Todo HS-00808 Instruction Manual

INSTRUCTION MANUAL

PAGE 22: MANUAL DE INSTRUCCIONES PAGE 40: BEDIENUNGSANLEITUNG PAGE 58: MANUEL D’INSTRUCTIONS

Welcome

Bienvenido

Willkommen

Bienvenue

4

ENGLISH

5

ENGLISH

THE MULTI-FUCTIONAL CRAFTING MACHINE

CONTENTS

General Safety Warnings ......................................................... 4

What’s in the Box? .................................................................. 5

Using the TODO™ Machine ..................................................... 6

Embossing with Folders ............................................................ 6

Die Cutting with Dies ............................................................ 7 - 8

Embossing with thin Dies ....................................................... 9

Die Cutting with Thick Dies ....................................................... 10

Letterpressing .......................................................................... 11

Hot Foiling ............................................................................. 12

Top Tips ................................................................................. 14

Settings Guide ........................................................................ 15

Frequently Asked Questions .................................................... 16

Cleaning Instructions / Trouble Shooting .................................. 17

Warranty .............................................................................. 18

Specication ......................................................................... 75

To reduce risk of injury, the user must read

and understand this instruction manual

before using the TODO™ machine. This

appliance is intended for domestic use

as described and in accordance with the

instructions provided in this manual.

Please read these instructions carefully and

retain for future use.

NEVER leave a TODO machine

unattended when in operation or

cooling down.

NEVER lift the TODO machine by the

roller mechanism.

WARNING

6

ENGLISH

GENERAL SAFETY WARNINGS

• Never leave the TODO™

unattended during operation or

whilst cooling.

• Ensure that the TODO heating plate

does not come into contact with

surfaces that may be damaged

through excessive heat.

• Regularly check the cord for

damage. Should the cord be

damaged in any way it must only be

replaced by the manufacturer, their

agent, or a similar qualied person

in order to avoid electric shock.

• Regularly check the unit, but do not

switch it on if it appears damaged

or is operating incorrectly. Do not

attempt to carry out any repairs to

the unit in any way, repairs must be

carried out by a suitably qualied

technician. There are no userserviceable parts inside.

• This appliance is not intended for

use by children or persons with

reduced physical, sensory or mental

capabilities, or lack of experience

and knowledge, unless they are

supervised by a person responsible

for their safety. Children should

not be allowed to play with the

appliance.

• Close supervision is necessary when

children are around and be aware

that units can be pulled off work

surfaces or similar areas by the

unwary.

• Never allow the cord to touch wet or

hot surfaces, become twisted or be

within the reach of children or

animals.

• Always allow the unit to cool before

attempting to move it and never

reposition or move the unit by

pulling the cord.

• Do not use this appliance for

anything other than the intended use.

• Unplug from socket when not in use

• or before cleaning.

• Pull on the plug, not the cord.

• Warning - This machine heats up to

approx. 80°C. When using metal

dies they will conduct heat and

therefore, become hot. Be careful

when removing metal dies from

the heating plate. Allow to cool for

30 minutes before

removing metal plates with your

hands. Alternatively, TODO offers

accessories such as silicone mat and

handling device.

• Do not immerse the TODO machine

or heating plate in water.

• Do not touch the heating plate of

the TODO machine with your hand

during operation.

• Do not overload the power socket.

• Never lift the TODO machine by the

roller mechanism.

7

ENGLISH

CONGRATULATIONS on purchasing

your TODO™ machine. TODO is the

ultimate paper crafting tool, which

inspires you to create boundless works

of art. The TODO machine is packed

full of possibilities, it’s a revolution.

From hot foiling, die cutting to

embossing and letterpressing, it frees

the paper artist within you.

This multi-functional crafting machine

works with a wide range of materials.

It is suitable for beginners to advanced

paper crafters and delivers outstanding

results.

WHAT’S IN THE BOX?

TODO™ Main Unit

Power Cable

Removable Heating Plate

3 x Cutting Mats (A/B/D)

1 x Embossing Mat (C)

Silicone Mat

Die Removal Tool

8

ENGLISH

USING THE TODO™ MACHINE

Work on a solid stable surface. Place the machine on a suitable rm, at and

substantial work surface, at a height that is comfortable for easy operation.

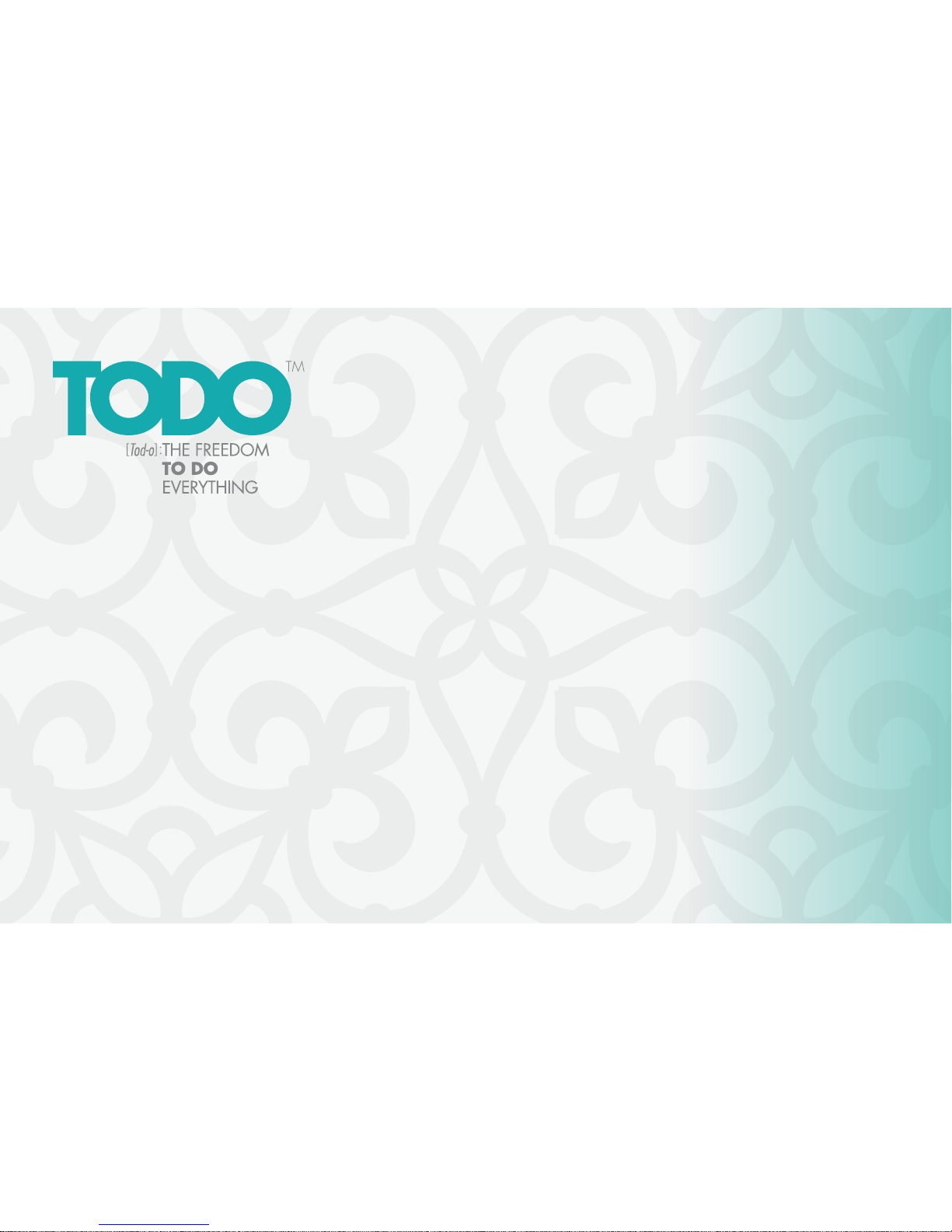

EMBOSSING WITH FOLDERS

An embossing folder is designed to give a plain piece of card a beautifully crisp

embossed design. There are many on the market, but these instructions will work

for all standard embossing folders.

1. Ensure the roller mechanism is to the side of the machine.

2. Place your C Plate on top of the base plate

3. Place your card inside your embossing folder and place your embossing folder

onto the C Plate.

4. Place your B Plate on top of the folder.

5. Adjust the pressure. The exact pressure will depend on the manufacturer of the

folder and the weight of material inside the folder. See settings table on page

15 for guidelines.

6. Turn the handle until the roller mechanism has gone over the complete folder.

7. Roll the mechanism to the opposite end of the machine, or back to the start and

remove the folder and card from the machine.

NOTE: You may feel the pressure increase slightly as the rollers go over the embossing folder. This

is supposed to happen. However, if you feel that you are having to force the rollers over the folder

reverse the rollers and reduce the pressure on the machine before trying again. DO NOT reset dial

during operation, always reverse the roller back before resetting the dial.

TIP: Try experimenting with different materials in

your embossing folders. Acetate, vellum and

chipboard can all be embossed to create

different looks. Just remember to adjust the

pressure for the different materials.

9

ENGLISH

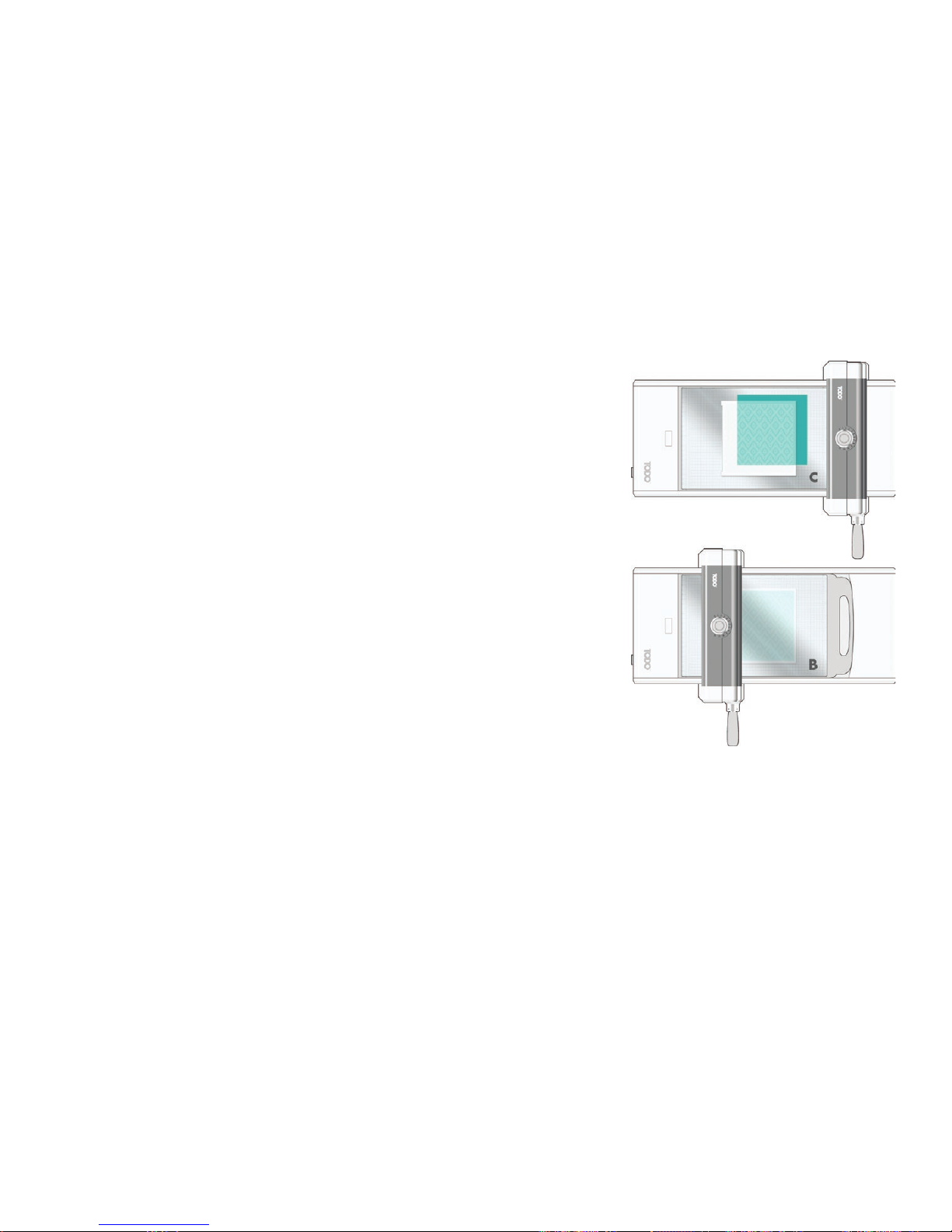

DIE CUTTING WITH DIES

There are a huge number of dies on the market that will work with your TODO™

machine. Here we will look at using Thin Metal Dies. Different brands and

thicknesses of dies will need different pressure. Please refer to the Setting Guide

for guidelines on using other types of die with your machine.

1. Ensure the roller mechanism is to the side of the machine.

2. Place your A Plate on top of the base plate

3. Place your die on the A Plate.

4. Place your material to be cut over your die and then your B Plate on top.

5. Adjust the pressure. The exact pressure will depend on the manufacturer of the

die and the weight of material. See settings table on page 15 for guidelines.

6. Turn the handle until the roller mechanism has gone over the complete die.

7. Roll the mechanism to the opposite end of the machine, or back to the start and

remove the die and card from the machine.

NOTE: You may feel the pressure increase slightly as the rollers go over the die. This is supposed to

happen. However, if you feel that you are having to force the rollers over the die reverse the rollers

and reduce the pressure on the machine before trying again. DO NOT reset dial during operation,

always reverse the roller back before resetting the dial.

NOTE: You will hear a cracking noise as the rollers go over the die; this is the die being pressed

through the card and into the cutting plate and is perfectly normal, although it can be alarming to hear

it the rst time. You will also see marks appearing on your cutting plate – this is all part of the cutting

process and is supposed to happen.

10

ENGLISH

DIE CUTTING WITH INTRICATE DIES

There will be some dies that are more difcult to cut than others. When you

experience this we recommend substituting the B plate for the D plate. The D plate

has a smaller surface area so the pressure can be focussed more on the dies area

and thinner so the roller is closer to the die itself.

1. Ensure the roller mechanism is to the side of the machine.

2. Place your A Plate on top of the base plate

3. Place your die on the A Plate.

4. Place your material to be cut over your die and then your D Plate on top.

5. Adjust the pressure. The exact pressure will depend on the manufacturer of the

die and the weight of material so you may need to adjust the dial up or down

to get the perfect pressure.

6. Turn the handle until the roller mechanism has gone over the complete die.

7. Roll the mechanism to the opposite end of the machine, or back to the start and

remove the die and card from the machine.

NOTE: You may feel the pressure increase slightly as the rollers go over the die. This is supposed to

happen. However, if you feel that you are having to force the rollers over the die reverse the rollers

and reduce the pressure on the machine before trying again. DO NOT reset dial during operation,

always reverse the roller back before resetting the dial.

NOTE: You will hear a cracking noise as the rollers go over the die; this is the die being pressed

through the card and into the cutting plate and is perfectly normal, although it can be alarming to hear

it the rst time. You will also see marks appearing on your cutting plate – this is all part of the cutting

process and is supposed to happen.

TIP: Due to the increased pressure you may nd

your D plate bends. To reduce the risk of this

occurring, alternate the side of the plate that gets

cut after each use.

11

ENGLISH

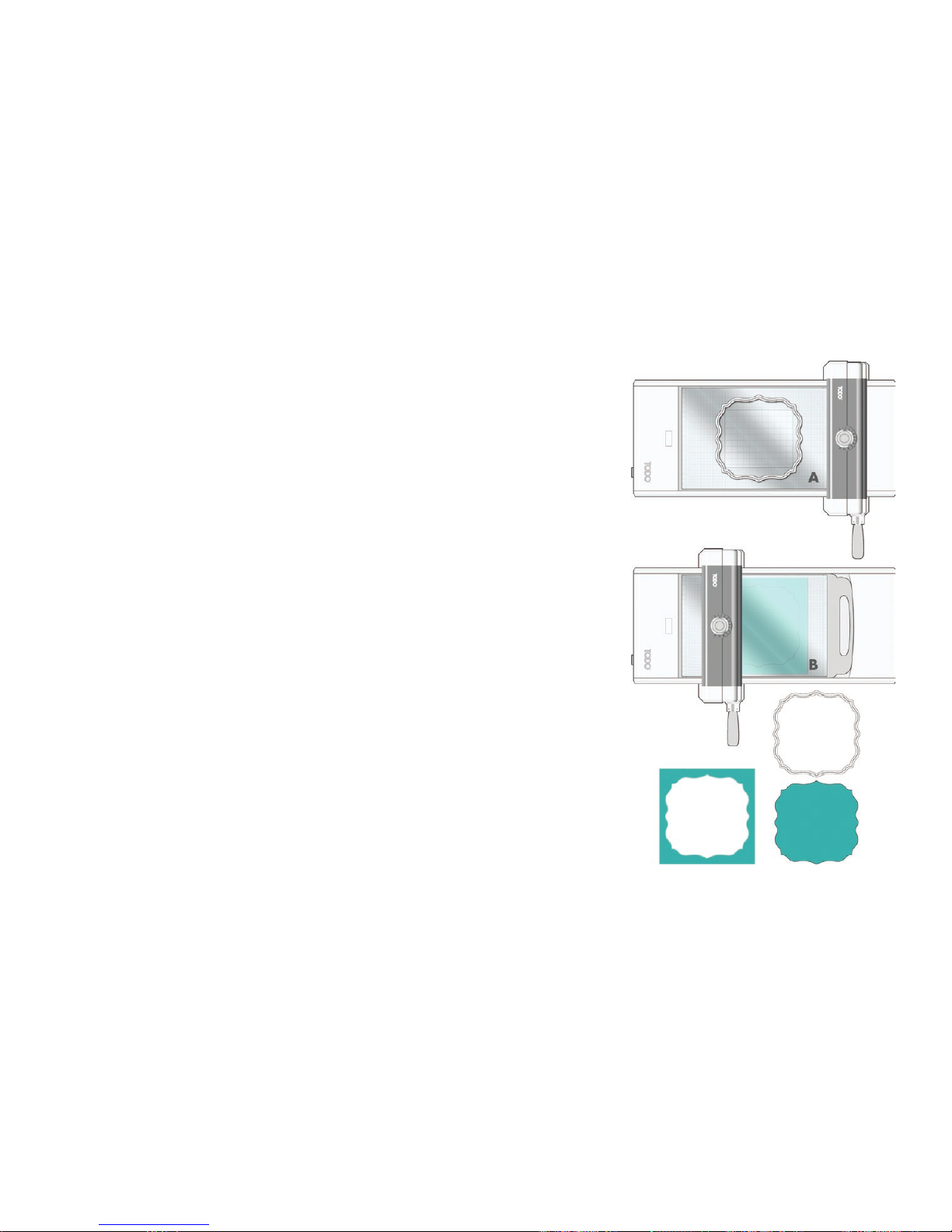

EMBOSSING WITH THIN DIES

Some thin dies have intricate detail that need to be embossed into the card. There

are many of these dies on the market, but these instructions will work for all

standard embossing dies.

1. Ensure the roller mechanism is to the side of the machine.

2. Place your A Plate on top of the base plate

3. Place your die on the A Plate.

4. Place the card to be embossed over your die with your C Plate on top.

5. Place your D Plate on top of the C Plate.

6. Adjust the dial FOUR INCREMENTS higher than the nomal cutting level for

the D plate (this will be the same increase if using the B plate instead). The

exact pressure will depend on the manufacturer of the die and the weight of

material so you may need to adjust the dial up or down to get the perfect

pressure.

7. Turn the handle until the roller mechanism has gone over the complete die.

8. Roll the mechanism to the opposite end of the machine, or back to the start and

remove the die and card from the machine.

NOTE: You may feel the pressure increase slightly as the rollers go over the die. This is supposed to

happen. However, if you feel that you are having to force the rollers over the die reverse the rollers

and reduce the pressure on the machine before trying again. DO NOT reset dial during operation,

always reverse the roller back before resetting the dial.

TIP: Due to the increased pressure you may nd

your D plate bends. To reduce the risk of this

occurring, alternate the side of the plate that gets

cut after each use.

12

ENGLISH

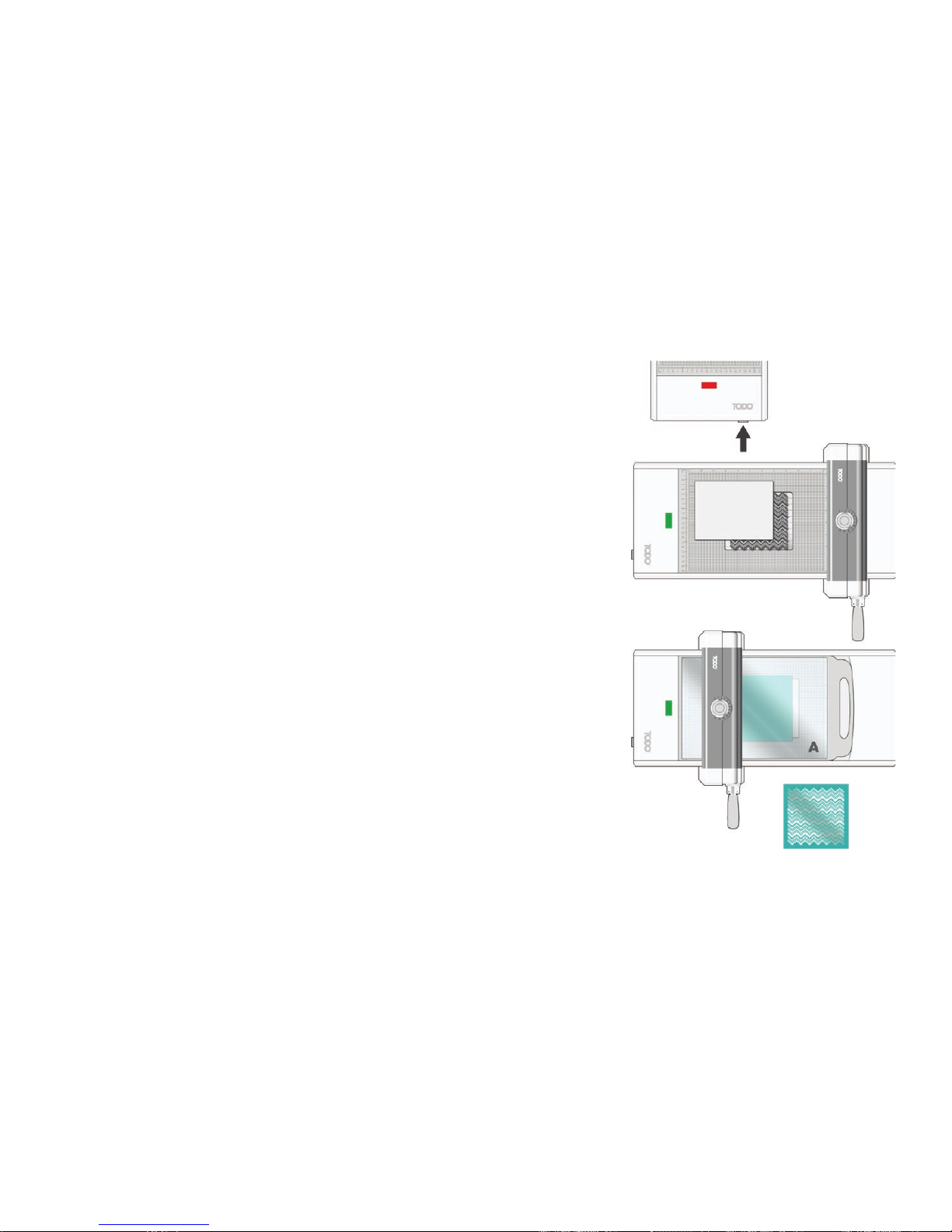

DIE CUTTING WITH THICK DIES

On rare occasions you may nd that the ‘Die Cutting with Dies’ instructions may

not work for thicker dies. In these situations the base plate insert can be removed.

The actual pressure needed to cut will vary depending on the actual die and the

weight of material that you are using, these instructions are for guidelines only.

1. Ensure the roller mechanism is to the end of the machine with the power

indicator light.

2. Take out the base plate insert, using the handle to lift it out.

3. Place the A plate into the base of the unit.

4. Place the die onto the A plate.

5. Place your material to be cut over your die and then your B plate on top.

6. Adjust pressure. The exact pressure will depend on the manufacturer of the die

and the weight of material. See settings table on page 15 for guidelines.

7. Turn the handle until the roller mechanism has gone over the complete die.

8. Roll the mechanism to the opposite end of the machine, or back to the start and

remove the die and card from the machine.

NOTE: You may feel the pressure increase slightly as the rollers go over the die. This is supposed to

happen. However, if you feel that you are having to force the rollers over the die reverse the rollers

and reduce the pressure on the machine before trying again. DO NOT reset dial during operation,

always reverse the roller back before resetting the dial.

NOTE: You will hear a cracking noise as the rollers go over the die; this is the die being pressed

through the card and into the cutting plate and is perfectly normal, although it can be alarming to hear

it the rst time. You will also see marks appearing on your cutting plate – this is all part of the cutting

process and is supposed to happen.

13

ENGLISH

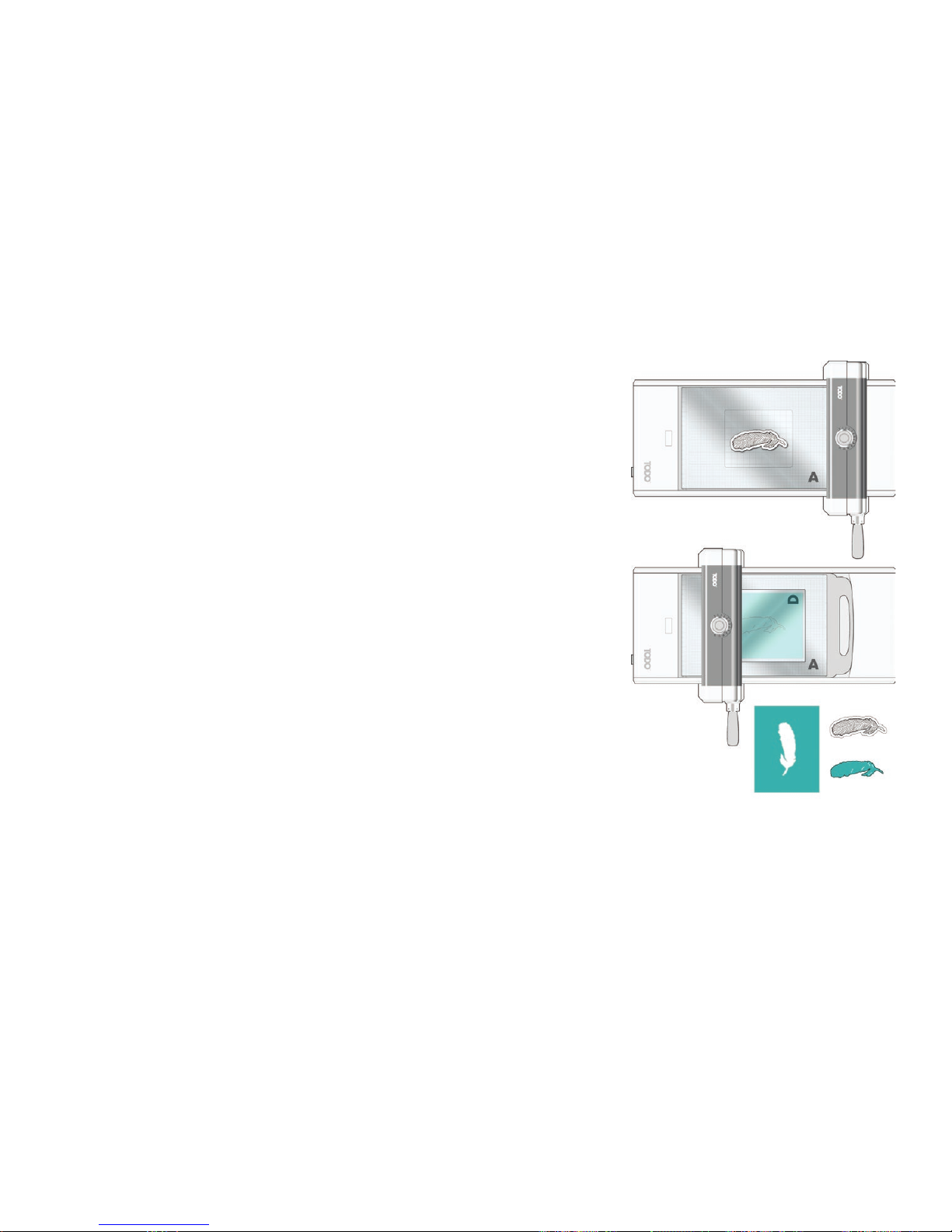

LETTERPRESSING WITH TODO™

Letterpress printing is traditionally a technique of relief printing using a printing

press. With your TODO machine you can use this centuries-old technique to

create some amazing crafty nishes.

There are two ways to use your multi-purpose stamps for letterpressing. You can

either use them plain to create a debossed impression on your cardstock, or you

can ink them to create a coloured and debossed impression on your cardstock.

Both of these techniques use the same method with your machine.

1. Ensure the roller mechanism is to the side of the machine.

2. Place your letterpress stamp anywhere on the base plate.

3. Place your card on top of the stamp and then place your C & A Plate on top

of the card.

4. Adjust the pressure. The exact pressure will depend on the manufacturer of the

stamp and the weight of material. See settings table on page 15 for guidelines.

5. Turn the handle until the roller mechanism has gone over the complete stamp.

6. Roll the mechanism to the opposite end of the machine, or back to the start and

remove the stamp and card from the machine.

NOTE: You will feel the pressure increase slightly as the rollers go over the stamp. This is supposed to

happen. However, if you feel that you are having to force the rollers over the stamp, reverse the rollers

and reduce the pressure on the machine before trying again. When letterpressing, if you add too

much pressure to your stamp it will cut the card. This isn’t a problem, other than you have to repeat the

process.

TIP: Pigment ink works best with your letterpress

stamps as other inks such as solvent-based will

dry too quickly on the stamps. Distress Inks will

give you a textured effect due to the ink bobbling

on the surface of the stamps.

14

ENGLISH

HOT FOILING WITH TODO™

Foil stamping is the application of metallic foil to paper where a heated die is

stamped onto the foil, making it adhere to the surface to leave the design of the

die on the paper. This technique has never been simpler now that you have your

TODO machine!

To hot foil you will need to switch on your TODO machine. When you switch it on

the centre metal panel on the base plate will slowly heat up. This takes

approximately 10-12 minutes to get to temperature (the indicator light will light up

green when the plate is at the correct temperature).

1. Ensure the roller mechanism is to the side of the machine.

2. Flick the switch to the on position to start the machine warming.

3. When the green indicator light is illuminated, place your foiling stamp onto the

metal panel in the centre of the plate.

WARNING: The foiling stamp will become hot very quickly. Always avoid touching

this with your ngers, use tool provided as explained on next page.

4. Place your foil on top of the stamp – the foil needs to go coloured side towards

the stamp – and place your material for foiling on top of this. Place your A

Plate over the top.

5. Adjust the pressure. The exact pressure will depend on the manufacturer of the

stamp and the weight of material. See settings table on page 15 for guidelines.

6. Turn the handle until the roller mechanism has gone over the complete stamp.

Roll the mechanism to the opposite end of the machine, or back to the start and

remove the stamp and material from the machine.

15

ENGLISH

HOT FOILING WITH TODO™ CONTINUED...

ALWAYS turn your TODO machine off immediately after you have nished

foiling. The plate will take approximately 30 minutes to cool down in order for

you to continue working with the machine.

TIP: Experiment with different materials with your foiling, don’t be afraid to try things like corduroy or

mount board. Remember the thicker the item you are foiling, the less pressure you will need on your

machine.

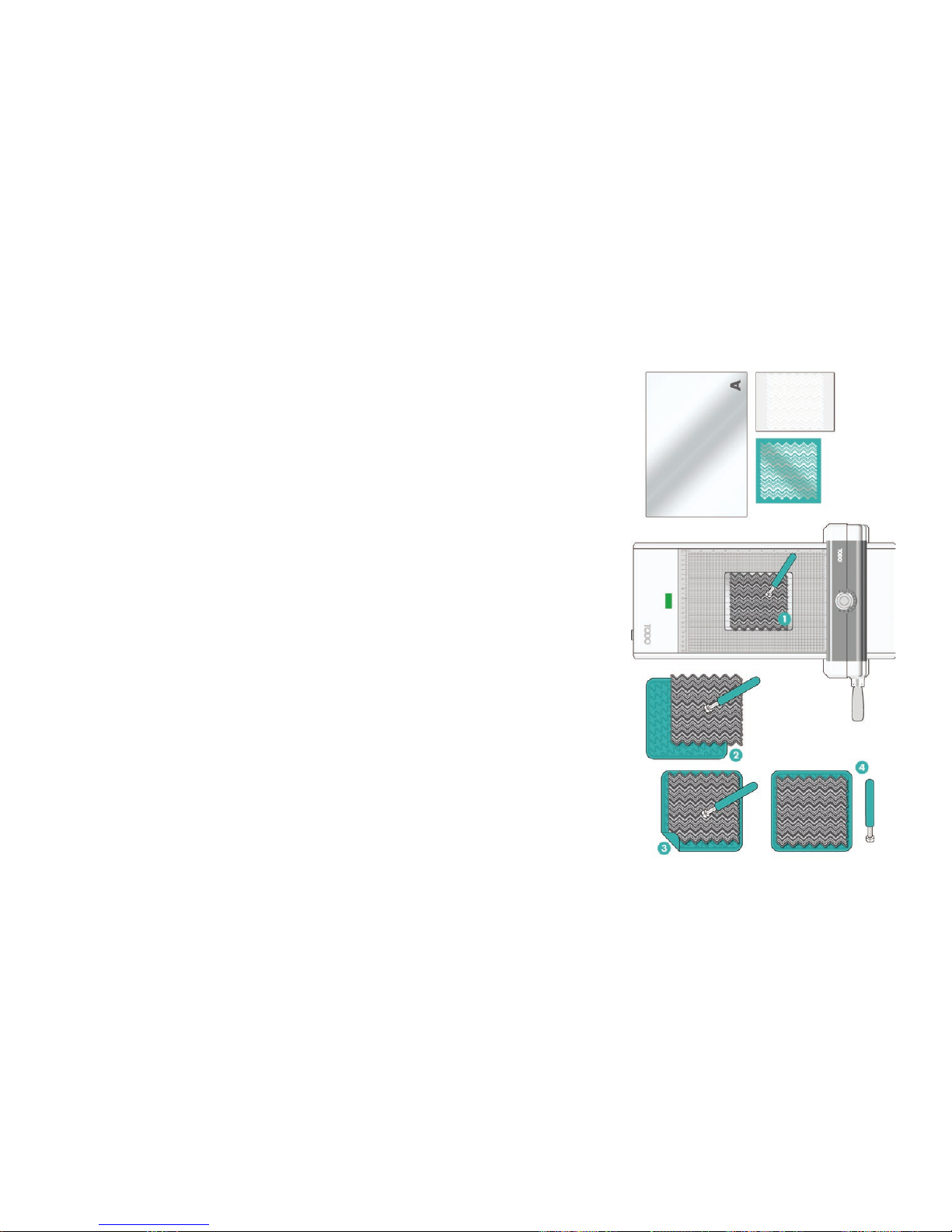

DIE REMOVAL TOOL

A die removal tool and silicone mat has been provided to remove the hot foiling

stamp from the base plate in order to change designs or reposition; do not use

your ngers.

Using the silicone end to hold the die removal tool, position the tool over the hot

foiling stamp so that the magnetic end securely holds the stamp in place. Once in

position, the removal tool will use the magnet on it’s metal base to hold the stamp

or die in position.

Place the hot foil stamp on the silicone mat and carefully remove the tool from the

stamp. Some of the smaller/thinner stamps might be difcult to release from the

magnet. To assist with this, fold over the corner of the silicone mat with your nger

and thumb, using a pinching motion release the stamp from the magnet.

Leave the hot foil stamp on the silicone mat until it has cooled down.

DO NOT TOUCH THE HOT DIES WITH YOUR FINGERS.

16

ENGLISH

TOP TIPS

• Store dies in dry conditions to avoid degradation of the metal.

• Shim between dies when storing to avoid scratching of the printing surface.

• Keep foils stored on the roll to avoid creasing or tearing as this will affect the resulting print.

• Pre-cut your paper to size to reduce waste.

• Fabric-topped ink pads apply ink better than sponged-topped ink pads.

• Blotting your ink pad applies ink more evenly and accurately than wiping it across the plates.

• Inking in small steps around the edge, from one side to the other provides a more effective and neater application of the

ink.

• Wipe off any excess ink with a damp paper towel or cotton swab. This helps prevent ink from getting into unwanted

spaces when you letterpress.

• Don’t be afraid to experiment with more than one colour of ink. Start by inking your plate with the lightest colour rst to

avoid contamination of your ink pads.

• Use up those negative patterns left behind on the foil. Turn one of the larger hot foil stamps so the pattern is facing down

and lay the foil on to this. Then place card over the top and run the TODO roller over the plate. You may get some hot

spots, but generally it’s really good.

• Why not try foiling over foil. This technique creates real impact!

• We recommend letterpressing / hot foiling one plate at a time. This will ensure you achieve the optimum results each time.

• Always ensure the card covers the foil to avoid residue on plates.

• Always alternate between sides when using the cutting plates. This will prolong the life of your plates and help to keep

their shape longer.

17

ENGLISH

SETTINGS GUIDE

TYPE PLATE SETTING

EMBOSSING

Folder C & B 5-8

DIE CUTTING

Thin Metal Dies* A & B 6-8

Complex (Intricate) Thin Metal Dies A & D 4-6

Thin Foam Topped Dies A 2-3

Thick Foam Topped Dies A & B† 3-5

HOT FOILING

TODO™ Hot Foil & Letterpress Stamp A 2-3

LETTERPRESSING

TODO™ Hot Foil & Letterpress Stamp C & A 6-8

NOTE: The weight of the material that you are using will determine the exact amount of pressure that

you need to use. For example, with paper or vellum you may need to increase the pressure, but with

a thicker card, such as 250gsm or 300gsm you may need to reduce the pressure down by one or two

settings to account for the extra thickness within the sandwich.

NOTE: If you have any difculties moving the roller over the sandwich, it may be caused by an

incorrect combination of plates or dial setting. Position the roller back to its starting position and check

your plate combination and/or try a different dial setting. Forcing the roller over an incorrectly stacked

sandwich will cause damage to your machine and will void the warranty.

† Remove Base Plate Insert / *Some complex dies may require an additional shim

DO NOT PUSH THE ROLLER HOUSING,

ALWAYS USE THE HANDLE TO MOVE THE

ROLLER BACK AND FORWARD.

NEVER LIFT THE TODO MACHINE BY THE

ROLLER MECHANISM.

ADJUST THE PRESSURE

0 = CLOSED ROLLERS

12 = FULLY OPEN ROLLERS

18

ENGLISH

FREQUENTLY ASKED QUESTIONS

My settings seem very different to those on the settings guide table.

The settings are wide to allow for all different thicknesses of materials. It is advisable to start in the middle of the range, so

you can adjust either way. If you have tried a variety of settings and you are not achieving the desired results please contact

your retailer.

What weight of cardstock works well with TODO™?

Around 180gsm to 240gsm works well and uncoated is fabulous!

I’m having difculty achieving a good Die Cut with TODO?

1. Try to run the die through twice and also rotate it. You will feel by the pressure of the machine.

2. D plate can replace the B plate in your cutting sandwich. This has a smaller surface area so the pressure is more focussed

on the Die itself.

3. Some of the more complex dies may need additional shim; Try placing a metal shim under the base plate in the well of the

machine. Note: The metal shim cannot be too thick so as to avoid damaging the electrical point.

I’m having difculty achieving a good hot foil nish with TODO?

1. Ensure that you wait for the machine indicator light to turn green. This should take approximately 10-12 minutes. If for

some reason the machine fails to heat up/turns green quicker than expected return the machine to your retailer.

2. Put the selected hot foil stamp onto the hot plate to warm up; this will ensure the heat has distributed through your chosen

stamp. Run the TODO roller over the hot foil sandwich – take your time to allow the foil to adhere properly to your media.

3. Ensure the foils used are compatible with the TODO machine and ensure they are not creased of damaged as this will

affect your results.

Can I emboss thin dies with embossed detail?

You can emboss and cut by adding your C plate to your normal cutting sandwich (between the card and the B/D plate). You

will need to increase your normal cutting level by 4 increments to allow for the extra height. E.g - A thin die normally cut at a

roller height of 4.5 should be increased to 8.5 after adding the C plate.

19

ENGLISH

CLEANING INSTRUCTIONS

To clean dies and plates use mild soapy water and a sponge. Make sure to dry the dies and plates thoroughly. Do not sub-

merge the machine or heating plate into water. Do not use abrasive cloths or scourers to clean the dies or plates.

For safety, after use, store out of reach of children.

TROUBLE SHOOTING

Unit doesn’t turn on

Check product is plugged in at the wall.

Check socket is working using an alternative product that is known to work.

Check fuse in the plug and replace if unsure (UK ONLY).

Plate doesn’t heat up

Check the unit is switched on at the wall and the heat dial is on. Ensure heating plate is correctly connected. If issue continues return the unit.

Roller doesn’t go to the end

Either change the setting on the dial or reduce the size of the sandwich, so it runs over the plate. Note: DO NOT change the

dial setting mid-way throughoperating.

Trouble adjusting the pressure dial

Ensure the roller has been rolled to either end of the unit, the roller cannot be adjusted mid-way – especially if it is still under

pressure. Note: The dial cannot be pushed down unless it is in line with either a whole or half number.

20

ENGLISH

HELP THE ENVIRONMENT

Your appliance contains valuable materials which can be recovered or recycled.

When you decide to replace your appliance, leave it at a local civic waste

collection point. For more detailed information about recycling of this product,

please contact your local Council, your household waste disposal service or the

shop or source where you purchased the product.

Due to our Policy of continuous development, the actual product may differ slightly

from the one illustrated in these instructions and on the packaging.

WARRANTY

TODO™ comes with a limited one year warranty. TODO is warranted to be free

of defects in workmanship and materials. Ideal Sourcing Ltd will replace a

defective product or parts without charge with proof of purchase. If the product is

damaged due to misuse or neglect the warranty is null and void.

For Customers in the following regions, return faulty items to:

UK CUSTOMERS US CUSTOMERS

Ideal Sourcing Ltd Notions Marketing Corporation

1 Sabre Way 1500 Buchanan S.W.

Peterborough Grand Rapids

PE1 5EJ MI 49507

This device complies with part 15 of the FCC

Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

NOTE: This equipment has been tested and

found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable

protection against harmful interference in a

residential installation. This equipment generates,

uses and can radiate radio frequency energy

and, if not installed and used in accordance with

the instructions, may cause harmful interference

to radio communications. However, there is no

guarantee that interference will not occur in a

particular installation. If this equipment does

cause harmful interference to radio or television

reception, which can be determined by turning

the equipment off and on, the user is encouraged

to try to correct the interference by one or more

of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the

equipment and receiver.

• Connect the equipment into an outlet on a

circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/TV

technician for help.

22

ESPAÑOL

23

ESPAÑOL

LA MÁQUINA DE ARTESANÍA MULTIFUNCIÓN

CONTENIDOS

Advertencias de seguridad generales ........................................ 24

¿Qué hay en la caja? ............................................................. 25

Utilización de la máquina TODO™........................................... 26

Grabado en relieve con cubiertas ............................................. 26

Corte con troqueles ............................................................ 27-28

Grabado en relieve con troqueles nos ...................................... 29

Corte con troqueles gruesos ..................................................... 30

Impresión tipográca con TODO™ ........................................... 31

Estampado en caliente con TODO™ ....................................32-33

Consejos principales ............................................................... 34

Guía de ajustes ...................................................................... 35

Preguntas más frecuentes ......................................................... 36

Instrucciones de limpieza / Resolución de problemas .................. 37

Garantía ............................................................................... 38

Especicaciones ..................................................................... 75

Para reducir el riesgo de lesiones, el

usuario debe leer y comprender este

manual de instrucciones antes de utilizar

la máquina TODO™. Este aparato está

concebido para uso doméstico tal como se

describe y de acuerdo con las instrucciones

proporcionadas en este manual.

Por favor, lea estas instrucciones

atentamente y consérvelas para un uso

futuro.

NO DEJE nunca una máquina

TODO sin atender cuando esté en

funcionamiento o enfriándose.

NO ELEVAR NUNCA la máquina

TODO por el mecanismo de rodillos.

ADVERTENCIA

Loading...

Loading...