#1, #2 & #3

Air injectors

#1, #2 & #3

Ignition coils

Tachometer

Warning indicators

Warning horn

Fuel-feed pump

(FFP)

Engine Control Unit

(ECU)

➞

➞

➞

➞

➞

➞

➞

➞

➞

➞

➞

➞

➞

➞

➞

Long-duration CDI (L-CDI)

The L-CDI or Long-arc duration CDI ignition system is used as the TLDI ignition system to maximize

combustion efficiency, fuel economy and minimize exhaust emissions. The L-CDI system offers a longer

plug sparking interval, via spark plug, than used with conventional two-stroke engines. This is designed to

ensure more complete combustion of the mixture in the chamber. L-CDI minimizes mis-firing and reduces

fluctuation in engine speed during idling to offer a much smoother engine feel when compared with

conventional two-stroke engines.

Throttle-Position Sensor (TPS)

The throttle-position sensor system is comprised of TPS1 and TPS2. These are used in combination to

detect throttle butterfly valve, position advancer arm position, and to relay the information to the ECU.

Crank-Position Sensor (CPS)

The crank-position sensor is designed to sense the encoder located above the ring gear on the flywheel in

order to detect crankshaft position and transmit the information to the ECU.

Water-Temperature Sensor (WTS)

Positioned on the water jacket installed on the cylinder, the water-temperature sensor (WTS) is used detect

temperature of the cooling water in the cylinder and relay the information to the ECU.

Oil Level Sensor

The oil level sensor is used to detect the level of remaining oil and relay the information to the ECU.

The oil level sensor operates by lighting the indicator on the tachometer and sounding the beeper when

engine oil is low.

Air Injectors

The air injectors are used to inject a fine mist of fuel and air into the combustion chamber for each piston.

The ECU determines the mixture and timing for injecting fuel according to current engine operating

conditions based on information relayed from the various sensors.

Fuel Injector

The fuel injectors supply the fuel in the air rail to the air injectors via the set pieces. The ECU determines the

mixture for injecting fuel according to current engine operation based on information relayed from the

various sensors.

1-8

1-9

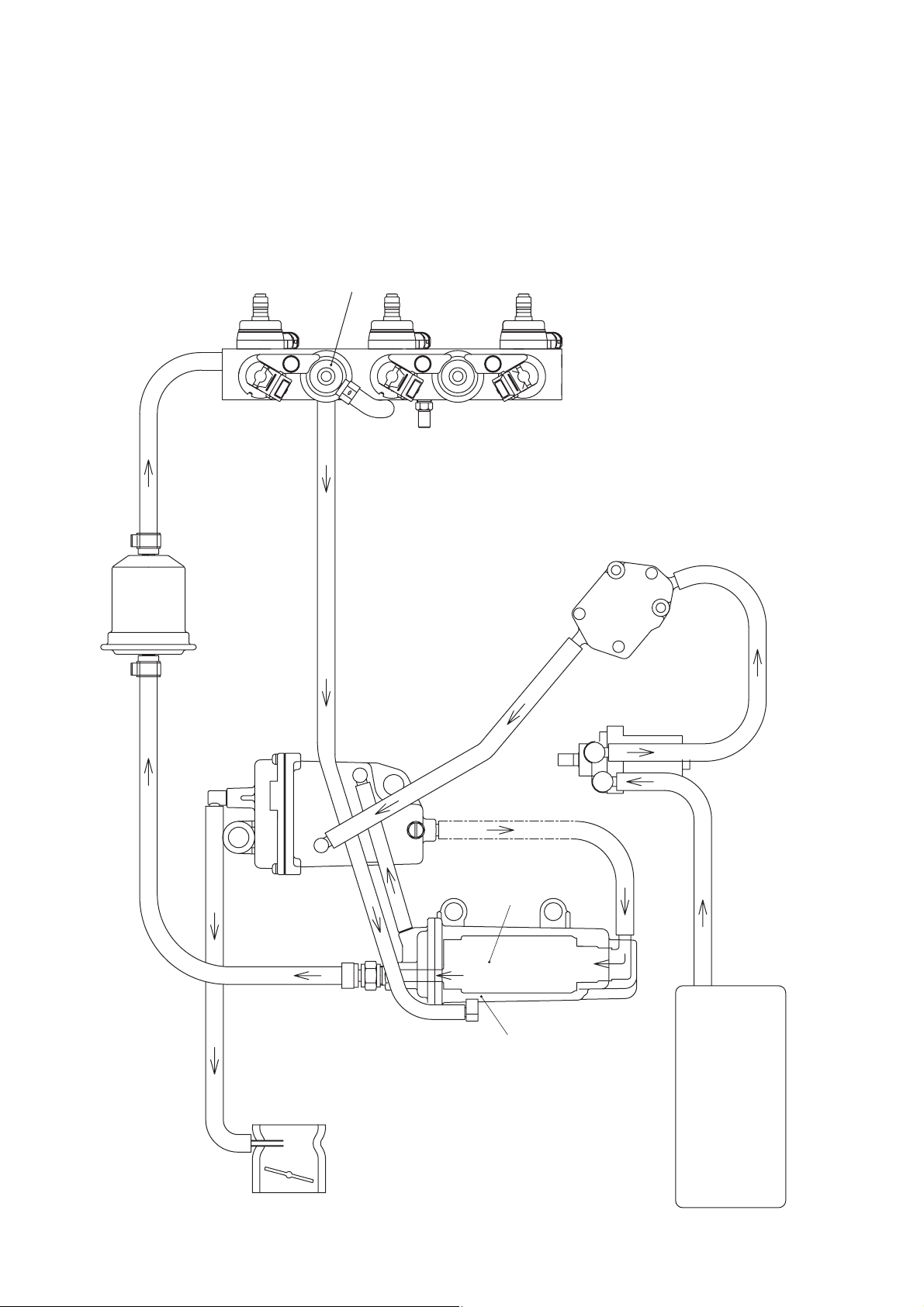

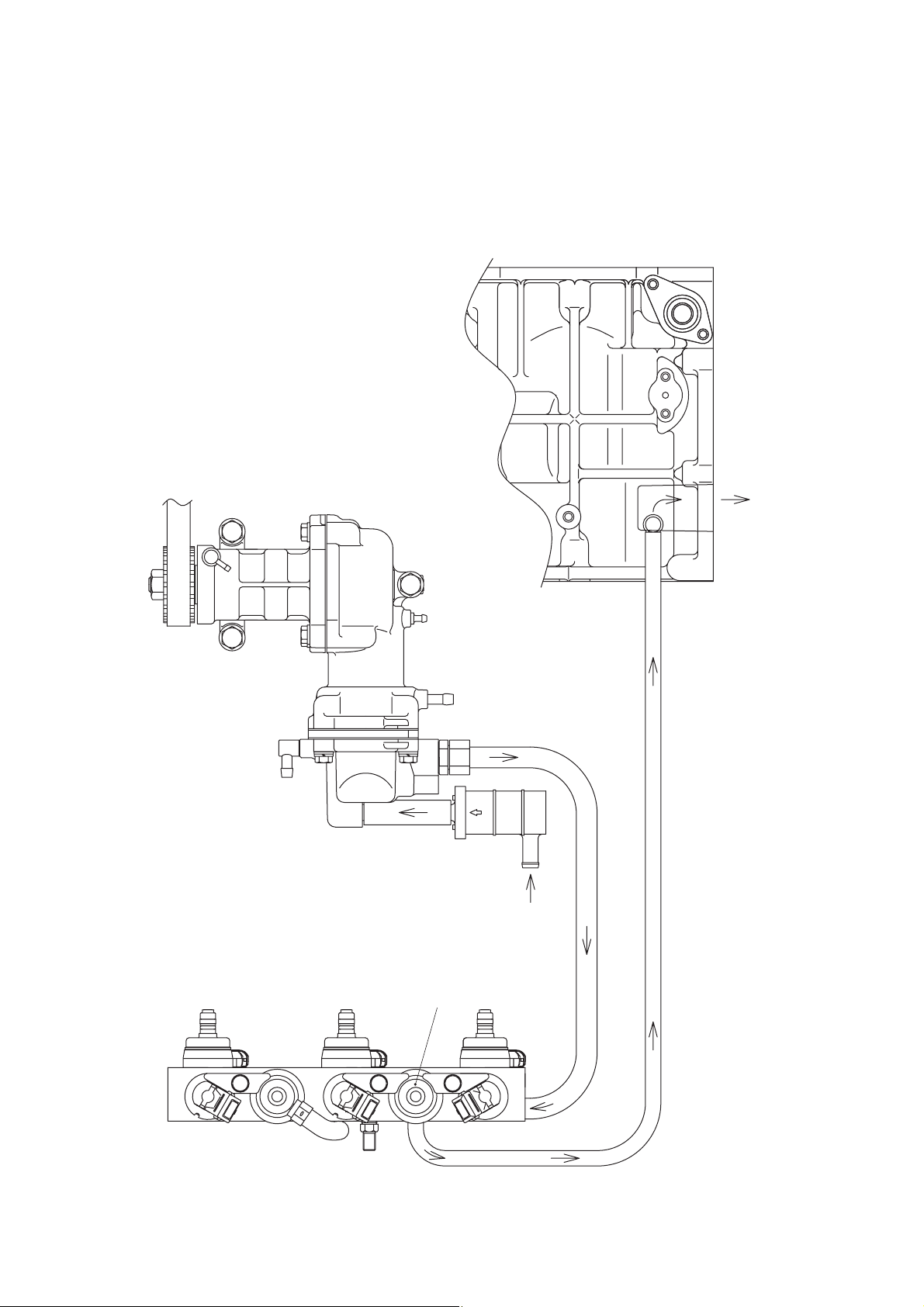

4. Fuel Supply System

!0

IN

O

U

T

Starting the engine activates the fuel pump e, which draws

gasoline from the fuel tank q and routes it through the fuel filter

w to the vapor separator r. The gasoline is pressurized in the

fuel-feed pump FFP t; then passes through the high-pressure

filter y to the air rail u, from there it is injected into the

combustion chambers. The fuel regulator i regulates

components t through u in order to maintain gasoline at a

differential pressure of 80 kPa (11.4 psi). Any excess gasoline is

depressurized and diverted through the FFP case o and back to

the vapor separator r. The returned gasoline contains air

bubbles left over from being pressurized at t. These bleed from

the top of the vapor separator r to the throttle body !0 and is

fed to the air intake system.

q

o

t

r

u

i

w

e

y

1-10

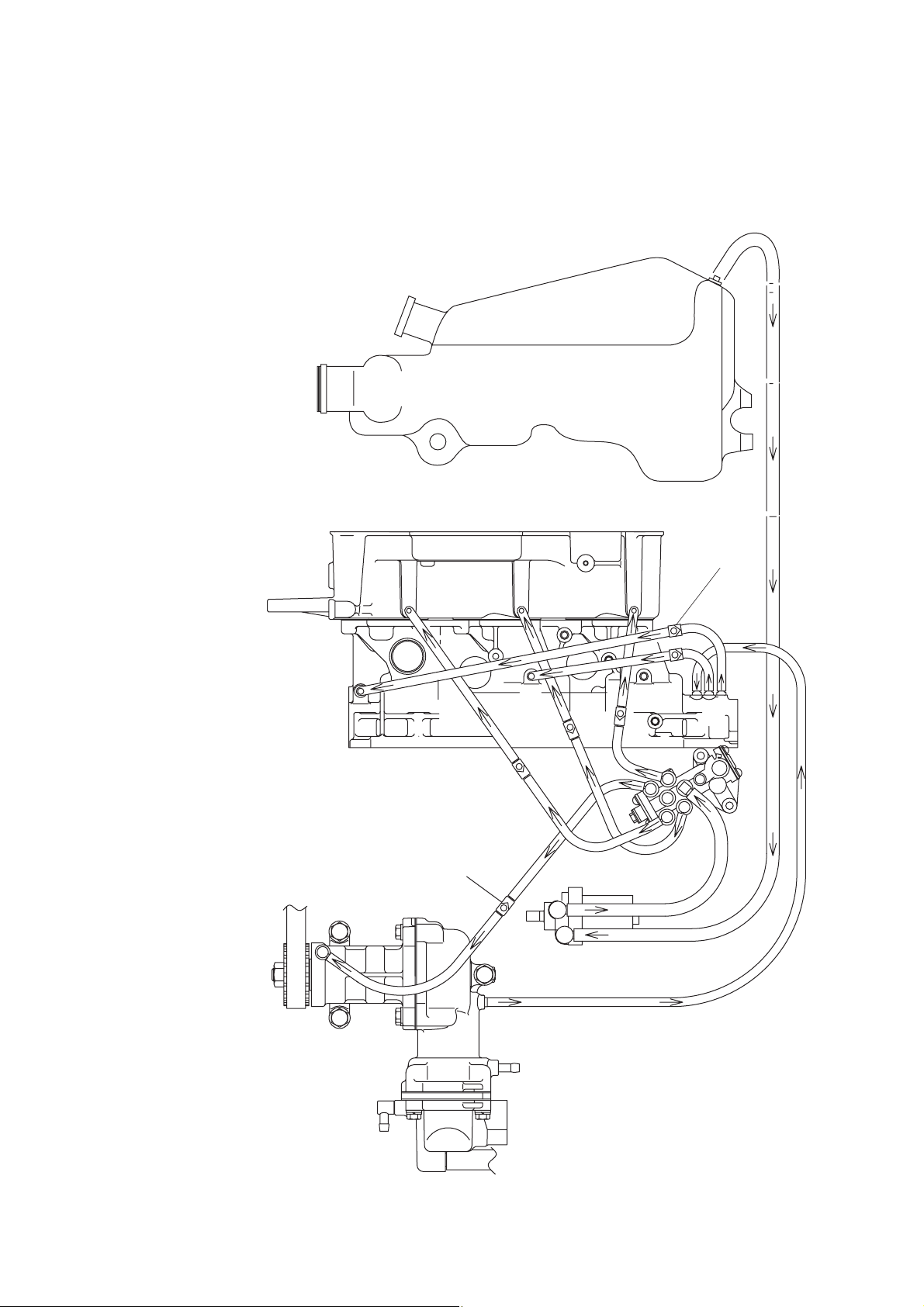

5. Air Supply System

e

r

q

t

w

Starting the engine operates the air compressor

w, draws air in through the air filter q and

sends compressed air through to the air rail e.

From there, the air is drawn in through the air

filter q and used as the air intake when injecting

the pressurized gasoline into the combustion

chamber pressurized by the air compressor w.

The air regulator r regulates components w

and e in order to maintain air at the optimum

combustion pressure of 550 kPa (79.8 psi). Any

excess air is depressurized and sent to the

exhaust t and discharged from the bottom of

the cylinder.

Exhaust

Intake

1-11

6. Oil Supply System

Starting the engine operates the oil pump q, which draws oil from

the oil tank w and routes it through the oil filter e to the oil pump q.

The oil pump channels the oil through four ports to #1 air box r, #2

air box t, #3 air box y and the air compressor u. Ports r, t and

y serve to lubricate the engine’s pistons, while port (7) lubricates

the air compressor.

TLDI includes a recirculation system in which the excess oil from the

air compressor u is diverted to #3 crankcase i for use in

lubricating the drive gear q. Any oil left over from there is diverted to

#1 crankcase o and the crankcase !0 where it is added to oil from

r and t and reused to lubricate the engine.

q

w

e

r

t

y

u

i

o

!0

Check valve

Check valve

1-12

Chapter 2 Servicing Information

1. General Precautions for Servicing...............................................2-3

2. Specifications and Standards Used in Servicing .......................2-4

3.

Lists of Points for Applying Sealant, Adhesive and Lubrication

.........2-10

4. Torque Table.................................................................................2-16

5. Special Tools................................................................................2-17

2

2-2

2-3

1. General Precautions for Servicing

Users of this manual should observe the following general precautions when

conducting disassembly and assembly work.

(1) Make sure that the outboard motor is securely mounted on a work stand before starting work.

(2) Take care not to scratch or damage painted surfaces and the mating surfaces where cylinders, the

cylinder head, the crankcase and other parts are joined.

(3) Always replace packing, gaskets, O-rings and split pins with new ones when reassembling engine parts.

Make a point of replacing snap rings as well.

(4) When replacing, be sure to use genuine Tohatsu brand parts and lubricants or products recommended

by Tohatsu.

(5) Always use the recommended special tools to ensure work is done properly.

(6) When disassembling and assembling components, make note of position marks, adding your own

marks if none are provided, as a way to ensure the various parts and components are properly mated

when being reassembled.

(7) To prevent smaller parts, such as bolts, nuts and washers from getting lost or damaged, where possible,

lightly insert or tighten them back in their original locations.

(8) As normal practice, check disassembled parts for any wear or damage by first wiping them clean; then

washing them in solvent.

(9) With reassembly operations it is essential to observe precise detail in centering, vacuum sealing,

lubricating (with oil or grease), packing parts and components, and connecting wiring and piping. Also

ensure there are no blockages in fluid lines.

1) When reassembling parts requiring numerous nuts and bolts (cylinder, crankcase etc.), begin by

alternately tightening diagonally opposed inner bolts, moving in a concentric circle; then tightening

the outer bolts. This will ensure that engine parts are assembled evenly and securely. (Use the

same procedure in the reverse order when disassembling.)

2) When installing oil seals, be careful not to scratch or reverse the sides that mate with the shaft and

always apply grease to the lip surfaces.

3) Confirm the correct quantity and thickness when applying sealant. Applying excessively will result in

the excess portion being excreted into or outside of the case, potentially causing damage. Adhere

strictly to the written instructions when applying adhesives.

4) Apply penetrating oil spray to nuts or bolts that are difficult to remove due to rust and wait 5 minutes

before removing.

5) For the various inspection specifications, torque values, special tools, and the points where sealant,

adhesive and grease are to be applied, refer to the relevant tables.

6) The various nuts, bolts and washers referred to in this manual are listed below.

Name Type Diameter Length

H820 Hexagon bolt 8 mm 20 mm

N8 Hexagon Nut 8 mm

L8 Hexagon Nut 8 mm

W8 Plain washer 8 mm

SW8 Spring washer 8 mm

Screw 620 Pan head screw 6 mm 20 mm

(10) Observe all necessary safety procedures to prevent accidents and injury during work operations.

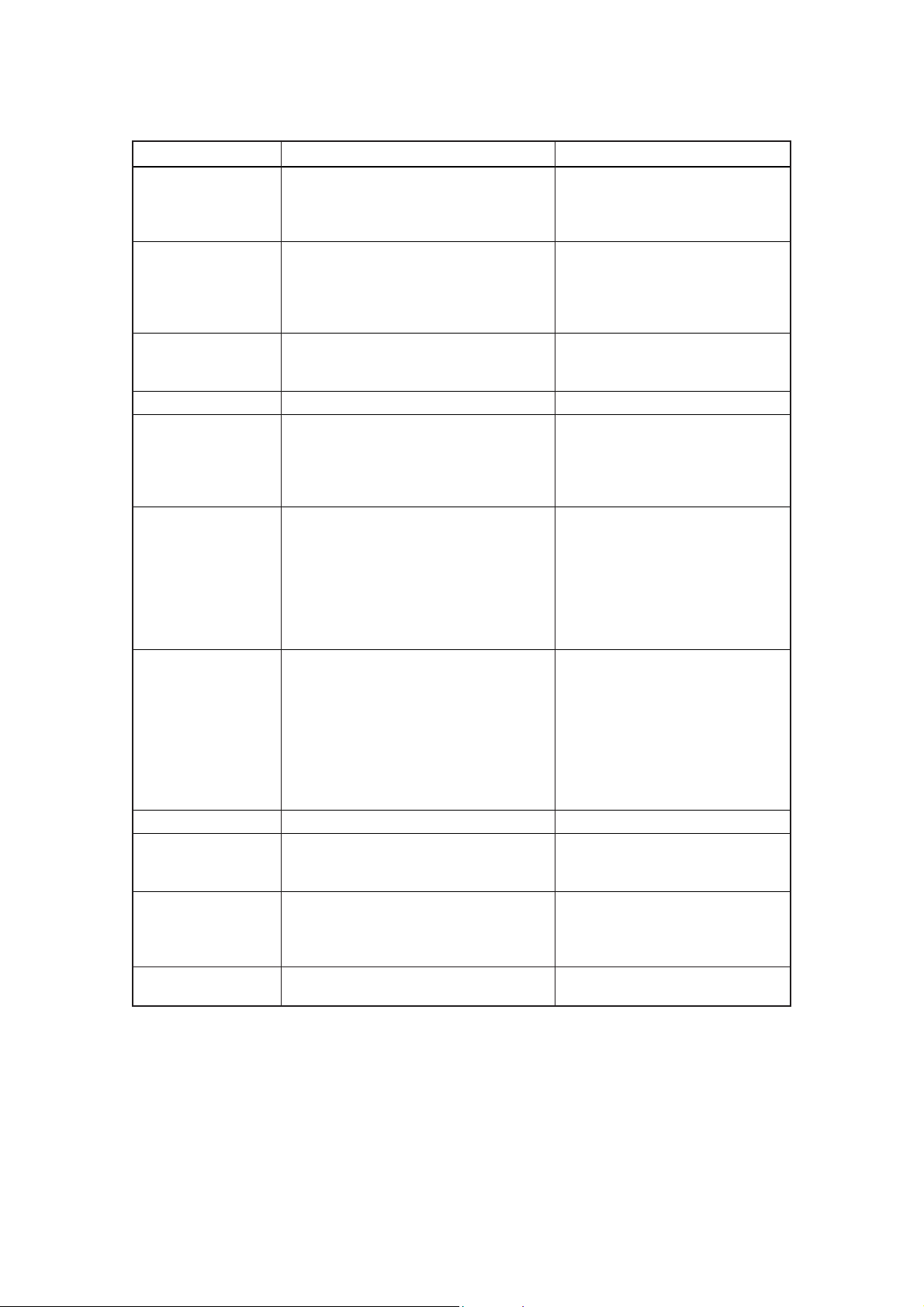

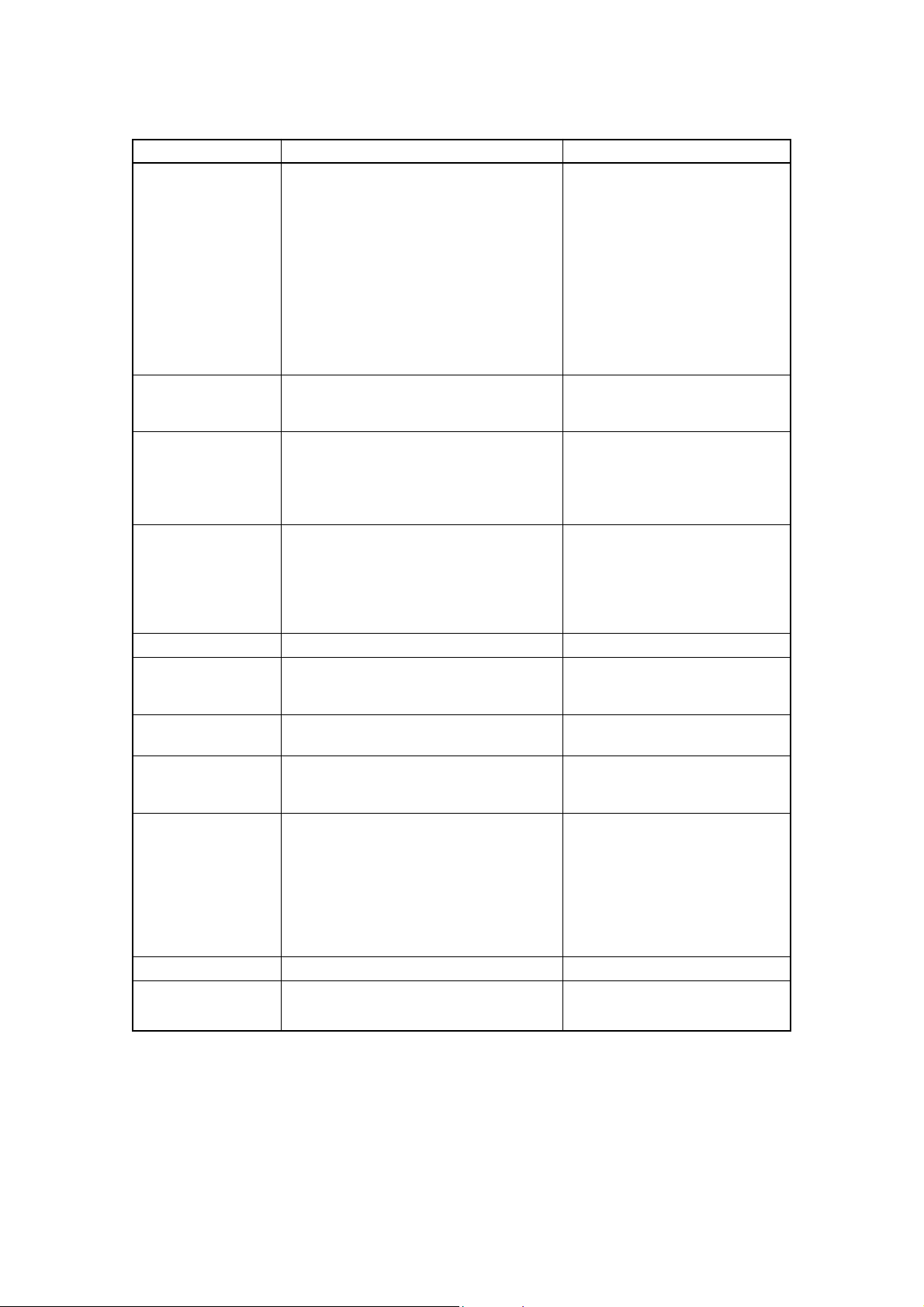

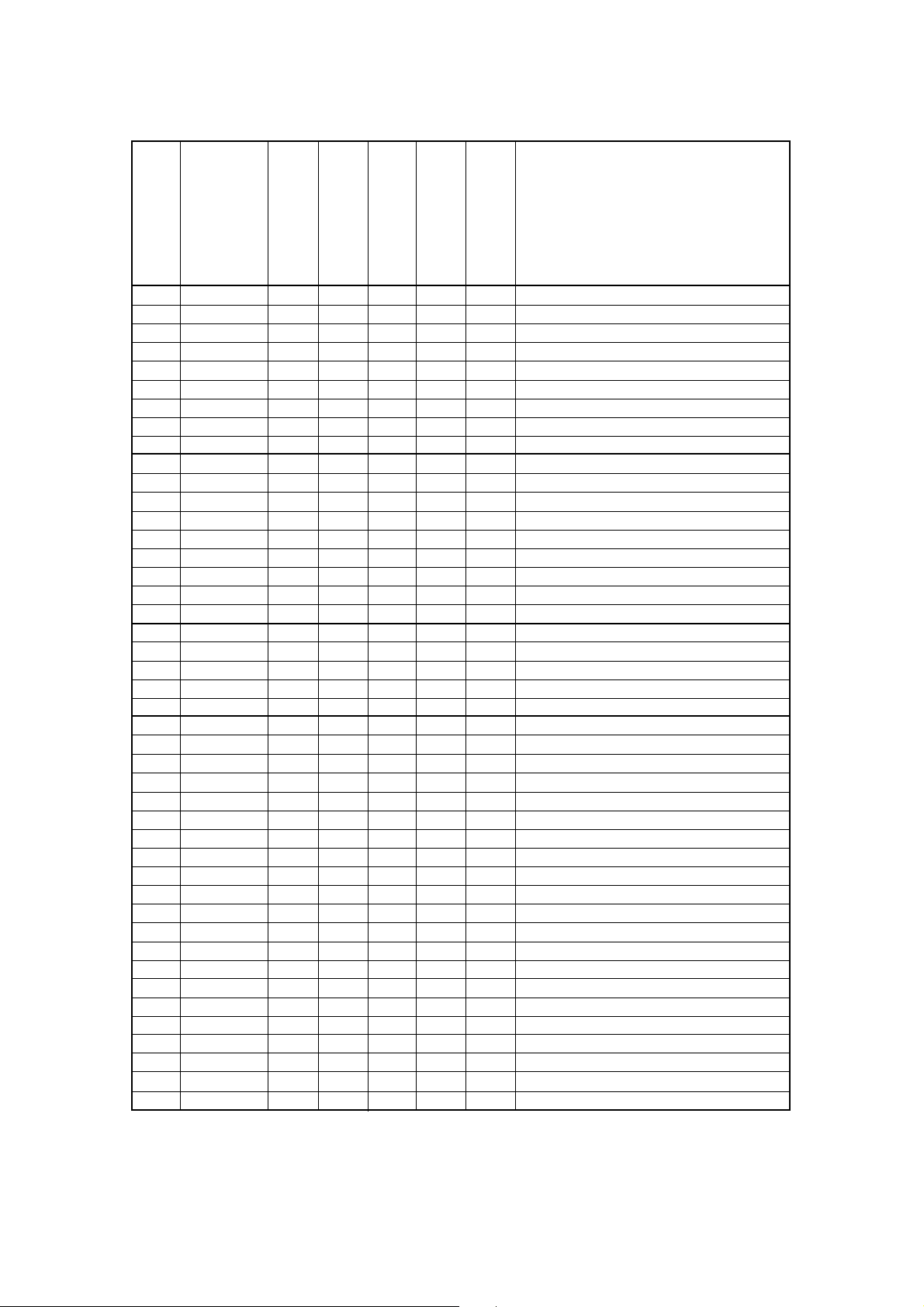

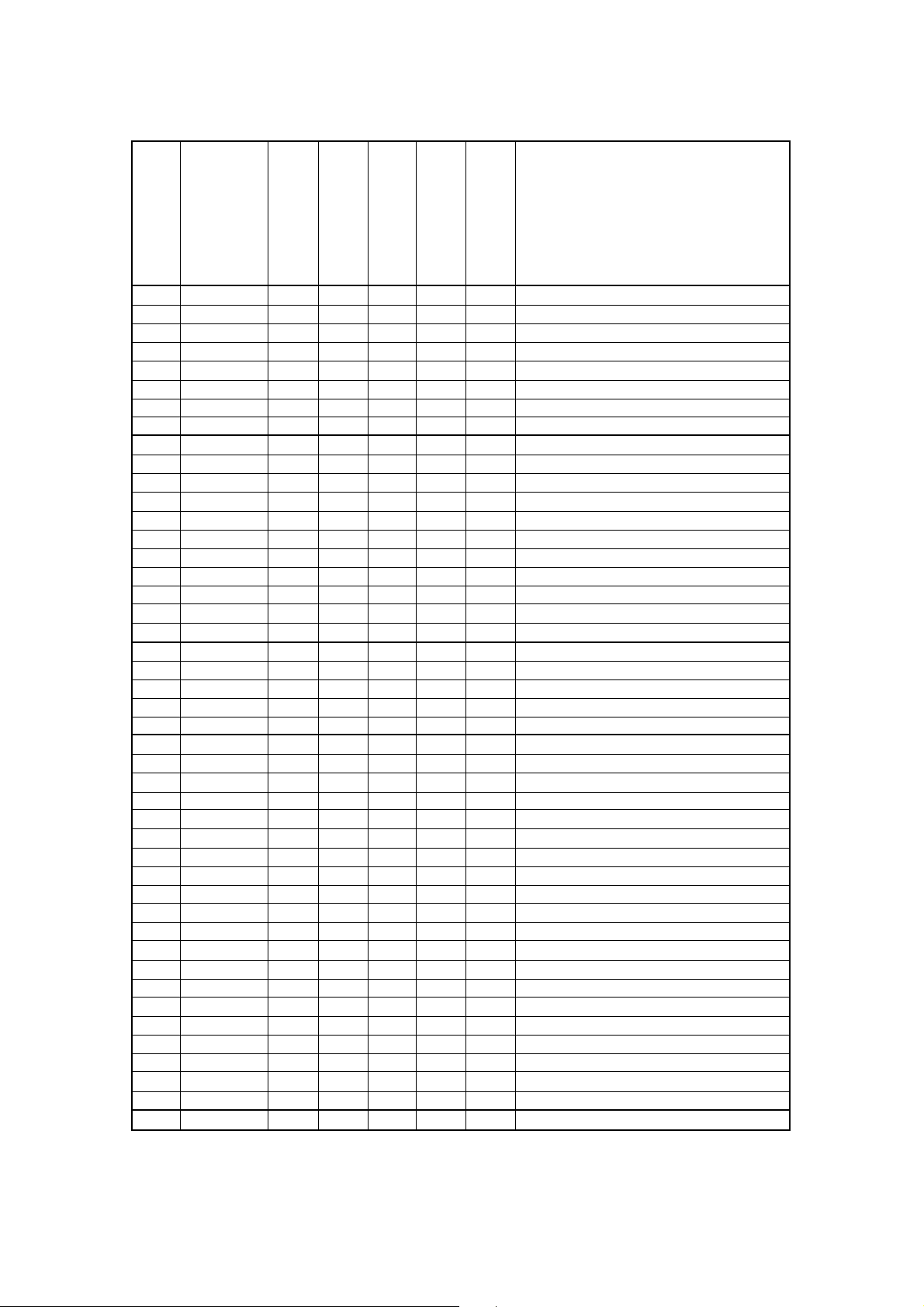

2. Specifications and Standards Used in Servicing

Name of Part Item to check Standard values

•67.96 mm (2.676 in)

Piston

•Top: 0.22 to 0.37 mm

(0.009 to 0.0145 in)

Piston ring •

Second and third: 0.33 to 0.48 mm

(0.013 to 0.019 in)

•0.05 mm (0.002 in)

Crankshaft

Connecting rod • Deflection

• Mating surface •0.03 mm (0.0012 in) or less for

scratches

Cylinder head •0.03 mm (0.0012 in) or less for

distortion

• Mating surface •0.03 mm (0.0012 in) or less for

scratches

•0.03 mm (0.0012 in) or less for

Cylinder

distortion

• Cylinder liner scratches and wear

•0.83 MPa (8.5 kg/cm2, 120 psi)

Engine block

Reed valve stopper • Lift height • 9.3 to 9.5 mm (0.366 to 0.374 in)

• Fails to close, is worn or damaged

Reed valve

•1.1Ω ±15% (Ambient temperature)

Ignition coil

•

12.5 kΩ ±15% (Ambient temperature)

ECU

• Low-speed ESG trigger •Approx. 3,000 rpm

• High-speed ESG trigger •Approx. 6,000 rpm

2-4

• Ring end gap

Note: If a ring gauge is unavailable,

measure the lower end of the

cylinder bore.

• Deflection

Measure with both ends supported on V

blocks.

• Compression

Measure after warming:

Remove all 3 spark plugs.

Remove air injector and fuel injector

connectors.

• Primary coil resistance (between black

& white and orange lines)

• Secondary coil resistance (between

high tension core and B line)

• Outer diameter

Measure at a point 12 mm (0.47 in)

above the lower edge of the piston skirt.

2-5

Service limit Servicing procedure

• 0.8 mm (0.031 in) or more

• 0.9 mm (0.035 in) or more

• 0.05 mm (0.002 in) or more

• Replace with new crankshaft.

• 2 mm (0.08 in) or more • Replace with new crankshaft assembly.

• Repair by polishing the surface plate, starting

with #240 to #400 grit sandpaper and finishing

with #600 grit sandpaper.

• Repair by polishing the surface plate, starting

with #240 to #400 grit sandpaper and finishing

with #600 grit sandpaper.

• Bore and hone to ø68.55 (2.699 in) + 0 to 0.02

mm (0 to 0.0008 in). Check ports and grind if

necessary.

Use oversize pistons and piston rings.

1) When difference in compression between

cylinders exceeds 0.1 MPa

(1.05 kg/cm

2

, 14.5 psi)

2) When abnormally higher than standard value 2) Remove carbon from piston crown and cylinder

head surfaces and clean exhaust gas bypass

valve.

• No longer conforms to standard value • Replace with new part.

• Valve reed fails to close

• Excessive wear on valve seat • Replace entire valve assembly.

• Valve is damaged

1) Bore and hone to ø68.55 (2.699 in) + 0 to 0.02

mm (0 to 0.0008 in). Check ports and grind if

necessary.

Use oversize pistons and piston rings.

• When the cylinder liner cannot be repaired using

#400 to #600 sandpaper due to excessive

scratching or scoring or when the difference

between the maximum and minimum points of

wear in liner bore is 0.06 mm (0.0024 in) or more

• Replace with new piston ring if cylinder liner

wear has not yet exceeded the repair limit.

• Scratch depth or distortion is 0.03 mm

(0.0012 in) or more

• Scratch depth or distortion is 0.03 mm

(0.0012 in) or more

Name of Part Item to check Standard values

Magneto

Spark plug

Crank-position

sensor (CPS)

Thermostat

Fuse

Pump impeller

Pump case liner

Guide plate

Propeller shaft

Drive shaft

Starter motor

Anode

Oil seals

2-6

• Sparking performance

Measured using spark tester

• Sparking order

• Alternator (max.)

• Charging performance

• Exciter coil resistance value (low-speed)

(W/R wire to W/L wire)

• Exciter coil resistance value (high-speed)

(Green wire to W/Y wire)

• Lighting coil resistance value

(Y to Y wire)

• Standard plug

• Plug gap

• Gap with encoder ring (flywheel)

• Pickup coil resistance value

(L wire to G wire)

• Opening and closing of thermostat valve

• Capacity

• Wear and cracks

• Damage to bearing

• Wear on lip of oil seal

• Damage to bearing

• Shaft run-out

• Wear on lip of oil seal

• Battery

• Output

• Brush length (wear limit)

• Commutator under-cut (wear limit)

• Commutator diameter (wear limit)

• Corrosion

• 10 mm (0.39 in) or more at

350 rpm

• #1 ⇒ #2 ⇒ #3

• 280 W

• 1,500 rpm12V 16.5A

• 5,500 rpm12V 18.5A

• 515Ω ±15%

(Ambient temperature)

• 71.8Ω ±15%

(Ambient temperature)

• 0.38Ω ±15%

(Ambient temperature)

• CHAMPION: RC10ECC

•1.0 to 1.1 mm (0.039 to 0.043 in)

•0.5 to 0.9 mm (0.019 to 0.035 in)

• 0.531Ω ± 15%

(Ambient temperature)

• Valve start temperature:

52°C (125.6°F)

• Valve full-open temperature:

65°C (149.0°F)

• Valve full-open lift:

3 mm (0.12 in) or more

• 15A × 2, 30A × 1

• 0.3 mm (0.012 in) or less (Using

both center holes for reference)

• 12V, 100AH-120AH

• 12V to 0.6 kW

• 12.5 mm (9.5 mm)

0.49 in (0.37 in)

• 0.5 to 0.8 mm (0.2 mm)

0.02 to 0.03 in (0.01 in)

• 30 mm (29 mm)

1.18 in (1.14 in)

2-7

Service limit Servicing procedure

1) 1.2 mm (0.047 in) or more 1) Repair so that plugs conform to standard values.

2) When electrodes show excessive wear 2) Replace with new spark plug.

• When sensor no longer conforms to standard • Repair so that sensor conforms to standard value.

value

• When fuse burns out • Replace with new fuse.

• When the tips, and upper and lower surface

lip areas show wear, cracks or damage • Replace with new assembly.

• When depth of wear is 0.1 mm (0.004 in) or more • Replace with new shaft.

• Replace with new shaft.

• 0.4 mm (0.016 in) or more • Repair so that shaft conforms to standard values.

• When depth of wear is 0.1 mm (0.004 in) or more • Replace with new shaft.

• Replace with new starter motor.

• When anode shows excessive corrosion • Replace with new anode.

• When lip area shows deterioration, heat

discoloration or damage or when wear • Replace with new oil seal.

reduces interference to 0.5 mm (0.02 in) or less

Name of Part Item to check Standard values

Power trim and tilt

Air compressor

Vapor separator

FFP

Air rail

Air regulator

Fuel regulator

Air injector

Fuel injector

TPS

Water temp sensor • Measured value for resistance • 2.45kW±10% (20°C, 68°F),

0.32kW±10% (80°C, 176°F)

Oil level sensor • Conductivity

Rectifiers

• Conductivity Refer to tester checkpoint Table

(Chapter 5).

2-8

Pump assembly:

• Relief valve opening pressure

• Spool check valve opening pressure

• Oil quantity

• Oil type

• Oil filter

Tilt cylinder:

• Shock absorber valve opening pressure

• Piston diameter

• Piston rod diameter

• Stroke

Motor:

• Rated timing

• Rated voltage

• Output

• Direction of rotation

• Cylinder bore

• Piston diameter

Measure at a point 10 mm above the

lower edge of the piston skirt.

• Piston ring end gap

• Reed valve tip clearance

• Drive belt

• Wear and damage on seal ring

• Float

• Wear and damage on seals and

grommets

• Wear and damage on O-rings

• Air pressure

• Fuel pressure

• Measured value for resistance

•

Operating condition (check for clicking sound

when 12 volts is applied to the terminal)

• Measured value for resistance

• Measured values of resistance between

connectors.

• Tilted up: 13.7 to 16.7 MPa

(140 to 170 kg/cm2) (1987 to 2421 psi)

• Tilted down: 2.0 to 3.3 MPa

(2.0 to 34 kg/cm2) (290 to 479 psi)

• Upper chest: 0.24 MPa

(2.4 kg/cm

2

) (348 psi)

• Lower chest: 0.12 MPa

(1.2 kg/cm

2

) (17 psi)

• 550 ml (18.6 US fl. oz)

• Power Torque fluid

(ATF Dexron III or equivalent

product)

• 150 mesh

• 3.4 to 5.4 MPa

(35 to 55 kg/cm

2

) (493 to 783 psi)

• 54 mm (2.13 in)

• 16 mm (0.63 in)

• 141 mm (5.55 in)

• 60sec.

• 12V (DC)

• 650W

• Forward/reverse

•

39.00 to 39.02 mm (1.53 to 1.54 in)

•

38.97 to 38.99 mm (1.534 to 1.535 in)

• Top: 0.10 to 0.25 mm

(0.004 to 0.098 in)

•Second: 0.10 to 0.25 mm

(0.004 to 0.098 in)

•Oil: 0.10 to 0.60 mm

(0.004 to 0.023 in)

• 0.2 mm (0.008 in) or less

•0.55 MPa (5.6 kgf/cm

2

) ±7%

(80 psi

±7%

)

• Measured air pressure

+ 0.07 MPa (0.7 kgf/cm

2

) ±10%

(10 psi

± 10%

)

•1.3 ±0.3Ω (Ambient temperature)

•

1.8 ± 0.1Ω (Ambient temperature)

•

Between upper and lower

connectors: 5.0Ω ±20%

•

Between upper and middle

connectors: resistance value (kΩ)

Fully closed

Full open

TPS1 4 to 5 0.5 to 1

TPS2 4 to 5 4 to 5

Service limit Servicing procedure

• When parts no longer conform to standard values • Replace with new parts.

• When parts show excessive wear or damage

• When parts show excessive wear or damage

• When parts showed deterioration or contamination • Replace with new parts.

by fuel

• When parts show excessive wear or damage • Replace with new parts.

• When parts show excessive wear or damage • Replace with new parts.

• When parts no longer conform to standard values • Replace with new parts.

• When parts no longer conform to standard values • Replace with new parts.

• When parts no longer conform to standard values • Replace with new parts.

• When parts no longer conform to standard values • Replace with new parts.

• When parts no longer conform to standard values

• When differences in resistance values between

upper, middle and lower connectors becomes

• Replace with new parts.

erratic

• When parts no longer conform to standard values • Replace with new parts.

• When short occurs in sensor • Replace with new parts.

• Replace with new parts.

2-9

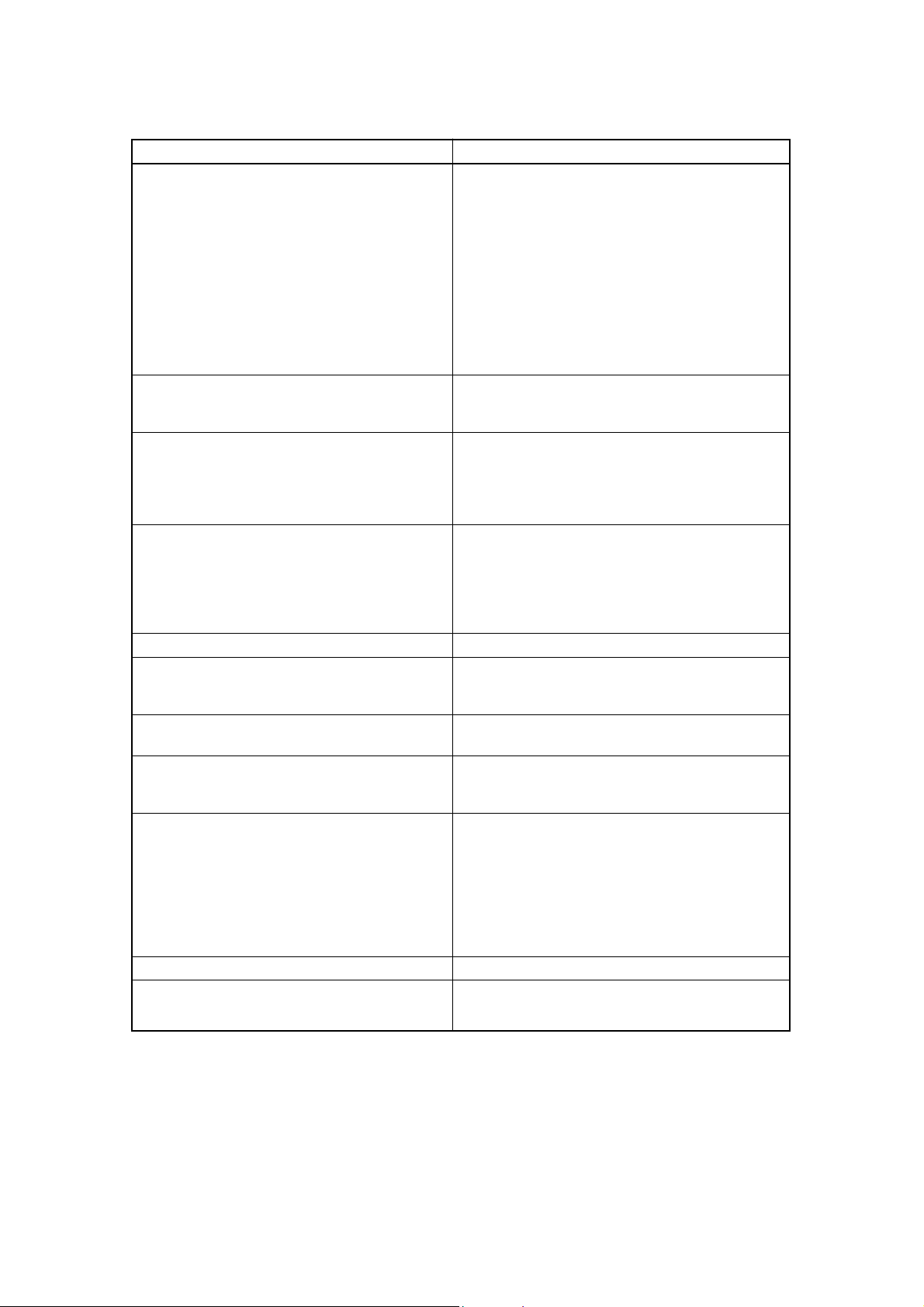

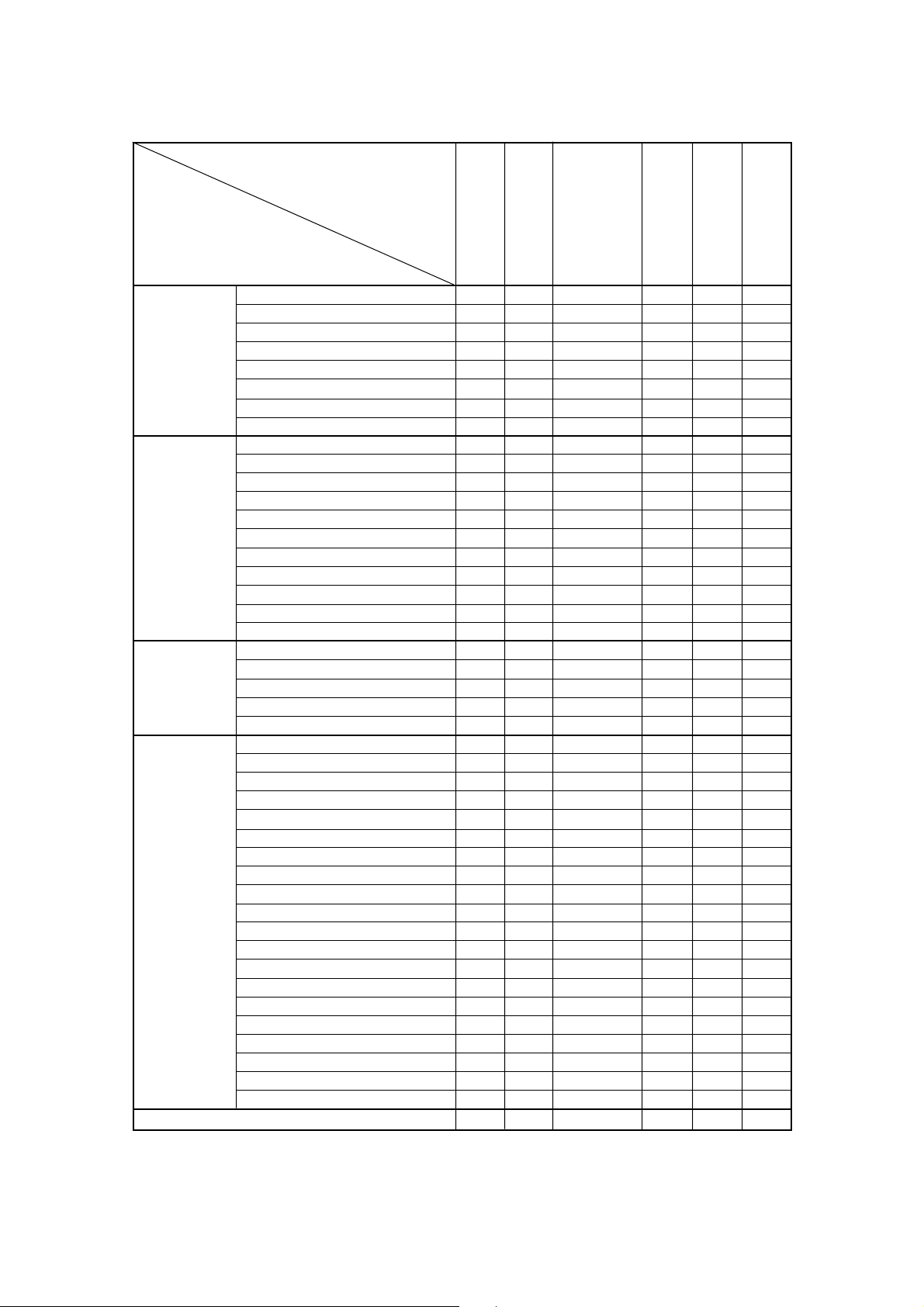

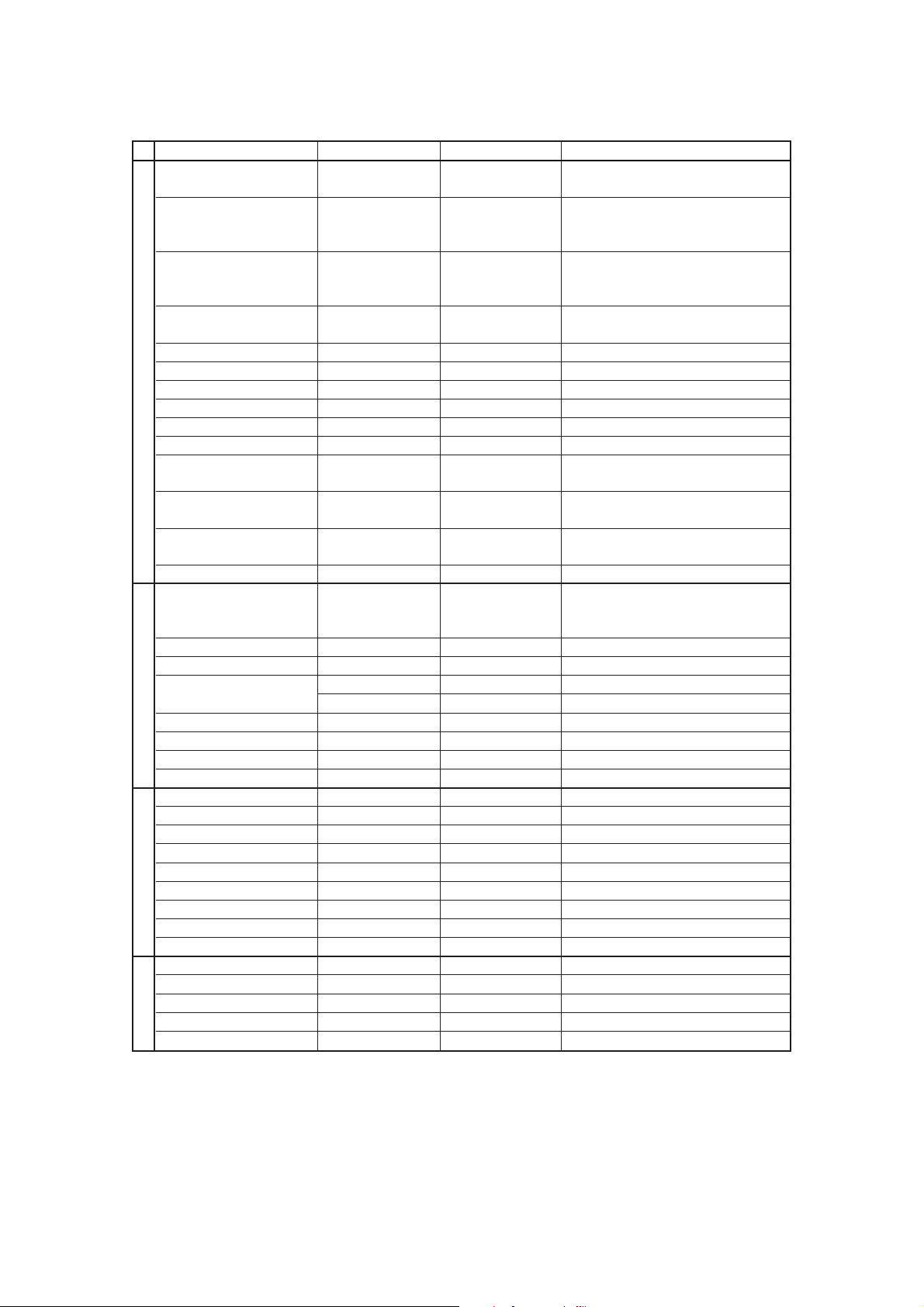

3.

Lists of Points for Applying Sealant, Adhesive and Lubrication

1342 1373B Adhesive 648 518 1741 G17

Primer 7471

Engine block Piston

Piston pin

Piston ring

Cylinder liner

Drive pulley ●●

Pulley nut ●●

Small-end bearing

Big-end bearing

Main bearing

Big-end bearing washer

Main bearing, upper

Main bearing, upper oil seal

Crankcase head O-ring

Crankshaft oil seal, lower

Drive shaft oil seal

Oil pump for drive gear

Oil pump for driven gear

Cylinder-crankcase mating surface ●●

Water temperature sensor

Spark plug gaps

Advancer arm

Throttle cam

Clutch

Ball joint gap

Cable joint (clutch)

Starter motor

Solenoid switch (starter motor), 2 locations

Solenoid switch (PT&T), 6 locations

Steering bar Grip

handle Bushing A

specifications Bushing B

Washer

Wave washer

Throttle shaft bushing

Shift lever shaft bushing

Seal ring

Wave washer

Shift lever stopper

2-10

Three Bond

Thread Lock

Three Bond

Thread Lock

Locitite

Sealant

Three Bond

Instant Adhesive

Three Bond

Adhesive

Locitite

Adhesive

2-11

LT-2 LOR#101 KS-64

●● Ring groove, piston pin hole and skirt

●● Skirt

●●

●● Inwall

Apply Loctite 648 to the punched side after

applying primer to the shaft and punched surface

●● Sliding surface

●● Sliding surface

●● Sliding surface

●● Sliding surface

●● Sliding surface

●● Lip area

●●

●● Lip area (on oil seal in crankcase head)

●● Lip area (on oil seal in crankcase head)

●●

●●

Confirm thickness of coating

●● O-ring

●● Plug seat and high tension cored

●● Sliding surface

●● Sliding surface

●● Sliding surface

●● Sliding surface

●● Sliding surface

b●● a●● a) Terminal, b) Pinion

●● Terminal

●● Terminal

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

*1: ATF Dexron # or equivalent product

Cold-&Heat-resistant

lithium grease

OBM grease

2st engine oil

Silicon grease,

Shinetsu grease

Oil Center

Research cold-

resistant grease

Specified

gear oil

Power torque

fluid *1

Remarks

2-12

1342 1373B Adhesive 648 518 1741 G17

Primer 7471

Air rail Air injector O-ring

Fuel injector O-ring

Fuel regulator O-ring

Air regulator O-ring

Compressions seal

Spark plug O-ring

Air hose L nipple O-ring

Fuel hose L nipple O-ring

Valve assembly

Air compressor

Air compressor piston ●●

Air compressor cylinder

Air compressor piston pin

Air compressor piston ring

Air compressor oil ring

Big-end needle bearing

Compressor housing oil seal

Compressor crankshaft B/G

Adapter hose joint ●●

FFP assembly Adapter hose joint ●●

Cable Terminal grommet

FFP upper grommet

FFP lower grommet

Pipe grommet

Gear case Gear B nut ●●

Propeller shaft housing

Propeller shaft housing O-ring

Propeller shaft oil seal

Propeller shaft

Propeller stopper

Propeller thrust holder

Water pump case, lower

Water pump case (lower) O-ring

Water pump case (lower) oil seal

Pump case bolt

Water pipe

Water pipe seal rubber, upper

Water pipe seal rubber, lower a●●

Water pipe seal lock rubber

Pump case

Engine base seal rubber ●●

Exhaust housing grommet ●● ●●

Idling port grommet ●● ●●

Trim tab retainer bolt

Drive shaft

Three Bond

Thread Lock

Three Bond

Thread Lock

Locitite Sealant

Three Bond

Instant Adhesive

Three Bond

Adhesive

Locitite

Adhesive

2-13

LT-2 LOR#101 KS-64

●● O-rings at 2 locations

●● O-rings at 2 locations

●● O-rings at 2 locations

●● O-rings at 2 locations

●● Air rail, 6 locations

●● Air rail, 3 locations

●● O-rings at 2 locations

●● O-rings at 2 locations

Taper screw

●● Entire outer surface

●● Entire outer surface

●● Apply when inserting pin

●● Entire outer surface

●● Entire outer surface

●● Rollers

●● Inner and outer area of lip

●● Rollers

●● Embedded section (M10PI.O)

●● Embedded section (M10PI.O)

●● Both inner and outer surfaces

●● Both inner and outer surfaces

●● Both inner and outer surfaces

Both inner and outer surfaces

Apply after cleaning all grease from threading

●● Lower inner surface

●●

●● Lip surface

●● Spline surface

●● Tapered surface

●● Spline Surface

●● Lower inner part

●●

●● Lip surface

●● Under-neck surface

●● ●● Upper surface

b●● Exterior

a) Pump case, b) Interior

●● Entire surface

●● Lightly on inner surface

Apply to one of the mating surfaces

Apply to one of the mating surfaces

●●

●● Apply to engine side spline

Cold-&Heat-resistant

lithium grease

OBM grease

2st engine oil

Silicon grease,

Shinetsu grease

Oil Center

Research cold-

resistant grease

Specified

gear oil

Power torque

fluid *1

Remarks

2-14

1342 1373B Adhesive 648 518 1741 G17

Primer 7471

Gear case Cam rod bushing

Cam rod bushing O-ring, 2.4 to 5.9

Cam rod bushing O-ring, 3.5 to 21.7

Cam rod bushing stopper bolt

Gear case lubricating oil

Gear case bolt ●●

Extension housing bolt ●●

Propeller shaft housing bolt ●●

Stern bracket Bracket bolt

section Bracket bolt cap

Stern bracket washer

Swivel bracket

Steering shaft

Steering shaft bushing

Steering shaft seal ring

Thrust plate

Mounting bolt, upper ●●

Mounting bracket

Tilt stopper

Motor cover, Filler lid hinge

upper Hook lever

Hook lever bushing

Hook lever seal ring

Filler lid seal rubber ●●

PT&T Section PT&T cylinder pin, upper

PT&T cylinder pin, lower

PT&T assembly bolt

PT&T sensor cam bolt

PT&T tilt stopper knob ●●

PT&T oil

Drag link

Control box

Tilt stopper knob ●●

Relief valve O-ring

Spool valve

backup ring

manual valve O-ring

Free piston

O-ring

backup spring

piston

Piston rod assembly

O-ring

backup ring

Nipples ●●

Three Bond

Thread Lock

Three Bond

Thread Lock

Locitite

Sealant

Three Bond

Instant Adhesive

Three Bond

Adhesive

Locitite

Adhesive

2-15

LT-2 LOR#101 KS-64

●● Entire surface

●●

●●

●● Under-neck surface

●● Oil capacity 500 ml

●● Under-neck surface

Under-neck surface

Under-neck surface

●● Fill with grease, apply grease to tapped hole

●● Inner surface

●● Both surfaces

●● Fill interior with grease

●● Sliding surface

●● Sliding surface

●●

●● Sliding surface

Thread

●● Spline surface

●● Sliding surface

●● Sliding surface

●● Sliding surface

●● Sliding surface

●● Sliding surface

●●

●● Sliding surface

●● Shaft surface

●● Use the specified lubricant

●● Sliding surface

●●

●●

●●

●●

●●

●●

●●

●●

●●

Each press-in port

Cold-&Heat-resistant

lithium grease

OBM grease

2st engine oil

Silicon grease,

Shinetsu grease

Oil Center

Research cold-

resistant grease

Specified

gear oil

Power torque

fluid *1

Remarks

2-16

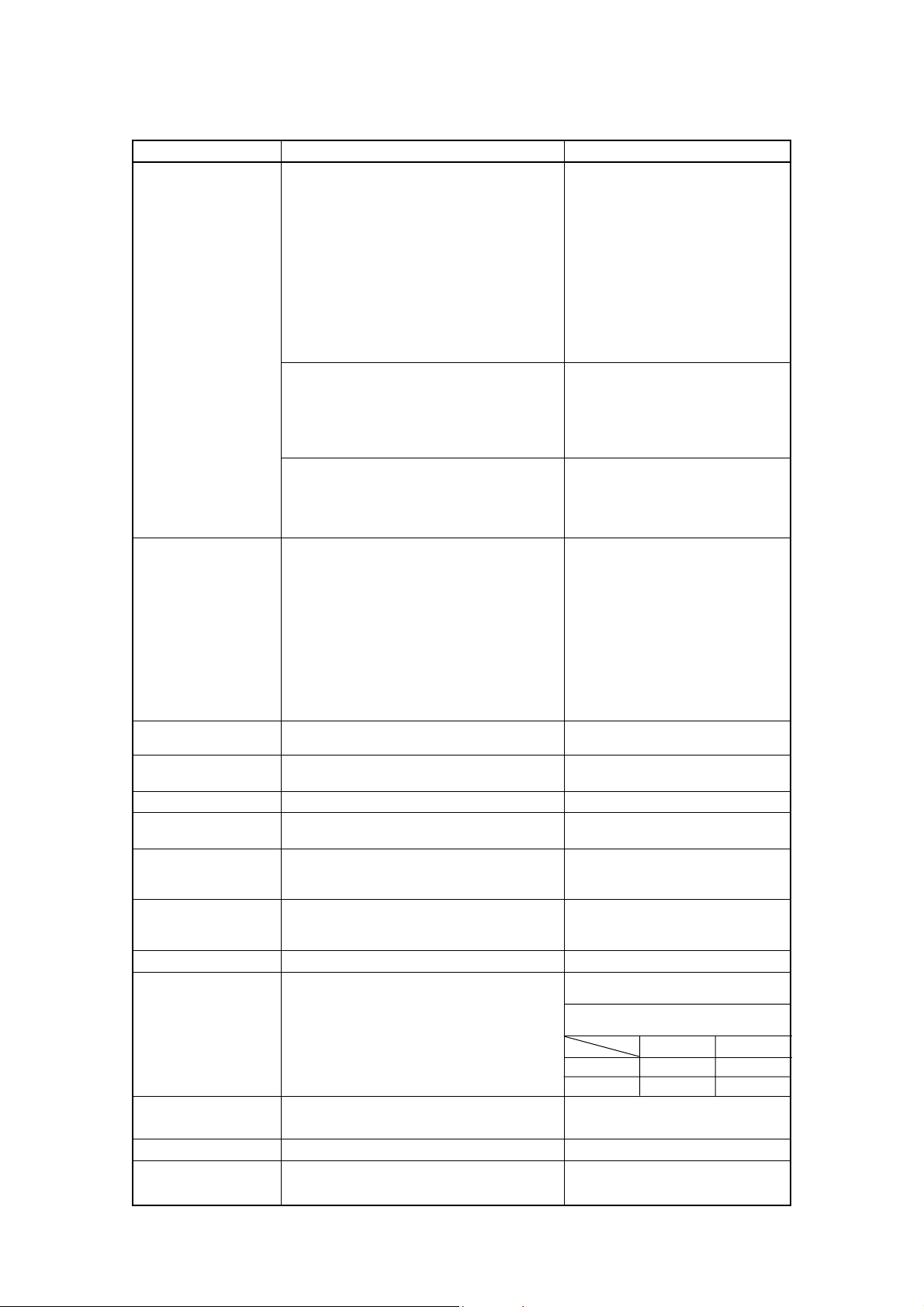

4. Torque Table

Item Part to tighten Initial torque (N-m) Full torque (N-m) Ib-ft

Cylinder head cover to

Bolt (M6)

q2.0 to 2.9

r

4.6 to 6.3 (0.5 to 0.6 kg-m) 3.6 to 4.4

cylinder head (0.2 to 0.3 kg-m)

Cylinder head cover

w12 to 15

cylinder head to Bolt (M8)

(1.2 to 1.5 kg-m)

e

29 to 34 (3.0 to 3.4 kg-m) 22 to 25

and cylinder block

12 to 15

Crankcase Bolt (M8)

(1.2 to 1.5 kg-m)

24 to 26 (2.4 to 2.6 kg-m) 17 to 19

Exhaust cover Bolt (M6)

3.9 to 5.9

7.8 to 9.8 (0.8 to 1.0 kg-m) 5.8 to 7.3

(0.4 to 0.6 kg-m)

Compressor head Bolt (M6) 7.8 to 9.8 (0.8 to 1.0 kg-m) 5.8 to 7.3

Air box Bolt (M6) 7.8 to 9.8 (0.8 to 1.0 kg-m) 5.8 to 7.3

Water temperature sensor — 20 to 23 (2.0 to 2.3 kg-m) 15 to 17

Driven pulley Nut, 10 (M10) 31 to 34 (3.2 to 3.5 kg-m) 23 to 25

Drive pulley Nut pulley (M30) 140 to 160 (14 to 16 kg-m) 102 to 116

Flywheel Nut, 18 (M18) 140 to 160 (14 to 16 kg-m) 102 to 116

Adapter, hose joint — 140 to 160 (14 to 16 kg-m) 102 to 116

Nut, hose joint — 140 to 160 (14 to 16 kg-m) 102 to 116

Valve core

—

0.4 to 0.6 (0.04 to 0.06 kg-m)

0.3 to 0.4

(included in valve assembly)

Sparkplug 25 to 30 (2.5 to 3.0 kg-m) 18 to 22

Cylinder block and

engine base to Bolt (M8) 19 to 21 (1.9 to 2.1 kg-m) 14 to 15

drive shaft housing

Bevel gear B

Nut, bevel gear B (M12)

40 to 58 (4 to 6 kg-m) 29 to 44

Stern bracket Nylon nut 7/8 24 to 26 (2.4 to 2.6 kg-m) 17 to 19

Mount rubber, upper Bolt (3/8) 30 to 34 (3.0 to 3.5 kg-m) 22 to 25

Mount rubber, lower Nylon nut (M12) 40 to 44 (4.0 to 4.5 kg-m) 29 to 33

Gear case Bolt (M8P1.25) 19 to 21 (1.9 to 2.1 kg-m) 14 to 15

Propeller nut — 29 to 39 (3.0 to 4.0 kg-m) 22 to 29

Fuel connector — 5.0 to 6.9 (0.5 to 0.7 kg-m) 3.6 to 5.1

Run yard stop switch —

2.0 to 2.5 (0.2 to 0.25 kg-m) 1.5 to 1.8

Lower cylinder pin Nut, 18 (M18) 69 to 88 (7 to 9 kg-m) 51 to 65

Oil plug (cap) — 2.9 to 4.9 (0.3 to 0.5 kg-m) 2.2 to 3.6

Manual valve — 2.0 to 2.9 (0.2 to 0.3 kg-m) 1.5 to 2.2

Motor screw —

1.6 to 2.2 (0.16 to 0.22 kg-m) 1.2 to 1.6

Motor assembly bolt — 4.9 to 6.9 (0.5 to 0.7 kg-m) 3.6 to 5.1

Oil pump bolt —

4.9 to 5.4 (0.5 to 0.6 kg-m) 3.6 to 4.4

Relief valve assembly — 12 to 14 (1.2 to 1.4 kg-m) 8.7 to 10.2

Check valve assembly — 8.8 to 9.8 (0.9 to 1.0 kg-m) 6.5 to 7.3

Tilt rod guide — 80 to 120 (8 to 12 kg-m) 58 to 87

M4

1 to 2 (0.1 to 0.2 kg-m)

1

M5

3 to 4 (0.3 to 0.4 kg-m)

2 to 3

M6

5 to 6 (0.5 to 0.6 kg-m)

3 to 5

M8 11 to 15 (1.1 to 1.5 kg-m) 8.0 to 11

M10 23 to 31 (2.3 to 3.1 kg-m) 17 to 22

Remark: Tightening order of cylinder head cover and cylinder head is q

⇒w⇒e⇒

r.

Power trim and tilt

Lower unitStandard torque

Engine

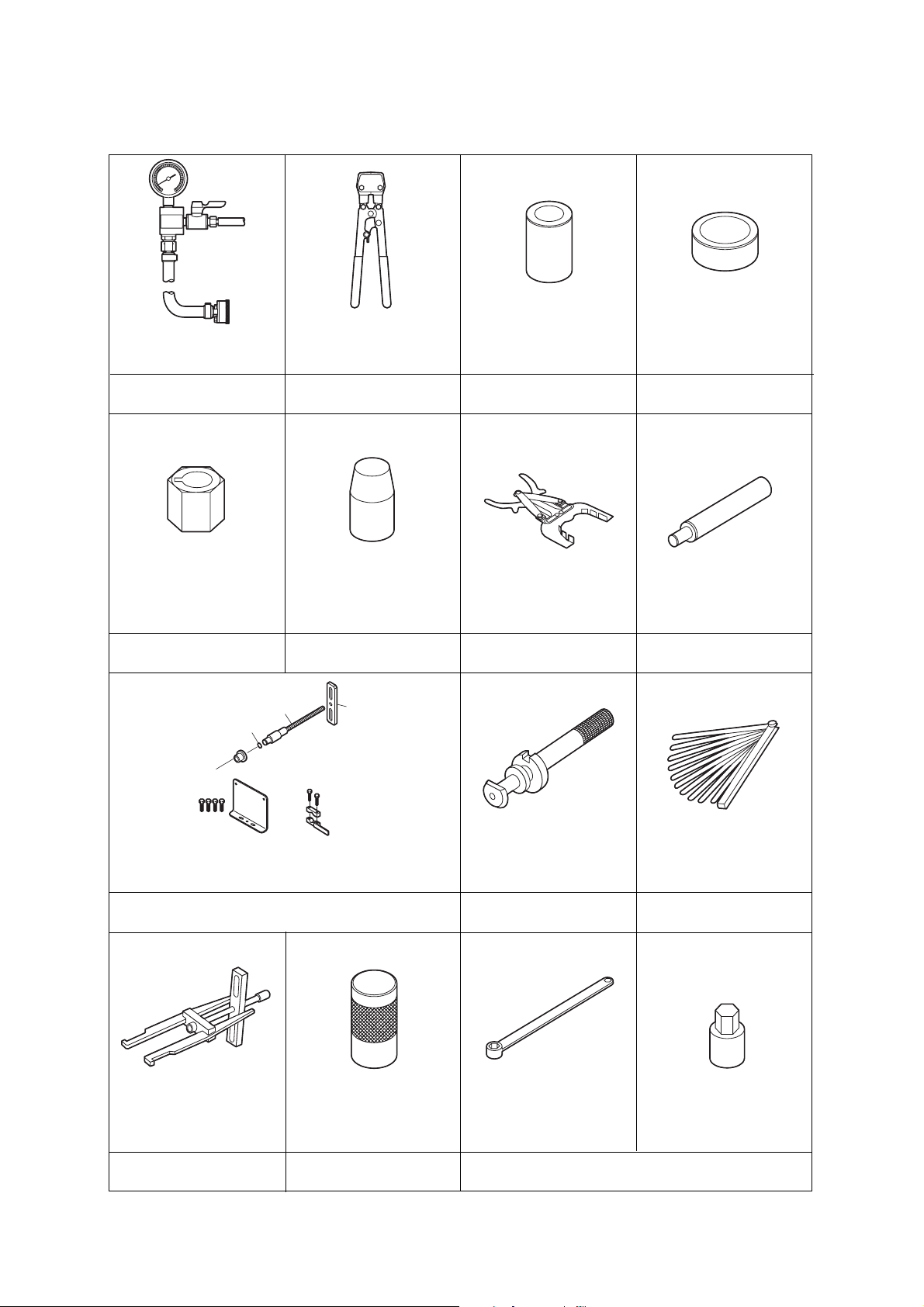

5. Special Tools

1. List of Special Tool

2-17

0.5

01.0

MPa

AIR

5.5MPa

3T5728800

FUEL

0.62MPa

3T5728680

3

T

5

7

2

8

7

1

0

3T5728150

3T5

728630

353-72245-1

332-60002-0

3A3-72713-0

345-72723-0

For removing and installing bevel gear B nut.

Pressure gauge assembly

3T5-72880-0

For measuring air rail fuel and

air pressure.

Crimping pliers

3T5-72864-0

For crimping OETIKER make

clamps.

Drive pulley press

3T5-72868-0

For press fitting in the drive

pulley.

Piston slider

3T5-72871-0

For installing the piston in the

air compressor.

Crankshaft holder

3T5-72815-0

O-ring setting tool (ø24)

3T5-72863-0

For installing O-rings on the

fuel injectors.

Piston ring wrench

353-72249-0

For installing and removing the

piston rings.

Piston pin tool

345-72215-0

For installing and removing

piston pins.

Backlash measuring tool

For measuring backlash between bevel gears A and B.

Thumbing gauge

3C8-72250-0

For measuring between bevel

gears A and B.

Filler gauge

353-72251-0

Bevel gear A bearing

puller assembly

345-72224-2

For removing bearing from

bevel gear A.

Bevel gear A bearing Setting tool

3C8-72719-0

For installing bevel gear

A bearing.

Bevel gear B nut wrench

346-72231-0

Bevel gear B nut socket

346-72232-0

For measuring clearances.

For removing and tightening

on the pulley nut.

Loading...

Loading...