Page 1

Place this chapter in the Toaster

TABLE OF CONTENTS

WARRANTY

1 WARNINGS

&

CAUTIONS

2

INTRODUCTION

3

SPECIFICATION CHART

3

INSTALLATION

4

PARTS IDENTIFICATION AND FUNCTION

6-7

EQUIPMENT SET

-

UP AND CLOSE PROCEDURES

9

TROUBLESHOOTING

10-11

ORDERING AND SERVICE INFORMATION

11

NON

-

SCHEDULED MAINTENANCE

12-17

Section of your Equipment Manual

MANUFACTURED

EXCLUSIVELY FOR

McDONALD'S®

By

Toastmaster®

A Middleby Company 1400

Toastmaster Drive Elgin, IL

60120 (847)741-3300 FAX (847)

741-4406 Middleby Corp 24 Hour

Service Hotline 1-800-238-8444

CONVEYOR TOASTERS

Models TC208M & TC240M

ELECTRICAL SCHEMATIC & WIRING

McDONALD'S TOASTER LIMITED WARRANTY|

All equipment manufactured by Toastmaster Commercial which is sold under the "Toastmaster" trademark and used for

commercial purposes is warranted against defects in materials and workmanship. The warranty runs for one year (see

exception*) from the date of original installation or 18 months from the original date of purchase, and is for the benefit of the

original purchaser only. ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, STATUTORY OR OTHERWISE,

INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR

PURPOSE ARE EXCLUDED. Seller shall in no event be liable for direct, indirect or consequential damages in connection

with Toastmaster Commercial products.

Seller's obligation under this warranty is limited to the repair of defects without charge, by a factory authorized service

agency or one of its sub-service agencies. Such repair service will be provided on customer's premises except in the case of

portable products.

Models that are considered portable (devices with cord and plugs except conveyor toasters) must be taken or shipped to the

closest authorized service agency, transportation charges prepaid.

This warranty is not effective if damage occurs because of accident, carelessness, improper installation, lack of proper set-up

supervision when required; or, because equipment is installed on a different voltage, steam or gas service then designated on

the equipment nameplate; or, if the equipment is installed or operated in any manner contrary to the installation and operation

instructions. In these cases, repairs will be made at a reasonable cost. Work performed by unauthorized personnel or service

agencies voids 'this warranty.

Authorized service agencies are located in principal cities throughout the United States. This warranty is valid in the 50

United States and is void elsewhere. Please consult your classified telephone directory, your food service equipment

distributor, or write the Factory Service Department, Toastmaster®, 1400 Toastmaster Drive, Elgin, Illinois 60120, for

information and other details concerning service of this warranty

.*NOTE: Exceptions - Model SS2, Sink Sanitizer warranty runs 90 days.

18-19

This manual is for the exclusive use of licensees and employees of McDonald”s Systems, Inc.

1995 McDonald’s Corporation Printed in March Printed in

All Rights Reserved EM T6 The United States of America

Page 2

INTRODUCTION

The Models TC208M & TC240M toaster is a

commercial conveyor toaster designed to uniformly

toast English muffins in large quantities, using either

batch or continuous feed methods. A partial load

switch permits individual muffin toasting without

changing batch settings.

The toaster is capable of producing up to 360 muffins

per hour.

WARNING: The toaster should be grounded according to local electrical codes to prevent the possibility

of electrical shock. It requires a grounded receptacle

with separate electrical lines, protected by fuses or

circuit breakers of the proper rating.

SAFETY

WARNING: In case of fire de-energize toaster at

disconnect switch. This will cut off power to the heating

elements and allow the toaster to cool thus reducing the

temperature and making it easier to stop the fire.

CAUTION: Use a fire extinguisher filled only with CO2 or

Halon which is suitable for electric powered equipment.

WARNING: Do not pick up the toaster by sticking fingers

into toaster entrance and exit openings. Electrical shock

and/or burns to the body can result.

CAUTION: For your safety do not store or use gasoline

or other flammable vapors or liquids in the vicinity of this

or any other appliance.

NOTE: Retain this manual for future reference. This

manual provides detailed information for installation

and operation of your Toaster. It also contains some

information to assist the operator in diagnosing

problems in the event of a malfunction. This manual is

an important tool for the operator and should be kept

readily available.

NOTE: Using any parts other than genuine

Toastmaster factory supplied parts relieves the

manufacturer of all liability.

NOTE: Toastmaster (Manufacturer) reserves the right

to change specifications and product design without

notice. Such revisions do not entitle the buyer to

corresponding changes, improvements, additions or

replacements for previously purchased equipment.

PRECAUTION: Hazard Communication Standard

(HCS)--The procedure(s) in this chapter include the

use of chemical products. These chemical products

will be highlighted with bold face letters followed by

the abbreviation (HCS). See the Hazard

Communication Standard (HCS) Manual for the

appropriate Material Safety Data Sheet(s) (MSDS).

WARNING: Use extreme care during electrical circuit

tests. Live circuits will be exposed.

NOTE: This piece of equipment is made in America

and has American sizes of hardware. All hardware

metric conversions are approximate and can vary in

size.

WARNING: Inspection, testing and repair of electrical

equipment should be performed only by qualified

service personnel. The toaster should be unplugged

when servicing, except when electrical tests are

required.

2

Page 3

TOASTER SPECIFICATION CHART

Model TC208M Model TC240M

Overall Dimensions:

Width

Depth (Includes 2-1/4" Back Guard)

Height (Includes 4" Legs)

16-1/2" (419mm)

x

24" (610mm)

x

16-1/2" (419mm)

x

24" (610mm)

x

16-1/4" (413mm)

16-1/4" (413mm)

Toasting Chamber Dimensions:

Width

Length

Height of Opening

11-1/2" (292mm)

x

15" (381 mm)

x

1 -5/8" (41 mm)

11-1/2" (292mm)

1-5/8" (41 mm)

x

15" (381mm)

x

Approximate Net Weight 51 Ibs (23 kg) 51 Ibs (23 kg)

Approximate Shipping Weight 56 Ibs (25 kg) 56 Ibs (25 kg)

Construction Formed & Welded Sheet Steel

Finish Stainless Steel

Cord 6 ft. (1.86m) 6ft. (1.86m)

Plug NEMA 6-30P (208V) NEMA 6-30P (240V)

Electrical

208V, 1 Ph, 50-60 Hz,

2 Pole, 3 Wire

240V, 1 Ph, 50-60 Hz,

2 Pole, 3 Wire

Total Wattage 3200 Watts 3600 Watts

Total Amperage 15.4 Amp 15.0 Amp

Main Panel Circuit Breaker 20Amp 20Amp

Pre-heat Time 20 Minutes 20 Minutes

Production Capacity 360 Muffins/Hour 360 Muffins/Hour

3

Page 4

INSTALLATION

WARNING:

A. Inspect for Shipping Damage

All shipping containers should be examined for

damage before and during unloading. This

equipment was carefully inspected and packaged

at the factory. The freight carrier has assumed

responsibility for its safe transit and delivery. If

equipment is received in damaged condition,

either apparent or concealed, a claim must be

made with the delivering carrier.

1. Apparent Damage or Loss - If damage or loss

is apparent it must be noted on the freight bill or

express receipt at the time of delivery, and it must

be signed by the carrier's agent (driver). If this is

not done, the carrier may refuse the claim. The

carrier will supply the necessary claim forms.

2. Concealed Damage or Loss - If damage or loss

is NOT apparent until after equipment is

unpacked, a request for inspection of concealed

damage must be made with carrier within 15

days. The carrier will make an inspection and will

supply necessary claim forms. Be certain to retain

all contents plus external and internal packaging

materials for inspection.

B. Unpacking Toaster

1. Remove staples from carton.

Before making any electrical connections be sure

the main electrical supply source is turned "OFF"

C. Electrical Connection

The Model TC208M & TC240M toasters are factory

equipped with cord and plug.

D. Checking the Installation

1. Turn main electrical supply source "ON".

2. Push Power ON/OFF Switch "ON". See Figure 1.

3. Check that conveyor is moving forward into

toaster.

4. Visually check that all heating elements are

heating and glowing red. See Figure 1.

5. Push PARTIAL LOAD Button. Check that Conveyor

speeds up for 20 +/-5 seconds and then returns to

original speed.

6. Push Power ON/OFF Switch "OFF".

7. Visually check that all heating elements are no

longer on.

8. Check that conveyor has stopped.

2. Lift out foam packing and poly bag from around

toaster.

3. Carefully lift toaster out of carton.

4. Remove all loose parts and the information

packet from the carton. Be sure all loose parts are

removed from the bottom of the carton.

5. Remove the toaster from the carton and

remove any parts or packing materials from inside

the toaster chamber. Check for any damage to

the unit or the loose parts.

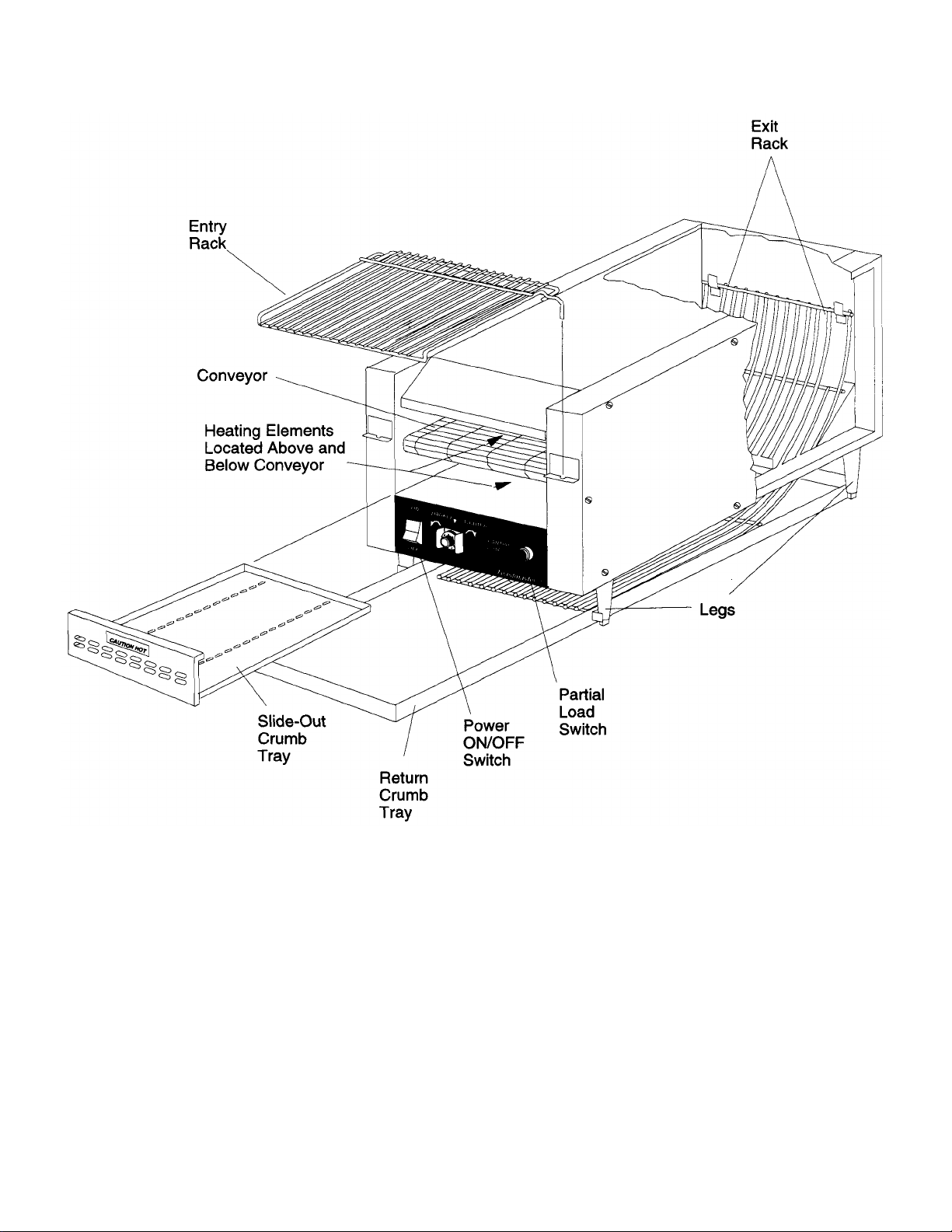

6. Install the 4" legs shown in Figure 1 and place

conveyor toaster in desired location.

7. Install the return crumb tray by positioning the

brackets on the side of the tray against the front

legs of the toaster as shown in Figure 1.

8. Install the entry rack, slide-out crumb tray and

exit rack as shown in Figure 1.

4

Page 5

Figure 1

5

Page 6

PARTS IDENTIFICATION AND FUNCTION

ITEM PART NO. DESCRIPTION QTY FUNCTION

1 7610842

TOP PANEL WELDMENT

1

Encloses top of toaster

2 7008168

SIDE PANEL

2

Encloses side componen

ts 3 30051

PANEL, TOP HEATER SUPPORT

1

Attaches to sidewall to support top heater

4 7008170

BOTTOM PANEL

1

Encloses electrical components

5 27470

-

0004

PAN GRILL

1

Protection from fan blades

6

7007044

BELTING

1

Belt which conveys items through toaster

7 3101215

BELT LINKS

3

Links which make up the conveyor belt

8

30067

FRONT ROLLER WELDMENT

1

Front shaft of conveyor

9 7610849

BEARINGS, FRONT ASSEMBLY

2

Bearing and spring assembly

10 7008178

BEARINGS, FRONT

2

Accepts either end of front conveyor shaft

11 3103262

SPRINGS

2

Apply pressure to conveyor

12

30063

REAR ROLLER WELDMENT

1

Rear shaft of conveyor

13 7006963

BEARING, REAR LEFT

1

Accepts left end of rear conveyor shaft

14 7006964

BEARING, REAR RIGHT

1

Accepts right end of rear conveyor shaft

15

7007045

SPROCKETS

2

Engage with both ends of chain to drive conveyor

16 7007605

CHAIN

1

Drives conveyor

17 3101212

MASTER LINK

1

Chain link used to diassemble chain

18 30247

RACK, ELEMENT GUARD

1

Protects elements

19 30050

TOP HEATING ELEMENT ASSEM

BLY 208V

1

Toasts top of item

19

30100

TOP HEATING ELEMENT ASSEMBLY 240V

1

Toasts top of item

20 31582

TOP HEATING ELEMENT 208V

3

Toasting element

20 31583

TOP HEATING ELEMENT 240V

3

Toasting element

21 30340

BUS BAR

3

Connects elements electrically

22 3102634

STRIP, MICA REAR

3

Insulation between heating elements and metal parts

23

2001327

NUT KEPS

6-32 9 Attaches elements

24 7008183

ELEMENT SUPPORT BRACKET

3

Supports and attaches heating elements

25 2000023

SCREW,

6-32 X 1/4,

SLT HEX

4

Attaches

elements

26 7008175

PANEL, TOP HEATER SUPPORT

1

Attaches to sidewall to support top heater

27 30209

BOTTOM HEATER SUPPORT, RIGHT

1

Attaches to right sidewall to support bottom heater

28 30054

BOTTOM HEATER SUPPORT, LEFT

1

Attaches to left sidewall

to support bottom heater

29 31585

BOTTOM HEATING ELEMENT 208V

1

Element toasts bottom of item

29

31587

BOTTOM HEATING ELEMENT 240V

1

Element toasts bottom of item

30 3B20A8801

SCREW WASH HEX HD

8-32 X 3/8" 26 Used to attach parts

31

30519

THERMA

L SNAP DISC

1

Turns toaster off when overheated

32 30697

TRANSFORMER

1

Converts from

208

or 240V to 120V for control circuit

33 3002757

MOTOR

1

Drives the conveyor

34 3002808

SPEED CONTROLLER

1

Controls speed of conveyor

35

30076

SPEED CONTROLL

ER KNOB

1

Turns speed controller to a set speed

36 30069

SPEED CONTROLLER GUARD

1

Knob guard

37 3003828

ON/OFF SWITCH

1

Completes circuit to components

38 27392

-

0002

FAN 1 Cools air in bottom compartment

39

27159

-

0003

CORD SET, COOLING FAN

1

Conn

ects fan with terminal block

40 21226

-

0007

SCREW FAN MOUNTING

4

Used to mount fan

41 3001226

FUSE

1

Shuts off current to motor if current draw is too high

42 30640

PLUG/CORD PIN

&

SLEEVE

-

Used in

U.S.A

.

1

Toaster cord

&

pin plug

42

31974

PLUG/CORD TW

IST LOCK

-

Used in

1

Toaster cord

&

twist lock plug

42 30641

PLUG/CORD PIN

&

SLEEVE

-

1

Toaster cord

&

pin plug

42 31973

PLUG/CORD TWIST LOCK

-

1

Toaster cord

&

twist lock plug

42

30640

PLUG/CORD PIN

&

SLEEVE

-

1

Toaster cord

&

pin plug

43 2001371

NUT, KEPS

10-32 4 Attaches top heater support panel

44 30075

PUSHBUTTON SWITCH w/LIGHT

-

GREEN

1

Momentary switch pushed for partial loads

45 30074

TIME DELAY RELAY

1

Activated by momentary switch to

speed up conveyor

46 30073

SOCKET, OCTAL RELAY

1

Mount for time delay relay

47 30118

RELAY ACCESS DOOR

1

Access for adjusting relay

48 27011

-

0017

TERMINAL BLOCK

1

Connects incoming power

49

7008180

ENTRY RACK

1

Loads items onto conveyor

50 7609868

EXI

T RACK

1

Delivers items to return crumb tray beneath toaster

51

30077

RETURN CRUMB TRAY

1

Receives items from conveyor and catches crumbs

52 7610845

SLIDE IN CRUMB TRAY

1

Catches crumbs from items inside toaster

53

1523B8301

LEGS,

4"

BLACK PLASTIC

4 Adjustable legs used to support the toaster

54

3100558

CAP LEG NON SKID

4

Non skid cap on leg

55 30861

LABEL

1

Caution label

56 321049

LABEL, CAUTION HOT

1

Caution label

57 31616

PANEL REAR

1

Maintains space between toaster and wall

58 30122

INSIDE PANE

L 1 Dissipates heat between toaster and rear panel

59 B301A8855

SCREW

16

Attaches side panel

Not shown

7005957

NAMEPLATE

1

Toastmaster logo

Not shown

3101254

INSULATION CLIPS

4

Used to hold insulation in place

Not shown

30864

WIRE HARNESS

1

Pro

vides connection between electrical components

U.S.A

Non/U.S.A & Germany

Non/U.S.A & Germany

Used in Germany

Not shown

30696 CONVEYOR TOASTER MANUAL

6

1

Toaster operation and maintenance

Page 7

Figure

2

7

7

Page 8

Set-Up:

EQUIPMENT SET-UP AND

CLOSE PROCEDURES

Close:

WARNING: Always disconnect electrical power or

unplug toaster and allow to cool before cleaning

or performing any service.

1. Insert the power cord into a proper 20 Amp.

electrical receptacle.

2. Install the return crumb tray by positioning the

brackets on the side of the tray against the front

legs of the toaster as shown in Figure 4.

3. Install the entry rack, slide-out crumb tray and exit

rack as shown in Figure 4.

4. Turn toaster on by pushing Power ON/OFF Switch

ON.

5. Allow 20 minutes for warm up.

6. Adjust DARKER/LIGHTER Knob to approximately

"5" for toasting a normal batch of 7 to 12 muffin

halves.

7. Loading muffins into toaster:

NOTE: Muffins are placed in toaster cut side up.

Batch Loading-

For batch loading stage muffins on bun spatula

and then place muffins on entry rack with rack in

lowered position. Raise entry rack to feed muffins

onto conveyor.

Continuous Loading-

For partial batch loading stage muffins directly on

entry rack with rack in raised position.

8. Press the PARTIAL LOAD Button for a batch of 6

muffin halves or less and the conveyor will speed

up. It will reset to normal speed automatically

when the partial load has been toasted.

WARNING: Always disconnect electrical power

or unplug toaster before cleaning or

performing any service.

9. Clearing Jams: Use extreme caution when

removing a product jam. It is always better to wait

for toaster to cool, if time permits, before removing

jammed product. Unplug toaster before clearing a

jam. CAUTION: When clearing jams use caution

to not damage elements.

1. With the conveyor running brush any crumbs off the

conveyor and onto the crumb pan below.

2. Turn off the toaster and disconnect electrical power or

unplug toaster. Then allow toaster to cool.

3. Clean the toaster exterior by wiping with a clean,

sanitized towel dampened with a hot solution of McD

All Purpose Concentrate (APC) (HCS) as drawn

from the sink proportioner. Rinse by wiping with a

clean, damp sanitized towel. DO NOT use abrasive

pads of scouring cleansers. They will scratch and dull

the finish.

4. Crumb trays and racks:

WARNING: Hot Surfaces - DO NOT TOUCH HOT

SURFACES OR REACH INTO TOASTER WHEN IT

IS HOT.

After the toaster has cooled, remove the slide-out

crumb tray and the return crumb tray by sliding them

out of the toaster.

CAUTION: Do not remove slide -out crumb tray

while conveyor is moving.

Remove the entry rack and exit rack from toaster.

5. Wash the slide -out crumb tray, return crumb tray and

racks in a hot solution of McD All Purpose Concen-

trate (APC) (HCS). Remove any gold discoloration

from the front of the slide -out crumb tray by

scrubbing with a McD No Scratch Pad.

Rinse well and sanitize by immersing in McD Sink

Sanitizer solution (HCS) (1 pak in 10 gallons of

warm water). Remove parts from sanitizer solution

and allow to air dry.

6. Reassemble all parts onto oven.

CAUTION: DO NOT use excessive water or submerge toaster in water. Electrical problems will

occur.

WARNING: DO NOT stick anything into the

toasting chamber as you may damage the

heating elements and cause electrical shock.

8

Page 9

WARNING

DO NOT OPERATE THE CONVEYOR TOASTER:

Premature failure of the heater elements will occur

and the toaster warranty will be void.

• on either of Its sides

• on its rear surface

• without legs

Figure 4

9

Page 10

TROUBLESHOOTING

PROBLEM

PROBABLE CAUSE

CORRECTIVE ACTION

Muffins must be at room temperature

Product toasted too dark or too light.

Toaster overheats and shuts down.

Toaster will not heat up.

DARKER/LIGHTER control knob

not set correctly.

Partial Load button not being

pressed when 6 or less items are

being toasted.

Using refrigerated or frozen muffins

Time Delay Relay not set correctly.

Cooling fan dirty.

Cooling fan unplugged.

Cooling fan defective. Call service agency.

Thermostat switch overheats and

opens.

Toaster not plugged in. Plug in toaster.

Set knob for correct darkness.

Press Partial Load button when

sliding loads of 6 or less items

onto conveyor.

before toasting. Allow a 2 day old

rotation when using fresh muffins.

Call service agency.

Clean the fan. Follow procedure on

Planned Maintenance Card 1.

Turn ON/OFF switch and main

power switch off, remove bottom

cover and check that plug on fan is

plugged in. Refer to Wiring

diagram.

Call service agency.

Toaster will heat up but

conveyor does not move.

Main power switch turned off. Turn main power switch on.

Defective ON/OFF switch. Replace switch.

Defective receptacle,

power cord or plug.

Thermostat switch is open. Call service agency.

Wire(s) loose. Call service agency.

Foreign object blocking conveyor.

Drive Motor fuse is blown.

Wire(s) loose

Plug into different receptacle.

Replace plug or power cord.

Turn ON/OFF switch and main

power switch off and remove

object from conveyor

Turn toaster off and call service

agency.

Call service agency.

10

Page 11

TROUBLESHOOTING Continued

p

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Noticeable burning smell. Toasted item stuck in toaster. Turn ON/OFF switch and main

Too many accumulated crumbs Turn toaster off and let it cool and

in slide-out crumb tray. then remove and clean slide -out

Items feed into machine but are not Exit rack not installed in machine. Install exit rack. Refer to Page5.

delivered to front of return crumb

tray. Item(s) stuck on exit rack. Turn ON/OFF switch off and

ORDERING/SERVICE INFORMATION Ordering

Parts

Service

If technical help is needed contact your local authorized

Use only genuine Toastmaster (manufacturer) replacement parts in your toaster. Use of parts other than those

supplied by manufacturer voids the warranty and U.L.

status.

Your authorized service agency has a parts price list

and will be glad to inform you of the cost of your parts

order.

service agency. Please have the following information

ready when you call:

NOTE: Model # and Serial # are found on the data plate,

refer to Figure 5.

Manufacturer:Toastmaster

Model #: TC208M or TC240M

Locate your desired part in the exploded parts drawing

and then find the item and part number of the part in the

Serial # ________________________

parts list.

List the following ordering information:

Problem with toaster and symptoms: ________

NOTE: Model # and Serial # are found on the data plate,

refer to Figure 5.

Model #:TC208M or TC240M

Manufacturer:Toastmaster

Serial #: _______________

ower switch off and remove

item from toaster.

crumb tray. Refer to Page 10.

remove item(s).

Item No(from parts list): _______________

Part No (from parts list): _______________

Return Policy

An RGA number (Return Goods Authorization) must be

obtained from Toastmaster before returning a product.

Description: _______________

Shipping charges must be prepaid by buyer. Returned

goods are subject to Toastmasters inspection and accep-

Order the required parts from your local authorized ser-

tance.

vice agency.

Delivery Date of Toaster: _______________

Local Service Agency:

Name _______________________

Number & Street _________________

City, State, Zip ___________________

Phone Number___________________

Page 12

NON-SCHEDULED MAINTENANCE

This section provides information for replacement of various parts and components as necessary. Before replacement

of any parts refer to the Troubleshooting Section for assistance in determining the cause of the problem and to verify

that replacement is required. If necessary contact your local authorized service agency for assistance.

CAUTION: Before performing any maintenance:

1. Turn toaster ON/OFF switch OFF.

2. Turn main power switch off.

3. Unplug toaster from receptacle.

4. Allow toaster to cool.

Tools Necessary: Flat blade screwdriver, Philips screwdriver, Set of Alien wrenches, Needle nose pliers, Regular

pliers, Set of sockets with handle

A. Top Heating Elements Replacement

1. Remove the toaster right side cover by removing the 6 screws.

2. Remove the 6 nuts from the right side top heater support panel.

3. Slide the heater assembly part way out and then disconnect the 2 wires from the heater terminals by removing

the 2 screws and nuts. Refer to Figure 6.

4. Remove the heat er assembly from the toaster and then remove the bus bar(s) and the mica strip from the

heater to be replaced. Refer to Figure 7.

5. Remove the 2 screws attaching the heater to the heater supports.

6. Replace the heater with the new one and reassemble part s in the reverse order they were removed. Be sure to

connect wires to heater terminals before sliding heater assembly all the way into toaster. Refer to Figure 7 to

be sure heater assembly and element guard are mounted on studs and inserted into holes.

12

Page 13

Figure 7

13

Page 14

B. Bottom Heating Elements Replacement

1. Remove the toaster right side cover by removing the 6 screws.

2. Loosen 4 motor mounting screws and move motor/shaft to the right and then remove the drive chain from the

motor sprocket.

3. Remove the 6 nuts from the right side bottom heater support panel and the 2 screws to remove the wires from

the heater terminals. Refer to Figure 8.

WARNING: Be careful not to bend or damage the heater terminals.

4. Remove heater assembly from toaster. It may be necessary to use a screwdriver to pry slightly at each end of

heater support bracket. Do not damage or bend the heater support panel.

5. Replace bottom heater element by removing 2 screws attaching it to heater support panel and attaching new

heater element.

6. Reassemble parts in the reverse order they were removed. Be sure to insert heater element into the 2 bracket

openings on the left side of toaster when sliding the heating element into the toaster. Refer to Figure 8. Also

position heater support against spring at end of shaft bearing when reassembling heater assembly into toaster.

7. Reassemble drive chain onto motor sprocket and then push the motor to the left to place tension on the chain.

The drive chain must be tight. Tighten the 4 motor mounting screws.

8. Connect wires to new heating element.

Figure 8

14

Page 15

C. Conveyor Belt Replacement:

1. Remove the right and left side covers by removing the 6 screws on each side. On right side of toaster use a

screwdriver to push the bearing as shown. With the hole in the bearing lined up with the slot in the retaining

plate, push the conveyor shaft thru the slot. See Figure 9.

2. To remove all tension on the conveyor belt push the conveyor shaft as far as possible toward the right side

until the left end of convey or shaft is free of the left side bearing. See Figure 9.

3. Turn the conveyor belt so the master links are at the front of the toaster. See Figure 9.

4. Using long nose pliers remove the three master links. Replace the belt or replace the damaged links in the belt.

5. Reassemble the master links into the conveyor belt.

6. Push the left side bearing with a screwdriver as shown in Figure 9 and reinsert the shaft into the bearing.

Release the shaft from the right side support slot and center the shaft between the side walls.

Figure 9

15

Page 16

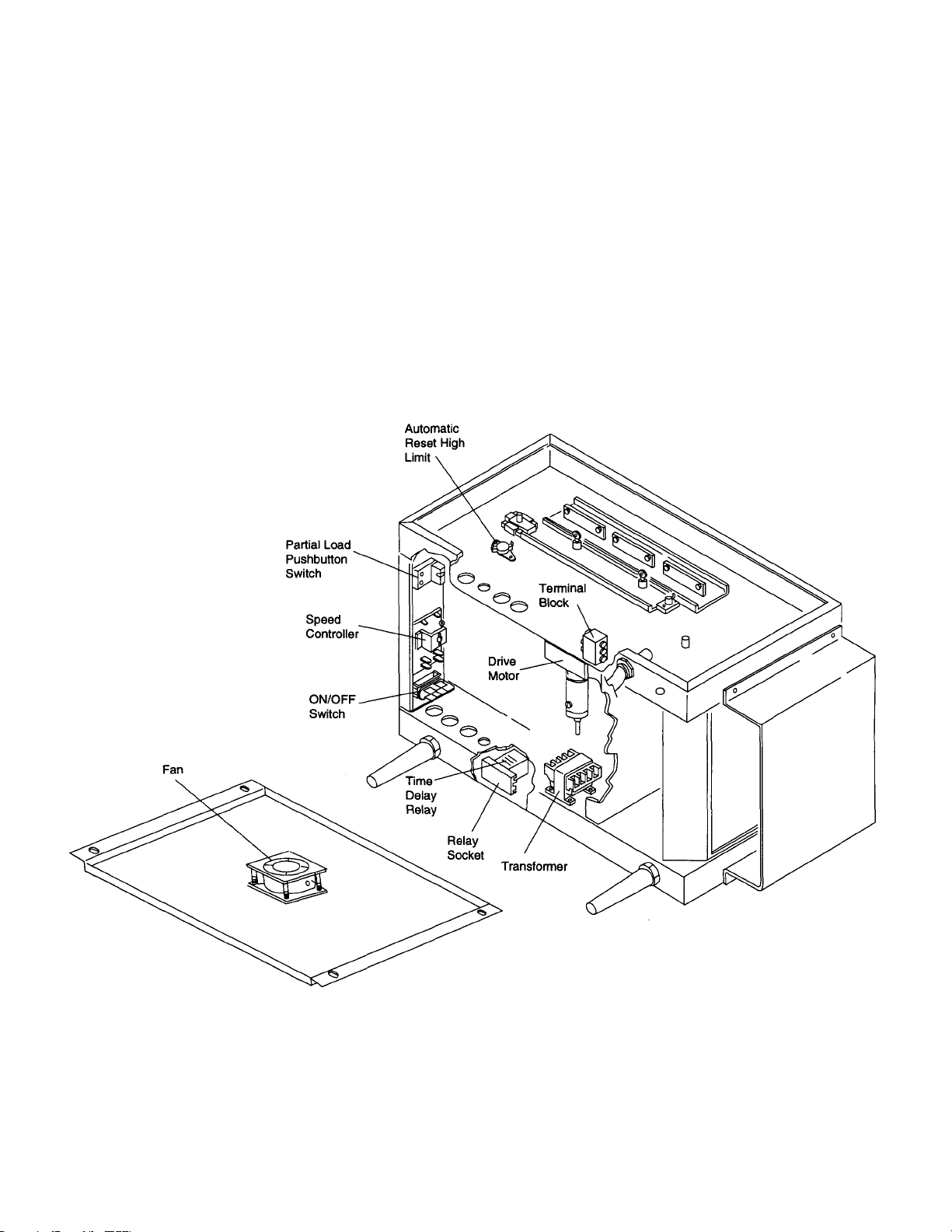

D. Electrical Components Replacement (Drive Motor, Transformer, Fan, On/Off Switch, Speed Controller,

Pushbutton Partial Load Switch)

1. Lift the toaster onto its side as shown.

2. Remove the bottom panel by removing the 4 screws.

3. The electrical components are now accessible. Remove wires one at a time from the old component and

replace them on the new component. Remove the screws and/or nuts attaching the old component to the

toaster and remove it. Mount the new component onto the toaster.

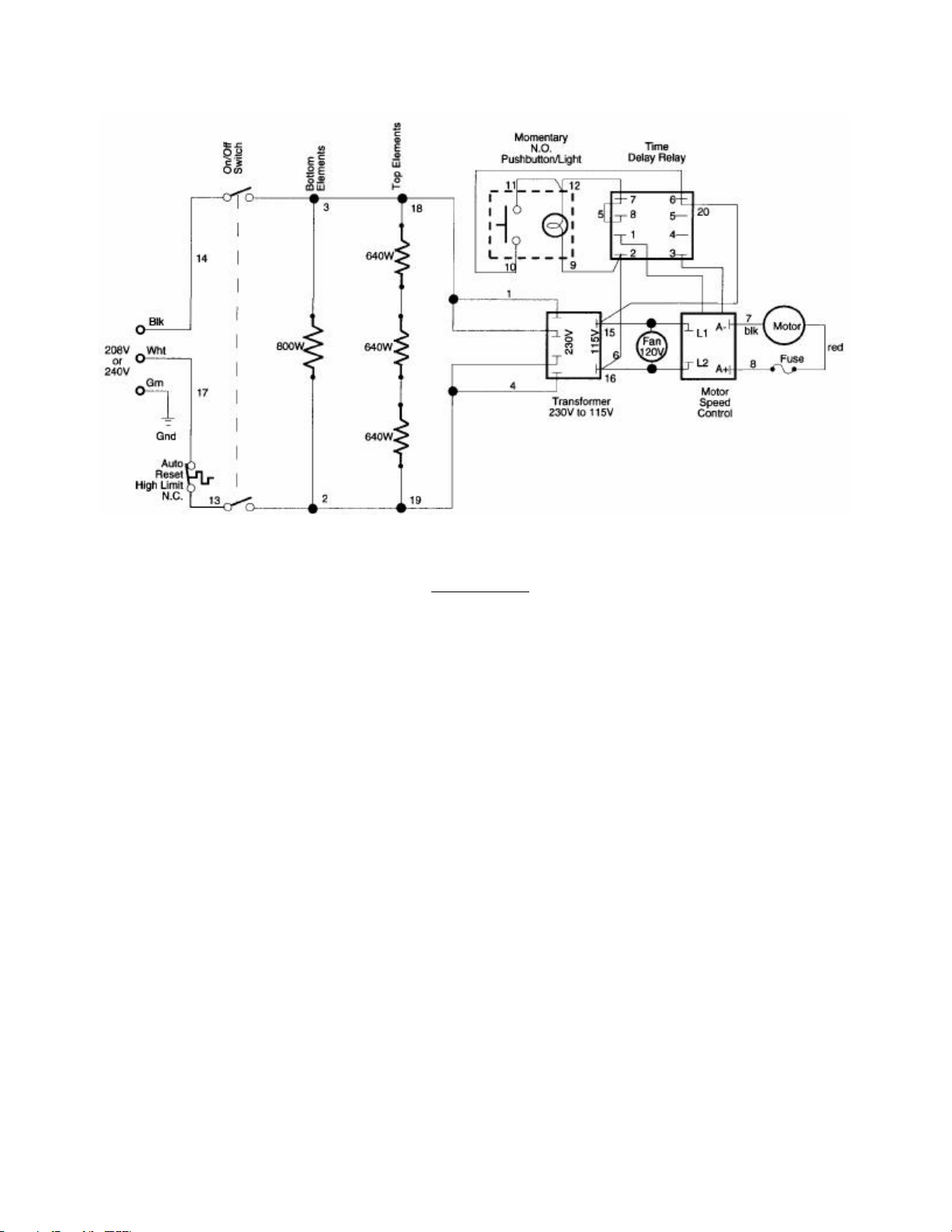

4. Use the wiring diagram to help connect the wires to the new component if necessary.

5. Replace bottom panel using the 4 screws that were removed.

Figure 10

Page 17

E. Time Delay Relay Replacement

1. Remove the door in the left side cover by removing 1 screw.

2. The time delay relay is now accessible. Remove the relay from its socket and replace with the new relay.

3. Replace the door in the left side cover.

F. Relay Socket Replacement

1. Remove the toaster left side cover by removing the 6 screws.

2. Remove the Time Delay Relay from the socket.

3. Remove wires one at a time from the old relay socket and replace them on the new relay socket. Remove the

screws attaching the old relay socket to the toaster and remove it. Mount the new relay socket onto the

toaster.

4. Use the wiring diagram to help connect the wires to the new relay socket if necessary.

5. Replace side cove r using the 6 screws that were removed.

6. Refer to MRC #19 for instructions to properly adjust time delay relay.

G. Automatic Reset High Limit Replacement

1. Remove the right side cover by removing 6 screws.

2. The Automatic Reset High Limit is now accessible. Remove wires one at a time from the old High Limit and

replace them on the new one. Remove the screws attaching the old High Limit to the toaster and remove it.

Mount the new High Limit onto the toaster.

3. Use the wiring diagram to help connect the wires to the new High Limit if necessary.

4. Replace side cover using the 6 screws that were removed.

17

Page 18

SCHEMATIC

Figure 11

18

Page 19

WIRING DIAGRAM

Figure 12

19

Loading...

Loading...