Tohatsu 5BS 04-93, 5 B, 5B 04-93, 5 BS User Manual

OWNER’S WAND E3:,00&

FOREWORD

Thank you for choosing a TOHATSU OUTBOARD MOTOR.

This manual describes its workings and its main features. Before using

the motor study these instructions and get to know what a fine engine

it is. Like any other piece of machinery it requires careful and knowledgeable attenlion, and in return it will give you excellent service over

the years. Our policy is one of continuous product improvement so we

reserve the right to incorporate changes without prior notice.

TOHATSU CORPORATION

v

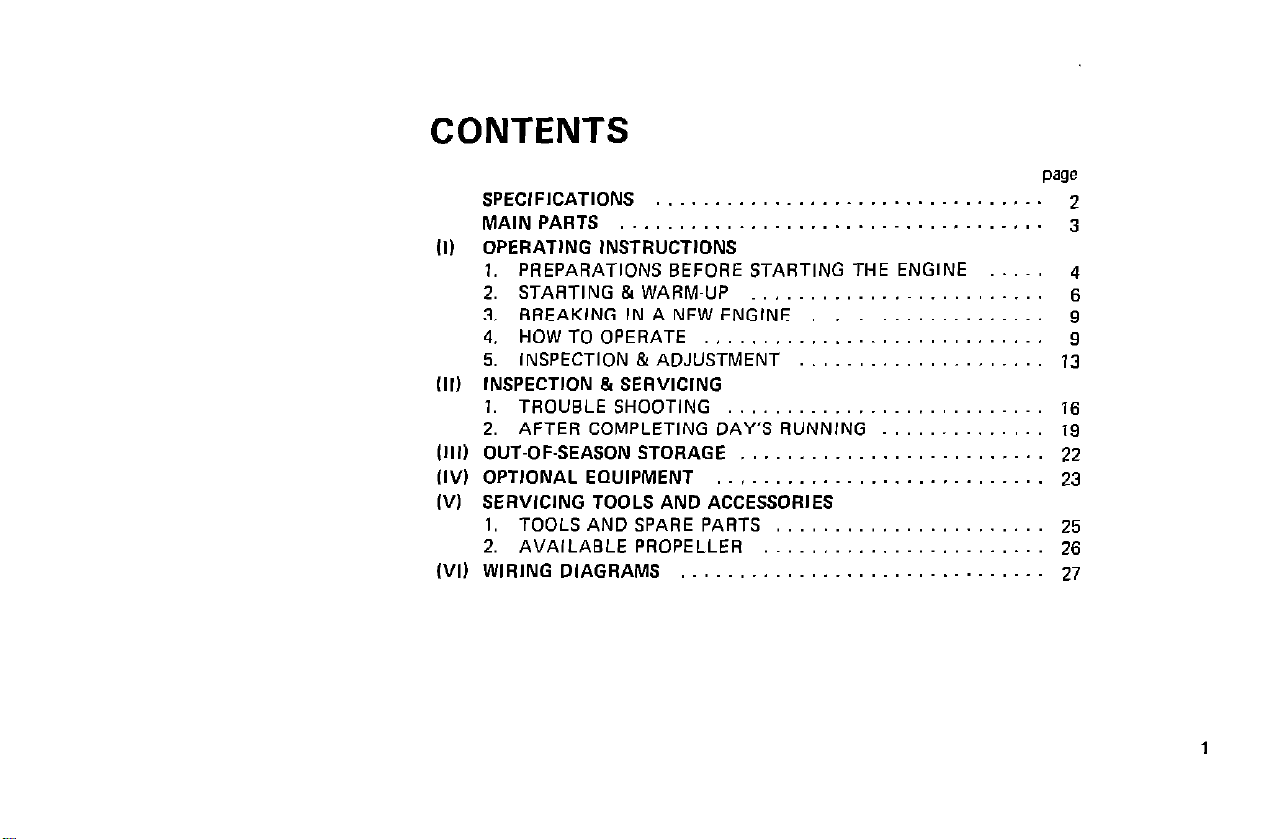

CONTENTS

SPECIFICATIONS .

MAINPARTS . .._...........................

(1) OPERATING INSTRUCTIONS

1. PREPARATIONS BEFORE STARTING THE ENGINE

2. STARTING 81 WARM-UP ~.

3. BREAKING IN A NEW ENGINE

4. HOWTOOPERATE .,..,.,._,.,_......,.,...

5. INSPECTION & ADJUSTMENT

(II) INSPECTION 5 SEAVICING

1. TROUBLESHOOTING ..,........,....,.,....

2. AFTER COMPLETING DAY’S RUNNING

(Ill) OUT-OF-SEASON STORAGE

III/I OPTIONAL EQUIPMENT .

(VI SERVICING TOOLS AND ACCESSORIES

1. TOOLS AND SPARE PARTS

2. AVAILABLE PROPELLER .~..,,..,......,....

(VI) WIRING DIAGRAMS _. _.

1

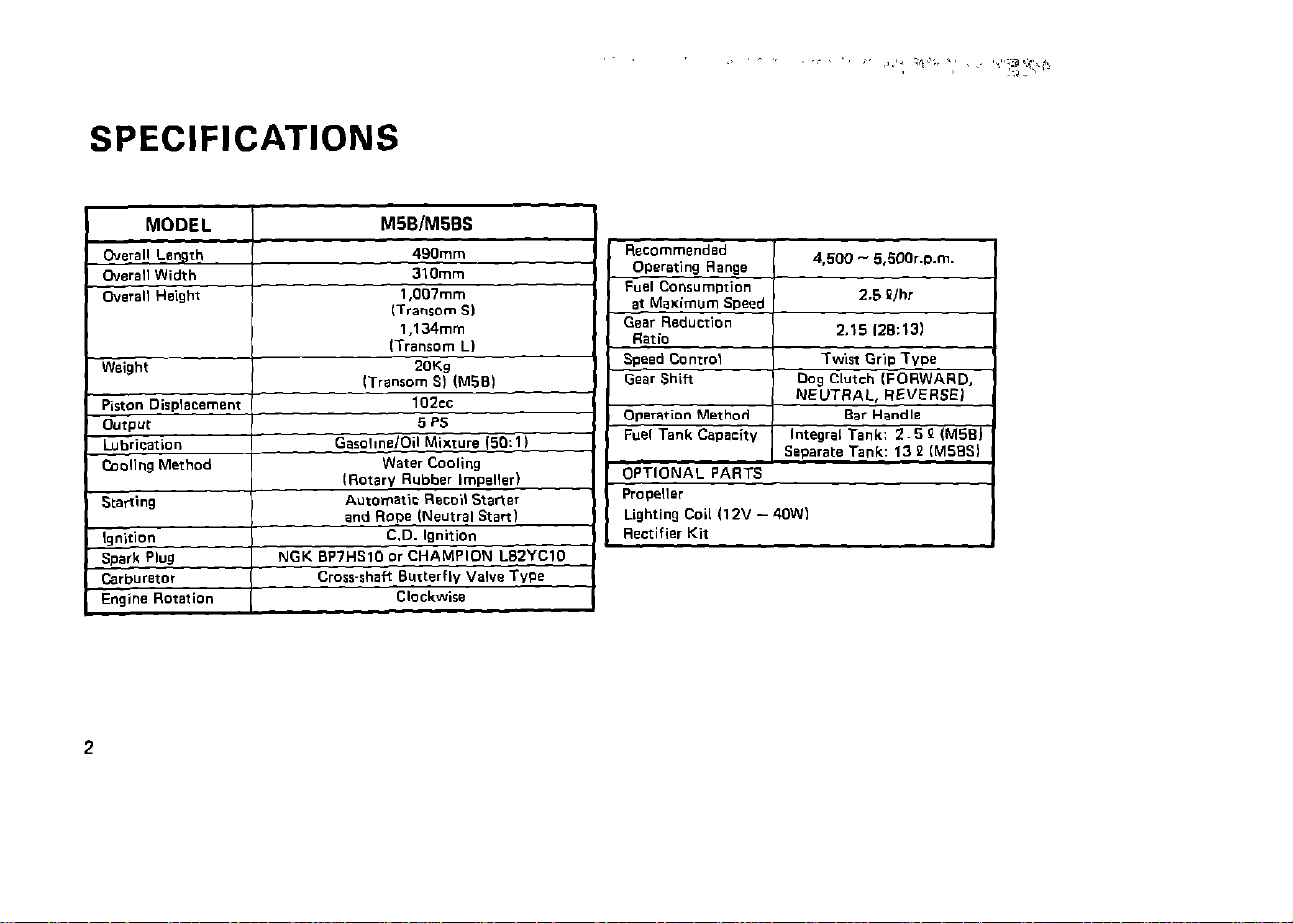

SPECIFICATIONS

Recommended

operating Range

Fuel Conr”mDrion

at Marimum Speed

Gear Reducrion

a-*;..

OPTlONAL PARTS

Propeller

Lighting Coil (12” - 4OWI

Rectifier Kit

4.500 - 5,5Wr.!%rn.

2.5 P/h,

2.15 12&131

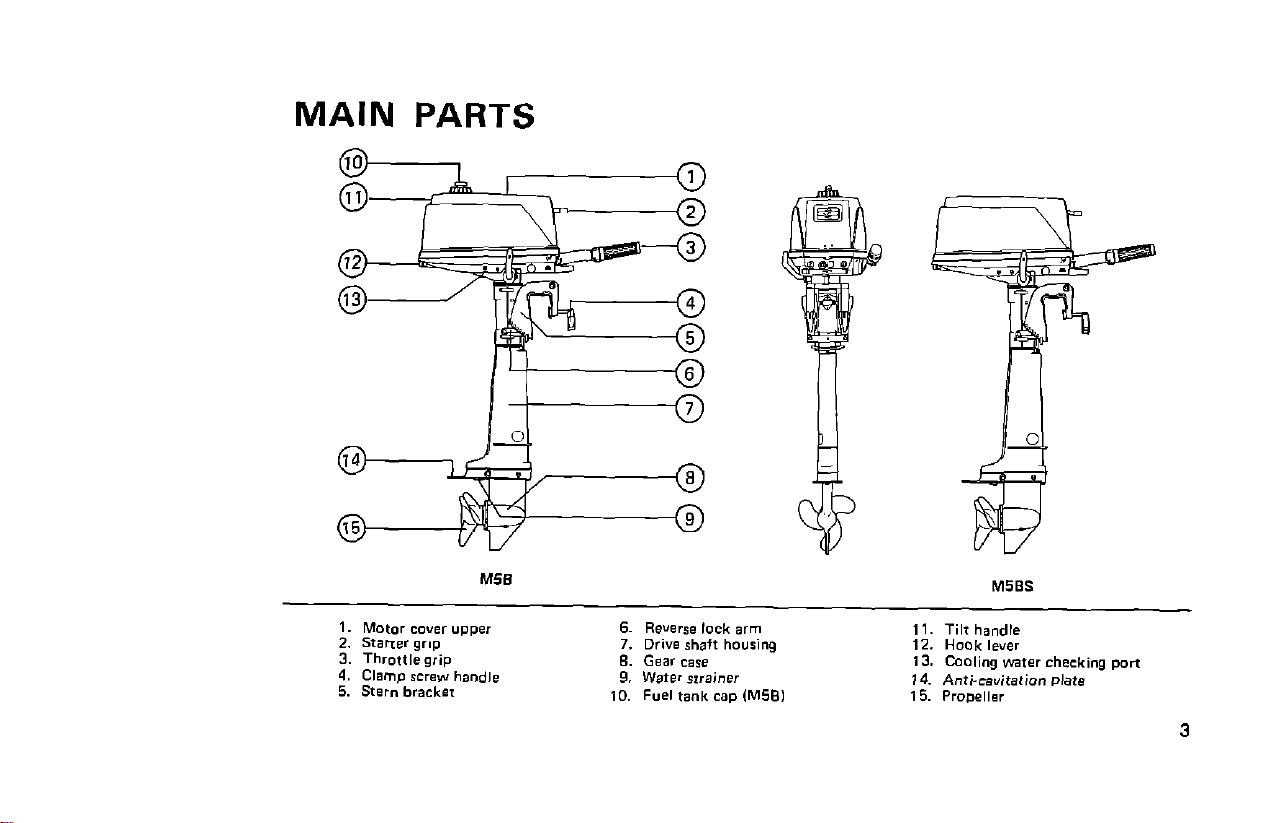

MAIN PARTS

( I) OPERATING INSTRUCTIONS

1. PREPARATIONS BEFORE STARTING

THE ENGINE

Gasoline with 86 OCTANE (A.K.I.) or over is recommended for easy starting and long life.

(1) Fuel

1) Check that there is sufficient fuel for the day’s

operation. Carry additional fuel for use in an

emergency and check it before running. Running

out of fuel can cause both inconvenience and

serious injury.

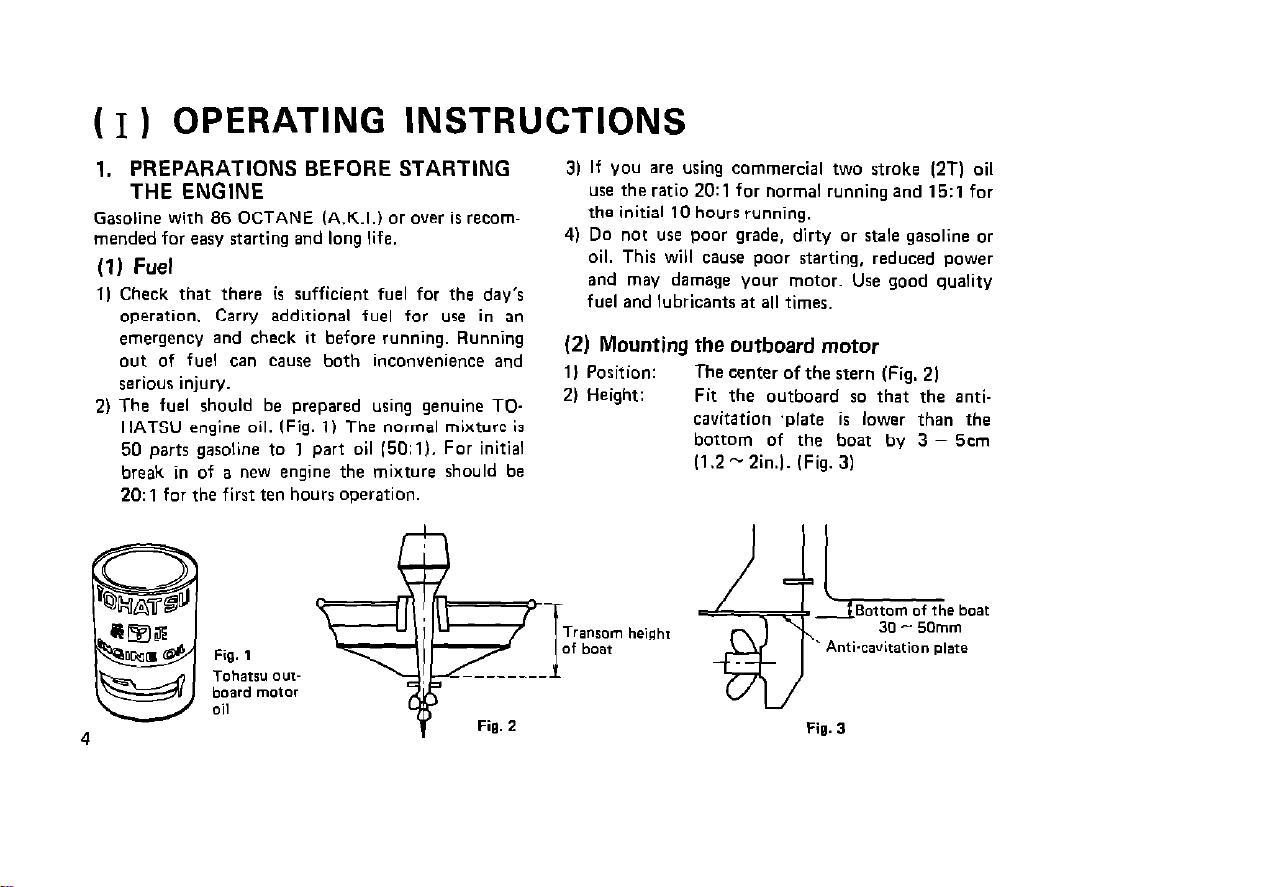

2) The fuel should be prepared using genuine TOHATSU engine oil. (Fig. 11 The normal mixture is

50 parts gasoline to 1 part oil 150:~). For initial

break in of a new engine the mixture should be

20: 1 for the first ten hours operation.

3) If you are using commercial two stroke (2T) oil

use the ratio 2O:l for normal running and 15:l for

the initial 10 hours running.

4) Do not use poor grade, dirty or stale gasoline or

oil. This will cause poor starting, reduced power

and may damage your motor. Use good quality

fuel and lubricants at all times.

(2) Mounting the outboard motor

11 Position:

2) Height:

The center of the stern (Fig. 21

Fit the outboard so that the anti-

cavitation ‘plate is lower than the

bottom of the boat by 3 - 5cm

11.2-2in.l. (Fig. 3)

Anti-cavitation plate

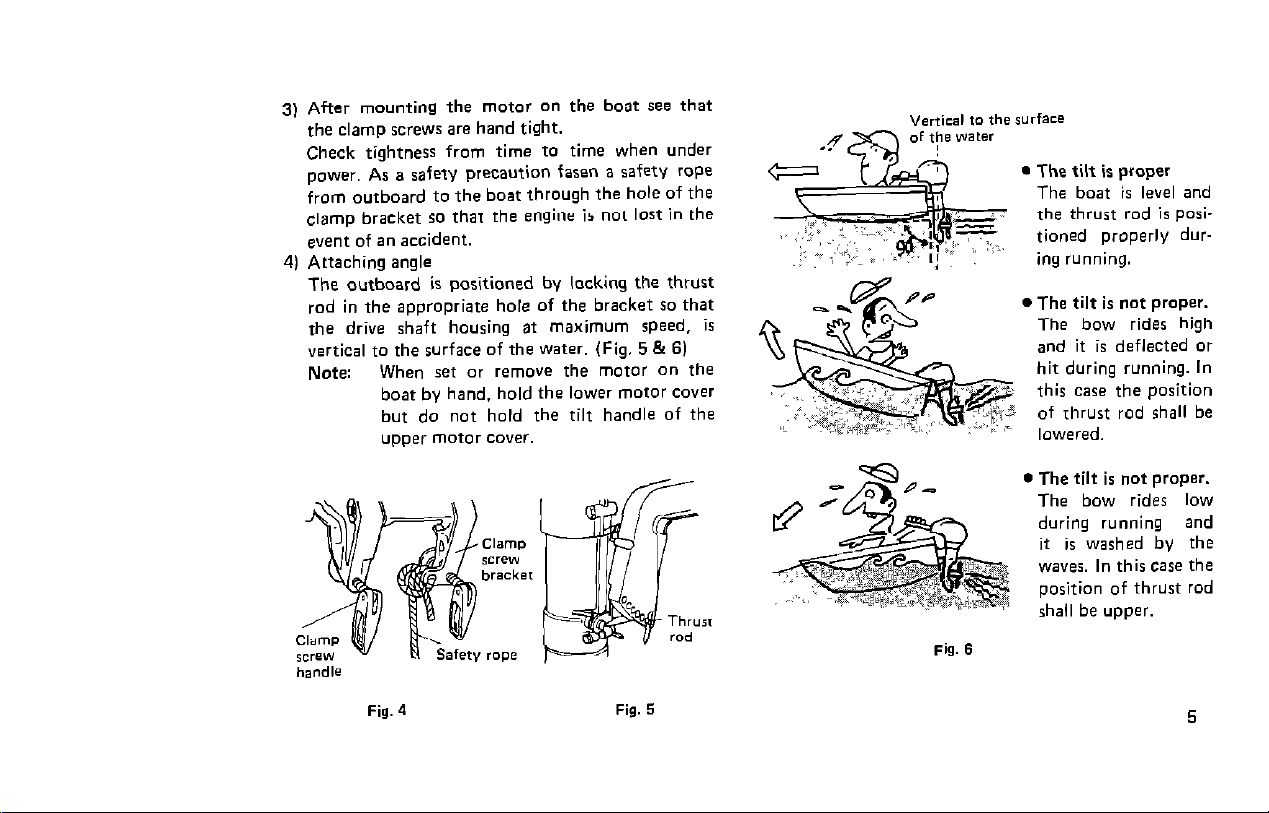

3) After mounting the motor on the boat see that

the clamp screws are hand tight.

Check tightness from time to time when under

power. As a safety precaution fasen a safetv rope

from outboard to the boat through the hole of the

clamp bracket so that the engine is not lost in the

event of an accident.

4) Attaching angle

The outboard is positioned by locking the thrust

rod in the appropriate hole of the bracket so that

the drive shaft housing at maximum speed, is

vertical to the surface of the water. (Fig, 5 & 6)

Note: When set or remove the motor on the

boat by hand. hold the lower motor cover

but do not hold the tilt handle of the

upper motor cover.

. The tilt is proper

The boat is level and

the thrust rod is positioned properly during running.

l The tilt is not proper.

The bow rides high

and it is deflected or

hit during running. In

this case the position

of Thrust rod shall be

lowered.

T3

d,

l The tilt is not proper.

The bow rides low

during running and

it is washed by the

waves. In this case the

position of thrust rod

shall be upper.

5

2. STARTING &WARM-UP

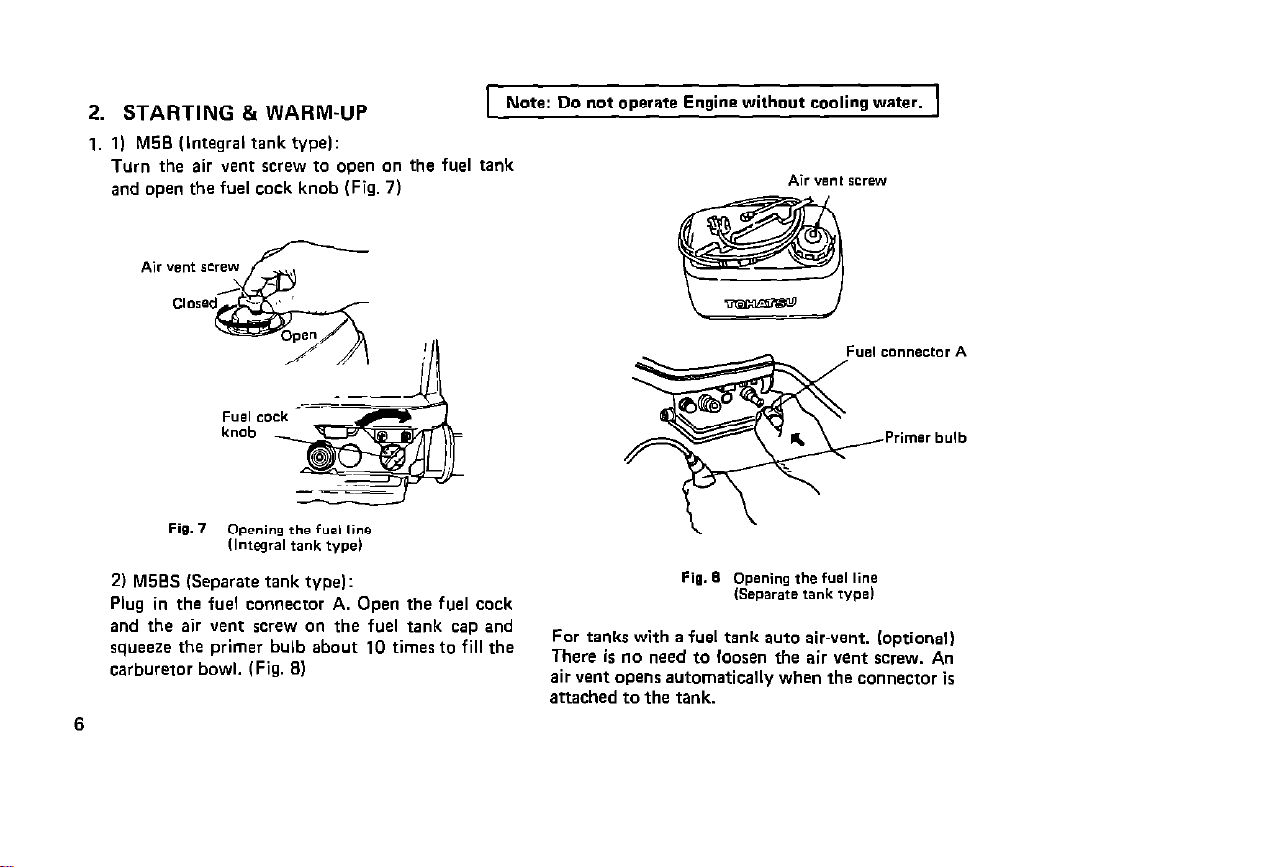

1. 1) M5B (Integral tank type):

Turn the air vent screw to open on the fuel tank

and open the fuel cock knob (Fig. 7)

2) M50S (Separate tank type):

Plug in the fuel connector A. Open the fuel cock

and the air vent screw on the fuel tank cap and

squeeze the primer bulb about 10 times to fill the

carburetor bowl. (Fig. 81

6

Note: Do not operate Engine without cooling water.

For tanks with a fuel tank auto air-vent. (optional)

There is no need to loosen the air vent screw. An

air vent opens automatically when the connector is

attached to the tank.

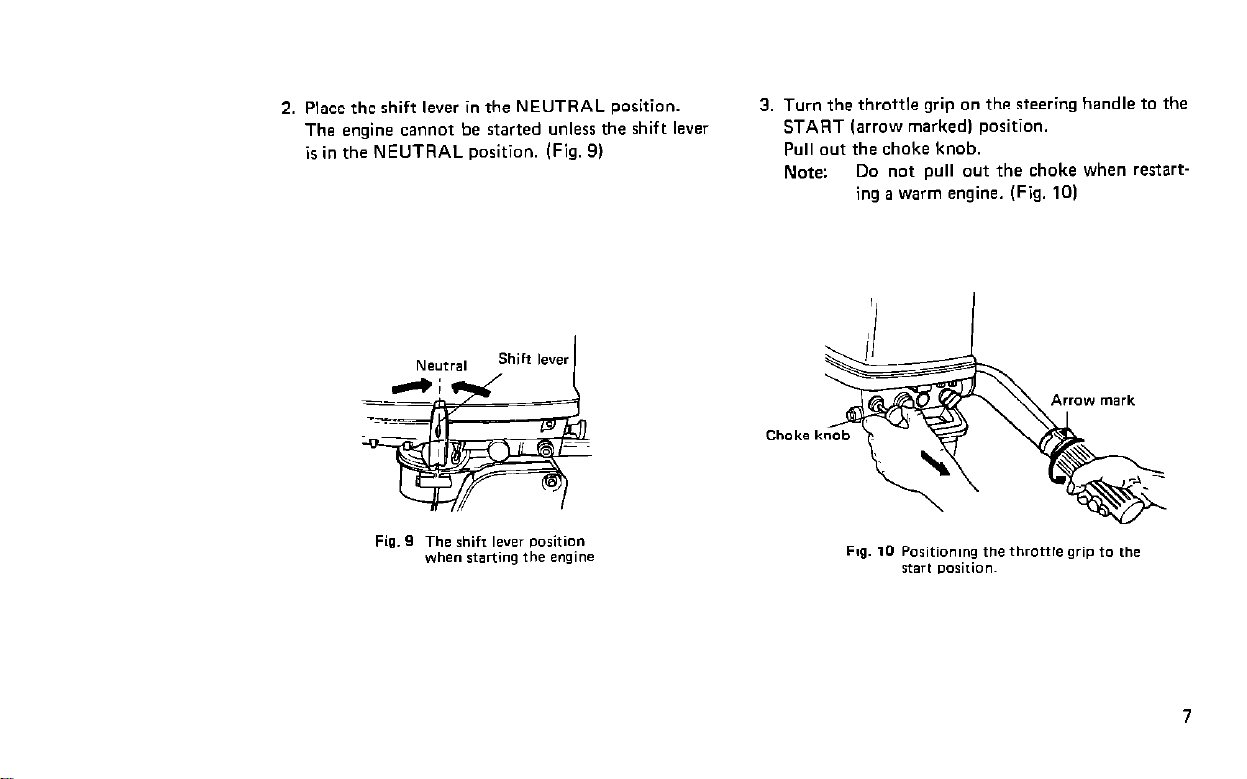

2. Place the shift lever in the NEUTRAL position.

The engine cannot be started unless the shift lever

is in the NEUTRAL position. (Fig. 9)

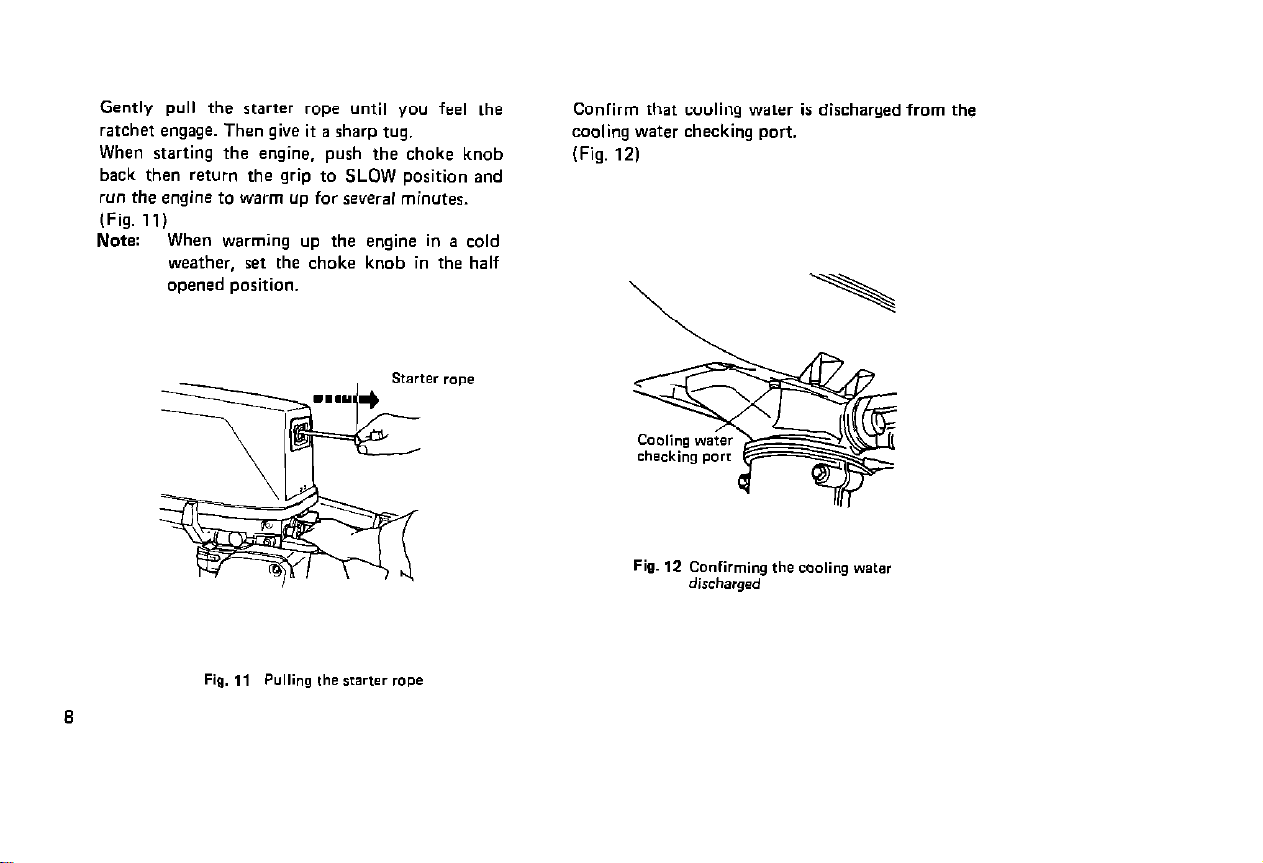

3. Turn the throttle grip on the steering handle to the

START (arrow marked) position.

Pull out the choke knob.

Note:

Do not pull out the choke when restarting a warm engine. (Fig. 10)

Gently pull the starter rope until you feel the

ratchet engage. Then give it a sharp tug.

When starting the engine. push the choke knob

back then return the grip to SLOW position and

run the engine to warm up for sever.4 minutes.

(Fig. 11)

Note: When warming up the engine in a cold

weather, set the choke knob in the half

opened position.

Confirm that cooling water is discharged from the

cooling water checking port.

(Fig. 12)

\

Loading...

Loading...