Toggle TOGL2448EL, TOGL2460EL, TOGL2472EL, TOGL3060EL, TOGL3072EL Assembly Instructions Manual

...

Assembly Instructions

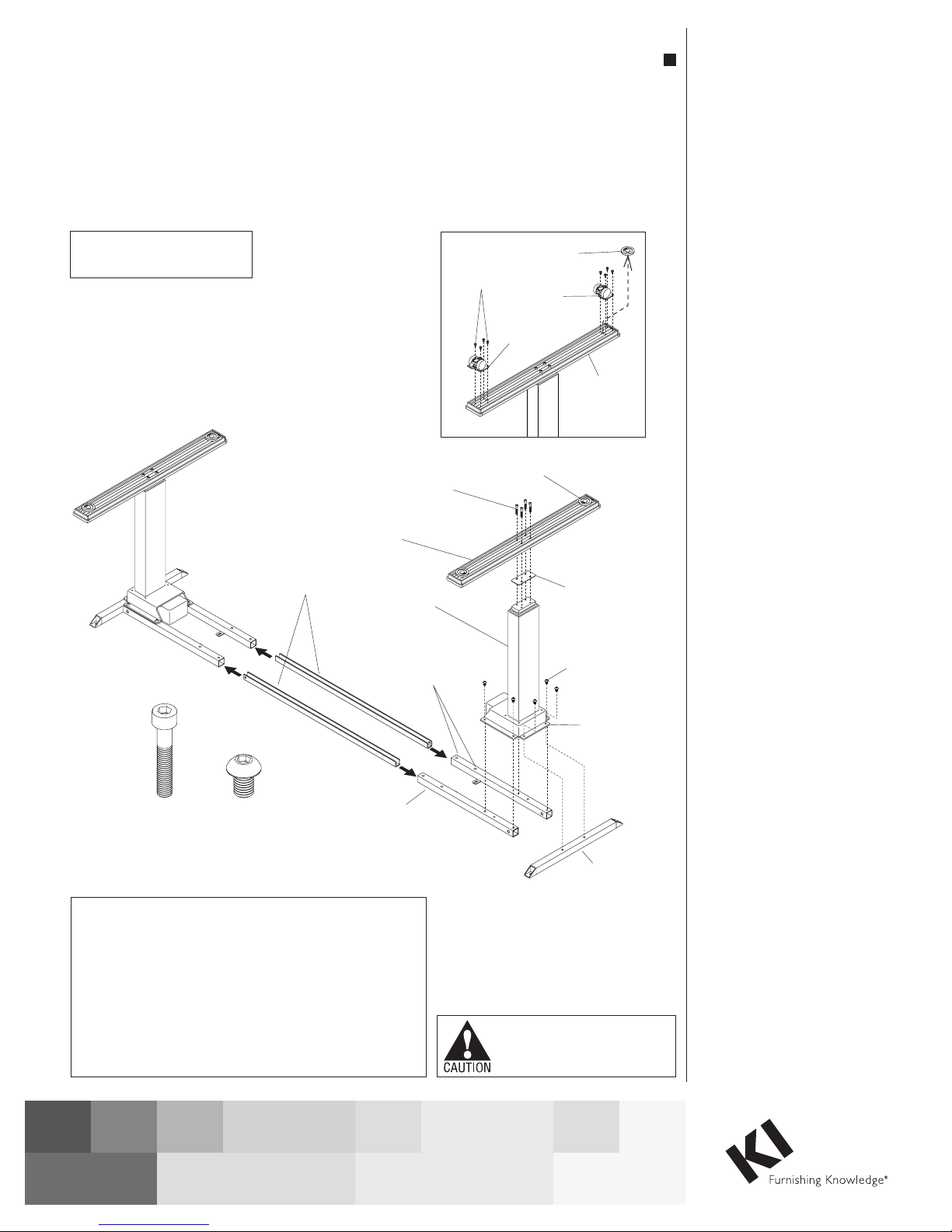

Figure 1

Toggle® Tables

Dual Motor Height Adjustable Base, Model EL

Motor-Operated Furnishing

-FOR COMMERICAL USE ONLY-

M6 x 35

socket head

cap screw

M8 x 12

button-head

machine screw

leg-to-leg

spanners

M6 x 35

socket head

cap screw

foot

leg

column

set screw

holes

cross-support

tube

#10-24 x /

Torx head

screws

Detail A

3

"

8

non-locking

locking

caster

adjustable

caster

glide

April 2017

adjustable

glide

foot

plate

button-head

machine screw

motor housing

end-support

foot

M8 x 12

mounting

flange of

tube

1. Carefully remove contents from

packaging, set out on a soft, clean

surface and refer to Figure 1

to identify the parts required for

assembly.

2. Position two cross-support tubes

(with mounting tabs down and

facing inward), and one

end-support tube out as illustrated.

Place a leg column assembly over

the three tubes, aligning all six

mounting holes on the flange of the

column with the mounting holes on

the three tubes. Using six

M8 x 12 button head machine

screws torqued to 9.5 ft/lbs, secure

the flange of the leg column to the

three base tubes (Figure 1).

3. Mount the foot to the leg column

by first positioning a plastic foot

plate over the mounting location

on the leg column. The plastic foot

plate should be oriented so the

raised flange faces down on the

leg to nest the foot plate in place.

Position a foot over the flat face

of the foot plate, aligning holes

in underside of the foot with the

mounting holes in the column, and

secure foot to column with four

M6 x 35 socket head cap screws.

Torque to 7.5 ft/lbs (Figure 1).

4. If casters are required, twist both

adjustable glides out of the foot.

Locking and non-locking casters

are supplied. Locking casters

should be located toward the

front, user side of the table for

easy access while the non-locking

casters are located to the back.

Using four #10-24 x 3/8” Torx

screws, carefully secure the casters

to the foot (Detail A).

ATTENTION: Following assembly, table must be “zero set”

prior to being placed into service. Failure to do so can cause

table to malfunction.

Table “Zero Setting”: Press and hold the Up button for

two seconds then release. Next, press and hold the Down

button until table has reached its lowest position then release

Down button. Then, press the Down button again and hold for

approximately 10 seconds. The table now re-set at its “Zero

Setting” position and is ready to operate.

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

5. Repeat steps 2 & 3 for second leg

assembly and step 4 if casters are

required (Figure 1).

6. Position two leg-to-leg spanners

with channel opening face up, then

slide both spanners into the open

ends of each base tube of both base

assemblies. Slide bases together,

but do not secure with set screws at

this time (Figure 1).

Toggle® Tables - Dual Motor Height Adjustable Base, Model EL

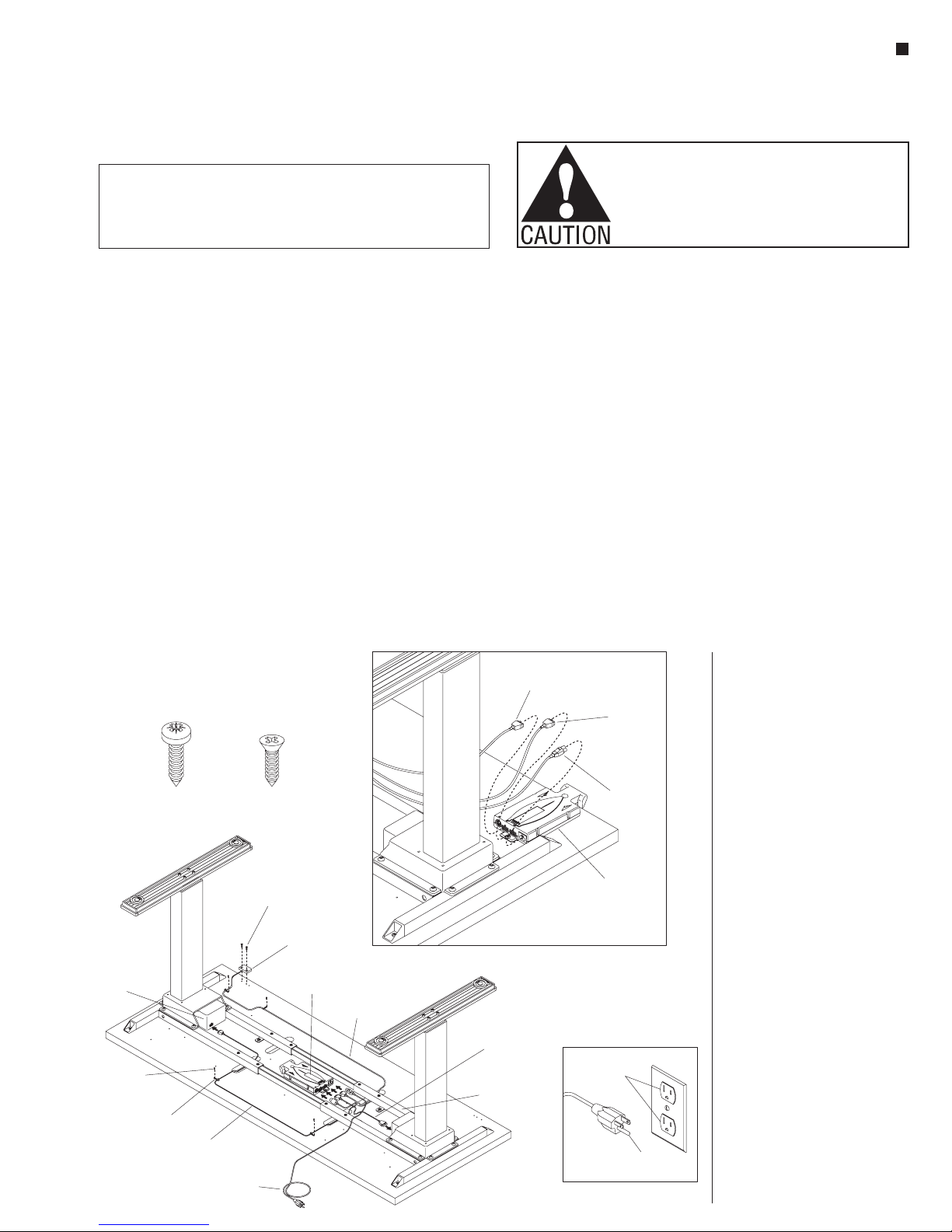

pan head screws

pan head screws

Figure 3 - 30 & 36 Table Depth

””

control

Assembly Instructions

7. Carefully turn table top upside

down on a soft protective surface

and set the base assembly onto

the underside of the top. Position

one base end, so base mounting

holes align with table top

mounting holes, and secure base

to top using four M5.5 x 22 pan

head screws. Slide the other base

end into position to align base

mounting holes to the table top

holes and secure with four

M5.5 x 22 pan head screws.

Insert and tighten eight M10 x 25

set screws as illustrated, through

the cross support tubes and

down to the leg-to-leg spanners.

Torque to 4.5 ft/lbs to secure

(Figure 2).

8. For 24” deep tables, the control

box must be mounted to the

underside of the table top

centered between the cross-tube

assemblies. Position the control

box over the pre-drilled mounting

holes and secure using two

M5.5 x 22 pan head screws

(Figure 2).

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

M5.5 x 22

table top

M10 x 25

set screws

(24 deep)"

Figure 2 - 24 Table Depth”

CAUTION: If Channels (Wire Troughs) are used they are not to be used for routing

extension cords. Power supply cords are not to be routed across or through more

than one complete unit/worksurface.

M5.5 x 22

pan head screws

M10 x 25

set screws

M5.5 x 22

pan head

screws

control

box

leg-to-leg

spanner

9. For 30” & 36” deep tables, the

control box may be mounted

to the underside of the table

top, either at the center of the

top between the cross-tube

assemblies (Figure 2), one of

two locations near the front of

the table (Figure 3), or centered

behind the cross-tube assemblies

(Figure 7). If using one of the two

front locations, the built in switch

on the control box will eliminate

the requirement for the key pad

(Figure 3).

2

M5.5 x 22

M10 x 25

set screws

M5.5 x 22

pan head

screws

table top

(30 or 36 deep)””

M10 x 25

set screws

cross-tube

assembly

M5.5 x 22

pan head screws

box

Toggle Tables - Electric Base

Assembly Instructions

Table Wiring

Note: Control cables can be routed

differently than shown. Illustration is for

reference only (Figure 3).

Note: When plugging leg control cord

ends in, make sure to push in straight to

avoid bending any pins in the electrical

control box or leg motor. The plug will

click when it is locked into place.

Note: If plug needs to be removed,

make sure power cord is un-plugged

from power source outlet first. Then

push down on release tab on the

control cable plug while simultaneously

pulling on the end to remove from the

socket.

1. : Plug the longer legLong Leg Cord

control cord into outer most hole

labeled “1” on control box. ThenLA

route cord to leg farthest from control

box. Use cut outs in table to route under

cross tubes. Plug other end into open

hole on leg motor (Figure 3).

2. The next hole toShort Leg Cord:

the right on the control box will be

utilized by the shorter leg control

cord. Plug short leg cord into control

box at the hole labeled “2” andLA

route to the leg motor socket that is

closest to the control box. Use cut

outs in table to route under the cross

tubes. Plug other end into open hole

on leg motor

(Figure 3).

3. The key pad can beKey Pad:

mounted in two locations. Both

locations are on the front side of

table top and opposite of electronic

control box (Figure 3). Using pre-

drilled holes, secure key pad to table

top with

M4.2 x 19 flat head screws. Once

key pad is mounted, route attached

cord to control box. Use Figure 3 for

cord routing reference and for the

optimal usage of zip tie points. Once

the key pad cord is routed to control

box, plug cord into the smallest hole

on box labeled “”(Figure 3).RC

Note: Make sure all cables are routed

correctly and plugged into correct

holes on control box and leg motor

locations before installing zip-ties.

4. Zip-ties: Included are four zip-ties

for use to keep cords tight to table.

Using Figure 3 for reference, wrap

the zip ties around the loose cords

and then mount the zip-tie to the

table top with a M5.5 x 22 pan head

screw into the pre-drilled holes. The

zip-ties have a built in mounting hole

which has to lay flat onto surface.

Make sure zip-ties and cables are

snug before moving to next step

5. The final cordPower Cord:

installed is the power cord. Plug

power cord into remaining open hole

which is elevated higher on the

control box then the rest. This hole is

labeled “ 110-120V”. Cord shouldAC

not be zip-tied or routed through cut

outs on table (Figure 3). Do not plug

in into power source at this time.

6. With two people, carefully turn

table to the upright position. Adjust

glides on feet to get table level. Plug

Power cord into power source and

test the height adjustable table. If

table is experiencing issues see the

trouble shooting guide in this

instruction.

Detail

GROUNDING INSTRUCTIONS

This product is for use on a nominal 120-volt circuit and has a grounding plug

that looks like the plug illustrated in Detail C. Make sure that the product is

connected to an outlet having the same configuration as the plug. No adapter

should be used with this product.

Table Wiring

Note: Control cables can be routed

differently than shown. 24” deep

tables must have the control box

mounted between the cross-tube

assemblies, which requires

installation of the “optional key pad”

(Figure 4). All 30” & 36” tables may

have the control box mounted either

between the cross-tube assemblies,

at one of the two locations behind

the cross-tube assemblies or one of

two locations at the front of the table

(Detail A). Mounting to the front of

the table does not require the use

of the “optional key pad”. Follow

directions appropriate to control box

mounting location.

Note: When plugging leg control

cord ends in, make sure to push in

straight to avoid bending any pins

in the electrical control box or leg

motor. The plug will click when it is

locked into place.

M5.5 x 22

pan head screws

leg motor

M5.5 x 22

pan head screws

(six)

zip-ties

(six)

leg control cord

(long)

Figure 4

M4.2 x 19

flat head screw

M4.2 x 19

flat head screw

(max torque is 1.5 ft/lbs)

key pad

(optional)

control

box

power

cord

Toggle® Tables - Dual Motor Height Adjustable Base, Model EL

Note: If any plug needs to be

removed, make sure power cord

is un-plugged from power source

outlet first. Then push down

on release tab on the control

cable plug while simultaneously

pulling on the end to remove

from the socket.

1. Leg Cord - Long: Plug the

longer leg control cord into one

of the two rectangular sockets on

the control box, then route cord

to the leg farthest from control

box. Use cut outs in the table

to route under the cross tubes

and/or use zip ties secured with

screws at pre-drilled locations.

Plug other end of the longer leg

control cord into the open socket

on leg motor (Figure 4).

Detail B - 30 & 36 Table with Front Control Box""

key pad

cord

2. Leg Cord - Short: The next

3. Optional Key Pad: The key pad

pre-drilled holes, secure key pad

flat head screws at 1.5 ft/lbs.

leg control cord

(long)

leg control cord

(short)

cross-tube

assembly

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and personal injury.

rectangular socket on the control

box is utilized by the shorter leg

control cord. Plug short leg cord

into control box and route to the

leg motor socket that is closest

to the control box. Use cut outs

in table to route under the cross

tubes. Plug other end of the

shorter leg control cord into open

socket on leg motor (Figure 4).

can be mounted on the front side

of table top (Figure 4). Using

to table top with two M4.2 x 19

Note: Do not overtighten screws.

Once key pad is mounted, route

attached cord to control box. Use

Figure 4 for cord routing reference

leg control cord

(short)

power

cord

control

box

grounded

outlet

grounding

C

pin

Assembly Instructions

and for the optimal usage of

zip-tie points. Once the key pad

cord is routed to control box, plug

cord into the round socket on box

(Figure 4).

Note: Make sure all cables are

routed correctly and plugged into

correct sockets on control box

and leg motor locations before

installing zip-ties.

4. Zip-ties: Six zip-ties are included

for keeping cords tight to table,

but it is not necessary to use all

six. Using Figure 4 for reference,

wrap the zip-ties around the loose

cords and then mount the zip-tie

to the table top with a M5.5 x 22

pan head screw into the

pre-drilled holes. The zip-ties

have a built in mounting hole

which must lay flat onto surface.

Make sure zip-ties and cables are

snug before moving to next step.

5. Power Cord: The final cord to

be installed is the power cord.

Plug power cord into remaining

open socket which is tri-lobe in

shape. Cord should not be

zip-tied or routed through cut outs

on table (Figure 4). Do not plug it

into power source at this time.

6. If optional wire trough was

specified for installation, go now

to page 4. If no wire trough is

specified, carefully turn table to

the upright position with the help

of another person. Adjust glides

on feet to level the table. Plug the

power cord into a grounded outlet

power source (Detail C). Note:

Power cord must have enough

slack so the table can cycle

through its entire range of motion.

7. The table must be “zero set”

prior to being placed into

service. Refer to table “zero

setting” instructions in the

trouble shooting guide on

page 6.

8. If the table is not operating

properly, see the trouble shooting

guide in this instruction.

3

Loading...

Loading...