Page 1

Place

this

Section

of

chaplef

your

irj

Toaqte.r

the

Equipment

Manual

MANUFACTURED

EXCLUSIVELY

FOR

McDONALD'S@

Toastmaster@

A Middleby

1400 Toastmaster

Elgin,

(708\7+1-3300

FAX

Middleby Corp

Hotline

Company

Drive

lL 60120

(708)741"4406

24 Hour

14W238-8444

Service

ooNVEYOR TOA-9TER$,

Models

TC208M,&

TC240M

tmcEoniios

rl.

WARRANW

WARNINGS

& CAUTIONS

TABLE

STATEMENT

CONTENTS

OF

INTRODUCTION

SPECIFICATION

CHART

orirrroUr-rirliirrrrrriirrrirtiii..r.j;44..i.i..,.r..r......i................

INSTALLATION.

PARTS

EOUIPMET.IT

TROUBLESHOOTING

ORDERING

NOI.I.SCHEDU

ELECTRICAL

IDENTIFICATION

SET-UP

AND

FUNCTION

AND CLOSE

PROCEDURES

GUIDE.......

AND

SERVICE

LED

MAINTENANCE

SCHEMATIC

All equipment

pytPoges

of

original

WARRANTIES,

WARRANTY

indirectorconsequentia|damagesinconnectionwithToastnasterConimercia|produdf'

Selle/s

of

its sub'seMce

Models

authodzed

Thiswanantyisnotefiectiveif

when

nameplate;

cases,

Autrcrized

and is void

Service

of this

'NOTE:

manufactured

wananted

is

installation

OR MERCHANTABILITY

obligation

that are considered

sEMce agency,

required;

or,

repairs will

service

elsewhere.

Departnent,Toastmaster'@,'l4ooToastTaster

warranty.

Exceptions

against

or 18

EXPRESS

under

this wananty

agencies.

or, because

if

the equipment

be made

agencies

Please

-

Model SS2,

INFORMATTON.

&

wlRING

McDONALD'S

by Toasfnaster

defects

in

months

OR IMPLIED,

Such repair

porhble

transportation

damageoccurs

equipment

is

at a

reasonable

are located

consultyour

materials

from

the

original

STATUTORY

OR FITNESS

is

limited

service

(devices

charges

is installed

installed

or operated

cost.

principal

in

classified

Sink

Sanitizer waranty

....

TOASTER

Commercial

to

will

with

becauseof

Work

which is spld

and

workmanship. The

purchase,

date

of

ON OTNENWISE,

FOR

PURPOSE,ABE.EXCLUDEP,

the repair

cord

prepaid.

of defects

provided

be

plugs

and

accident,

on a ditferent voltage,

in

any manner

performed

cities

throughout

telephone

tirive,

runs

LIMITED

underthe Toaq@astef

and is

wittrout

on custom6fs

except conveyor

carelgssness,

boritrary

by unauthoiiziid

the United

directory,

Elgin, tttinoii

90 days.

yourfood

W

warranty

slteam

ootz0, forinformation

runs for one

for

thebenefit

INCLUDING WTHOUT

chargd, by a fastory autirorized

ptefiised

iFproperingtallation,lackof

to.tire'insbilation

States. This wananty is valid

ol the original

Seller shalf in no

except in

toasters)

iti

seMce

oas

pell*clnnet

service

equipmentOistributor,

must

oi service ag6niies

2

3

3

4

..............6-

7

9

10-

,.........-..

:l

-1

1

1

12.17

ji;;.r.;.i,...;..;

...r....

traqemark

yeai (see

be taken or

then

anb ope-ritton iistfucdons.'tii

and otherdetailsconcemingservice

and used

exceptionl) frqm the.

purchaser

LIMITATION AruY

event

tne.ca*e of

prope.rsg!:upsupeMsion

desionated

fqr

oniir. ALl Offidn

liabte

be

seMce agency or one

portabld

shipped to the closest

on thE.eouioment

voiOsttris

50

in the

write

or

1

8-1 9

qgmlnerght

dite,

INAPUEO

for direot,

-proOlc,ts.

...

.;...

;

tteie

wananty.

United States

Factory

the

.1995

McDonald's

@

All Rights

Reserved

This

manual

Corporation

is for

the

exclusive

use of licensees

Printed

and employees

in March

EM

T6

of McDonald's Systems, lnc.

Page 2

i!:

.

'":

rr,:,'

'

,i:.

:

.$-OilelsTC208M

Thd

conv6!'or

muffins

ous f eed

mutfin

tobster

large

in

methods.

toasting

INTRODUCTION

TC240M toaster

&

designed to unifonily""toist

quantities,

partial

A

without changing

either batch.or continu-

using

load switch

batch settings.

iqq

permits

comqleroial

-English

individual

'i..

WARNTNG:,

disconnec't

elements

temperature

switch.

allow

and

and

SAFETY

ln case

making

of

will cut off

This

the toestertro

it easier

de-endr:gize

fire

power

eoplthus

to Stop

toaster

the

to

reduoing

the fire.

at

heating

the

capable of

The toaster

is

hour.

WARNING,'The

electrical

local

ing to

lt requii-€S a

proper

tnis

detailg$

your

Toag-t-6;,

the

-qplptof

maliun*ioin,

and Shouid

any

supplied

assist

of a

operatof

the

shock.

electrical

of the

Retain

provides

of

n

Using

electrical

separate

breakers

NOTE:

manual

operatio

tion to

event

for

NOTE:

terfactory

liability.

NOTET

to

notiee. Such

sponding

rnents

Toastmaster

change

changes,

previously pr.rrchased

for

specifications

revisions do not

producing

toaste_r

should be

csde$ tO

up

to 360

grounded

p"rpve.6[the. possibility

gblntlg;dl1€lg.eptacle

lines,

prirtddted

by

fuSes

rating.

mah$id

in-

This-

parts

otherthan

parts

relieves the manufacturer of all

(lr/lanufacturer)

product

and

entitle

rdference.

installatign

,Sofne,

ridblems

t'iiiiportant

available.

genuineToastmas-

reserves

design

buyer to

the

improvernents, additions

equipmenl

muffins

per

acqord-

of

rrdth

or cirosit

This

and

informa'

in the

tool

the dght

without

cone-

or replace-

CAUTION:

Halon which

ARN

W

toaster

into

and/or

CAUTION:

orotherflammable

other

any

WARNING,'

Live circuits

tests.

Use afireextinguisherfilled

suitable

is

pick

not

Do

I N G,'

entrange

bums

to

and exft

the body

Foryour,safety

vapors oiiiquiOs

appliance.

Use extreme

willbe exposed.

toaster

lhe

powered

for electric

up

ope,nings.

cah'resdlt'

nOtstol'e

do

during

care

onlywith

by stickin

Elgctrical

vicinity of

in the

electrical

CO.

equipment.

g

fi n

shock

o-i use

gasoline

this or

circuit

ge

or

rs

...

PREQAUTION:

procedure(q)

*The

(HCS)

of chgmical

highli$hted

viation

(HCS)

Sheei(s)

N

Of

has American

ccinversions

WenUWA,'

equipmentshould

persorihe].

vicing,

prgd.uqts,

fvith'bold

(HCS).

See the

Manual'fsr

(MSoS).'

piece

: f nis

E

sizgs of h4r{wgre. All hardware metric

are approximatb

Inspection, testing and repair

The

lpastef

excep!

when electricaltests

the

'

of

be

Hazard Communication Standard

chapter

in

this

These chemigal

face

letters

follou/ed

include the

productq

by thg

use

will be

abbre-

HazardComri'iuriication Standbrd

appropriate Material Safety Data

equipment

performed

slroulfl be

is

made in America and

and

can

only

vary in

qualified

by

qnplgggFd

size.

electrical

of

service

when

ser-

dre required.

Page 3

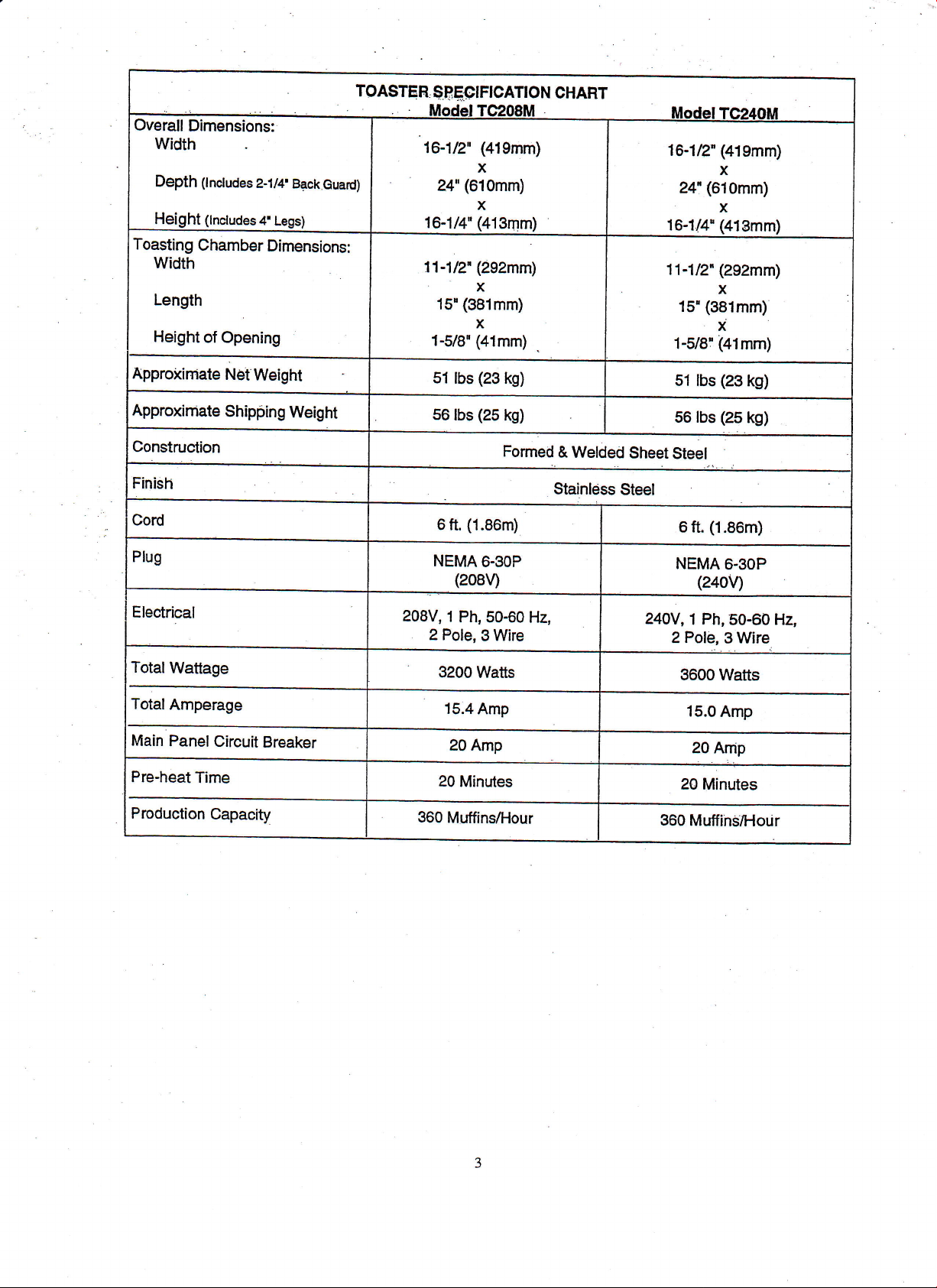

overall

width

Depth

Height

_

Toastin

g

width

Length

Height

Dimensions:

(tnctudes

(tnctudes

Chamber

of Opening

2-114.

4'Legs)

Dimensions:

Back

TOASTER,

Guard)

SREo|F|CAT|ON

llaelal Tt\tnall

16-112'

(419mm)

CHART

x

24'(61Omm)

x

16-114'(413qm)

11-112'(292mm)

x

15'(381mm)

x

1-5/8" (41mm)

16-1n'(419mm)

x

(61Omm)

24"

x

16-114'(418mm)

11-112^

(292mm)

x

15'(381mm)

x

1-57sr

1a.tmm)

Approiciniate

Approxiniate

Net

Shipping

Construction

Finish

Cord

Plug

Electrical

Totalwattage

TotalAmperage

Main

Panel

Pre-heat

Production

Circuit

Time

Capacity

Weight

Weight

Breaker

51

lbs

56lbs

6tt.

NEMA

(208V)

208V,1

2 Pole,

3200

15.4

20

20

360

Mutfins/Hour

(23

kg)

(25

kg)

Formed

(1.86m)

6.30P

Ph,50-60

3

Watts

Amp

Hz,

Wire

Amp

Minutes

& Welded

Stainless

Sheet

Steel

240V,1

51

56lbs

Steel

2 Pole,

360

(23

lbs

(25

(1.86m)

6ft.

NEMA

(240V)

Ph,

3600 Watts

15.0

Amp

20

Anip

20

Minutes

Muffin3/Flour

kg)

kg)

6.30P

50-60 Hz,

3 Wire

Page 4

INSTALLATION

WARNING:

A.

tnspect

All

age bef ore and'durin

carefully

freight

transft

aged

must

1. Apparent

apparent

receipt

the canie/s

carder

necessary

2.

NOT

request

made

an inspection

Be

internal

for

Shipping

shipping

Concealed

certain

containe.rs

inspected and

carder has dssunied

and delivery.

condition, either

be made

Damage

it must be noted on

the time of delivery,

at

may refuse the claim.

ctaim

apparent

for inspection of concealed

with carrier within 1 5

to

packaging

Damage

should be ercamined for dam-

g

unload

lf equipment is received in dam-

apparent or concealed, a claim

the

with

agent

Damage

until after

and

retain

delivering canier.

or Loss

(driver).

forms

or

will

supply

all

matedals for inspection.

g.

in

packaged

responsibil'rty for its sale

-

the freight

and it

lf this

The

Loss - lf damage

equipment

days. The

neoessary

contents

This eq uipment

at the factory.

lf

damage or

bill or

must be

is

not done, the

canierwill supplythe

is unpacked, a

damage must be

carrier

claim

plus

extemal

was

The

loss

express

signed

by

loss is

or

will make

forms.

and

is

giioie

'

ttiE

C.

maliihd

niain

Electricalconnection

ModelTC2OSM

The

equipped

Checking

D.

1. Turn

2. Fr,rsh

3. Check

4.Visually

glowing

and

5. Push

speeds

any etestricat

electrical

cord

with

the Installation

electrical

main

PowerON/OFF

conveyor

that

checkthat

red.

PARTIAL LOAD

for 20

up

originalspeed.

6. Push

PowerOIVOFF

connections

supply

TC24OM

&

and

Plug.

supply

souroe

is turned

toasters

source

Switeh'ON".

is

all heating

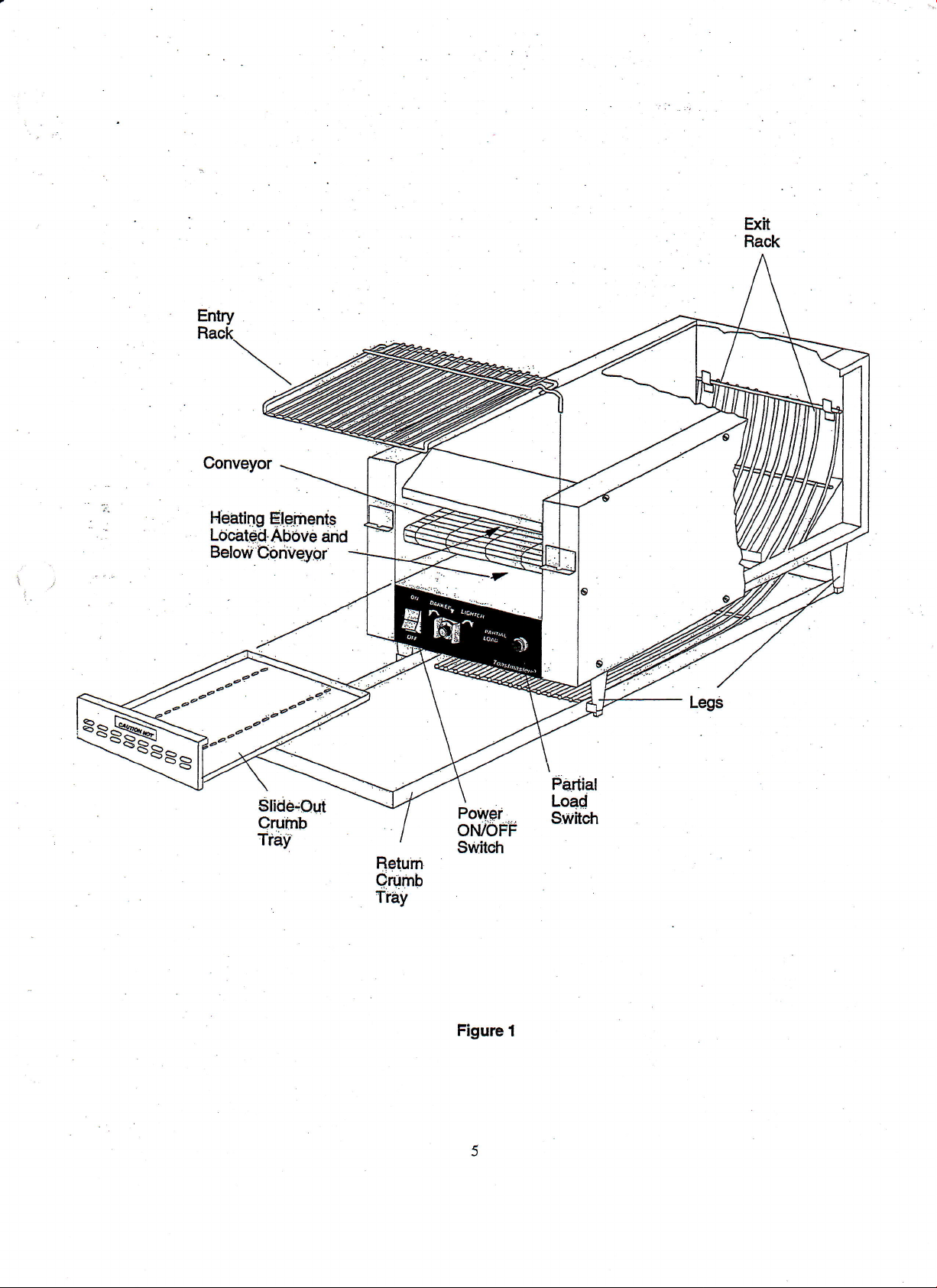

Figure 1.

See

moving

Button.

f

orward

elements

Checkthat

+/-5 seconds and

Switch'OFF'.

be

"OFF

factory

are

oON".

Figure

See

into toaster.

are heating

conveyor

retums to

then

sure

1.

Unpacking

B.

1. Remove staples

Litt out

2.

toaster.

Carefully lift toaster

3.

4. Remove

from the carton.

the bottom of the carton.

from

5. Remove the

parts

chamber.

loose

Instatl the 4'

6.

conveyor

7. Install the retum crumb tray by

brackets

of the

Toaster

from

carlon.

packing

foam

loose

all

Be sure all

toaste r:f rom the carton and remove any

packing

or

Check

parts.

toaster

on the side of the tray against

toaster as shown in

materials

for any

legs

in desired location.

and

out of carton.

parts

and

damage to the unit or the

shown in Figure 1

poly

the

loose

from

Figure

bag frorn around

information

parts

inside the toaster

positioning

1.

packet

are removed

place

and

the

the front legs

Visually

7.

longer

8.

on.

Checkthat

that all

eheck

conveyor

heating elements

has stopped.

are

no

8. Installthe

rack as shown

entry raclg

slide-out crumb

in Figure

tray and exit

1.

Page 5

l=leatiqg

Locate.d

BeloW

Ele^mentS

Above

C6nveygr

Slideiout

Crgrnb

Tiai

and

Retum

Crumb

fray

Figure

1

Page 6

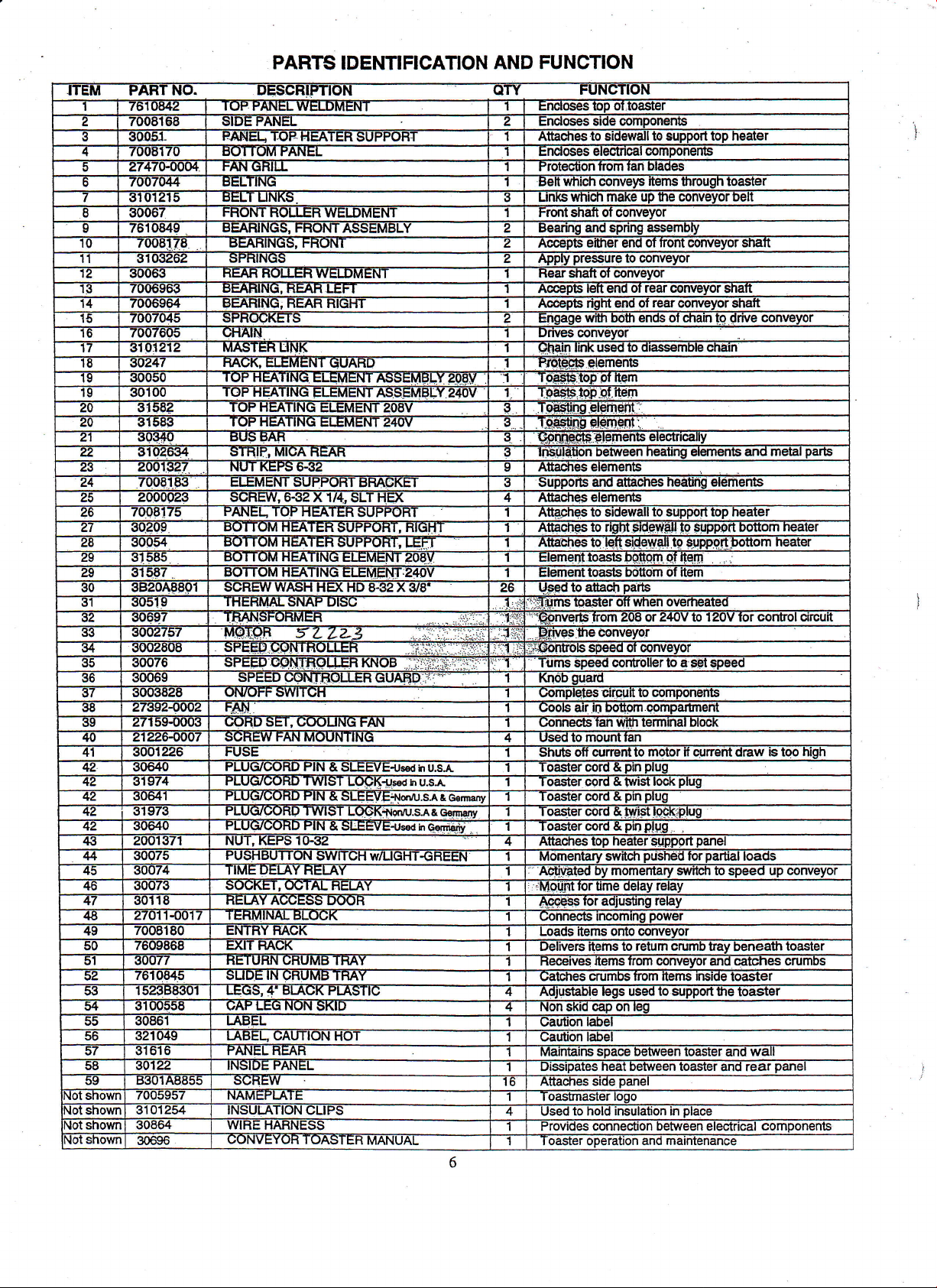

PARTS

ITEM PART

2

o

4

5

U

7 irt 0121 c

I 30067

I ,/ti'1(,64

10 /uu6l EtAH|NGS, F.tic)NI

tt

1Z ijgotru

13 70059ttit

14 7006964

15

16 7007tr05

IU

'19

't9

2Q 3156?

20 315CiJ

21 s99+o

'zz

'4t

24

25 zwogzs

z6 7004775

ZT ou4uv

?6

29 315E5

29 sl567

30

iJl

32

w

;J4 UIruZUUU

35 3(ru70

36

37

Itu 273SZW2

ity z/lcv-(ruuu

4{) il1zlztt4xruI

41

42

4Z

4? 9064'l

42

+z 30tro

rts

4 30075

45 30074 TIME

46

47

I

49

50

51

52

c5

b4

55

56 321049 [-AEEL, CAUTION

57

5U 301z,2

59 EiturAu6S5 D\ TTEYY

{ol snown

{ol snown

shown 30664 WITtb,

{ot

{o1 snown

NO. DESCRIPTION OTY

761UU,{tz

7008168 UIIJE FANEL 2

3005r-

/U t,9I

/t,UU]

:a74794rutJ4 FATT

I\.T

A|\trL WtrLL'MtrNI

FANEI.

T,OP. I-IEATER

IUM TANEL Encloses

(iruLL

70"0704/. EELTING

TJELI

UNKU 3 unl(s

FFIONI

BEARINGS,

31fft262 SPRINGS z Apply

79o7045 ['FROCKETS

31Q7212

I.IEAF{

t'EAIiINCi,

tsbATtING,

UNAIN

MASTER UNK

FIgLLER WELDMENT

FRONT ASSEMBLY z

HL,LLETT WELUM

F{EAFi,LEFT 1 ACCepls |en eno

REAR FIIGHT Acceots r

30247 RAOK, ELEMENTGUARD I':I9I€$S

I

3UU5U

EO]UU

3102634

z9913Zl

z0u6l6i:, trr-trMtrN I Durr(Jrl

30u54

3B20A8SO1

it05rc

)vt

300,2757 Mf,z.r.:f,rr

3(Xr69

3003EZE

3()ul2;.6 FU!'E

3(,b40

iJ1914

3197:J t'LUG/(ruHp I WIIJT

2w1371 NUt, ntrru

i'UU/l' Drervl\tr,l, wl'lL rltru\I iMqU.Ft

c0llu

27011-OO17 I EITMINAL ELOGK

7008180 ENTRY FACK

FIEAI INCi.

9I'

| 9r. FrtsAr rNu

FttsAI

I()F

BUS BATI

u I Ffirir MruA FttsAH it hsuFlon Detvveen neafng ebments and

NU I nErU

uuFitrw, a-,52

I'AT.TEL

D\.rr r Lrvr nEAr

E'lJl

tsL)| I(JM HtsATING

EOTTOM TIEATI

SCREW WASH

I HEFIMAL SNAI'

l.It IYDrLrl.tMEn

IN(i

b-3i.

TOF

HEATER

tlt,M nERt Ert

>

ol-EE!J..|9Sr!! r !:ILTLLEn

sl'EEu sdlN

Sl'EbD

IJN/L'TT

r!I

|,Irrnu

U(iFTEW FAN

I"LU{i/U9f{lJ

rLU(:i/(J(,tlL, I

l-LUg/UUt{U l'lN

rLUL'/UL,rtU

PUSHEUTTON

i{EIAY

!

(j()NTf,tgLLEFl

DYYI I L'N

l/\.r\JLlll1:

I

OE

r

1(}-itz

DELAY

;tstis

A(

MgUN I ING

t'lN

rlN

RELAY

/tru9u56 EXr I tlAgK

i'UUT I Hts I UFTN UHUMts

7610645 t'UDts, IN

152388301

c'tw556 UAl.LELi N{JN

co6til LAUtsL

31616 rANtrL HEAI1

/uu595/ NAMEI'I.AIh

grg'rzb4

30696

LE\iU,

INSIDE PANEL

INSULAI ION GLIPS

U9NVEY9H I

gftUME

E r_ALit\

3-

FIAfINESS

FUNCTION

IDENTIFICATION

AND

'l

FUNCTION

Encloses K

E!

SU PPORT

Attachesto sidewall

'l

Protestion

Een wnicn Cronveys

u/hich mal(e

Front snan ot conveyor

Bearing and spring assemb

ACCepts

2

I

tsN I

Rear

2 Engage

qnajn

1

ELEMtsN

tsLbMEN

ELEMENT Z4OV U

x 1t+.,

Ert Durr\rnl, ntr':n I

NG ELEMENT.[;240V 1 Element toasts

HE)( HD 8.32 X 3/8'

LLLg

H9|-LEH

WIS I

SWTTCH WUGHT€BEEN

I ASlitsMtsLY

t ASS_EM9LY 24OV

I ItFUl(,t\E I i,

HE 4 Afaches

uLt

SUPPOFT

UUrrLrFil,

ELEMENT 2O8V Element

U]!iU

& SLEEVE{re€d

LOgK{s€d h U.St 1 Toaster

at ttLEEVE-Non/t

LgGK{'lqdlJ.S-A

at l'LEEVE{rs€d h

uooH

KNQts

GUABD

f't|I

Lt

._....- ,,::i-,

...:,."::.;,.i tvgs.me

.

j:i.r,

.,

:1ij..

_ili

Ti

h u.S.A 1

.S-A &

G€man}

e cflrgny

G€rriar

''l

TOASls.top

't

it

r"9

U

I

Attaches

suppolb and attaches

Attaohes to sldewall

I

Attacttes to ilght std€well

Alrqcnes

26

"-:(i0llV€[S

'''l:ii.:

ilitl,romrc|s

lhob

compEtes crpun

'l

cools air in botl9m companment

'l

Lonnec6

4

useo to

DnuIs oII curTer[ ro

1

Toaster cord &

1 Toaster cord

1 Toalsfer G6id &,

-Toaster

'l

4 Ataches too heateaauDoort Danel

Momenrary swncn

1

'l

I /\ccess

1

Loads rtems onto conveyor

Delivers items to

1

Fleceives ftems

cabhes crumbs

4 AOJU$aDle |egs USeO lO SUppOn ne

Non sKicl c€

4

rLAU

I'KIU

I }tAY

TBAY

t lV

Caution

HOT

Caution label

Marntarns

LllsstDates neat between toa$er and

Attaches sicle

16

Toasfnaster logo

4 Usecl to holcl insulation in

-Providesconnecfi

OASTER

MANUAL

Toaster oDeration

enner

pressure

shaft

wiul Dour

fink used to

igts

toasts bo-tqm oJ rteql

to atiach

)d

rns

toaster otf

I UmS Speeo oornror|er to a set speeo

ouad

mount tan

@rd & twist

cord&Tin

tor

foaedjusting relay

label

6

of toaster

t0 support top heater

electncal

from tan

9l€ln9ols

pFments

elements

elemenE

lo.lqE

nOm

conveyor

speeo or agnveyor

components

blades

'tems

nrcUgn toaster

up rle conveyorDelt

oI nont conveyor snan

eno

to conveyor

of convEyor

0t rear @nveyor snan

m eno ot

rear

convevor snan

enos ol cnarn

yor

dt€lssemDle chain

ltem

0f

item

ll:

electrlcal

heauno elements

to support top

support bottom

to

ts'^{flLlg€qppq4,Dllqrn

bouom ol nem

parts

when overheatecl

24UV

i|06 Ot

lO IZOV l0r

to crmponenb

ran

wfin Iermtnat

pin

pin plug

&

lwrgt

time delay

retum

trom conveyor

fiom

DON|eq

space Detween

panel

onbeiw6eleffi icafcomoonents

and maintenance

m9tor

plug

plug

lock

lspf

iptug

plg$

pusneo

relay

crumb trav

nems

DtocK

|I cullem

lor

loasler and

place

dnve

Io

heater

qrErw

parBat

toaos

beneatn

oatches crumDs

and

inside

toaster

toaster

conveyor

metal

heater

n9ar9!

COnrOl C|rcUn

rs

roo

toaster

wa[

panel

rear

parts

nlgn

Page 7

Figure

2

Page 8

EQUIPMENT

AND

CLOSE

SET-UP

PROCEDURES

Set-Up:

1.

Insert the

receptacle.

2. InstAtl the retu m

on

toaster

3. Install the ehtry rapk,

as shown in Figurd

4.

Tum

oN.

Allow 20 minutes

5.

6. Adjust

tor toasting

7.

Loading mutfins

NOTE: Muffins

Batch

For

then

position.

veyor.

Continuous Loading.

For

rack with rack

Press the

8.

mutfin halves

It will reset

partial

WARN ING

unplug toaster

service.

power

coid into a

cruihb

the side

as

the

of

shown in

tray against

4.

toaster

on by

for warm

DARKER/LIGHTER

a normal batch

into

placed

are

Loading-

batch

place

loading

mtrffins

stage muffins

on entry rack

Raise entry rack

partial

bata.h loadi

in raised

PARTIAL

less

or

to normal

load

has been

: Always

before

propgi

tray by

20 Amp.

positioning

the front

Figure

pushing

4.

slide-out

Power

crurnb

up.

Knob

to

approximately'S"

of 7

to

12

toaster:

in

toaster cut

on bun

with rack in lowered

feed

to

g

n

stage m uff

muffins onto

ins di rectly on

position.

LOAD Button for

and the

speed

conveyorwill

automatically

toasted.

discon4gct

cl6aning

electrical

or

electrical

the brackets

legs

of the

tray and

OIVOFF

exit rack

Switch

mutfin halves.

side up.

spatula

entry

a batch

speed

when

power

performing

.

and

eon-

of

6

up.

the

or

any

Close:

WAR N[NG : Always

unplug toaster and allow to

performing

or

1. With the conveyor

oonveyor and onto the crumb

Tum off the toaster

2.

unplug toaster.

disconneet electrical

cool

any service.

running

bnrsh

pan

diseonnect

and

Then

allow toasterto cool;

before cleaning

any crumbs off

below.

electrical

3. Clean the toaster exterior by wiping with a clean,

sanitized

All

from the sink

clean,

pads

towel dampehed with a hot

Purpose

Goncenbate

propoitioper.

(APC)

Rinse by wiping with a

damp sanitized towel. DO NOT

of

scoudng

cleansers. They

solution of

(HCS)

will scratch and dull

the finish.

4. Crumb

WARNING: Hot Surface€ - DO

SURFACES OR

trays

and racks:

REACI.I

NOT

INTO TOASTER WHEN IT

power

or

the

power

or

McD

as drawn

abrasive

uge

TOUCH HOT

ts HoT.

After the

crumb

out of the toaster.

CAUTION: Do not remove

while

RempVe the

Wagtr

5.

racK

trate

f rom

bing

toaster has

and

tray

conveyor

the

i3

retum

moving.

entry rack

thg

S1ide.gut

in

ahot

(APG)

(HCS).

crumbtray, retum crumb

-s-olution

Remove

the f rorit of the

a

with

McD No Scratch Pad.

cooled,

remove

the

slide-out

crumb tray by sliding them

slide-out crumb tray

and exit rack

from toaster.

tray and

of McD All Purpose Concen-

gold

any

discoloration

slide-out crumb tray by scrub-

9. Clearing Jams:

product

a

jam.

cool, if timepermits,

Unplug toasterbefore

clearing

WARNING:

ing

jams

DO NOT

chamber

use caution

elements and

Use e:<femecautionwhen

lt is always

b6lore redi'oving

you

as

cause

belterto waitfortoasterto

jammed

clearing

djdm,CAUTION:

to not damAge

stick

anything into

may damage

electrical

shock.

the

elements.

the

removing

product.

When

toast

heating

Rinse well and sanitize

Sanitizer solution

allow

I

:

.

all

Remove

wa-fm,,WFJ.gr).

titifi

An-ci

'!;::i:ij::fii'

...i.

i,,.,:"

;l

6r'r,iddh$sefible

CAUTION: DO

merge

toaster in

occur.

by immersing in McD Sink

(HCS)

pak

(1

parts

in 10

from sanitizer solu-

galtons

to air dry.

parts

onto oven.

NOT use excessive water

water. Electrical

pfobiems

of

or sub-

will

Page 9

Rack

Entrv

Posilion

Product

And lnto

t

RAISE

ln Raised

For Feeding

Gonveyor

Onto

Toaster

\

r

PARTIAL LOAD

Button

DARKER/LIGHTER

ControlKnob

WARNING

NOT OPERATE THE

DO

Premature

and

.

on either of its sides

.

on

.

without

failure

the

toaster warranty will

CONVEYOR

iE rear surface

legs

of the heater elements

TOASTER:

be void,

will occur

Figure

9

4

Page 10

TROUBLESHOOTING

Product

toaster

t,it[JuLEM

toastdd t6o

overneats

dark or too

and shuts

light.

clown.

PROBABLE

DARKERAIGHf

not

set corectly.

Partial

preqsed

items'qr€

Load

when

bOing

Using refdgerated

Time

Delay Relay not set conectly.

L;OOllng

Cooling

tan

fan

CAUSE

ER control

6 or

not being

less

button

toasted.

orfrozen muffins.

dirty,

unplugged.

knsb

CORREGTIVE

AGTION

Set knob for correcf darkness.

Press

PartialLoad button

sliding lobds of

6 or

when

less

items onlo conveyor.

Mutfins

temperature before

must be

room

at

toasting.

Allow

a2 day old rotation when using

fresh

muffins.

Callservice agency.

that

in.

plug

Referto

proceoure

Card 1.

ulean

Ine tan. Fo[ow

on Plannned

Tum ON/OFF

power

cover and check

on fan is

Wiring

Maintenance

switch and main

switch

off, remove bottom

plugged

diagram.

Toaster will

r

oa$er

conveyor does

wlil

not heat

neat up

up.

Du

not move.

Cooling

Thermostat

and

Forelgn

Drive

fan defective.

opens.

oDJeet:blocKng

Motorfuse

switch

is

overheats

conveyor.

blown.

Callseruice agency.

Callservice agency.

Hrug

In loasrer.

Tum

Replace switch.

Plug into

Replace

Callseruice

Callservice

I um L|N/(JFF

power

object from

Turn

d$Qn0li

powerswiich

main

different

plug

or

agency:

agency.

Swncn ano maln

switch

off

conveyor.

toaster off

..

,

receptacle.

power

and

and

.r,,,'

on.

cord.

remove

call

service

Wire(s)

loose.

10

Oallservice

ag€ncy.

Page 11

TRO-U

BLE-S

H I O.'T| N,g, C,e nti

ued

n

PROBLEM

Noticeable

nems teed

delivdred

tray.

ORDERI

Ordering

Use

only

parts

ment

supplied by

bum,ing

into

machine

to front

NG/SERVICE

Parts

genu.ine

in

ToastmasJer (manufactu.rer)

yourtoaster.

rnanufacturer

status.

Yourauthorized

be

glad

your

will

Locale

and.tfe-r.r find

parts

list.

List the

following

NOTE: Modet

refer

Model

Man

Figure

to

#:TC208M

uf actu renToastmaste

service

to inform

desired

the

item

ordering

# and

5.

orTC240M

Serial#:

smell.

but

of retum

Use

voids

agency

you

of the

paft

in

part

and

information:

Seia!

#

r

Toasted

Too

in

are

not

crumb

tsxfi racK

Item(s)

INFORMATION

parts

of

has

cost

the

exploded

number

are found

the

wananty

pads

a

of

otherthan

price

your parts

parts

of the

on

the data

PHOBABLE

item

many

accum'ulated

slide-out

crumb tray.

not

installecl in

stuck on

reptace-

those

and

U.L.

list

and

order.

drawing

part

in

the

plafte,

CAUSE

stuck in toaster.

crumbs

machine.

exit rack.

Service

lf

iechnicat

seMce agency.

ready when

NOTE: Model

refer

Manuf

Model#:

Serial#

Problem

help is needed

you

to Figure

actu rer:Toastmaste

TG208M

with

toaster

Tum

power

item

Tum

then remove

orunib

rn$4il

Tum

remove

Please

call:

#

and Sefiat#

5.

orTG2&M

and

CORRECTIVE

Ol,l/OFF

sffich

from

toaster.

toaster

tray.

exfi racK. HeTerrc

OIVOFF

item(s).

csntact

have

the

are found

I

ACTION

switch and

6ff and

otf and

and

clean slide

Referto Page 10.

switch off

your

local

following

on

symptoms:

main

rembve

let

it

cool and

Hage

and

authorized

information

plate,

data

the

-out

5.

(from

Date

&

Street

State,

Number

parts

Zp

Item No(from

Part

No

Description:

Order

the required

vrce

agency.

Delivery

LocalService

Name

Number

City,

Phone

list):

parts

list):

parts

of Toaster:

Agency:

from

your

local

authorized

ser-

Retum

An

Policy

RGA

obtained

Shipping

goods

are

tance.,

DahFi!.iri&d

A

ha.ioftoidr

Figure

Data

Plate

t1

number

from Toastmaster

charges

subjectto

(Return

must be

'i,

5

Locatioh

Goods

before

prepaid

Toastmasters

Authorization)

returning

buyer.

by

inspection

must

product.

a

Returned

and

be

accep-

Page 12

.

,i.. . i':.. . .: . i

NON.SCHEDULED

CE

replaeement

verify

and to

parts

Before

provides

refer

This sectiori

of any

replaoement

that

GAUTION:

infonnition for replacement

the Trgr.rbleshooting Section for

to

required. lf

is

performing

necessary contact

any maintenanoe:

1. Turn

toaster ON/OFF

ofvari'ous

parts

assistance

your

local authorized

switch

OFF.

.nrnponents

und

determining

in

service

necessary.

as

cause of the,

the

agency

problem

for

assistance.

Before

3:llill,l!1i"3lJil.;.#l!l"iT;"".

4. Allow

Toots

pliers,

A. Top

Neeessary:

Set.ot sockets

Heating Elements Replacement

Remove the

1.

Remove the

2.

3. Slide

2 screws and nuts.

the

4. Removetheheaterassemblyfromthetoasterandthenremovethebusbar(s)andthemicastripfrorntheheater

to be replaced. Fleferto

Flat

blade

with handle

toaster right side cover

6 nuts from the

the heater assembly

toaster

screwdriver, Phillps

right

part

Refer

Figure

cool.

to

screwdriver,

by removing

side top.heatersupport

way out and

to Figure 6.

7.

the

then disconh€ctthe

Set of

6 screws.

panel.

wrenches,

Allen

wires from the

2

Needle nose

heaterterminals

pliers,

Ftegular

removing

by

Remove the

5.

Replace the heater

6.

connect wires to heaterterminals

be sure heater assernbly

2 screws attaching the heater to the

with the new one and reasemble

before sliding

and element

heater

heater

guard

are

mounted

Disconnect and

Top

Heating

Element Assembly

in

this

supporls,

parts

assembly

wires

position

reverse order they

in

the

allthe

studs and

on

with

removed.

were

way into toaster.

inserted into

Top

holes.

Heating

Element

Assembly

Refer

Be sure

to Figure

7

to

io

Figure 6

Page 13

Mount

assembly

studs

heater

onto

when

reassembling

Plate

with

studs

and holes

mounted

inside

which

on right

wallof

is

oven

Element

must

into

end when

reassembling

guard

be inserted

3 holes

at each

Figure 7

13

Page 14

B. Bottom

Heating

Elements

Replacement

1. Rernove

Loosen

Z.

motor

g.

Remove the

the

4

sprocket.

heater terminals.

WARNING:

Remove

4.

heater

support

S. Replace

heater element.

Reassemble

6.

openings on

position

Reassemble

7 .

drive chain

The

Connect

8.

the toaster

right side cover

motor mounting

nuts from the

6

Refer to Figure

Be careful

not to

heater assembly

in

Do not

thE

reverse

bottom

parts

bracket.

heater element by removing 2 screws

the left side of

screws

right

bend or damage

from

toaster. tt may be necessary

damage or bend the

toaster

removing the

by

move motor/shaft

and

side bottom

heater support

8.

order they

were

when sliding

heater support against spring at end of

drive chain

must

wires to new

onto motor

sprocket

be tight. Tighten the 4 motor mounting

heating element.

and

6 screws

to the

the heater

heater

attaching

removed.

heatirig

the

shatt

bearing

push

then

right and then

panel

and the

terminals.

a screwdriver

to use

support

panel.

it to heater

Be sure to

insert heater

element into the

when

reassembling

motor to

the

screws.

remove

2 screws

to

support

toaster.

heater

the left to

the drive

remove the

to

pry

slightly

panel

and

element into

Refer to

assembly

place

tension on

chain from the

wires from

aJ

attaching

each

end of

new

the 2 bracket

into

8. Also

toaster.

Figure

the chain.

When reassembling

assembly:

heater

The heater

elements

positioned

the bracket

openings.

must be

between

wjrgs

BoJtom

Heqting

A6Sdmbly

The heater support

must

bearing spring.

Eieinent

be againsl the

Heating

Bottom

Element

nssembly

Figure 8

t4

Page 15

C. Conveyor

1.

Remove

screwdriverto

plate,

Belt Replacement:

the right

push

push

the

conveyor

and left

the

bearing

side

shaft

covers

as

shown.

thru

the slot.

by removing

With

the hole in

See Figure

the

6 screws

on

the bearing

g.

each

lined

side. On

up witn

right

side of toaster

tne slot

use

a

in the retaining

2. To remove

the

left end of

3. Tum

4.

Using

5. Reassemble

Pushthe

6.

the

shaft

all tbnsion

conveyor

the

long nose

the master

leftside

from the

on

conveyor

belt

so

pliers

remove

bearing

right

side

the

conveyor

shaft

is free

the

master

the three

links

into

the

with

ascrewdriverasshown

support

push

bett

of

the

left side

links

are

master

conveyor

slot

and center

conveyor

the

bearing.

the front

at

links. Replace

shaft

see Figure

of

the toaster.

the

belt.

in

g

Figure

the shaft

as far

possible

as

9.

See Figure

belt

replace

or

and reinsertthe

between

the side walls.

toward

the

g.

the damaged

intothe

shaft

bearing.

right

links

side

until

in

the belt.

Flelease

Figure

t)

9

Page 16

D. Electrical

Pushbtrtton

Components

Partidl

Load Switeh)

Replacement

(Drive

Motor,

Transformer,

Fan, On/Off

Switch, Speed

Controller,

1. Lift

2.

3.

the toaster onto its

Remove the

The electrical

them on the

rernove it. Mount the

Use the wiring

4.

Replaoe

5.

bottom

side

as shown.

panel

bottom

by r6moving

the 4 sciews

components are now accessible.

new componeht. Remove

new component

diagram to help connect

panel.using

the 4

Partial

Load

Fushbutton

Swtbh

screws that were removed.

Screws

the

onto the

wires

the

Remove

wires

and/or

toaster.

the new

to

one at a

nutS aftaching

time

the

component if

rom

f

the old

compohent to

old

necessary.

component

and replace

the toaster and

Speed

Conttolter

3----

Transtormei

Figure

l6

10

Page 17

1. Remove the

2. The time

Replace

3.

door in

the left side

delay relay is now

the door in the

F. Relay Socket Replacement

by

cover

accessible. Remove

left

side cover.

removing

the

1 screw.

relay from its socket and

replace with the

new

relay.

1. Remove the toaster

.2.

3.

Remove

Remove

the Time

wires one at

screws attaching

Use

3.

4. Replace

5. Refer

G. Automatic

1. Remove

2.

3. Use

4.

the wiring diagram to help

side cover using

to MRC #19 for instructions

Reset High Limit

the right

The

Automatic Reset High

replace

Mount

them on the new

the new

the wiring

Replace

side cover using

left side cover

Delay Relay

a time from

the old relay

side cover

High Limit

diagram to

removing

by

from the

the old relay

socket to the

connect

the 6 screws

that were removed.

properly

to

Reptacement

by removing

Limit

one.

onto

now

is

Remove the

the toaster.

help connect

the

6 screws

that were removed.

6 screws.

the

socket.

socket

toaster

the wires

adjust

6

screws.

and replace

and remove it.

the new

to

time

delay

them on the new relay socket.

Mount the new

relay socket if necessary.

relay.

accessible. Remove wires

attaching

the old High

the new High Limit if necessary.

the

screws

wires to

one

relay

socket

at a

from the old

time

Limit to the toaster

Remove

the

onto the toaster.

High Limit and

and remove it.

3Aa-s37^

oosT

1n

LI

Page 18

gE

F>

FG

6

o

b9

6>

FO9

tr2e

o*

>b

6

=

el

L

kl

>l

tul

EI

8l

E:,

o

=

Et

ll

E,-l,,8

ot E

OE

18

|eEF?

Page 19

/ ti;

i/

'i

E5

B6 s

FI<

,'

/r/

//l

i/i

i/

// ,/

//i/ i

r/i /

tt; !

/// i

ryi

/i/

'i/4,

////\

i//

iii

,i5,

I /t

\,\,

\\

i\

>l

<l

aEl

3l

6l

CIl

Zl

EI

=l

$

g

.E,

lL

€€E

rD-<

€fl

EE

E

ao

<cE

-=-

€68

a6:5

(/,

0- o-

19

Loading...

Loading...