TOHATSU NB-1000, 2 Stroke Cylinder Series Service Manual

PNo. 003-21035-1

0509 NB 1000

Printrd in Japan

ドキュメント105.8.23 1:33PMページ1

TABLE OF CONTENTS

Service Safety

General Service Information

Fuel System

Powerhead

Midsection

1

2

3

4

5

Gearcase

Electrical System

6

7

1-/ 2-Cylinder

i

SECTION 1

SERVICE SAFETY

TABLE OF CONTENTS

Introduction·························································································································· 1-2

Safety Statements················································································································ 1-2

Safety Precautions ··············································································································· 1-3

Workmanship Standards······································································································ 1-5

Test Tank Guidlines ·············································································································· 1-7

1-/ 2-Cylinder

1-1

SECTION 1

Inadequate knowledge of safe shop practices can

result in severe injury or death. Review general

safety procedures and specific safety information

provided for each procedure prior to beginning

any repairs.

WARNING

INTRODUCTION

Marine manufacturers are required to comply with special regulations

and standards to ensure their products are safe and reliable for the

consumer. As the marine technician, it is your responsibility to keep

these products safe when performing normal rigging, repair and

maintenance operations.

It is not possible to foresee all safety hazards which may occur or

to include all the knowledge of an experienced technician in a

single service manual. Therefore, it is assumed that those using this

manual have a working knowledge of 2-cycle outboard engines and the

proper technical training for servicing them.

This section discusses safe shop practices and general safety

concerns relevant to the operations performed throughout this

manual. Read this section carefully and follow all safety statements in

this manual as they pertain to the procedures at hand. Remember,

always use common sense when servicing outboard engines!

SAFETY STATEMENTS

The following safety statements are found throughout this manual

and indicate information which, if ignored, could result in safety

hazards or faulty service techniques:

KC-5030

DANGER

Indicates the presence of a hazard which, if ignored,

WILL result in severe injury or death.

WARNING

Indicates the presence of a hazard which, if ignored,

COULD result in severe injury or death.

CAUTION

Indicates the presence of a hazard which, if ignored,

COULD result in minor personal injury or damage

to product, equipment, or other property.

NOTE

Indicates special information to facilitate the installation,

operation, or maintenance of the product or further

clarify information which is important but not hazard

related.

1-2

1-/ 2-Cylinder

SAFETY PRECAUTIONS

KC-4075.3

Handling Outboard Engines

• Never disable the neutral switch start-in-gear prevention system

to accommodate installation of a foot control or other option.

Always test the neutral switch and emergency stop switch before

returning an engine to the customer.

SERVICE SAFETY

• Lifting devices and hardware must be of suitable capacity for the

weight of the outboard engine. Some models are equipped with

a fixed hanger on the powerhead. Hanger may be used to lift the

complete engine or to remove the powerhead unit. Be aware the

engine may swing outward when lifted by the hanger.

• Engine stands must be in good condition, of adequate size, and

mounted properly to prevent unexpected shifting or collapse.

• Engine covers are guards to prevent personal contact with the

spinning flywheel and high voltage components such as spark

plugs and coils. Never wear jewelry or loose clothing near a

running engine. Keep hands, arms and hair away from the

flywheel. Never touch electrical components when the engine is

running.

•Two people working on a running engine must use extreme caution

and be aware of one another. Never attempt to start an engine or

operate any controls, including steering, before signaling your

partner.

•To prevent accidental startup during operations which may cause

the flywheel to turn, always perform the following steps:

1. Turn the ignition key to OFF and remove the key.

KC-5000

KC-4090

2. Disable the engine ignition system.

3. Shift engine to NEUTRAL and verify propeller shaft is not in

gear.

• Rotating propellers are not equipped with guards and can cause

severe injury or dismemberment. Always stay clear of rotating

propellers and make sure there is no possibility of engine startup

before removing or installing a propeller. The propeller nut must

always be tightened to torque specification prior to starting the

engine.

1-/ 2-Cylinder

1-3

SECTION 1

KC-5050

•Avoid running the engine at high RPM. Engine speed can easily

increase to excessive RPM when under a no load condition. To

avoid engine damage during testing, always use the correct test

propeller and keep engine speed below 2000 RPM.

• Run engines only in well ventilated areas to prevent exposure to

Carbon Monoxide (CO) gas. Direct and prolonged exposure to

CO wiII cause brain damage or death.

• Always wear eye protection, protective clothing, gloves and use

other applicable safety equipment when work activities present

the risk of personal injury.

Lead Acid Batteries

• Never check battery charge by placing a metal object across the

terminal posts; sparks may occur, resulting in serious burns.

•Avoid contact with battery acid. lf battery acid is spilled on skin,

thoroughly wash area with plenty of water. If battery acid gets

into eyes, flush eyes with water for at least 15 minutes and get

prompt medical attention.

• Never remove charger cables from a battery when the charger is

energized; sparks and explosion are possible. To remove charger

cables, follow these steps:

1. Turn the charger to OFF.

2. Disconnect the charger power cord from its power source.

3. Remove the charger cables from the battery posts.

• Batteries emit explosive vapor through the vented caps during

charging. Never charge or test batteries near sparks or flames;

explosion can result. Extinguish all smoking materials and flame

producing devices before charging and make sure the charging

area is weII ventilated.

KC-5032

KC-4080

• Make sure battery vents are not clogged or pressure may build

and cause battery to explode.

1-4

1-/ 2-Cylinder

Hazardous Materials

KC-5001

• Gasoline vapors are highly flammable and can cause an

explosion. Never smoke or allow sparks or flames nearby when

handling fuel Always store gasoline in a shaded, well ventilated

area in an approved safety container.

•Ventilate gasoline fumes as soon as detected. Be aware that

appliance pilot lights, such as those in furnaces and water

heaters, can ignite gasoline vapors and cause explosion.

• Never use gasoline as a cleaner, and always clean up fuel spills

immediately and properly dispose of rags in an approved safety

container.

• Read and follow the safety labels on products used around the

shop. Adhesives, lubricants, solvents, and fuel additives are

usually poisonous and flammable. Store and dispose of these

products properly.

Shop Environment

• Make sure the shop and your work area are properly ventilated.

SERVICE SAFETY

KC-5040

KC-0135

• Shops must be equipped with the proper tools and safety

equipment such as fire extinguisher, eye flushing device, and first

aid kit.

• Keep the shop clean and free of clutter. Clean up spills on the

floor as soon as possible to prevent someone from slipping.

WORKMANSHIP STANDARDS

1. Avoid damage to the mating surfaces of crankcase and cylinder

assembly. Do not use a sharp metal scraper to clean these areas.

2. Replace gaskets, O-rings, seals, cotter pins, lock nuts, and spring

pins when removed during repair operations.

3. Use only genuine factory replacement parts and accessories.

4. Use recommended special tools when specific repairs require

them.

5. Calibrate measurement tools and test equipment on a regular

basis.

6. Clean aIl metal parts with solvent before inspection and assembly

operations.

KC-5055

7. Use penetrating solvents when necessary to remove rusted or seized

hardware.

1-/ 2-Cylinder

1-5

SECTION 1

8. Keep all removed parts separated for ease of identification during

assembly.

9. Locate alignment marks on components being disassembled. If

marks are not present and should be, scribe or match mark them

yourself to ensure the pieces are assembled properly.

10. Follow torque sequences and specifications where they apply.

First, tighten each bolt in the specified sequence. Use the same

sequence to torque each bolt to final specification. Special torque

specifications are listed at the beginning of each section. Standard

torque specifications for common fasteners are listed in Section 3.

11. Use lubricant when assembling seals to prevent damage to the

seal lips. Make sure seal lips are facing the correct direction.

12. Use the correct type and amount of sealing compound on metal

to metal surfaces.

13. When using compressed air to clean or dry parts, make sure air

supply is regulated not to exceed 25 psi [172 kPa /1.76 kg/cm

2

].

14. Replace missing or damaged safety labels on the engine before

returning it to the customer.

1-6

1-/ 2-Cylinder

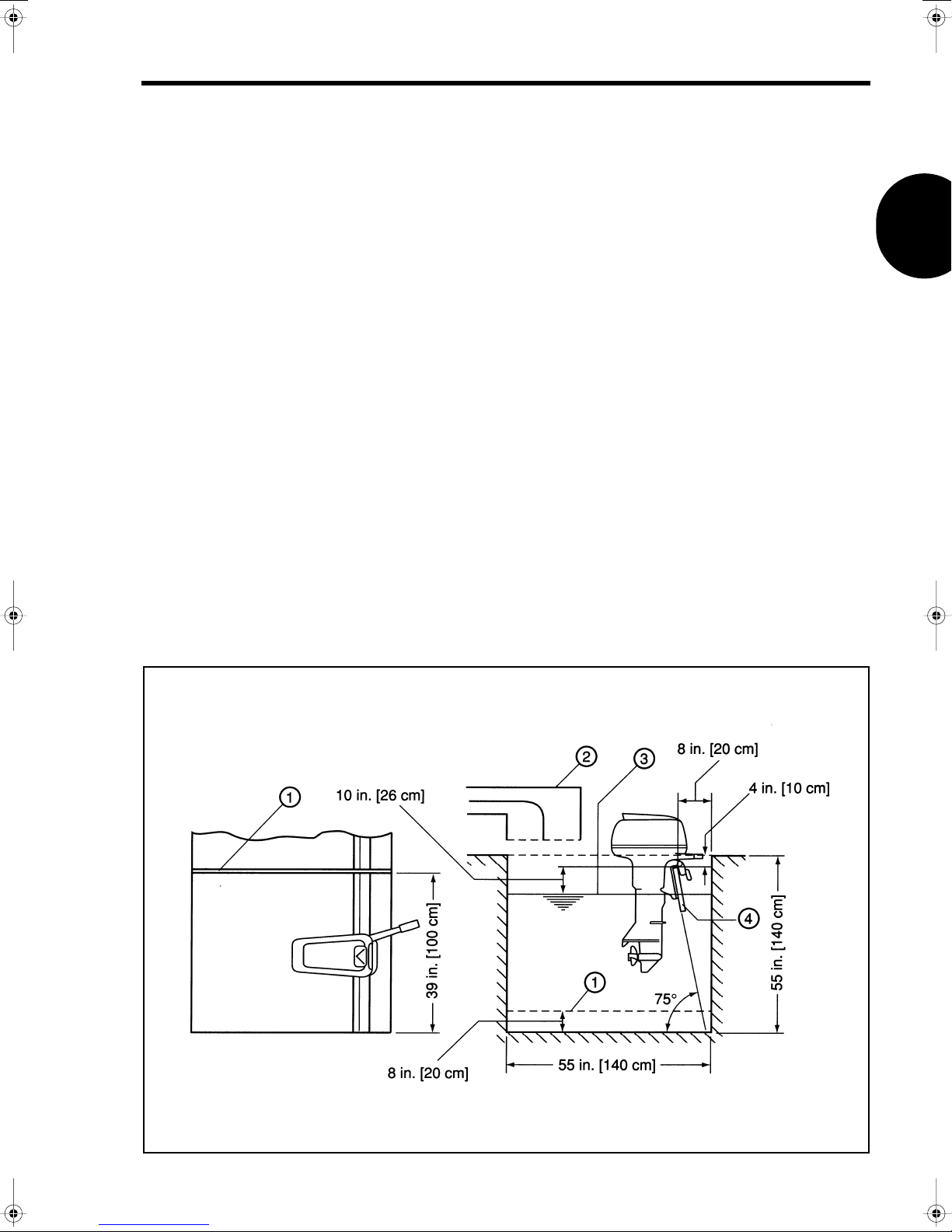

TEST TANK GUIDELINES

When properly setup, test tanks provide a safe and controlled environment

in which to perform outboard engine adjustment and testing procedures.

Test tanks must be setup to the minimum dimensions shown. If multiple

engines wiII be installed in the tank, secure partition plate

minimum dimensions are maintained for each outboard engine installed.

In addition, adhere to the following guidelines to prevent engine damage:

• Continuous usage raises the water temperature in the tankwhich

can lead to engine seizure. Make sure water temperature in the

tank does not exceed 77°F [25°C].

• Repeated use introduces carbon into the water which can adhere

to the engine cooling system and degrade its ability to cool the

engine. Always replace dirty tank water at regular intervals with

clean, fresh water.

• Exhaust gases produced during engine operation can collect

around the engine, causing suction into the carburetors and

affecting engine performance. To prevent this condition, install

forced ventilation equipment

engine and work area.

(2)

to remove gases away from the

(1)

so that the

SERVICE SAFETY

•Water may splash out of the tank during testing. Maintain water

leveI

(3)

in the tank as illustrated.

• Keep transom board

tank bottom to ensure near vertical engine position.

(4)

at an approximately 75° angle to the

1-/ 2-Cylinder

T1016

1-7

SECTION 2

GENERAL SERVICE

INFORMATION

TABLE OF CONTENTS

General Precautions············································································································· 2-2

Abbreviations and Symbols ································································································· 2-3

Unit Conversions·················································································································· 2-4

Service Specifications·········································································································· 2-5

Engine Specifications········································································································· 2-17

Lubrication Chart ··············································································································· 2-20

Periodic Inspections··········································································································· 2-24

Break-ln Procedure ············································································································ 2-27

Tune-Up Procedure ············································································································ 2-28

Emergency Stop Switch and Lanyard················································································ 2-29

Synchronization and Linkage Adjustments········································································ 2-30

Carburetor Adjustment······································································································· 2-36

Anodes - Inspection and Testing ······················································································· 2-38

1-/ 2-Cylinder

2-1

SECTION 2

GENERAL PRECAUTIONS

Before performing any service work on the outboard engine, read

and understand Section 1 - Service Safety.

Use only genuine factory replacement parts with equivalent

characteristics such as type, material, and strength. Failure to do

so may result in product malfunction and injury to the operator or

passengers.

Follow the

value for a certain fastener is not listed in the

Values

Rather than just repairing a bad part, use repair kits and overhaul

kits when applicable to ensure complete and efficient repair of the

complete component. Wear not readily noticed on other parts can

lead to malfunction soon after the repair.

When indicated in a procedure, use manufacturer special tools. ln

some cases, the use of substitute tools will damage the part.

When using compressed air to clean or dry parts, make sure air

supply is regulated not to exceed 25 psi [172 kPa / 1.76 kg/cm

Standard Torque Values

chart at the beginning of each section.

chart when a special torque

Special Torque

2

].

2-2

1-/ 2-Cylinder

GENERAL SERVICE INFORMATION

ABBREVIATIONS AND SYMBOLS

Abbreviations

A

AC

AH

approx.

API

ATDC

BTDC

°C

CCA

cm

3

cm

cm3/min

cu-in

DC

DVA

Kg-m

°F

fl oz

fl oz/min

ft

ft-lb

ft-Ibf/min

g

gal/hr

gal

GL

GM

HP

I.D.

in

in-lb

kg

2

kg/cm

ESG

kPa

kW

ampere

alternating current

ampere-hour

approximately

American Petroleum Institute

after top dead center

before top dead center

degree Celsius

cold cranking amp

centimeter

cubic centimeter

cubic centimeter per minute

cubic inch

direct current

direct volt adapter

kilogram meter

degree Fahrenheit

fluid ounce (U.S.)

fluid ounce (U.S.) per minute

foot

foot pound

foot pound force per minute

gram

gallon (U.S.) per hour

gallon (U.S.)

gear lubricant

General Motors Company

horsepower (U.S.)

inside diameter

inch

inch pound

kilogram

kilogram per square centimeter

electronic speed governor

kilopascal

kilowatt

L

L/hr

lb

mL

mm

mV

N

N·m

NMMA

No.

O.D.

oz

PS

psi

qt

RPM

SAE

sec.

t

TDC

V

VAC

VDC

W

Symbols

°

+

±

Ω

µ

%

liter

liter per hour

pound

milliliter

millimeter

millivolt

newton

newton meter

National Marine

Manufacturers Association

number

outside diameter

ounce

horsepower (metric)

pound per square inch

quart (U.S.)

revolution per minute

Society of Automotive Engineers

second

short ton 2000 lb

top dead center

volt

volt alternating current

volt direct current

watt

angular degree

plus

minus

plus or minus

ohm

micro

percent

1-/ 2-Cylinder

2-3

SECTION 2

UNIT CONVERSIONS

Unit Prefixes

Prefix Symbol Power

mega M x 1,000,000

kilo k x 1,000

centi c x 0.01

milli m x 0.001

micro µ x 0.000001

Units of Length

mile x 1.6090 = km

ft x 0.3050 = m

in x 2.5400 = cm

in x 25.4000 = mm

km x 0.6210 = mile

mx3.2810 = ft

cm x 0.3940 = in

mm x 0.0394 = in

Units of Volume

gal (U.S.) x 3.78540 = L

qt (U.S.) x 0.94635 = L

cu-in x 0.01 639 = L

cu-in x 16.38700 = mL

fl oz (U.S.) x 0.02957 = L

fl oz (U.S.) x 29.57000 = mL

3

cm

cm

3

x 1.00000 = mL

x 0.03382 = fl oz (U.S.)

Units of Torque

ft-lb x 1.3558 = N-m

ft-lb x 0.1383 = kg-m

in-Ib x 0.1130 = N-m

in-lb x 0.0115 = kg-m

kg-m x 7.2330 = ft-lb

kg-m x 86.8000 = in-lb

kg-m x 9.8070 = N-m

N-m x 0.7376 = ft-lb

N-m x 8.8510 = in-lb

N-m x 0.1020 = kg-m

Units of Pressure

psi x 0.0689 = bar

psi x 6.8950 = kPa

psi x 0.0703 = kg/cm

bar x 14.5030 = psi

bar x 100.0000 = kPa

bar x 29.5300 = in Hg (60°F)

kPa x 0.1450 = psi

kPa x 0.0100 = bar

kPa x 0.0102 = kg/cm

2

kg/cm

2

kg/cm

2

kg/cm

in Hg (60°F) x 0.0333 = bar

in Hg (60°F) x 3.3770 = kPa

in Hg (60°F) x 0.0344 = kg/cm

x 14.2200 = psi

x 0.9807 = bar

x 98.0700 = kPa

2

2

2

Units of Mass

lb x 0.45360 = kg

oz x 28.35000 = g

kg x 2.20500 = lb

gx0.03527 = oz

Units of Force

lbf x 4.4480 = N

lbf x 0.4536 = kgf

Nx0.2248 = lbf

Nx0.1020 = kgf

kgf x 2.2050 = lbf

kgf x 9.8070 = N

Units of Power

HP x 1.01400 = PS

HP x 745.70000 = W

HP x 550.00000 = ft-lbf/s

PS x 0.98630 = HP

PS x 735.50000 = W

PS x 542.50000 = ft-lbf/s

Wx0.00134 = HP

Wx0.00136 = PS

Wx0.73760 = ft-lbf/s

kW x 1.34100 = HP

kW x 1.36000 = PS

kW x 737.56000 = ft-lbf/s

ft-lbf/s x 0.00181 = HP

ft-Ibf/s x 0.00184 = PS

ft-lbf/s x 1.35600 = W

Units of Temperature

°F = (1.8 • °C) + 32

°C = 0.556 • (°F - 32)

2-4

1-/ 2-Cylinder

GENERAL SERVICE INFORMATION

SERVICE SPECIFICATIONS

Standard Torque Values

To rque

Size

M4 10 - 17 0.8 - 1.4 1 - 2 0.1 - 0.2

M5 26 - 35 2.2 - 2.9 3 - 4 0.3 - 0.4

M6 44 - 52 3.6 - 4.3 5 - 6 0.5 - 0.6

M8 97 - 133 8 - 11 11 - 15 1.1 - 1.5

M10 204 - 274 17 - 22 23 - 31 2.3 - 3.1

These torque values apply only when a special torque specification is not listed in the

Values

chart at the beginning of each section.

in-lb ft-lb N-m kg-m

Special Torque

1-/ 2-Cylinder

2-5

SECTION 2

2

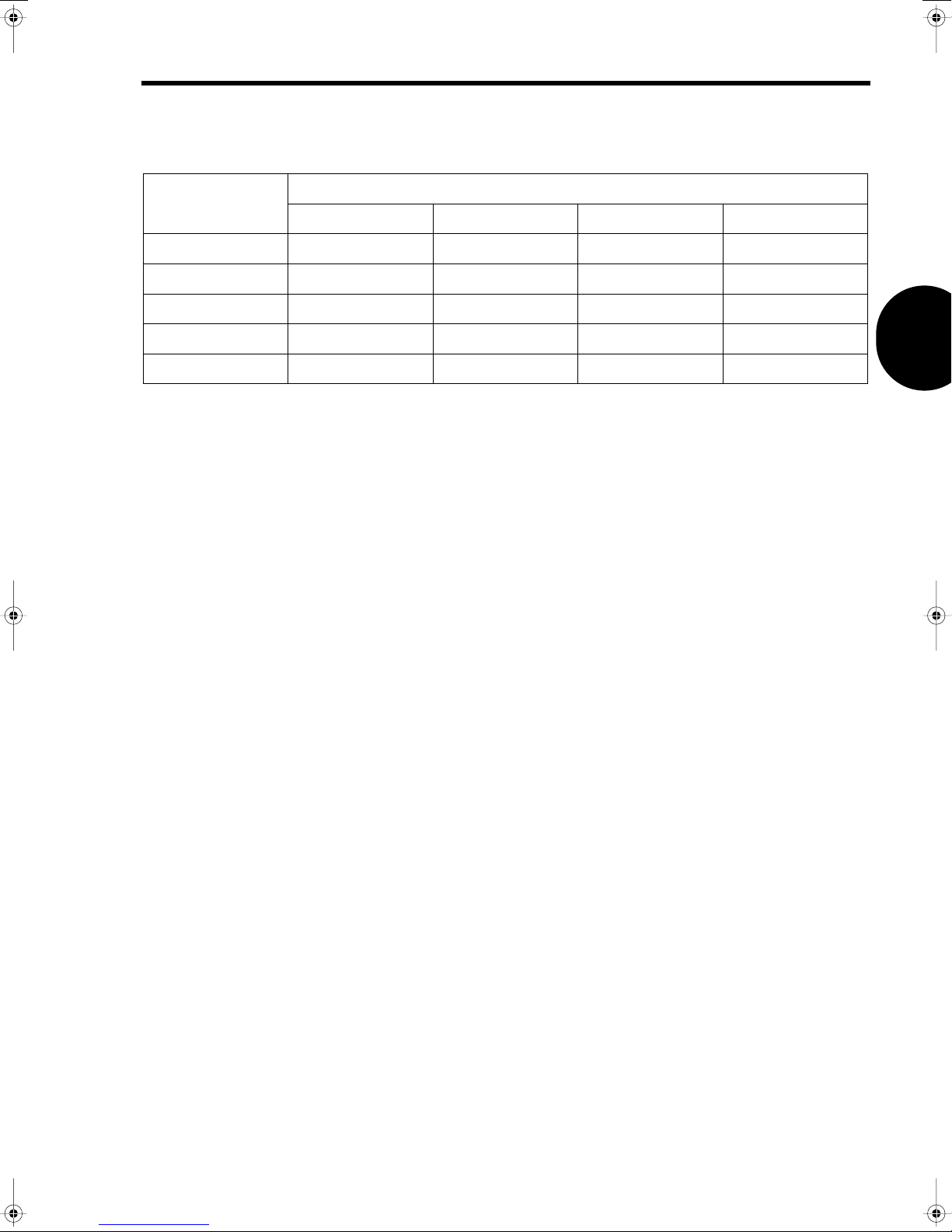

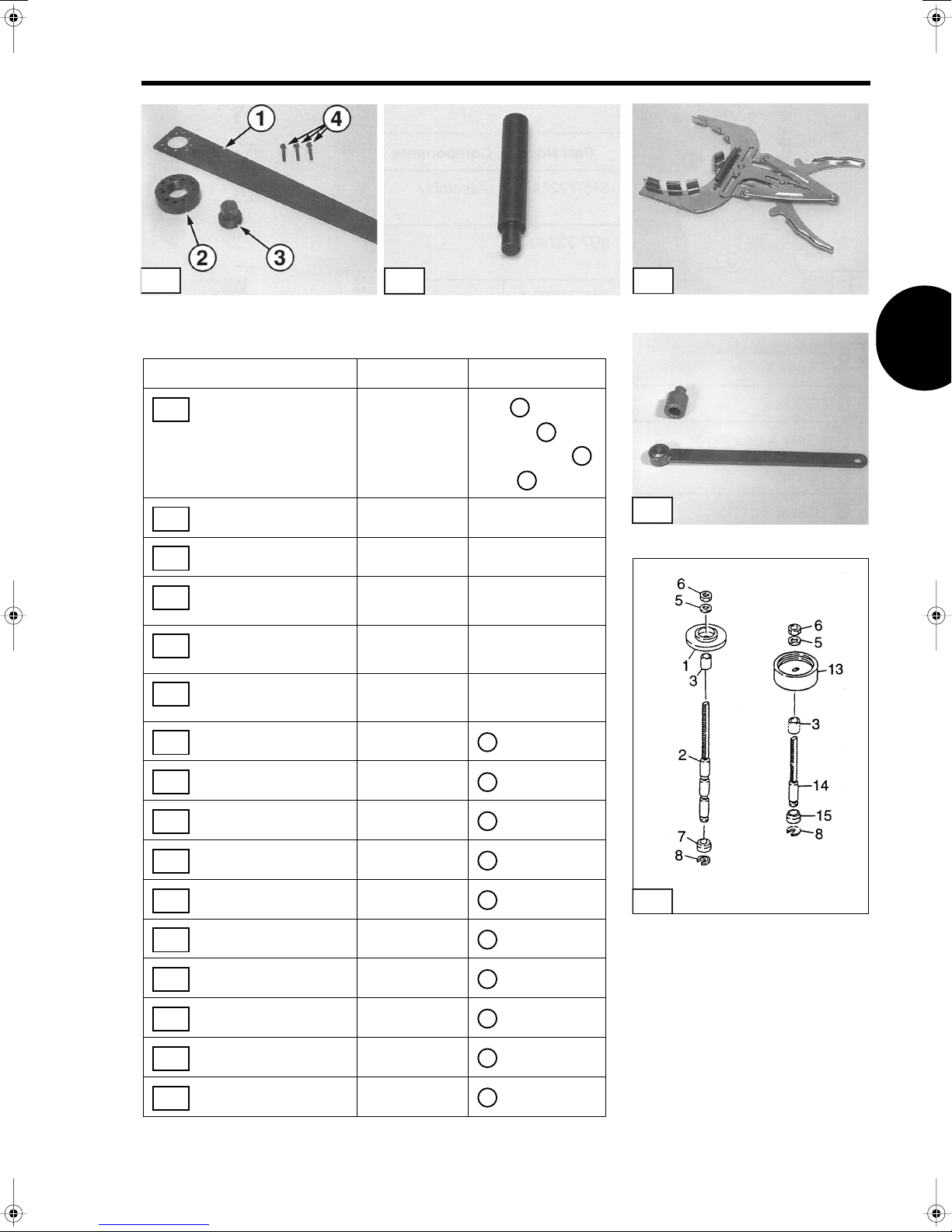

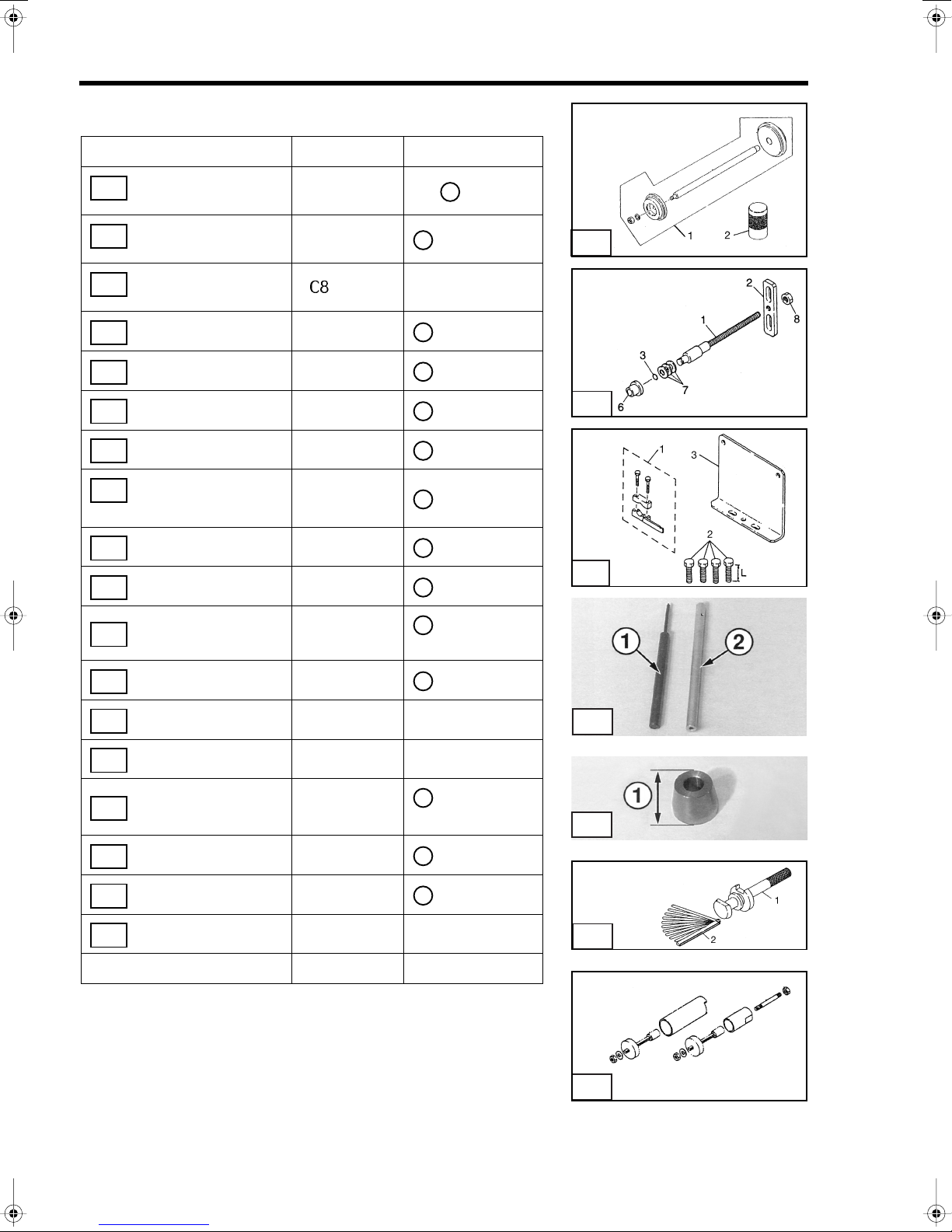

Manufacturer Special Tools Required - 1-2 Cylinder

2.5

/

3.5

Tool Description Part No. Components

Flywheel Puller

1

Assembly

Spring Pin Tool

2

Spring Pin Tool

2

Tool Box 353-72254-0

✳

: For 3.5B

✳

✳

309-72214-0

or

3V1-72211-0

345-72227-0

345-72228-0

Arm

1

Adapter

Pressing Bolt

Bolts

Pin Punch

HoIIow Punch

2

3

4

1

1

2

T1900

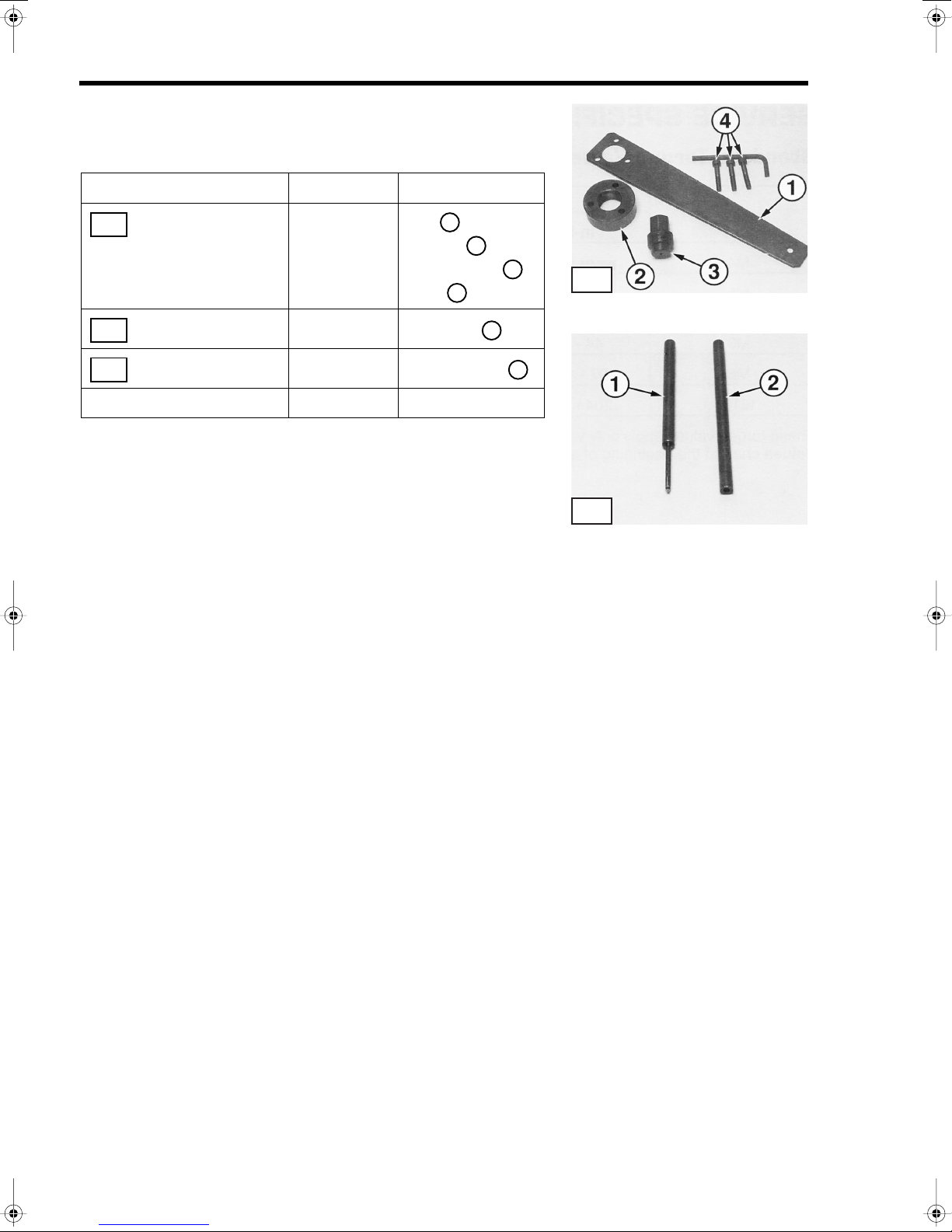

T1902

2-6

1-/ 2-Cylinder

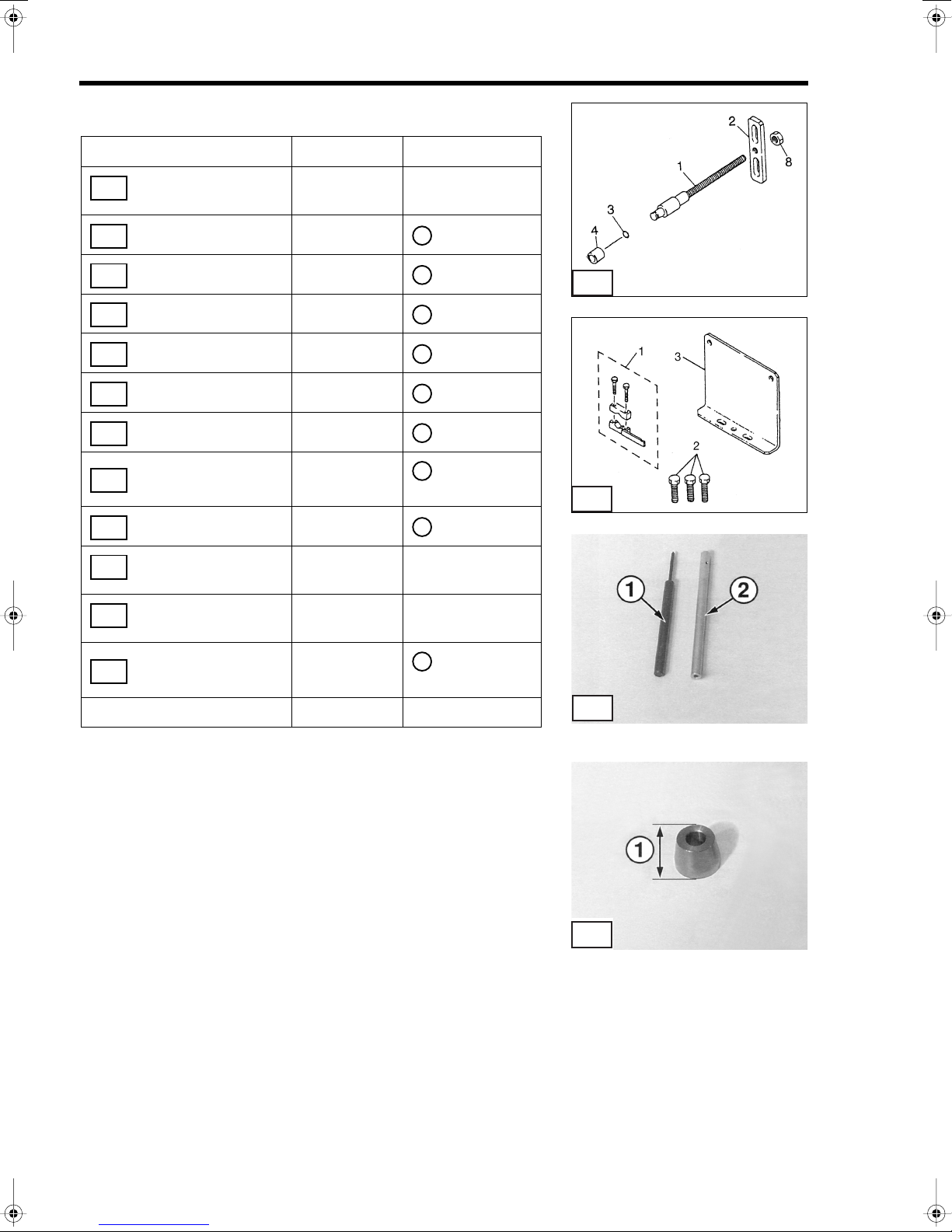

GENERAL SERVICE INFORMATION

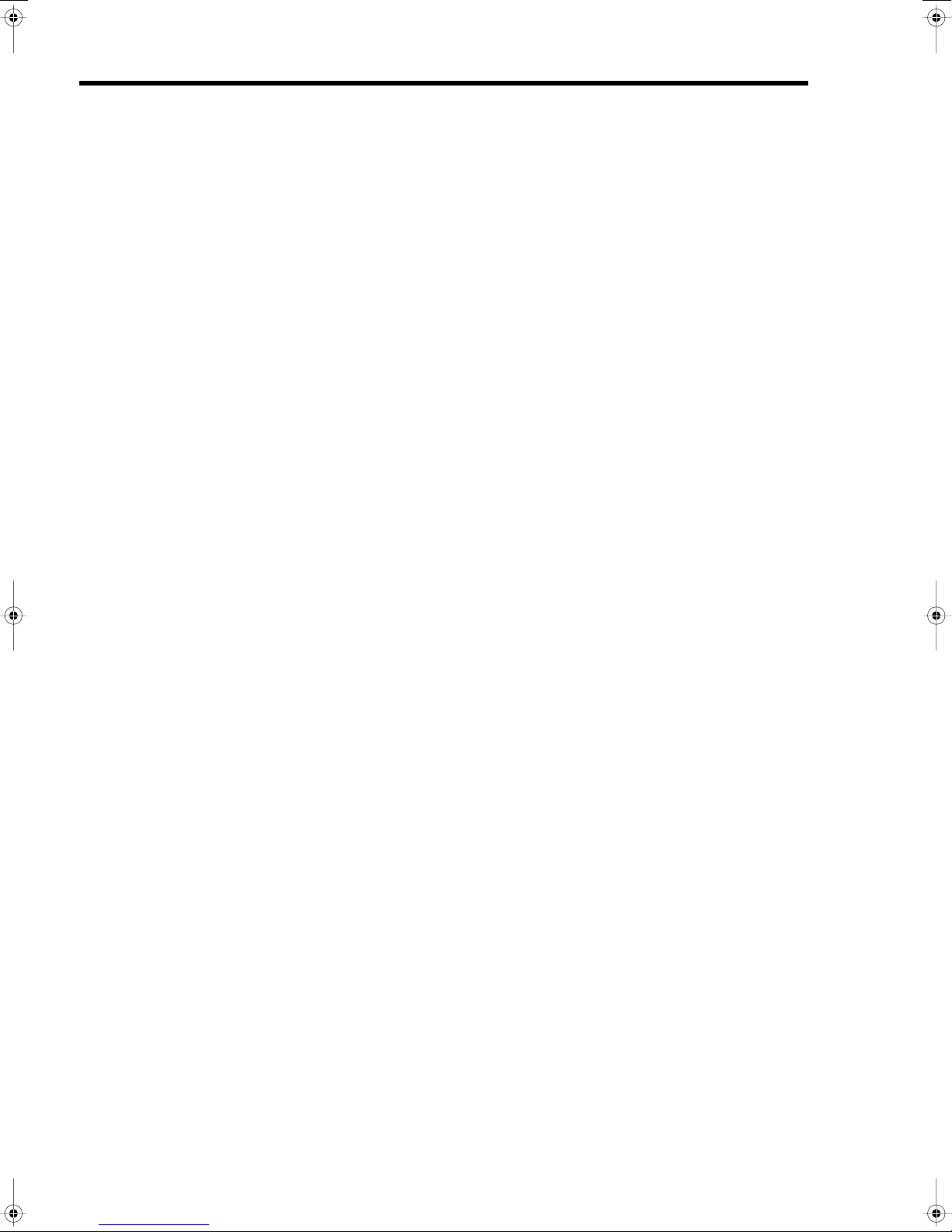

1

4

1

3

T1908

5

1

5

Tool Description Part No. Components

Flywheel Puller

1

Assembly

Piston Pin Tool

2

Piston Ring Tool

3

Driveshaft Needle

6

Bearing Tool Assembly

Backlash Measuring

4

Tool

Sub Assembly

4

T1904

369-72211-0

332-72215-0

353-72249-0

369-72900-0

369-72740-0

369-72730-0

2

Arm

Adapter

Pressing Bolt

Bolts

Kit

Except

and

2

1

2

3

T1901

3

3

4

T1906

T1907

Arm

4

Clamp Assembly

4

Spring Pin Tool

5

(3 mm Dia.)

Spring Pin Tool

5

(3 mm Dia.)

Spring Pin Tool

5

(3.5 mm Dia.)

Spring Pin Tool

5

(3.5 mm Dia.)

Tool Box 353-72254-0

1-/ 2-Cylinder

369-72727-0

3B7-72720-0

345-72227-0

345-72228-0

369-72217-0

369-72218-0

2

3

Pin Punch

HoIIow Punch

Pin Punch

HoIIow Punch

2

6

4

2-7

SECTION 2

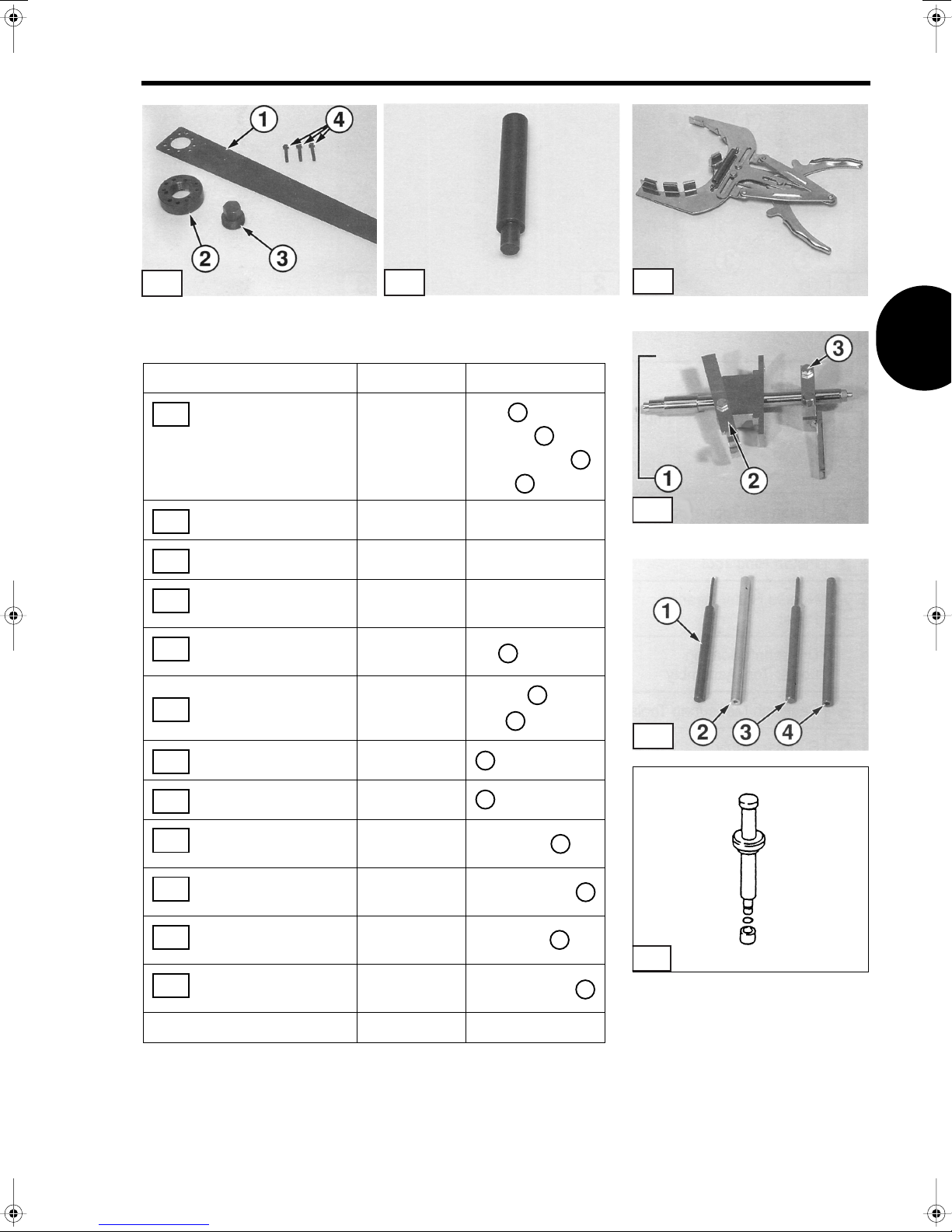

4

1

2

3

T1907

5

1

T1904

8/9.8

Tool Description Part No. Components

Flywheel Puller

1

Assembly

Piston Pin Tool

2

Piston Ring Tool

3

Driveshaft Needle

Bearing Tool Assembly

Backlash Measuring

5

Tools

Sub Assembly

5

2

369-72211-0

332-72215-0

353-72249-0

3B2-72900-0

369-72740-0

369-72730-0

Arm

Adapter

pressing Bolt

Bolts

Kit

Except

and

3

T1910

1

2

3

4

T1906

4

1

2

3

Arm

5

clamp Assembly

5

spring Pin Tool

6

(3 mm Dia.)

spring Pin Tool

6

(3 mm Dia.)

spring Pin Tool

6

(3.5 mm Dia.)

spring Pin Tool

6

(3.5 mm Dia.)

Tool Box 353-72254-0

2-8

3B2-72727-0

3B7-72720-0

345-72227-0

345-72228-0

369-72217-0

369-72218-0

2

3

Pin Punch

HoIIow Punch

Pin Punch

HoIIow Punch

6

4

T1908

1-/ 2-Cylinder

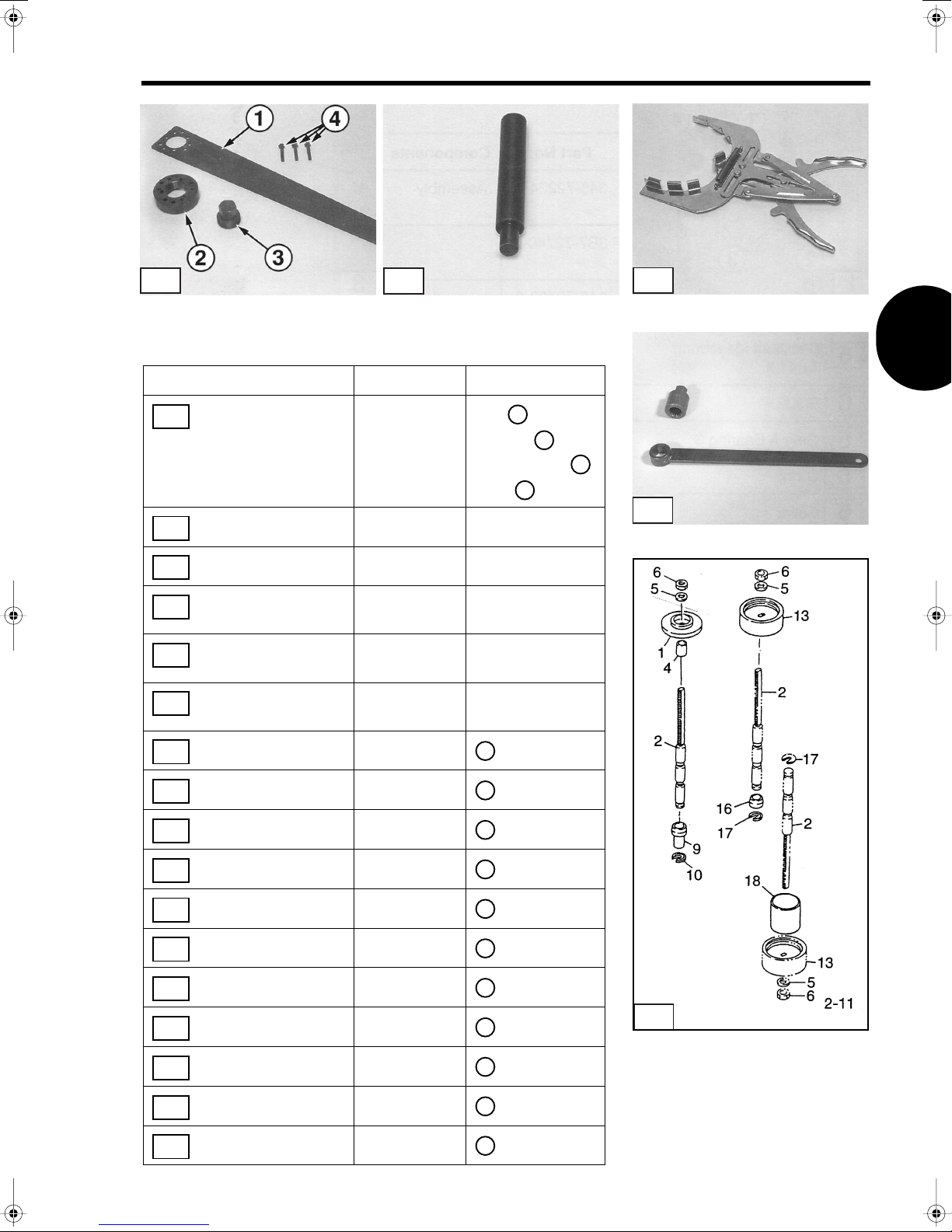

GENERAL SERVICE INFORMATION

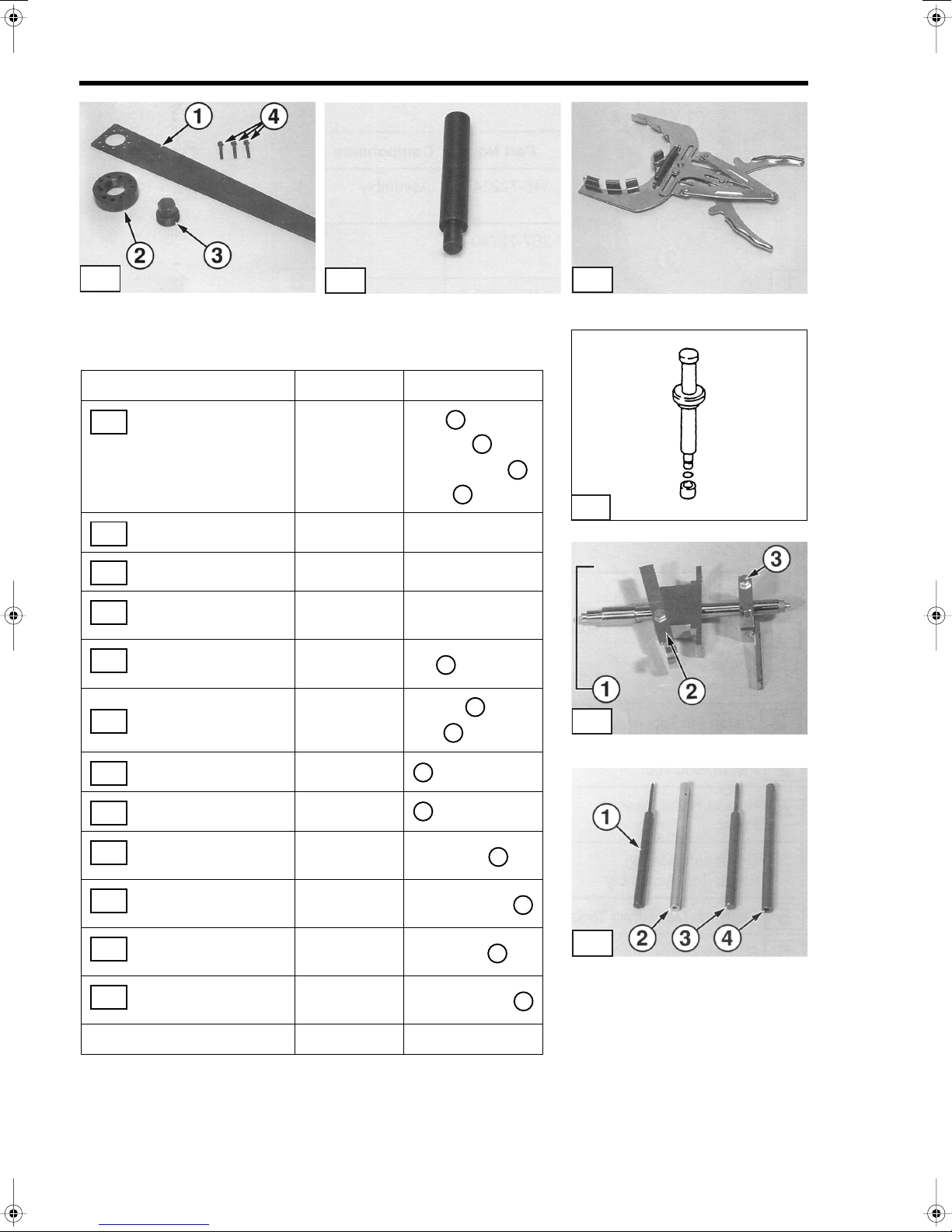

1

2

3

5 56 57 58 513

14

15

5

1

9.9/15/18

Tool Description Part No. Components

Flywheel Puller

1

Assembly

Piston Pin Tool

2

Piston Ring Tool

3

Wrench, Bevel Gear B

4

Nut

Socket, Bevel Gear B

4

Nut

Needle Roller Bearing

5

Puller

T1904

2

369-72211-0

332-72215-0

353-72249-0

346-72231-0

350-72232-0

3C8-72700-0 Kit

Arm

1

Adapter

pressing Bolt

Bolts

2

4

T1910

3

3

4

T1906

T1918

Flange A

5

Shaft

5

Shaft Stopper A

5

Washer

5

Nut, 12P=1.25

Guide A

Retainer A

Flange B

Shaft B

5

Guide B

5

3C8-72701-0

346-72702-0

350-72704-0

346-72707-0

346-72706-0

350-72705-0

350-72703-0

346-72701-5

350-72702-5

350-72705-5

1-/ 2-Cylinder

2-9

SECTION 2

8

T1800

8

9.9/15/18 Continued

Tool Description Part No. Components

Backlash Measuring

6

Tool Kit

Shaft

6

Plate

6

O-ring

6

Collar

6

Nut, M10

6

Clamp Assembly

7

Bolt, H625

7

Plate, Dial Gauge

7

Spring Pin Tool

8

(3 mm Dia.)

Spring Pin Tool

(3 mm Dia.)

3C8-72234-0 Kit

345-72723-0

3A3-72724-0

332-60002-0

350-72245-0

930191-1000

3B7-72720-0

910191-0625

3B7-72729-0

345-72227-0 Pin Punch

345-72228-0 Hollow Punch

1

2

3

4

, 2 nuts

8

1

for lower

2

pump case

3

6

7

Clutch Pin Snap Tool

9

Tool Box 353-72254-0

350-72229-0

= 1.85 in

1

47 mm

9

T1799

2-10

1-/ 2-Cylinder

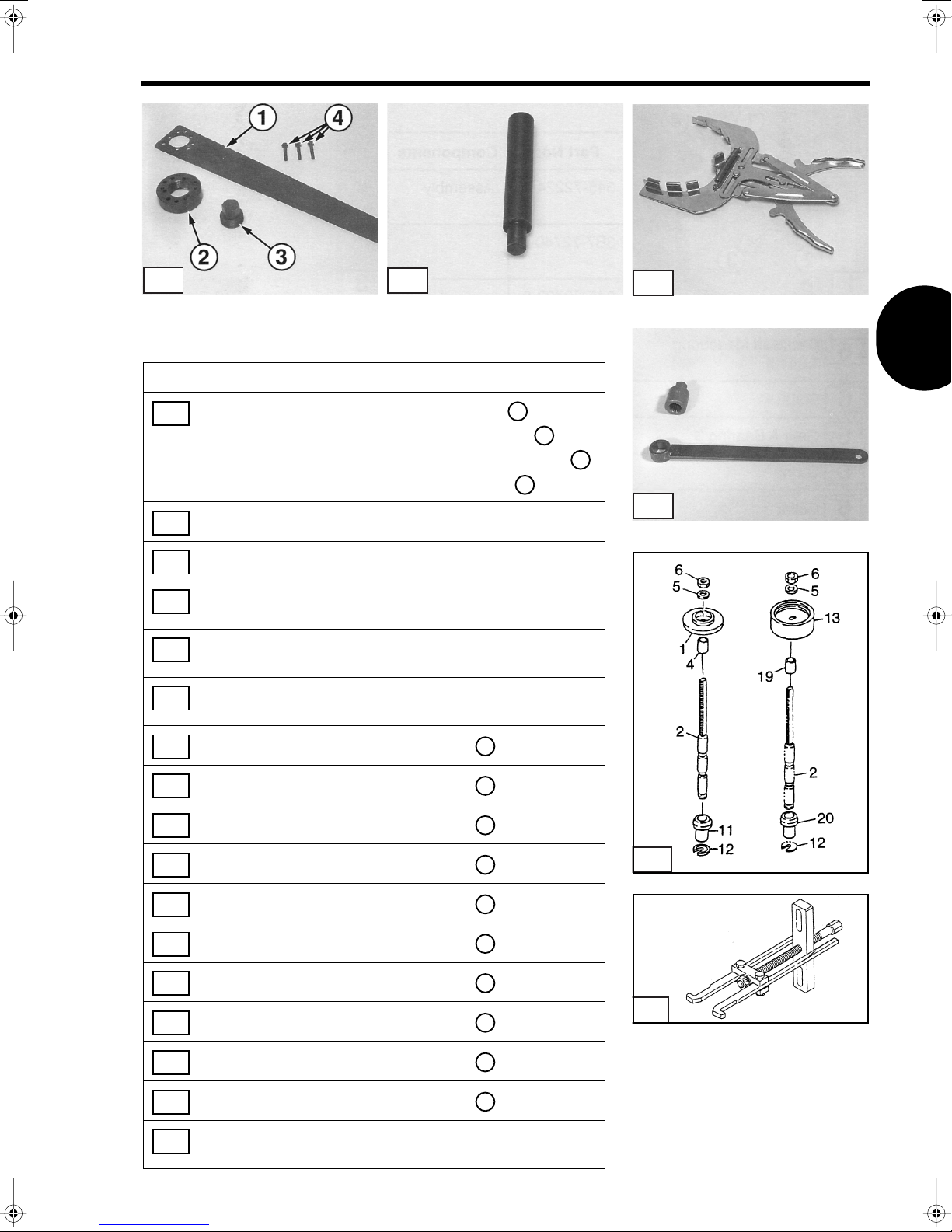

GENERAL SERVICE INFORMATION

4

5

1

T1904

25/30

Tool Description Part No. Components

Flywheel Puller

1

Assembly

Piston Pin Tool

2

Piston Ring Tool

3

Wrench, Bevel Gear

B Nut

Socket, Bevel Gear B

4

Nut

Needle Roller

5

Bearing Puller

2

369-72211-0

345-72215-0

353-72249-0

346-72231-0 Wrench

346-72232-0 Socket

3C8-72700-0 Kit

Arm

Adapter

Pressing Bolt

Bolts

3

T1910

1

2

3

4

4

T1906

T1918

Flange A

5

Shaft

5

Shaft Stopper

5

Washer

5

Nut, 12P=1.25

5

Guide A

5

Retainer A

5

Flange B

5

Guide B

5

Retainer B

5

Spacer

5

3C8-72701-0

346-72702-0

346-72704-0

346-72707-0

346-72706-0

346-72705-0

346-72703-0

346-72701-5

346-72705-5

346-72703-5

346-72708-0

1

2

4

5

6

9

10

13

16

17

18

1-/ 2-Cylinder

2-11

SECTION 2

9

25/30 Continued

Tool Description Part No. Components

Bevel Gear

6

Bearing Puller

Bearing Outer

7

Press Kit

Bevel Gear Bering

7

Installing Tool

Backlash Measuring

8

TooI Kit

Shaft

8

Plate

8

O-ring

8

ColLar

8

Cone Disk

8

Spring, d=12

Nut, M10

8

3A3-72755-0 Assembly

3B7-72739-0

346-72719-0

3C8-72234-0 Kit

345-72723-0

3A3-72724-0

332-60002-0

346-72245-1

3B7-72734-0

930191-1000

Kit,

1

, Ø 32 mm

2

1

2

3

5

, 2pcs

7

6

7

8

Clamp Assembly

9

Bolt, H625

9

Dial Gauge Plate

9

Spring Pin Tool A

10

(3 mm Dia.)

Spring Pin Tool B

10

(3 mm Dia.)

Clutch Pin Snap Tool

11

Shimming Gauge

12

Thinkness Gauge

12

Rubber Mount Puller

13

Tool Box 353-72254-0

3B7-72720-0

910191-0625

3B7-72729-0

345-72227-0 Pin Punch

345-72228-0 HoIIow Punch

346-72229-0

346-72250-0

353-72251-0

361-72760-0 Kit

1

for lower

2

pump case

3

= 1.97 in

1

50 mm

1

2

10

11

12

T1800

T1799

2-12

13

T1929

1-/ 2-Cylinder

GENERAL SERVICE INFORMATION

4

5

1

T1904

40

Tool Description Part No. Components

Flywheel Puller

1

Assembly

Piston Pin Tool

2

Piston Ring Tool

3

Wrench, Bevel Gear

B Nut

Socket, Bevel Gear

4

B Nut

Needle Roller

5

Bearing Puller

2

Arm

369-72211-0

345-72215-0

353-72249-0

346-72231-0 Wrench

345-72232-0 Socket

3C8-72700-0 Kit

Adapter

Pressing Bolt

Bolts

T1910

1

2

3

4

3

T1906

4

T1918

Flange A

5

Shaft

5

Shaft Stopper A

5

Washer

5

Nut, 12P=1.25

5

Guide A

5

Retainer A

5

Flange B

5

Shaft Stopper B

5

Guide

5

Bevel Gear

6

Bearing Puller

3C8-72701-0

346-72702-0

346-72704-0

346-72707-0

346-72706-0

345-72705-0

345-72703-0

346-72701-5

345-72704-5

345-72705-5

3A3-72755-0 Assembly

1

2

4

5

6

11

12

13

19

20

6

1-/ 2-Cylinder

2-13

SECTION 2

2

10

T1800

40 Continued

Tool Description Part No. Components

Bearing Outer

7

Press Kit

Bevel Gear Bering

7

Installing Tool

Backlash Measuring

8

Tool

Shaft

8

Plate

8

O-ring

8

Collar

8

Cone Disk

8

Spring, d=12

Nut, M10

8

Clamp Assembly

9

Bolt, H625

9

3B7-72739-0

3C8-72719-0

3

-72234-0

345-72723-0

3A3-72724-0

332-60002-0

353-72245-1

345-72763-0

930191-1000

3B7-72720-0

910191-0625

1

Kit,

, Ø 42 mm

2

Kit

1

2

3

6

, 3 pcs

7

8

1

for lower

pump case

7

8

9

Plate, Dial Gauge

9

Spring Pin Tool A

10

Spring Pin Tool B

10

Clutch Pin Snap Tool

11

Shimming Gauge

12

Thickness Gauge

12

Rubber Mount Puller

13

Tool Box 353-72254-0

3B7-72729-0

345-72227-0 Pin Punch

345-72228-0 Hollow Punch

345-72229-0

3C8-72250-0

353-72251-0

361 -72760-0 Kit

3

= 2.36 in

1

60 mm

1

2

11

12

13

T1799

2-14

1-/ 2-Cylinder

GENERAL SERVICE INFORMATION

General Equipment Required

Water Pressure Gauge, 0 - 15 psi [0 - 103 kPa / 0 - 1 kg / cm2]

Fuel Pressure Gauge, 0 - 15 psi [0 - 103 kPa / 0 - 1 kg / cm

To rque Wrench, 0 - 150 in-lb [0 - 17 N·m / 0- 1.7kg-m]

To rque Wrench, 0 - 750 ft-lb [0 - 1000 N·m / 0 - 100 kg-m]

Dial Gauge, minimum scale 0.0001 in [0.01 mm]

Micrometer Set or Dial Caliper, minimum scale 0.0001 in [0.01 mm]

Telescoping Gauge, Inside Micrometer Set, or Dial Caliper, minimum scale 0.0001 in [0.01 mm]

Variable Load High Rate Discharge Tester,

Analog Multimeter,

Digital Multimeter,

Electronic Specialties® Model M-530 or equivalent

Electronic Specialties® Model KD 3200 or equivalent

Digital Pulse Tachometer, 10 - 6000 RPM,

Electronic Specialties® Model 700 or equivalent

Electronic Specialties® Model 321 or equivalent

Ammeter, 0 - 100 A

Gearcase Pressure Tester,

Gearcase Vacuum Tester,

Stevens® S-34 or equivalent

Stevens® V-34 or equivalent

Engine Compression Gauge, 0 - 300 psi [0 - 2000 kPa / 0 - 20 kg/cm2]

Spark Gap Tester,

Stevens® S-13C, S-48, or equivalent

Flexible Fuel Tubing, 1/4 in I.D. x 5 in [6 mm I.D. x 127 mm]

Flexible Fuel Tubing, 3/8 in I.D. x 5 in [9.5 mm I.D. x 127 mm]

Industrial Thermometer, minimum 300°F [150°C]

®

Heat-Resistant Container,

Pyrex

Bearing Puller

Seal Pullers

Seal Installers

Heat Gun

Hydrometer

2

]

1-/ 2-Cylinder

2-15

SECTION 2

Consumables Required

Threadlocker,

Threadlocker,

Gasket Dressing,

Gasket Sealant,

Anaerobic Gasket Maker,

Silicone Sealant,

Super Bond Adhesive,

Cleaning Pads,

Low Temperature Lithium Grease

Genuine Grease or Equivalent Friction Surface Marine Grease

Power Trim/Tilt Fluid,

IsopropyI Alcohol

Cleaning Solvent

Gasket Remover

Gear Lubricant,

Engine Lubricant,

Automotive Crankcase Oil, flashpoint above 300°F [150°C]

Battery Spray Protector,

Electrical Shrink Tubing, various diameters

Loctite® 242

Loctite® 243

Permatex® Hylomar® Aerosol High-Temp Gasket Dressing

Permatex® High Tack Gasket Sealant

Loctite® 518

Permatex® Hi-Temp RTV Silicone Gasket

Permatex® Super Glue Gel

Scotch-Brite® Abrasive Pads

Nisseki® power torque fluid or GM approved automatic transmission fluid

Genuine gear oil or APl grade GL5, SAE #80 - #90

Genuine engine oil or NMMA certified TC-W3 oil

Permatex® Battery Protector & Sealer

2-16

1-/ 2-Cylinder

GENERAL SERVICE INFORMATION

ENGINE SPECIFICATI0NS

Operation

Power

2.5 .................................................. 2.5 HP [1.8 kW]

3.5 .................................................. 3.5 HP [2.6 kW]

5 ........................................................ 5 HP [3.7 kW]

8 ........................................................ 8 HP [5.9 kW]

9.8 .................................................. 9.8 HP [7.2 kW]

9.9 .................................................. 9.9 HP [7.3 kW]

15 .................................................. 15 HP [11.0 kW]

18 .................................................. 18 HP [13.2 kW]

25 .................................................. 25 HP [18.4 kW]

30 .................................................. 30 HP [22.1 kW]

40 .................................................. 40 HP [29.4 kW]

Full Throttle RPM Range

2.5 ........................................................3800 - 5200

3.5A

/ 3.5B2.........................................4200 - 5300

2

5 ...........................................................4500 - 5500

8 ...........................................................4500 - 5500

9.8 ........................................................5000 - 6000

9.9 ........................................................4500 - 5300

15, 18 ...................................................5200 - 5800

25 .........................................................5000 - 6000

30 .........................................................5150 - 5850

40 .........................................................5200 - 5800

lN

Idle RPM GEAR NEUTRAL

2.5, 3.5A2...............................1100 —

3.5B

......................................1100 1300

2

5 .............................................. 850 1000

8, 9.8 ....................................... 750 950

9.9, 15, 18 ............................... 800 950

25, 30 ...................................... 900 1050

40 ............................................ 850 1000

Fuel Consumption at Full Throttle

2.5 ............................................. 0.37 g/hr [1.4 L/hr]

3.5 ............................................. 0.45 g/hr [1.7 L/hr]

5 ................................................ 0.66 g/hr [2.5 L/hr]

8 .................................................. 1.0 g/hr [4.3 L/hr]

9.8 ............................................. 1.35 g/hr [5.1 L/hr]

9.9 ............................................. 1.45 g/hr [5.5 L/hr]

15 .............................................. 1.93 g/hr [7.3 L/hr]

18 .............................................. 2.25 g/hr [8.5 L/hr]

25 ............................................ 3.30 g/hr [12.5 L/hr]

30 ............................................... 3.96 g/hr [15 L/hr]

40 ............................................... 4.49 g/hr [17 L/hr]

Test Propeller

2.5, 3.5A2............................................ 309-64111-0

................................................... 3F0-64111-0

3.5B

2

5 ......................................................... 369-64111-0

8, 9.8 .................................................. 3B2-64111-0

9.9, 15, 18 .......................................... 362-64111-0

25, 30 ................................................. 364-64111-5

40 ....................................................... 348-64111-0

Powerhead

Number of Cylinders

2.5, 3.5, 5 .............................................................. 1

8, 9.8, 9.9, 15, 18, 25, 30, 40 ................................ 2

Displacement

2.5, 3.5 .....................................4.6 cu. in [74.6 cm3]

5 ..............................................6.22 cu. in [102 cm

8, 9.8 .......................................10.3 cu. in [169 cm

9.9, 15 ...................................15.07 cu. in [247 cm

18 ..........................................17.94 cu. in [294 cm

25, 30 ....................................26.18 cu. in [429 cm

40 ..........................................30.08 cu. in [493 cm

Standard Bore

2.5, 3.5 ........................................... 1.85 in [47 mm]

5 ..................................................... 2.17 in [55 mm]

8, 9.8 .............................................. 1.97 in [50 mm]

9.9, 15 ............................................ 2.17 in [55 mm]

18 ................................................... 2.36 in [60 mm]

25, 30 ............................................. 2.68 in [68 mm]

40 ................................................... 2.76 in [70 mm]

Stroke

2.5, 3.5 ........................................... 1.69 in [43 mm]

5, 8, 9.8 .......................................... 1.69 in [43 mm]

9.9, 15, 18 ...................................... 2.05 in [52 mm]

25, 30 ........................................... 2.323 in [59 mm]

40 ................................................. 2.520 in [64 mm]

Piston Clearance

2.5, 3.5 ............0.0024 - 0.0035 in [0.06 - 0.09 mm]

5 ..........................0.008 - 0.020 in [0.02 - 0.05 mm]

8, 9.8 ...................0.008 - 0.020 in [0.02 - 0.05 mm]

9.9, 15, 18 .......0.0020 - 0.0035 in [0.05 - 0.09 mm]

25, 30 ..............0.0024 - 0.0039 in [0.06 - 0.10 mm]

40 ....................0.0020 - 0.0039 in [0.05 - 0.10 mm]

Piston Ring End Gap

2.5, 3.5, 5, 8, 9.8 ............................ 0.007 - 0.013 in

[0.18 - 0.33 mm]

9.9, 15, 18 ...........0.008 - 0.019 in [0.20 - 0.40 mm]

25, 30 ..................0.013 - 0.019 in [0.33 - 0.48 mm]

40 ........................0.008 - 0.016 in [0.20 - 0.40 mm]

3

]

3

]

3

]

3

]

3

]

3

]

1-/ 2-Cylinder

2-17

SECTION 2

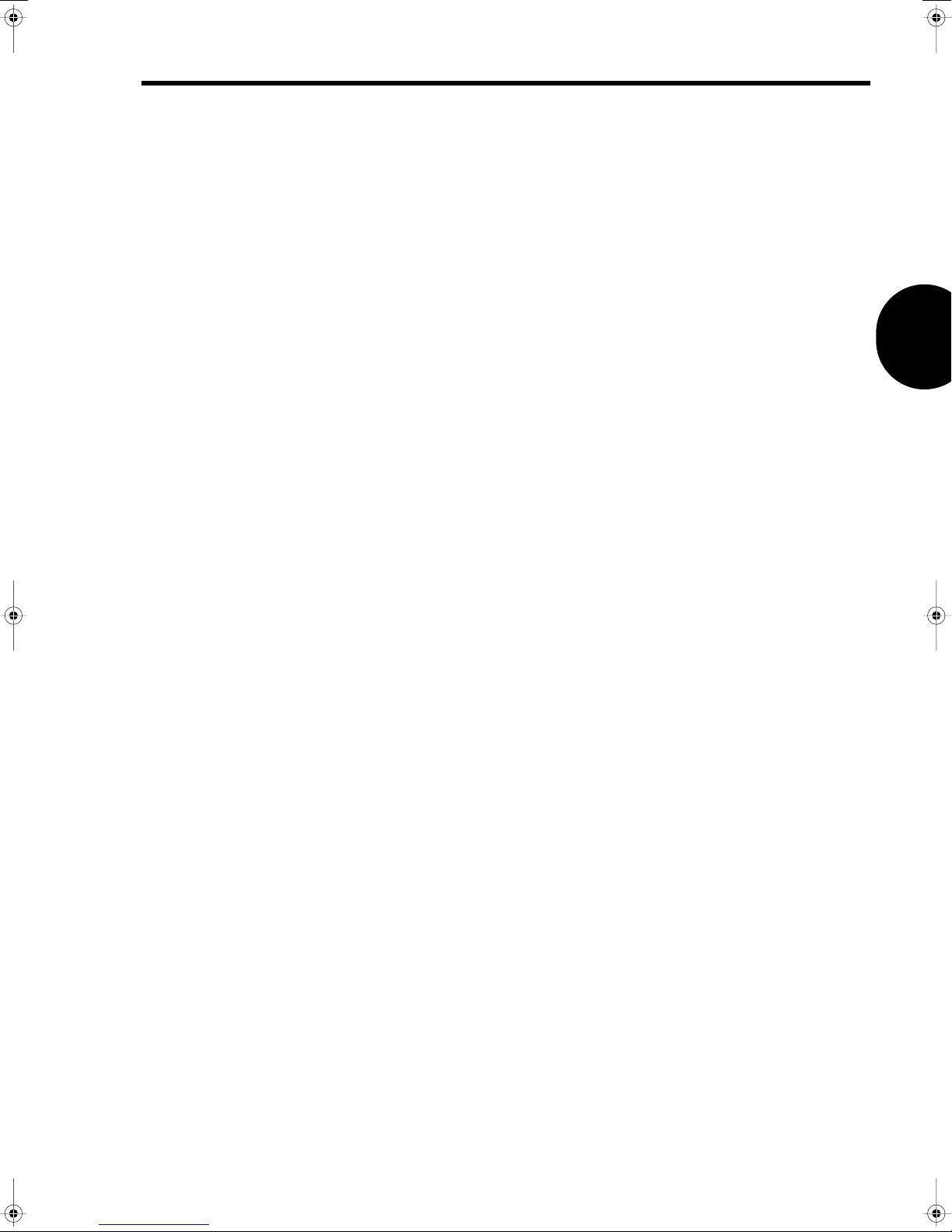

Crankshaft Dimensions

T1044

Dimension

2.5, 3.5 ..................1.417 ± 0.002 in [36 ± 0.05 mm]

5.............................1.575 ± 0.002 in [40 ± 0.05 mm]

8, 9.8......................1.654 ± 0.002 in [42 ± 0.05 mm]

9.9, 15, 18................1.890 ± 0.004 in [48 ± 0.1 mm]

25, 30......................2.047 + 0 in [52 + 0 mm]

40..........................2.071 + 0 in [52.6 + 0 mm]

Dimension

2.5, 3.5...................................................................N/A

5.............................................................................N/A

8, 9.8.........................0.984 ± 0.002 in [25 ± 0.05 mm]

9.9, 15, 18.................1.299 ± 0.002 in [33 ± 0.05 mm]

25, 30........................1.496 ± 0.002 in [38 ± 0.05 mm]

40...........................1.591 ± 0.002 in [40.4 ± 0.05 mm]

1

-

0.001 - 0.02

-

0.002 - 0.05

2

Gearcase

Gear Ratio

2.5, 3.5.............................................................. 13 : 24

5........................................................................ 13 : 28

8, 9.8................................................................. 13 : 27

9.9, 15, 18......................................................... 13 : 24

25, 30................................................................ 12 : 23

40...................................................................... 13 : 25

Lubricant

Capacity

2.5A, 3.5A .....................Approx. 3.0 U.S. fl oz [90 mL]

3.5B ............................Approx. 6.1 U.S. fl oz [180 mL]

5..................................Approx. 6.6 U.S. fl oz [195 mL]

8, 9.8.........................Approx. 10.8 U.S. fl oz [320 mL]

9.9, 15, 18.................Approx. 12.5 U.S. fl oz [370 mL]

25, 30..........................Approx. 9.5 U.S. fl oz [280 mL]

40..............................Approx. 14.2 U.S. fl oz [420 mL]

................................ Genuine manufacturer

gear oil or API GL5, SAE #80 - #90

Clutch System

2.5, 3.5A........................ None (Forward gear only)

3.5B.............................................. Dog clutch type

(Forward gear and Neutral only)

5, 8, 9.8, 9.9, 15, 18, 25, 30, 40 ........... Dog clutch

type (Forward-Neutral-Reverse)

Electrical System

Ignition Type............. Flywheel magneto capacitor

discharge

Ignition Timing

See Ignition Timing Adjustment in Section 2

Spark Plug (with resistor)

2.5, 3.5 .................................. NGK BPR6HS-10 or

Champion RL87YC10

5, 8, 9.8 .................................. NGK BPR7HS-10or

Champion RL82YC10

9.9, 15, 18, 25, 30, 40 ............. NGK BR7HS-10 or

Champion RL82C10

Spark Plug Gap

AII Models .............0.035 - 0.039 in [0.9 - 1.0 mm]

Battery

2.5, 3.5 .......................................................... None

5 .........................None (Optional - 12V 30 - 35 AH

recommended)

8, 9.8 .........................None (Optional - 12V 40 AH

recommended)

9.9, 15, 18 .................None (Optional - 12V 40 AH

recommended)

25, 30 ........................None (Optional - 12V 40 AH

recommended)

40 ..............................None (Optional - 12V 70 AH

recommended)

Engine Fuse

2.5, 3.5 .......................................................... None

5 ................................None (With Optional Battery

Charger - 10A)

8, 9.8 .........................None (With Optional Battery

Charger or Starter - 15A)

9.9, 15, 18 .................None (With Optional Battery

Charger or Starter - 15A)

25, 30, 40 ..................None (With Optional Battery

Charger or Starter - 15A)

2-18

1-/ 2-Cylinder

GENERAL SERVICE INFORMATION

Alternator

2.5, 3.5 ............................................................None

5 ................................... None (Optional - 12V 60W)

8, 9.8 ............................ None (Optional - 12V 80W)

9.9, 15, 18, 25, 30, 40 ...............................12V 80W

Charging Performance (at 1500 RPM)

N/A

Charging Performance (at 5500 RPM)

5 (Optional).........................................................4 A

8, 9.8, 9.9, 15, 18, 25, 30, 40 .............................5 A

Number of Tachometer-to-Alternator

Coil Impulses

2.5, 3.5 .............................................................. N/A

5 ............................................................................ 2

8, 9.8, 9.9, 15, 18, 25, 30, 40 ................................ 4

Alternator Coil Resistance

2.5, 3.5 .............................................................. N/A

5 ......................................................... 0.31 - 0.47

8, 9.8 .................................................. 0.24 - 0.36

9.9, 15, 18, 25, 30 .................... Y-W : 0.65 - 0.98

Y-B : 0.31 - 0.47

W-B : 0.37 - 0.55

40 ............................................. Y-W : 0.65 - 0.98

Y-B : 0.31 - 0.47

W-B : 0.37 - 0.55

Fuel and Lubricant System

Required Fuel, Lubricant, and Mix Ratio

See Fuel System Requirements in Section 3

NOTE

A special mix ratio is required during

break-in. See “Break-ln” at end of

this section.

Carburetor

2.5, 3.5 ...........................................SIide valve type

carburetor, float feed

5, 8, 9.8, 9.9, 15,

18, 25, 30, 40 ........................... Butterfly valve type

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

carburetor, float feed

lgnition Coil Resistance (±25%)

Primary Coil

2.5, 3.5 ............................................... 0.18 - 0.24

5 ........................................................... 0.2 - 0.38

9.9, 15, 18, 25, 30, 40 ............................ 0.2 - 0.3

Secondary Coil

2.5, 3.5 ................................................ 2.7 - 3.7

5 .......................................................... 3.0 - 4.4 KΩ

8, 9.8 ............................................... 1.95 - 3.25 KΩ

9.9, 15, 18 ........................................... 4.1 - 6.1 KΩ

25, 30, 40 ............................................ 4.1 - 6.1 KΩ

K

Ω

Ω

Ω

Ω

1-/ 2-Cylinder

2-19

SECTION 2

2

T1946

T1947

T1948

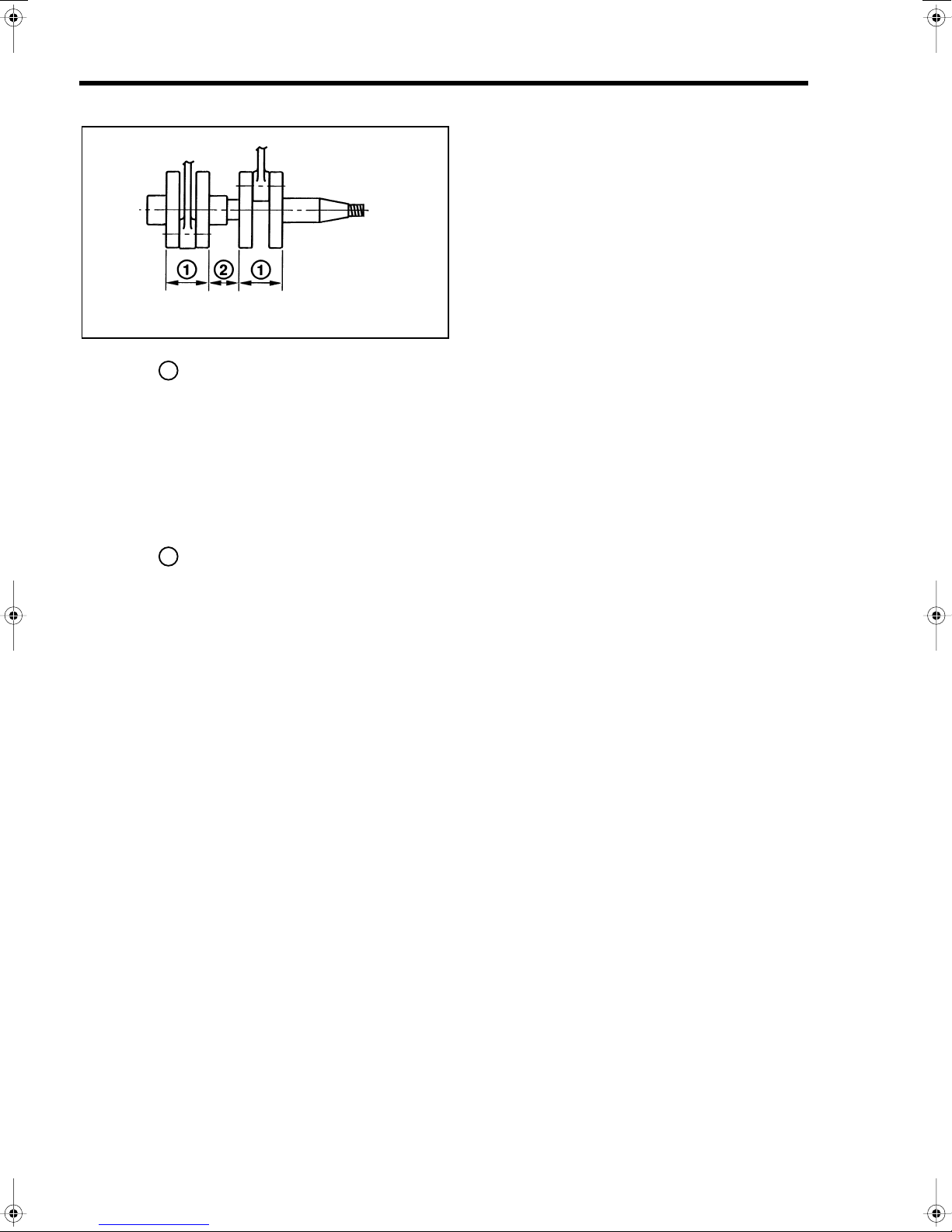

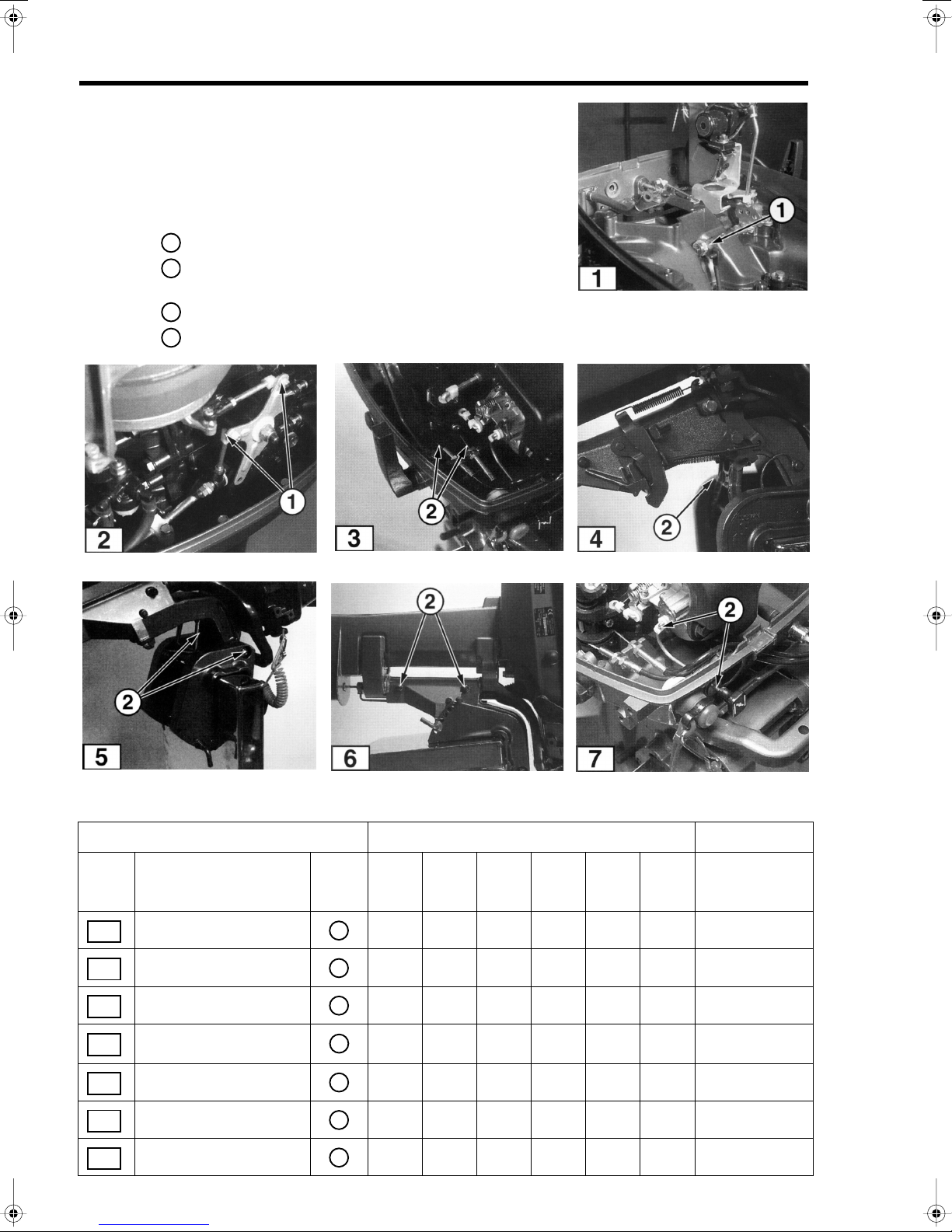

LUBRICATION CHART

NOTE

Recommended intervals are for freshwater

recreational operation. Decrease interval by 50% for

salt water and severe duty (commercial) operation.

Lube Type: = Low Temperature Lithium Grease

1

= Genuine Grease or equivalent Friction

Surface Marine Grease

3

= Non-flammable solvent

4

= Genuine Gear Oil or API Grade GL5 #80 - #90

T1943

T1942

T1944 T1945

Lubrication Points and Lubricant Engine Model Frequency

Fig. Location

1

2

3

4

5

6

7

2-20

Shift Lever Mechanism •••••• 50

Throttle Linkage • • • 50

Throttle Cable • • 50

Tilt Stopper •••••• 50

Bracket Bolt •••••• 50

Bracket Shaft ••••• 50

Carburetor Choke Rod ••••• 50

Lube

Type

1

1

2

2

2

2

2

2.5

3.5 5

8

9.8

9.9

15

18

25

30 40

Hours

1-/ 2-Cylinder

GENERAL SERVICE INFORMATION

T1955

T1956

T1957

T1949

T1801

T1950

T1953

T1951

T1954

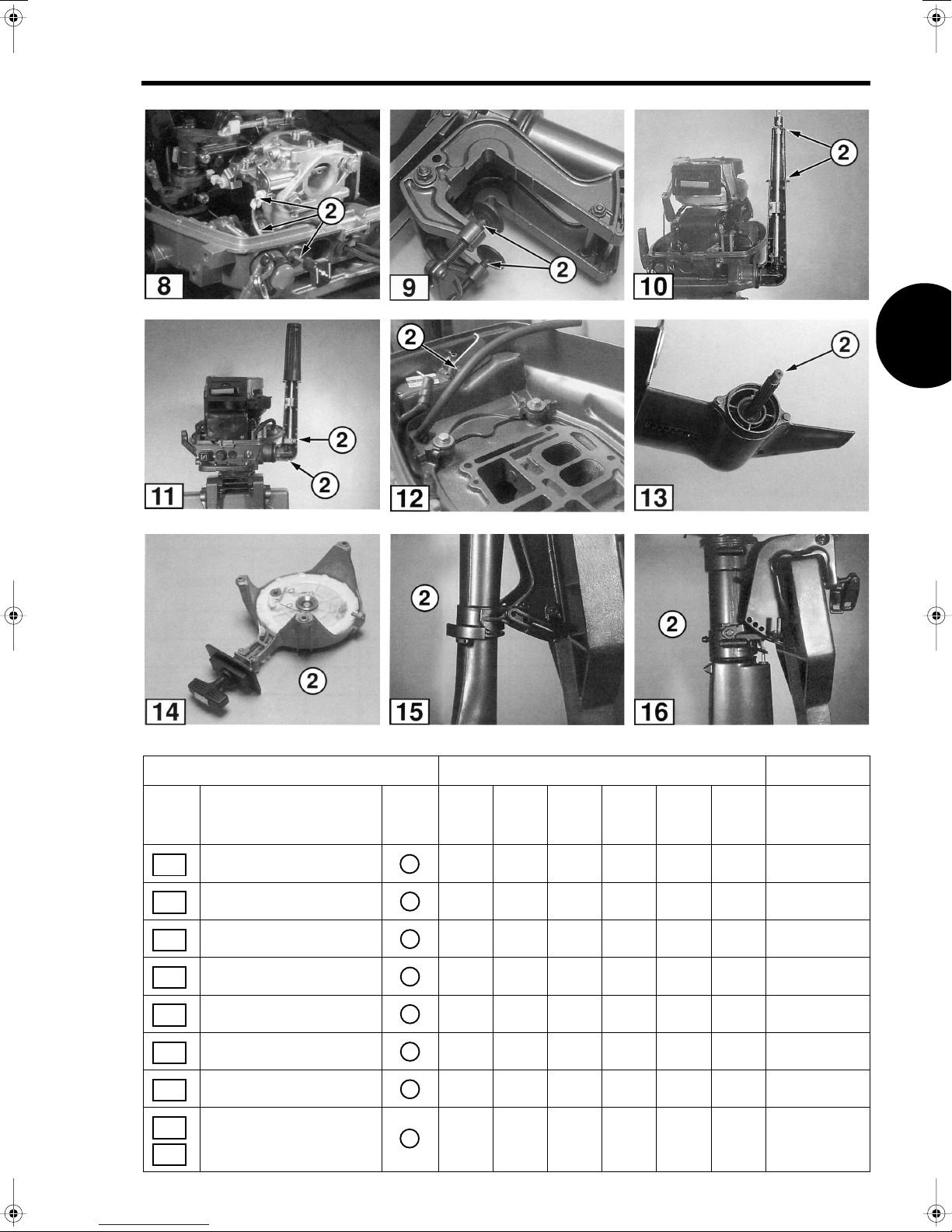

Lubrication Points and Lubricant Engine Model Frequency

Fig. Location

8

9

10

11

12

13

14

15

Choke Mechanism •••••• 50

Clamp Screw •••••• 50

Grip • • • • • 50

Handle •••••• 50

Hook Lever Mechanism • • • • • 50

Propeller Shaft •••••• 50

Recoil Starter •••••• 50

Reverse Lock •••••• 50

16

1-/ 2-Cylinder

Lube

Type

2

2

2

2

2

2

2

2

2.5

3.5 5

8

9.8

9.9

15

18

25

30 40

Hours

2-21

Loading...

Loading...