Page 1

Medium Duty Counterline

INSTALLATION - OPERATION - MAINTENANCE

Griddle Models TMDG-24, TMDG-36

(shown) and TMDG-48

Charbroiler Models TMDC-24,

TMDC-36 (shown) and TMDC-48

Open Top Models TMDO-12,

TMDO-24 and TMDO-36 (shown)

Middleby Philippines Corporation

113 Technology Ave., Laguna Technopark Inc., Binan, Laguna, Philippines 4024

Phone (632) 5208170 - Fax (632) 5208191 - www.middleby.com

~

MANUAL MDC 0804-MDO-MDC

Page 2

SAFETY PRECAUTIONS

Before installing and operating this equipment, be sure everyone involved in its operation is fully trained and

aware of precautions. Accidents and problems can be caused by failure to follow fundamental rules and

precautions.

The following symbols, found throughout this manual, alert you to potentially dangerous conditions to the

operator, service personnel, or to the equipment.

DANGER

WARNING

CAUTION

NOTICE

This symbol warns of immediate hazards that will result in serve injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in

injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in

injury, product damage, or property damage.

This symbol refers to information that needs special attention or must be fully

understood, even though not dangerous.

WARNING

FIRE HAZARD

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

Keep area around appliances free and clear of combustibles.

Purchaser of equipment must post in a prominent location, detailed instructions to be followed in

the event the operator smells gas. Obtain the instructions from the local gas supplier.

Be sure this Operator’s Manual and important papers are given to the proper authority to retain

for future reference.

Toastmaster

WARNING

Asphyxiation can result from improper ventilation. Do not obstruct the flow of combustion and

ventilation air to and from your cooking equipment.

NOTICE

®

PAGE 2

Page 3

MEDIUM DUTY COUNTERLINE

Congratulations! You have purchased one of the finest pieces of commercial cooking equipment on the

market.

You will find that your new equipment, like all Toastmaster equipment, has been designed and manufactured to meet the toughest standards in the industry. Each piece of toastmaster equipment is carefully

engineered and designs are verified through laboratory tests and field installations. With proper care and

field maintenance you will experience years of reliable, trouble-free operation. For best results, read

this manual carefully.

TABLE OF CONTENTS

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Table of Contents

Specifications 4

Installation 9

Operation 12

Cleaning 14

Adjustments 16

Troubleshooting 18

Parts 21

Read these instructions carefully before attempting installation. Installation and initial startup should be

performed by a qualified installer. Unless the installation instructions for this product are followed by a

qualified service technician (a person experienced in and knowledgeable with the installation of commercial gas an/or electric cooking equipment) then the terms and conditions on the Manufacturer’s Limited

Warranty will be rendered void and no warranty of any kind shall apply.

In the event you have questions concerning the installation, use, care, or service of the product, write to:

MIDDLEBY COOKING SYSTEM

Philippine Factory : 113 Technology Ave., Laguna Technopark, Binan

Laguna, Philippines, 4024 * Tel. Nos. (632) 520-8170 to 79 Fax No.: (632) 520-8191

USA Factory : 1400 Toastmaster Drive, Elgin, IL 60120 Tel. (847) 741-3300

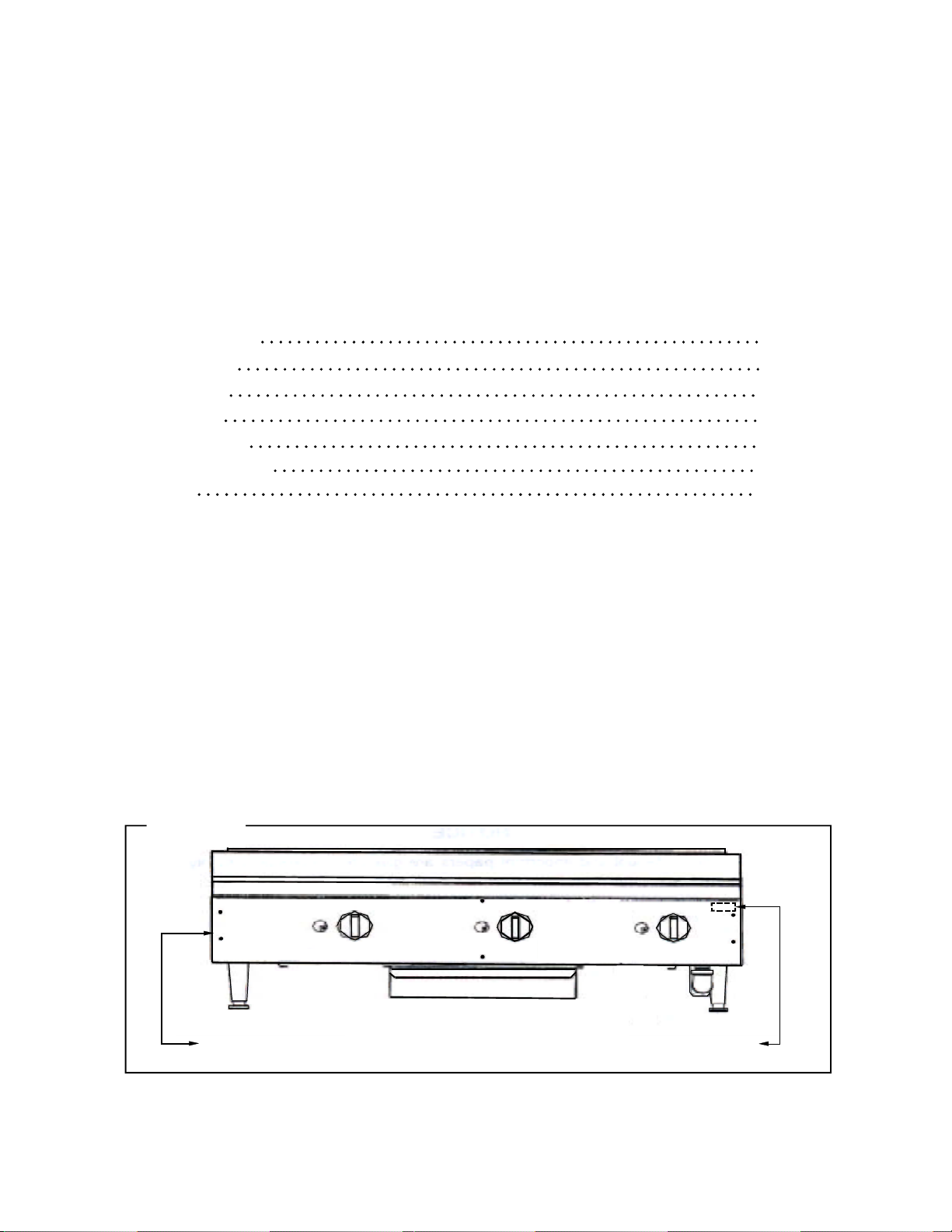

The serial plate is located on the interior side of the valve panel, as shown below:

~

Figure 1

PAGE3

Serial plate is located on the outer left side and upper right side of front panel

Toastmaster

®

Page 4

SPECIFICATIONS

MEDIUM DUTY COUNTERLINE

SPECIFICATIONS

NOTICE

Installation must comply with National Fuel Gas Code, ANSI Z223.1, Natural Gas Installation Code,

CAN/CGA-B149.1, or the Propane Instalation Code, CAN/CGA-B149.2, as applicable.

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association, Inc. states in its NFPA 96 latest edition that local codes are the “authority” having

jurisdiction” when it comes to installation requirements for equipment. Therefore, installations should

comply with all locals codes.

Toastmaster reserves the right to change specifications and product design without notice. Such

revisions do not entitle the buyer to corresponding changes, additions, or replacements for previously purchased equipment.

This product is intented for commercial use only, not for household use.

GAS SUPPLY

The Serial Plate is located on the interior side of the valve panel (see Figure 1 on page 3). It indicates the

type of gas the unit is equipped to burn. All Toastmaster equipment is adjusted at the factory. Check type

of gas on serial plate.

These models are design-certified for operation on natural or propane gases. The unit is shipped configured for natural gas. A kit for conversion to using propane gas is included (see instructions in kit or page 9

of this manual).

This appliance should be connected ONLY to the type of gas for which it is configured.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas

required for satisfactory performance. Fluctuations of more than 25% on natural gas or 10% on propane

gas will create problems and affect burner operating characteristics. A 1/8” pressure tap is located on the

manifold to measure the manifold pressure.

An adequate gas supply line to the unit should be no smaller than the inside diameter of the pipe from the

unit to which it is connected.

Purge the supply line to clean out dust, dirt, or other foreign matter before connecting the line to the unit.

All pipe joints and connections must be tested thoroughly for gas leaks. Use only soapy water for testing

on all gases. NEVER use an open flame to check for gas leaks. All connections must be checked for

leaks after the unit has been put into operation. Test pressure should not exceed 14” W.C.

CAUTION

THIS APPLIANCE AND ITS INDIVIDUAL SHUTOFF VALVE MUST BE DISCONNECTED FROM

THE GAS SUPPLY PIPING SYSTEM DURING ANY PRESSURE TESTING OF THAT SYSTEM

AT TEST PRESSURES IN EXCESS OF 1/2 PSIG (3.45 kPa).

THIS APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY CLOSING ITS INDIVIDUAL MANUAL SHUTOFF VALVE DURING ANY PRESSURE TESTING OF THE

GAS SUPPLY PIPING SYSTEM AT TEST PRESSURES EQUAL TO OR LESS THAN 1/2 PSIG

(3.45 kPa).

SPECIFICATIONS

Toastmaster

®

PAGE 4

Page 5

MEDIUM DUTY COUNTERLINE

SPECIFICATIONS

CLEARANCES

WARNING

There must be adequate clearance between units and adjacent construction. Clearance must also

be provided for servicing and for operation.

Minimum Clearances from COMBUSTABLE construction:

Griddle Models Open Top Models

Sides 4” 6”

Back 4” 6”

Bottom 4” 6”

Minimum Clearances from NON-COMBUSTABLE construction:

Griddle Models Charbroiler Models Open Top Models

Sides 0” 4” 0”

Back 0” 4” 0”

Bottom 4” 4” 4”

VENTILATION

WARNING

Improper ventilation can result in personal injury or death. Ventillation which fails to propely remove

flue products can cause headaches, nausea, or could result in death.

All units must be installed in such a manner that the flow of combustion and ventilation air are not

obstructed. Provisions for adequate air supply must be provided. Do not obstruct the front of the

unit at the top by the control panel as combustion air enters these areas.

NOTICE

Proper ventillation is the owner’s responsibility. Any problem due to improper ventilation will not be

covered by the warranty.

All units must be installed in such a manner that the flow of combustion and ventillation air are not obstructed. Provisions for an adequate air supply must be provided. Do not obstruct the front or rear of the

unit, as combustion air enters through this area. Be sure to inspect and clean the ventillation system

according to the ventillation equipment manufacturer’s instruction.

In case of unsatisfactory performance on any appliance, check the appliance with the hood exhaust fan in

the “OFF” position. Do this only long enough to check equipment performance. Then turn the fan back on

and left it run to remove any exhaust that may have accumulated during the test.

SPECIFICATIONS

PAGE 5

Toastmaster

®

Page 6

SPECIFICATIONS

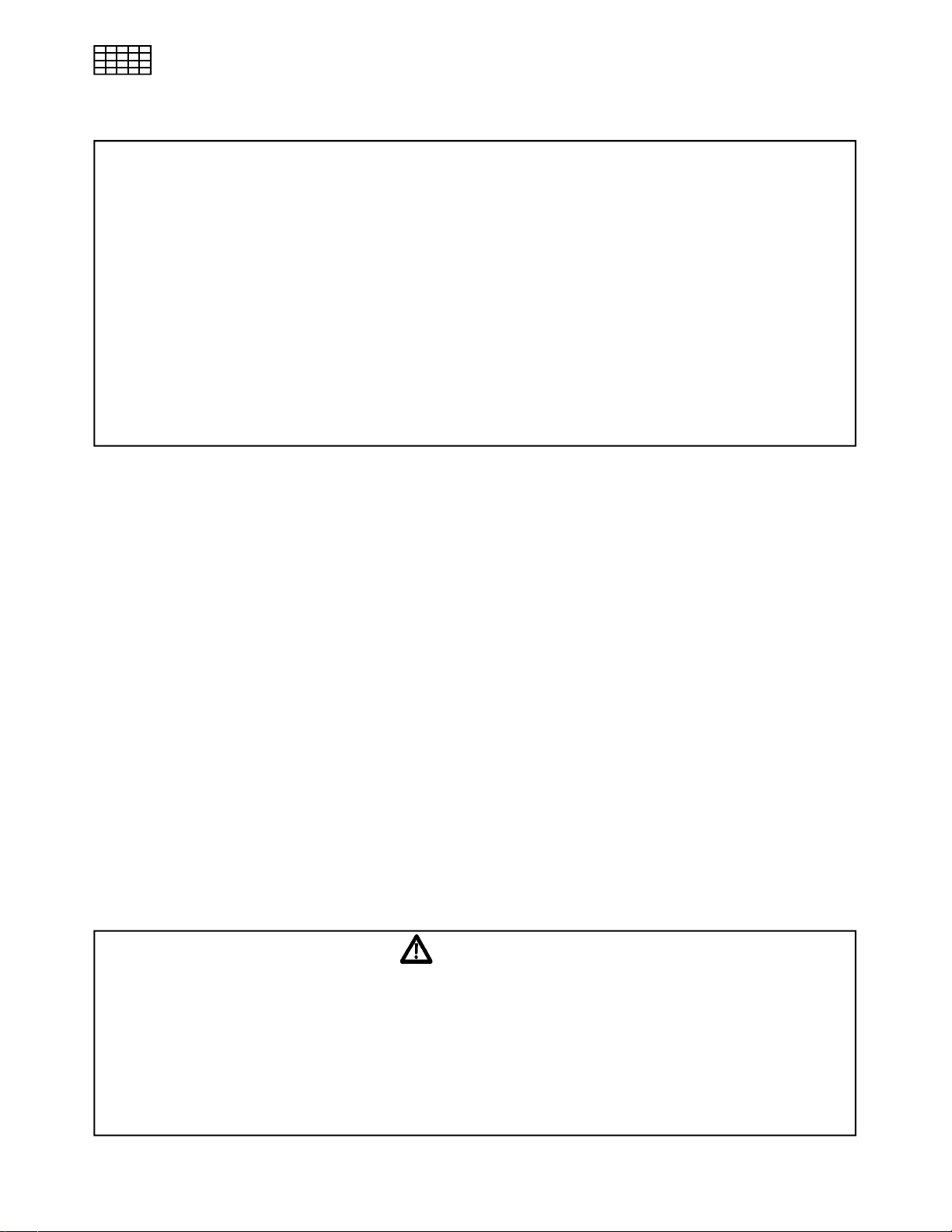

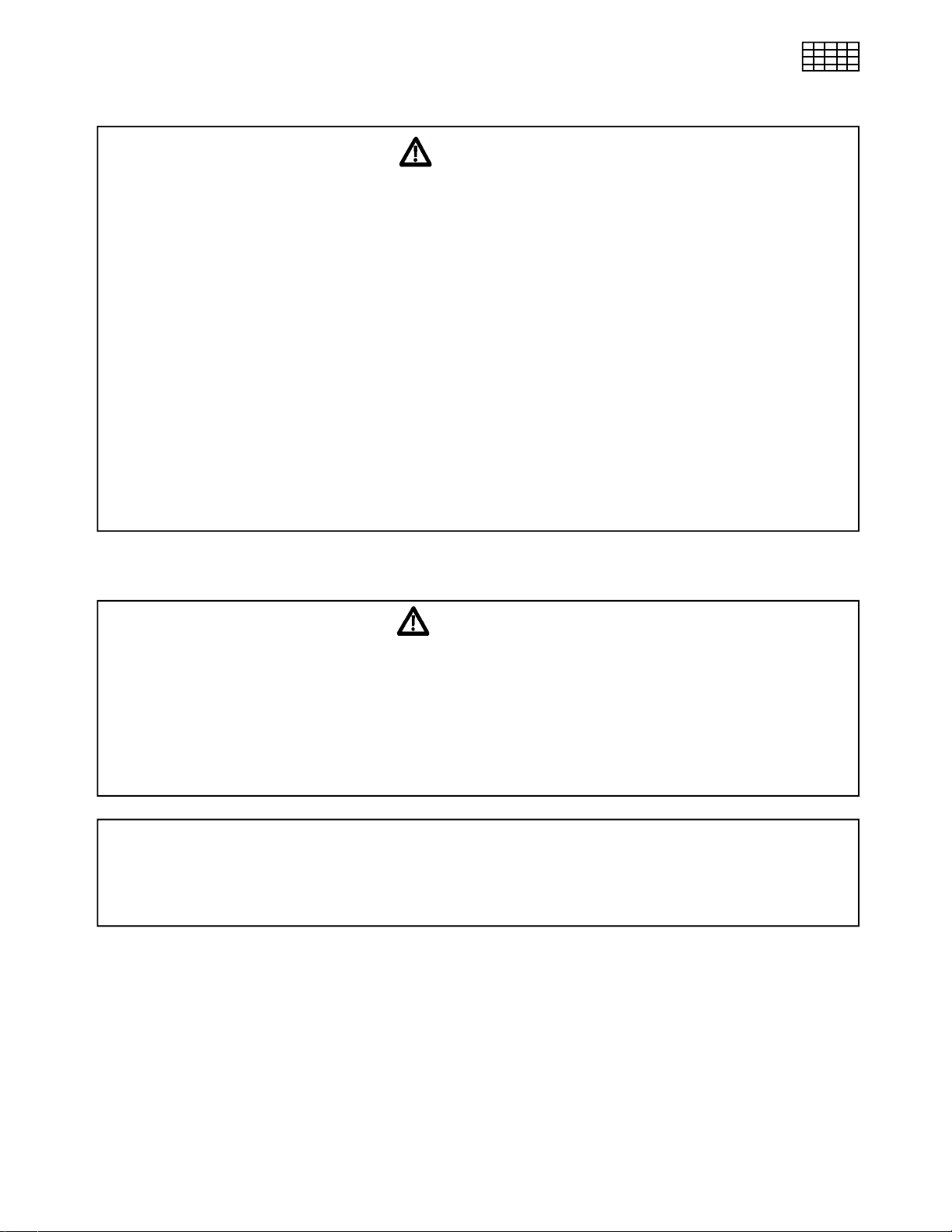

Figure 2

DIMENSIONS OF GRIDDLE

MEDIUM DUTY COUNTERLINE

Toastmaster

TMDG-24

TMDG-36

TMDG-48

®

Model

“A” (Width) Number and Size of Burners

24”

36”

48”

2@30,000

3@30,000

4@30,000

Total BTU

60,000

90,000

120,000

SPECIFICATIONS

PAGE 6

Page 7

MEDIUM DUTY COUNTERLINE

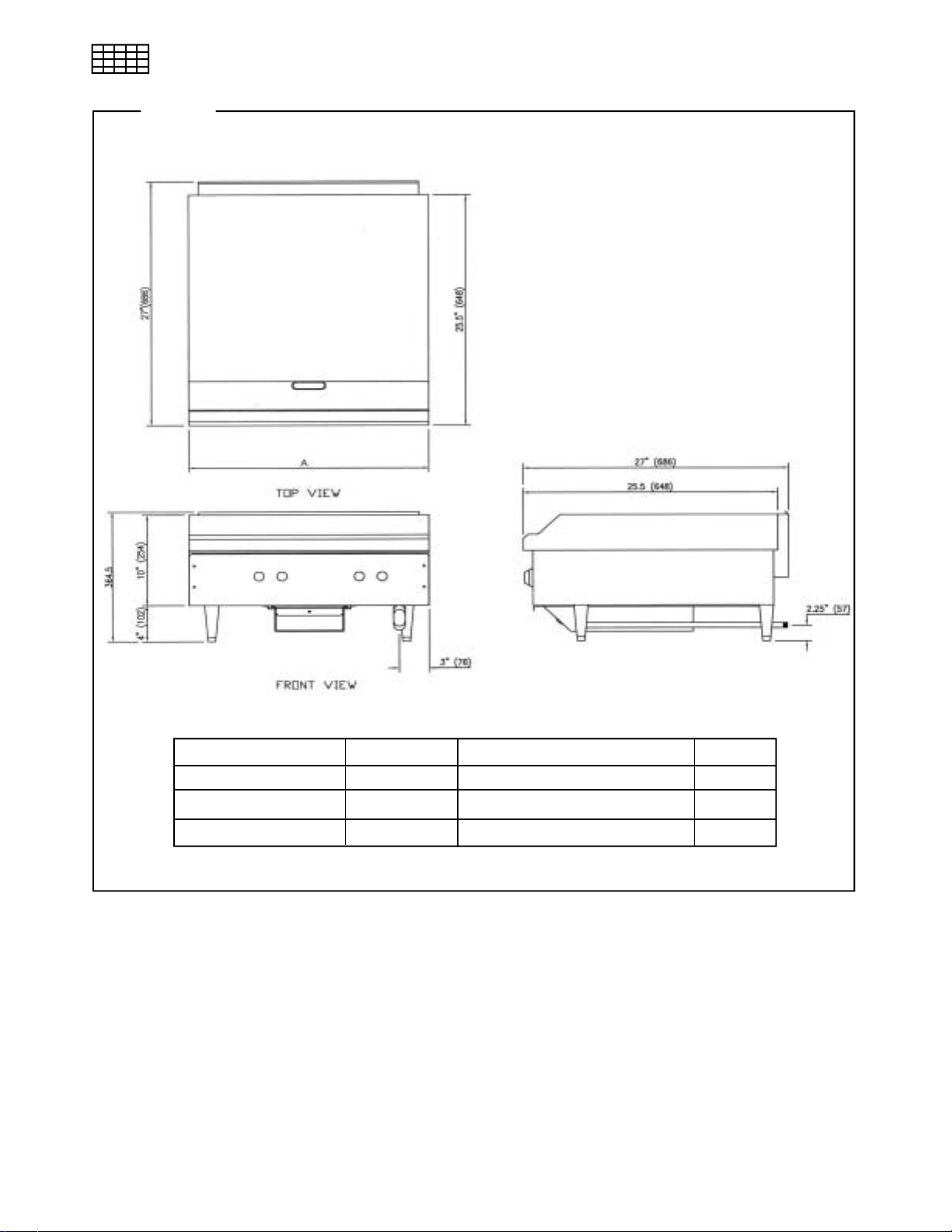

Figure 3

DIMENSIONS OF CHARBROILER MODELS

SPECIFICATIONS

SPECIFICATIONS

PAGE 7

Model

TMDC-24

TMDC-36

TMDC-48

“A” (Width) Number and Size of Burners

24”

36”

48”

2@30,000

3@30,000

4@30,000

Total BTU

60,000

90,000

120,000

Toastmaster

®

Page 8

SPECIFICATIONS

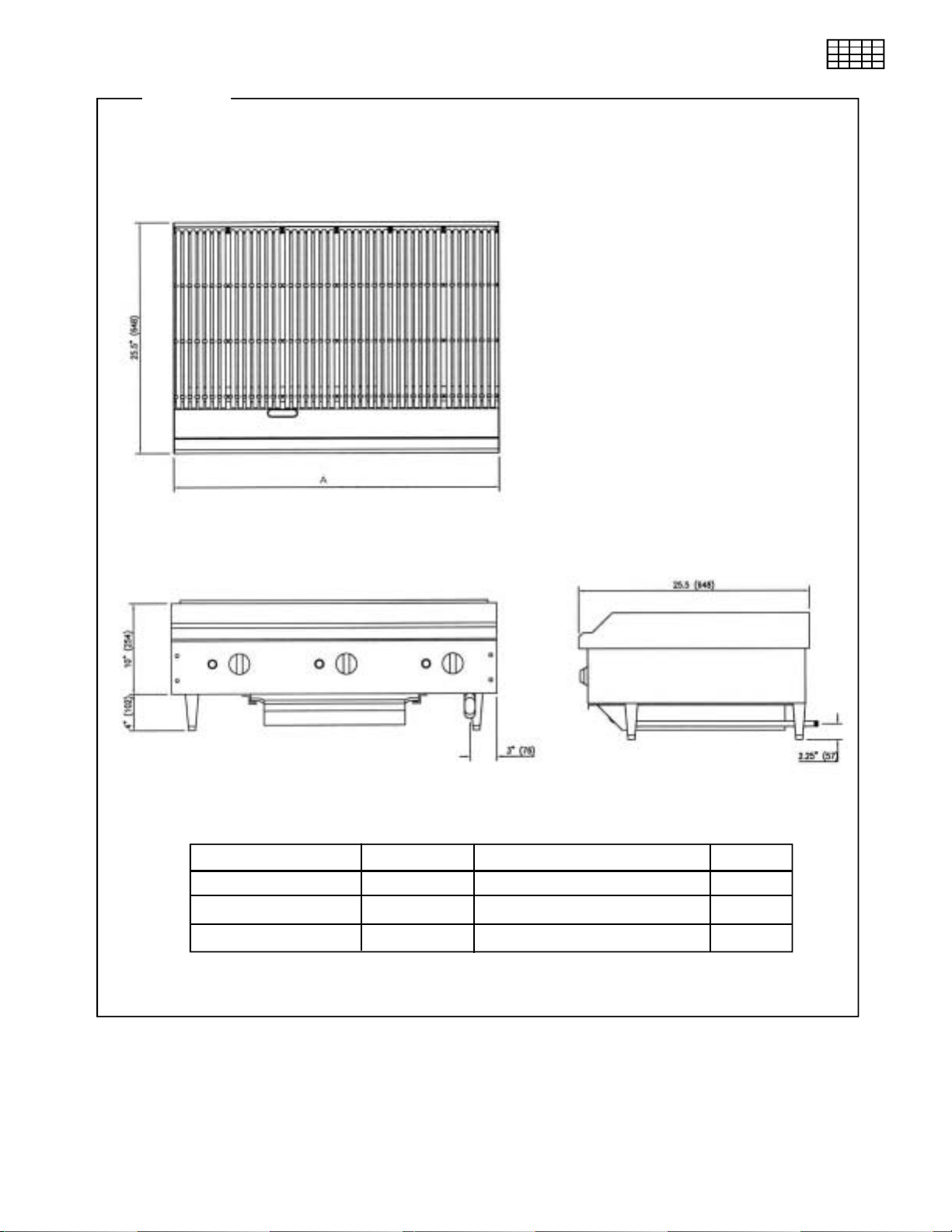

Figure 4

DIMENSIONS OF OPEN TOP MODELS

MEDIUM DUTY COUNTERLINE

Toastmaster

Model

TMDO-12

TMDO-24

TMDO-36

“A” (Width) Number and Size of Burners

12.25”

24.375”

36.50”

2@20,000

4@20,000

6@20,000

Total BTU

40,000

80,000

120,000

SPECIFICATIONS

®

PAGE 8

Page 9

EDIUM DUTY COUNTERLINE

M

Installation

INSTALLATION

NOTICE

Installation must comply with National Fuel Gas Code, ANSI Z223.1, Natural Gas Installation Code,

CAN/CGA-B149.1, or the Propane Instalation Code, CAN/CGA-B149.2, as applicable.

These installation procedures must be followed by qualified personnel or warranty will be void.

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association, Inc. states in its NFPA 96 latest edition that local codes are the “authority having

jurisdiction” when it comes to installation requirements for equipment. Therefore, installations should

comply with all locals codes.

Step 1: Unpack

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If damaged equipment is received, either

apparent or concealed, a claim must be made with the delivering carrier.

Apparent damage or loss must be noted on the freight bill at the time of delivery. The freight bill must

then be signed by the carrier representative (Driver). If the bill is not signed, the carrier may refuse

the claim. The carrier can supply the necessary forms.

A request for inspection must be made to the carrier within 15 days if there is concealed damage or

loss that is not apparent until after the equipment is uncrated. The carrier should arrange an inspection. Be certain to hold all contents plus all packing material.

1. Uncrate carefully. Report any hidden damage to the freight carrier IMMEDIATELY.

2. Do not remove any tags or labels until unit is installed and working properly.

Step 2: Convert Unit to Use Propane Gas (if necessary)

Each unit is shipped equipped with fixed orifice hoods appropriate for use with natural gas. If propane gas

will be used, convert the unit for use with propane gas by the following procedure:

1. Remove the front panel by removing the knobs and screws on the front.

2. For charbroiler and open top models, remove the grates and burners to access the orifices from

above. For griddle models, slide the burner toward the rear of the unit to access the orifices (see

diagram on page 22), OR remove the griddle plate to access the orifices by removing two nuts at the

rear of the unit.

3. Remove the natural gas orifices and install the furnished propane orifices.

4. Re-install the burners.

5. Re-install the front panel.

6. Remove the hex-threaded plug from the pressure regulator. Inside is a removable insert. Pull the

insert out, turn it around, and put it back in so that the end with the letters “LP” is now facing you.

INSTALLATION

Re-attach the hex-threaded plug. The pressure regulator is now set for 10” (25.4cm) water column.

7. Check the pressure.

PAGE 9

Toastmaster

®

Page 10

INSTALLATION

Provided orifices are size #45 for natural gas and #55 for propane gas. For special gas mixtures, and for

altitudes above 2,000 feet, consult factory for appropriate orifice sizes.

MEDIUM DUTY COUNTERLINE

Step 3: Connect Gas Supply

All units are shipped from the factory equipped for use with natural gas. If the unit is to be used

with propane gas, the orifices must be replaced and the pressure regulator converted (see Step

2 on previous page).

If this equipment is being installed at over 2,000 feet altitude and that information was not specified when

ordered, contact the appropriate authorized Toastmaster Service Representative of the Toastmaster Service Department. Failure to install with proper orifice sizing in poor performance and may void the warranty.

The Serial Plate is located on the interior side of the valve panel (see Figure 1 on page 3). It indicates the

type of gas the unit is equipped to burn. All Toastmaster equipment is adjusted at the factory. Check type

of gas on serial plate.

These models are design-certified for operation on natural or propane gases. For natural gas,

the convertible regulator is set to deliver a 4”W.C. pressure to the manifold. For propane gas, it

is set to deliver 10” W.C.

If applicable, the vent line from the gas appliance pressure regulator shall be installed to the outdoors in

accordance with local codes or, in the absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code, CAN/CGAB149.2, as applicable.

This appliance should be connected ONLY to the type of gas for which it is equipped.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas

required for satisfactory performance. Fluctuations of more than 25% on natural gas or 10% on propane

gas will create problems and affect burner operating characteristics. A 1/8” pressure tap is located on the

manifold to measure pressure.

An adequate gas supply line to the unit should be no smaller than the I.D. of the pipe from the unit to which

it is connected.

Purge the supply line to clean out dust, dirt, or other foreign matter before

Use pipe joint compound that is suitable for use with LP gas on all threaded connections.

connecting the line to the unit.

CAUTION

ALL PIPE JOINTS AND CONNECTIONS MUST BE TESTED THOROUGHLY FOR GAS LEAKS.

USE ONLY SOAPY WATER FOR TESTING ON ALL GASES. NEVER USE AN OPEN FLAME

TO CHECK FOR GAS LEAKS. ALL CONNECTIONS MUST BE CHECKED FOR LEAKS AFTER THE UNIT HAS BEEN PUT INTO OPERATION. TEST PRESSURE SHOULD NOT EXCEED 14” W.C.

Step 4: Position Unit for Operation

1. Check that the unit is level. The length of each leg is adjustable by screwing the bottom portion of the

leg in or out. The unit must be level for proper operation!

INSTALLATION

2. Check for adequate clearances around the unit (see page 5).

3. Check for adequate ventilation (see page 5).

Toastmaster

®

PAGE 10

Page 11

M

EDIUM DUTY COUNTERLINE

Installation

Step 5: Adjust Air Shutters and Pilot Heights

All units are adjusted at the factory. However, burner air shutters and pilot heights should be checked at

installation and adjusted if necessary. On new installations, start with the burner of the unit(s) furthest from

the gas input to the manifold. This will purge the system of air.

1. Turn main gas supply “ON”.

2. Follow the instructions on pages 12 to 13 light the pilots and burners.

3. If the burner flame is strong but lifting from the burner, loosen the screw on the air shutter and close

the shutter a little at a time until the flame settles back onto the burner.

Step 6: Condition Griddle Surface

For griddle and thermostatic-griddle models, the new griddle surface should be carefully tempered and

cared for in order to avoid possible damage. To break in a new griddle, first wipe it clean. Next, light all the

griddle burners and turn them to low for one hour. Then gradually bring each griddle up to frying temperature. Next, spread three or four ounces of beef suet, or as a substitute, baking soda, to season it. Never

allow water on a hot griddle and never wash it with soap and water.

INSTALLATION

PAGE 11

Toastmaster

®

Page 12

OPERATION

MEDIUM DUTY COUNTERLINE

OPERATION

DANGER

EXPLOSION HAZARD

Purchaser of equipment must post in a prominent location, detailed instructions to be followed in the

event the operator smells gas. Obtain the instructions from the local gas supplier.

CAUTION

To eliminate gas build up which could result in an explosion, in the event of main burner ignition failure

a five minute purge period must be observed prior to re-establishing ignition source.

CAUTION

Top section pilots, when out, do not interrupt the flow of gas to the burners. Consequently, it is the

responsibility of the operator to check the ignition of the burners, immediately after burner value has

been turned “ON”. Should ignition fail after 10 seconds, turn off burners, wait 5 minutes, and then try

again.

LIGHTING AFTER GAS HAS BEEN SHUT OFF

When turning the main gas supply on after the gas supply has been shut off, do the following:

1. Make sure all of the control valves are in the “OFF” position.

2. Turn on the gas supply.

3. Light the pilots as described below.

GRIDDLE

Each 12”-wide griddle section has a knob on the front panel that directly controls the flow of gas, and so the

heat. Turn the knob clockwise to increase the heat; turn it counterclockwise to reduce the heat.

At the end of each day’s use, turn all knobs to the “OFF” position. After each period of use, allow the griddle

surface to cool normally. After the griddle has cooled, coat the griddle surface with a light film of cooking oil

to protect the surface from moisture.

To light the pilot of a griddle section, do the following:

1. Turn all control knobs to the “OFF” position.

2. Light the pilot tube located next to each burner. The pilot flame can be adjusted by turning the screw

on the end of the pilot fitting.

3. Turn burner knobs to “HI” position. The burners should have a 1/2” to 5/8” steady blue flame. Adjust

if necessary.

OPERATION

4. To turn burners off, turn knob to “OFF” position.

Toastmaster

®

PAGE 12

Page 13

MEDIUM DUTY COUNTERLINE

OPERATION

CHARBROILERS MODELS

Each 12”-wide charbroiler section has a knob on the front panel that directly controls the flow of gas,

and so the heat. Turn the knob clockwise to increase the heat; turn it counterclockwise to reduce the

heat.

At the end of each day’s use, turn all knobs to the “OFF” position.

To light the pilot of a charbroiler section, do the following:

1. Turn all control knobs to the “OFF” position.

2. Light the pilot tube located next to each burner. The pilot flame can be adjusted by turning the screw

on the end of the pilot fitting.

3. Turn burner knobs to “HI” position. The burners should have a 1/2” to 5/8” steady blue flame. Adjust

if necessary.

4. To turn burner’s off, turn knob to “OFF” position.

OPEN-TOP BURNER MODELS

Each 12”-wide open-top burner section has two knobs on the front panel that directly control the flow of

gas to the section’s two burners, and so control the heat. Turn a knob clockwise to increase the heat;

turn it counterclockwise to reduce the heat.

At the end of each day’s use, turn all knobs to the “OFF” position.

To light the pilots of an open-top burner section, do the following:

1. Turn all gas valves to the “OFF” position.

2. Check to make sure pilots are in the correct position.

3. Light the pilots.

4. Adjust the pilot flame as necessary.

5. Turn burner knobs to “HI” position. Each burner flame should be steady blue and impinge on the

underside of a pot placed on the support grate. Adjust if necessary.

6. To turn burners off, turn knob to “OFF” position.

OVERNIGHT SHUTDOWN

Turn knobs to the OFF” position to turn the burners off.

Figure 5

OPERATION

PAGE 13

Main Gas Supply Valve

Toastmaster

®

Page 14

CLEANING

MEDIUM DUTY COUNTERLINE

CLEANING

Toastmaster equipment is constructed with the best quality materials and is designed to provide durable

service when properly maintained. To expect the best performance, your equipment must be maintained

in good condition and cleaned daily. Naturally, the frequency and extent of cleaning depends on the amount

and degree of usage.

EXTERIOR AND TOP SECTIONS:

1. Keep exposed, cleanable areas of unit clean at all times.

Daily:

A. Remove, empty, and clean grease drawers and dirt trays.

B. Clean griddle drain chutes.

Monthly:

A. Clean around burner air mixers and orifices if lint has accumulated.

B. Visually assure proper pilot operation.

STAINLESS STEEL SURFACES

1. To remove normal dirt, grease and product residue from stainless steel that operates at LOW

temperature, use ordinary soap and water (with or without detergent) applied with a sponge or

cloth. Dry thoroughly with a clean cloth.

2. To remove grease and food splatter, or condensed vapors, that have BAKED on the equipment, apply

cleanser to a damp cloth or sponge and rub cleanser on the metal in the direction of the polishing lines

on the metal. Rubbing cleanser, as gently as possible, in the direction of the polished lines will not

mark the finish of the stainless steel. NEVER RUB WITH A CIRCULAR MOTION. Soil and burnt

deposits which do not respond to the above procedure can usually be removed by rubbing the surface

with SCOTCH-BRITE scouring pads or STAINLESS scouring pads. DO NOT USE ORDINARY STEEL

WOOL, as any particles left on the surface will rust and further spoil the appearance of the finish.

NEVER USE A WIRE BRUSH, STEEL SCOURING PADS (EXCEPT STAINLESS), SCRAPPER, FILE

OR OTHER STEEL TOOLS. Surfaces which are marred collect dirt more rapidly and become more

difficult to clean. Marring also increases the possibility of corrosive attack. Refinishing may then be

required.

3. To remove heat tint - Darkened areas sometimes appear on stainless steel surfaces where the area

has been subjected to excessive heat. These darkened areas are caused by thickening of the

protective surface of the stainless steel and are not harmful. Heat tint can normally be removed by

the foregoing, but tint which does not respond to this procedure calls for a vigorous scouring in the

direction of the polish lines, using SCOTCH-BRITE scouring pad in combination with a powered

cleanser. Heat tint action may be lessened by not applying, or by reducing heat to equipment during

slack periods.

BURNERS - GENERAL

Little attention is needed, but if spillage should occur, it may be necessary to clean around pilot areas, air

mixer and under burners. Use a wire brush if necessary.

Periodically, burners (particularly open top type) should be removed and cleaned. Allow interior to drain.

Dry thoroughly before replacing.

Toastmaster

®

CLEANING

PAGE 14

Page 15

MEDIUM DUTY COUNTERLINE

CLEANING

CARE OF GRIDDLES

New griddles should be carefully tempered and cared for in order to avoid possible damage. To break in a

new griddle, first wipe it clean. Next, light all the griddle burners and turn them to low for one hour. Then

gradually bring each griddle up to frying temperature. Next, spread three or four ounces of beef suet, or as

a substitute, baking soda, to season it. Never allow water on a hot griddle and never wash it with soap and

water.

Use a Norton Alundum Griddle Brick to clean the griddle. Always remember to heat griddle slowly because

quick heat may cause costly damage. Griddle plates cannot be guaranteed against damage due to

carelesness. Never place utensils on griddle. Do not overheat griddle above 550°F, as this will cause

warpage or breakage.

Do not use any type of steel wool. Small particles may be left on the surface and get into food products.

Do not clean spatula by hitting the edge on the griddle plate. Such action will only cut and pit the griddle

plate, leaving it rough and hard to clean.

Do not waste gas or abuse equipment by leaving valves at “Full On” position or thermostat at a high

temperature if not required. During idle periods, set valves at “Low” position or thermostats to low temperature settings to keep griddle warm. Reset valves or thermostats, as required, for periods of heavy

load. Turn valves or thermostats to “OFF” at end of daily operation.

CLEANING

PAGE 15

Toastmaster

®

Page 16

ADJUSTMENTS

MEDIUM DUTY COUNTERLINE

ADJUSTMENTS

WARNING

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED

TECHNICIAN WHO IS EXPERIENCED IN, AND KNOWLEDGEABLE WITH, THE OPERATION OF

COMMERCIAL COOKING EQUIPMENT. HOWEVER, TO ASSURE YOUR CONFIDENCE,

CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR RELIABLE SERVICE, DEPENDABLE

ADVICE OR OTHER ASSITANCE, AND FOR GENUINE FACTORY PARTS.

In case of problems in operation at initial installation, check type of gas and manifold pressure and compare with information listed on the serial plate.

GAS PRESSURE REGULATOR

The convertible pressure regulator is factory set at 4”W.C. for natural gas. (To convert for use with propane

gas (10”W.C.), follow the procedure on page 9). To check the manifold pressure:

1. Turn all burner gas valve to “OFF” position.

2. Turn main gas valve to entire unit off.

3. Remove front panel and locate 1/8” plug in manifold.

4. Remove plug and install a fitting appropriate to connect a manometer.

5. Turn on main gas to unit and light pilots.

6. Turn all burners and ovens to full “ON” position and read manometer.

7. If manometer does not read 4”W.C. for natural gas (or 10”W.C. for propane gas), check the incoming

gas line for proper pressure.

8. Remove manometer fitting and replace plug in manifold.

9. Repeat step 5.

10. Replace front panel.

TOP PILOTS: NON-AERATED (YELLOW-TIPPED FLAME) TYPE

Outage is often caused by an unstable flame due to over-adjustment to the point where the flame is leaving

its port, or “blowing off”.

Often, in an effort to improve ignition, the pilots are increased too much and result in this unstable condition.

These pilots are adjusted by inserting the blade of a screwdriver into the slot on the small valve, located on

the manifold. The maximum flame size is approximately 3/4” with a slight yellow tip. The first indication of

over-adjustment is evident when the yellow tip begins to stream into black streaks and generate carbon.

Continued over-adjustment leads to the unstable lifting and blowing condition.

ADJUSTMENTS

ALL TOP BURNERS

All burners have a primary air adjustment by means of an air shutter on the mixer face.

Loosen screw and rotate mixer cap until a clear, stable blue flame is obtained. The flame should not be

yellow tipped nor should it blow off the burner ports.

Toastmaster

®

PAGE 16

Page 17

MEDIUM DUTY COUNTERLINE

ADJUSTMENTS

All orifices sizes and burner rate are properly set at the factory and should not be altered.

Over-rated burners cause poor burner and pilot performance, resulting in less heat, and wasted gas.

Over-gassed burners DO NOT heat griddles as those that are properly adjusted. Such conditions also

create “hot spots” on griddles. Floating and unstable burner and pilot flames will result when solid tops are

lowered into position because the rear openings of the burner compartment are not adequate to vent the

enormous flue products generated by over-gassed burners. The “unburned” gas will ignite at the rear and

burn in this section and even up inside the backguard or shelf venting system, causing structural members

in this area to deteriorate. Also, some of these hot flue products will vent forward into the manifold compartment resulting in problems with valves and thermostats due to overheating. AGAIN, over-rated burners

waste energy and cause service problems.

ADJUSTMENTS

PAGE 17

Toastmaster

®

Page 18

TROUBLESHOOTING

MEDIUM DUTY COUNTERLINE

TROUBLESHOOTING

Consult the following table and the flowchart that begins on the following page.

Problem Look for

All burners and pilots in unit will not turn on -Main gas supply to unit is “OFF”

All burners produce excessive carbon deposits -Incorrect gas type supplied to unit.

-Incorrect supply pressure.

Only some burners in a unit produce excessive -Incorrect orifices.

carbon deposits -Primary air not adjusted properly.

Only some pilots produce excessive carbon -Pilot gas not adjusted properly.

deposits -Incorrect pilot office.

Top burner will not come on -Manual valve for top burner in “OFF”

position

-Pilot out.

Top section pilot will not stay ignited -Pilot gas not adjusted properly

-Clogged orifice.

-Draft condition.

-Improper ventilation system.

-Air in gas line.

TROUBLESHOOTING

Toastmaster

®

PAGE 18

Page 19

MEDIUM DUTY COUNTERLINE

Common checks for all top

configurations.

TROUBLESHOOTING

OPEN TOP BURNER

TROUBLESHOOTING.

NOTE : Griddle Tops

Check that the burners are set

level in the support brackets.

Check that the burners are

clean and all ports are clear.

Remove each burner and check

that the venturi is clean and free

of buildup and debris.

With each burner removed check that

the orifice size is correct and clean and

free of buildup and debris.

Remove the knobs and carefully

lower the top valve cover panel.

Check that each burner valve and

orifice is in alignment with the burner.

Shut off the main gas supply.

NOTE : Griddle must be raised

and secured or removed.

CAUTION! Before raising or

removing Griddle Tops.

Remove the knobs and carefully

lower the top valve cover panel.

Observe the inlet

pressure.

Install a pressure tap in the main gas line

before the range pressure regulator and

install a manometer.

Turn on the main gas supply.

Re-light all pilots.

Light all burners on the range.

TROUBLESHOOTING

PAGE 19

Inlet pressures for gases are:

Natural = 5 to 7 in. water column

Propane = 11 to 14 in. water column

If the inlet pressure is low, all equipment

on the main gas line should be lit and the

pressure adjusted.

Shut off the range burners and

main gas and remove the

pressure tap.

Continue on next page.

Toastmaster

®

Page 20

TROUBLESHOOTING

Continued from

Previous Page

With the gas supply shut off,

install a pressure tap on the

manifold in the plugged tap

provided.

Install a manometer

on the pressure tap.

Turn on the gas

supply to the range.

MEDIUM DUTY COUNTERLINE

Re-light the pilots and turn

on all the burners.

Observe the manifold

pressure.

Manifold pressure are:

Natural gas = 4 in. water column

Propane gas = 10 in. water column

If the pressure is low, check the

incoming line for obstructions.

Shut off the burners and main gas

and remove the pressure tap.

Replace the pressure tap

plug in the manifold.

Test each burner.

Each burner should have a

steady blue flame on each port

of the burner.

Propane burners may have a small

amount of yellow tipping. This is normal.

If the flame is rising up off of the ports

adjust the burner shutter closed.

If the flame is long and yellow

adjust the burner shutter open.

NOTE : Griddle burners may

be long and float when cold.

Allow the top to heat before

making burner adjustments.

TROUBLESHOOTING

Toastmaster

Re-light the pilots.

Install the grates or

griddle tops.

®

Propane burners may have a

slight popping noise when

turned off. This is normal.

Reinstall the front

panel and knobs.

PAGE 20

Page 21

MEDIUM DUTY COUNTERLINE

PARTS

PARTS

NOTICE

INSTALLATION OF OTHER THAN GENUINE TOASTMASTER PARTS WILL VOID THE

WARRANTY ON THIS EQUIPMENT.

The serial plate is located inside of the front panel (see Figue 1 and page 3).

Replacement parts may be ordered either through a Toastmaster Authorized Parts Distributor or a Toastmaster Authorized Service Agency.

When ordering parts, please supply the Model Number, Serial Number, Part Number, and Description.

For parts not listed, consult a Toastmaster Authorized Parts Distributor or Toastmaster Authorized Service

Agency. Consult the Toastmaster authorized Parts/Service Distributor list for the Authorized Parts supplier in your area. If this list is not available, call Toastmaster at (847) 741-3300 to obtain this list.

Index of Parts Diagrams

Page Number

22

22

24

Description

Parts for Griddle Models TMDG-24, TMDG-36 and TMDG-48

Parts for Charbroiler Models TMDC-24, TMDC-36 and TMDC-48

Parts for Open-Top Models TMDO-12, TMDO-24 and TMDO-36

PARTS

PAGE 21

Toastmaster

®

Page 22

PARTS

Medium Duty Counterline /Medium Duty Griddle

1

3

4

MEDIUM DUTY COUNTERLINE

2

8

12

13

5

6

10

7

Toastmaster

9

11

14

15

PARTS

®

PAGE 22

Page 23

MEDIUM DUTY COUNTERLINE

PILOT 020 PROP.

KNOB, CONTROL

Medium Duty Counterline /Medium Duty Griddle

QUANTITY

Key Part Number 24 36 48 Description

1 S1146910 1 1 1 ELBOW STREET BLK 3/4"

2 S1178815 1 1 1 REGULATOR, PRESSURE (N/LP)

3 S1038099 2 3 4

4 S1178816 2 3 4 EXTENSION PILOT

5 S1008755 2 3 4 ORIFICE #55, (1.32) BRASS LP

1850351 2 3 4 ORIFICE #45, (2.08) BRASS NAT.

6 S1178821 2 3 4 VALVE, PILOT ADJUSTING

7 S1177704 2 3 4

8 1800205 1 POLYPANEL MDC/MDG 24"

1800206 1 POLYPANEL MDC/MDG 36"

1800207 1 POLYPANEL MDC/MDG 48"

9 S1178202 2 3 4 VALVE, HI-OFF NAT/LP

10 1100439 1 1 1 PIPE, BI 3/4" X 20" SCH 80

11 1100059 1 1 1 NIPPLE, BI, 3/4" X 2

12 1850318 1 MANIFOLD MDC/MDG 24"

1850186 1 MANIFOLD MDC/MDG 36"

1850187 1 MANIFOLD MDC/MDG 48"

13 S1147007 1 1 1 PLUG, PIPE BLK, 1/8"

14 1952678 2 3 4 BURNER (U) DOUBLE HOLES

15 S1172857 1 1 1 LEGS SET OF 4/CMS,2001

PARTS

PARTS

PAGE 23

Toastmaster

®

Page 24

PARTS

Medium Duty Counterline Open Top

3

4

1

5

2

MEDIUM DUTY COUNTERLINE

10

12

8

11

9

12

13

14

7

Toastmaster

16

15

17

18

PARTS

®

PAGE 24

Page 25

MEDIUM DUTY COUNTERLINE

Medium Duty Counterline Open Top

QUANTITY

Key Part Number 12 24 36 Description

1 1850303 1 2 3 PILOT TUBE FRONT MDO

2 1850304 1 2 3 PILOT TUBE REAR MDO

3 S1008755 2 4 6 ORIFICE #55, (1.32) BRASS LP

S1008745 2 4 6 ORIFICE # 45, (2.08) BRASS NAT.

4 S1178202 2 4 6 VALVE, HI-OFF NAT/LP

5 S1177704 2 4 6 KNOB, CONTROL

6 S1177111 1 2 3 BURNER ASSEMBLY 26K SHO

7 S1177439 1 2 3 BURNER CAST REAR 400C

8 1850128 2 4 6 PILOT LIGHT 20 OD X 17 L

9 S1147007 1 1 1 PLUG, PIPE BLK, 1/8"

10 1850307 1 MANIFOLD MDO 12"

1850319 1 MANIFOLD MDO 24"

1850202 1 MANIFOLD MDO 36"

11 S1178944 1 1 1 TAIL PIPE MDO

12 S1166004 1 2 3 FITTING DOUBLE PILOT 3/16

13 S1146904 1 1 1 ELBOW BLK 3/4" 90 DEGREE

14 S1181100 2 4 6 GRATE COUNTER TOP

15 1146910 1 1 1 ELBOW STREET BLK 1/8"

16 S1178815 1 1 1 REGULATOR PRESSURE (N/LP)

17 S1172857 1 1 1 LEGS SET OF 4/CMS,2001

18 1800198 1 POLYPANEL MDO 12"

1800208 1 POLYPANEL MDO 24"

1800209 1 POLYPANEL MDO 36"

PARTS

PARTS

PAGE 25

Toastmaster

®

Page 26

MEDIUM DUTY COUNTERLINE

A product with the Toastmaster name incorporates the best in durability and low maintenance. We

all recognize, however, that replacement parts and occasional professional service may be necessary to extend the useful life of this unit. When service is needed, contact a Toastmaster Authorized Service Agency, or your dealer. To avoid confusion, always refer to the model number. Serial

number, and type of your unit.

Toastmaster

Philippine Factory : 113 Technology Ave., Laguna Technopark, Binan

Laguna, Philippines, 4024 * Tel. Nos. (632) 520-8170 to 79 Fax No.: (632) 520-8191

USA Factory : 1400 Toastmaster Drive, Elgin, IL 60120 Tel. (847) 741-3300

MANUAL MDC0804-MDO-MDC

®

~

Loading...

Loading...