TOHATSU MFS2.5B, MFS3.5B, 2.5B, 3.5B Owner's Manual

OWNER’S

MANUAL

MFS

2.5B

3.5B

OB No.003-11085-7

ENOM00001-0

READ THIS MANUAL BEFORE USING THE OUTBOARD MOTOR. FAILURE TO FOLLOW THE

INSTRUCTIONS AND SAFETY PRECAUTIONS IN THIS MANUAL CAN RESULT IN SERIOUS

INJURY OR DEATH. KEEP THIS MANUAL IN A SAFE LOCATION FOR FUTURE REFERENCE.

Copyright © 2009-2012 Tohatsu Corporation. All rights reserved. No part of this manual may be reproduced

or transmitted in any from or by any means without the express written permission of Tohatsu Corporation.

YOUR TOHATSU OUTBOARD MOTOR

ENOM00002-0

OWNER REGISTRATION AND IDENTIFICATION

Upon purchasing this product, be sure that the WARRANTY CARD is correctly and completely filled out and mailed to the addressee noted there on. This WARRANTY CARD

identifies you as the legal owner of the product and serves as your warranty registration.

TO THE EXTENT PERMITTED BY APPLICABLE LAW, YOUR OUTBOARD MOTOR WILL

NOT BE COVERED BY THE APPLICABLE LIMITED WARRANTY, IF THIS PROCEDURE IS

NOT FOLLOWED.

ENOM00003-0

PRE-DELIVERY CHECK

Be sure that the product has been checked by an authorized TOHATSU dealer before you

take delivery.

ENOM00004-0

Limited Warranty

Please refer to the TOHATSU outboard motor Limited warranty provided to you with this

product, the terms and conditions of which, as amended from time to time, are incorporated by reference into the manual.

3

4

ENOM00005-0

Serial Number

In the space below, please record the outboard motor’s serial number (indicated both on

the lower motor cover and on the cylinder block). The serial number will be needed in the

event of theft or to quickly identifying the outboard motor type.

Serial Number:

ENOM00006-0

To You, Our Customer

Thank you for selecting a TOHATSU outboard motor. You are now the proud owner of an

excellent outboard motor that will service you for many years to come.

This manual should be read in its entirety and the inspection and maintenance procedures

described later in this manual should be followed carefully. Should a problem arise with the

outboard motor, please follow the troubleshooting procedures listed at the end of this

manual. If the problem persists, contact an authorized TOHATSU service shop or dealer.

We hope you will enjoy your outboard motor and wish you good luck in your boating

adventures.

TOHATSU CORPORATION

CONTENTS

GENERAL SAFETY INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2. NAMES OF PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3. LOCATIONS OF WARNING LABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1. Mounting the outboard motor on boat . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5. PRE-OPERATING PREPARATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

1. Recommended gasoline types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2. Low permeation fuel hose requirement . . . . . . . . . . . . . . . . . . . . . . . . . . .17

EQUIPPED FOR UNITED STATES AND CANADA MODEL

3. EPA pressurized fuel tank requirements . . . . . . . . . . . . . . . . . . . . . . . . . .18

EQUIPPED FOR UNITED STATES AND CANADA MODEL

4. Recommended engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5. Altitude adjustment kit requirement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6. Break-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7. ESG (A device preventing over revolution). . . . . . . . . . . . . . . . . . . . . . . . . 21

6. ENGINE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Before starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1. Filling the fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2. Feeding the fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3. Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4. Warming up the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5. Forward and reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6. Stopping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7. Trim angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

8. Tilt up, tilt down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9. Outboard motor position in tilt up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7. REMOVING AND CARRYING THE OUTBOARD MOTOR. . . . . . . . . . . . . . 34

1. Removing the outboard motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2. Carrying the outboard motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3. Storing the outboard motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

8. TRAILERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9. ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1. Steering friction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

2. Throttle grip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10. INSPECTION AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1. Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2. Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

3. Off-season storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4. Pre-season check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5. Motor submerged in water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6. Cold weather precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

7. Checking after striking underwater object. . . . . . . . . . . . . . . . . . . . . . . . . 48

11. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

12. TOOL KIT AND SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

13. OPTIONAL ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

14. PROPELLER TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

INDEX

7

GENERAL SAFETY INFORMATION

1. SPECIFICATIONS

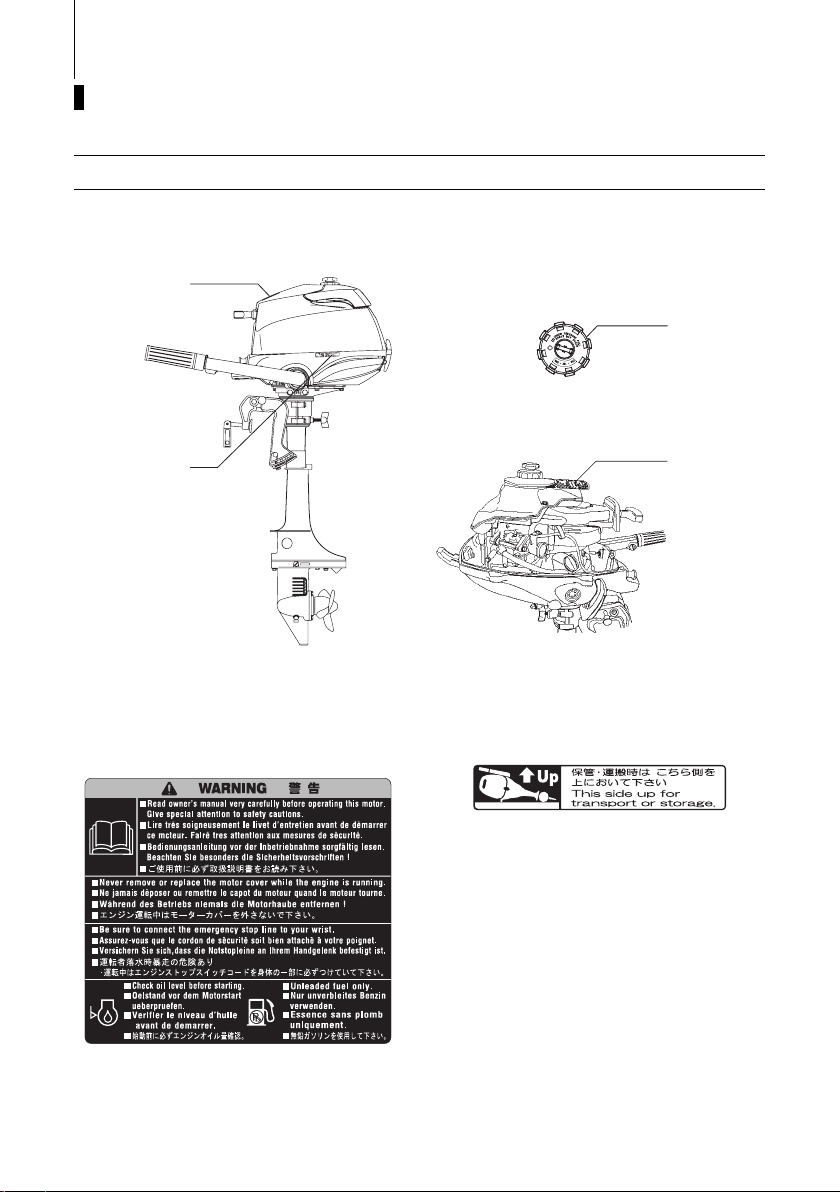

2. NAMES OF PARTS

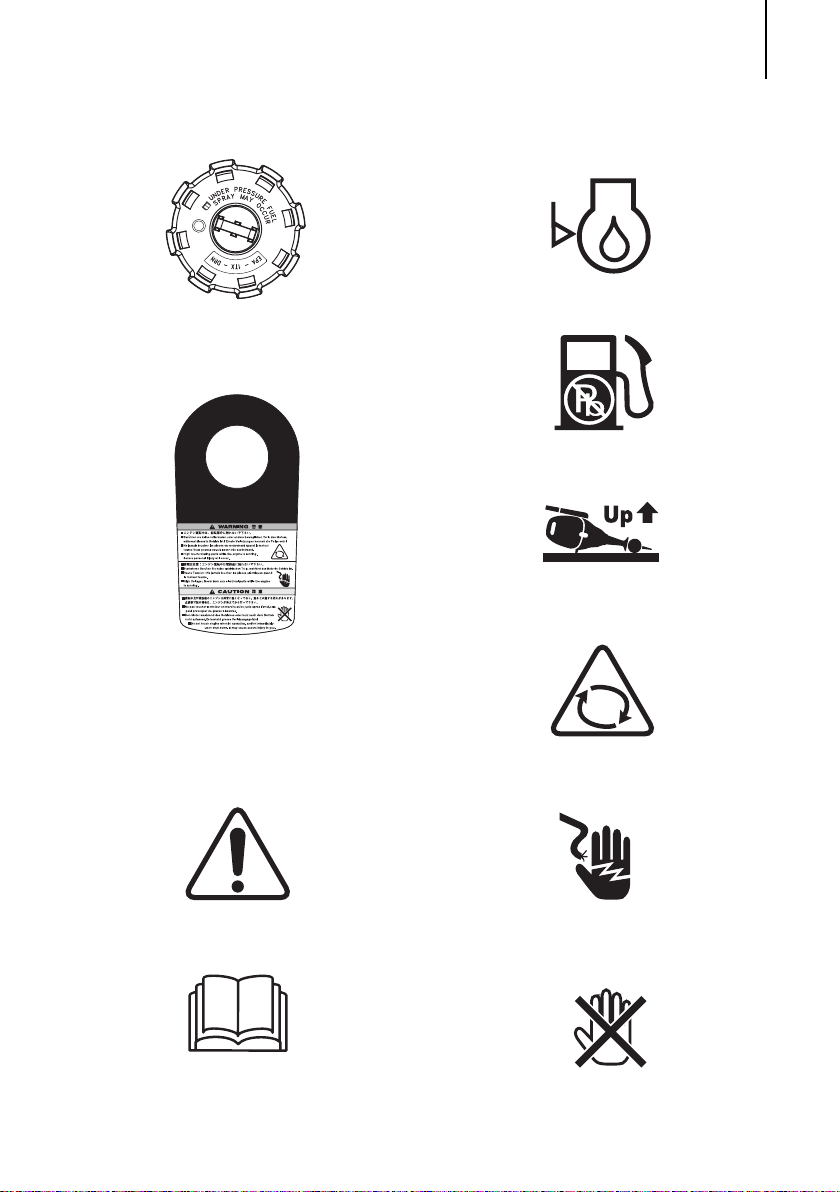

3. LOCATIONS OF WARNING LABELS

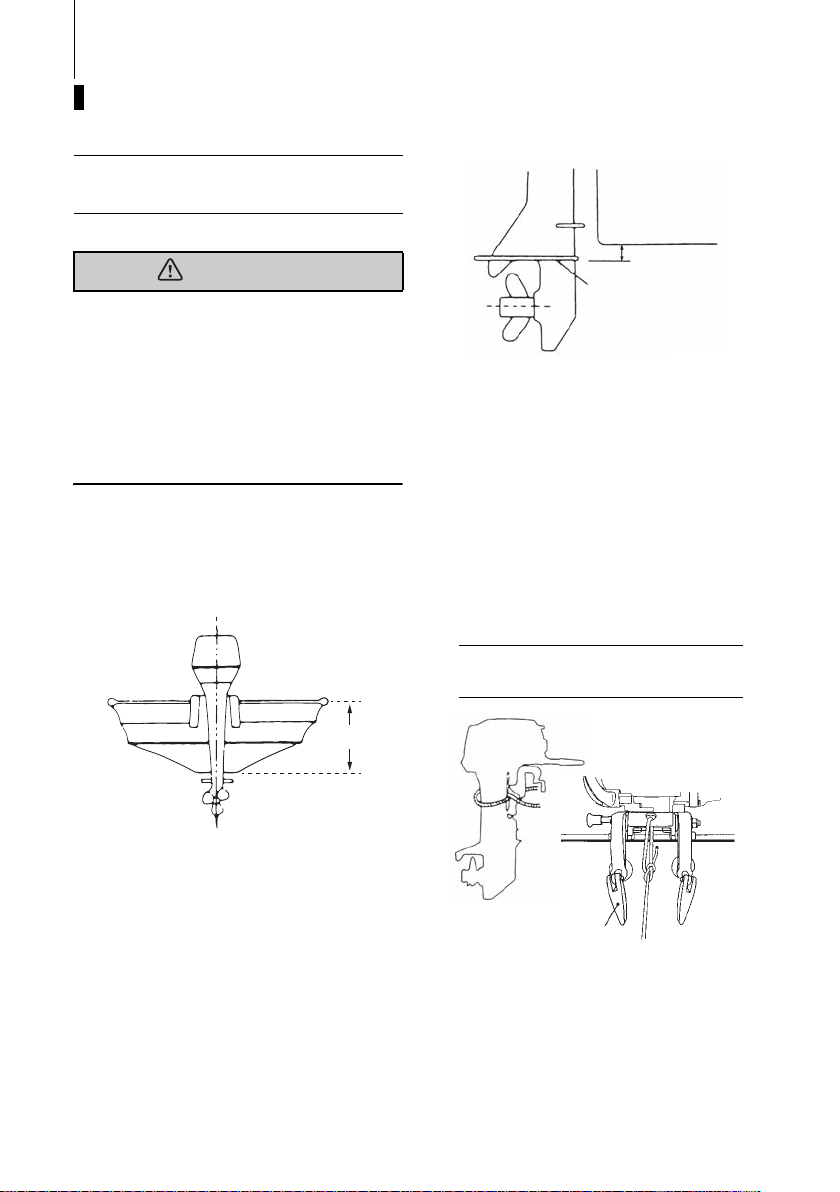

4. INSTALLATION

5. PRE-OPERATING PREPARATIONS

6. ENGINE OPERATION

7. REMOVING AND CARRYING THE

OUTBOARD MOTOR

8. TRAILERING

9. ADJUSTMENT

10.INSPECTION AND MAINTENANCE

11.TROUBLESHOOTING

12.TOOL KIT AND SPARE PARTS

13.OPTIONAL ACCESSORIES

14.PROPELLER TABLE

8

GENERAL SAFETY INFORMATION

ENOM00007-0

NOTICE: DANGER/WARNING/CAUTION/Note

Before installing, operating or otherwise handling your outboard motor, be sure to thoroughly read and understand this Owner’s Manual and carefully follow all of the instructions. Of particular importance is information preceded by the words “DANGER,”

“WARNING,” “CAUTION,” and “Note.” Always pay special attention to such information to

ensure safe operation of the outboard motor at all times.

ENOW00001-0

DANGER

Failure to observe will result in severe personal injury or death, and possibly property damage.

ENOW00002-0

WARNING

Failure to observe could result in severe personal injury or death, or property damage.

ENOW00003-0

CAUTION

Failure to observe could result in personal injury or property damage.

ENON00001-0

Note

This instruction provides special information to facilitate the use or maintenance of the outboard

motor or to clarify important points.

ENOM0008-0

EMERGENCY STOP SWITCH

The Emergency Stop Switch will stall the outboard motor when the stop switch tether is

pulled off. This stop switch tether can be attached to the operator of the outboard motor

to minimize or prevent injuries from the propeller in case the operator falls overboard.

We highly recommend use of the Emergency Stop Switch tether.

ENOW00004-0

WARNING

Accidental activation of the Emergency Stop Switch (such as the tether being pulled out in

heavy seas) could cause passengers to lose their balance and even fall overboard, or it

could result in loss of power in heavy seas, strong currents, or high winds. Loss of control

while mooring is another potential hazard.

To minimize accidental activation of the Emergency Stop Switch, the 500 mm (20 inch.) stop

switch tether is coiled and can extended to a full 1300 mm (51 inch.).

GENERAL SAFETY INFORMATION 9

ENOM00009-0

SAFE OPERATION OF BOAT

As the operator/driver of the boat, you are responsible for the safety of those aboard and

those in other boat around yours, and for following local boating regulations. You should

be thoroughly knowledgeable on how to correctly operate the boat, outboard motor, and

accessories. To learn about the correct operation and maintenance of the outboard motor,

please read through this manual carefully.

It is very difficult for a person standing or floating in the water to take evasive action should

he or she see a power boat heading in his/her direction, even at a slow speed. Therefore,

when your boat is in the immediate vicinity of people in the water, the outboard motor

should be shifted to neutral and shut off.

ENOW00005-0

WARNING

SERIOUS INJURY IS LIKELY IF A PERSON IN THE WATER MAKES CONTACT WITH A MOVING BOAT, GEAR HOUSING, PROPELLER, OR ANY SOLID DEVICE RIGIDLY ATTACHED TO

A BOAT OR GEAR HOUSING.

ENOM00010-0

SERVICING, REPLACEMENT PARTS & LUBRICANTS

We recommend that only an authorized service shop perform service or maintenance on

this outboard motor. Be sure to use genuine parts, genuine lubricants, or recommended

lubricants.

ENOM00011-0

MAINTENANCE

As the owner of this outboard motor, you should be acquainted with correct maintenance

procedures. It is the operator’s responsibility to perform all safety checks and to ensure

that all lubrication and maintenance instructions are complied with for safe operation.

Please comply with all instructions concerning lubrication and maintenance. You should

take the engine to an authorized dealer or service shop for periodic inspection at the prescribed intervals.

Correct periodic maintenance and proper care of this outboard motor will reduce the

chance of problems and limit overall operating expenses.

ENOM00012-0

MOUNTING

Outboard motor mounting must be performed by trained service person(s) using lift or

hoist with sufficient capacity.

10

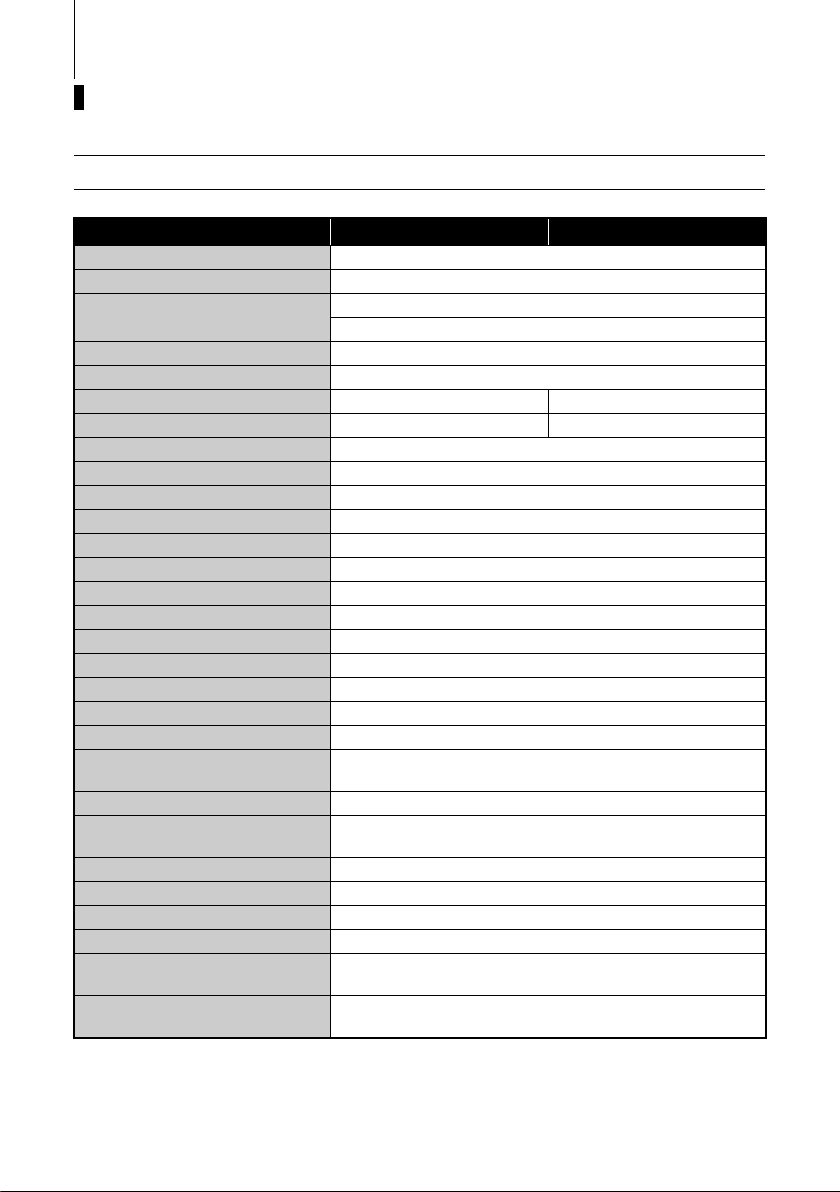

SPECIFICATIONS

EENOM00201-0

2.5B, 3.5B

Item MODEL 2.5B 3.5B

Overall Length mm (in) 690 (27.2)

Overall Width mm (in) 363 (14.3)

Overall Height S·L mm (in)

Transom Height S·L mm (in) 435 (17.1) 562 (22.1)

Weight S·L kg (lb) 18.4 (41) 19.4 (43)

Output kW (ps) 1.8 (2.5) 2.6 (3.5)

Max. Operating Range rpm 4500–5500 5000–6000

Idle Speed in Forward Gear rpm 1200

Idle Speed in Neutral Gear rpm 1300

Engine Type 4-Stroke

Number of Cylinder 1

Bore × Stroke mm (in) 55 × 36 (2.17 × 1.42)

Piston Displacement mL (Cu in) 85.5 (5.2)

Exhaust System Above propeller exhaust

Cooling System Water cooling

Engine Lubrication Splashing system

Starting System Manual starter

Ignition System Ignitor

Spark Plug NGK DCPR6E

Tri m Po sitio n 4

Engine Oil mL (fl.oz.)

Gear Oil mL (fl.oz.) Genuine Gear Oil or API GL5, SAE #80-90, Approx. 180 (6.1)

Fuel

Clutch Dog clutch system (F-N)

Fuel Tank Capacity L (US gal) 1.0 (0.26) Integral tank

Gear Reduction Ratio 2.15 (13 : 28)

Emission Control System EM (Engine modification)

Operator Sound Pressure

(ICOMIA 39/94) dB (A)

Hand Vibration Level

(ICOMIA 38/94) m/sec2

Remark: Specifications subject to change without notice.

Except for USA and Canada model 1026 (40.4) 1153 (45.4)

For USA and Canada model 1040 (40.9) 1167 (45.9)

NMMA FC-W certified 10W-30 or

API SF, SG, SH, SJ, SL or SM, Approx. 300 (10)

Unleaded regular gasoline : Pump posted 87 Octane

(research octane rating of 91)

80.1

8.9

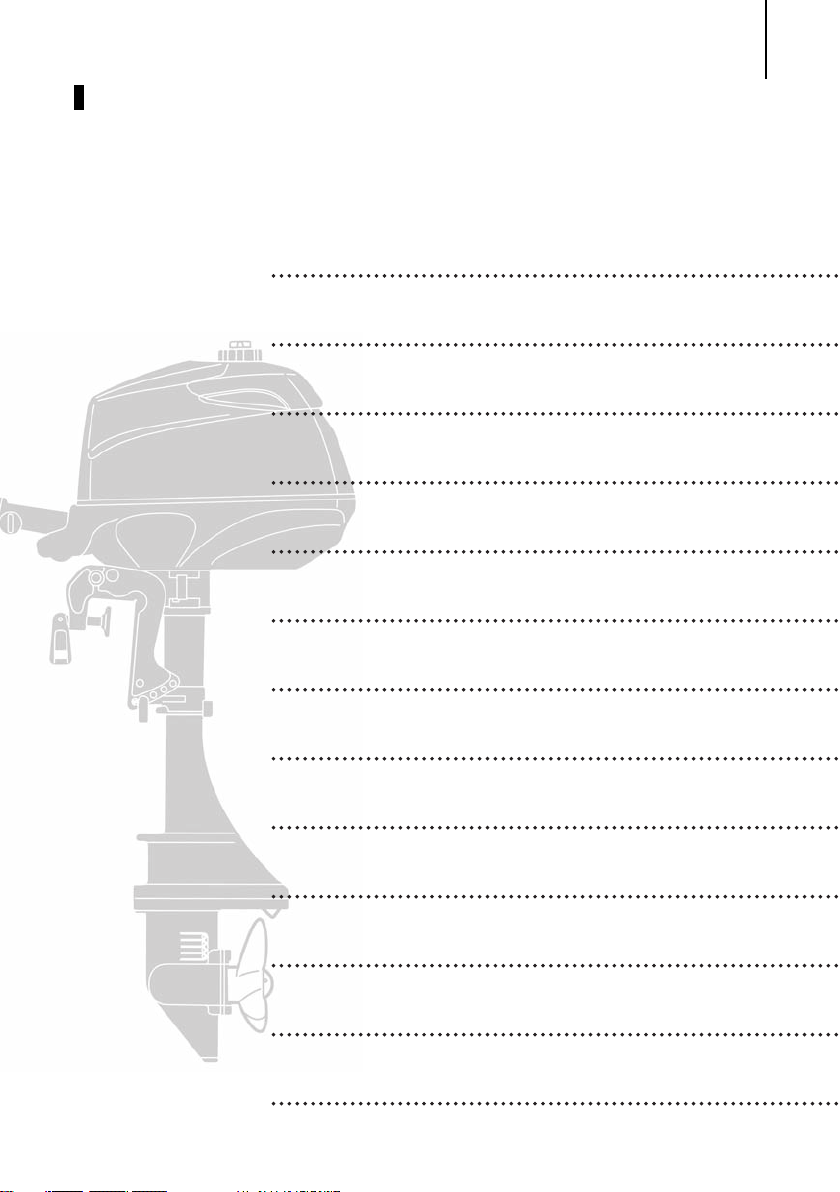

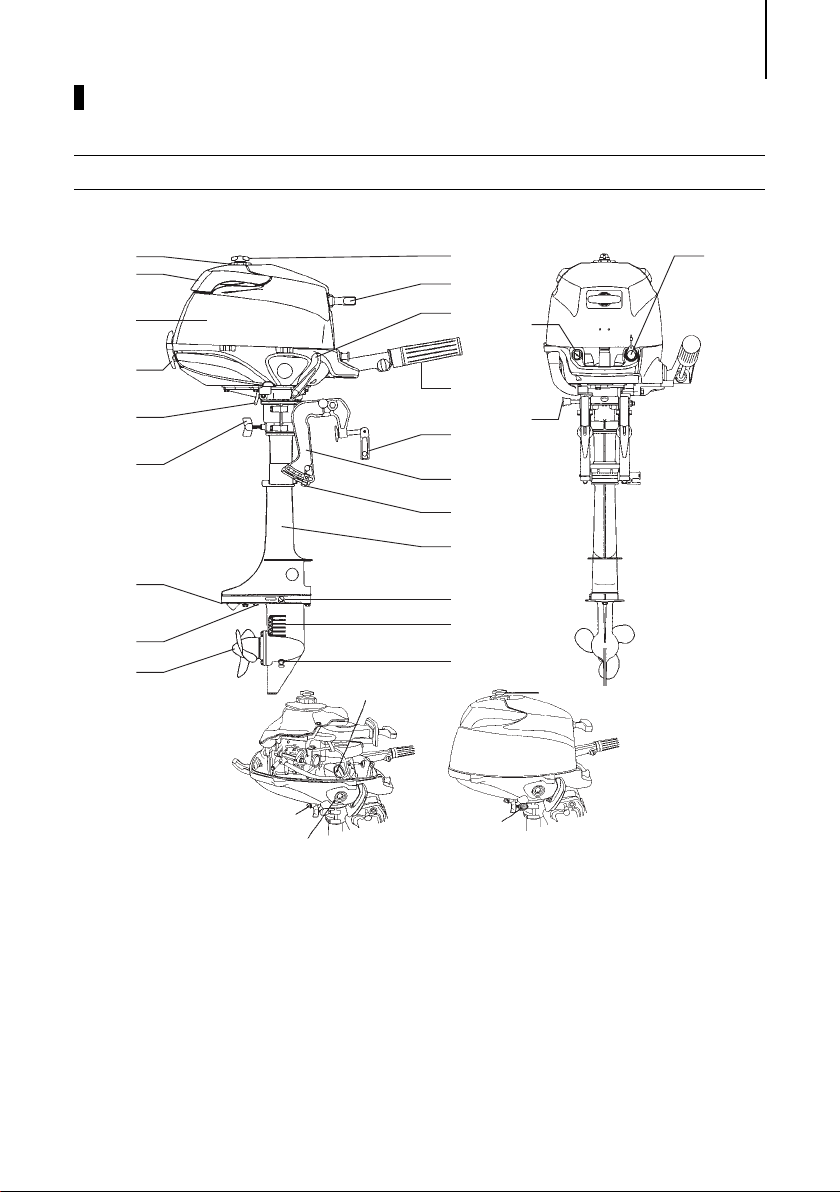

NAMES OF PARTS

1

2

3

8

9

11

10

13

14

15

16

19

17

18

21

20

22

12

4

5

6

7

23

24

25

26

28

27

A

ENOF00201-0

ENOM00202-0

2.5B, 3.5B

11

1

Fuel Tank Cap

2

Tilt Handle

3

Top C owl

4

Cowl Latch

5

Cooling Water Check Port

6

Steering Adjustment Screw

7

Anti Ventilation Plate

8

Anode

9

Propeller

10

Oil Plug (Lower) (Fill)

11

Water Inlet

12

Oil Plug (Upper) (Level)

13

Drive Shaft Housing

14

Thrust Rod

15

Clamp Bracket

16

Clamp Screw

17

Throttle Grip

18

Shift Lever

19

Starter Handle

20

Air Vent Screw

21

Choke Knob

22

Stop Switch

23

Tilt Stopper

24

Engine Oil Filler Cap

25

Engine Oil Drain Screw

26

Engine Oil Level Gauge

27

Air Vent Screw

28

Fuel Cock

A

: Integral Fuel Tank

12

2

4

3

1

ENOF00202-0

LOCATIONS OF WARNING LABELS

ENOM00203-0

Locations of warning labels

1.

Warning label regarding owner’s manual, top cowl, engine stop switch,

engine oil level and unleaded gasoline.

ENOF00005-0

2.

Warning label on position of outboard

motor when setting down.

3.

Only for USA and CANADA models

ENOF00253-0

Warning regarding fuel tank cap (See

pages 22–24).

4.

ENOF00012-0

ENOF00254-0

ENOF00114-0

ENOF00115-0

ENOF00117-0

Rotating part, high voltage, high temperature warning label.

LOCATIONS OF WARNING LABELS 13

Check oil level

ENOF00116-0

Use unleaded gasoline only

Lay as indicated

ENOF00203-0

Warning, rotating object

ENOM00204-0

Symbols

Individual symbol marks means as

described below.

Warning/Caution

Read manual thoroughly

ENOF00249-0

Warning, high voltage

ENOF00204-0

Warning, high temperature

ENOF00205-0

14

1

ENOF00207-0

INSTALLATION

ENOM00024-0

1. Mounting the outboard motor on

boat

ENOW00006-0

WARNING

Most boats are rated and certified in terms

of their maximum allowable horsepower,

as shown on the boat’s certification plate.

Do not equip your boat with an outboard

motor that exceeds this limit. If in doubt,

contact your dealer.

Do not operate the outboard motor until it

has been securely mounted on the boat in

accordance with the instructions below.

ENOM00025-0

Position ... Above keel line

Set engine at center of boat.

1

1

30–50 mm

(1.2–2 in)

2

ENOF00206-0

1. Bottom of hull

2. Anti ventilation plate

To attach the outboard motor to the boat,

tighten the clamp screws by turning their

handles.

Also, use the bolts to secure the outboard

motor brackets on transom board.

Secure the outboard motor with a rope to

prevent loss overboard.

ENON00002-0

Note

A rope is not included in the standard

accessories.

2

ENOF00014-0

1. Center of boat

2. Boat transom

ENOM00204-0

Transom matching

Be sure that the anti ventilation plate of the

outboard motor is below the water surface.

If the above condition cannot be met due

to the shape of the bottom of your boat,

please consult your authorized dealer.

1. Clamp screw

INSTALLATION 15

ENOW00007-0

CAUTION

Before beginning the running test, check

that the boat with maximum capacity

loading floats on the water in a proper

attitude. Check the position of water

surface on the driveshaft housing. If the

water surface is near the bottom cowling, in high waves, water may enter the

engine cylinders.

Incorrect outboard motor mounting

height or existence of underwater

object(s), such as hull bottom design,

bottom surface conditions or underwater accessories, can cause water spray

possibly reaching the engine through an

opening of the bottom cowling during

cruising. Exposing the engine to such

conditions for extended periods can

lead to severe engine damage.

ENOW00213-0

WARNING

If the length of security line being used is

long enough to allow the outboard to disengage off the boat transom but is too

short to not allow the outboard to submerge behind the boat and stop running,

the outboard could continue running and

propel itself back into the boat with the

propeller rotating under power. This

exposes the occupants to serious injury or

death.

personal injury. Be sure that fasteners

are tightened to the specified torque (30

Nm (3.0 kgf) 13 ft-lb). Check the fasteners for tightness from time to time.

Be sure to use outboard mounting fas-

teners included in the outboard motor

package or their equivalents in terms of

size, material, quality and strength.

Tighten fasteners to the specified torque

(30 Nm (3.0 kgf) 13 ft-lb). Test cruise to

check if fasteners are tightened

securely.

Outboard motor mounting must be per-

formed by trained service person(s)

using lift or hoist with sufficient capacity.

ENOW00008-0

CAUTION

Mounting bolts should be installed with the

bolt head at inside surface of the transom.

Mounting bolts installed with the threaded

end at the inside surface of the transom

can cause personal injury.

ENON00201-0

Notes

1. Apply sealing agent such as silicone

sealed between bolts and transom

board holes before tightening bolts.

2. Be sure to tighten mounting bolt nuts to

specified torque.

ENOW00009-0

WARNING

Mounting the outboard motor without

following this manual can lead to unsafe

conditions such as poor maneuverability, lack of control or fire.

Loose clamp screws and/or mounting

bolts can lead to the release or displacement of the outboard motor, possibly

resulting in lost of control and/or serious

16

PRE-OPERATING PREPARATIONS

ENOW00016-0

DANGER

Consult an authorized dealer for details on

handling gasoline, if necessary.

Gasoline and its vapors are very flammable

and can be explosive.

When carrying a fuel tank containing gasoline:

Close the air vent screw of fuel tank cap,

or gasoline vapor will be emitted

through the air vent screw, creating a

fire hazard.

Do not smoke.

When or before refueling:

Stop the engine, and do not start the

engine during refueling.

Do not smoke.

Be careful not to overfill fuel tank. Wipe

up any spilled gasoline immediately.

When or before cleaning the gasoline tank:

Dismount fuel tank from the boat.

Place the fuel tank away from every

source of ignition, such as sparks or

open flames.

Do the work outdoors or in a well venti-

lated area.

Wipe off gasoline well immediately if

spilt.

After cleaning gasoline tank:

Wipe off gasoline well immediately if

spilt.

If the fuel tank is disassembled for

cleaning, reassemble carefully. Imperfect assembly may cause a fuel leak,

possibly leading to fire or explosion.

Dispose aged or contaminated gasoline

in accordance with local regulations.

ENOM00030-0

1. Recommended gasoline types

ENOW000017-0

CAUTION

Use of improper gasoline can damage your

engine. Engine damage resulting from the

use of improper gasoline is considered

misuse of the engine, and damage caused

thereby will not be covered under the limited warranty.

ENOM00031-0

FUEL RATING

TOHATSU engines will operate satisfactorily when using a major brand of unleaded

gasoline meeting the following specifications:

USA and Canada — having a posted

pump Octane Rating of 87 (R+M)/2 minimum. Premium gasoline (92 [R+M]/2

Octane) is also acceptable. Do not use

leaded gasoline.

Outside USA and Canada — Use

unleaded gasoline with declared octane

rating of 90 RON or over. Use of premium

gasoline of 98 RON is also allowed. Use of

name-brand leaded gasoline may be

allowed only if unleaded gasoline is not

available.

ENOM00205-0

GASOLINES CONTAINING

ALCOHOL

The fuel system components on your

TOHATSU engine will withstand up to 10%

alcohol content in the gasoline. But if the

gasoline in your area contains either methanol (methyl alcohol) or ethanol (ethyl alcohol), you should be aware of certain

PRE-OPERATING PREPARATIONS 17

adverse effects that can occur. These

adverse effects are more severe with

methanol. Increasing the percentage of

alcohol in the fuel can also worsen these

adverse effects. Some of these adverse

effects are caused because the alcohol in

the gasoline can absorb moisture from the

air, resulting in a separation of the water/

alcohol from the gasoline in the fuel tank.

These may cause increased:

Corrosion of metal parts

Deterioration of rubber or plastic parts

Fuel permeation through rubber fuel

lines

Starting and operating difficulties

ENOW00018-0

WARNING

Fuel leakage can cause fire or explosion,

potentially leading to severe injury or loss

of life. Every fuel system part should be

checked periodically, and especially after

long term storage, for fuel leak, change of

hardness of rubber, expansion and/or corrosion of metals. In case any indication of

fuel leakage or degradation of fuel part is

found, replace relevant part immediately

before continuing operation.

If the use of gasoline containing alcohol is

inevitable, or presence of alcohol is suspected in the gasoline, it is recommended

to add a filter that has water separating

capability, and check the fuel system for

leaks and mechanical parts for corrosion

and abnormal wear more frequently.

And, in case any of such abnormality is

found, discontinue the use of such gasoline and contact our dealer immediately.

Damages resulting from the use of gasolines that contain alcohol are not covered

under the limited warranty.

ENOW00019-0

WARNING

Do not fill the fuel tank over capacity. The

rise of gasoline temperature may cause

gasoline to expand which, if overfilled, may

leak through air vent screw when it is open.

Leaking gasoline is a dangerous fire hazard.

ENOW00020-0

CAUTION

When operating a TOHATSU engine on

gasoline containing alcohol, storage of

gasoline in the fuel tank for long periods

should be avoided. Long periods of storage, common to boats, create unique problems. In cars, alcohol blend fuels normally

are consumed before they can absorb

enough moisture to cause trouble, but

boats often sit idle long enough for phase

separation to take place. In addition, internal corrosion may take place during storage if alcohol has washed protective oil

films from internal components.

ENOM00033-0

2. Low permeation fuel hose

requirement

EQUIPPED FOR UNITED STATES AND

CANADA MODEL

Required for outboards manufactured for

sale, sold, or offered for sale in the United

States.

TOHATSU engine has used fuel hoses

for The Environmental Protection

Agency (EPA) requires from January 1,

2011.

Loading...

Loading...