Tohatsu 60, 70, 120, 90, 140 User Manual

TOHATSU

OUTBOARDS

No.003-11039-4

Copyright © 2007 Tohatsu Corporation. All rights reserved. No part

of this manual may be reproduced or transmitted in any form or by

any means without the express written permission of Tohatsu

Corporation.

~. :

,!. .,

YOUR TOHATSU OUTBOARD MOTOR

OWNER REGISTRATION AND IDENTIFICATION

Upon purchasmg this product, be sure your dealer* fills out the WARRANTY

CARD correctly and completely and mails I[ to the distributor. This card

identifies you as the legal owner of the product and serves as your warranty

registration.

If this procedure is not followed, your outboard motor will not be covered by

warmntly.

* : In this manual. “dealer” always means an authorized TOHATSU dealer.

PRE-DELIVERY CHECK

Be sure that the product has been checked by the dealer before the delivery

Limited Warranty

This TOHATSU product is fully guaranteed against defective materials and

workmanshlp for the period from the date of purchase. provided that the

purchase has been registed in accordance with the above.

The limited warranty will not apply to the normal wear and tear of parts.

adjustments. tune-ups. or to any damage caused by:

1)Use or operation NOT conforming to the instructions described in this

owner’s manual.

2) Participation in or preparation for racing or other competitive activities,

3) Water entering the engine or the engine room.

4) Damage of an accidents, collisions. contact with foreign materials, or

submersion.

5) Growth of marine organisms on motor surfaces.

6) Any other careless use or operation.

7) Normal deterioration.

The limited warranty does not cover maintenance items. The following items

are some examples not to be covered by the limited warmnty.

spark plugs. anode. trim-tub. propeller, fuel filter, oil filter, carbon brush,

starter rope, shear-pin. split-pin. bolt-nut-washer. wire cable, rubber goods:

pump impeller, oil seal, “0”.ring. fuel pipe, primer bulb. etc., viny tube.

The limited warranty will become void if the product has been altered,

modified, or repaired by anyone other than a company or service firm

authorized by TOHATSU.

The limited warranty will cover only your TOHATSU product and will not

cover rhe boat the product is mounted on, the trailer. equipment. or accessories

associated with the product.

Serial Number

In the space below. please record the engine’s serial number (indicated both on

the lower motor cover and on the cylinder block). This number will come in

handy in the event of theft or to help in quickly identifying the product types

Serial Number :

To You, Our Customer:

Thank you for selecting a TOHATSU product. You are now the proud owner of

an exellent outboard engine that will service you for many years to come.

We would like to poinr out that carefree usage can only be assured on condition

that this manual is read through in its entirety and the maintenance routines

described later in this manual are followed carefully. Should difficulty arise

with the engine, please follow the troubleshooting procedures listed at the end

of this manual. If the problem persists. contact an authorized TOHATSU

service shop or your dealer.

We hope you will get much enjoyment from this product and wish you good

luck in your boating adventures.

TOHATSU CORPORATION

NOTICE: DANGER/WARNING/CAUTION/Note

Before operating your outboard motor, be sure to thoroughly read and

understand this Owner’s Manual and follow all of the instructions shown. Of

particular importance is information preceded by the words “DANGER,”

“WARNING. ” “CAUTION.” and “Note.” Always pay special attention to such

information to ensure safer and trouble-free operation at all times.

Failure to observe will result in severe personal injury or death.

Fadura to observe could result in severe personal injury or death.

I

I

I

A

CAUTION

Failure to observe could result in minor personal injury or product or

property damage.

Note:

This instruction provides special information to facilitate the use or

maintenance of the outboard or to clarify important points.

EMERGENCY STOP SWITCH

The stop switch will cut off the engine when the stop switch line is pulled out.

This lme can be attached to the body of the operator, effectively preventing

injuries from the propeller in case he/she falls overboard.

We highly recommend use of the stop switch line because it can save the life of

the operator if somethings bad happens. However. we would also like to point

out the drawbacks of the switch. Accidental activation of the switch (such as the

line being pulled out in heavy seas) could cause passengers to lose their balance

and even fall overboard, or it could result in loss of power in heavy seas, strong

currents, or high winds. Loss of control while mooring is another potential

hazards

To prevent such hazardous situations. the 500 mm line is coiled and can

extended to a full 1.300 mm.

WARNINGS

As the operation/driver of the boat, you are responsible for the safety of those

aboard and those in other crafts around yours and for following local boating

regulations. Therefore you should possess thorough knowledge of correct

operation of the boat. its accessories, and the engine. To learn about the correct

operation and maintenance of the engine, please read through this manual

carefully.

It is very difficult for a person standing or floating in the water to take evasive

action should he or she see a power boat heading in his/her direction, even at a

slow speed. Therefore, when your boat is in the Immediate vicinity of people in

the water. the engine should be shifted to neutral and shut off.

SERIOUS INJURY IS LIKELY IF A PERSON IN THE WATER MAKES

CONTACT WITH A MOVING BOAT, GEAR HOUSING, PROPELLER, OR

ANY SOLID DEVICE RIGIDLY ATTACHED TO A BOAT OR GEAR

HOUSING.

It is the operator’s responsibility to perform al1 safety checks and to ensure that

all lubrication and maintenance instructions are complied with for safe

operation. It is also the operator’s responsibility to return the unit to the local

dealer for periodic inspection.

Correct periodic maintenance and good care of this outboard engine will lessen

the chance of problems and keep overall opemting expenses at a minimum.

SERVICING, REPLACEMENT PARTS & LUBRICANTS

Only let an authorized TOHATSU service shop perform serving or maintenance

on this product. Be sure to use genuine parts and genuine lubricants or

recommended lubricants.

MAINTENANCE

As the owner of this outboard engine, you should be acquainted with its correct

maintenance Please comply with all instructions on lubrication and

maintenance. and return the engine to the dealer or service shop for periodic

inspection at the prescribed intervals.

Troublefree operation cannot be expended unless the engine receives adequate

periodic maintenance. If maintenance is performed periodically, it is not likely

that a costly overhaul will ever be required.

USE OF SERVICE SHOP

When subjecting your TOHATSU product to a check or repair, please be sure

to use a TOHATSU dealer authorized by TOHATSU or a TOHATSU agent.

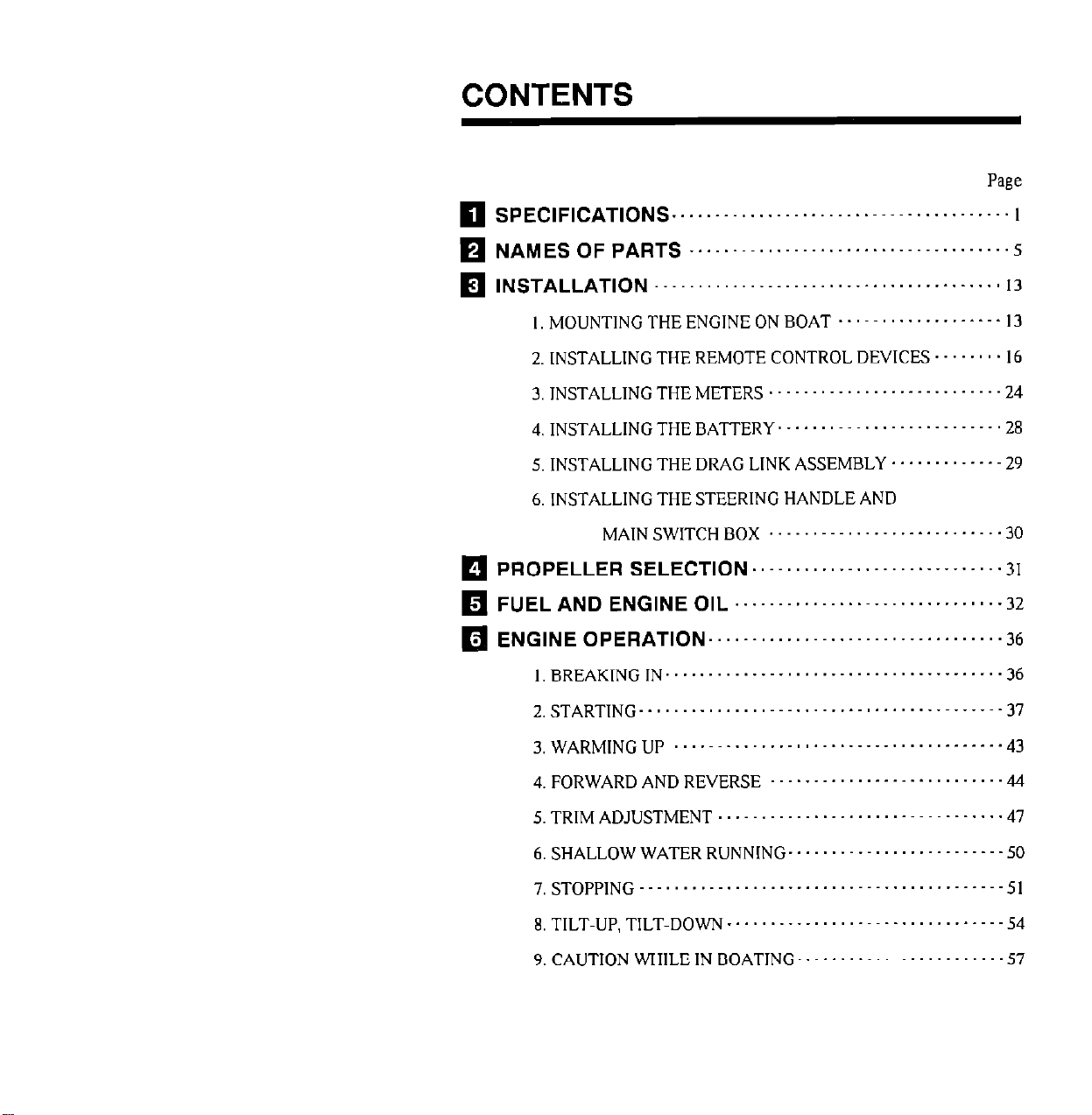

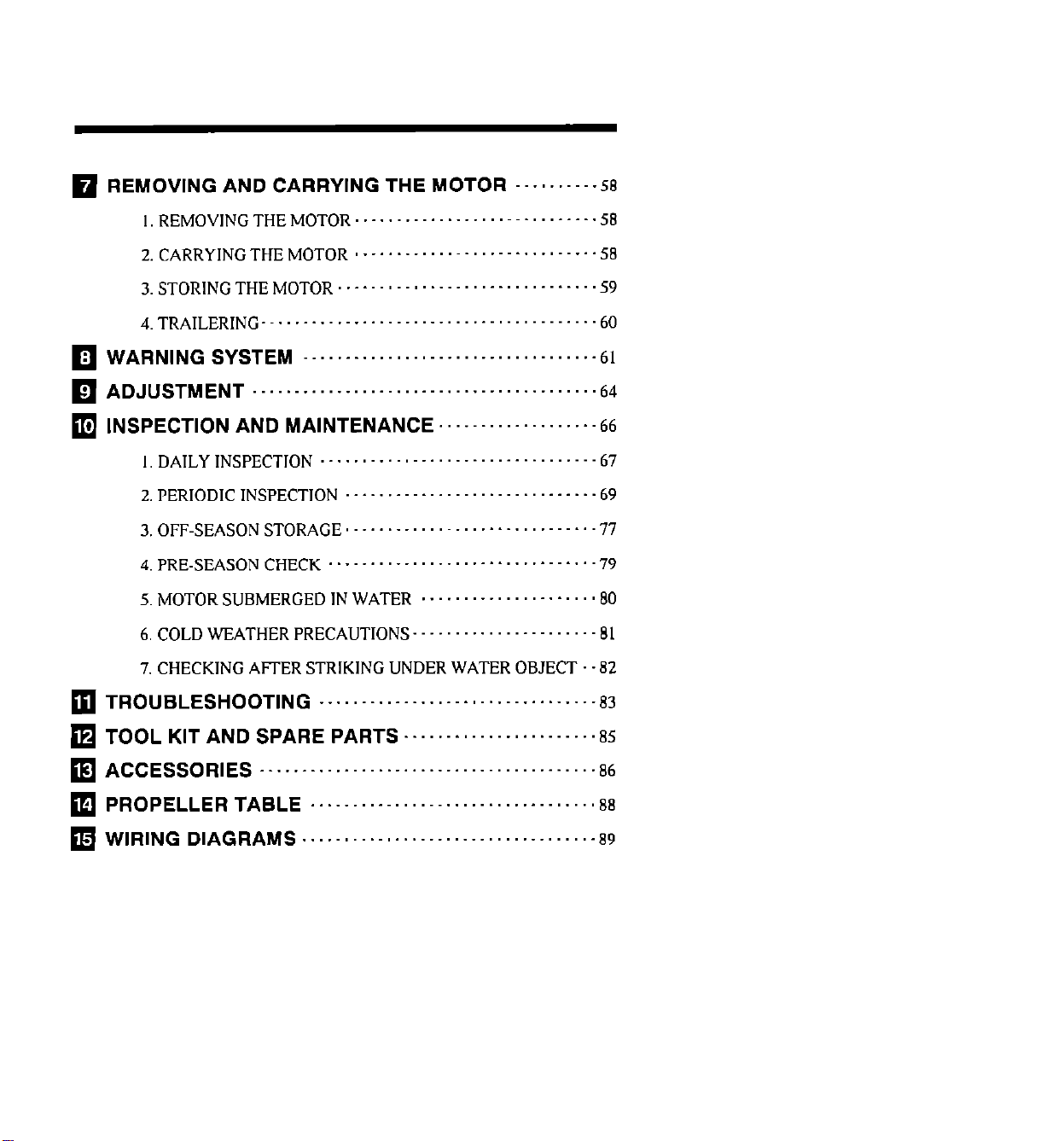

CONTENTS

SPECIFICATIONS

Page

....................................... ,

NAM ES OF PARTS ....................................

,N TALLAT,ON

El s

I.MOUNTINGTHEENGINEONBOAT

2.INSTALLlNGTHEREMOTECONTROLDEVICES~~~~~~~~l6

-, ,,.JCJ-,,,JL,NG ',-HE METERS ..........................

4, INS',-ALL,NG ,-HE BATTERY. .........................

5.INSTALLINGTHEDRAGLINKASSEMBLY~~~~~~~~....-2 9

6.lNSTALLINGTHESTEERlNCHANDLEAND

PROPELLER SELECTION ............................ .3,

q

........................................ ,3

. ..--..............I 3

,+,,N SWITCH BOX ...........................

F”EL ANO ENG,NE O,L .............................

ENG,NE OPE=AT,ON.

................................

,.BREAK,NG,N.......................................3 6

2.START,NG..........................................3 7

3, W,&RM,NG Up .............. ......................... 3

.5

.24

28

-,,,

..3 2

.36

4. FORWAR,, AN,, REVERSE ...........................

5. TR,M ADJUSTMENT ................................

6, SHALLOW WATER RUNNING ........................

&,

.47

.50

,.STOPP,NG..........................................5,

REMOVING AND CARRYING THE MOTOR --.‘..---.58

0

,,*EMO”,NG-j-“EMOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5*

2, CARRYING THE MOTOR . . . .58

j.STOR,NCT”EMOTOR . . . .._.__...___................ 59

4.TRA,LERING........................................~O

: WARN,NG SYSTEM _. _. _, _, _. _. . -6,

. ADJUSTMENT _. _. _. _. _. _. _. . _. _. .&,

ii

I INSPECTION AND MAINTENANCE...---...-.-......-66

q

,, DAILY ,NSpECT,ON . . . .67

2, PER,(-JD,C ,NSPE(y-,ON _. -69

3, OFF-SEASON STORAGE.. . . . .77

4. PRE.SEASON CHECK . . . . . .-/9

5.MOTORSUBMERGED1NWATER ..-....--.....-.....,80

6,COLDWEATHERPRECAUTIONS----.........---....--81

7. CHECKING AFTER STRIKING UNDER WATER OBJECT ..82

q TRO,,BLES,,OOTlNG . . . . . . . . . . . . . . . . . . . . . . . ,y,

q

TOOL KIT AND SPARE PARTS --...-.....-.....---...a5

ACCESSORIES . _. _. _. _. &j

A PROPELLER TABLE .._. . . . . . . . . . . . . .~a

:

WlR,NG DIAGRAMS.. _. _, _. _. _. -89

q

q

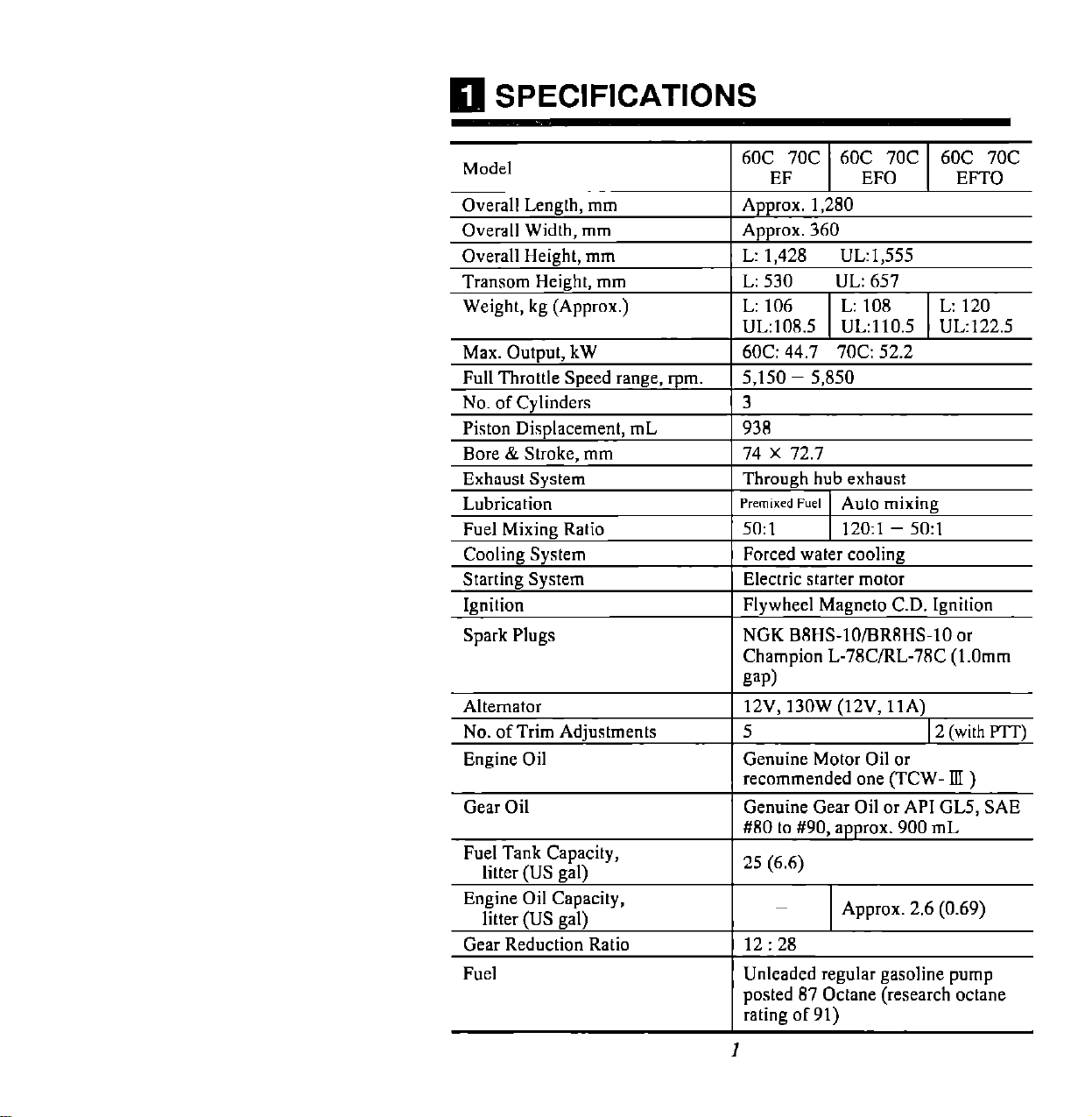

SPECIFICATIONS

Model

Overall Length, mm Approx. 1,280

OVerall

Transom Height, mm

Weight, kg (Approx.)

Mar Ontmt kW

Fol

No. of Cylinders

Piston Displacement, mL

Bore & Stroke, mm

Exhaust System

Lubrication

Fuel Mixing Ratio

Cooling System

Starting System

Ignition

Spark Plugs

Alternator

No. of Trim Adjustments

Engine Oil

Gear Oil

Fuel Tank Capacity,

Engine Oil Capacity,

Gear Reduction Ratio

Fuel

Width, mm Approx. 360

;ht, mm L: 1,428 UL:1,555 Overall Heig

-_.

c---3 -- .’

I Throttle Speed range, ‘pm. 1 5,150 - 5,850

litter (US gal)

litter (US gal)

6OC 7oc 6OC 7oc 6OC 7oc

EF EFO EFTO

L: 530 UL: 657

L: 106 L: 108 L: 120

UL:lO8.5 UL:110.5 uL:122

fine: 44~7 7llr.Y 53.~2

(3

1 93R

1 74 X 72.7

Through hub exhaust

premixed hel 1 Auto mixing

5O:l 1 12O:l - 5O:l

Forced water cooling

Electric starter motor

Flywheel Magneto CD. Ignition

NGK BXHS-lO/BRRHS-10 or

Champion L-78C/RL-78C (l.Omm

gap)

IZV, 130W (12V, 11A)

5 12 (with PTT)

Genuine Motor Oil or

recommended one (TCW- Ill )

Genuine Gear Oil or API GL5, SAE

#SO to #90, approx. 900 mL

25 (6.6)

Approx. 2.6 (0.69)

12 : 28

Unleaded regular gasoline pomp

posted 87 Octane (research octane

rating of 91)

,.5

-

I

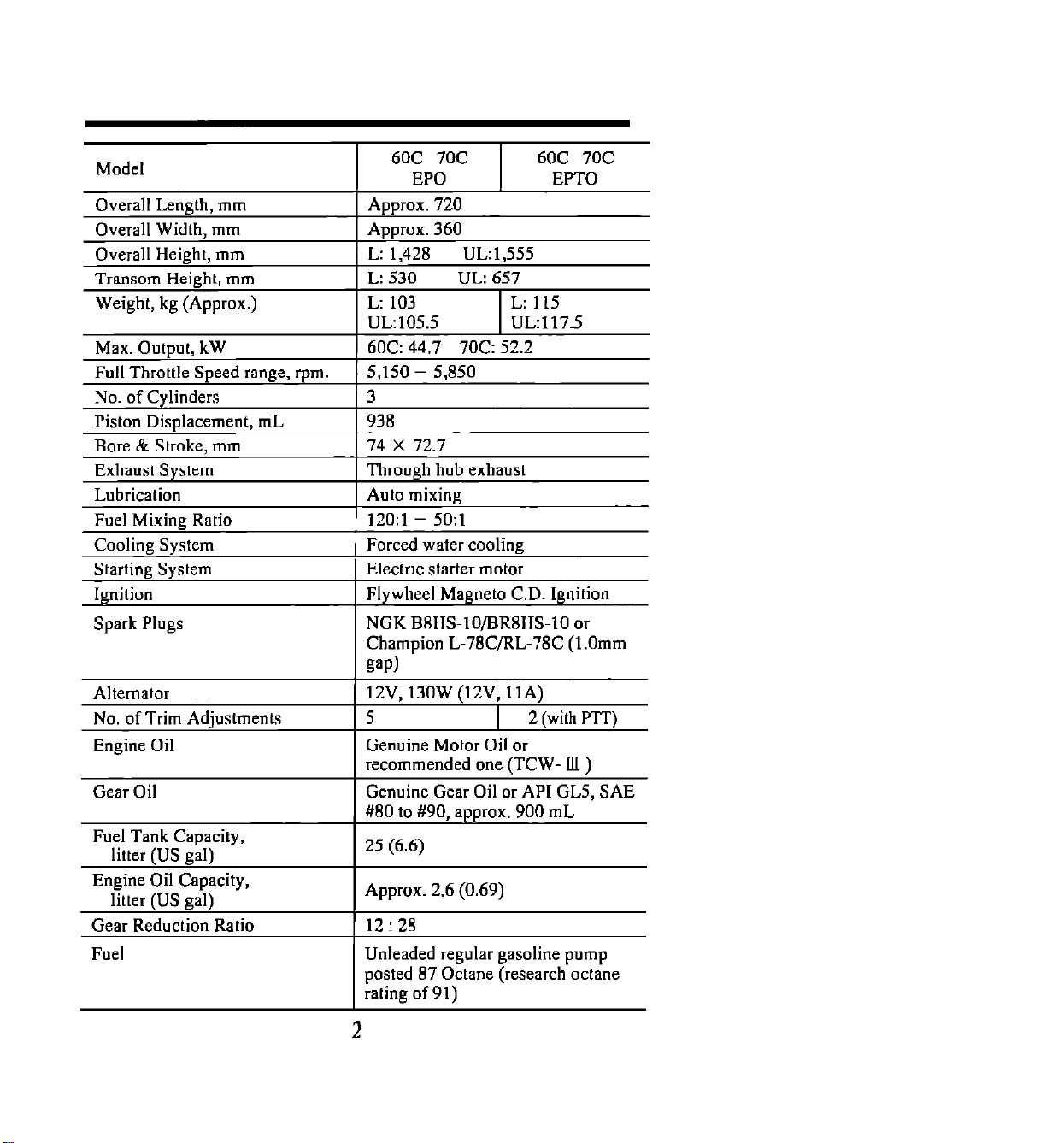

Model

Overall Leng ;th, mm

Overall Width, mm

Overall Height, mm

Transom Height, mm

Weight, kg (Approx.)

Max. Output, kW 60C: 44.7 70C: 52.2

Full Throttle Speed range, ‘pm. 5,150 - 5,850

No. of Cylinders

Piston Displacement, mL 938

Bore & Stroke, mm 74 X 72.7

Exhaust System Through hub exhaust

Lubrication Auto mixing

Fuel Mixing Ratio 12O:l - 5O:l

Cooling System Forced water cooling

Starting System Electric starter motor

Ignition Flywheel Magneto CD. Ignition

Spark Plugs NGK BRHS-lO/BRBHS-10 or

Alternator

No. of Trim Adjustments

Engine Oil

Gear Oil Genuine Gear Oil or API GL5, SAE

Fuel Tank Capacity,

litter (US gal)

Engine Oil Capacity,

litter (US gal)

Gear Reduction Ratio

Fuel Unleaded regular gasoline pump

60C 70C

I

EPO EPTO

Approx. 720

Approx. 360

L: 1,428 lJL:1,555

L: 530 UL: 657

L: 103 L: 115

lJL:105.5 UL:117.5

3

Champion L-78ClRL-78C (l.Omm

k!w1

12V, 13OW (12V, 11A)

5 1 2(withF’lT)

Genuine Motor Oil or

recommended one (TCW- lJl1

MO to #90, approx. 900 mL

25 (6.6)

Approx. 2.6 (0.69)

12: 28

posted 87 Octane (research octane

rating of 91)

60C 70C

I

2

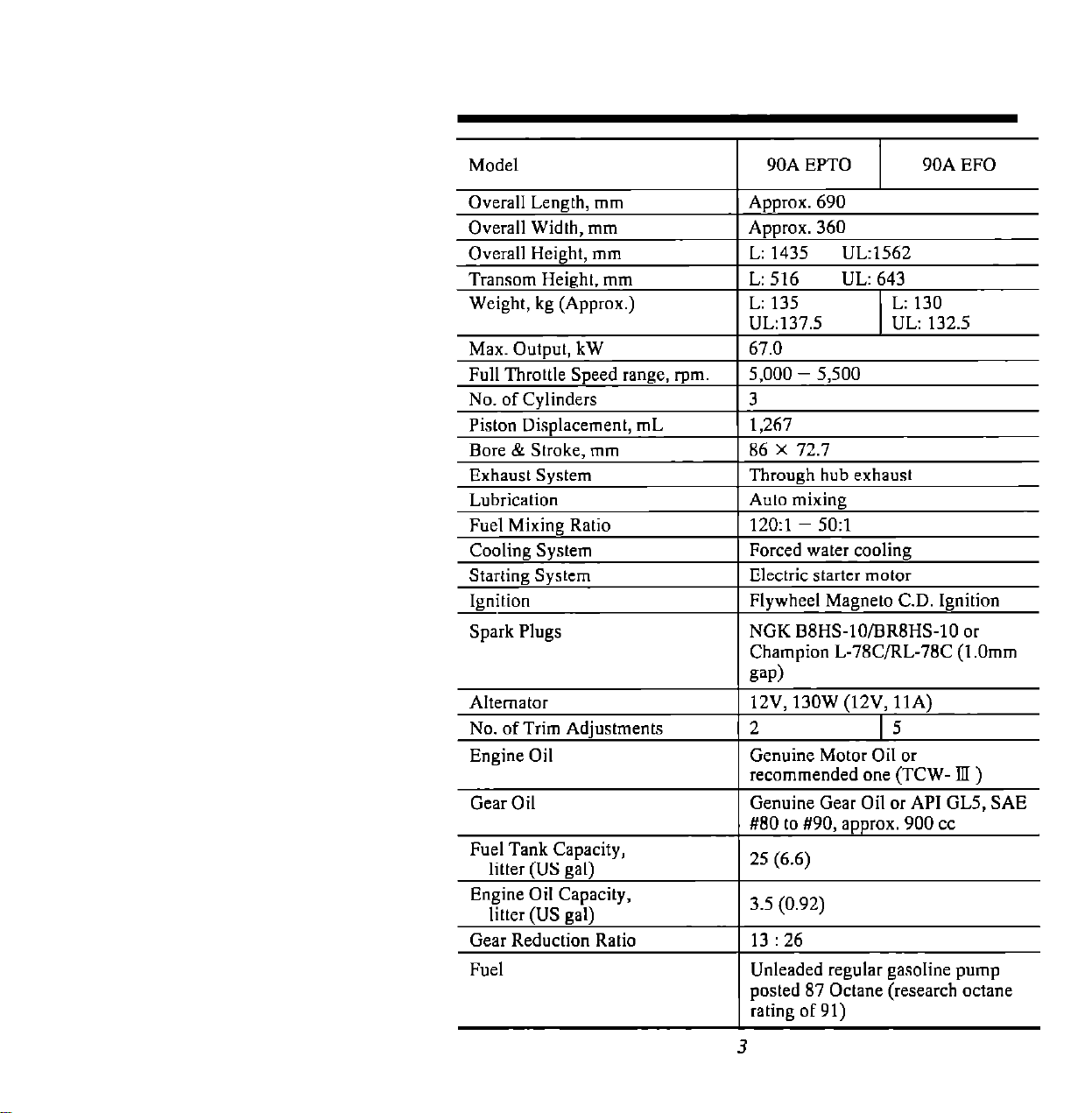

Model 90A EPTO

90A EFO

Overall Length, mm

Overall Width. mm

Overall Height, mm Overall Heieht. mm

Transom Height, mm Transom Height, mm

Weight, kg (Approx.) Weight, kg (Approx.)

Max. Output, kW

Full Throttle Speed range, rpm.

No. of Cylinders

Piston Displacement, mL

Bore & Stroke, mm

Exhaust System

Lubrication

Fuel Mixing Ratio

Cooling System

Starting System

Ignition

Spark Plugs

Alternator

No. of Trim Adjustments

Engine Oil

Gear Oil

Fuel Tank Capacity,

litter (US gal)

Engine Oil Capacity,

litter (US gal)

Gear Reduction Ratio

Aourox. 690

r,

Approx.

L: 1435

360

UL:1562

L: 516 UL: 643

L: 135

UL:137.5

I L: 130

1 UL: 132.5

67.0

5,000 - 5,500

3

1,267

86 X 72.7

Through hub exhaust

Auto mixing

12O:l ~ 5O:l

Forced water cooling

Electric starter motor

Flywheel Magneto CD. Ignition

NGK BgHS-lO/BRNHS-10 or

Champion L-78ClRL-IEtC (1 .Omm

gap)

12V, 130W (12V, 11A)

.T I c

Genuine Motor Oil or

recommended one (TCW- m )

Genuine Gear Oil or API GL5, SAE

#NO to #90, approx. 900 cc

25 (6.6)

3.5 (0.92)

13 ~26

Fuel

Unleaded regular gasoline pump

posted 87 Octane (research octane

rating of 91)

3

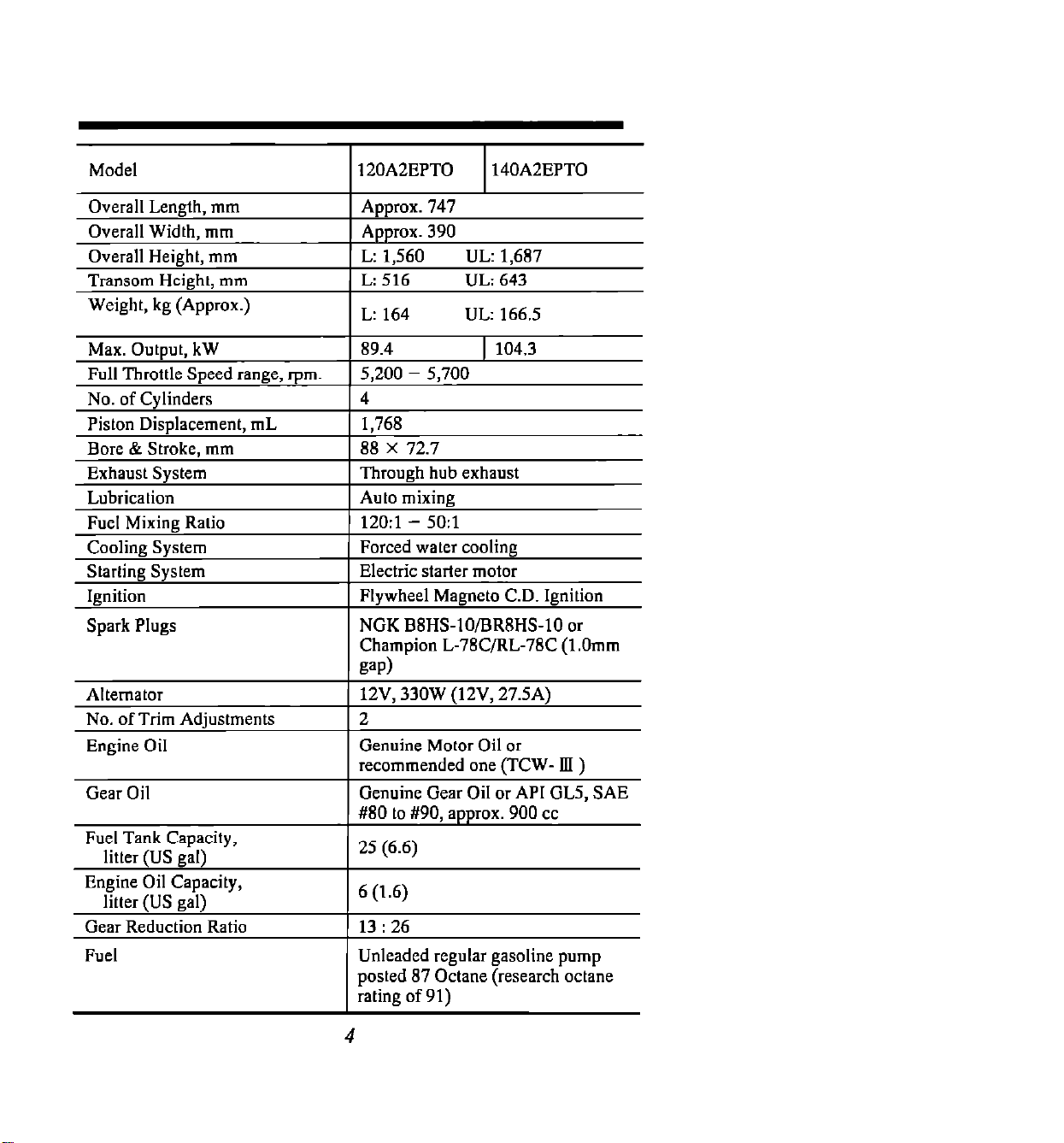

Overall Length. mm

Overall Width, mm

Overall Height, mm

Transom Height, mm

Weight, kg (Approx.)

120A2EPTO

140A2EPTO

I

Approx. 747

Approx. 390

L: 1,560 UL: 1,687

L: 516 UL: 643

1 L: 164 UL: 166.5

Max. Output. kW

89.4 1 104.3

Full Throttle Speed range, ,-pm. 5,200 - 5,700

No. of Cylinders

4

Piston Displacement, mL 1,768

Bore & Stroke, mm 88 X 72.7

Exhaust System

Lubrication

Through hub exhaust

Auto mixing

Fuel Mixing Ratio 12O:l - 5O:l

Cooling System Forced water cooling

Starting System

Ignition

Electric starter motor

Flywheel Magneto CD. Ignition

Spark Plugs NGK B8HS-lO/BRRHS-10 or

Champion L-78C/RL-78C (l.Omm

gad

Alternator

12V, 330W (12V, 27.5A)

No. of Trim Adjustments 2

Engine Oil

Genuine Motor Oil OI

recommended one (TCW- III )

Gear Oil

Genuine Gear Oil or API GL5, SAE

#80 to #90, approx. 900 cc

Fuel Tank Capacity,

litter (US gal)

Engine Oil Capacity,

litter (US gal)

Gear Reduction Ratio

25 (6.6)

6 (1.6)

13 : 26

FoeI Unleaded regular gasoline pump

posted 87 Octane (research octane

rating of 91)

4

q

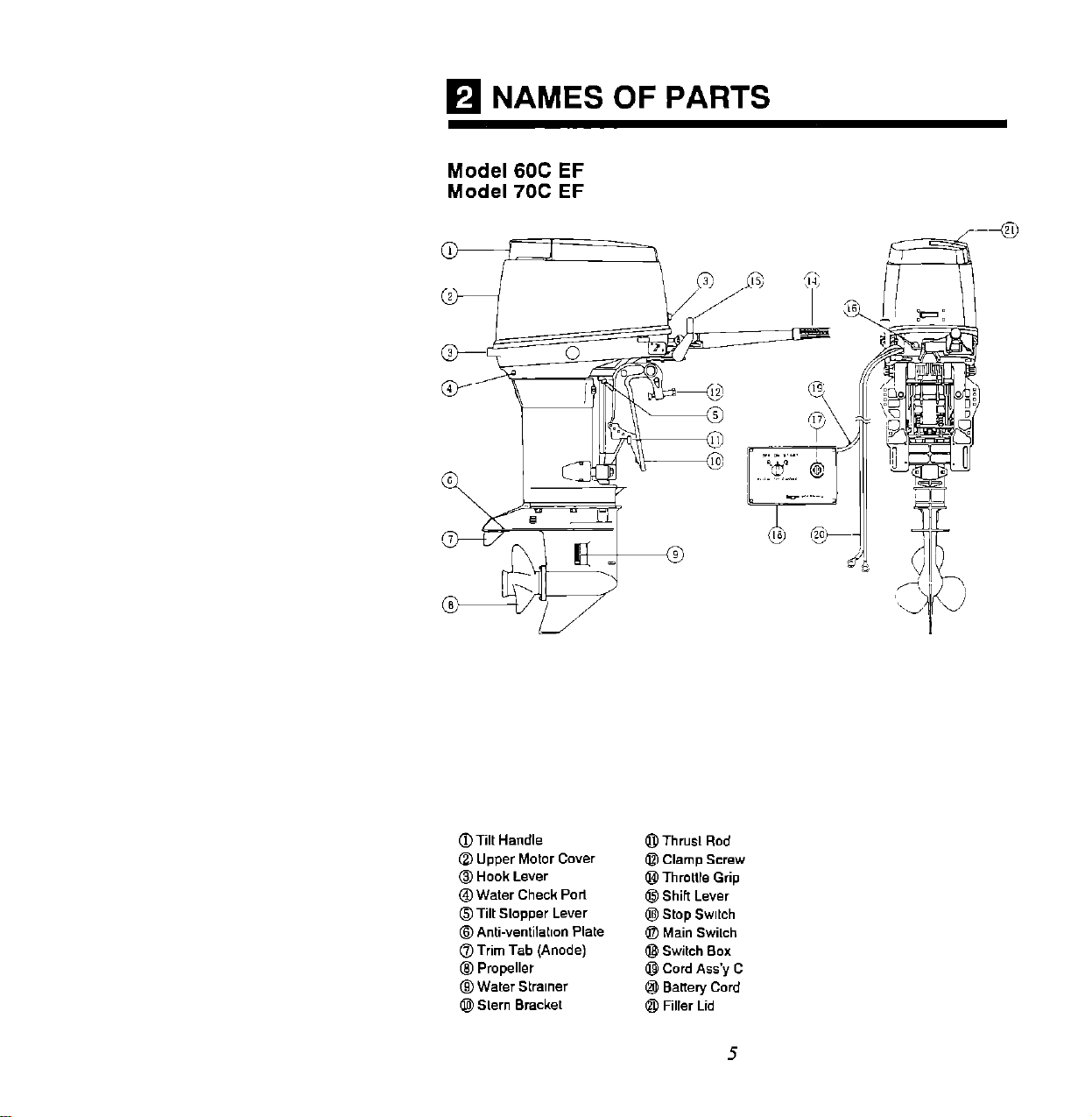

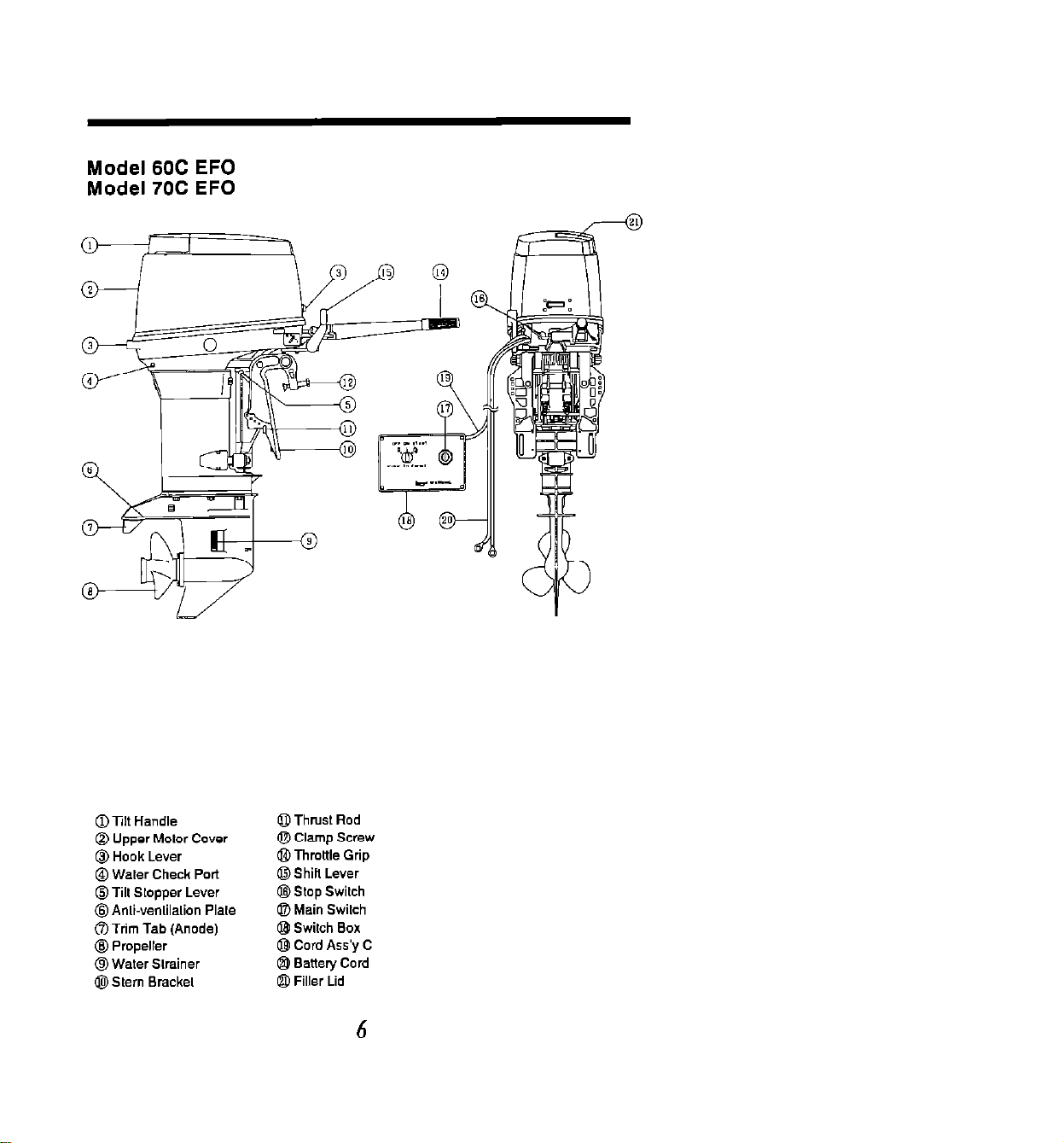

NAMES OF PARTS

Model 6OC EF

Model 7OC EF

aTilt Handle

@Upper Motor Cover

@Hook Lever

@I Water Check Pori

@Tilt Slopper Lever

8 Anti-ventilallon Plate

@I Trim Tab (Anode)

@I Propeller

@Water stmner

@ Slern backeel

0 Thrusl Rod

@ aamp screw

03 ThroNe Grip

03 Shift Lever

@Stop Swtch

0 Main Swilch

@Switch Box

@Cord Ass’y C

@ Sanery Cord

@ Filler Lid

Model 60C EFO

Model 70C EFO

am, Handle

0 Upper Motor Cover

Q Hook Lever

@ Water Check Port

Q Till Slopper Lever

@ Anli-venlilalion Plale

@Trim Tab (Anode)

Q Propeller

@I Water Slminer

@Stern Erackel

@Thrust Rod

@Clamp screw

@ Thronle Grip

@I Shift Lever

@J Stop Switch

0 Main Switch

0 Switch Box

C$ Cord Ass’y C

@ Battery Cord

D Filler Lid

6

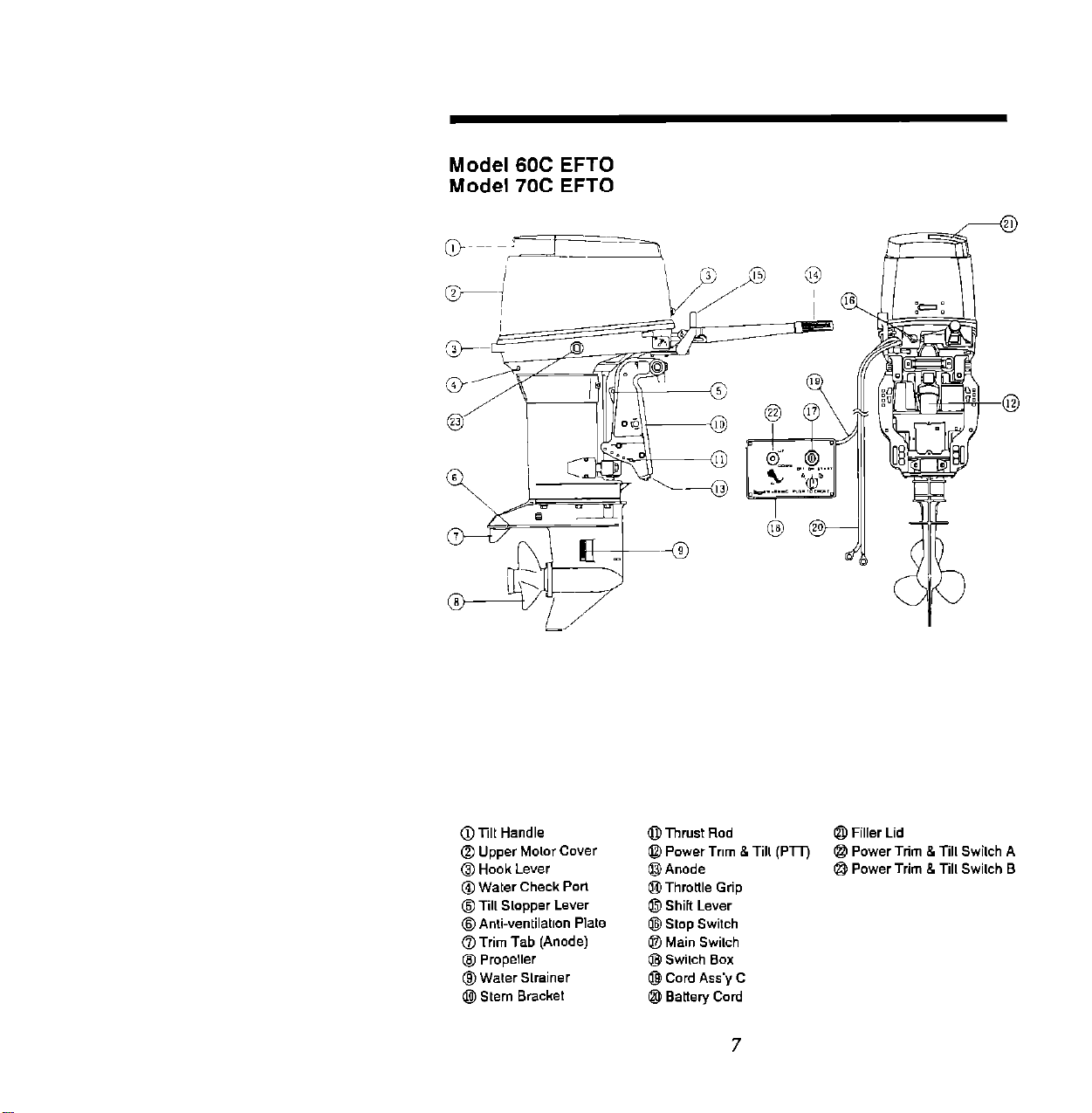

Model 60C EFTO

Model 70C EFTO

@Tilt Handle

@ Llpper Mobr cover

@Hook Lever

@Water Check Poll

Q Till Stopper Lever

Q Am-ventilalfon Plate

0 Trim Tab (Anode)

Q Propeller

@Waler Slrainer

@I stern Bracket

@l-must Rod CC Filler Lid

@I Power Tram 8 Till (PTQ @ Power Trim B Till Swilch A

0 Anode @ Power Trim 8 Till Swilch B

@Thronle Grip

03 Shin Lever

@I Slop Switch

@ Main Swilch

03 Swilch Box

0 Cord Ass’y C

@ Battery cord

7

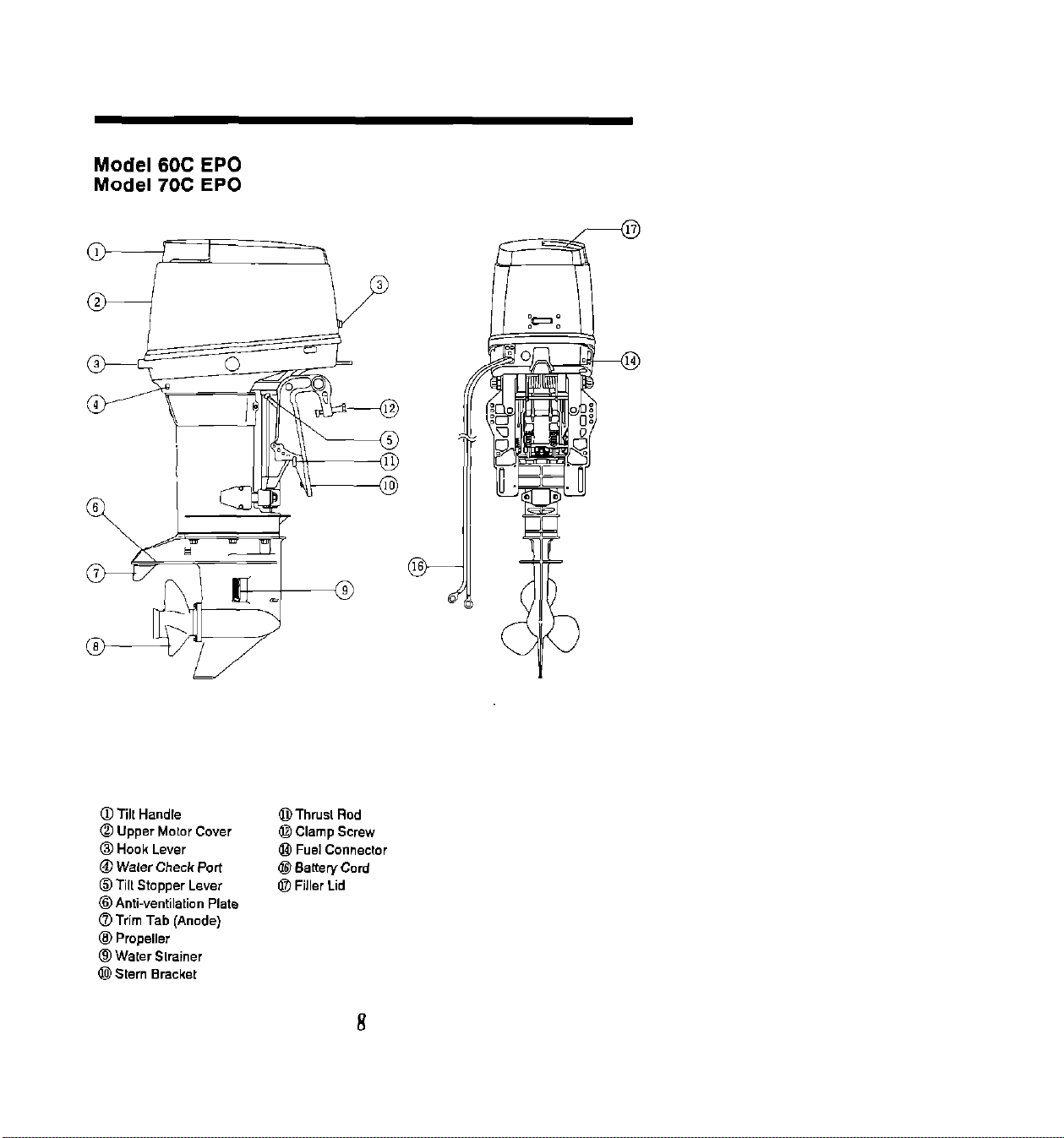

Model 60C EPO

Model 7OC EPO

0 Till Handle

@Upper Molar Cover

0 Hook Lever

@ Water Check Port

0 Till Stopper Lever

8 Anti-ventilation Plate

0 Trim Tab (Anode)

@Propeller

8 Waler Slrainer

@Stern Bracket

8

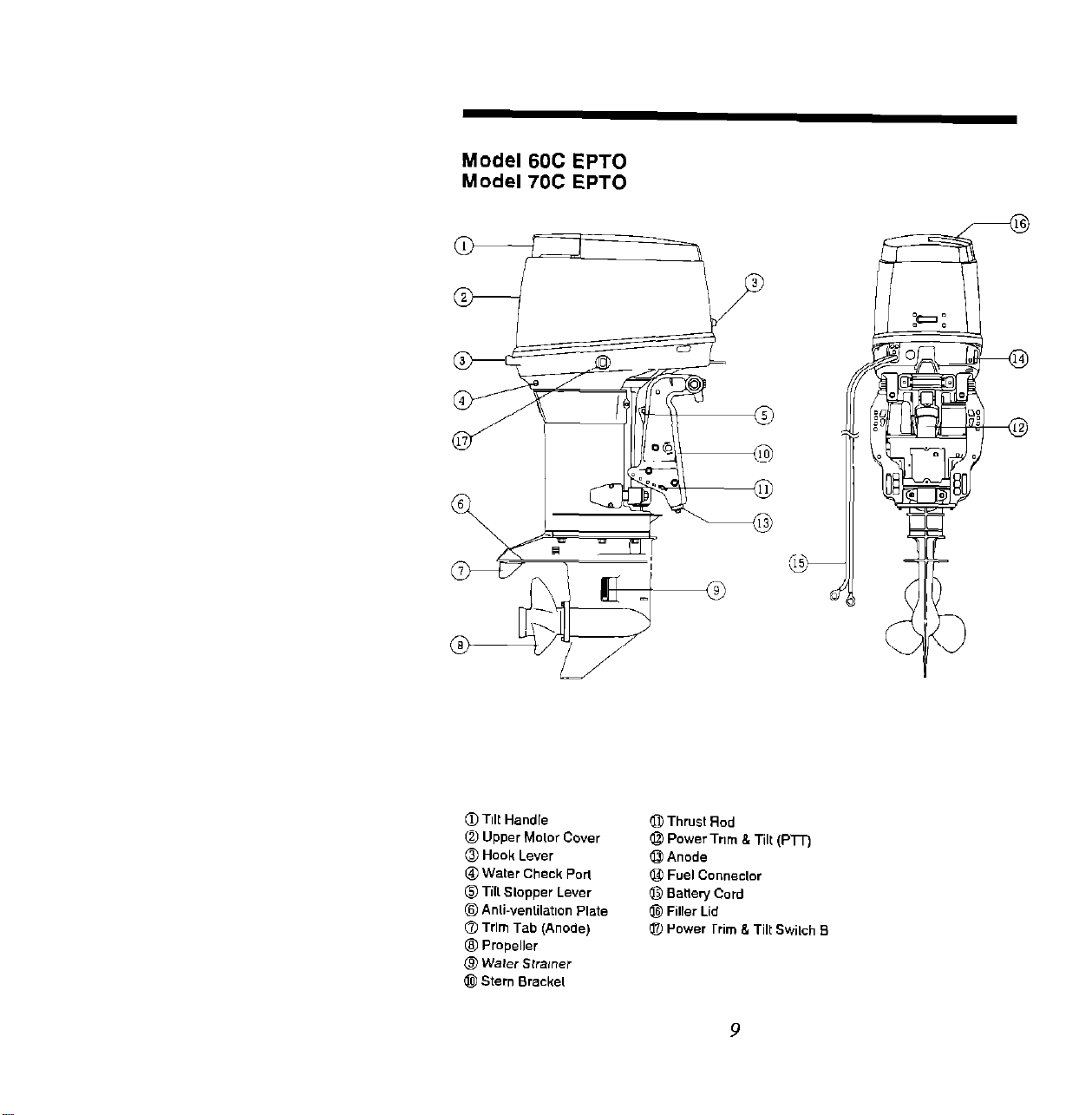

Model 6oC EPTO

Model 70C EPTO

OTlll Handle

0 Upper Motor Cover

0 Hook Lever

@Water Check PO,,

Q Till Slopper Lever

@ Anli-venlilatlon Plate

0 Trim Tab (Anode)

@Propeller

8 Water sm,ner

0-G Stern Bracket

@I Thrust Rod

@Power Trim &Tilt (Pm

@Anode

@Fuel Conneclor

@ Battery Cord

@ Filler Lid

Q? Power Trim & Tilt Swilch B

9

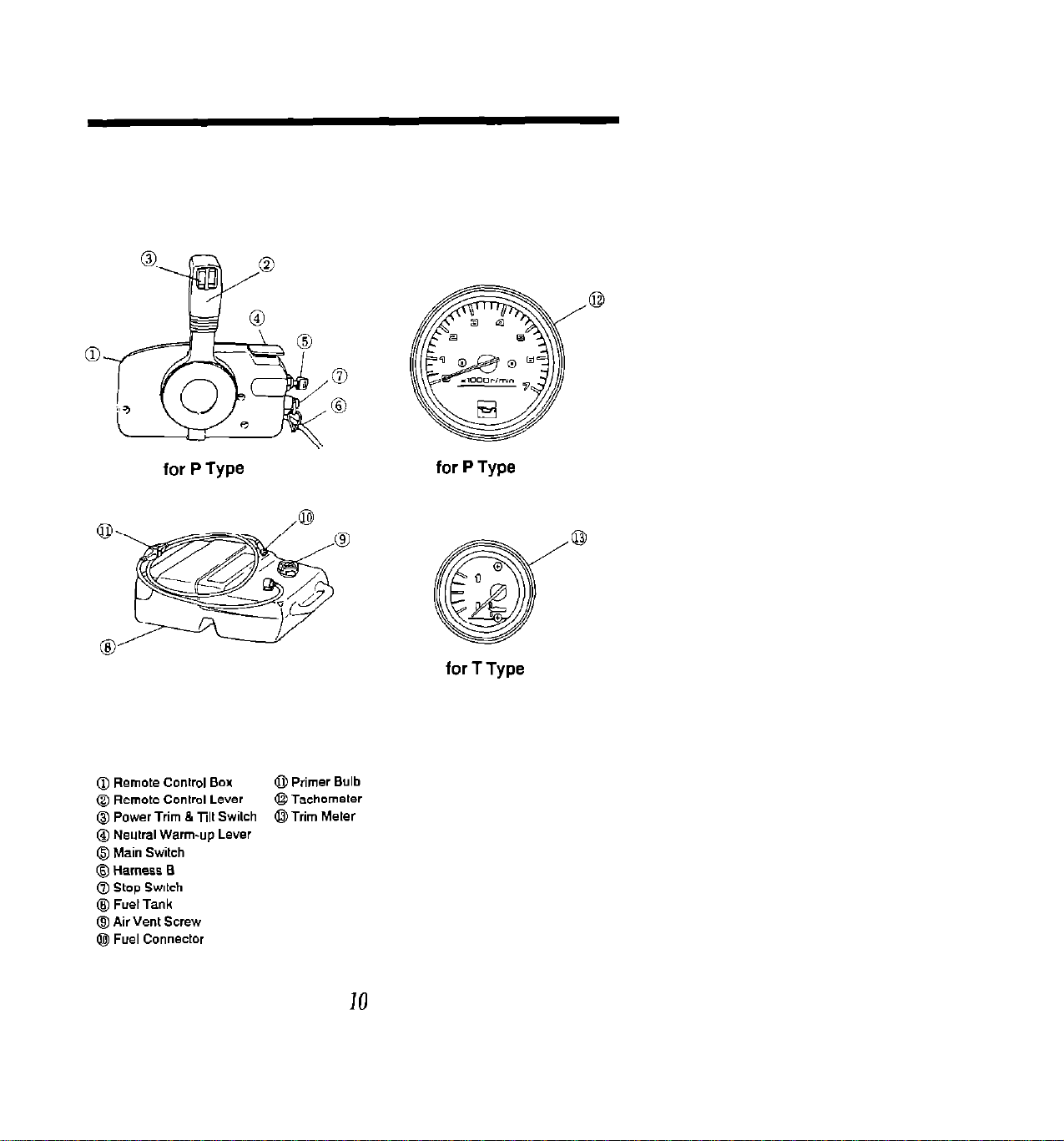

for P Type

for P Type

for T Type

Q Remote Control Box

Q Remote Contml Lever

Q Power Trim & lX Swilch

@ Neuld Warm-up Lever

Q Main Swilch

Q Harness B

0 Stop Swllch

Q Fuel Tank

Q Air Vent Screw

@Fuel Connector

CD Primer Bulb

@Tachometer

@Trim Meter

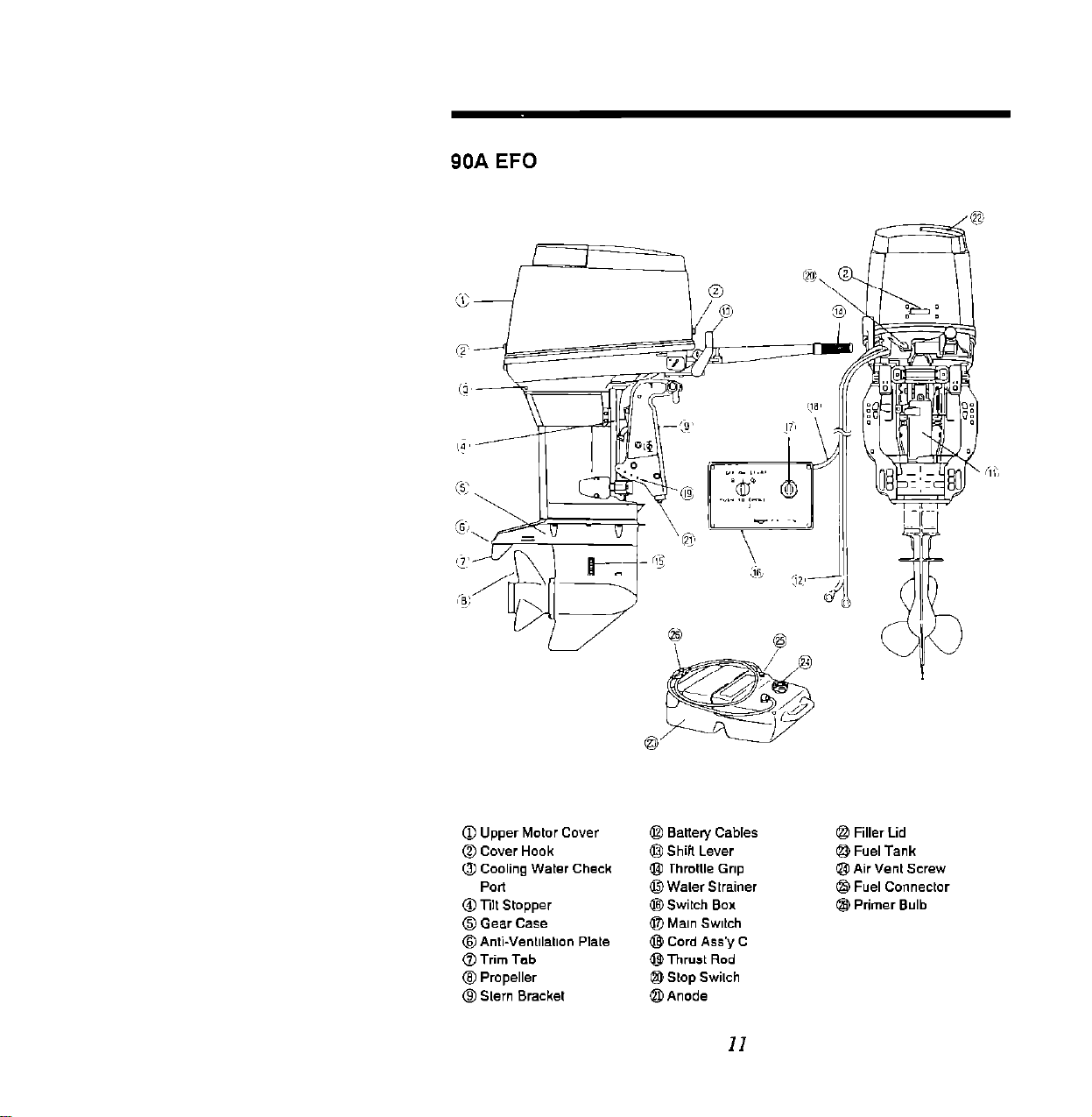

90A EFO

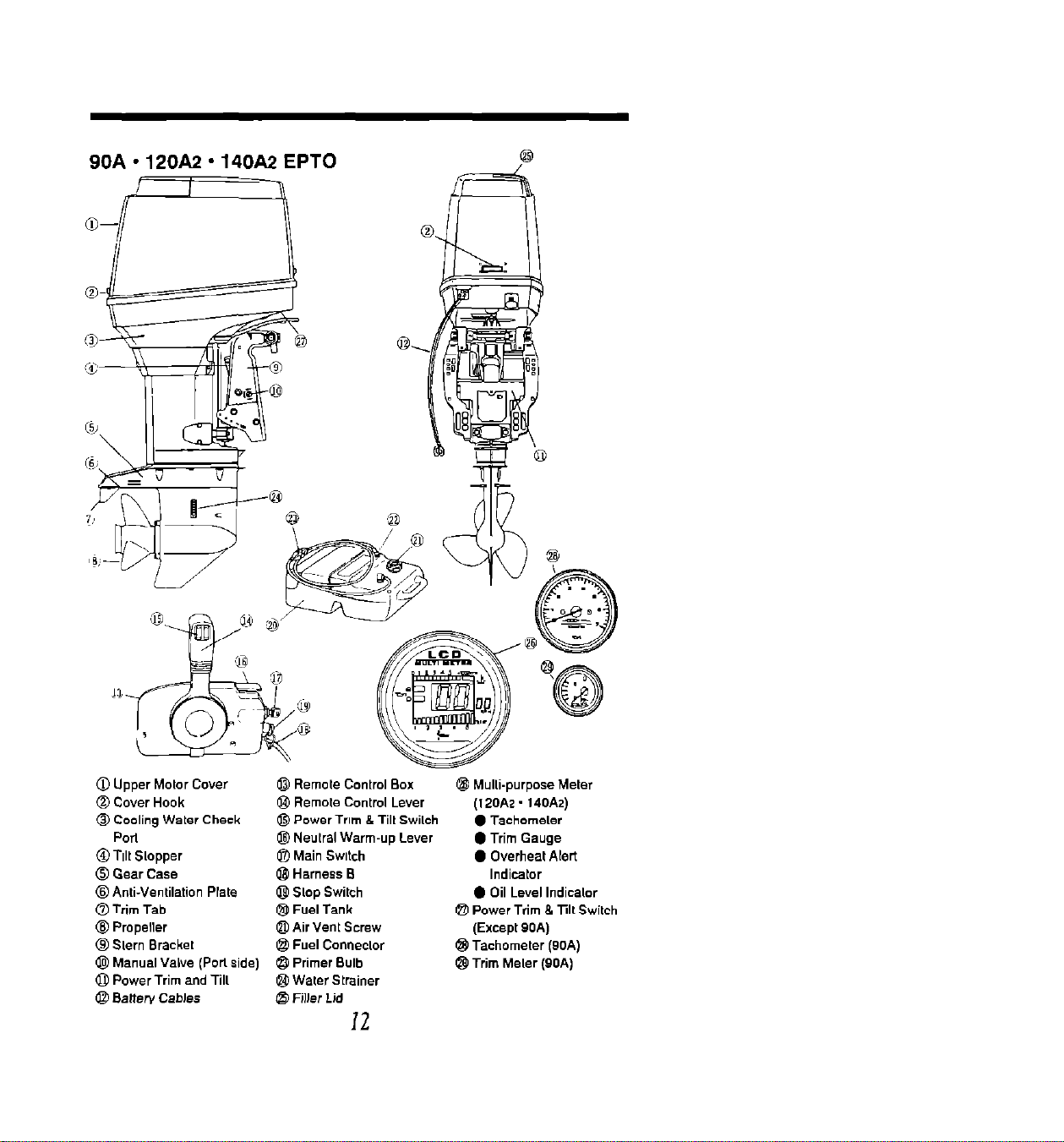

90A * 12OA2 - 14OA2 EPTO

I

”

I

1

0 Upper Motor Cover

0 Cover Hook

0 Cooling Water Check

Porl

@T~lt Stopper

0 Gear Case

8 Anti-Ventilation Plate

0 Trim Tab

@Propeller

8Slern Bracket

@Manual Valve (Port side)

0 Power Trim and Tilt

@I aanew Cables

cQ Remote Control Box

@ Remote Control Lever

03 Power Trim B Tilt Switch

03 Neutral Warm-up Lever

@I Main Switch

@Harness B

@Stop Switch

@, Fuel Tank

@Z Air Vent Screw

@Fuel Connector

@Primer Bulb

@Water Strainer

@Filter Lid

12

@ Multi-purpose Meter

(,20Ai!. 140Az)

l

Tachometer

l

Trim Gauge

l

Overheat Alert

Indicator

0 Oil Level lndicalor

0 Power Trim & lilt Switch

(Except SOA)

@Tachometer (@,A)

@Trim Meter (gOA)

m INSTALLATION

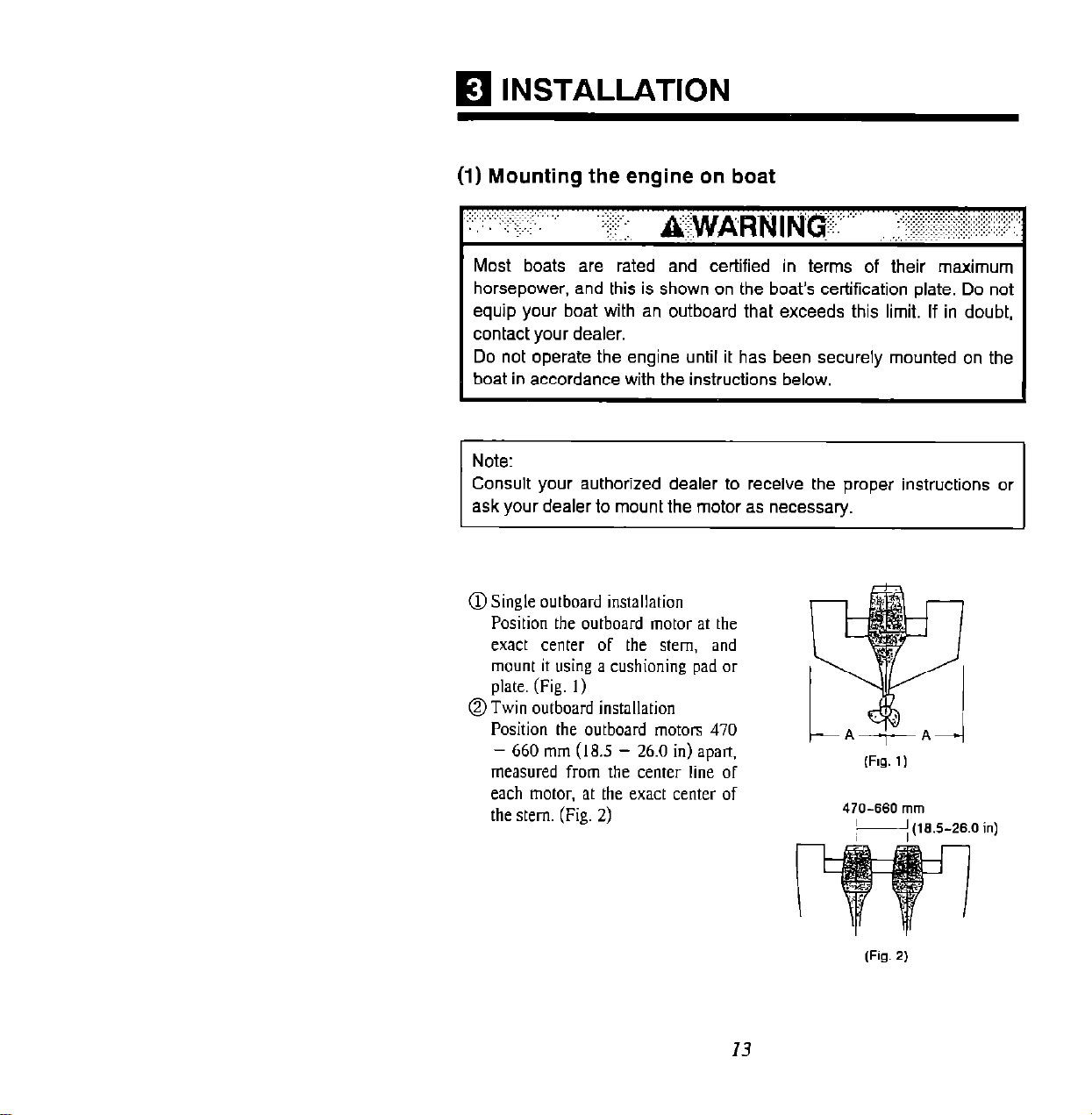

(1) Mounting the engine on boat

Most boats are rated and certified in terms of their maximum

horsepower, and this is shown on the boat’s certification plate. Do not

equip your boat with an outboard that exceeds this limit. If in doubt,

contact your dealer.

Do not operate the engine until it has been securely mounted on the

boat in accordance with the instructions below.

Note:

Consult your authorized dealer to receive the proper instructions or

ask your dealer to mount the motor as necessary.

@Single outboard installation

Position the outboard motor at the

exact center of the stem. and

mount it using a cushioning pad or

plate. (Fig. 1)

@Twin outboard installation

Position the outboard motors 470

- 660 mm (18.5 - 26.0 in) apart.

measured from the center line of

each motor. at the exact center of

the stem. (Fig. 2)

Pg. 1)

470~560 mm

13

(Fig. 2)

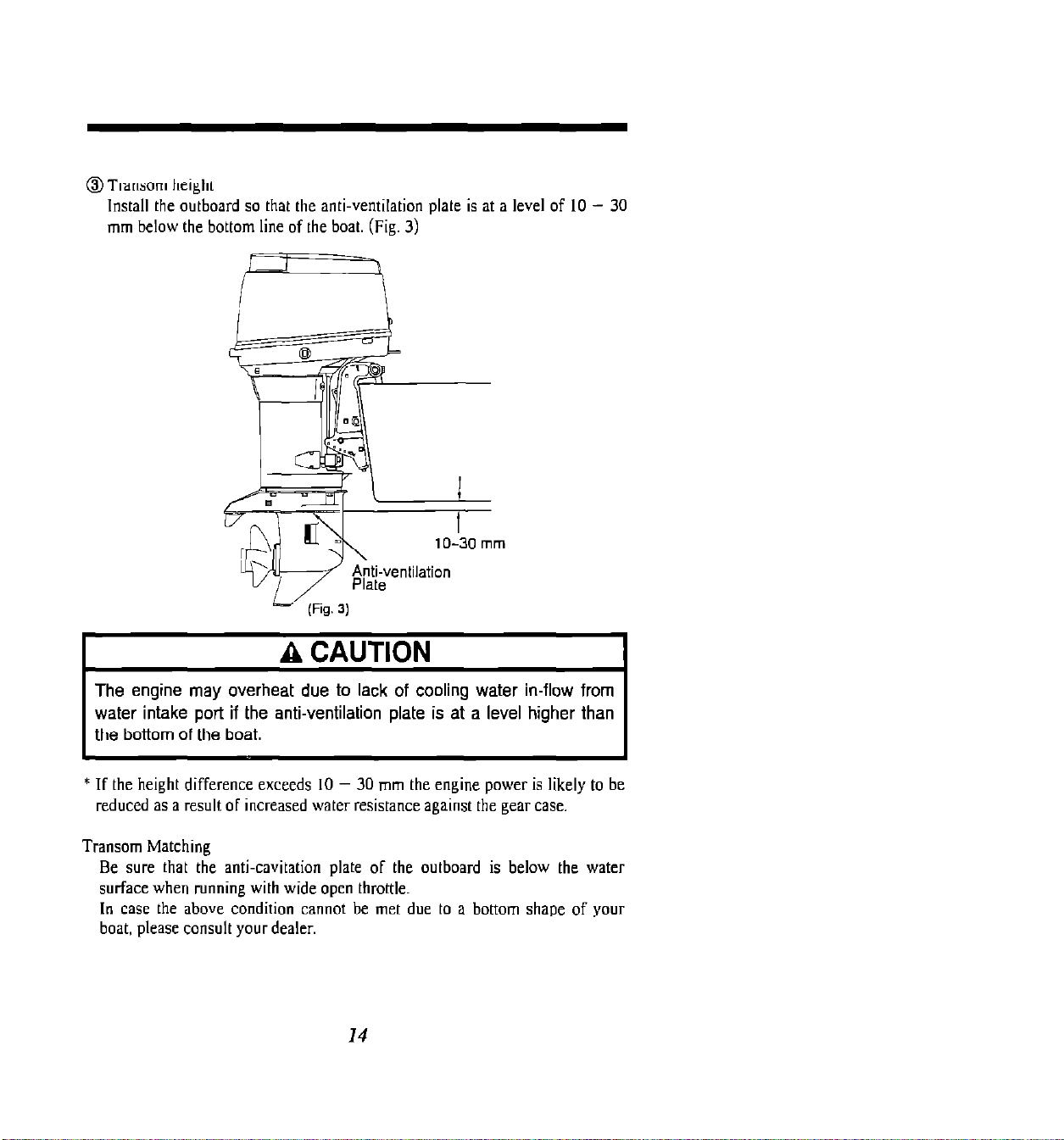

@Transom height

Install the outboard so that the anti-ventilation plate is at a level of 10 - 30

mm below the bottom line of the boat. (Fig. 3)

A

CAUTION

The engine may overheat due to lack of cooling water in-flow from

water intake port if the anti-ventilation plate is at a level higher than

the bottom of the boat.

I

* If the height difference exceeds IO - 30 mm the engine power is likely to be

reduced as a result of increased water resistance against the gear case.

Transom Matching

Be sure that the anti-cavitation plate of the outboard is below the water

surface when running with wide open throttle.

In case the above condition cannot be met due to a bottom shape of your

boat, please consult your dealer.

14

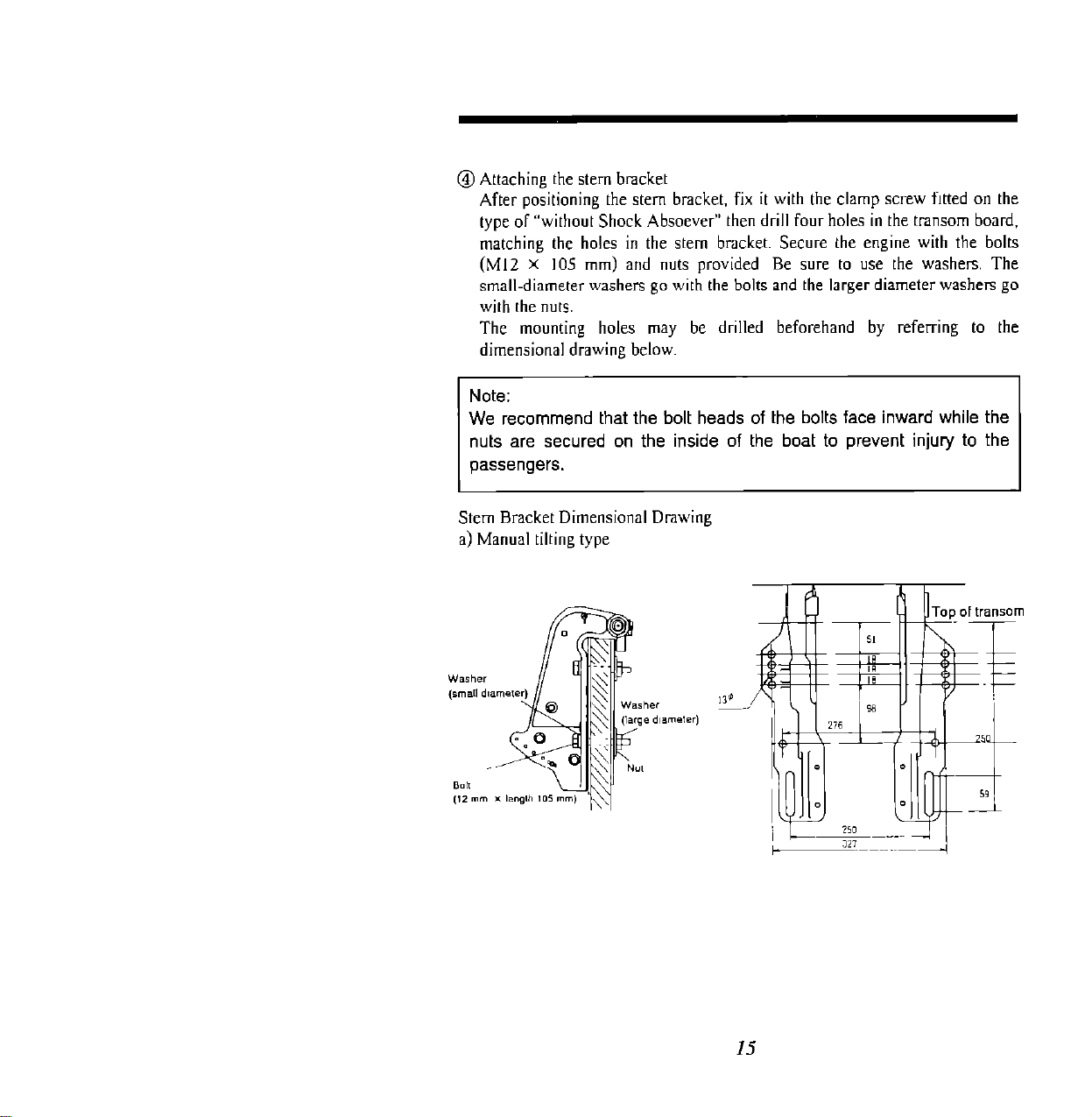

@I Attaching the stem bracket

After positioning the stem bracket, fix it with the clamp screw fitted on the

type of “without Shock Absoever” then drill four holes in the transom board.

matching the holes in the stern bracket. Secure the engine with the bolts

(Ml2 X 105 mm) and nuts provided Be sure to use the washers The

small-diameter washers go with the bolts and the larger diameter washers go

with the nuts.

The mounting holes may be drilled beforehand by referring to the

dimensional drawing below.

Note:

We recommend that the bolt heads of the bolts face inward while the

nuts are secured on the inside of the boat to prevent injury to the

passengers.

Stem Bracket Dimensional Drawing

a) Manual tilting type

15

i C

-

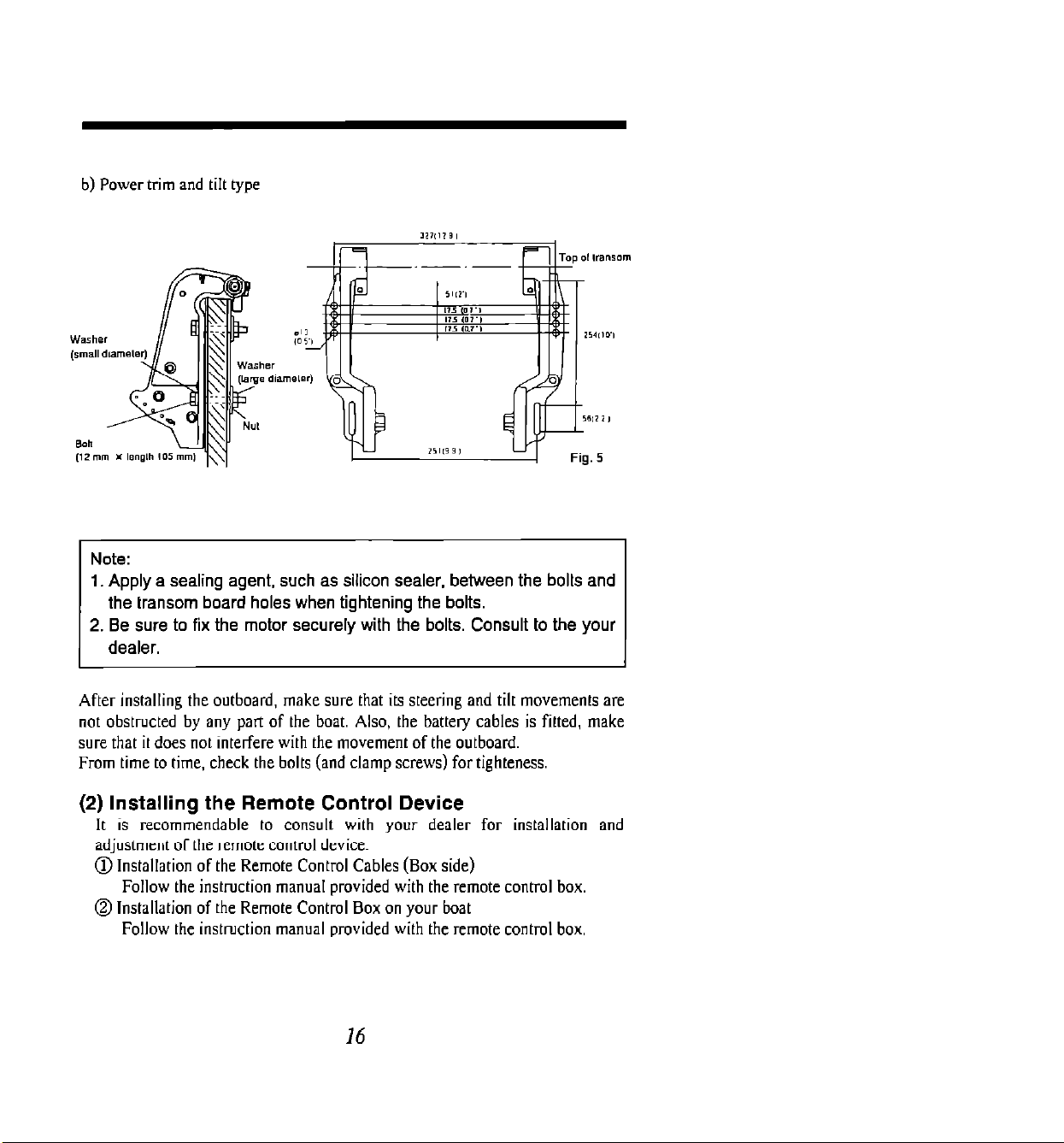

b) Power trim and tilt type

Note:

1. Apply a sealing agent, such as silicon sealer, between the bolts and

the transom board holes when tightening the bolts.

2. Be sure to fix the motor securely with the bolts. Consult

dealer.

to

the your

After installing the outboard. make sure that its steering and tilt movements are

not obstructed by any part of the boat. Also, the battery cables is fitted, make

sore that it does not interfere with the movement of the outboard

From time to time, check the bolts (and clamp screws) fortighteness.

(2) Installing the Remote Control Device

It is recommendable to consult with your dealer for installation and

adjustment of the remote control devices

@I Installation of the Remote Control Cables (Box side)

Follow the instruction manual provided with the remote control box.

@Installation of the Remote Control Box on your boat

Follow the instruction manual provided with the remote control box.

16

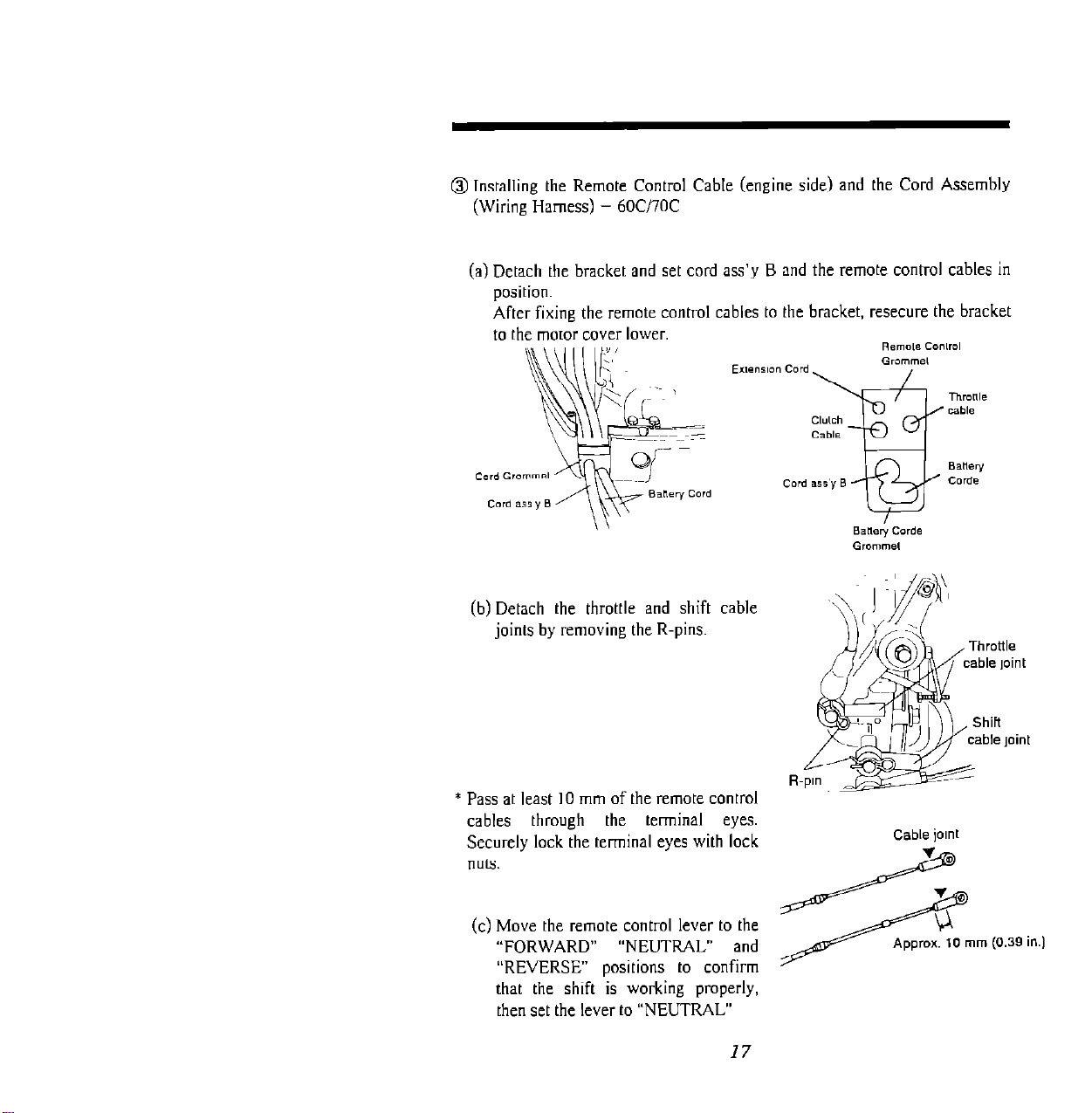

@Installing the Remote Control Cable (engine side) and the Cord Assembly

(Wiring Harness) - 6OC/7OC

(a) Detach the bracket and set cord ass’y B and the remote control cables in

position.

After fixing the remote control cables to the bracket, resecure the bracket

to the moror cover lower.

s.,enmn Cord

(b) Detach the throttle and shift cable

joints by removing the R-pins.

Flemo,e tonlrol

ThW”k

cable

* Pass at least 10 mm of the remote control

cables through the terminal eyes.

Securely lock the terminal eyes with lock

nuts.

(c) Move the remote control lever to the

“FORWARD” “NEUTRAL” and

“REVERSE” positions to confirm

that the shift is working properly,

then set the lever to “NEUTRAL”

17

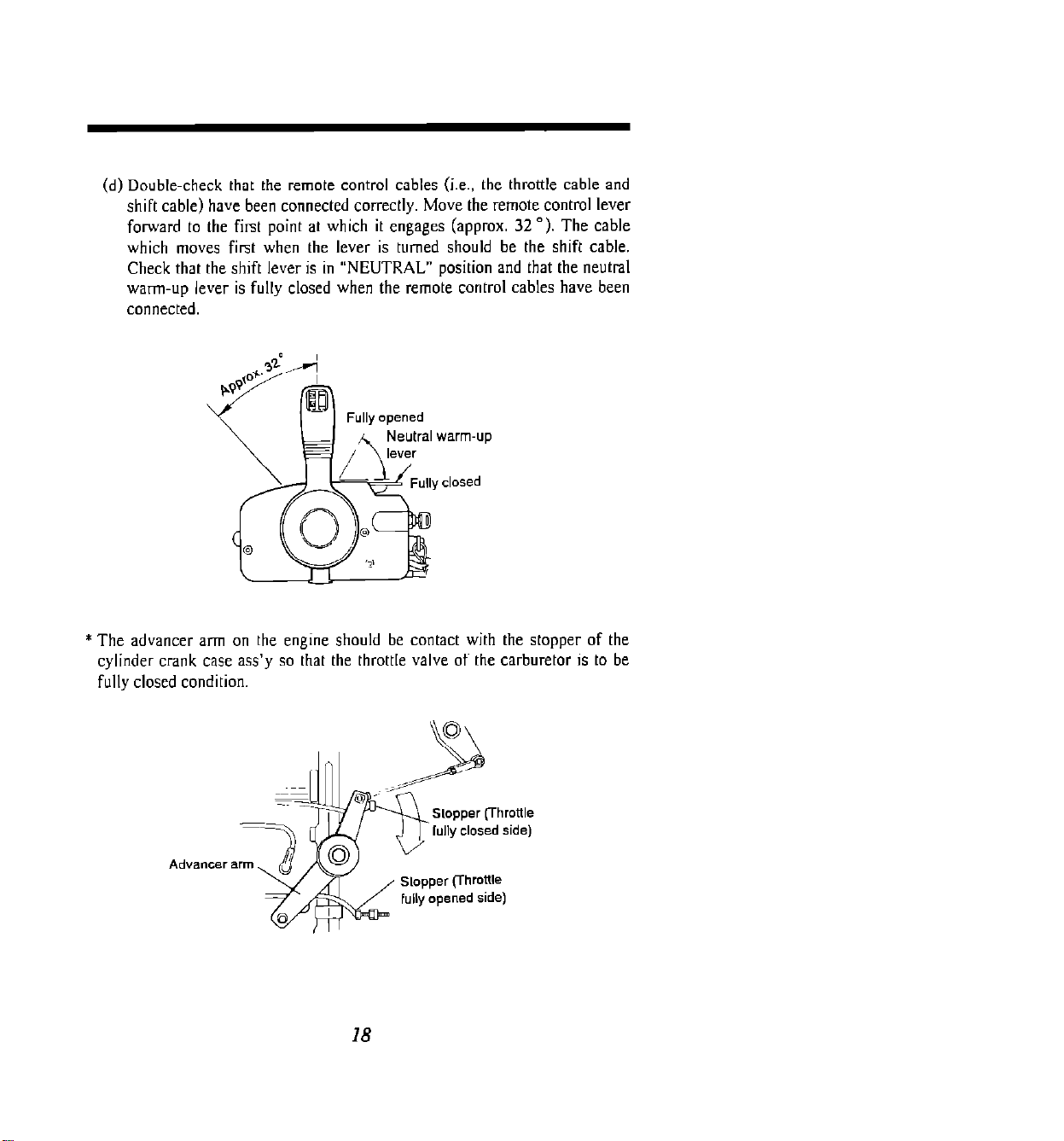

(d) Double-check that the remote control cables (i.e.. the throttle cable and

shift cable) have been connected correctly. Move the remote control lever

forward to the first point at which it engages (approx. 32 “). The cable

which moves first when the lever is turned should be the shift cable.

Check that the shift lever is in “NEUTRAL” position and that the neutral

warn-up lever is fully closed when the remote control cables have been

connected.

*The advancer arrr on the engine should be contact with the stopper of the

cylinder crank case ass’y so that the throttle valve of the carburetor is to be

fully closed condition.

18

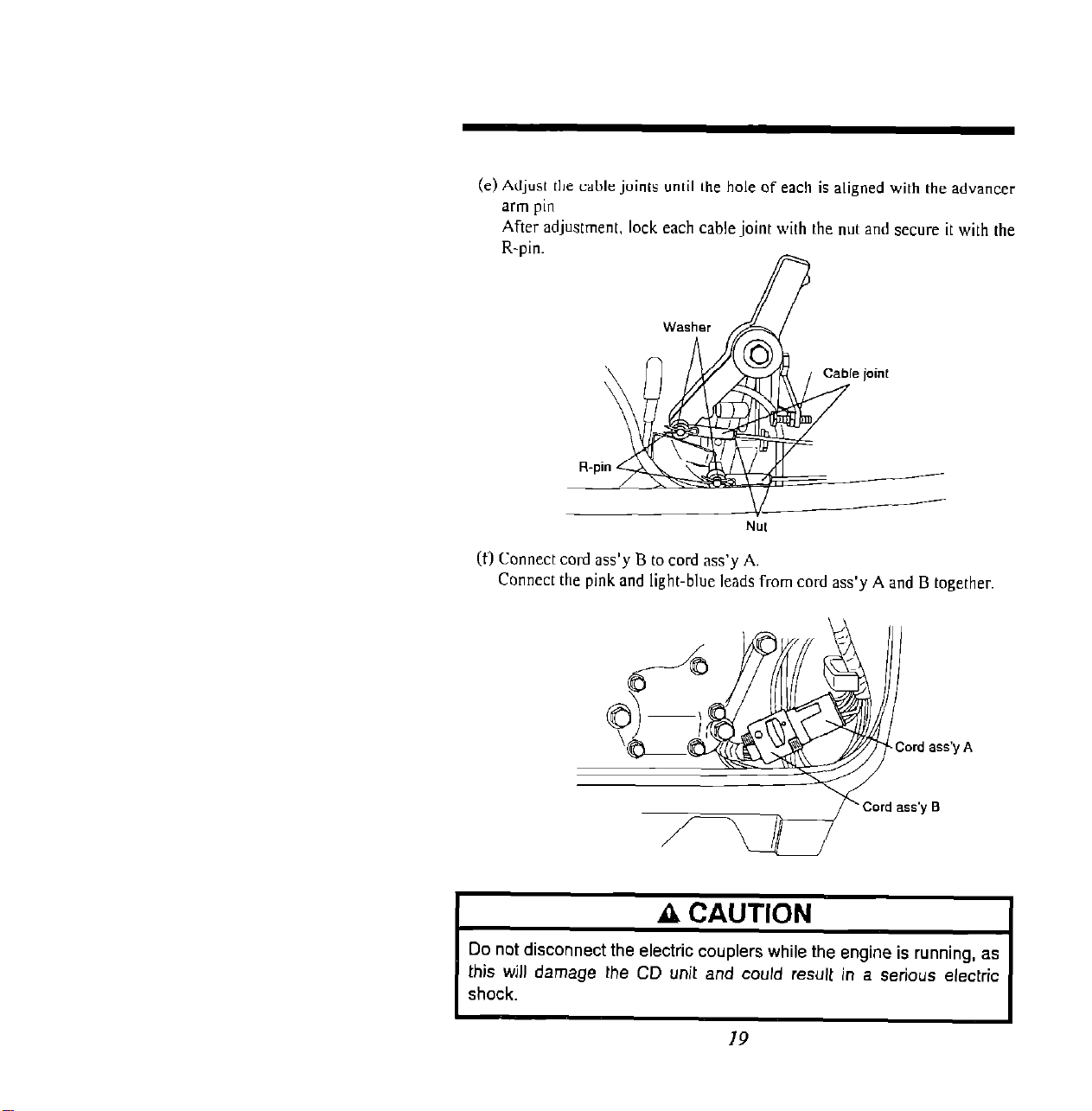

(e) Adjust the cable joints until the hole of each is aligned with the advancer

arm pin

After adjustment, lock each cable joint with the nut and .secure it with the

R-pin.

(f) Connect cord ass’y B to cord ass’y A.

Connect the pink and light-blue leads from cord ass’y A and B together.

A CAUTION

Do not disconnect the electric couplers while the engine is running, as

this will damage the CD unit and could result in a serious electric

shock.

19

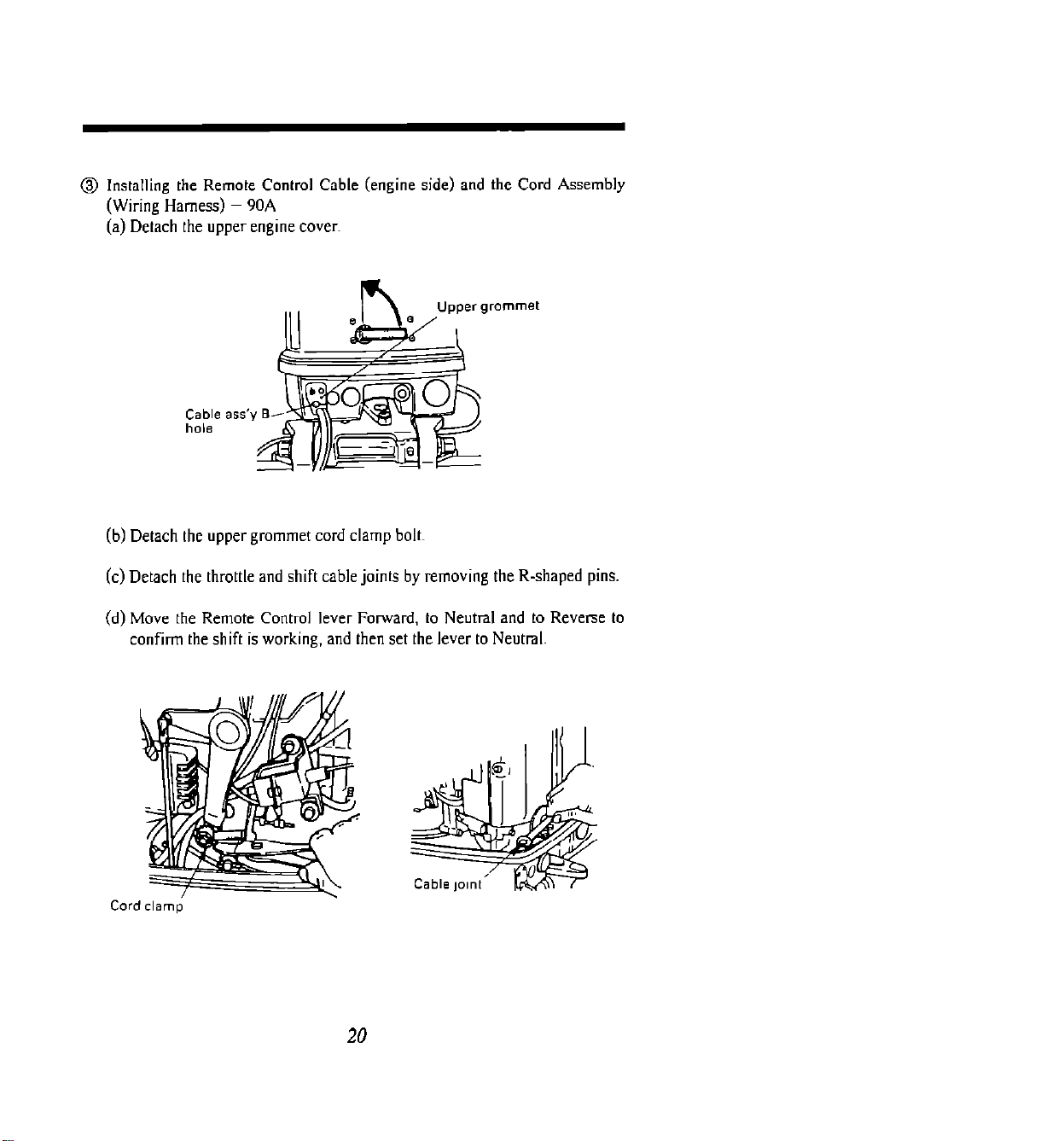

@ Installing the Remote Control Cable (engine side) and the Cord Assembly

(Wiring Harness) - 90A

(a) Detach the upper engine ccwer~

(b) Detach the upper grommet cord clamp bolts

(c)Detach the throttle and shift cable joints by removing the R-shaped pins.

(d) Move the Remote Control lever Forward to Neutral and to Reverse to

confirm the shift is working. and then set the lever to Neutral.

Cord clamp

20

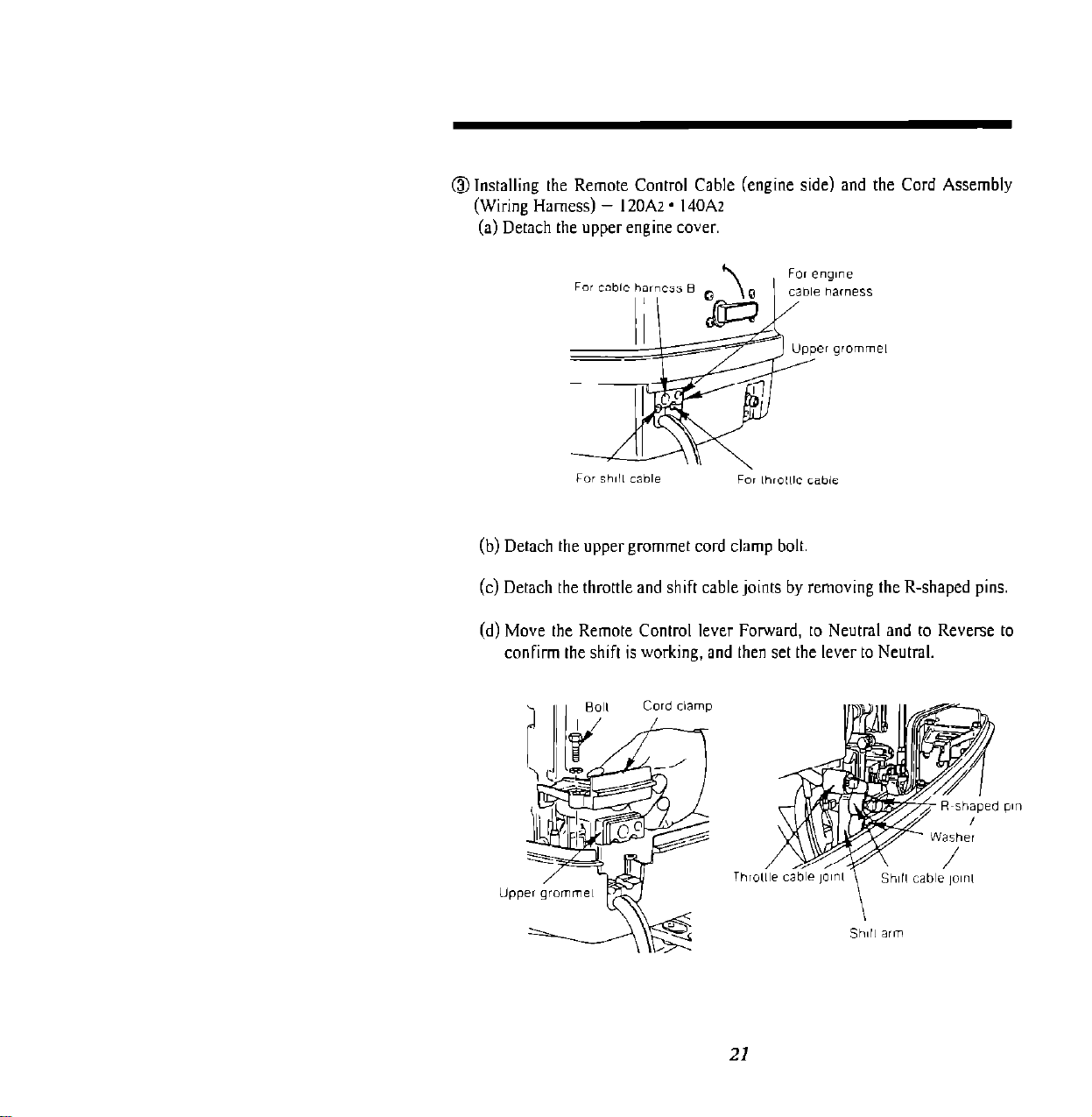

@Installing the Remote Control Cable (engine side) and the Cord Assembly

(Wiring Harness) - l2OA2 * 140A2

(a) Detach the upper engine cover.

(b) Detach the upper grommet cord clamp bolt.

(c) Detach the throttle and shift cable joints by removing the R-shaped pins.

(d) Move the Remote Control lever Forward, to Neutral and to Reverse to

confirm the shift is working, and then set the lever to Neutral.

21

Loading...

Loading...