TOHATSU EVERRUN MX 40D2, EVERRUN MWX 50D2, EVERRUN MX 50D2 Owner's Manual

GB

OWNER’S MANUAL

F

MANUEL

DE L’UTILISATEUR

ES

MANUAL

DEL PROPIETARIO

MX 40D

MX 50D

MWX 50D

OB No.003-11098-2

2

2

2

MX 40D

2

MX 50D

2

MWX 50D

2

OB No.003-11098-2

OWNER’S

MANUAL

READ THIS MANUAL BEFORE USING THE OUTBOARD MOTOR. FAILURE TO FOLLOW THE

INSTRUCTIONS AND SAFETY PRECAUTIONS IN THIS MANUAL CAN RESULT IN SERIOUS

INJURY OR DEATH. KEEP THIS MANUAL IN A SAFE LOCATION FOR FUTURE REFERENCE.

Copyright © 2013 Tohatsu Corporation. All rights reserved. No part of this manual may

be reproduced or transmitted in any from or by any means without the express written

permission of Tohatsu Corporation.

YOUR TOHATSU OUTBOARD MOTOR

OWNER REGISTRATION AND IDENTIFICATION

Upon purchasing this product, be sure that the WARRANTY CARD is correctly and completely filled out and mailed to the addressee noted there on. This WARRANTY CARD

identifies you as the legal owner of the product and serves as your warranty registration.

TO THE EXTENT PERMITTED BY APPLICABLE LAW, YOUR OUTBOARD MOTOR WILL

NOT BE COVERED BY THE APPLICABLE LIMITED WARRANTY, IF THIS PROCEDURE IS

NOT FOLLOWED.

PRE-DELIVERY CHECK

Be sure that the product has been checked by an authorized TOHATSU dealer before you

take delivery.

Limited Warranty

Please refer to the TOHATSU outboard motor Limited warranty provided to you with this

product, the terms and conditions of which, as amended from time to time, are incorpo-

rated by reference into the manual.

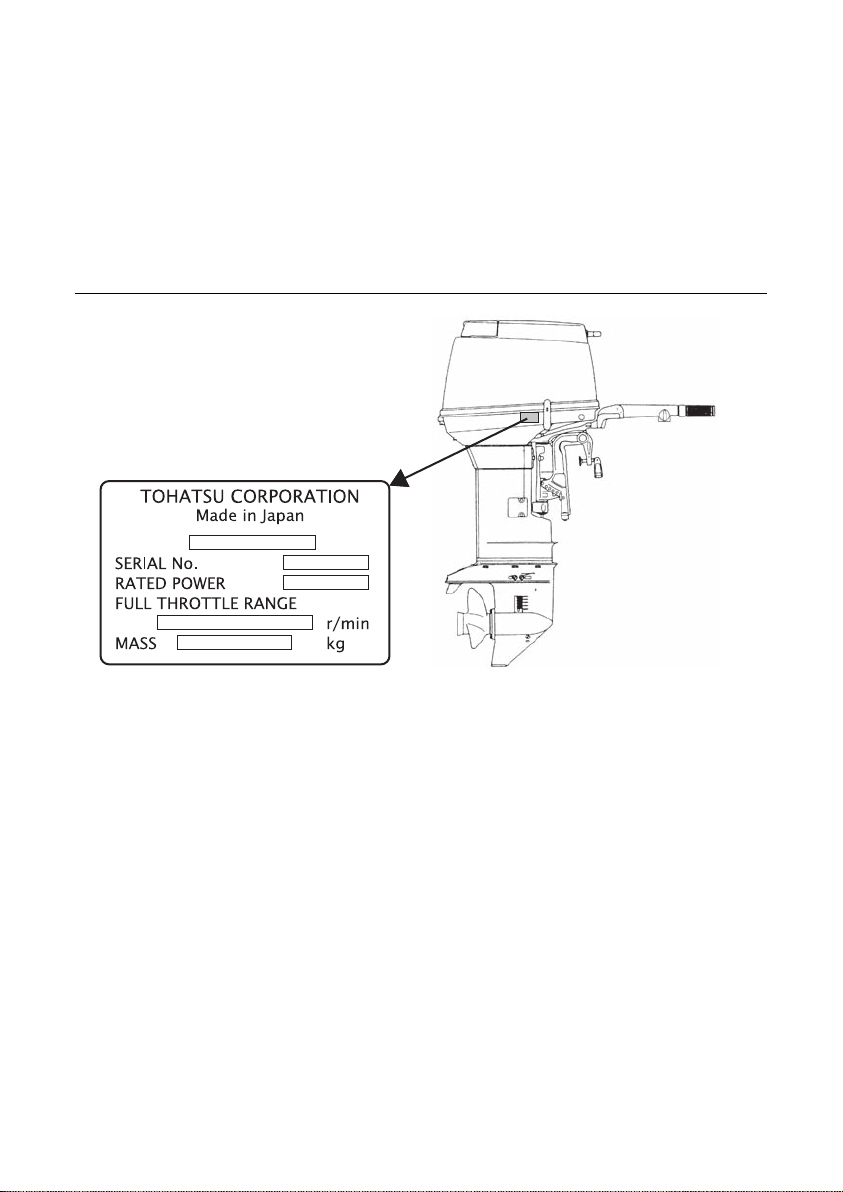

Serial Number

In the space below, please record the outboard motor's serial number (indicated both on

the bottom cowl and on the cylinder block). The serial number will be needed in ordering

spare parts and the event of theft or to quickly identifying the outboard motor type.

Serial Number :

To You, Our Customer

Thank you for selecting a TOHATSU outboard motor. You are now the proud owner of an

excellent outboard motor that will service you for many years to come.

This manual should be read in its entirety and the inspection and maintenance procedures

described later in this manual should be followed carefully. Should a problem arise with the

outboard motor, please follow the troubleshooting procedures listed at the end of this

manual. If the problem persists, contact an authorized TOHATSU service shop or dealer.

We hope you will enjoy your outboard motor and wish you good luck in your boating

adventures.

TOHATSU CORPORATION

CONTENTS

GENERAL SAFETY INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

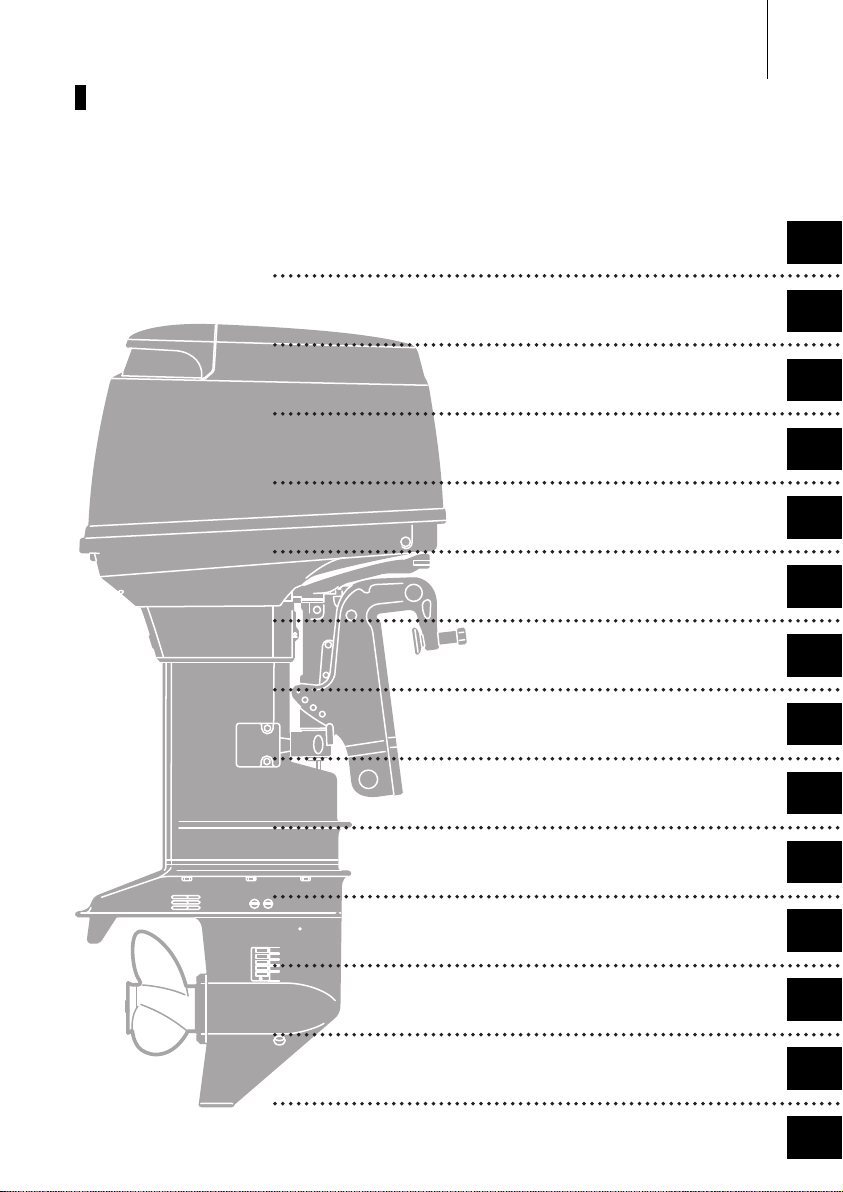

2. NAMES OF PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1. Mounting the outboard motor on boat . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2. Propeller Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3. Installing the battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4. PRE-OPERATING PREPARATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

1. Recommended gasoline types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2. Recommended engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3. Break-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5. ENGINE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

1. Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2. Warming up the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3. Forward and reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4. Shallow water running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5. Stopping the engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6. Trim angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7. Mooring with the engine tilted up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6. REMOVING AND CARRYING THE OUTBOARD MOTOR. . . . . . . . . . . . . . 33

1. Removing the outboard motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2. Carrying the outboard motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3. Storing the outboard motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7. TRAILERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8. ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

1. Trim tab adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

2. Steering load adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3. Throttle grip turning load adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9. INSPECTION AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

1. Daily inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2. Periodic inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3. Off-season storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

4. Pre-season check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

5. Checking after striking underwater object . . . . . . . . . . . . . . . . . . . . . . . . .52

6. If the engine becomes submerged in water. . . . . . . . . . . . . . . . . . . . . . . .52

7. Precautions in cold weather. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

11. TOOL KIT AND SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

12. OPTIONAL ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

13. PROPELLER TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

14. WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

53

INDEX

7

GENERAL SAFETY INFORMATION

1. SPECIFICATIONS

2. NAMES OF PARTS

3. INSTALLATION

4. PRE-OPERATING PREPARATIONS

5. ENGINE OPERATION

REMOVING AND CARRYING THE OUTBOARD MOTOR

6.

7. TRAILERING

8. ADJUSTMENT

9. INSPECTION AND MAINTENANCE

1

2

3

4

5

6

7

8

9

10. TROUBLESHOOTING

11. TOOL KIT AND SPARE PARTS

12. OPTIONAL ACCESSORIES

13. PROPELLER TABLE

14. WIRING DIAGRAM

10

11

12

13

14

8

DANGER

WARNING

CAUTION

WARNING

GENERAL SAFETY INFORMATION

NOTICE : DANGER/WARNING/CAUTION/Note

Before installing, operating or otherwise handling your outboard motor, be sure to thoroughly read and understand this Owner's Manual and carefully follow all of the instruc-

tions. Of particular importance is information preceded by the words "DANGER,"

"WARNING," "CAUTION," and "Note." Always pay special attention to such information to

ensure safe operation of the outboard motor at all times.

Failure to observe will result in severe personal injury or death, and possibly property damage.

Failure to observe could result in severe personal injury or death, or property damage.

Failure to observe could result in personal injury or property damage.

Note

This instruction provides special information to facilitate the use or maintenance of the outboard

motor or to clarify important points.

EMERGENCY STOP SWITCH

The Emergency Stop Switch will stall the outboard motor when the stop switch tether is

pulled off. This stop switch tether can be attached to the operator of the outboard motor

to minimize or prevent injuries from the propeller in case the operator falls overboard.

We highly recommend use of the Emergency Stop Switch tether.

Accidental activation of the Emergency Stop Switch (such as the tether being pulled out in

heavy seas) could cause passengers to lose their balance and even fall overboard, or it

could result in loss of power in heavy seas, strong currents, or high winds. Loss of control

while mooring is another potential hazard.

To minimize accidental activation of the Emergency Stop Switch, the 500 mm (20 inch.) stop

switch tether is coiled and can extended to a full 1,300 mm (51 inch.).

SAFE OPERATION OF BOAT

WARNING

As the operator/driver of the boat, you are responsible for the safety of those aboard and

those in other boat around yours, and for following local boating regulations. You should

be thoroughly knowledgeable on how to correctly operate the boat, outboard motor, and

accessories. To learn about the correct operation and maintenance of the outboard motor,

please read through this manual carefully.

It is very difficult for a person standing or floating in the water to take evasive action should

he or she see a power boat heading in his /her direction, even at a slow speed. Therefore,

when your boat is in the immediate vicinity of people in the water, the outboard motor

should be shifted to neutral and shut off.

SERIOUS INJURY IS LIKELY IF A PERSON IN THE WATER MAKES CONTACT WITH A MOV-

ING BOAT, GEAR HOUSING, PROPELLER, OR ANY SOLID DEVICE RIGIDLY ATTACHED TO

A BOAT OR GEAR HOUSING.

SERVICING, REPLACEMENT PARTS & LUBRICANTS

We recommend that only an authorized service shop perform service or maintenance on

this outboard motor. Be sure to use genuine parts, genuine lubricants, or recommended

lubricants.

9

MAINTENANCE

As the owner of this outboard motor, you should be acquainted with correct maintenance

procedures. It is the operator's responsibility to perform all safety checks and to ensure

that all lubrication and maintenance instructions are complied with for safe operation.

Please comply with all instructions concerning lubrication and maintenance. You should

take the engine to an authorized dealer or service shop for periodic inspection at the prescribed intervals.

Correct periodic maintenance and proper care of this outboard motor will reduce the

chance of problems and limit overall operating expenses.

MOUNTING

Outboard motor mounting must be performed by trained service person(s) using lift or

hoist with sufficient capacity.

10

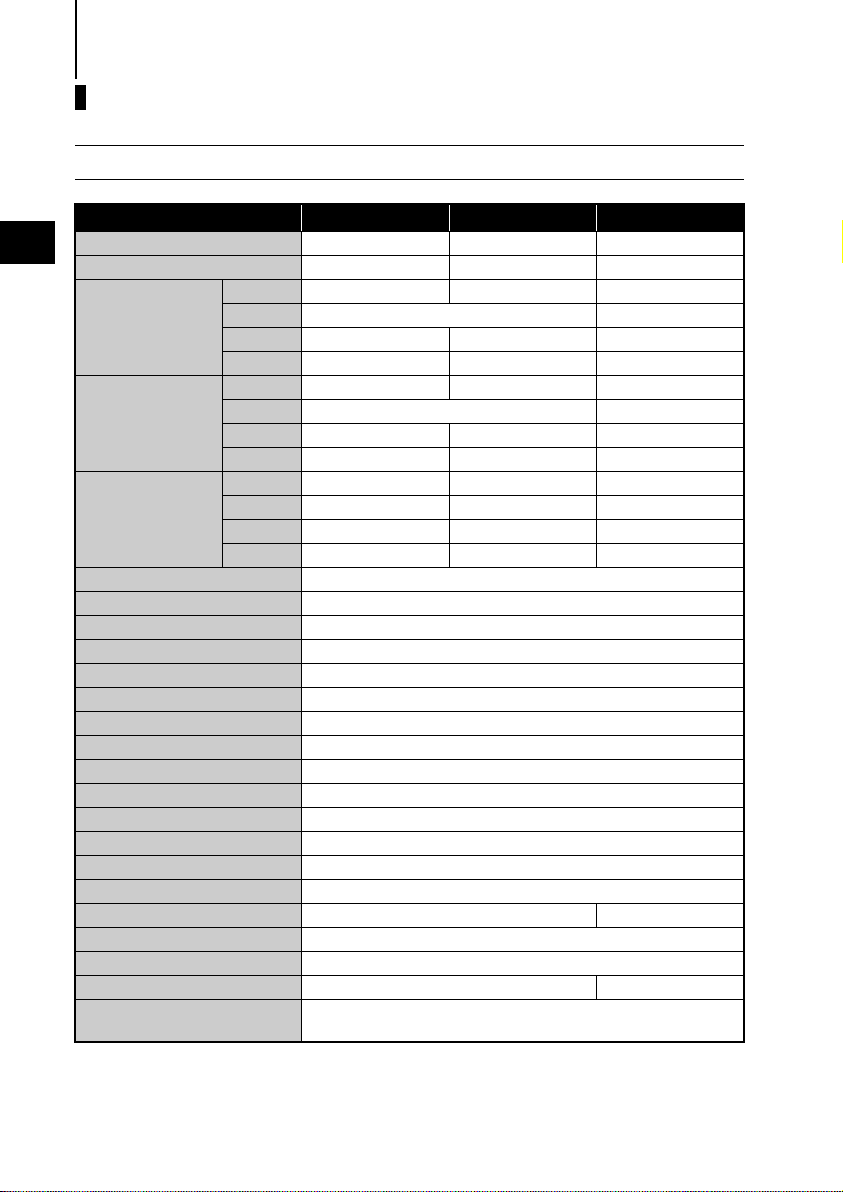

SPECIFICATIONS

X40D2/50D2 MF, EF WX50D2 MF

Item MODEL

Overall Length mm (in) 1143 (45.0) 1145 (45.1)

1

Overall Width mm (in) 384 (15.1) 384 (15.1)

S mm (in) 1225 (48.2)

Overall Height

Tra nsom Height

Weight

Output kW (ps) MX40D2: 29.4 (40) MX50D2: 36.8 (50)

Max. Operating Range rpm 5000-5800

Number of Cylinders 3

Piston Displacement mL (Cu in) 697 (42.53)

Bore x Stroke mm (in) 68 x 64 (2.68 x 2.52)

Exhaust System Through hub exhaust

Engine Lubrication Premixed Fuel

Fuel mixing Ratio 50 : 1

Cooling System Forced water cooling

Starting System Manual

Ignition System Flywheel Magneto C.D. Ignition

Spark Plugs NGK B8HS-10

Tri m Po sition 6

Engine Oil Genuine Motor Oil or recommended one (TCW-III)

Gear Oil* approx. 500mL approx. 700mL

Fuel Tank Capacity L (US gal) 25 (6.6)

Engine Oil Capacity L (US gal)

Gear Reduction Ratio 1.85 (13 : 24) 1.92 (12 : 23)

Fuel

* Genuine Gear Oil or API GL5, SAE #80 to #90

Remark: This specifications might change without a previous notice.

L mm (in) 1352 (53.2) 1413 (55.6)

LL mm (in) 1427 (56.1)

UL mm (in) 1479 (58.2)

S mm (in) 403 (15.9)

L mm (in) 530 (20.9) 550 (21.7)

LL mm (in) 570 (22.5)

UL mm (in) 657 (25.9)

S kg (lb) 72 (159)

L kg (lb) 73.5 (162) 78.5 (173.1) 79 (174)

LL kg (lb) 74 (163)

UL kg (lb) 75 (165)

X40D2/X50D2 MF X40D2/X50D2 EF WX50D2 MF

Unleaded regular gasoline pump posted 87 Octane (research octane

rating of 91)

11

1

2

3

4

5

6

7

8

9

18

17

12

11

10

19

20

21

5

15

14

13

22

16

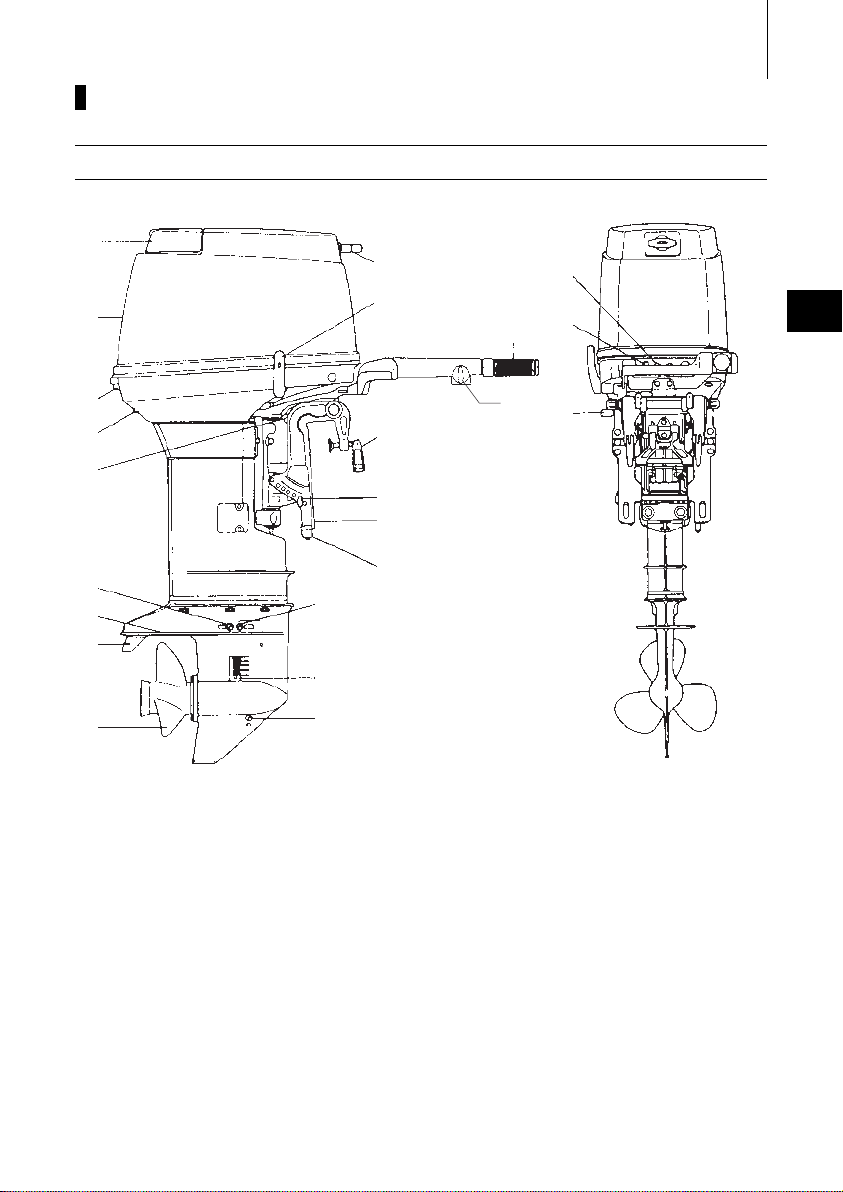

NAMES OF PARTS

X40D2/50D2 MF, EF WX50D2 MF

2

1 Tilt Handle

2 Top Cowl

3 Hook Lever

4 Water Check Port

5 Reverse Lock Lever

6 Water Plug

7 Anti-ventilation Plate

8 Tri m Tab

9 Propeller

10 Oil Plug (lower)

11 Water Strainer

12 Oil Plug (upper)

13 Clamp Bracket

14 Thrust Rod

15 Clamp Screw

16 Throttle Grip

17 Adjust Nut

18 Shift Lever

19 Starter Handle

20 Stop Switch

21 Choke Knob

22 Anode

12

WARNING

AA

470 - 660 mm

(18.5 - 26.1 in)

CAUTION

INSTALLATION

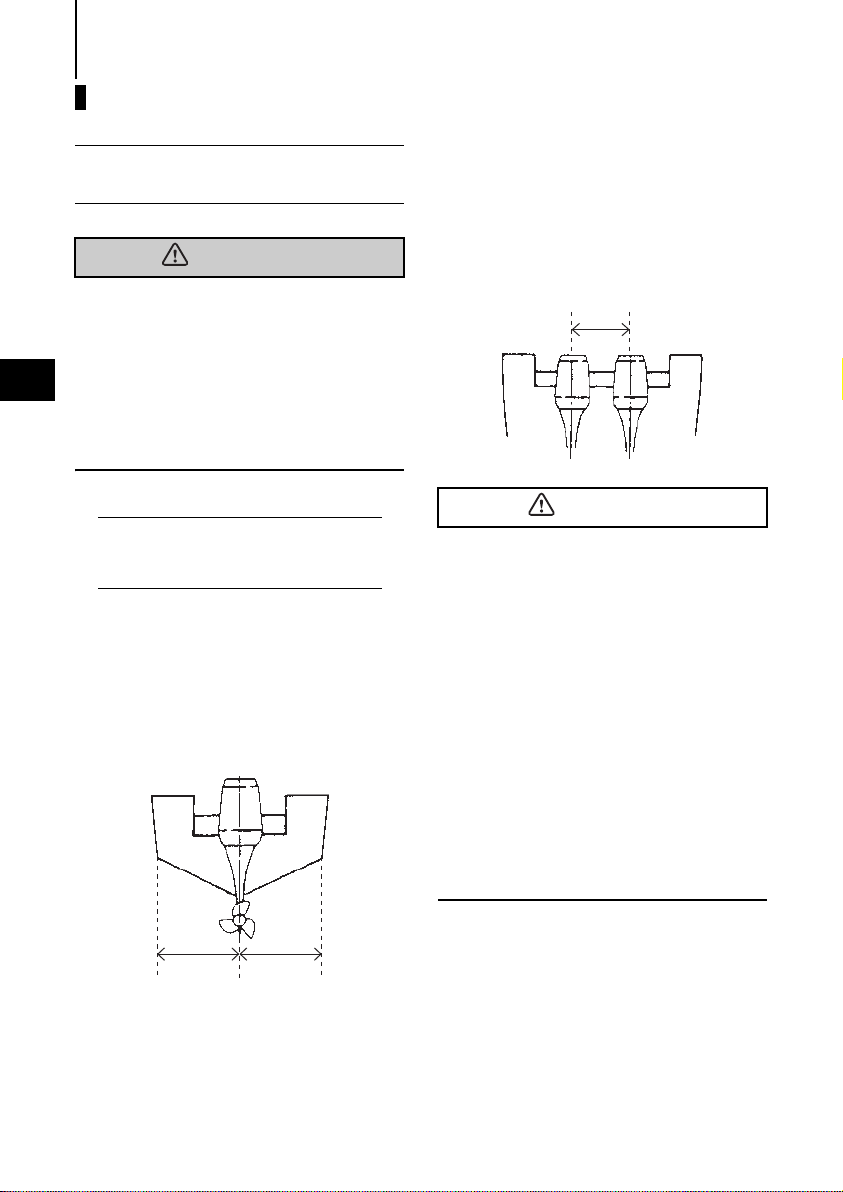

1. Mounting the outboard motor on boat

Most boats are rated and certified in terms

of their maximum allowable horsepower,

as shown on the boat’s certification plate.

Do not equip your boat with an outboard

motor that exceeds this limit. If in doubt,

3

contact your dealer.

Do not operate the outboard motor until it

has been securely mounted on the boat in

accordance with the instructions below.

Note

Consult your authorized dealer to receive

the proper instructions or ask your dealer to

mount the motor as necessary.

Installation

Single-engine Installation

Position the outboard engine at the exact

center of the stern, and mount it using a

cushioning pad or plate.

Twin-engine Installation

When installing two outboard engines, be

sure to keep an interval of approximately

470 - 660 mm (18.5 - 26 in) between the

two.

Before beginning the running test, check

that the boat with maximum capacity

loading floats on the water in a proper

attitude. Check the position of water

surface on the driveshaft housing. If the

water surface is near the bottom cowling, in high waves, water may enter the

engine cylinders.

Incorrect outboard motor mounting

height or existence of underwater

object(s), such as hull bottom design,

bottom surface conditions or underwater accessories, can cause water spray

possibly reaching the engine through an

opening of the bottom cowling during

cruising. Exposing engine to such conditions for extended periods can lead to

severe engine damage.

INSTALLATION 13

Anti-ventilation Plate

10 ~ 30mm (0.4~1.2 in.)

CAUTION

WARNING

Transom H e i g h t

Install the engine with the Anti-ventilation

Plate at a level 10~30mm (0.4~1.2in.)

below the bottom of the boat.

Transom Matching

Be sure that anti ventilation plate of the

outboard is below the water surface when

running with wide open throttle.

In case the above condition cannot be met

due to the shape of your boat, please con-

sult your authorized dealer.

Overheating may occur if the Anti-ventilation Plate is at a level higher than the bottom of the boat, as a result of a lack of

cooling water.

If the height difference exceeds 10~30mm

(0.4~1.2 in) engine power performance is

likely to be reduced as a result of

increased water resistance to the gear

case assembly.

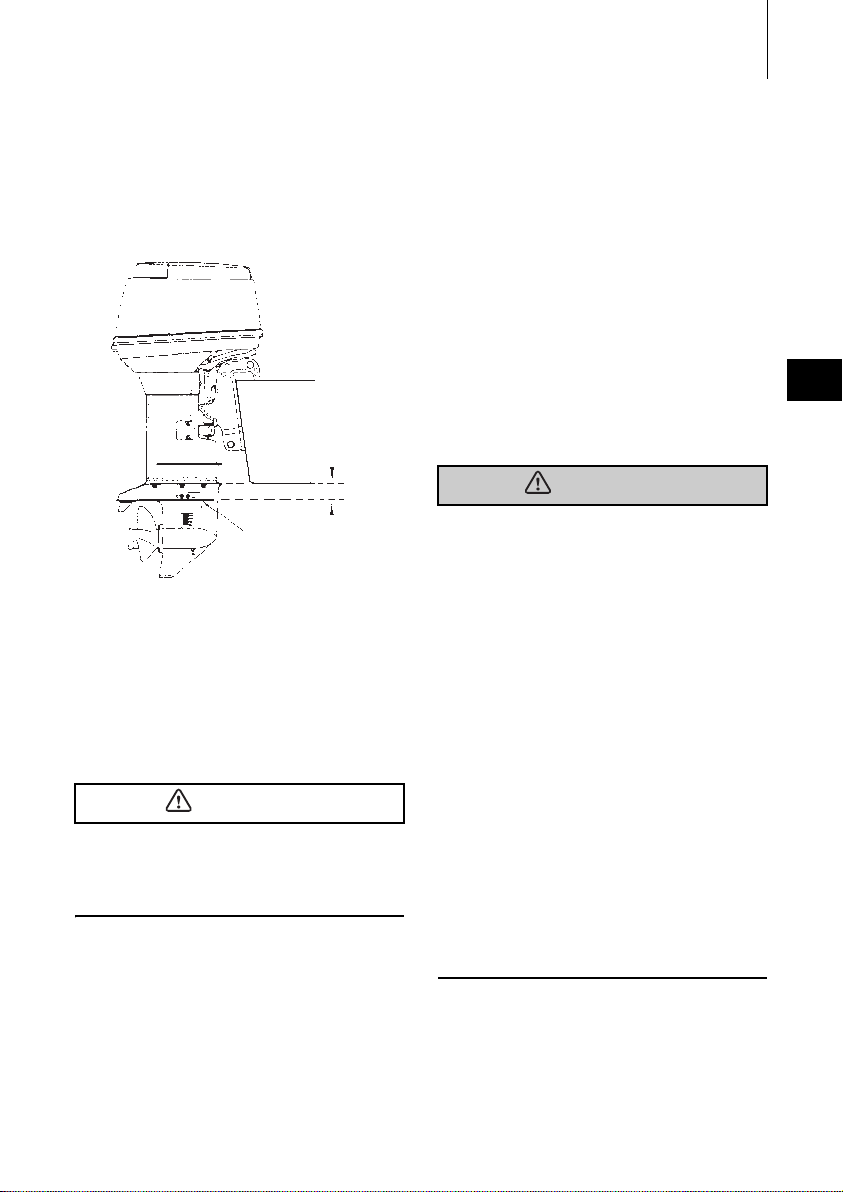

Attaching the Clamp Bracket

After positioning the Clamp Bracket, fix it

with clamp screw then drill four holes in

the transom board, matching the holes in

the Clamp Bracket. Secure the engine with

the supplied bolts (M12 x 105mm) and

nuts. Be sure to use the washers. Use the

larger diameter washers inside of the transom board and use the small diameter

washers outside of the clamp bracket.

The mounting holes may be drilled beforehand by referring to the dimensional drawing.

Mounting the outboard motor without

following this manual can lead to unsafe

conditions such as poor maneuverability, going out of control or fire disaster.

Loose clamp screws and/or mounting

bolts can lead to the release or displacement of the outboard motor, possibly

resulting in lost of control and/or serious

personal injury. Be sure that fasteners

are tightened to the specified torque (30

Nm (3.0kgf) 13ft·lb). Check the fasteners

for tightness from time to time.

Be sure to use outboard mounting fas-

teners included in the outboard motor

package or their equivalents in terms of

size, material, quality and strength.

Tighten fasteners to the specified torque

(30 Nm (3.0kgf) 13ft·lb). Test cruise to

check if fasteners are tightened

securely.

Outboard motor mounting must be per-

formed by trained service person(s)

using lift or hoist with sufficient capacity.

3

INSTALLATION14

Washer

(large diameter)

Bolt

(12mm x length 105mm)

Washer

(small diameter)

Nut

ø13

ø13

234(9.21”)

39(1.54”)

222(8.74”)

248(9.76”)

26(1.02”

)

204(8.03”)

25(0.98”)

25(0.98”)

64(2.52”)

89(3.50”)

117(4.61”)

102(4.02”)102(4.02”)

117(4.61”)

Top of tr a n som

CAUTION

Clamp Bracket

Dimensional Drawing

Manual tilting type

3

2. Propeller Selection

Propeller must be selected that will allow

the engine to reach recommended rpm

when cruising at wide-open throttle.

Wide-open throttle rpm range

5000–5800 rpm

Genuine propellers are listed on PROPELLER TABLE of this manual.

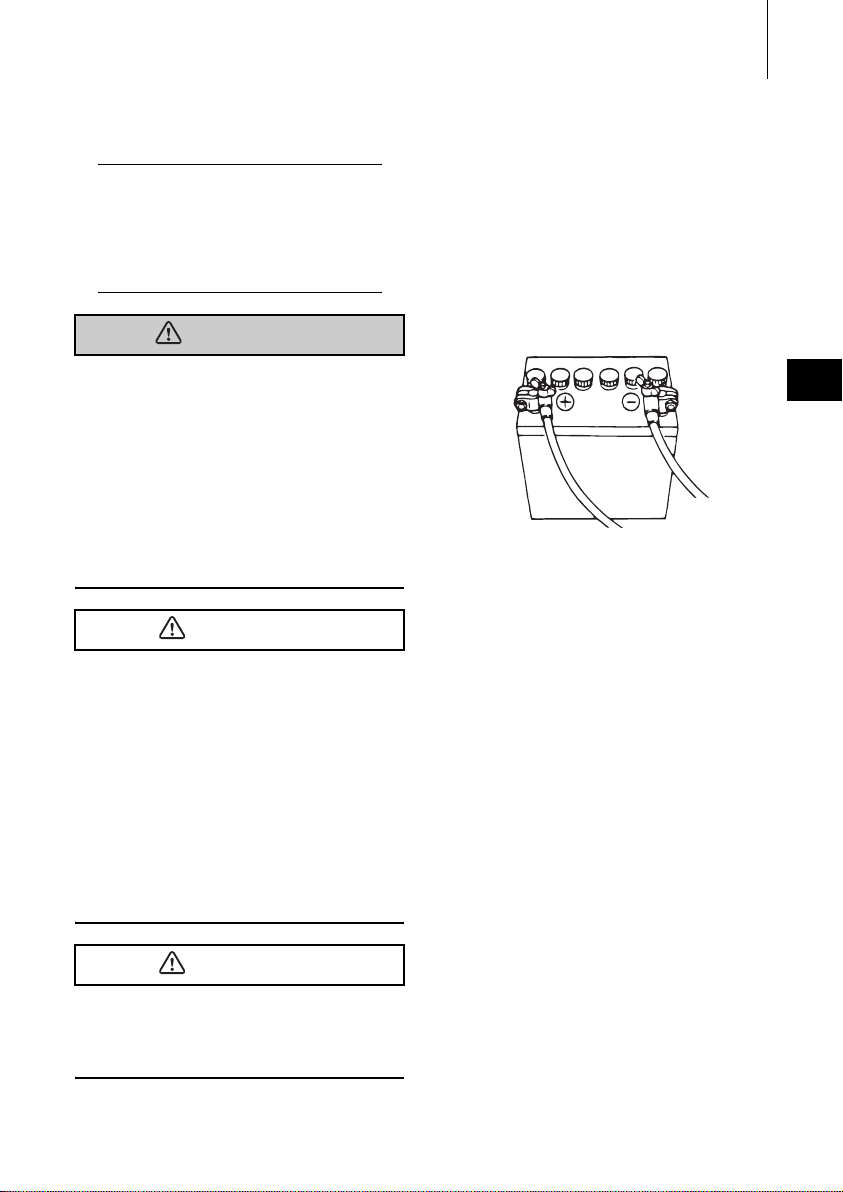

3. Installing the battery

1

Place the battery box in a convenient

position away from possible water

spray. Securely fasten both the box and

the battery so they do not shake loose.

WARNING

Battery electrolyte contains sulfuric acid

and thus is hazardous, causing a burn if it

comes in contact with your skin, or poisonous if swallowed.

Keep battery and electrolyte away from

reach of children.

Mounting bolts should be installed with the

bolt head at inside surface of the transom.

Mounting bolts installed with the threaded

end at the inside surface of the transom

can cause personal injury.

When handling the battery, be sure to:

Read all warnings shown on the battery

case

Prevent electrolyte from coming in con-

tact with any part of your body. Contact

can cause serious burn or, if it comes in

contact with your eye, loss of sight. Use

safety glasses and rubber gloves.

In case battery electrolyte comes in contact with:

Skin, flush thoroughly with water.

Eye, flush thoroughly with water, and

then seek immediate medical treatment.

In case battery electrolyte is swallowed:

Seek immediate medical treatment.

Note

2

1

Minimum recommended battery: 12V, 70AH

(800 Marine Cranking Amps (MCA) or 650

Cold Cranking Amps (CCA))

Specifications and features of batteries vary

among the manufacturers. Cons ult the

manufacturer for details.

WARNING

Battery generates explosive hydrogen gas.

Be sure to:

Charge the battery in a well-ventilated

place.

Place the battery away from any source

of fire, sparks and open flames such as

burners or welding equipment.

Do not smoke when handling the bat-

tery.

Do not smoke near the battery when the

battery is charging.

CAUTION

Make sure that the battery leads do not

get stuck between the outboard motor

and boat when turning, etc.

The starter motor may fail to operate if

the leads are incorrectly connected.

Be sure to correctly connect the (+) and

(—) leads. If not, the charging system

will be damaged.

Do not disconnect the battery leads

from battery while the engine is operating, the electrical parts could be damaged.

Always use a fully charged battery.

INSTALLATION 15

2

Connect the positive lead (+) to the pos-

itive terminal (+) of the battery, and then

connect the negative lead (—). When

disconnecting the battery always

remove the negative lead (—) first. After

connecting the positive terminal (+),

securely place a cap on it to prevent

short circuits.

1. Battery cord (red)

2. Battery cord (black)

3

CAUTION

Do not use a battery that is not recommended. Use of a battery not recommended can lead to poor performance of,

and/or damage to, the electrical system.

16

DANGER

CAUTION

PRE-OPERATING PREPARATIONS

Consult an authorized dealer for details on

handling of gasoline, if necessary.

Gasoline and its vapors are very flammable

and can be explosive.

When carrying a fuel tank containing gasoline:

Close the air vent screw of fuel tank cap,

or gasoline vapor will be emitted

through the air vent screw, creating a

fire hazard.

Do not smoke.

4

When or before refueling :

Stop the engine, and do not start the

engine during refueling.

Do not smoke.

Be careful not to overfill fuel tank. Wipe

up any spilled gasoline immediately.

When or before cleaning the gasoline tank :

Dismount fuel tank from the boat.

Place the fuel tank away from every

source of ignition, such as sparks or

open flames.

Do the work outdoors or in well venti-

lated area.

Wipe up any spilled gasoline immedi-

ately.

1. Recommended gasoline types

Use of low-quality gasoline results in a

short engine life as well as starting difficulties and other engine problems.

We recommend use for Fuel stabilizer.

Use of unleaded gasoline

Use a major brand of automotive unleaded

gasoline with a minimum posted octane

rating of 91RON. Automotive gasoline that

contain fuel injector cleaner are preferred

for added internal engine cleanliness.

Leaded gasoline is acceptable in areas

where unleaded gasoline is not available.

After cleaning gasoline tank :

Wipe up any spilled gasoline immedi-

ately.

If the fuel tank is disassembled for

cleaning, reassemble carefully. Imperfect assembly may cause a fuel leak,

possibly leading to fire or explosion.

Dispose of aged or contaminated gaso-

line in accordance with local regulations.

PRE-OPERATING PREPARATIONS 17

CAUTION

WARNING

Use of alcohol free gasoline

Use of gasoline containing alcohol can

cause engine starting and/or operating difficulties, wear of and damages to engine

parts, and deterioration of chemical parts,

which may lead to shortening of your outboard motor’s life.

Note

The adverse effect caused by the alcohol

content is more severe with methanol than

with ethanol.

TOHATSU recommend the use of gasoline

if its ethanol content is less than 10% or

methanol content is less than 5%, only in

case alcohol free gasoline is not available.

The alcohol component of the gasoline

absorbs moisture from the air, which may

disturb regular fuel flow in the fuel system,

and also accelerate rusting of engine

parts.

Mixing of the moisture in the engine oil can

also deteriorate the properties of the lubricant.

If the use of gasoline containing alcohol is

inevitable, or presence of alcohol is sus-

pected in the gasoline, it is strongly recommended to add a filter that has water

separating capability, and check the fuel

system for leaks and mechanical parts for

corrosion and abnormal wear more frequently.

And, in case any of such abnormality is

found, discontinue the use of such gaso-

line and contact our dealer immediately

.

Damages resulting from the use of gasolines that contain alcohol ar

e not covered

under the limited warranty.

Fuel tank capacity : 25 liters (6.6 U.S. gal)

Fuel Tank : When using a fixed fuel tank in

place of genuine fuel tank, it is recommended to select a one with a structure

facilitating interior cleaning.

Do not fill the fuel tank over capacity. The

rise of gasoline temperature may cause

gasoline to expand which, if overfilled, may

leak through air vent screw when it is open.

Leaking gasoline is a dangerous fire hazard.

4

PRE-OPERATING PREPARATIONS18

CAUTION

10L

(0.2:10)

(0.4:10)

(0.5:25)

(1:25)

2L 25L 30L

0.1L

0

0.2L

0.3L

0.4L

0.5L

0.6L

0.7L

0.8L

0.9L

1.0L

1.1L

1.2L

1:25

1:50

Fuel by Oil Mixing (1:25, 1:50)

Gasoline

Oil

2. Recommended engine oil

Use a genuine engine oil or recommended

one (TCW3). Refer to your Distributor.

Will not recommend use of other two

stroke engine oil.

Do not mix different brands of oil.

Mixing different brands of oil, or different

types of oil even if the brand is the same,

may cause gelling, resulting in possible filter screen blockage. This could result in

4

serious engine damage because of

impaired lubrication performance.

Note

Use of engine oils that do not meet these

requirements will result in reduced engine

life, and other engine problems.

Add engine oil into fuel oil tank. The mixing

ratio with gasoline is 1 : 50 (one part oil

and 50 parts gasoline). Mix well by hand.

The mixing ratio during break-in running is

1 : 25.

Mixing Ratio

Engine Oil : Gasoline

During break-in 1 : 25

After break-in 1 : 50

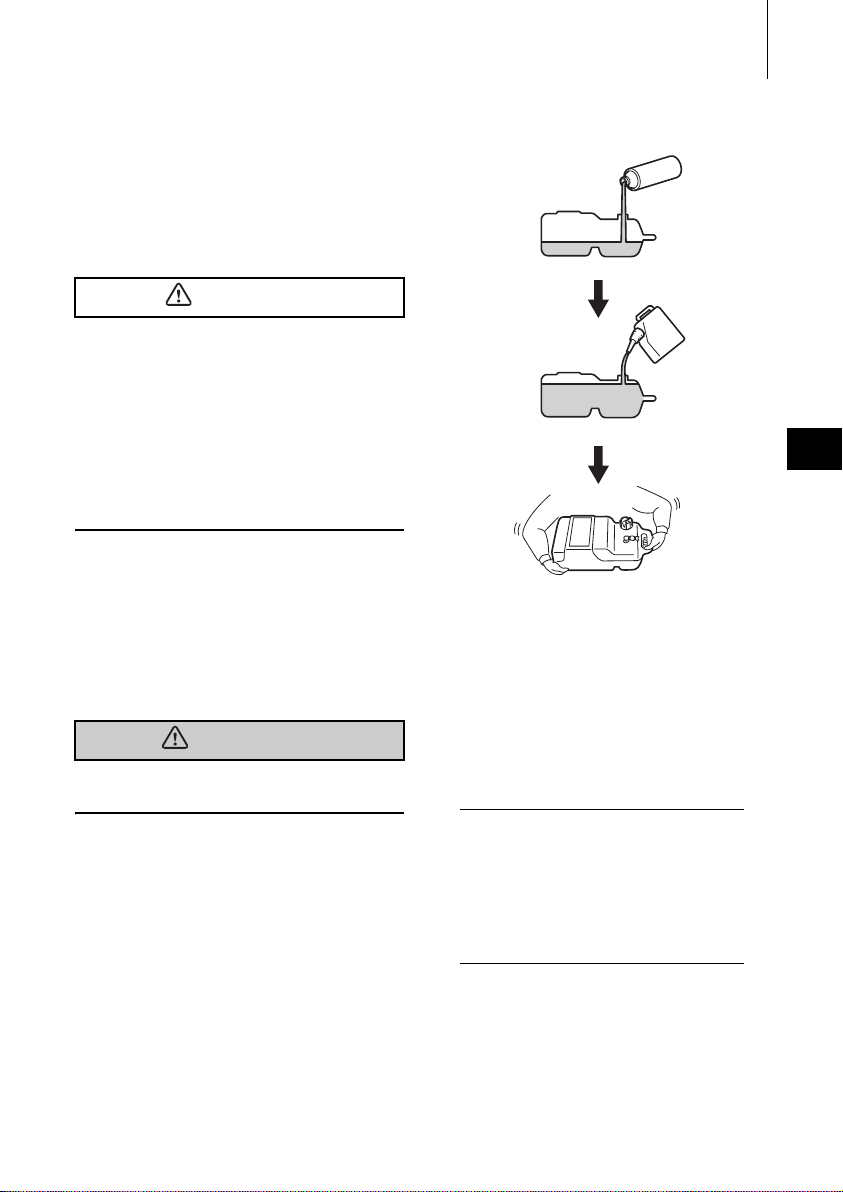

Engine oil – gasoline mixing

CAUTION

WARNING

procedure

For quantities of engine oil and gasoline to

be pre-mixed, refer to table in Recommended engine oil (p. 18).

Do not use other than two stroke engine

oil with specified grade, or the engine

may be damaged.

Do not use fuel prepared in other than

specified mixing ratio.

- Lack of engine oil can cause severe

engine trouble such as piston seizure.

- Excess of engine oil can shorten spark

plug life, and/or cause increase of noxious exhaust.

When portable fuel tank is used for

operation of outboard motor(s):

1

Pour engine oil into fuel tank, and then,

gasoline.

2

Put cap on the tank, and close tightly.

3

Close air vent plug tightly.

Loose cap or air vent plug can cause leak

of fuel during shaking the tank.

4

Shake the tank to mix engine oil and

gasoline well and even.

When fuel tank built in the boat is

used for operation of outboard

motor(s):

1

Prepare separate fuel container for premixing.

PRE-OPERATING PREPARATIONS 19

2

Pour engine oil into fuel container, and

then, gasoline.

3

Put cap on the container, and close

tightly.

4

Shake the container to mix engine oil

and gasoline well and even.

5

Pour the mixture into fuel tank.

Notes

It is recommended to pre-mix by using

separate fuel container. Attempting to

pre-mix in the fuel tank built-in the boat

can make the mixture uneven.

If built-in fuel tank is used for mixing,

pour engine oil into the tank little by little

while putting gasoline into the tank.

4

PRE-OPERATING PREPARATIONS20

CAUTION

DANGER

3. Break-in

Your new outboard motor and lower unit

require break-in for the moving components according to the conditions

described in the following time table.

4

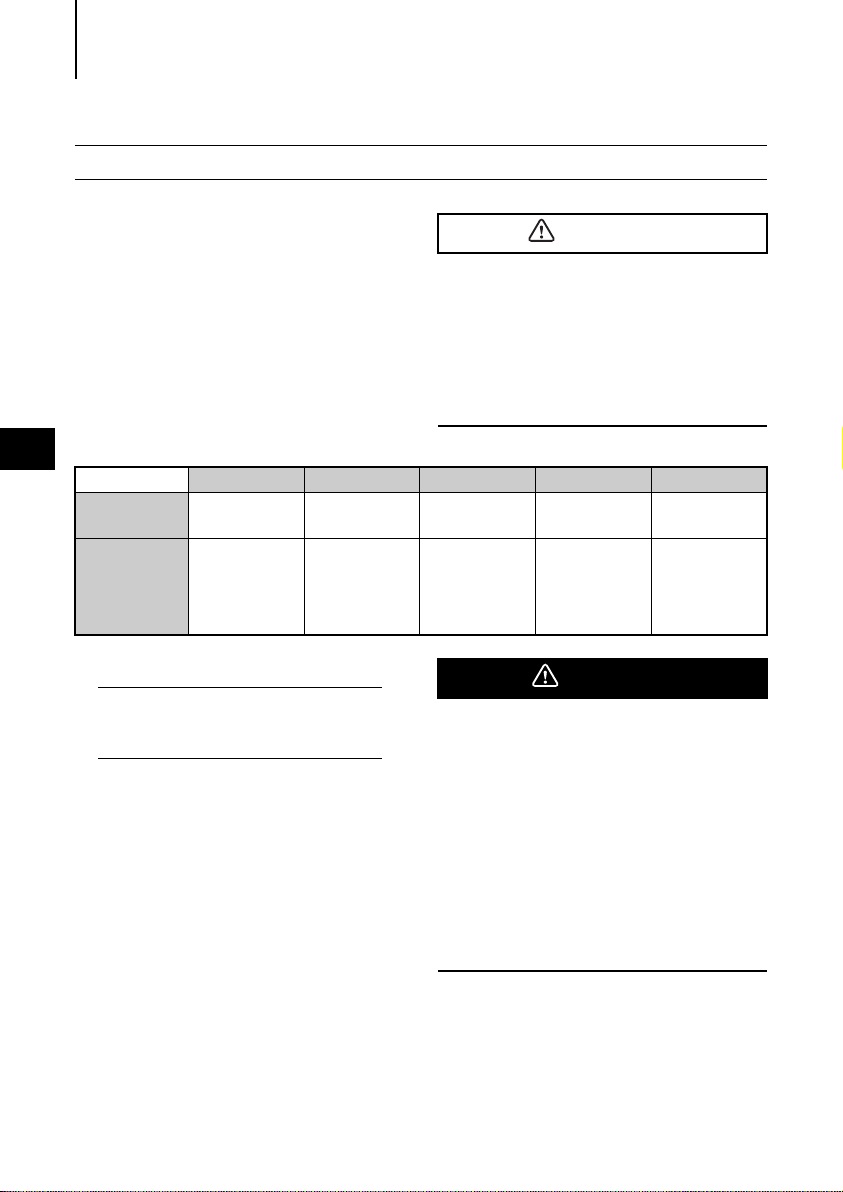

1-10min 10min-2hrs 2-3hrs 3-10hrs After 10hrs

Throttle

Position

Speed

Idle

Less than 1/2

throttle

Approx.

3,000 rpm max

Operating the outboard motor without

break-in can shorten service life of the

product.

If any abnormality is experienced during

the break-in:

Discontinue the operation immediately.

Have the dealer check the product and

take proper action(s) if necessary.

Less than 3/4

throttle

Full throttle run

allowed for 1 min

every 10 min

3/4 throttle

Approx.

4,000 rpm.

Full throttle run

allowed for 2 min

every 10 min

Full throttle

available

Note

Proper break-in allows outboard motor to

deliver it full performance for longer service

life.

Fuel mix ratio for break-in

Gasoline 25: Genuine Engine Oil 1

25:1 when using genuine engine oil or

the recommended one (TCW3).

Do not operate the outboard motor in

closed area or area with no forced ventilation.

Exhaust gas emitted by this outboard

motor contains carbon monoxide that will

cause death if inhaled continuously. Inhaling the gas initially causes symptoms such

as feeling of sickness, drowsiness and

headache.

During operation of the outboard motor :

Keep peripheral area well ventilated.

Always attempt to stay on the windward

side of emission.

WARNING

WARNING

CAUTION

ENGINE OPERATION

21

1. Starting

In case engine starts in gear, do not start

cruising. Stop engine immediately and consult an authorized dealer.

Note

The engine will not start unless the switch

lock has been properly connected into the

emergency stop switch.

Do not operate the engine with gear case

out of water.

Severe personal injury, or engine damage

will result.

Never fill up portable fuel tanks on board to

avoid fire or explosion resulting from

spilled gasoline. If gasoline is ever spilled

on board, wipe it up thoroughly. Fuel tanks

must always be filled up on land.

Preparations

1

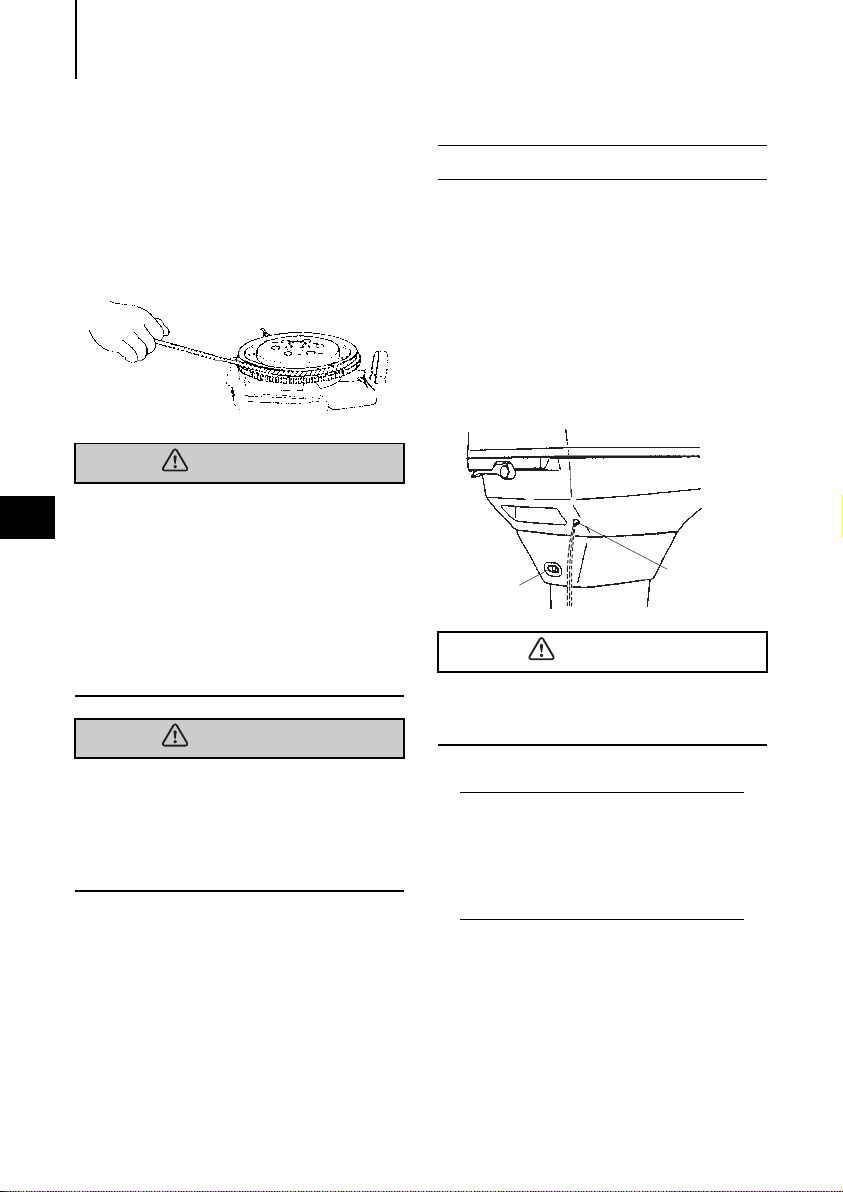

Loosen the air vent screw on the tank

cap.

2

Connect the fuel connector to the

engine.

5

5

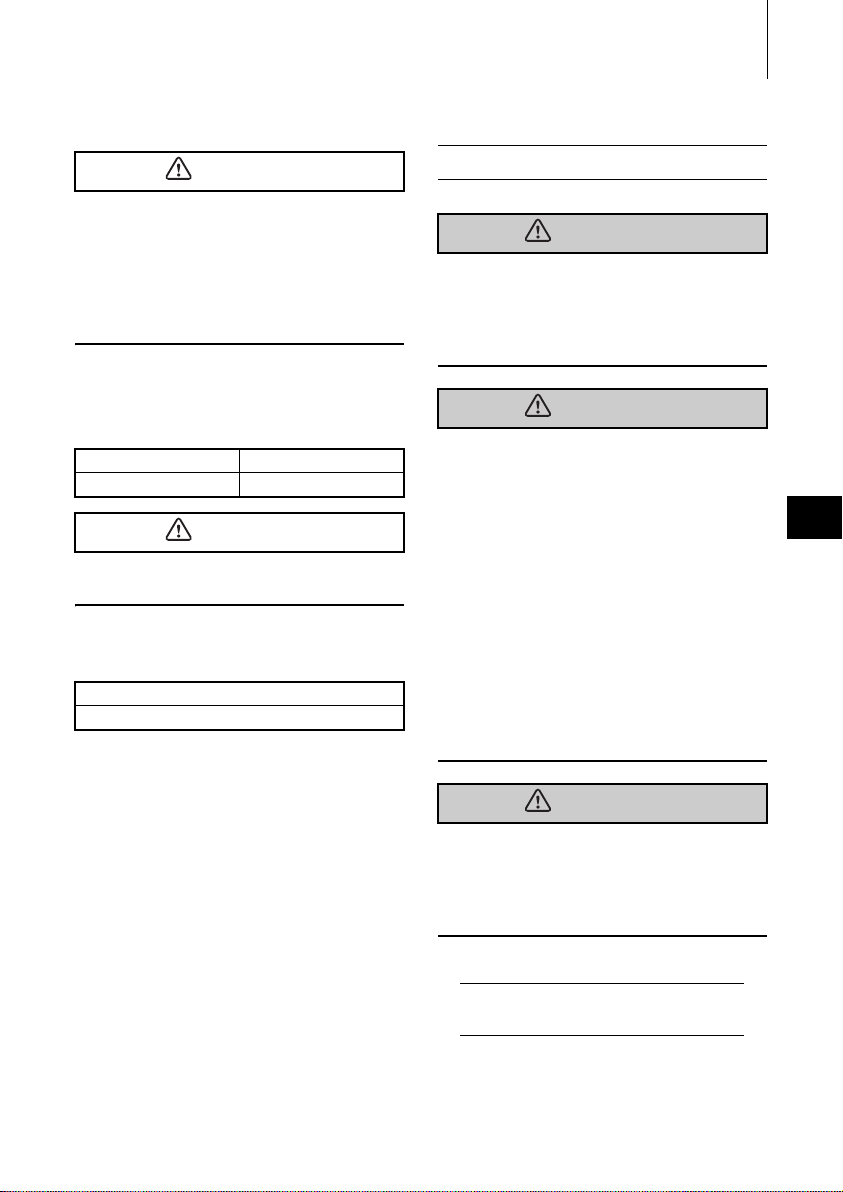

Lock

Stop switch

Engine side

Fuel tank side

CAUTION

R

N

F

ENGINE OPERATION22

3

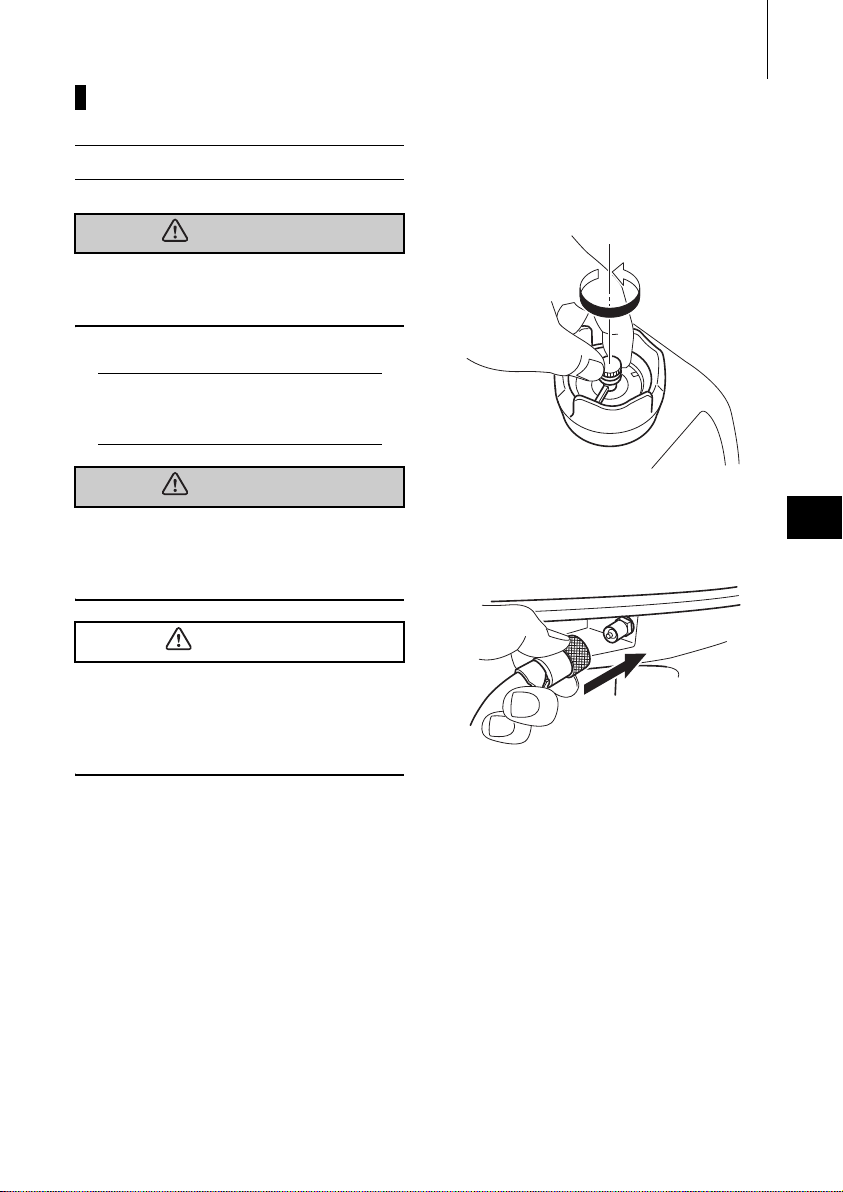

Install a lock in the stop switch.

4

Feed fuel to the carburetor by squeez-

ing the primer bulb until firm.

Starting

F type

1

Set the shift lever to Neutral

If the engine starts in gear, do not use it.

Contact an authorized dealer.

Note

Start-in-gear protection prevents engine

from starting at other than neutral shift. Ingear starting of engine will move the boat

immediately, potentially leading to falling

down or causing passenger(s) to be thrown

overboard due to inertial force.

2

Turn the throttle grip so that the indicator line meets the "START" mark.

ENGINE OPERATION 23

WARNING

OFF

ON

START

3

Pull the choke knob fully.

Notes

Operation of the choke knob is not

required if the engine is warm.

If engine does not start with 4 or 5 times

starting operation, push the knob back

and restart.

MF type

4

Pull the starter rope slowly until resis-

tance is met.

Give it a sharp tug to start the engine.

Severe personal injury, or engine damage

will result.

EF type

4

Insert the main switch key.

5

Turn the ma i n switch key to START

position.

6

The key returns to the original position,

automatically.

7

When starting the engine, push the

choke knob back.

8

Carefully turn the throttle grip to

“SLOW”.

5

5

Turn the handle grip to its original posi-

tion gradually once the engine has

started.

6

Push back the choke knob slowly.

7

Carefully turn the throttle grip to

“SLOW”.

Do not operate the engine with gear case

out of water.

CAUTION

Do not keep turning starter motor for over

5 seconds, or the battery may be consumed, potentially making the engine starting impossible and/or damaging the

starter.

If cranking over 5 seconds fails to start

engine, return main switch to “ON”, and

crank engine again after 10 seconds or

more.

ENGINE OPERATION24

WARNING

WARNING

Idle port

Cooling water

check port

CAUTION

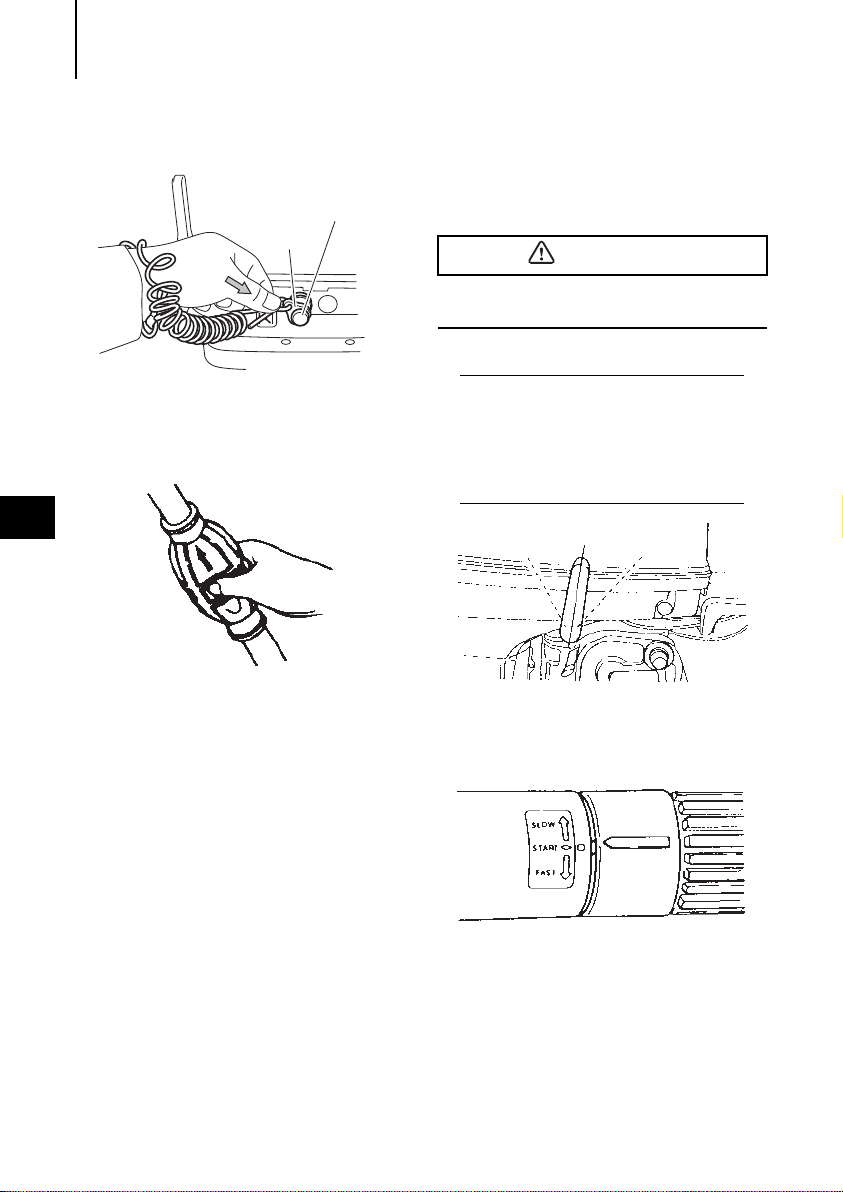

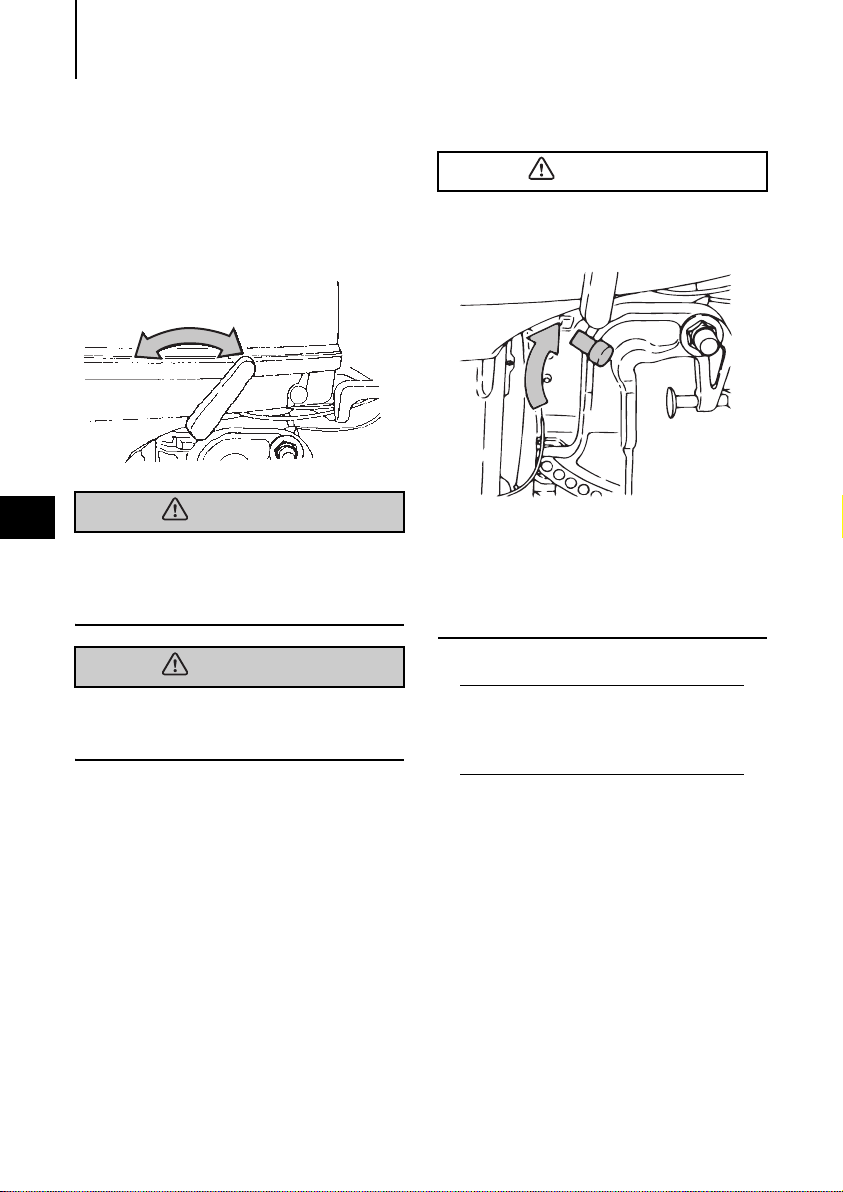

Manual Rope Start - - - in case of

trouble with the Recoil Starter

Wind the starter rope around the flywheel

a few turns. Give it a sharp tug to start the

engine. Use a socket wrench or similar to

get a firm grip on the end of the rope.

Be careful that your clothes or other items

do not get caught in the rotating engine

5

parts.

To prevent accident and injury, do not reattach the recoil starter after the engine

has been started using the emergency

starter rope. Be sure to put the top cowl

back on.

Immediately contact an authorized dealer

when reaching shore.

2. Warming up the engine

Before driving the boat, let the engine run

at low speed for approximately three minutes to let it warm and allow the oil to circulate through the machine. If the engine is

not warmed up beforehand, the engine life

will shorten greatly. During the warm-up

operation, confirm that cooling water is

discharged from the check port and idle

port.

Be sure to warm up engine well before

starting cruise. Operating cold engine can

give damage to it.

Be sure that no bystander(s) is within 2

meters from back of starting operator.

Do not operate the outboard motor with

top cowl removed from the power unit,

or contacting turning flywheel which can

lead to serious personal injury.

Note

Idle speed may be higher during warming

up of engine. If shifted to Forward or reverse

during warming up, it may be difficult to shift

back to neutral. In such case, stop engine,

shift to neutral, and restart engine to warm

up.

Be sure to stop engine immediately if cool-

CAUTION

CAUTION

WARNING

WARNING

WARNING

ing water check port is not discharging

water, and check if cooling water intake is

blocked. Operating engine could lead to

overheating potentially leading to engine

damage. Consult an authorized dealer if

the cause cannot be found.

Engine speed

Proper idle speed after warm-up operation.

Clutch in (In gear) Clutch off (Out of gear)

750rpm 900rpm

Do not shift to "F" or "R" until turning into

proper idle speed.

Do not exceed the full-throttle engine

speed.

Wide-open throttle rpm range

5000–5800 rpm

ENGINE OPERATION 25

3. Forward and reverse

Before shifting into forward or reverse,

make sure that boat is properly moored

and outboard motor can be steered fully to

the right and left. Make sure that no swimmer(s) is ahead or astern of the boat.

Attach other end of emergency stop

switch tether to the operator's clothing

or arm and keep it attached during

cruising.

Do not attach the tether to a part of

clothing that can be torn easily when

pulled.

Arrange the tether so that will not be

caught by any object when pulled.

Be careful not to pull the tether acciden-

tally during cruising. Unintentional stop

of engine can cause loss of control of

outboard motor. Rapid loss of engine

power can lead to falling down or causing passenger(s) to be thrown over

board.

5

Be sure to connect the emergency tethered

stop hook to your waist or clothing.

The engine will shut down when the switch

lock becomes disconnected from the

engine.

Note

Do not increase engine speed unnecessarily

in reverse.

ENGINE OPERATION26

Reverse

(R)

Forward

(F)

WARNING

WARNING

CAUTION

F type

Turn the throttle grip toward "SLOW" and

move the Shift Lever quickly to Forward or

Reverse when the engine speed has

reached the lowest rpm.

Before moving the Shift Lever to

Reverse, make sure the Reverse Lock is

engaged (in up position).

5

Severe damage, and personal injury, may

occur if shifting at high engine speed.

Engine must be in the slow idle position

before shifting is attempted.

Before shifting, make sure that no swimmer(s) or obstacle(s) is ahead or astern of

the boat.

Do not increase the engine speed

unnecessarily while reversing.

The Shift Lever cannot be turned from

Neutral to Reverse unless the throttle

grip has been turned fully toward

"SLOW".

Note

Frequent shifting to forward or reverse can

accelerate wear or degradation of parts. In

such case, replace gear oil earlier than the

period specified.

ENGINE OPERATION 27

WARNING

WARNING

CAUTION

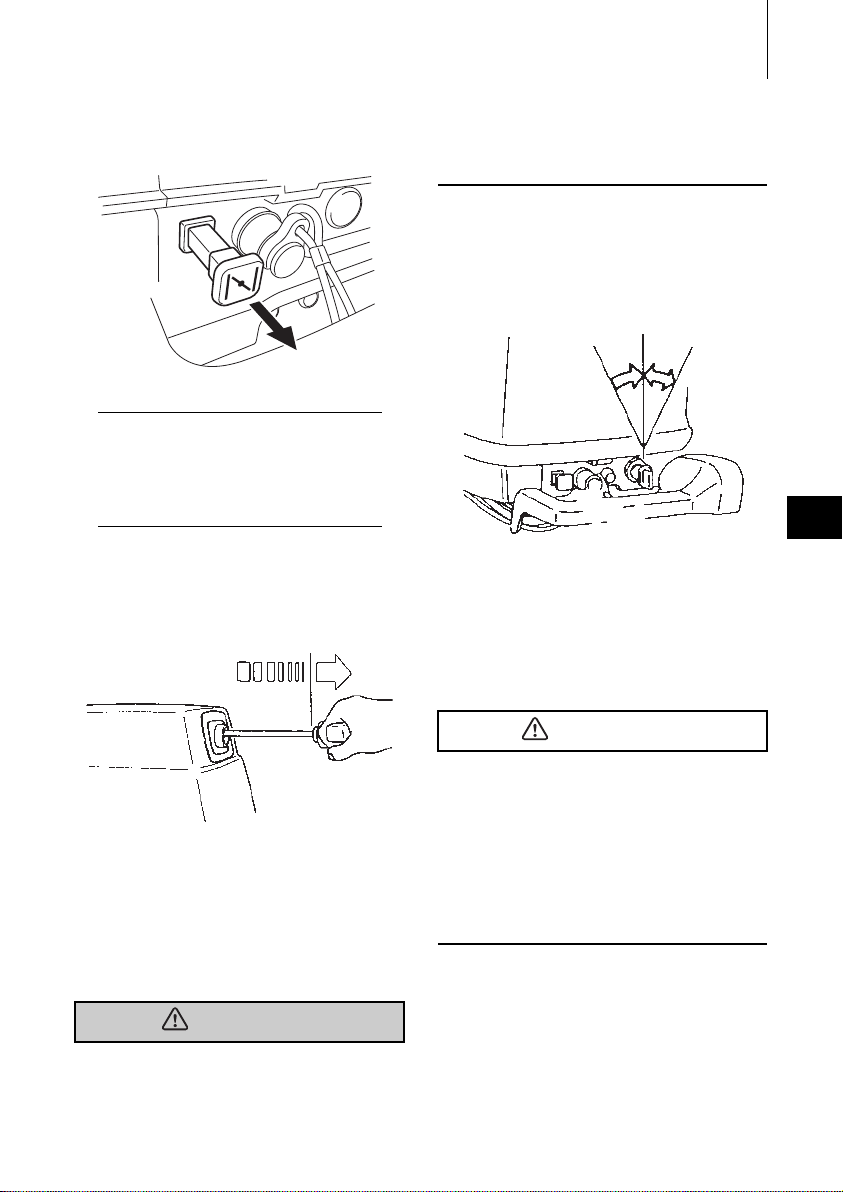

Reverse

lock lever

4. Shallow water running

During shallow water operation, be careful

not to place your hand between the swivel

bracket and the stern bracket.

Be sure to tilt the outboard down slowly.

Note

Slow down to trolling speed, and shift into

neutral before setting outboard motor to

shallow water drive position.

Run at lowest possible speed during

cruising using shallow water drive.

Tilt lock is disabled when in shallow

water drive position.

When driving shallow water, be careful

not to strike outboard motor against sea

bottom, or propeller may be pushed out

of water, resulting in loss of control.

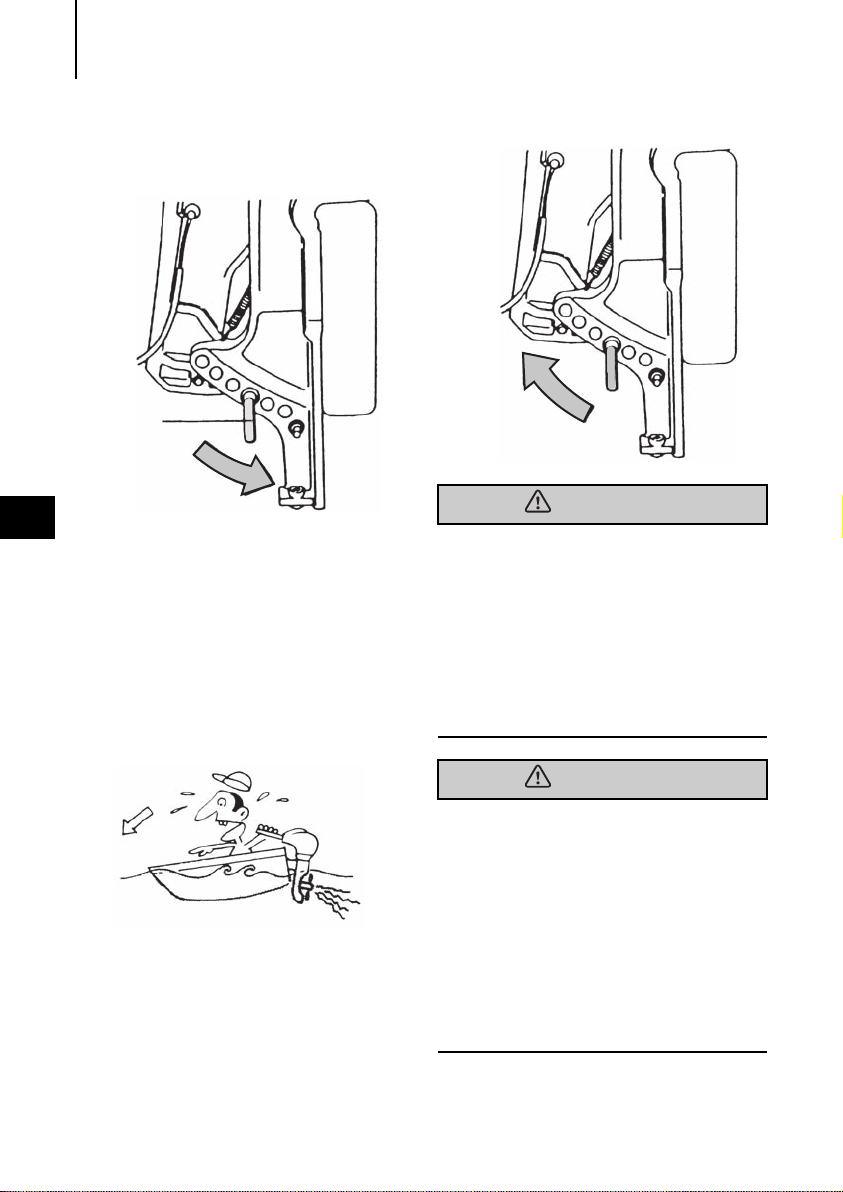

F type

1

Set the Reverse Lock Lever provided on

the starboard side to "Release" by turning it downward.

2

Tilt the engine up approx.

45° and lower it. The engine will now be

set to the shallow water setting.

5

While in shallow water drive position, do

not operate the outboard in reverse. Operate the outboard at slow speed and keep

the cooling water intake submerged.

ENGINE OPERATION28

WARNING

CAUTION

3

Releasing the shallow water setting

a.Turn the Reverse Lock Lever upward to

set them in "LOCK" position.

b.Tilt up the engine slightly and then let it

go down. The shallow water setting is

then released.

c.The engine is released from shallow

water setting, and locked at normal

running position.

5

5. Stopping the engine

Do not shift into Reverse during planning,

or control will be lost leading to serious

personal injury, boat may swamp, and/or

hull may be damaged.

Do not shift into Reverse during cruis-

ing, or control may be lost, falling down

or causing passenger(s) to be thrown

overboard. Leading to serious personal

injury, and steering system and/or shifting mechanism may be damaged.

Never stop the engine immediately after a

full throttle run. Keep it running for two or

three minutes at idling speed (Shift Lever

set to Neutral) to allow it to cool down.

F type

1

Reduce the engine speed to idling rpm.

2

Keep pressing on the Stop Switch or

pull out the lock plate/ The engine will

then stop.

ENGINE OPERATION 29

CAUTION

Air vent screw

Perpendicular to the

water surface

Notes

After stopping the engine, close the air

vent screw on the tank cap.

Disconnect the fuel connector of the

engine or the fuel tank.

Disconnect the cables from the battery if

the engine will not be used for an

extended period of time.

3

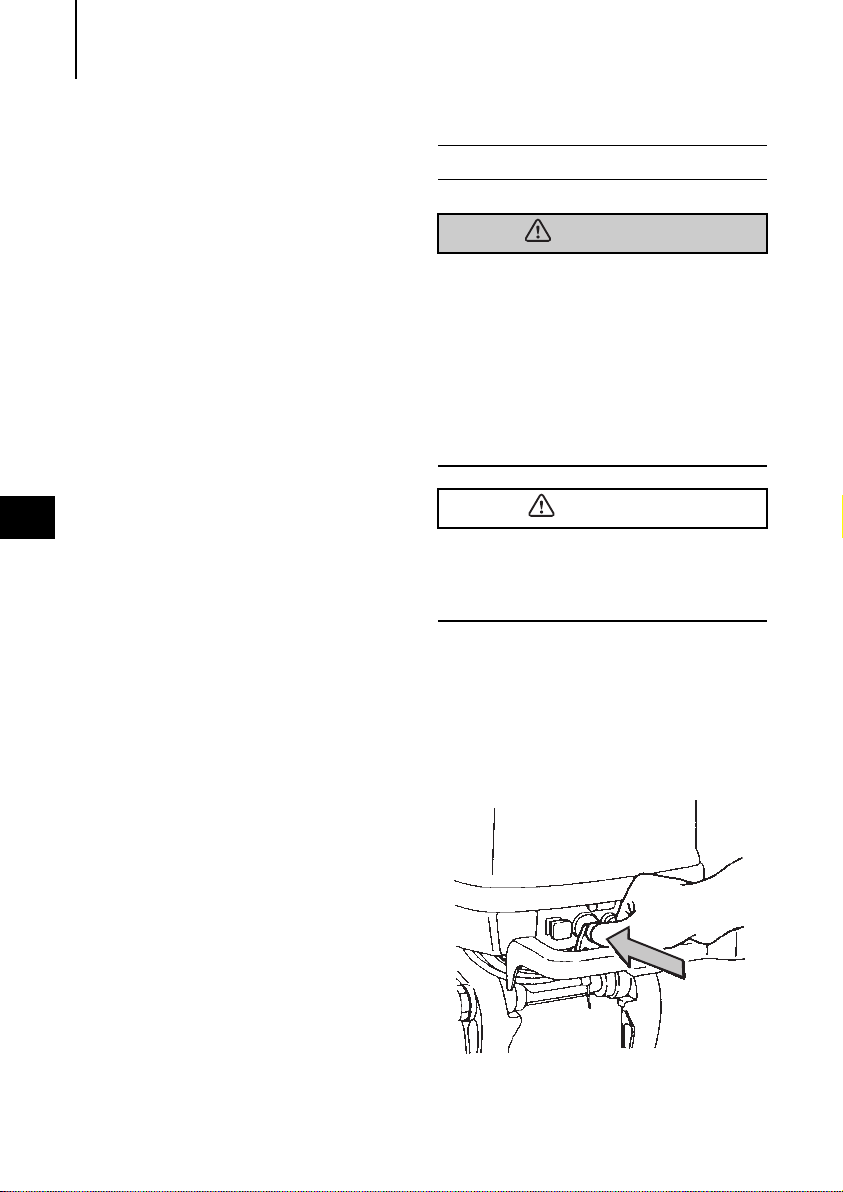

Disconnect the fuel connector from the

engine.

Never fill up portable fuel tanks on board to

avoid fire or explosion resulting from

spilled gasoline. If gasoline is ever spilled

on board, wipe it up thoroughly. Fuel tanks

must always be filled up on land.

4

Close the air vent screw on the fuel tank

cap.

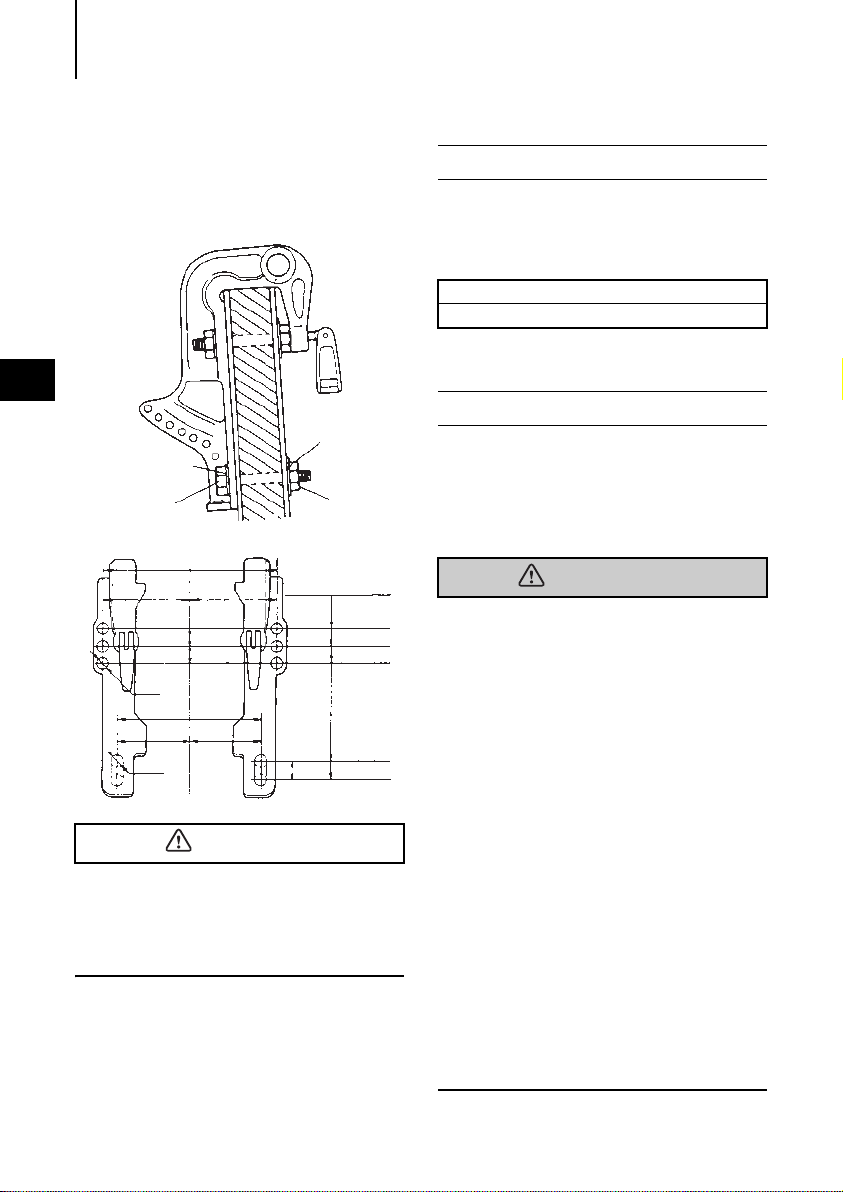

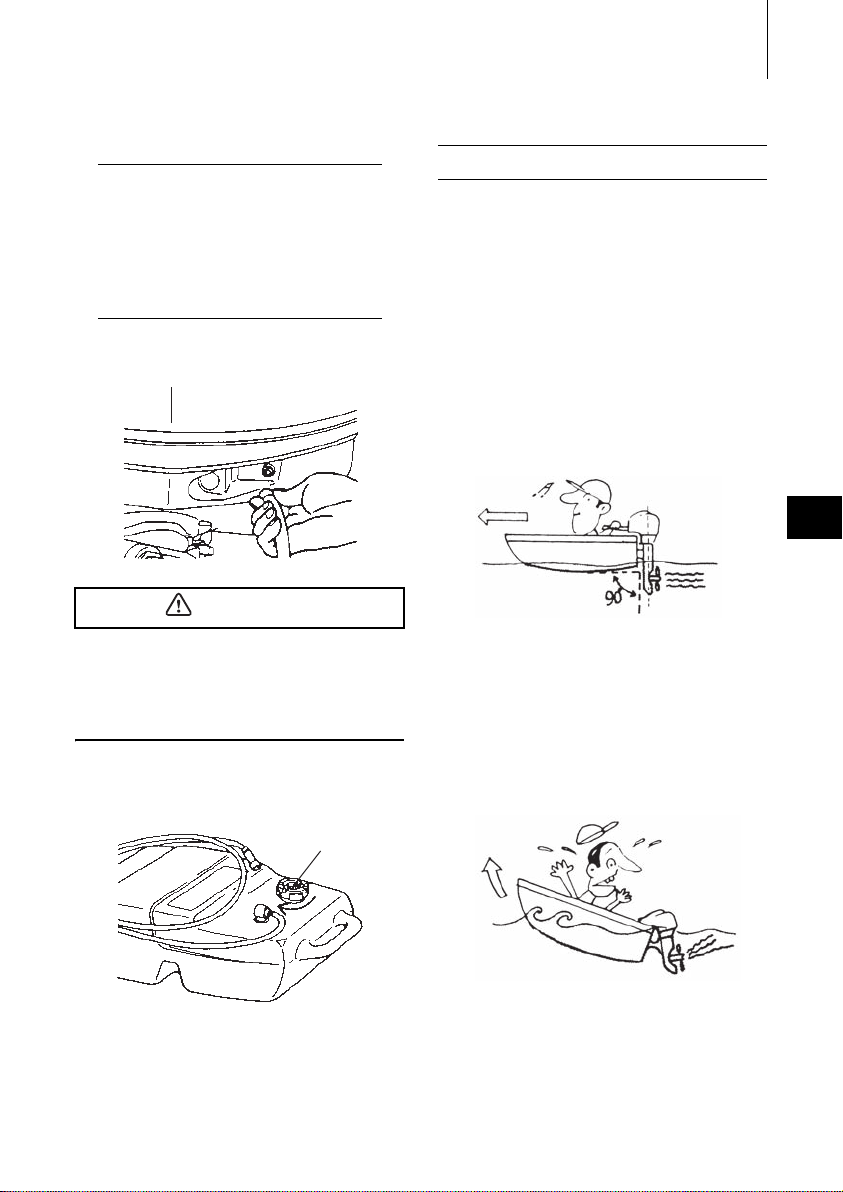

6. Trim angle

The following instructions explain how to

set the best trim angle of the boat.

F type

The trim angle is adjusted by setting the

thrust rod in the correct thrust rod hole.

Proper trim angle

The trim angle is optimum when the boat

is parallel to the water surface while running.

5

Improper trim angle (bow rises too

high)

If the trim angle is excessive, the bow will

rise out of the water and the speed will

decrease.

Furthermore, the bow may sway or the

bottom may slam the water while cruising.

ENGINE OPERATION30

Select a lower hole

Thrust rod

Select a higher hole

Upward

WARNING

WARNING

In this case, decrease the trim angle by

setting the thrust rod in a lower hole.

5

Improper Trim Angle (bow dips into

the water)

If the trim angle is too small, the bow will

dip into water, the speed will decrease,

and water may enter the boat.

In this case, the trim angle should be

increased by setting the thrust rod in a

higher hole.

Do not put hand or finger in between

outboard motor body and clamp bracket

when adjusting trim angle to prevent

injury in case the outboard motor body

falls.

Unsuitable trim position can cause loss

of control of boat.

When testing a trim position, run boat

slow initially to see if it can be controlled

safely.

Excessive trim up or down may lead to

unstable boat operation, potentially causing the steering difficulty that leads to accident during cruising.

Do not cruise at high speed if improper

trim position is suspected. Stop the boat

and readjust trim angle before continuing cruise.

For outboard motor model with PTT

switch on the bottom cowl, do not operate the switch during cruising, or control

of boat may be lost.

Loading...

Loading...