TOHATSU 200 Series, BF175AK3, 225A Series, BF200AK3, BF225AK3 Service Manual

BFT

200/225A

OB No.62ZY300Z

14-01 NB

Introduction

Before reading this manual

Thisservicemanualprovidesinformationthatisneededforinspection,serviceandrepairof

applicableoutboardmotors.Forourcustomers'safeandcomfortableuseoftheproductsfor

longterm,itisessentialtomaintaintheperformanceandqualityoftheoutboardmotors.To

ensure this, the maintenance and service have to be done properly by service technicians

with fundamental knowledge and skills. This manual is utilized so that our customers can

alwaysusetheiroutboardmotorwithfullsatisfaction.

As this document contains information from the Honda Motor's Service Manual, the

documentcontainsinformationaboutmodelsthatarenotsoldbyourcompany.Additionally,

themodelnamesandpartnumbersofthespecialtoolsmentionedinthisdocumentarethe

namesandnumbers usedbyHondaMotor Co.,Ltd.Please alter themodelnames andpart

numbersasfollows.

Change model names with "BF" to "BFT".

Example: BF*** -> BFT***

Add "HCO-" at the beginning of part numbers of special tools.

Example: 07GD-0010100-OS -> HCO-07GD-0010100-OS

Introduction

Avant de lire le présent manuel

Le présent manuel d’entretien fournit les informations nécessaires au contrôle, à l’utilisation et à la réparation

des moteurs hors-bords concernés. Pour une utilisation de nos produits par nos clients, à long terme, en toute

sécurité et tout confort, il est capital de veiller à maintenir les performances et la qualité du hors-bord. Pour

garantir ce point, l’entretien et la maintenance doivent être assurés en bonne et due forme par des techniciens

en entretien et réparation disposant des connaissances et compétences clés. Le présent manuel est prévu pour

que nos clients puissent toujours utiliser leur moteur hors-bord pour leur plus grande satisfaction.

Ce document contient des informations provenant du manuel de réparation des moteurs Honda, mais il contient

aussi des informations sur des modèles qui ne sont pas vendus par notre société. De plus, les noms de modèle

et les numéros de pièce des outils spéciaux mentionnés dans ce document sont les noms et les numéros

utilisés par Honda Motor Co., Ltd. Veuillez modifier les noms de modèles et les numéros de pièces de la façon

suivante :

Changer les noms de modèle comprenant "BF" en "BFT".

Exemple: BF *** -> BFT ***

Ajouter "HCO-" au début des numéros de pièce des outils spéciaux.

Exemple: 07GD-0010100-OS -> HCO-07GD-0010100-OS

Introducción

Antes de leer este manual

Este manual de servicio brinda la información que se requiere para la inspección, el servicio y la reparación

de los correspondientes motores fuera de borda. Para que nuestros clientes puedan utilizar los productos

durante largo tiempo de forma segura y cómoda, resulta fundamental mantener el desempeño y la calidad

de los motores fuera de borda. Para garantizar esto, el mantenimiento y el servicio deben ser ejecutados

correctamente por ténicos de mantenimiento con el conocimiento y las habilidades requeridas. La utilización de

este manual permitirá a nuestros clientes utilizar siempre su motor fuera de borda con plena satisfacción.

Debido a que este documento contiene información extraía del manual de servicio de Honda Motor, el mismo

contiene información acerca de modelos que no son vendidos por nuestra empresa. Adem s, los nombres de

los modelos y los núeros de piezas de las herramientas especiales mencionadas en este documento son los

nombres y núeros utilizados por Honda Motor Co., Ltd. Modifique los nombres de los modelos y los núeros de

piezas como se indica a continuación.

Cambie los nombres de los modelos con "BF" a "BFT".

Ejemplo: BF *** -> BFT ***

Añda "HCO-" al inicio de los núeros de piezas de las herramientas especiales.

Ejemplo: 07GD-0010100-OS -> HCO-07GD-0010100-OS

Einführung

Vor dem Durchlesen dieses Handbuchs

Dieses Service-Handbuch enthält die Information, die zur Inspektion, Service und Reparatur der jeweiligen

Außenbordmotoren benötigt wird. Zur Sicherheit unserer Kunden und für eine komfortable, langfristige

Benutzung der Produkte ist es unumgänglich, die Leistung und Qualität der Außenbordmotoren instand zu

halten. Um dies zu gewährleisten, müssen Wartung und Service von Fachkräften mit dem entsprechenden

Wissen und Fähigkeiten durchgeführt werden. Dieses Handbuch wird genutzt, damit unsere Kunden ihren

Außenbordmotor zur vollen Zufriedenheit benutzen können.

Da dieses Dokument Information des Honda Motor Service-Handbuchs enthält, findet man auch Information

über Modelle, die nicht von unserem Unternehmen verkauft werden. Des Weiteren werden die in diesem

Dokument erwähnten Modellbezeichnungen und Teilenummern von Spezialwerkzeugen von Honda Motor Co.,

Ltd benutzt. Die Modellbezeichnungen und Teilenummern wie folgt abändern:

Modellbezeichnungen "BF" in "BFT" abändern.

Beispiel: BF*** -> BFT***

"HCO" vor die Teilenummern der Spezialwerkzeuge setzen.

Beispiel: 07GD-0010100-OS -> HCO-07GD-0010100-OS

How to use this manual

How to use this manual

A Few Words About Safety

SERVICE INFORMATION

The service and repair information contained in this manual is intended for use by qualified, professional technicians. Attempting

service or repairs without the proper training, tools, and equipment could cause injury to you and/or others. It could also damage

this Honda product or create an unsafe condition.

This manual describes the proper methods and procedures for performing service, maintenance, and repairs. Some procedures

require the use of special tools. Any person who intends to use a replacement part, service procedure, or a tool that is not

recommended by Honda must determine the risks to their personal safety and the safe operation of this product.

If you need to replace a part, use Honda Genuine parts with the correct part number or an equivalent part. We strongly recommend

that you do not use replacement parts of inferior quality.

For Your Customer’s Safety

Proper service and maintenance are essential to the customer’s safety and the reliability of this product. Any error or oversight

while servicing this product can result in faulty operation, damage to the product, or injury to others.

Improper service or repairs can create an unsafe

condition that can cause your customer or others to

be seriously hurt or killed.

Follow the procedures and precautions in this manual and other service materials carefully.

For Your Safety

Because this manual is intended for the professional service technician, we do not provide warnings about many basic shop safety

practices (e.g., Hot parts-wear gloves). If you have not received shop safety training or do not feel confident about your knowledge

of safe servicing practices, we recommend that you do not attempt to perform the procedures described in this manual.

Some of the most important general service safety precautions are given below. However, we cannot warn you of every

conceivable hazard that can arise in performing service and repair procedures. Only you can decide whether or not you should

perform a given task.

Failure to properly follow instructions and precautions can cause you to be seriously hurt or killed.

Follow the procedures and precautions in this manual carefully.

Important Safety Precautions

Make sure you have a clear understanding of all basic shop safety practices and that you are wearing appropriate clothing and

using safety equipment. When performing any service task, be especially careful of the following:

• Read all of the instructions before you begin, and make sure you have the tools, the replacement or repair parts, and the skills

required to perform the tasks safely and completely.

• Protect your eyes by using proper safety glasses, goggles, or face shields anytime you hammer, drill, grind, or work around

pressurized air, pressurized liquids, springs, or other stored-energy components. If there is any doubt, put on eye protection.

• Use other protective wear when necessary, for example gloves or safety shoes. Handling hot or sharp parts can cause severe

burns or cuts. Before you grab something that looks like it can hurt you, stop and put on gloves.

• Protect yourself and others whenever you have equipment hoisted in the air. Anytime you lift this product with a hoist, make sure

that the hoist hook is securely attached to the product.

Make sure the engine is off before you begin any servicing procedures, unless the instruction tells you to do otherwise. This will

help eliminate several potential hazards:

• Carbon monoxide poisoning from engine exhaust. Be sure there is adequate ventilation whenever you run the engine.

• Burns from hot parts. Let the engine and exhaust system cool before working in those areas.

• Injury from moving parts. If the instruction tells you to run the engine, be sure your hands, fingers, and clothing are out of the

way.

Gasoline vapors and hydrogen gasses from batteries are explosive. To reduce the possibility of a fire or explosion, be careful when

working around gasoline or batteries.

• Use only a nonflammable solvent, not gasoline, to clean parts.

• Never store gasoline in an open container.

• Keep all cigarettes, sparks, and flames away from the battery and all fuel-related parts.

0-1

INTRODUCTION

This supplement covers the construction, function, and

servicing procedures of the Honda BF175AK3/200AK3/

225AK3 outboard motor.

For service information that is not covered in this

supplement, please refer to the BF175AK1/200AK1/

225AK1 (62ZY300) base shop manual.

All information contained in this manual is based on the

latest product information available at the time of

printing. We reserve the right to make changes at

anytime without notice.

How to use this manual

GENERAL INFORMATION

SERVICE INFORMATION

MAINTENANCE

TROUBLESHOOTING

FUEL SYSTEM

ENGINE COVER/COVER LOCK

1

2

3

4

5

6

No part of this publication may be reproduced, stored in

a retrieval system, or transmitted, in any form, by any

means, electronic, mechanical, photocopying,

recording, or otherwise, without prior written permission

of the publisher. This includes text, figures, and tables.

As you read this manual, you will find information that is

preceded by a symbol. The purpose of this

message is to help prevent damage to this Honda

product, other property, or the environment.

SAFETY MESSAGES

Your safety and the safety of others are very important.

To help you make informed decisions, we have

provided safety messages and other safety information

throughout this manual. Of course, it is not practical or

possible to warn you about all the hazards associated

with servicing these products. You must use your own

good judgement.

You will find important safety information in a variety of

forms, including:

· Safety Labels – on the product.

· Safety Messages – preceded by a safety alert symbol

and one of three signal words, DANGER,

WARNING, or CAUTION.

These signal words mean:

You WILL be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

You CAN be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

You CAN be HURT if you don’t follow

instructions.

CHARGING SYSTEM

IGNITION SYSTEM

STARTING SYSTEM

OTHER ELECTRICAL

COOLING SYSTEM

LUBRICATION SYSTEM

ENGINE REMOVAL/INSTALLATION

CYLINDER HEAD

CYLINDER BLOCK

GEAR CASE (STANDARD ROTATION)

GEAR CASE (COUNTER ROTATION)

MOUNT

TRIM/TILT

CONTROLS

TECHNICAL FEATURES

WIRING DIAGRAMS

INDEX

The marked sections contain no changes.

They are not covered in this supplement.

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

· Instructions – how to service these products correctly

and safely.

© Honda Motor Co., Ltd.

SERVICE PUBLICATION OFFICE

Date of Issue: May 2013

0-2

i

MEMO

dummytext

SPECIFICATIONS ·········································1-2

1. GENERAL INFORMATION

1

1-1

dummyheaddummyhead

GENERAL INFORMATION

GENERAL INFORMATION

SPECIFICATIONS

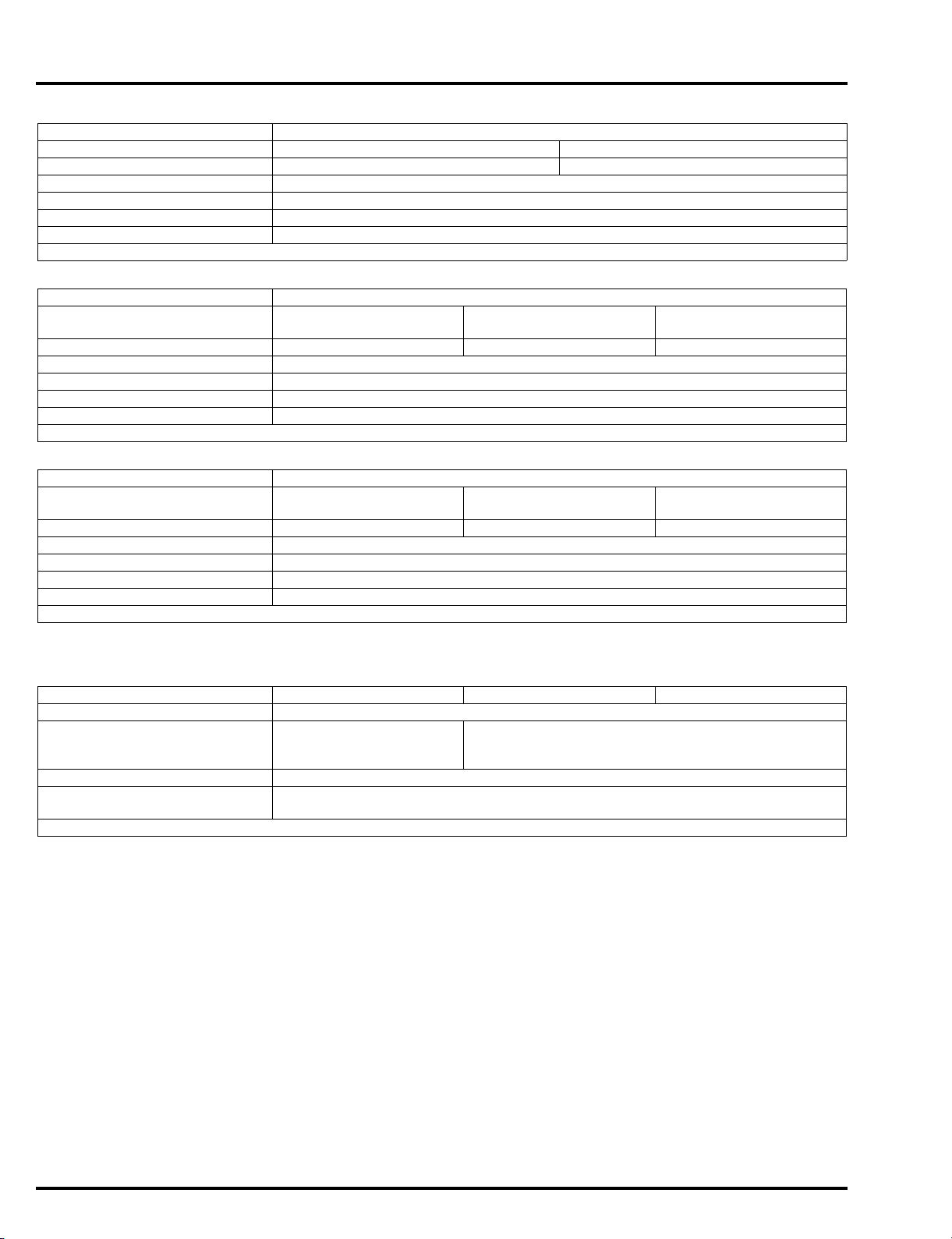

TYPE DESCRIPTION

It may be necessary to refer to this chart for reference purposes when reading this manual.

Model BF175AK3

Type XD/XT/XU XXD/XXT

Shaft Length type XL XXL

Counter Rotation –

Remote control

Power Trim/Tilt

Tachometer ( )

Trim meter ( )

XL: Extra long, XXL: Extra-extra long

( ): Optional part

The power trim/tilt type motors use an electric/hydraulic power cylinder to trim or tilt the motor.

Model BF200AK3

Type LU XU/XT/XD XCU/XCT/XCD XXU/XXT/XXD

Shaft Length type L XL XXL

Counter Rotation – – –

Remote control

Power Trim/Tilt

Tachometer ( )

Trim meter ( )

XL: Extra long, XXL: Extra-extra long

( ): Optional part

The power trim/tilt type motors use an electric/hydraulic power cylinder to trim or tilt the motor.

Model BF225AK3

Type LU/LD XU/XD/XT XCU/XCD/

XCT

Shaft Length type L XL XXL

Counter Rotation – – –

Remote control

Power Trim/Tilt

Tachometer ( )

Trim meter ( )

XL: Extra long, XXL: Extra-extra long

( ): Optional part

The power trim/tilt type motors use an electric/hydraulic power cylinder to trim or tilt the motor.

XXU/XXT/

XXD

XXCU/

XXCT/XXCD

1-2

dummyheaddummyhead

GENERAL INFORMATION

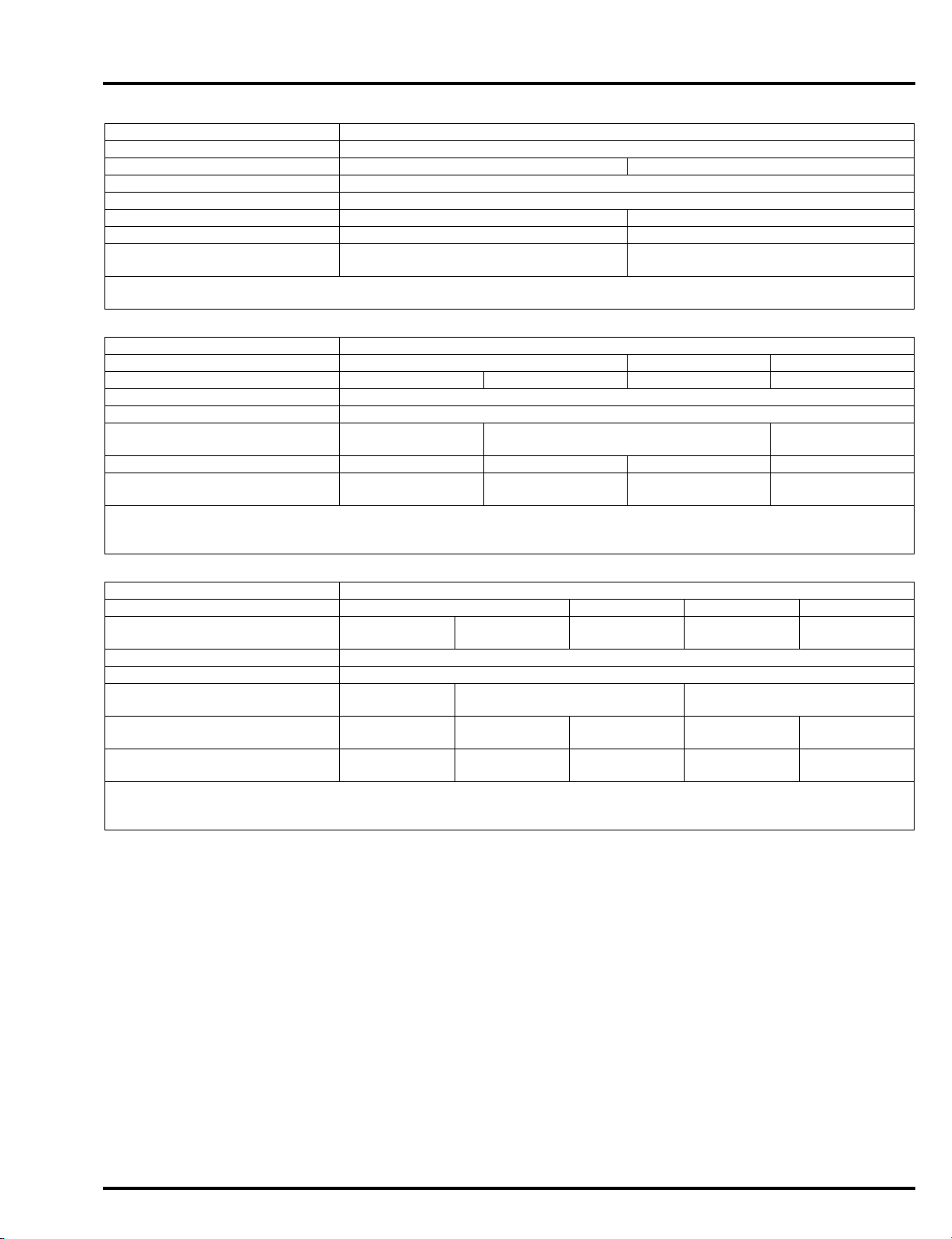

DIMENSIONS AND WEIGHTS

Model BF175AK3

Description code BAJJ

Type XD/XT/XU XXD/XXT

Overall length 920 mm (36.2 in)

Overall width 625 mm (24.6 in)

Overall height 1,797 mm (70.7 in) 1,924 mm (75.7 in)

Dry weight (*1) 270 kg (595 lbs) 275 kg (606 lbs)

Operating weight

(including oil) (*1)

*1: With propeller mounted.

Aluminum type 3.0 kg (6.6 lbs)

Model BF200AK3

Description code BAEJ BAFJ BAEJ

Type LU XU/XT/XD XCU/XCT/XCD XXU/XXT/XXD

Overall length 920 mm (36.2 in)

Overall width 625 mm (24.6 in)

Overall height 1,670 mm

Dry weight (*1) 265 kg (584 lbs) 270 kg (595 lbs) 273 kg (602 lbs) 275 kg (606 lbs)

Operating weight

(including oil) (*1)

*1: With propeller mounted.

LU, XU, XT, XD, XXU, XXT and XXD types: Aluminum type 3.0 kg (6.6 lbs)

XCU, XCT and XCD types: Stainless type 6.0 kg (13.2 lbs)

(65.7 in)

274 kg (604 lbs) 279 kg (615 lbs) 282 kg (622 lbs) 284 kg (626 lbs)

279 kg (615 lbs) 284 kg (626 lbs)

1,797 mm (70.7 in)

1,924 mm

(75.7 in)

Model BF225AK3

Description code BAGJ BAHJ BAGJ BAHJ

Type LU/LD XU/XT/XD XCU/XCT/

XCD

Overall length 920 mm (36.2 in)

Overall width 625 mm (24.6 in)

Overall height 1,670 mm

(65.7 in)

Dry weight (*1) 267 kg

(589 lbs)

Operating weight

(including oil) (*1)

*1: With propeller mounted.

LU, LD, XU, XT, XD, XXU, XXT and XXD types: Aluminum type 3.0 kg (6.6 lbs)

XCU, XCT, XCD, XXCU, XXCT and XXCD types: Stainless type 6.0 kg (13.2 lbs)

276 kg

(608 lbs)

1,797 mm (70.7 in) 1,924 mm (75.7 in)

272 kg

(600 lbs)

281 kg

(619 lbs)

275 kg

(606 lbs)

284 kg

(626 lbs)

XXU/XXT/

XXD

277 kg

(611 lbs)

286 kg

(631 lbs)

XXCU/

XXCT/XXCD

280 kg

(617 lbs)

289 kg

(637 lbs)

1-3

dummyheaddummyhead

GENERAL INFORMATION

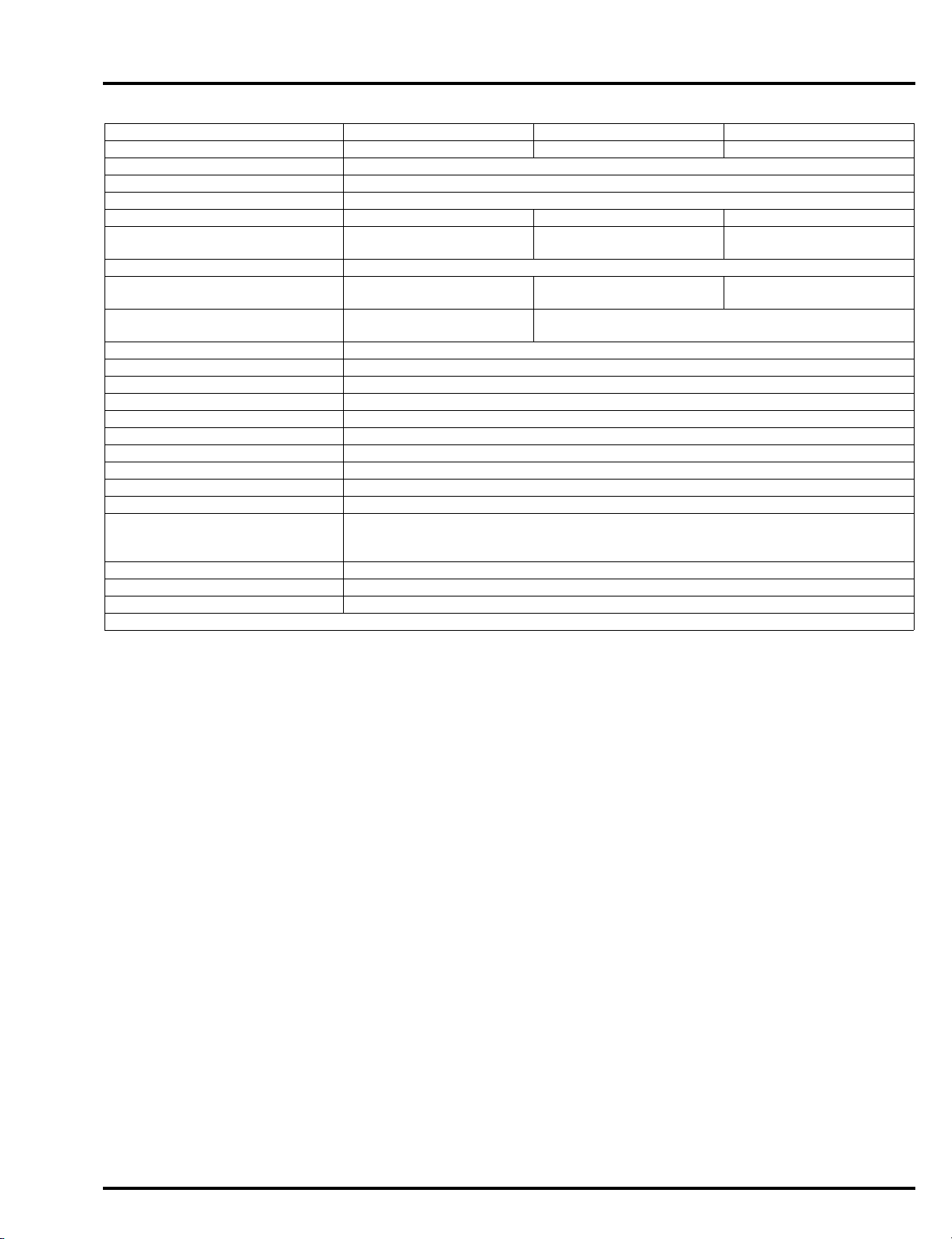

FRAME

Model BF175AK3

Type XD/XT/XU XXD/XXT

Transom height (*1) 635 mm (25.0 in) 762 mm (30.0 in)

Tilting angle (*1) 68°

Tilting stage Stageless

Trim angle (*1) – 4° to 16°

Swivel angle 30° right and left

*1: Transom angle is at 12°.

Model BF200AK3

Type LU XU/XCU/XT/

XCT/XD/XCD

Transom height (*1) 508 mm (20.0 in) 635 mm (25.0 in) 762 mm (30.0 in)

Tilting angle (*1) 68°

Tilting stage Stageless

Trim angle (*1) – 4° to 16°

Swivel angle 30° right and left

*1: Transom angle is at 12°.

XXU/XXT/XXD

Model BF225AK3

Type LU/LD XU/XCU/XT/

XCT/XD/XCD

Transom height (*1) 508 mm (20.0 in) 635 mm (25.0 in) 762 mm (30.0 in)

Tilting angle (*1) 68°

Tilting stage Stageless

Trim angle (*1) – 4° to 16°

Swivel angle 30° right and left

*1: Transom angle is at 12°.

XXU/XXCU/XXT/

XXCT/XXD/XXCD

NOISE AND VIBRATION

Model BF175AK3 BF200AK3 BF225AK3

Control system Remote control

Sound Pressure Level At

Operator’s Ear (2006/42/EC,

ICOMIA 39–94)

Uncertainty 1 dB (A)

Vibration (2006/42/EC, ICOMIA

38–94)

Reference to: ICOMIA Standard: as it specifies the engine operating conditions and measurement conditions.

78 dB (A) 79 dB (A)

Not Exceed 2.5 (m/s

2

) rms

1-4

dummyheaddummyhead

GENERAL INFORMATION

ENGINE

Model BF175AK3 BF200AK3 BF225AK3

Description code BEAJJ BEAEJ BEAGJ

Type 4-stroke, O.H.C., 6-cylinder

Displacement 3,471 cm

Bore x stroke 89.0 x 93.0 mm (3.50 x 3.66 in)

Rated power (*1) 128.7 kW (175 PS) 147.1 kW (200 PS) 165.5 kW (225 PS)

Maximum torque 265 N·m

Compression ratio 9.4 :1

Fuel consumption ratio

(at rated power)

Fuel consumption ratio

(at continuous maximum power)

Cooling system Forced water circulation by impeller pump with thermostat

Ignition system Fully transistorized, battery ignition

Ignition timing 0° at 650 min

Spark plug IZFR6K-11E (NGK)

Fuel supply system Programmed fuel injection

Fuel injection system Electronic control

Fuel injection nozzle Multi-point type

Fuel Unleaded gasoline with a pump octane rating of 86 or higher

Fuel pump Electric and mechanical plunger type

Lubrication system Pressure lubrication by trochoid pump

Lubrication capacity 8.8 liters (9.3 US qt, 7.7 Imp qt)

Starter system Electric starter

Stopping system Primary circuit ground

Exhaust system Underwater type

*1: at 5,500 min

-1

(rpm)

(27.0 kgf·m, 195 lbf·ft)

336 g/kW·h 337 g/kW·h 336 g/kW·h

349 g/kW·h 334 g/kW·h

[Without oil filter replacement: 7.6 liters (8.03 US qt, 6.69 Imp qt)]

[With oil filter replacement: 7.8 liters (8.24 US qt, 6.86 Imp qt)]

(29.8 kgf·m, 215 lbf·ft)

3

(211.7 cu in)

292 N·m

-1

(rpm) B.T.D.C.

295 N·m

(30.1 kgf·m, 218 lbf·ft)

1-5

dummyheaddummyhead

MEMO

dummytext

2. SERVICE INFORMATION

2

ENGINE & FRAME TORQUE VALUES ········2-2

CABLE/HARNESS ROUTING·······················2-3

TUBE ROUTING ·········································2-18

2-1

dummyheaddummyhead

SERVICE INFORMATION

SERVICE INFORMATION

ENGINE & FRAME TORQUE VALUES

OTHERS

Item

Power tilt relay mounting bolt/

washer

Fuse/relay junction box terminal bolt M6 x 1.0 8.5 0.87 6.3

Fuse/relay junction box mounting

bolt

Connector holder mounting bolt M6 x 1.0 5.0 0.51 3.7

Block fuse screw/washer M5 x 0.8 3.2 0.33 2.4

Plug maintenance cover special bolt M6 x 1.0 10 1.0 7

HO2S sealing bolt (*1) M10 x 1.25 10 1.0 7

*1: XT, XCT, XXT, XXCT type:

Do not remove the HO2S sealing bolt.

When installing the HO2S sealing bolt by mistake, tighten it to the specified torque at above list.

Thread Dia. and pitch Torque values

mm (in) N·m kgf·m lbf·ft

M6 x 1.0 5.0 0.51 3.7

M6 x 1.0 5.0 0.51 3.7

Remarks

2-2

dummyheaddummyhead

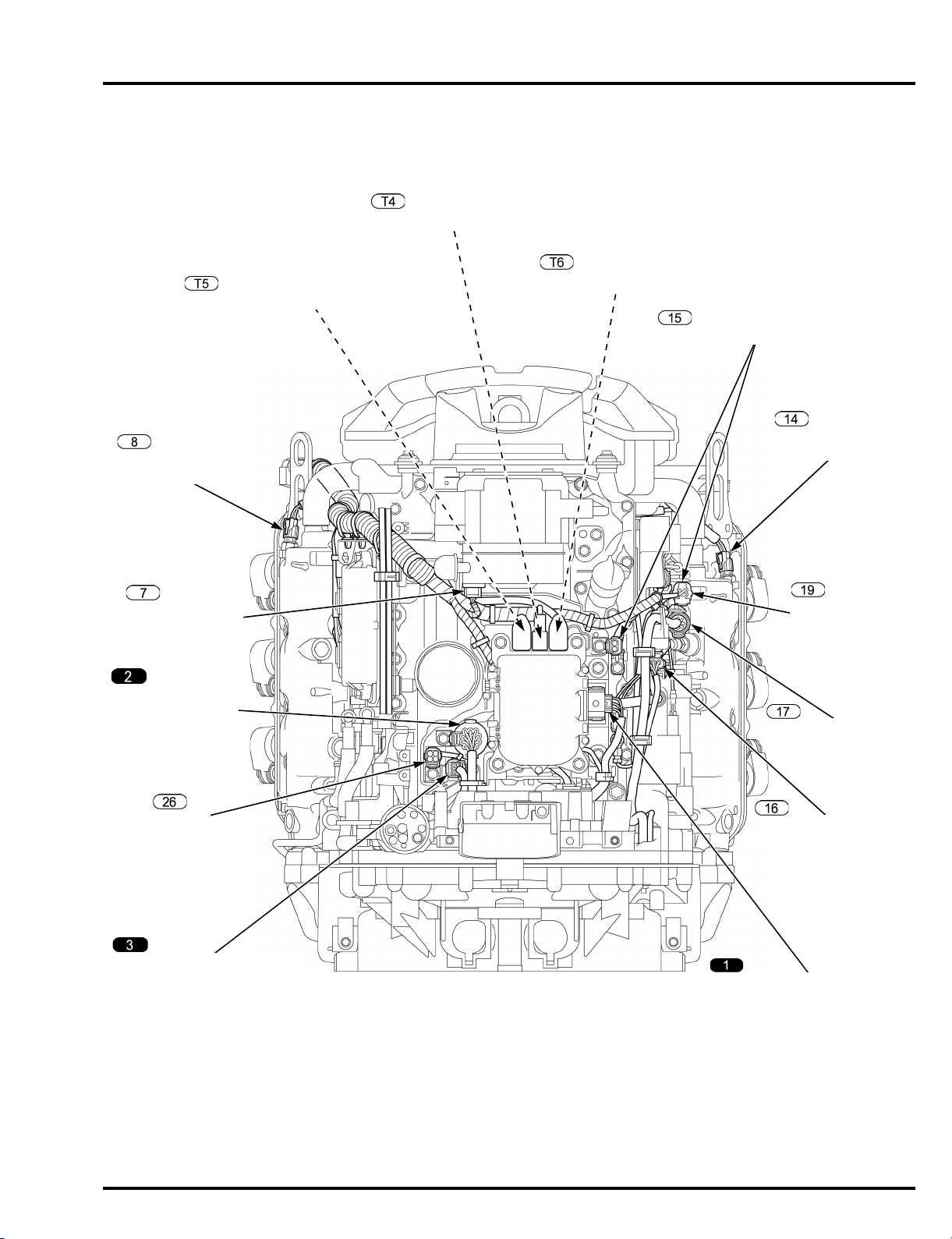

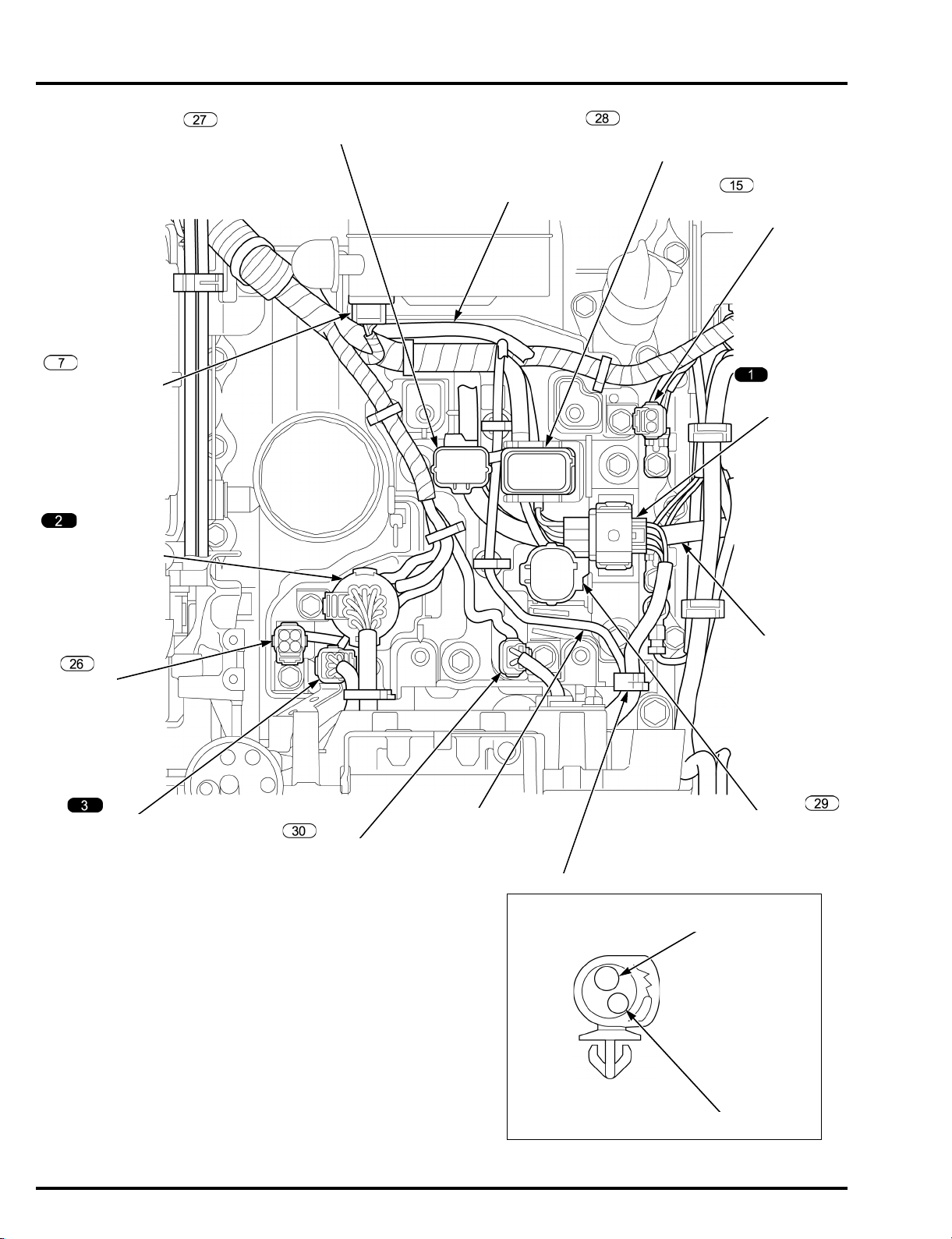

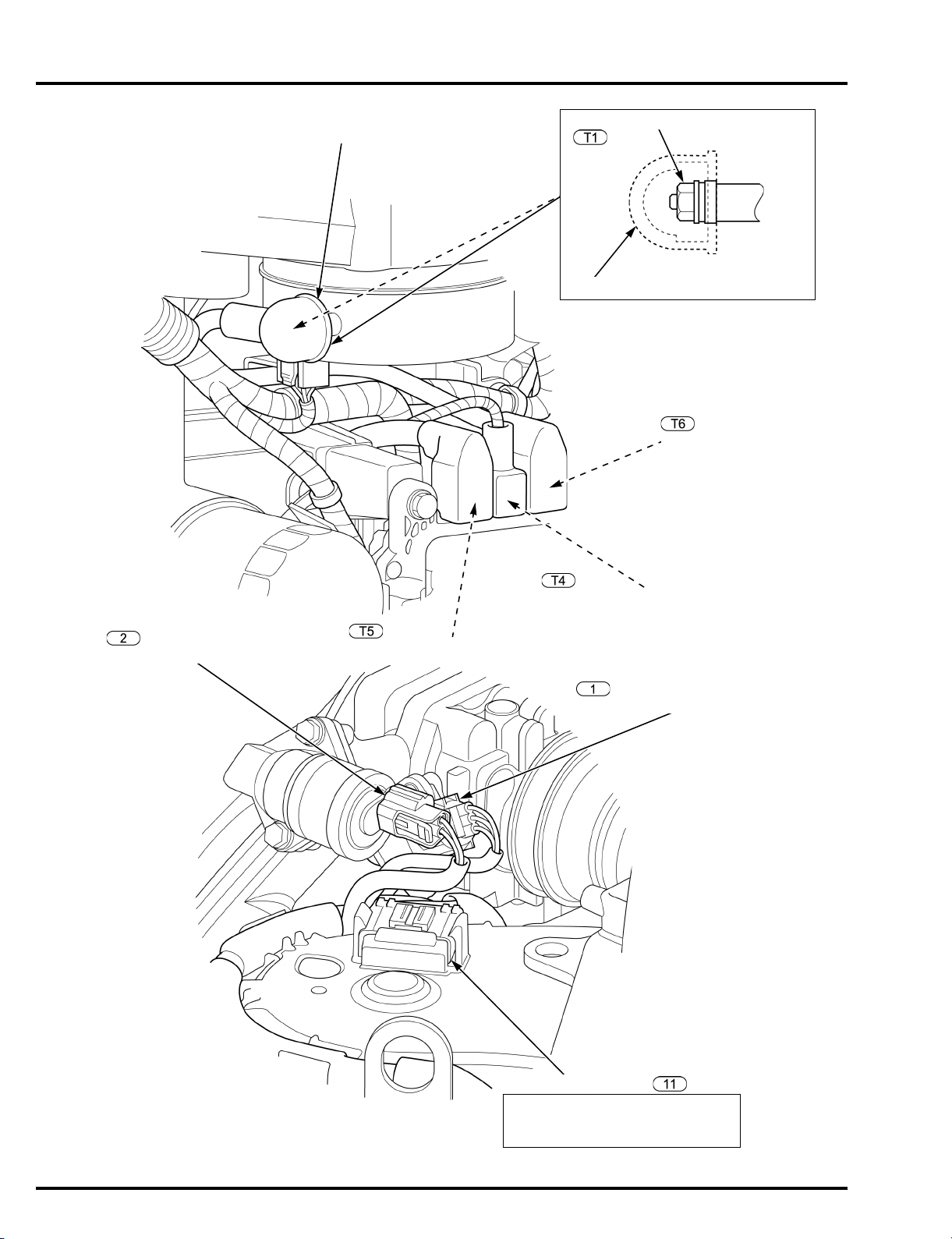

POWER TILT MOTOR

2P CONNECTOR

INTERFACE 6P CONNECTOR

INDICATOR PANEL WIRE

HARNESS 6P CONNECTOR

HO2S

4P CONNECTOR

(Except XT, XCT,

XXT, XXCT types)

SWITCH PANEL

WIRE HARNESS

14P CONNECTOR

ACG CABLE TERMINAL

POWER TILT RELAY WIRE TERMINAL

EMT SENSOR 2

2P CONNECTOR

TRIM ANGLE SENSOR

3P CONNECTOR

DLC 4P

ALTERNATOR

4P CONNECTOR

EMT SENSOR 1

2P CONNECTOR

STARTER CABLE 1 (+) TERMINAL

TACHO PULSE 2P CONNECTOR

CABLE/HARNESS ROUTING

SERVICE INFORMATION

2-3

dummyheaddummyhead

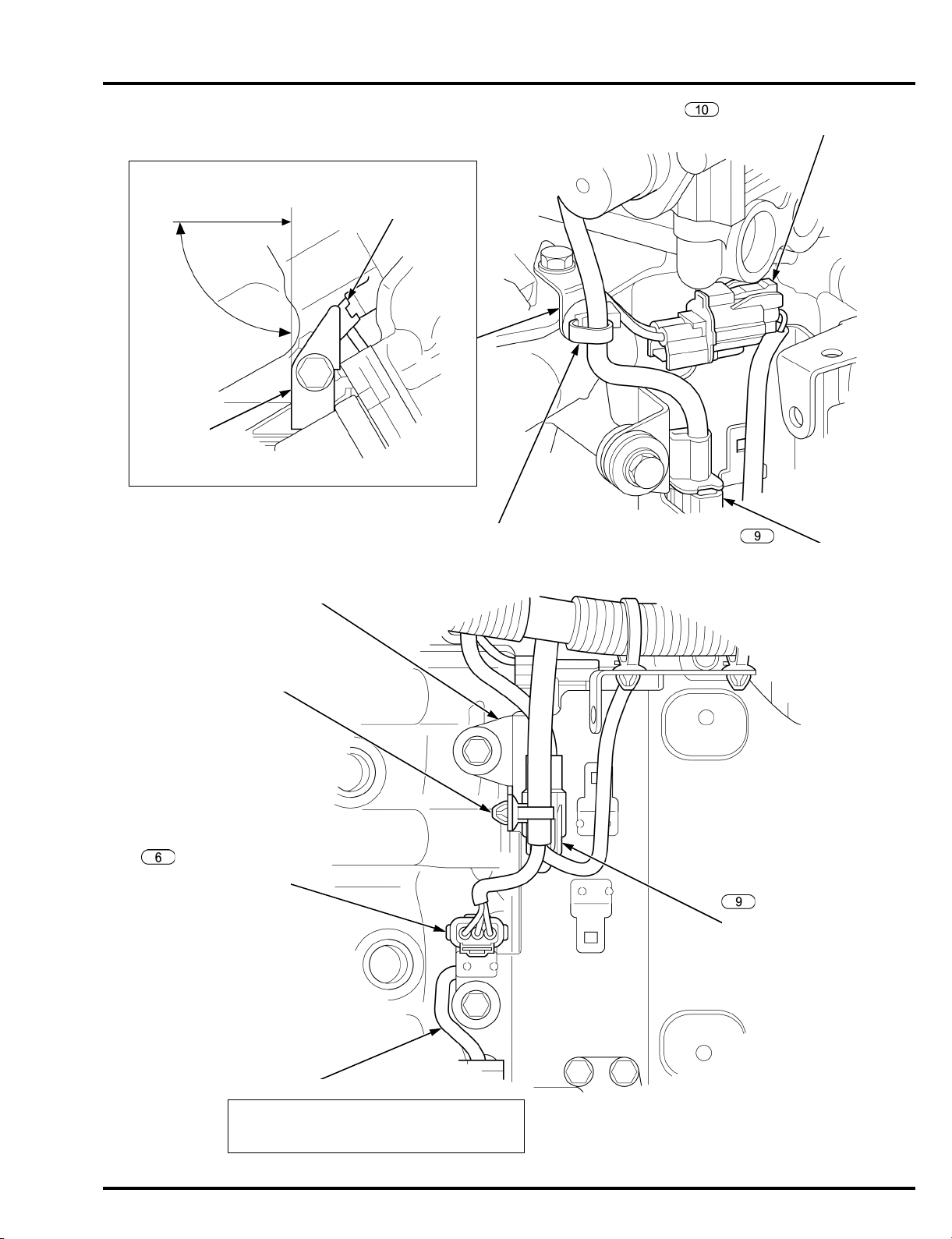

FUSE/RELAY JUNCTION BOX 8P CONNECTOR

NMEA INTERFACE WIRE

(Optional part)

POWER TILT

RELAY WIRE

TERMINAL

INTERFACE

6P CONNECTOR

ALTERNATOR

4P CONNECTOR

SWITCH PANEL

WIRE HARNESS

14P CONNECTOR

DLC 4P

INDICATOR PANEL

WIRE HARNESS

6P CONNECTOR

NEUTRAL SWITCH

2P CONNECTOR

STARTER CABLE 1 (+)

HARNESS BAND CLIP

TACHO PULSE

2P CONNECTOR

ACG CABLE

STARTER CABLE 1 (+)

FUSE/RELAY JUNCTION BOX

10P CONNECTOR

FUSE/RELAY JUNCTION BOX

23P CONNECTOR

SERVICE INFORMATION

2-4

dummyheaddummyhead

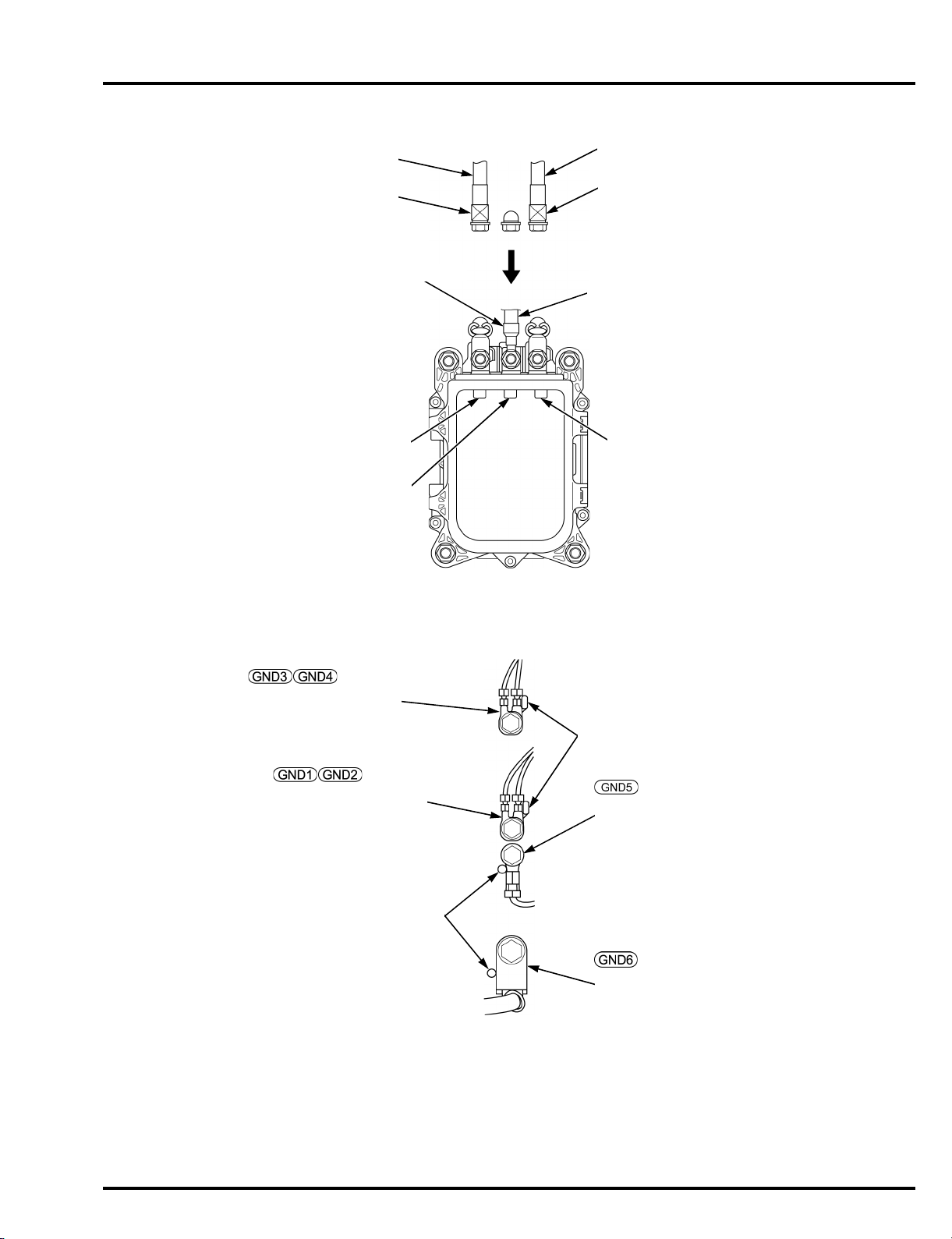

MAIN WIRE HARNESS

GROUND TERMINALS

POWER TILT RELAY CABLE

GREEN TAPE

YELLOW TAPE

GREEN

YELLOW

RED

ACG CABLE

RED TAPE

STARTER CABLE 1 (+)

MAIN WIRE HARNESS

GROUND TERMINALS

STOPPER

POWER TILT RELAY

GROUND TERMINALS

STARTER CABLE GROUND

(BATTERY GROUND TERMINAL)

STOPPER

SERVICE INFORMATION

2-5

dummyheaddummyhead

INDICATOR PANEL

WIRE HARNESS

NMEA INTERFACE WIRE

(Optional part)

STARTER CABLE (–)

SWITCH PANEL WIRE HARNESS

STARTER CABLE 1 (+)

STARTER CABLE 2 (+)

STARTER CABLE (–)

STARTER CABLE 1 (+)

NMEA INTERFACE WIRE (Optional part)

NMEA INTERFACE WIRE

(Optional part)

SWITCH PANEL

WIRE HARNESS

SHIFT CONTROL CABLE

STARTER CABLES

FUEL TUBE A

SPEEDOMETER TUBE

(Optional part)

INDICATOR PANEL

WIRE HARNESS

THROTTLE

CONTROL CABLE

NMEA INTERFACE WIRE

(Optional part)

SERVICE INFORMATION

2-6

dummyheaddummyhead

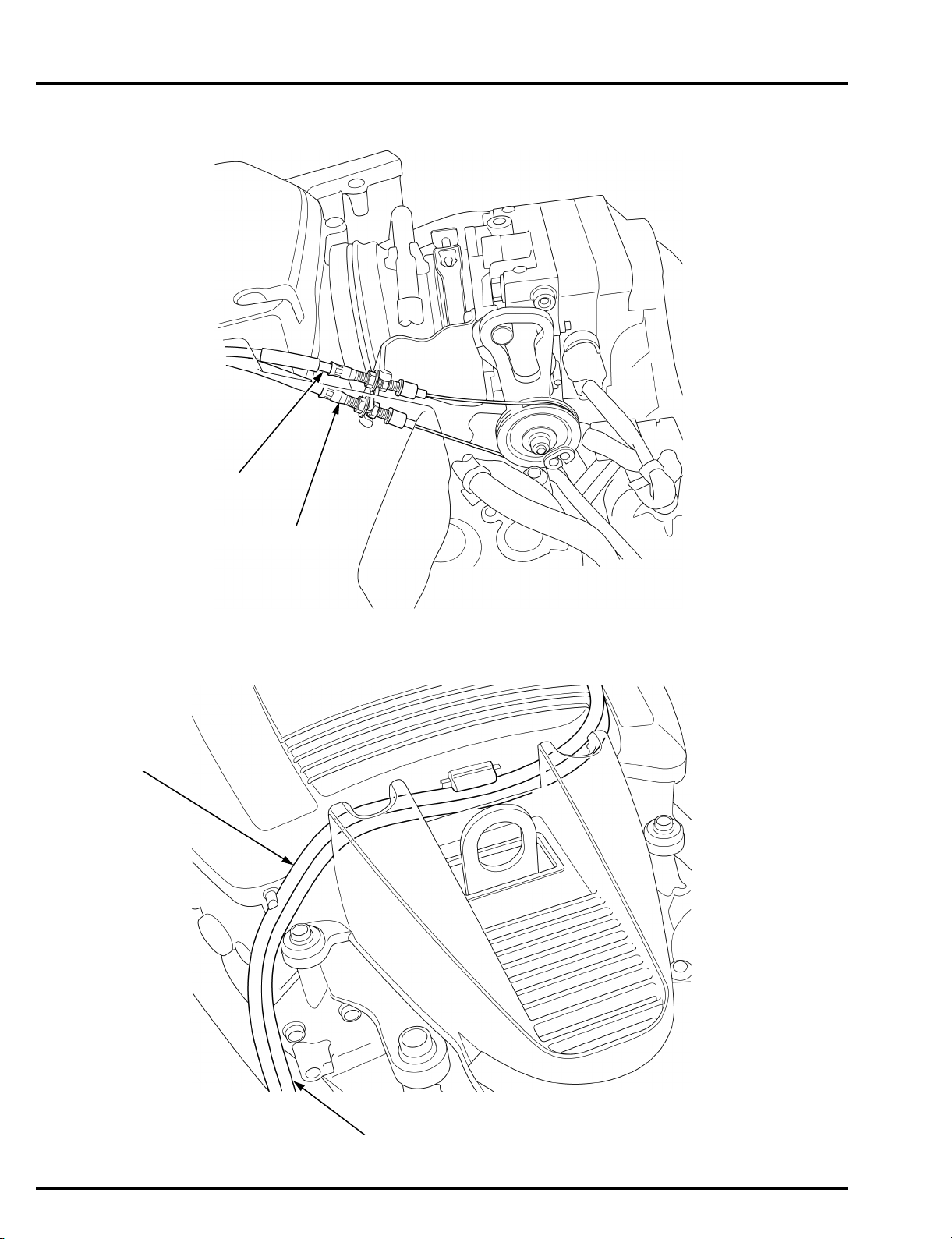

AIR FLOW CLAMP

IAC VALVE 2P CONNECTOR

Install the air flow clamp as shown.

AIR FLOW CLAMP

TP SENSOR 3P CONNECTOR

TP SENSOR

3P CONNECTOR

No.1 DIRECT

IGNITION COIL

3P CONNECTOR

No.2 DIRECT

IGNITION COIL

3P CONNECTOR

No.3 DIRECT

IGNITION COIL

3P CONNECTOR

POWER TILT SWITCH 3P CONNECTOR

THROTTLE

CABLE A

THROTTLE

CABLE B

ALTERNATOR

4P CONNECTOR

ECM 36P

CONNECTOR A (Gray)

EMT SENSOR 1 2P CONNECTOR

MAIN WIRE HARNESS

ECM 36P CONNECTOR B (Black)

SERVICE INFORMATION

2-7

dummyheaddummyhead

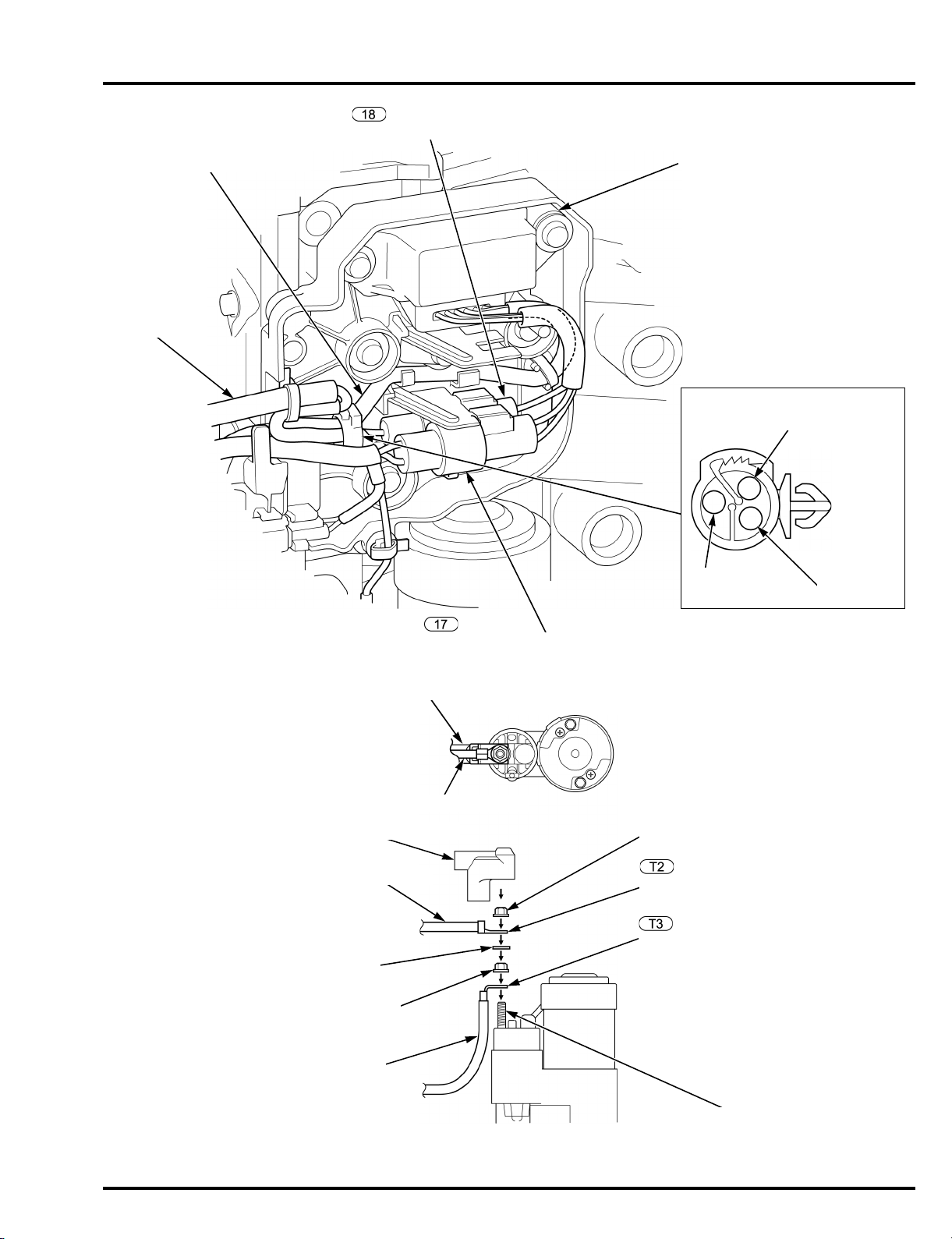

Install the joint connector 1 as shown.

After installation, check the main wire

harness for twist.

ACG CABLE TERMINAL

STARTER CABLE 1 (+) TERMINAL

POWER TILT RELAY WIRE TERMINAL

IAC VALVE 2P CONNECTOR

TP SENSOR 3P CONNECTOR

JOINT CONNECTOR 1

COVER

ALTERNATOR B TERMINAL

COVER

SERVICE INFORMATION

2-8

dummyheaddummyhead

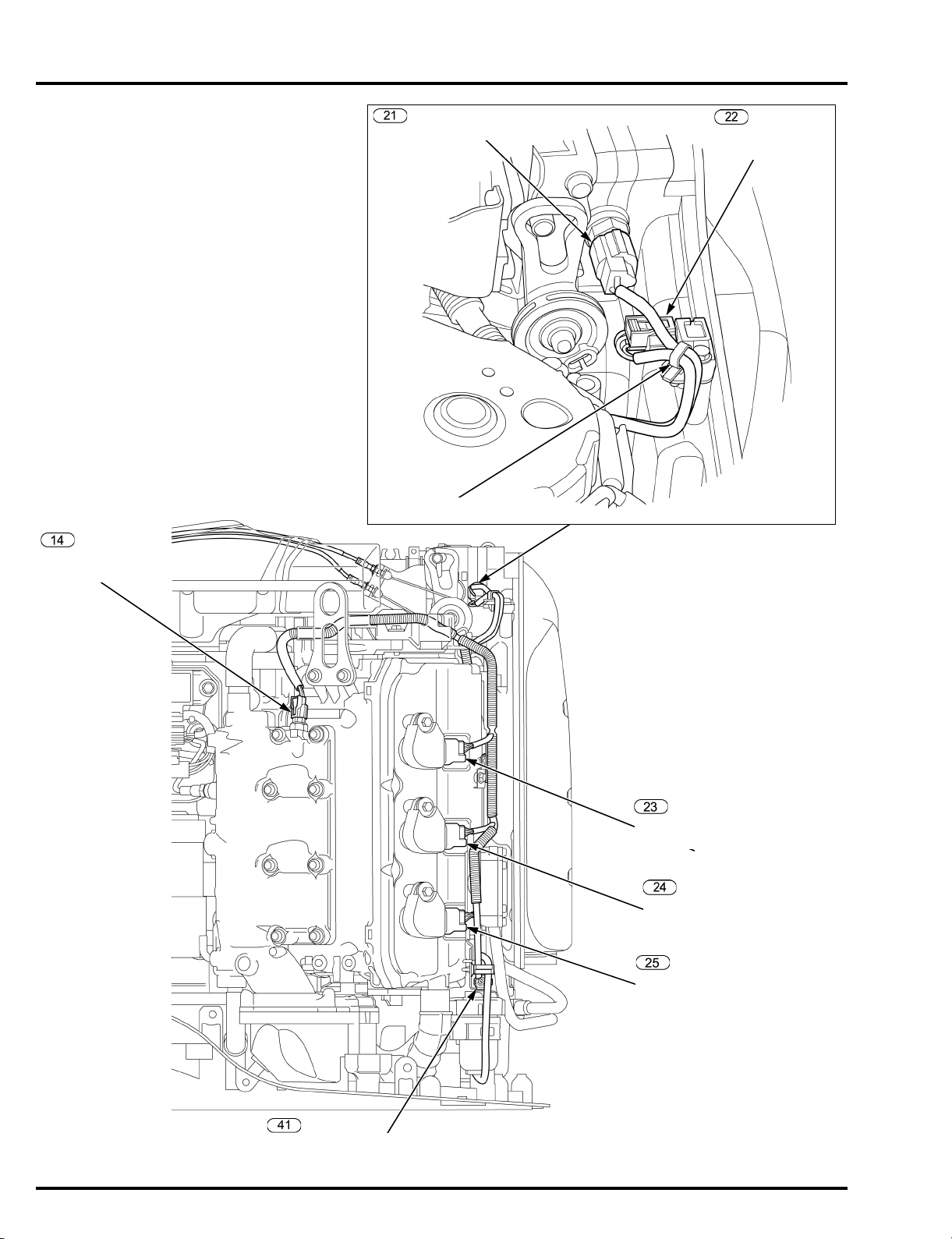

VTEC SOLENOID VALVE

1P CONNECTOR

(BF225 only)

HARNESS BAND CLIP

Install the power tilt switch wire from the outside

of the ECM bracket and check that the wire do

not interfere with the ECM bracket.

CKP SENSOR 2P CONNECTOR

ECM BRACKET

HARNESS BAND CLIP

POWER TILT SWITCH

3P CONNECTOR

POWER TILT SWITCH WIRE

VTEC SOLENOID VALVE

1P CONNECTOR

(BF225 only)

Align the stay with the center of grommet.

Cruising direction

GROMMET

90°

STAY

SERVICE INFORMATION

2-9

dummyheaddummyhead

EMT SENSOR 2

2P CONNECTOR

No.4 DIRECT IGNITION COIL

3P CONNECTOR

No.5 DIRECT IGNITION COIL

3P CONNECTOR

No.6 DIRECT IGNITION COIL

3P CONNECTOR

WATER LEVEL SENSOR 2P CONNECTOR

IAT SENSOR 2P CONNECTOR

MAP SENSOR

3P CONNECTOR

HARNESS BAND CLIP

SERVICE INFORMATION

2-10

dummyheaddummyhead

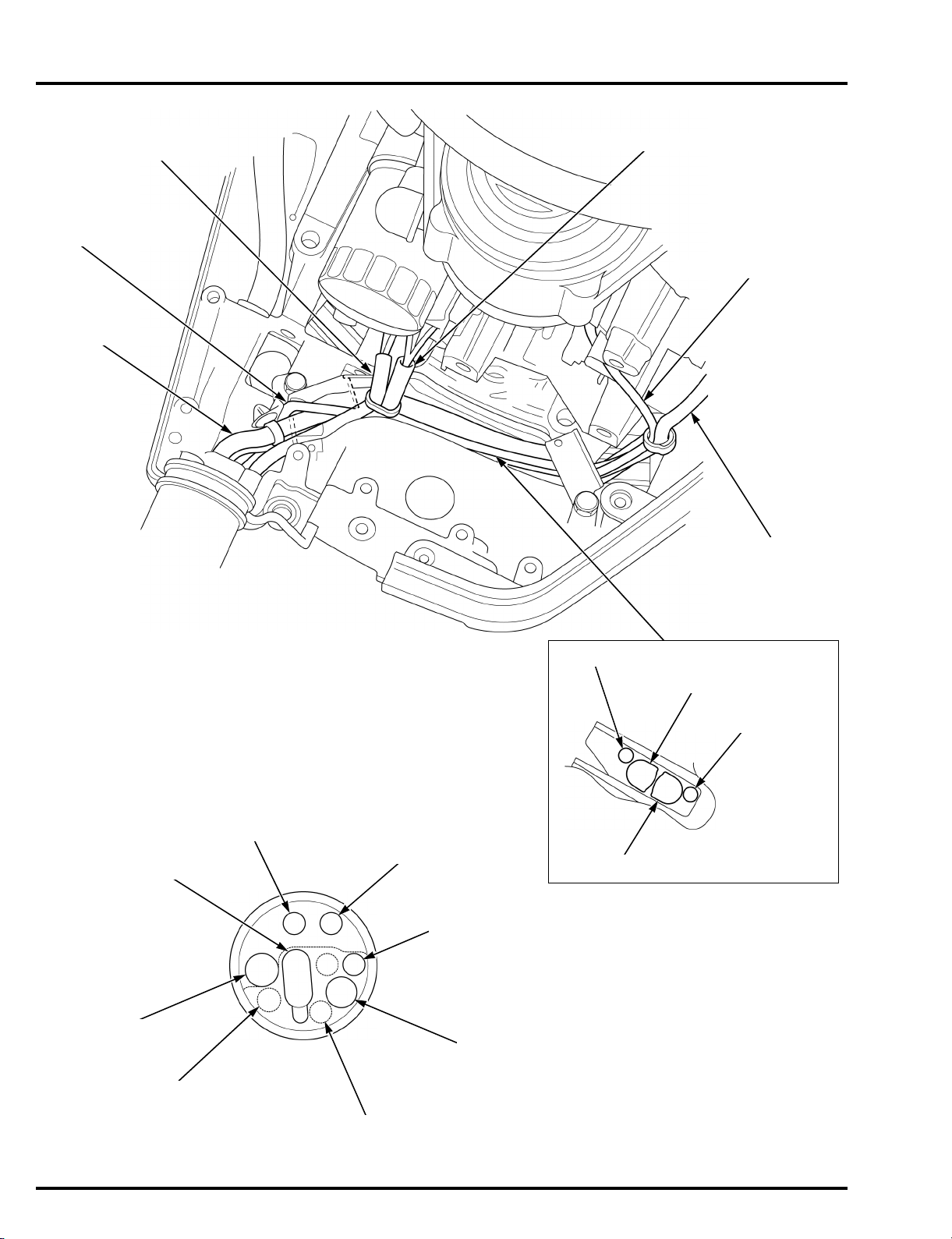

WIRE HARNESS CLIP

POWER TILT MOTOR 2P CONNECTOR

TACHO PULSE 2P CONNECTOR

TRIM ANGLE SENSOR

3P CONNECTOR

INTERFACE 6P CONNECTOR

POWER TILT MOTOR WIRE

POWER TILT RELAY

GROUND TERMINALS CABLE

TRIM ANGLE

SENSOR WIRE

POWER TILT RELAY CABLE

POWER TILT

MOTOR WIRE

POWER TILT RELAY

GROUND TERMINALS CABLE

WIRE HARNESS CLIP

HO2S 4P CONNECTOR

(Except XT, XCT, XXT,

XXCT types)

POWER TILT RELAY

2P CONNECTOR

POWER TILT RELAY

1P CONNECTOR

POWER TILT MOTOR

2P CONNECTOR

POWER TILT MOTOR 2P CONNECTOR WIRE

POWER TILT RELAY CASE

POWER TILT MOTOR

2P CONNECTOR/

POWER TILT RELAY

1P CONNECTOR WIRE

POWER TILT RELAY

GROUND TERMINALS

CABLE

MAIN WIRE

HARNESS

GROUND CABLE

HO2S 4P

CONNECTOR

(Except XT, XCT,

XXT, XXCT types)

SERVICE INFORMATION

2-11

dummyheaddummyhead

THROTTLE CABLE B

THROTTLE CABLE A

THROTTLE CABLE B

THROTTLE CABLE A

SERVICE INFORMATION

2-12

dummyheaddummyhead

WIRE HARNESS CLIP

POWER TILT RELAY

POWER TILT RELAY

GROUND TERMINALS CABLE

POWER TILT RELAY 1P CONNECTOR

POWER TILT MOTOR 2P CONNECTOR

STARTER CABLE 2 (+)

POWER TILT RELAY CABLE

STARTER TERMINAL COVER

POWER TILT RELAY CABLE

WASHER (8 mm)

STARTER CABLE 2 (+)

STARTER MOTOR B

TERMINAL NUT (8 mm)

STARTER MOTOR B TERMINAL

STARTER MOTOR B TERMINAL NUT (8 mm)

MAIN WIRE

HARNESS

POWER TILT

RELAY CABLE

POWER TILT RELAY GROUND

TERMINALS CABLE

MAIN WIRE

HARNESS

STARTER CABLE 2 (+) TERMINAL

POWER TILT RELAY CABLE TERMINAL

SERVICE INFORMATION

2-13

dummyheaddummyhead

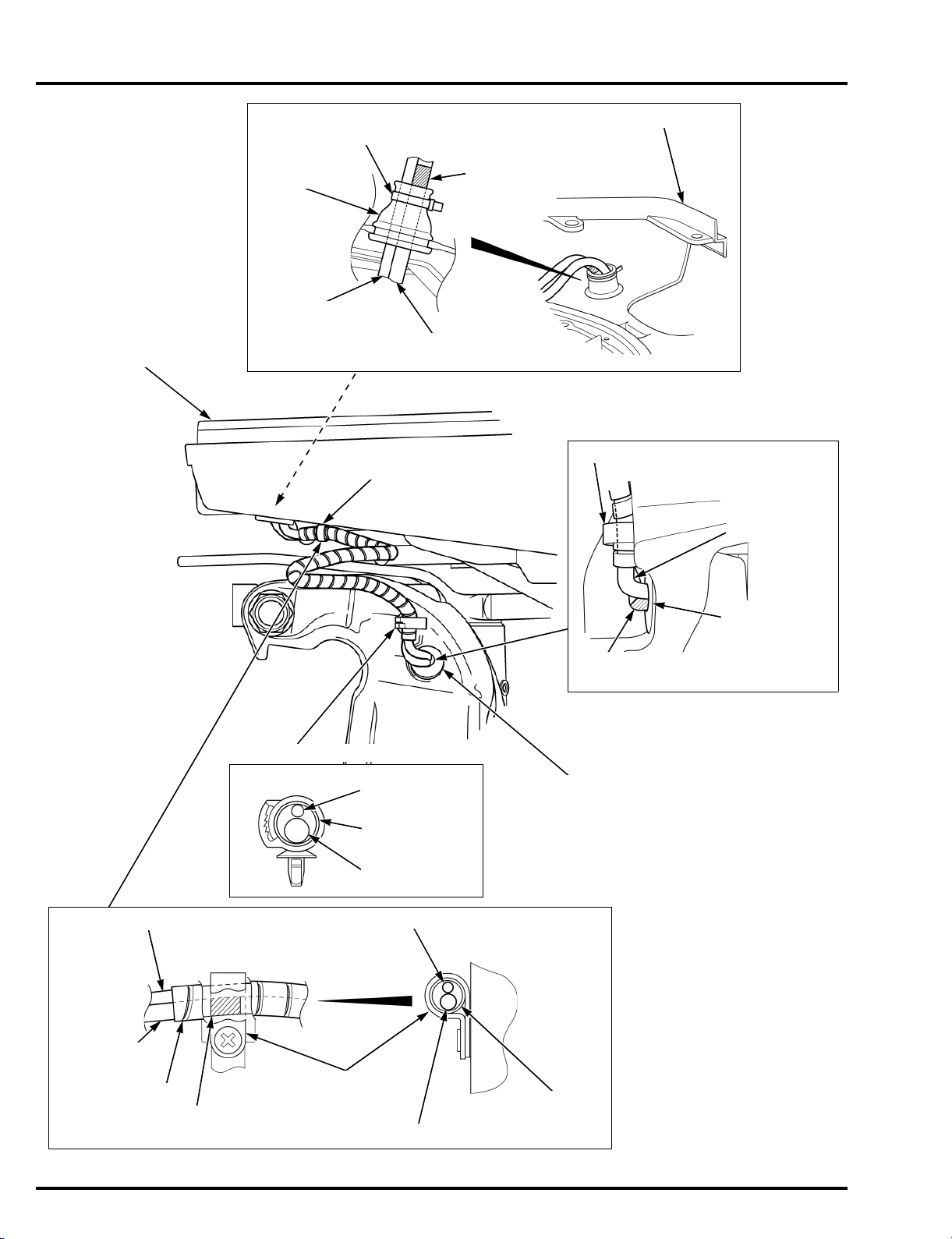

L. ENGINE UNDER COVER

CLIP

MOTOR CORD BUSHING

TRIM ANGLE

SENSOR WIRE

SPIRAL TUBE

POWER TILT

MOTOR WIRE

WIRE HARNESS CLIP

TRIM ANGLE

SENSOR WIRE

MOTOR CORD

BUSHING

Align the tape end with the

motor cord bushing end.

WIRE HARNESS CLIP

WIRE BAND (Cut off the surplus band

remaining it about 5 mm (0.2 in))

UNDER CASE

GROMMET

TRIM ANGLE

SENSOR WIRE

POWER TILT MOTOR WIRE

Align the white tape end with

the under case grommet end.

L. ENGINE UNDER COVER

TRIM ANGLE SENSOR WIRE

POWER TILT

MOTOR WIRE

SPIRAL TUBE

Align the tape end of the power trim/tilt motor wire

with the clip end.

POWER TILT MOTOR WIRE

SPIRAL TUBE

TRIM ANGLE SENSOR WIRE

CLIP

SERVICE INFORMATION

2-14

dummyheaddummyhead

SWIVEL CASE

R. STERN BRACKET

TRIM ANGLE SENSOR

POWER TILT MOTOR

POWER TILT MOTOR WIRE

Check the wire for twist.

TRIM ANGLE SENSOR WIRE

Check the wire for slack.

SERVICE INFORMATION

2-15

dummyheaddummyhead

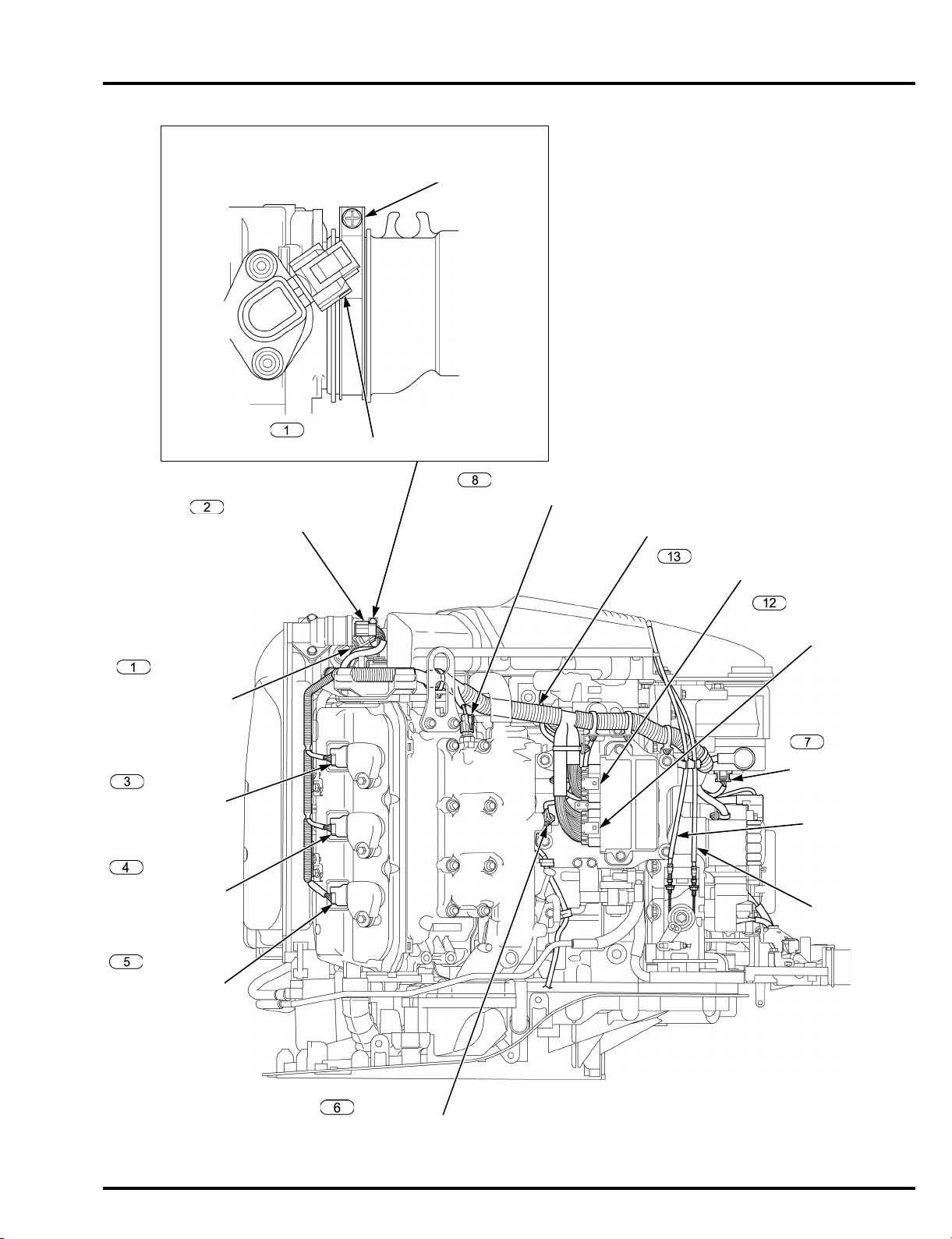

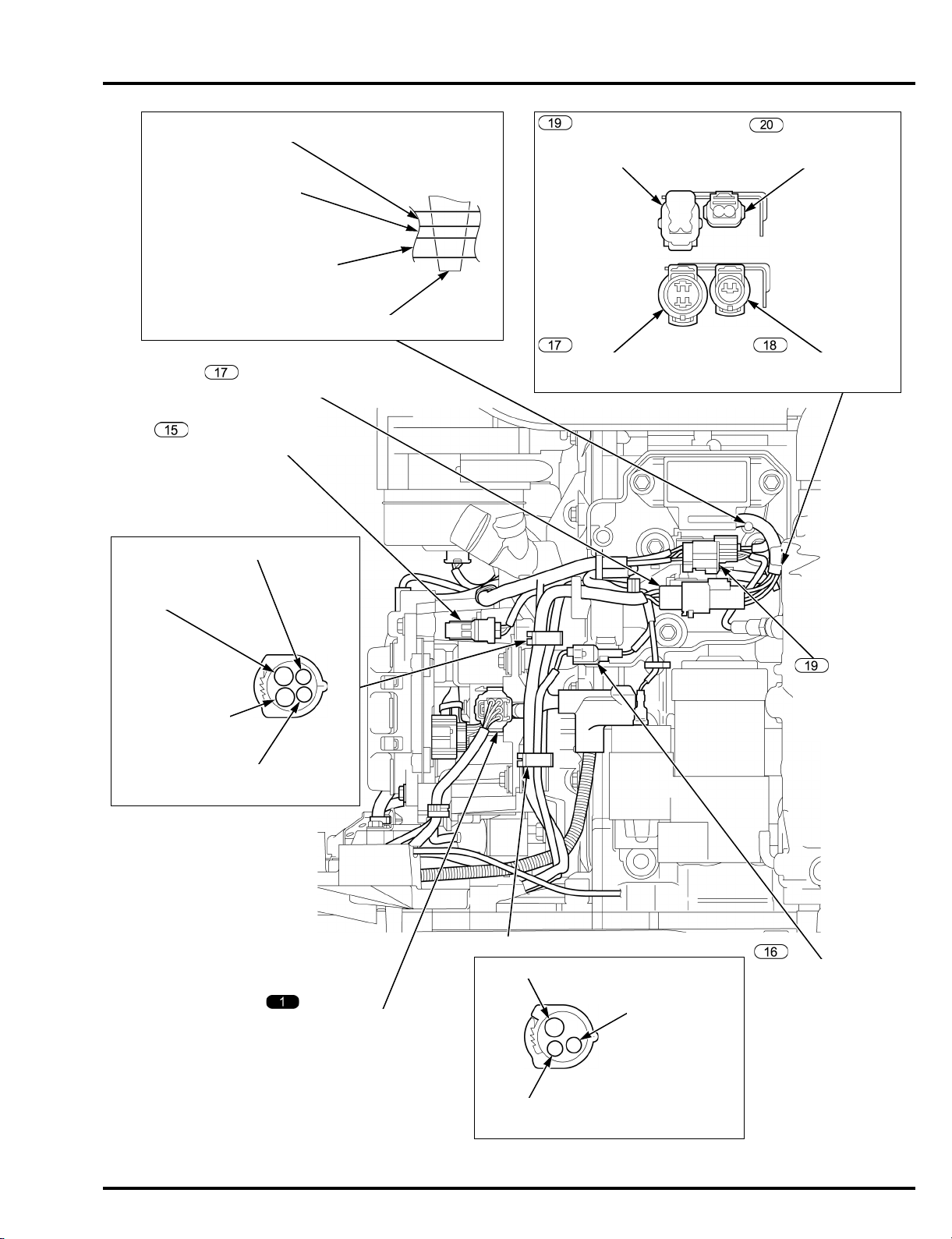

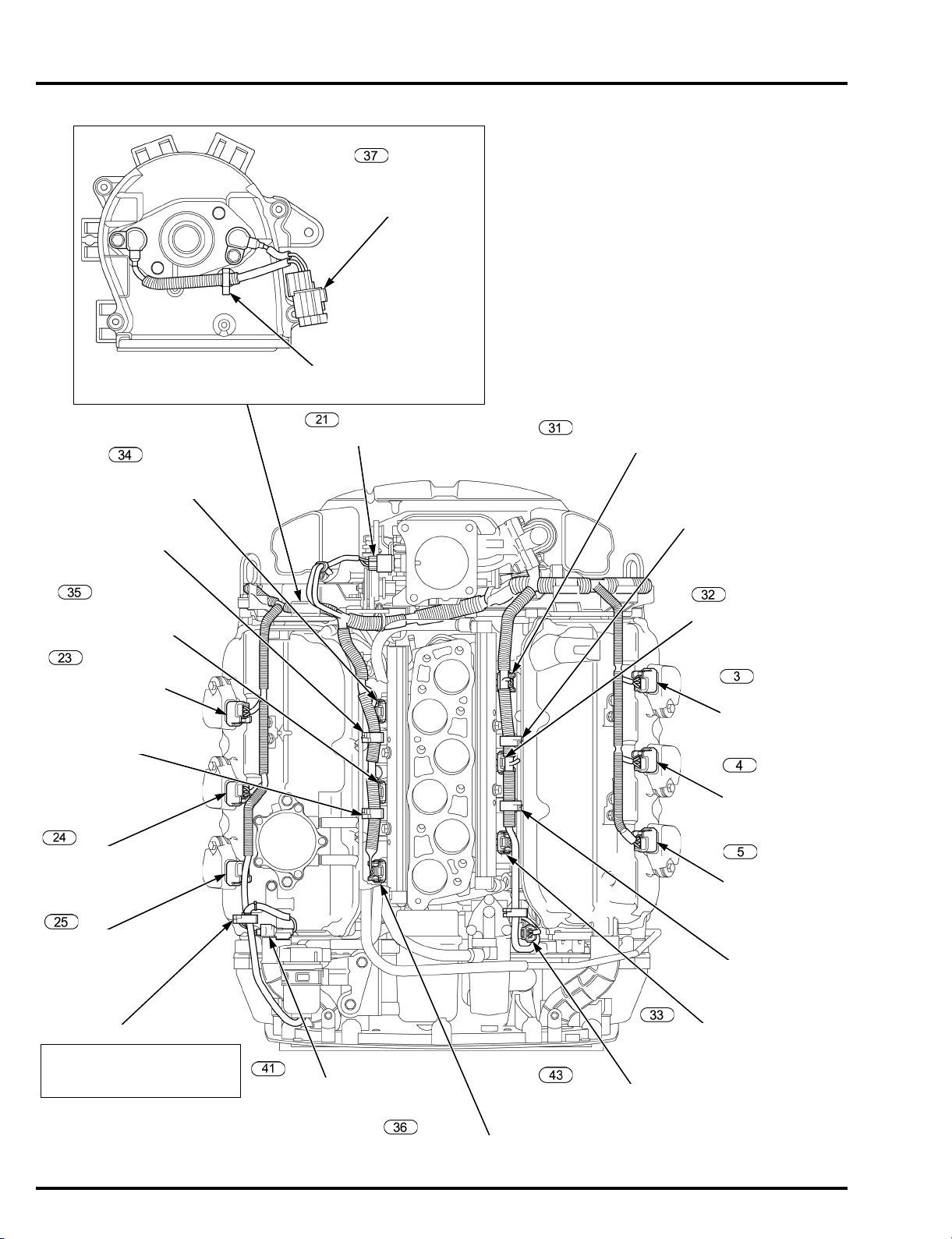

L. TIMING BELT BACK COVER

Align the band end of the water

level sensor wire (sensor side)

with the harness clip end.

No.1 FUEL INJECTOR 2P CONNECTOR

WIRE HARNESS CLIP

No.2 FUEL INJECTOR

2P CONNECTOR

No.1 DIRECT

IGNITION COIL

3P CONNECTOR

No.2 DIRECT

IGNITION COIL

3P CONNECTOR

No.3 DIRECT

IGNITION COIL

3P CONNECTOR

WIRE HARNESS CLIP

No.3 FUEL INJECTOR

2P CONNECTOR

FUEL PUMP (HIGH PRESSURE SIDE)

2P CONNECTOR

No.6 FUEL INJECTOR 2P CONNECTOR

WATER LEVEL SENSOR

2P CONNECTOR

HARNESS BAND CLIP

No.6 DIRECT

IGNITION COIL

3P CONNECTOR

No.5 DIRECT

IGNITION COIL

3P CONNECTOR

No.4 DIRECT

IGNITION COIL

3P CONNECTOR

WIRE HARNESS CLIP

No.5 FUEL INJECTOR

2P CONNECTOR

WIRE HARNESS CLIP

No.4 FUEL INJECTOR

2P CONNECTOR

IAT SENSOR 2P CONNECTOR

CMP SENSOR 1

CMP SENSOR 2

4P CONNECTOR

HARNESS BAND CLIP (Cut off the surplus

band remaining it about 10 mm (0.4 in))

SERVICE INFORMATION

2-16

Loading...

Loading...