TOA-DKK TB-31 Instruction Manual

HAND HELD TURBIDITY METER

MODEL TB-31

No. TB3-LB16000E

Please keep this instruction manual close at hand of the persons who are in charge of

the operation of this product.

Before operating this product, please read this instruction manual carefully for its

correct handling.

Model: TB-31 Introduction

Introduction

(a) Thank you for your purchase of the Model TB-31 Hand Held turbidity meter (hereinafter called the

instrument or the product). The instrument has a waterproof construction suitable for on-site

measurements and a clock function and data memory function indispensable in data management.

In addition, consumed power is lowered up to 1/7 compared with the conventional products.

(b) An AC adapter, external printer, and RS-232C connection cable can be connected to the instrument

main body as optional devices. The data of measured value and calibration value can be printed by

the printing function of an external printer.

(c) Since important items are described in “Safety Information”, read the contents carefully. After

reading this manual, store it in a convenient place.

-

1 -

Model: TB-31 Safety Information

Safety Information

(1) Meaning of markings

The signal terminology and symbols related to warnings in the instruction manual are defined below.

The alert symbol mark (

also means “Refer to the instruction manual.”

:

Indicates the degree of hazard which can lead to death or serious injury if you fail to operate the

product properly.

Serious injury means an injury such as loss of sight, burns (high temperature or low temperature),

electric shock, bone fracture and poisoning, and the aftereffects of the injury remains or the injury

requires hospitalization or long periods of outpatient treatment.

:

Indicates the degree of hazard/loss which can result in injury or property damage if you fail to operate

the product properly.

Injury means an injury not requiring hospitalization or long periods of outpatient treatment and refers

to burns or electric shock. Property damage refers to widespread damage to the home, household

goods and livestock, pets, equipment, materials, etc. (damage to other than the product itself).

: General caution mark) indicates the possibility of hazard or damage and

【IMPORTANT】

〔NOTE〕

①, ②, ③ Indicates item numbers such as the ones used in operations.

Indicates important matters other than

matters such as preventing damage to the product main body, preventing data

destruction, preventing wasting time, maintaining performance, and observing

regulations.

Indicates comments, reasons, background information, a case example and other

items to help the reader understand the meaning.

Indicates reference items.

(2) Safety compliance items

Explosion, fire, electric shock, and battery leakage

Do not use the product in an area where explosive gas or flammable gas exists.

Do not place the product in a fire or burn it. Doing so may cause an explosion or fire

inside the product.

Always verify that the power is off before connecting or disconnecting the plug, AC

adapter cover, or input/output cover. Water or reagent entering the product may short

the circuits and cause electric shock or fire.

When the product will not be used for a long time, always remove the AA size alkali

battery or AA size rechargeable nickel hydride battery.

Liquid may leak from the battery.

and . They are the

-

2 -

Model: TB-31 Safety Information

Tumbling

When working at the measurement point, prevent the tumbling using such as a safety

belt, etc. In addition, to prevent injury, wear a helmet, life jacket, safety boots, etc.

Waterproofing

The construction of the product becomes waterproof (IP67) only when the sensor,

battery cover, AC adapter cover, and input/output cover are installed properly.

Do not touch the instrument with wet hands or wash it with water when the sensor

has been removed or the battery cover, AC adapter cover, or input/output cover is

opened. Besides, do not install or store the product where water or reagent may

enter it.

Mixing in

Do not drop the instrument body into the measurement tank. Doing so may cause

trouble.

Disassembly and Modification

Do not disassemble or modify the sections of the product that are not described in

the instruction manual. The product can be damaged.

Caution Label Lost

If any caution label affixed to this product becomes too difficult to read or lost, please

order a new one through your local sales agent or our sales office and affix it to its

original position.

(3) Notes on use of the instruction manual

Important items such as “Safety compliance items” are described in this manual. Handle the manual

as follows:

(a) The instruction manual is required not only at the start of operation but also required when

maintenance is performed or in case a failure occurs. Please keep the manual at hand all the time so

that the operator who actually operates the product can read the manual at any time.

(b) If the manual is lost or too smeared to read, please order a new copy through your local sales agent

or directly from our sales office.

(c) Some of the diagrams used in the manual or on product labels may be modified with part of their

shapes or displays omitted or they may be described in abstract form. In addition, numbers etc.

shown on the screen example are just examples for such cases.

(d) The contents of the manual may be changed without prior notice for reasons such as to improve

performance.

(e) Intellectual property right of the manual belongs to DKK-TOA. All or part of the manual must not

be reproduced without permission.

-

3 -

Model: TB-31 Warranty

Warranty

(1) Warranty Coverage

DKK-TOA Corporation (DKK-TOA) warrants its products against defective material or workmanship for the warranty

period.

(a) The warranty period is two years from the date of delivery to the original user.

(b) Specific written agreements with DKK-TOA, if any, shall take precedence over this warranty.

(c) The limitation of warranty described herein may not apply where applicable laws do not allow such limitation.

(2) Limited Warranty

This warranty does not cover the cases listed below.

(a) Direct or indirect failure or damage caused by the use of the product for a purpose or in a manner not prescribed by

the specifications or the instruction manual for the product.

(b) Direct or indirect failure or damage caused by force majeure, including but not limited to an act of God, natural

disaster such as earthquake, storm and flood damage, and lightning, fire, accident, abnormal voltage, salt damage,

gas damage, labor unrest, acts of war (declared or undeclared), terrorism, .civil strife, or acts of any governmental

jurisdiction.

(c) Failure or damage caused by any repair or modification not authorized by DKK-TOA.

(d) Failure or damage caused by the transport, moving, or dropping of the product after the purchase that is not

attributable to DKK-TOA.

(e) Electrodes, sensors, and consumables (The warranty period for each part has priority when the period is shorter

than that for the main unit of the product. If the customer requires any part after more than six months from the

date of manufacture, consult DKK-TOA or its distributor.)

( f ) Failure or damage caused by the use of consumables, parts, or software not supplied by DKK-TOA.

(g) Malfunctions or damage caused by the use of connecting equipment not supplied by DKK-TOA.

(h) Loss of data, settings, programs, or software stored on the product not attributable to DKK-TOA.

( i ) Any product other than DKK-TOA’s, if specified by the purchaser or user, that incorporates, or is incorporated into

or combined with DKK-TOA’s products (*1). In such cases, this warranty covers DKK-TOA’s products only.

( j ) Any product not under proper maintenance in accordance with the instruction manual furnished by DKK-TOA.

(k) Products without a nameplate (excluding products proved to have been delivered by DKK-TOA).

EXCEPT AS EXPRESSLY SET FORTH IN THE PRECEDING SENTENCES, DKK-TOA MAKES NO

WARRANTY OF ANY KIND WHATSOEVER WITH RESPECT TO ANY PRODUCT. DKK-TOA EXPRESSLY

DISCLAIMS ANY WARANTY IMPLIED BY LAW, INCLUDING BUT NOT LIMITED TO ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

LIMITATION OF REMEDIES: In the event that a defect is discovered within the warranty period, DKK-TOA or its

authorized distributor will, at its option, repair or replace the defective product or its part, or will refund the purchase

price of the product. THIS IS THE EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

LIMITATION OF DAMAGES: IN NO EVENT SHALL DKK-TOA BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY KIND FOR BREACH OF ANY WARRANTY, NEGLIGENCE, ON THE

BASIS OF STRICT LIABILITY, OR OTHERWISE.

(3) Others

(a) Product parts for maintenance (*2) will normally be supplied for five years (*3) from the date manufacturing and

sales are discontinued.

(b) The cause of any malfunction or damage shall be determined by a DKK-TOA technician.

(c) For repairs, contact a local distributor in your country or state.

*1: Warranties for products from other companies must be maintained by the user.

*2: Maintenance parts refers to parts that are required to maintain operation of the product.

*3: This five-year period is subject to availability of parts or their replacement.

P30 <1>

-

4 -

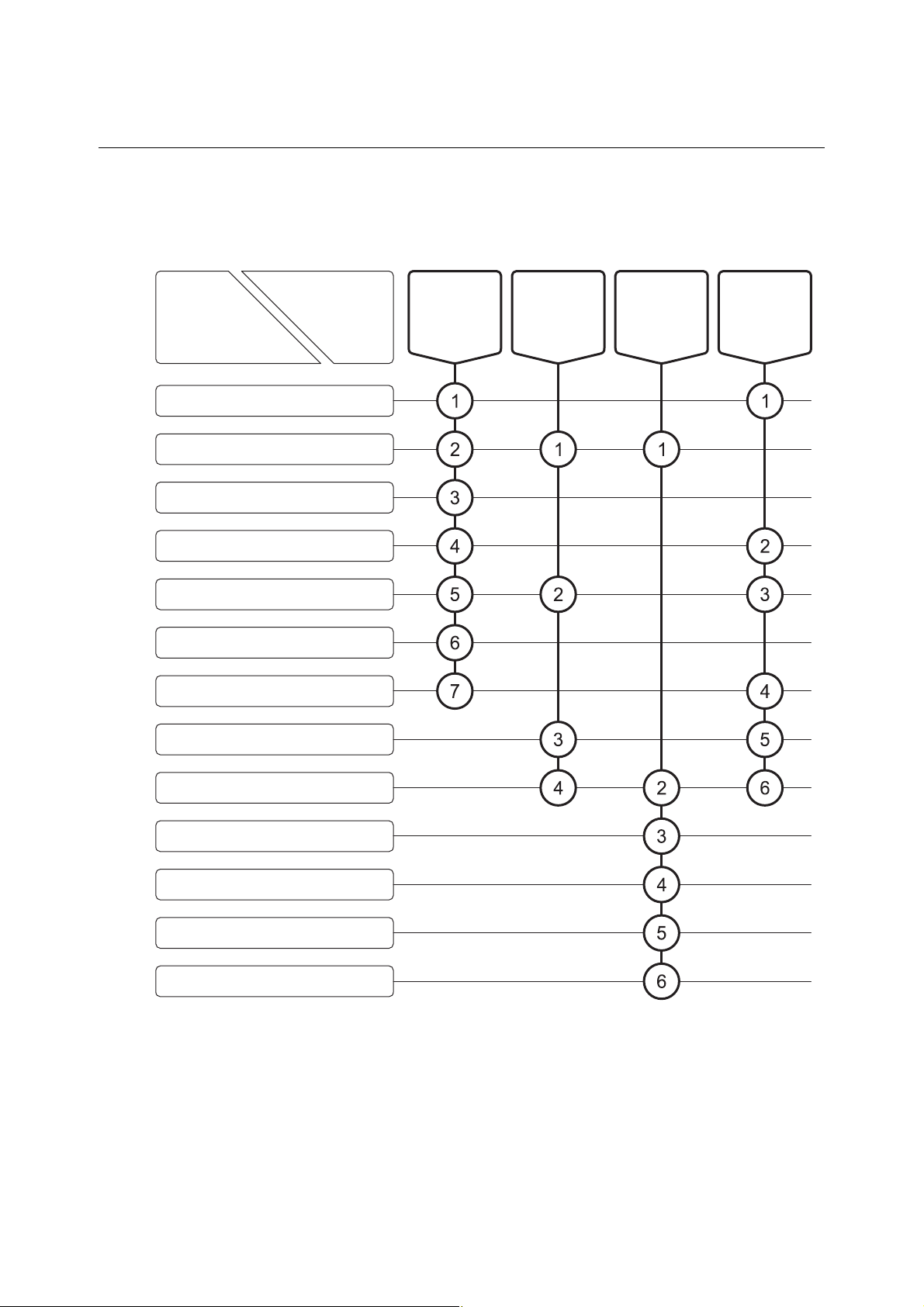

Model: TB-31 Reading Guide

Reading Guide

Refer to the necessary sections of this instruction manual depending on your purposes such as

understanding the outline of this product or starting the product as shown below. The numbers in

circles indicate sections to be referred to in sequential order.

Section

●Introduction

●Safety Information

1. Content of package

2. Specifications and Functions

3. Name and Function of Each Part

4. Preparations

5. Basic Operation

Purpose

Start (start-up) Understand the

Perform

respective

operations

Maintenance

and inspection,

and

troubleshooting

outline of this

product

6. How to Use Various Functions

7. Functions by Optional Devices

Connection

8. Maintenance and Inspection

9. Troubleshooting

10. Transport, Storage, and Disposal

11. Parts/Options List

-

5 -

Model: TB-31 Table of Contents

Table of Contents

●Introduction

●Safety Information

(1) Meaning of markings ⋅⋅⋅⋅ 2

(2) Safety compliance items ⋅⋅⋅⋅ 2

(3) Notes on use of the instruction manual ⋅⋅⋅⋅ 3

●Warranty

●Reading Guide

1. Content of Package ··················································· 9

··········································································································· 1

··························································································· 2

·················································································································· 4

··································································································· 5

2. Specifications and Functions ···································· 10

(1) Specifications ⋅⋅⋅⋅ 10

(2) Functions ⋅⋅⋅⋅ 11

3. Name and Function of Each Part ······························ 12

(1) Main body and operation panel ⋅⋅⋅⋅ 12

(2) Display ⋅⋅⋅⋅ 13

(3) Turbidity sensor (Model ELL-011) ⋅⋅⋅⋅ 15

4. Preparations ····························································· 16

4.1 Loading the Batteries ······················································································ 16

4.2 Installing and Removing the Protective Cover ·················································

(1) Installing the protective cover ⋅⋅⋅⋅ 19

(2) Removing the protective cover ⋅⋅⋅⋅ 19

4.3 Turbidity Sensor Connection ··········································································· 21

4.4 Turbidity Sensor Preparation ···········································································

19

23

5. Basic Operation ························································ 24

5.1 Operation Screens Map··················································································· 24

5.2 Turning on the Power ······················································································ 25

5.3 Time Setting ···································································································· 26

5.4 Calibration Data Display and Deletion ····························································· 27

(1) When deleting the calibration data ⋅⋅⋅⋅ 27

(2) Calibration data display ⋅⋅⋅⋅ 27

(3) Calibration data deletion ⋅⋅⋅⋅ 28

-

6 -

Model: TB-31 Table of Contents

5.5 Performing the Calibration ··············································································· 29

(1) One-touch zero calibration ⋅⋅⋅⋅ 29

(2) Span calibration ⋅⋅⋅⋅ 30

5.6 Measurement ·································································································· 34

(1) Measurement by real-time mode ⋅⋅⋅⋅ 35

(2) Measurement by batch mode ⋅⋅⋅⋅ 37

5.7 Ending Measurement ······················································································ 39

6. How to Use Various Functions ·································· 40

6.1 Auto Hold Function ··························································································

(1) Memory execution by auto hold ⋅⋅⋅⋅ 40

6.2 Data Memory Function ···················································································· 42

(1) Data number setting ⋅⋅⋅⋅ 42

(2) Memory execution by manual key ⋅⋅⋅⋅ 43

(3) Memory data recall and erasing ⋅⋅⋅⋅ 44

6.3 Interval Function ····························································································· 45

(1) Interval function and time settings ⋅⋅⋅⋅ 45

(2) Memory execution by interval ⋅⋅⋅⋅ 47

6.4 Display Range Switching Setting ····································································· 49

6.5 Measurement Unit Setting ··············································································· 50

6.6 Response Setting ···························································································· 51

6.7 Temperature Calibration Function ··································································· 52

6.8 Memory Overwrite On/Off Setting ···································································· 54

6.9 Buzzer On/Off Setting ·····················································································

6.10 Auto Power Off Setting ···················································································· 56

40

55

7. Functions by Optional Devices Connection ··············· 57

7.1 Connection of Optional Devices ······································································ 57

(1) Connection of AC adapter ⋅⋅⋅⋅ 57

(2) Connection of analog output cable ⋅⋅⋅⋅ 58

(3) Connection of external printer connection cable ⋅⋅⋅⋅ 59

(4) Connection of RS-232C connection cable ⋅⋅⋅⋅ 59

7.2 Printing Function by External Printer ······························································· 61

(1) Printing of calibrated value ⋅⋅⋅⋅ 61

(2) Printing of measured value ⋅⋅⋅⋅ 62

7.3 RS-232C Communication Function ································································· 65

(1) RS-232C communication format ⋅⋅⋅⋅ 65

(2) Data collection software ⋅⋅⋅⋅ 70

-

7 -

Model: TB-31 Table of Contents

7.4 Connection of Recorder ···················································································

(1) Connection of analog output cable ⋅⋅⋅⋅ 71

(2) Analog output specifications ⋅⋅⋅⋅ 72

(3) Analog output cable terminals wiring ⋅⋅⋅⋅ 72

8. Maintenance and Inspection ····································· 73

8.1 Instrument Body Maintenance ········································································· 73

8.2 Turbidity Sensor Maintenance ········································································· 74

(1) Daily maintenance ⋅⋅⋅⋅ 74

(2) When not recovered even by daily maintenance ⋅⋅⋅⋅ 75

8.3 Battery Replacement Period ············································································

9. Troubleshooting ························································ 77

9.1 Safety Precautions When an Abnormality Occurred ········································ 77

9.2 Error Display ··································································································· 78

9.3 Other Troubles and Countermeasures ····························································· 79

9.4 How to Reset the System ················································································ 81

71

76

(1) Returning all data and parameters to their factory setting ⋅⋅⋅⋅ 81

(2) Returning data other than the clock data and measured data to their

factory setting ⋅⋅⋅⋅ 81

10. Transport, Storage, and Disposal ······························ 82

10.1 Transport ········································································································· 82

10.2 Storage ············································································································ 83

10.3 Disposal ·········································································································· 83

11. Parts/Options List ····················································· 84

(Last page ⋅⋅⋅⋅ 86)

-

8 -

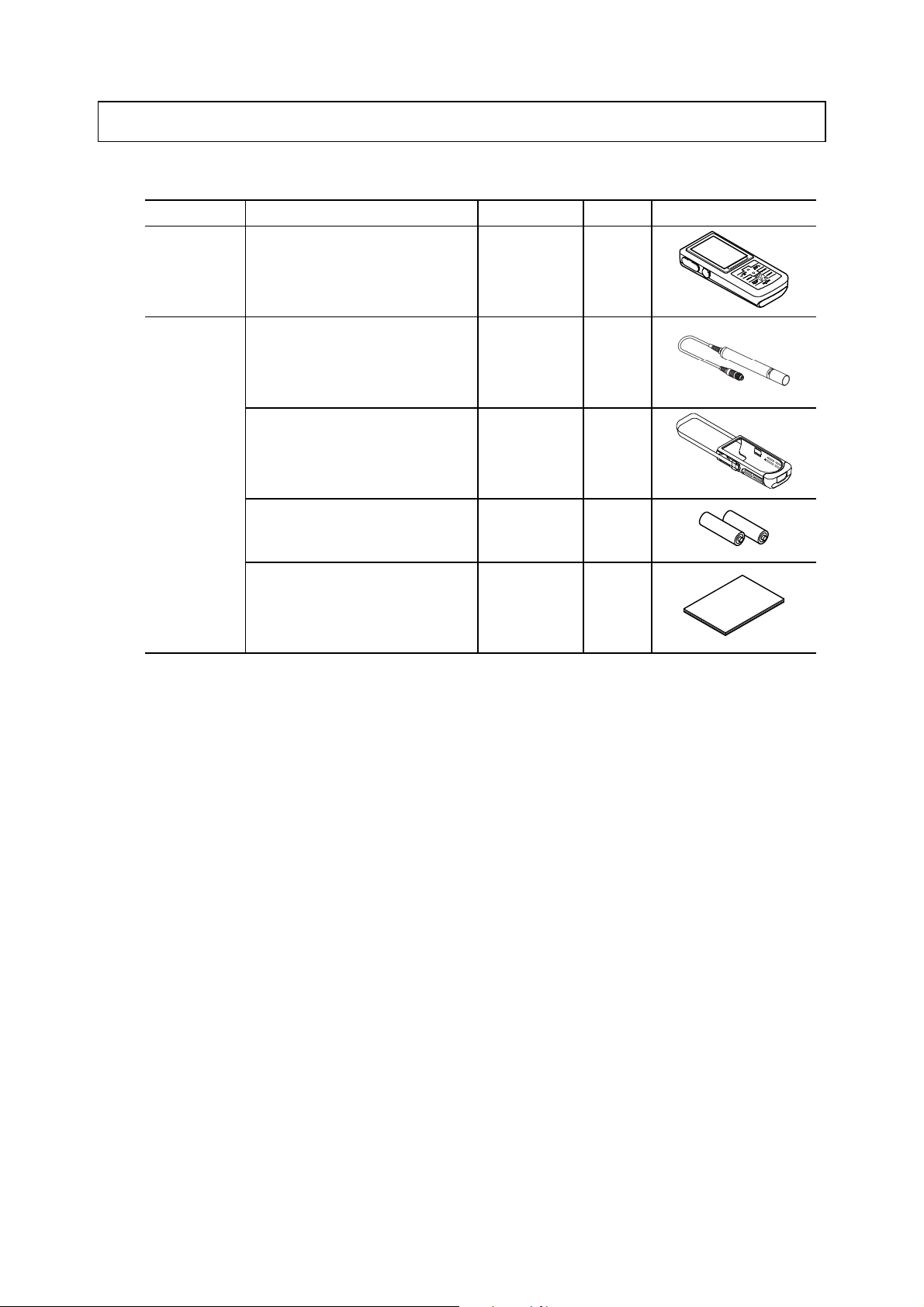

Model: TB-31 1. Content of Package

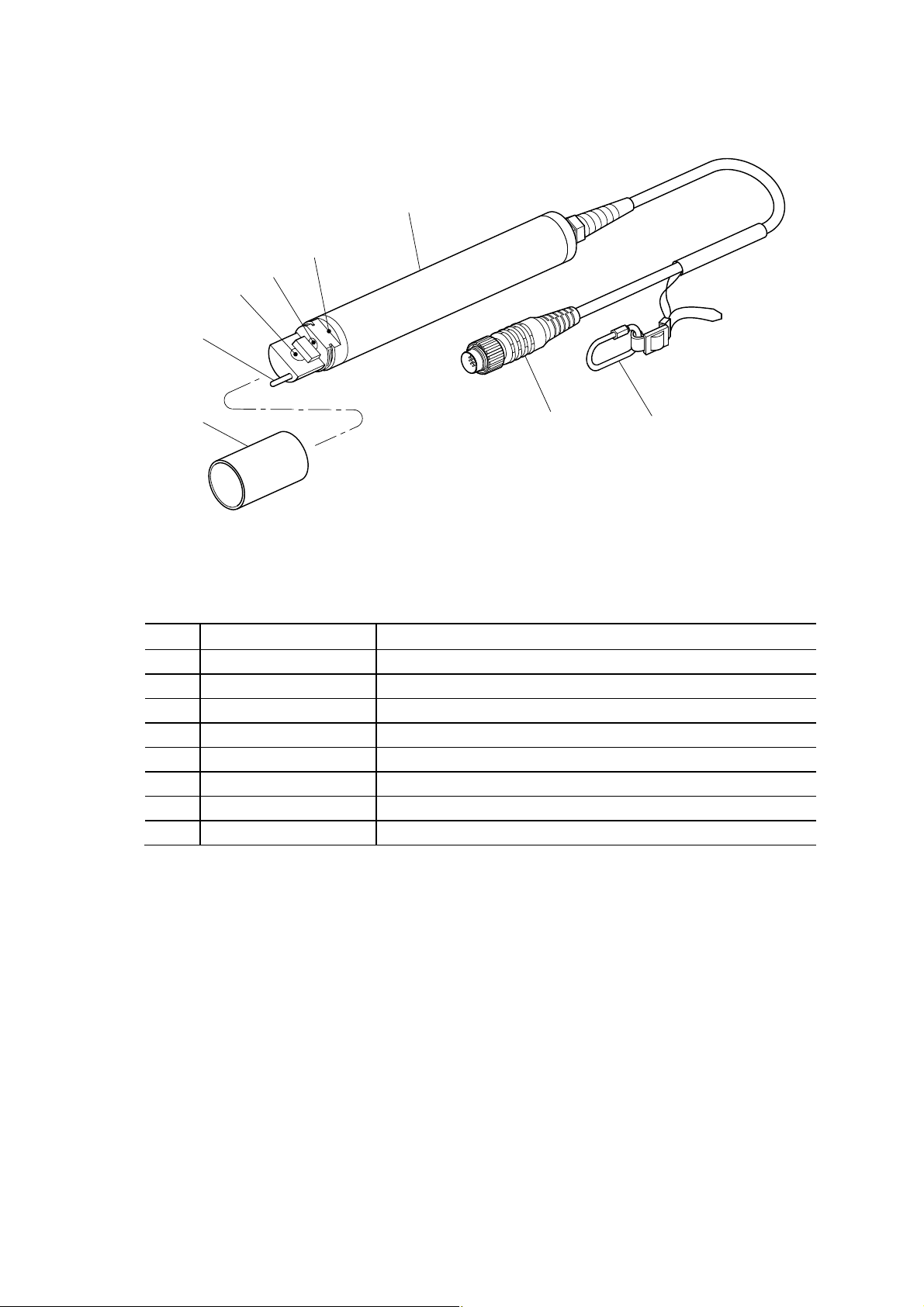

1. Content of Package

Content of Package List

Classification Description Model Quantity Appearance

Main body Hand held turbidity meter TB-31 1

Accessories Turbidity sensor (Standard: Cable

length 2m) (with built-in memory)

*1

ELL-011 1

Protective cover (with shoulder

belt)

AA size dry battery *2

(sample supply)

Instruction manual

7258070K 1

−

−

2

1

〔NOTE〕 *1: This accessory is not supplied if only main body is ordered.

*2: Attached dry batteries are supplied as sample. Since the battery life may be extremely

short, replace it with an AA size alkali dry cell battery or AA size rechargeable Nickel

hydride battery available on the open market.

-

9 -

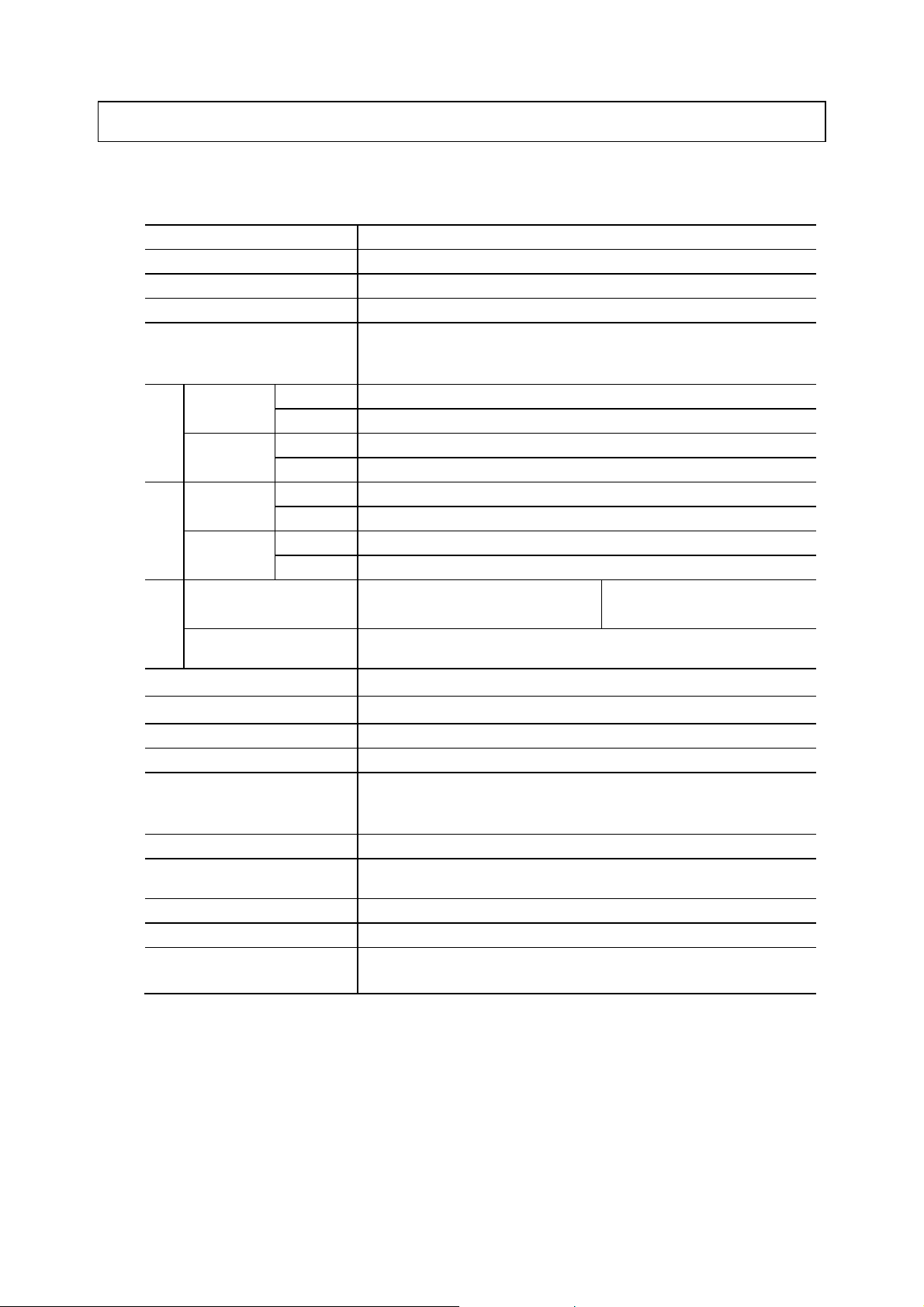

Model: TB-31 2. Specifications and Functions

2. Specifications and Functions

(1) Specifications

Product name Hand held turbidity meter

Model TB-31

Measuring method Near infrared 90 degree scattering light measurement

Measuring object Turbidity, temperature

Display Digital

Simultaneous display of turbidity, temperature, and time (month and day,

hour and minute)

Turbidity Range 0.0 to 80.0NTU(mg/L), 0 to 800NTU(mg/L)*1

Resolution 0.1NTU(0.0 to 80.0NTU(mg/L)), 1 NTU(0 to 800NTU(mg/L))

Temperature Range 0.0 to 50.0ºC (However, test water shall not be frozen.)

range

Measuring

Turbidity Range 0.0 to 88.0NTU(mg/L), 0 to 880NTU(mg/L)

Temperature Range −5.0 to 110.0ºC

range

Display

Turbidity Within ±0.5NTU (0.0 to 80.0)

ty

Temperature Within ±0.5ºC

Repeatabili

Resolution 0.1ºC

Resolution 0.1NTU(0.0 to 80.0NTU(mg/L)), 1 NTU(0 to 800NTU(mg/L))

Resolution 0.1ºC

Within ±5NTU (0 to 800)

At fixed conditions

At fixed conditions

Calibration Zero, Span calibration

Water depth Within 50m (0.5MPa or equivalent)

Water Proof IP67 *2

Printing function *3 Interface is standard equipment, printer is optional

RS-232C interface

(Communication conditions

fixed) *3

Analog output Turbidity value, temperature value, range value

Power supply AA size alkali dry cell battery (2), AA size rechargeable nickel hydride

Main body dimensions Approx. 35 (Height) × 68 (Width) × 173 (Depth) mm

Main body weight Approx. 280g

Performance guarantee

temperature range

*1: NTU indicates turbidity calibrated using a formazin standard solution and mg/L indicates turbidity

calibrated using a kaolin standard solution.

*2: Invalid when no sensor is connected or external input/output (optional) is used.

*3: Cannot be used simultaneously

*4: 0 to 40

o

C when optional AC adapter and external printer used.

External input and output (Uninsulated)

battery (2) or AC adapter (optional) *3

0 to 45ºC *4

However, for turbidity sensor, temperature shall not be changed rapidly.

-

10 -

Model: TB-31 2. Specifications and Functions

〔NOTE〕 • This sensor is not for continuous measurements. When you want to perform simple

monitoring, make the maximum continuous usage time approximately 24 hours.

• To maintain measurement accuracy, careful cleaning is necessary.

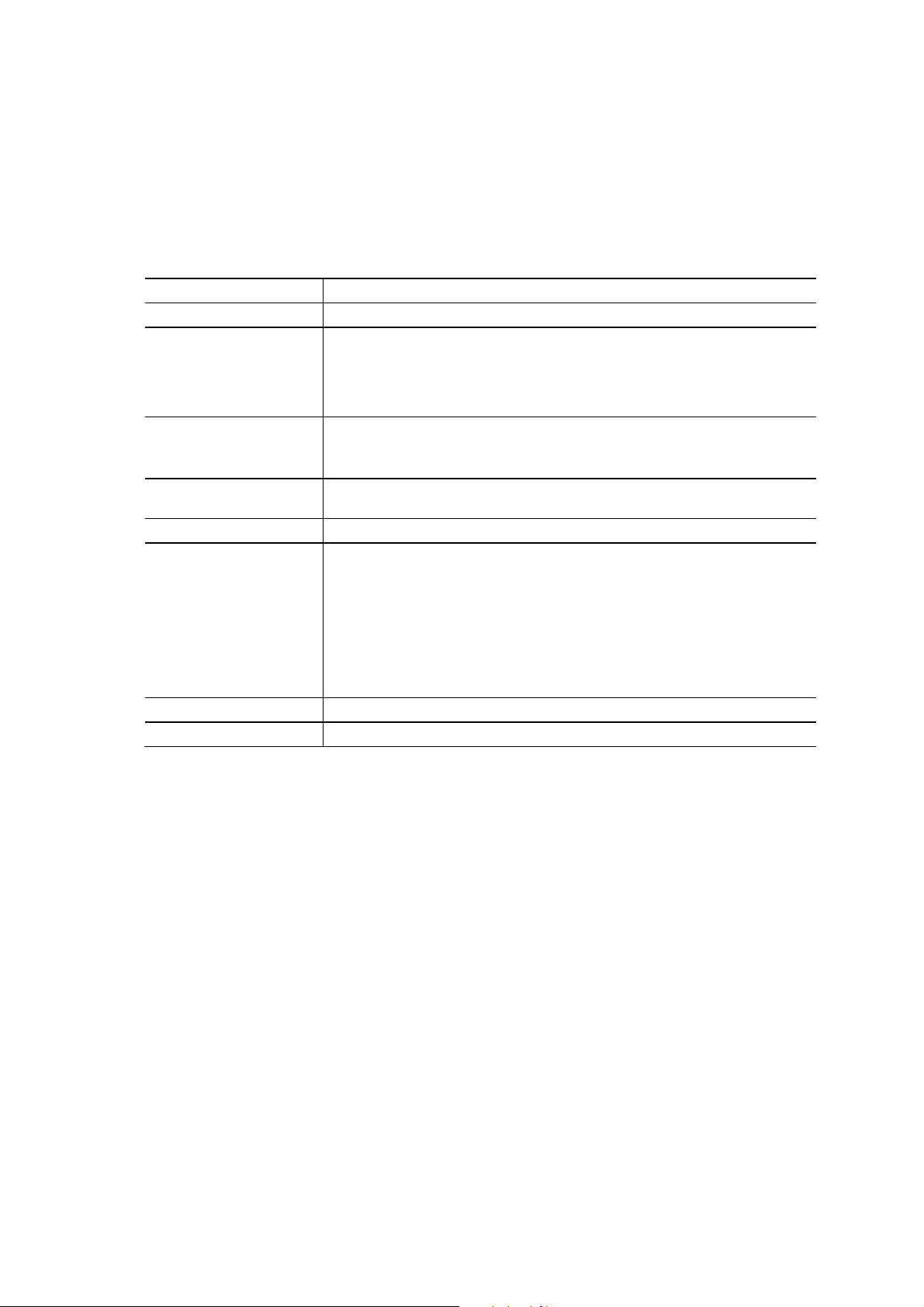

(2) Functions

Clock function Built-in

Data storage 1000 data (measured date & time, turbidity value, temperature)

Interval time function [OFF / S interval / L interval]

Data memory*1 of

Short interval: 00 mins 01 secs to 99 mins 59 secs

Long interval: 00 hours 02 mins to 99 hours 59 mins

Auto power off On/Off setting is possible.

ON: Power is turned off when key operation is not performed for 10 mins/20

mins/30 mins/60 mins.

Temperature calibration

function

Auto hold function Provided

Printing function When external printer is connected:

RS-232C interface Standard equipped (Interactive) (Uninsulated)

Analog output Standard equipped (Uninsulated)

1 point calibration

1. Printing of measured value

• Manual printing

• Printing using interval time function

• Printing of stored data

• Printing using auto hold function

• Printing of calibration data

*1 When an external printer is connected, the minimum interval becomes 5 seconds.

-

11 -

Model: TB-31 3. Name and Function of Each Part

3. Name and Function of Each Part

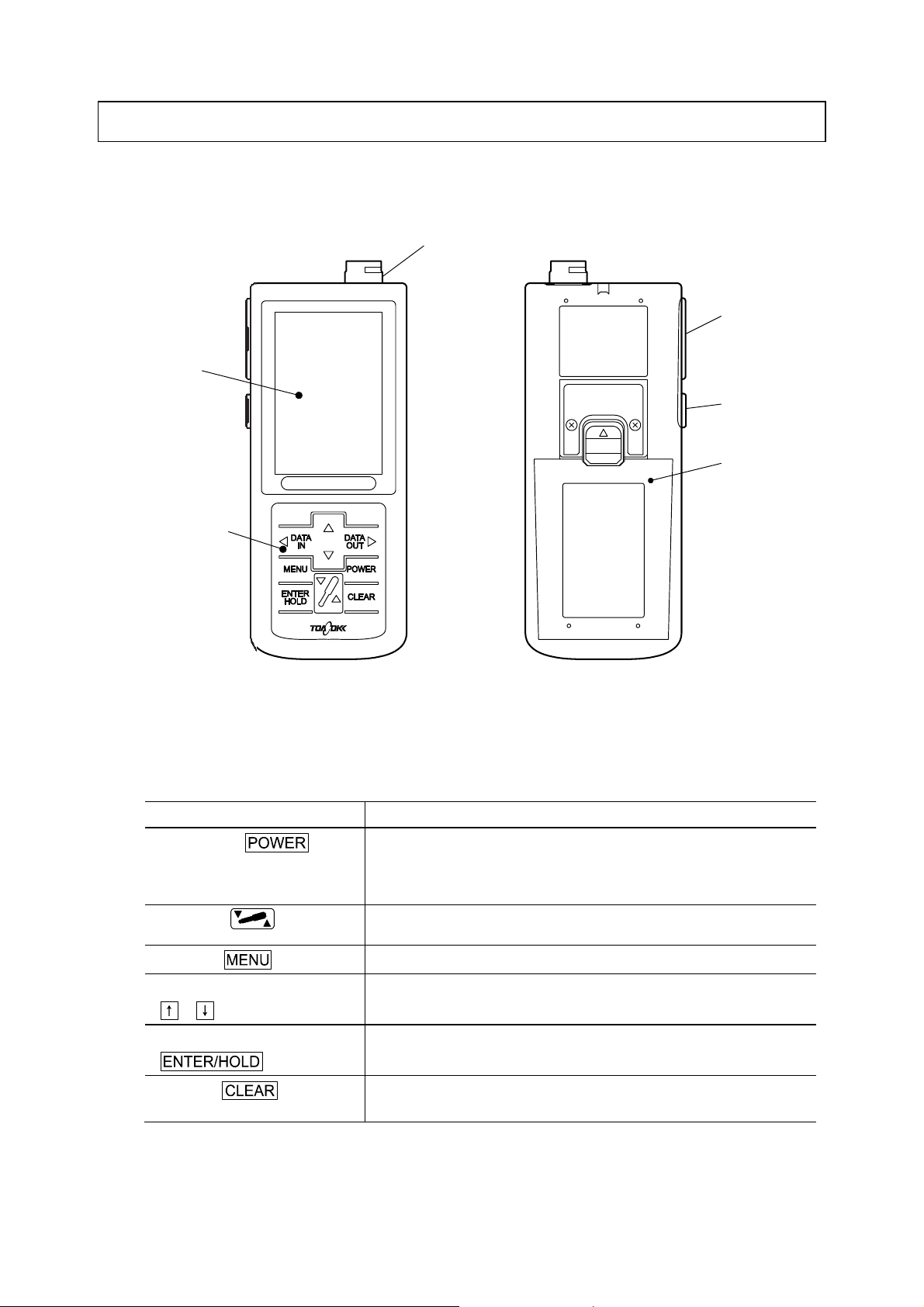

(1) Main body and operation panel

Sensor jack

Input/output cover

Display

AC adapter

cover

Battery cover

Operation

panel

Names of Main Body

Types and Functions of Operation Panel Keys

Type of key ( Notation in text) Function

Power switch ( )

Sensor key ( )

Menu key ( )

Up key, down key

( , )

Enter/hold key

( )

Clear key ( )

• When pressed for 2 seconds or more, the power is turned on and off

(ON/OFF).

• When pressed for less than 2 seconds, the display returns directly to

the Measurement standby screen from any other screen.

• When pressed for 2 seconds or more, one-touch zero calibration is

executed.

• Switches to the Menu screen.

• Change values (increase/decrease) and switch selectable functions.

• Enters values and executes the auto hold function.

• Switches to the next screen.

• Clears the calibration value, etc.

• Returns to the previous screen.

-

12 -

(To be continued)

Model: TB-31 3. Name and Function of Each Part

(Continued from previous page)

Type of key ( Notation in text) Function

Data in/left arrow key

( )

Data out/right arrow key

( )

• Saves the measured value.

• Selects the MODE, No., INT., CLOCK, C., or etc. mark at the Menu

screen.

• Displays the saved measured value.

• Selects the MODE, No., INT., CLOCK, C., or etc. mark at the Menu

screen.

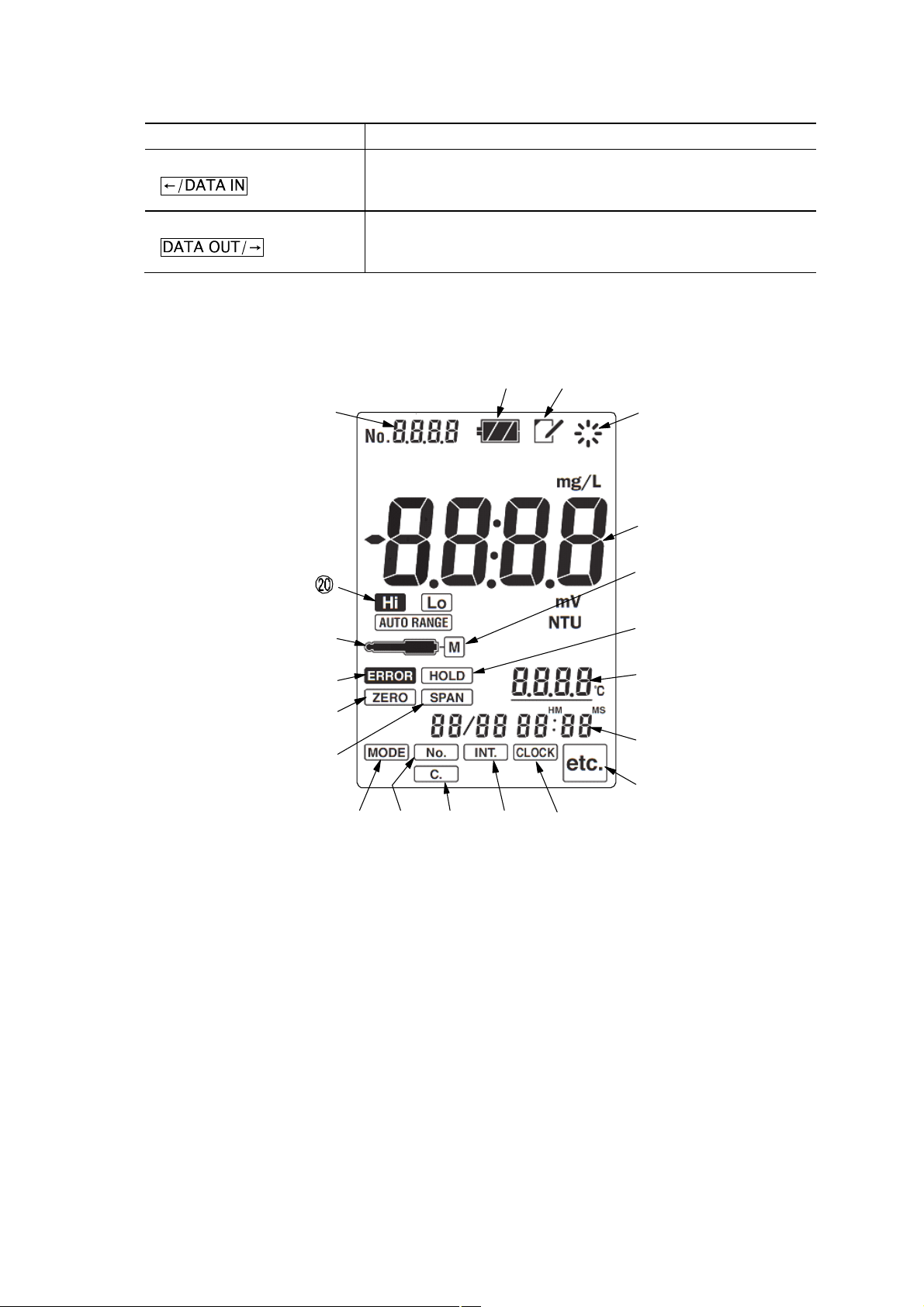

(2) Display

②

①

⑥

⑧

⑩

⑪

⑭⑮ ⑯ ⑰ ⑱

Display

③

④

⑤

⑦

⑨

⑫

⑬

⑲

-

13 -

Model: TB-31 3. Name and Function of Each Part

Names and Functions of Display

No.

① Data number display • Displays the data number.

② Battery mark

( )

③ Memory mark

( )

④ Operation display mark

(

⑤ Main display • Displays the turbidity value.

⑥ Sensor mark

( )

⑦ M mark

(M)

⑧ Error mark

(

⑨ Hold mark

(

⑩ Zero mark

(

⑪ Span mark

( )

⑫ Temperature display • Displays the temperature measured value.

⑬ Date/time display • Displays the current date/time (Month/day Hour : minute)

⑭ MODE mark

(

⑮ No. mark

(

⑯ C. mark

(

⑰ INT. mark

(

⑱ CLOCK mark

(

⑲ etc. mark

(

⑳ Range mark

(

Names

(Notation in text)

s

)

ERROR

HOLD

MODE

No.

INT.

CLOCK

etc.

)

)

)

)

)

)

)

)

)

)

Functions

• Displays the remaining battery capacity (4-step display).

• Lights when memory data is displayed.

• Displays the operation state.

• Lights when an sensor is connected.

• Lights when the body is combined with a “Cal-memo” sensor.

• Blinks when an error occurs.

• Lights when the measured value is being held (hold standby state).

• Blinks during auto hold execution.

• Lights steadily after one-touch zero calibration execution.

• Blinks at one-touch zero calibration execution.

• Lights steadily after span calibration execution.

• Blinks at span calibration execution.

• After temperature calibration execution, displays an underline.

• Lights when the batch mode and real-time mode are switched.

• Lights when the data number is set.

• Lights when the calibration value is confirmed or set.

• Lights when the interval function/time is set or the interval is

executed.

• Blinks in the interval standby state.

• Lights when clock adjustment is set.

• Lights at each setting such as auto power off reset.

• Displays the range. (Hi / Lo / AUTO RANGE)

(Hi: 0 to 800, Lo: 0.0 to 80.0, AUTO RANGE: Auto range)

-

14 -

Model: TB-31 3. Name and Function of Each Part

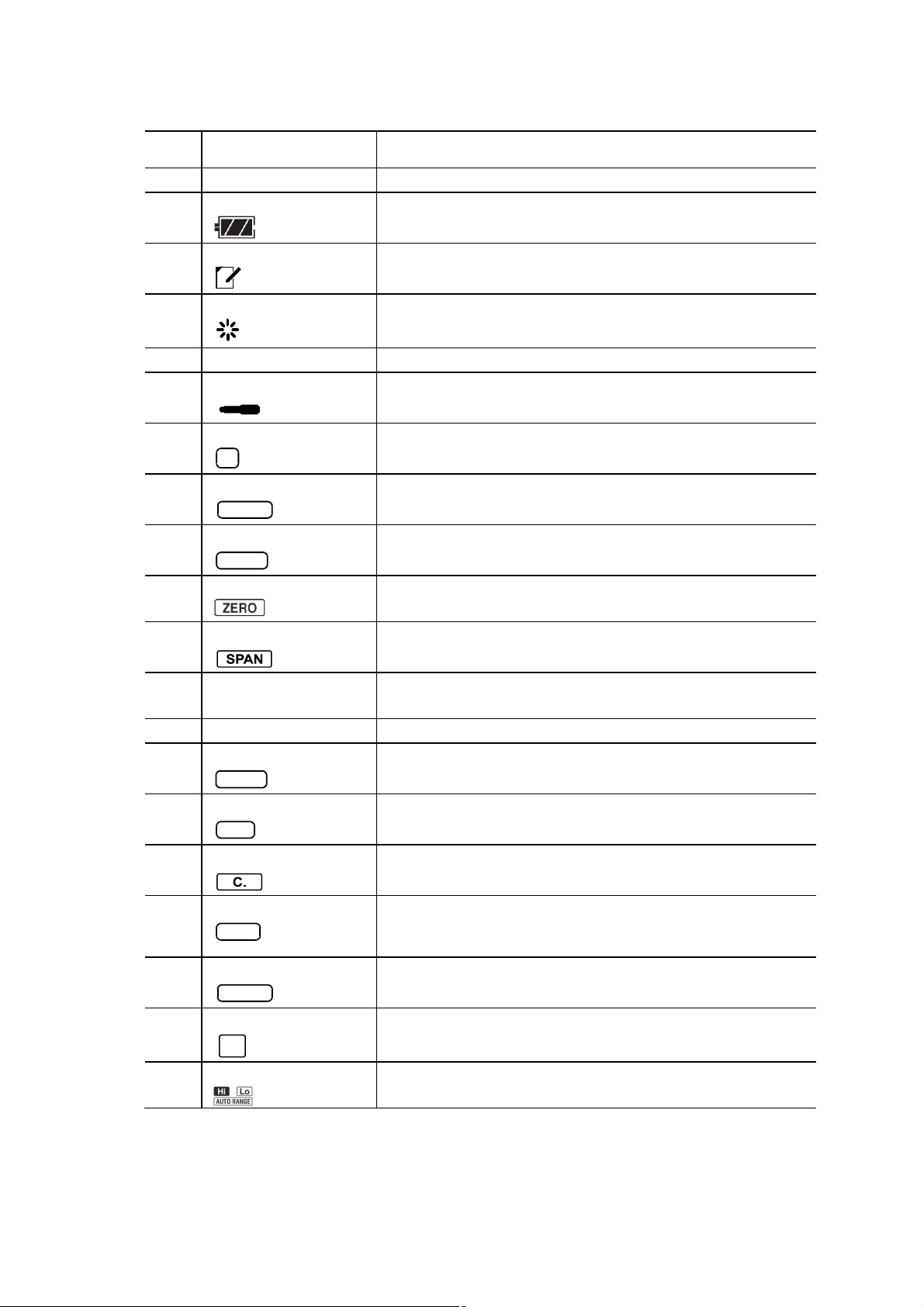

(3) Turbidity sensor (Model ELL-011)

②

③

④

⑤

⑥

⑦

Turbidity Sensor (Model ELL-011)

①

⑧

Names and Contents of Turbidity Sensor (Model ELL-011)

No. Names Contents

① Plug • Plug for connecting the sensor to the instrument body.

② Body

③ Air vent groove

④ Light-emitting part

⑤ Light-receiving part

⑥ Temperature sensor

⑦ Protective tube • Installed to the body at measurement.

⑧ Cable fixing bracket • Bracket for fixing the cable to the instrument body.

-

-

-

-

-

-

15 -

Model: TB-31 4.1 Loading the Batteries

4. Preparations

4.1 Loading the Batteries

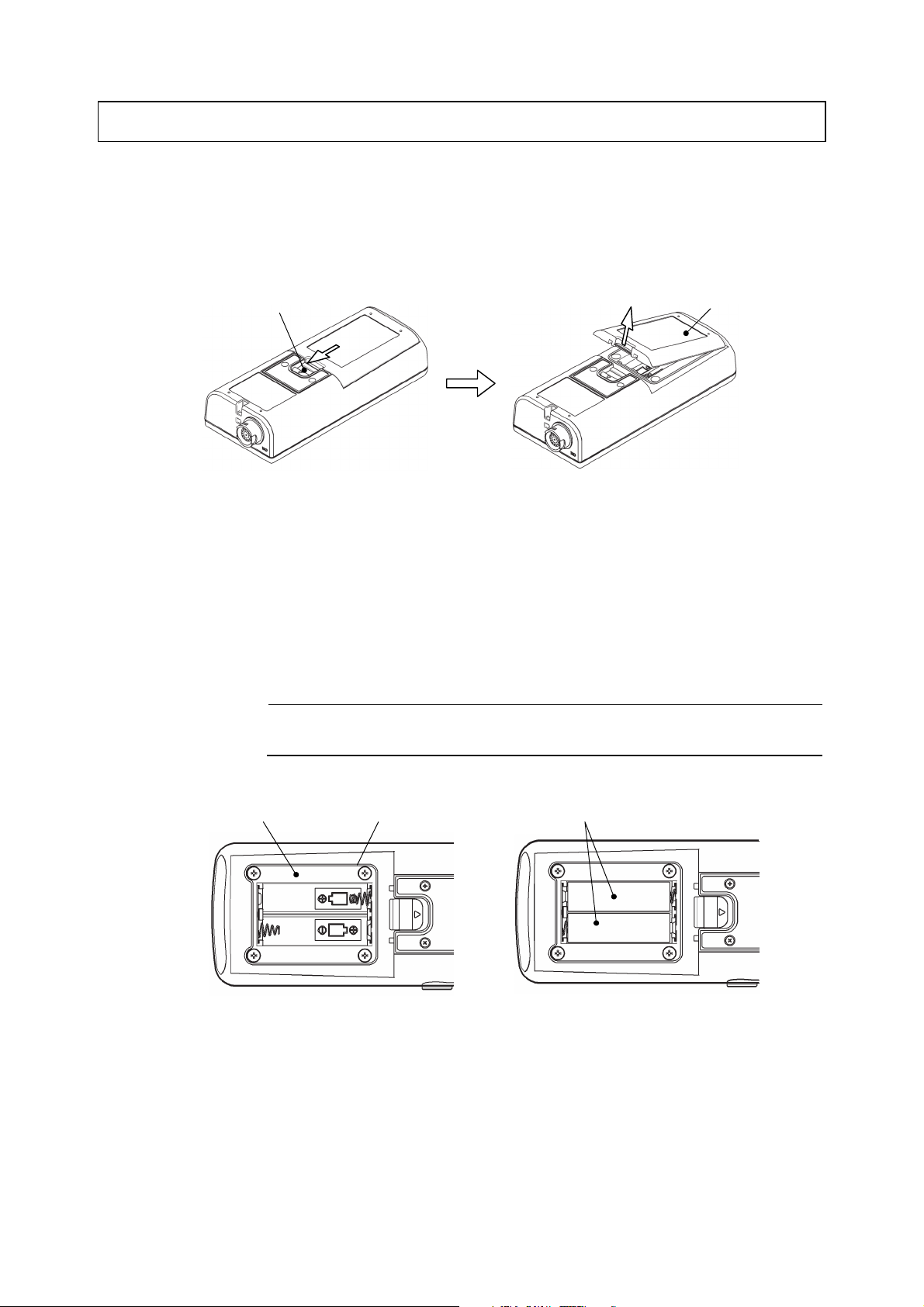

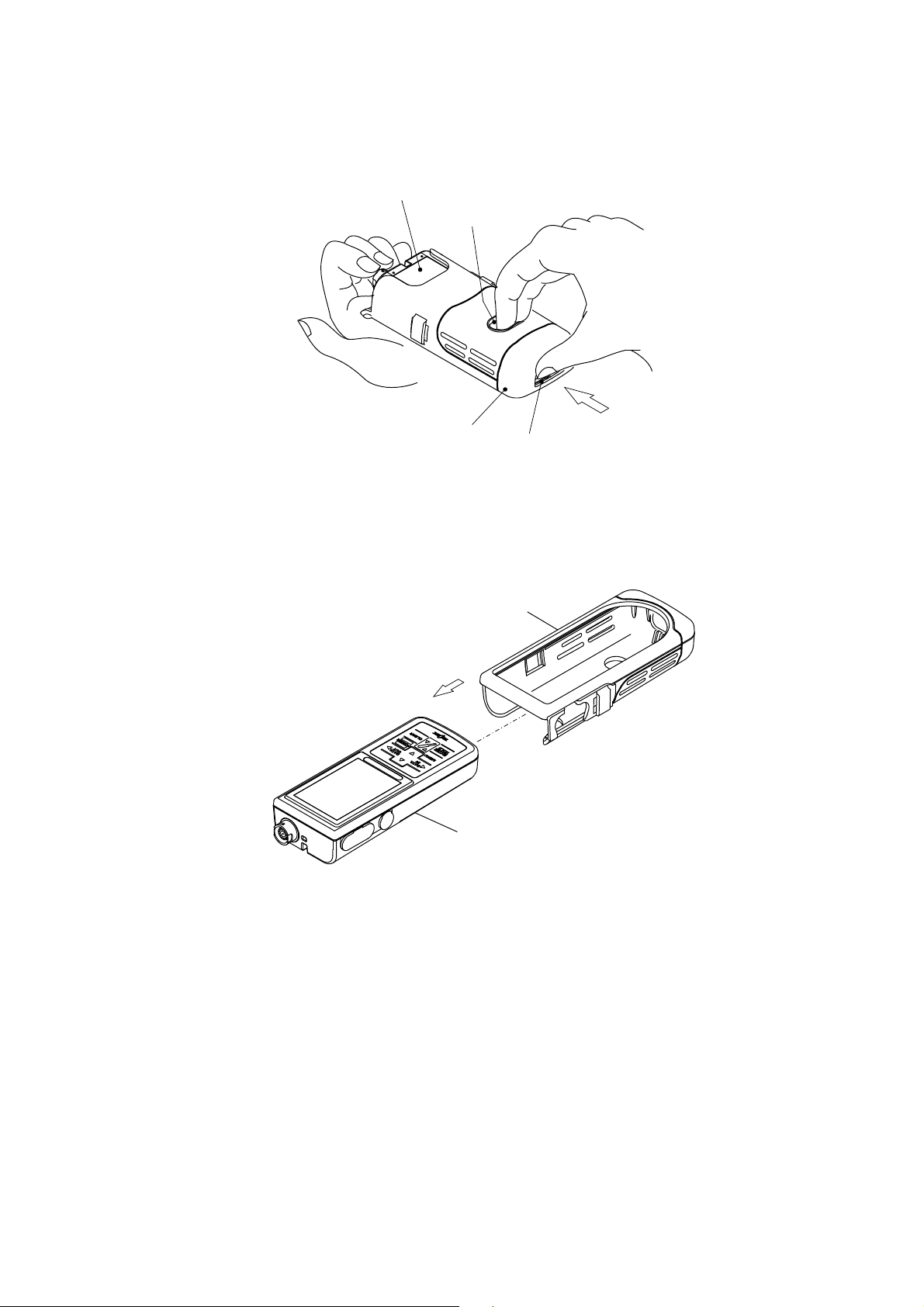

① Remove the battery cover. ⋅⋅⋅⋅⋅⋅ After sliding the battery cover holder in the arrow direction

with your finger, remove the battery cover while pulling both ends of the battery cover with your

fingers.

Battery cover holder

Removing the Battery cover

② Load the batteries. ⋅⋅⋅⋅⋅⋅ After checking the battery loading direction of the battery compartment,

load AA size alkali dry cell batteries (2 pieces) or AA size rechargeable nickel hydride batteries (2

pieces).

•When alkali dry cell batteries are used, the battery drive time is about 120 hours for the

continuous measurement and about 7000 times for the batch measurement. (The drive time may

be different depending on the battery capacity, usage environment, etc.)

• See 8.3 “Battery replacement period” for the battery replacement period.

【IMPORTANT】 • When loading the batteries, be sure that the “+” and “–” polarities are

correct.

Battery cover

Battery compartment

③ Check the packing. ⋅⋅⋅⋅⋅⋅ Verify that the packing is properly installed to the battery cover

(inside).

Rib

Loading the Batteries

-

16 -

Batteries (2 pieces)

Model: TB-31 4.1 Loading the Batteries

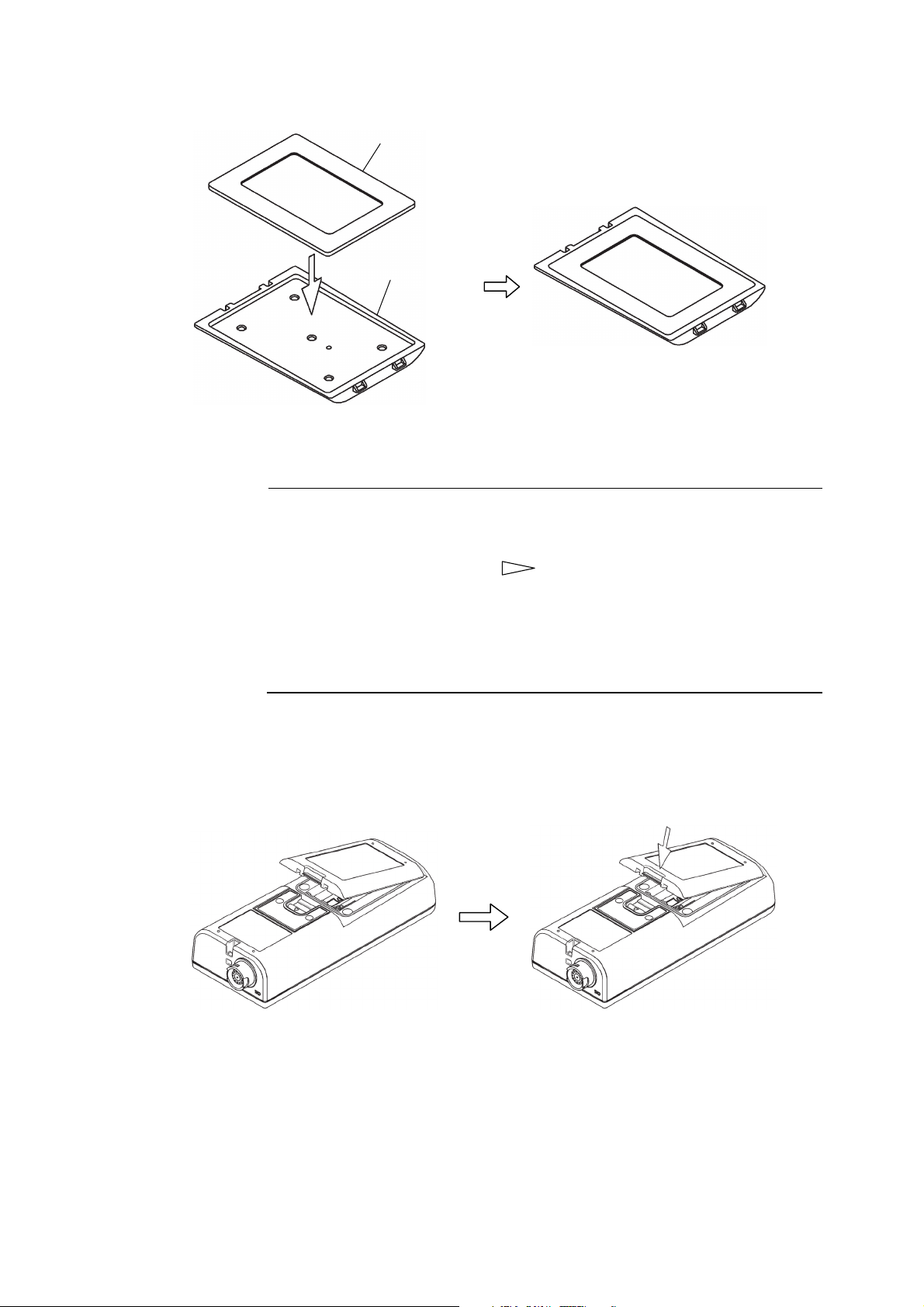

Packing

Battery cover (inside)

<State with packing installed properly>

<When replacing>

Checking the Packing

【IMPORTANT】 • When installing the battery cover, confirm that the packing and the rib

(part which seals the packing) are not scratched, deteriorated or dusty.

• If the packing is scratched, cracked, or otherwise deteriorated, always

replace it with new packing. (

the packing and rib are dusty, clean up them. In each case, the

waterproofing function cannot be guaranteed if used as is.

• When replacing the packing, refer to the figure shown above and confirm

that the packing is installed properly. If the packing is separated from the

battery cover, re-install it properly.

④ Install the battery cover. ⋅⋅⋅⋅⋅⋅ Hook the tab of the battery cover to the body and install the cover

to the body by pushing it in the arrow direction. At this time, confirm that the end of the battery

cover holder is firmly inserted into the notch of the battery cover. If it is not firmly inserted, push

the battery cover against the instrument body.

11. “Parts/Options List”) In addition, if

Hooking the Battery Cover Tab Installing the Battery Cover

-

17 -

Model: TB-31 4.1 Loading the Batteries

End of battery cover

holder is not firmly

inserted into the notch

of the battery cover.

Checking the end of the Battery Cover Holder

End of battery cover

holder is firmly inserted

into the notch of the

battery cover.

-

18 -

Model: TB-31 4.2 Installing and Removing the Protective Cover

4.2 Installing and Removing the Protective Cover

Injury

Handle the instrument body carefully so as not to damage it. If the body is damaged

by mistake the broken pieces may cause injury.

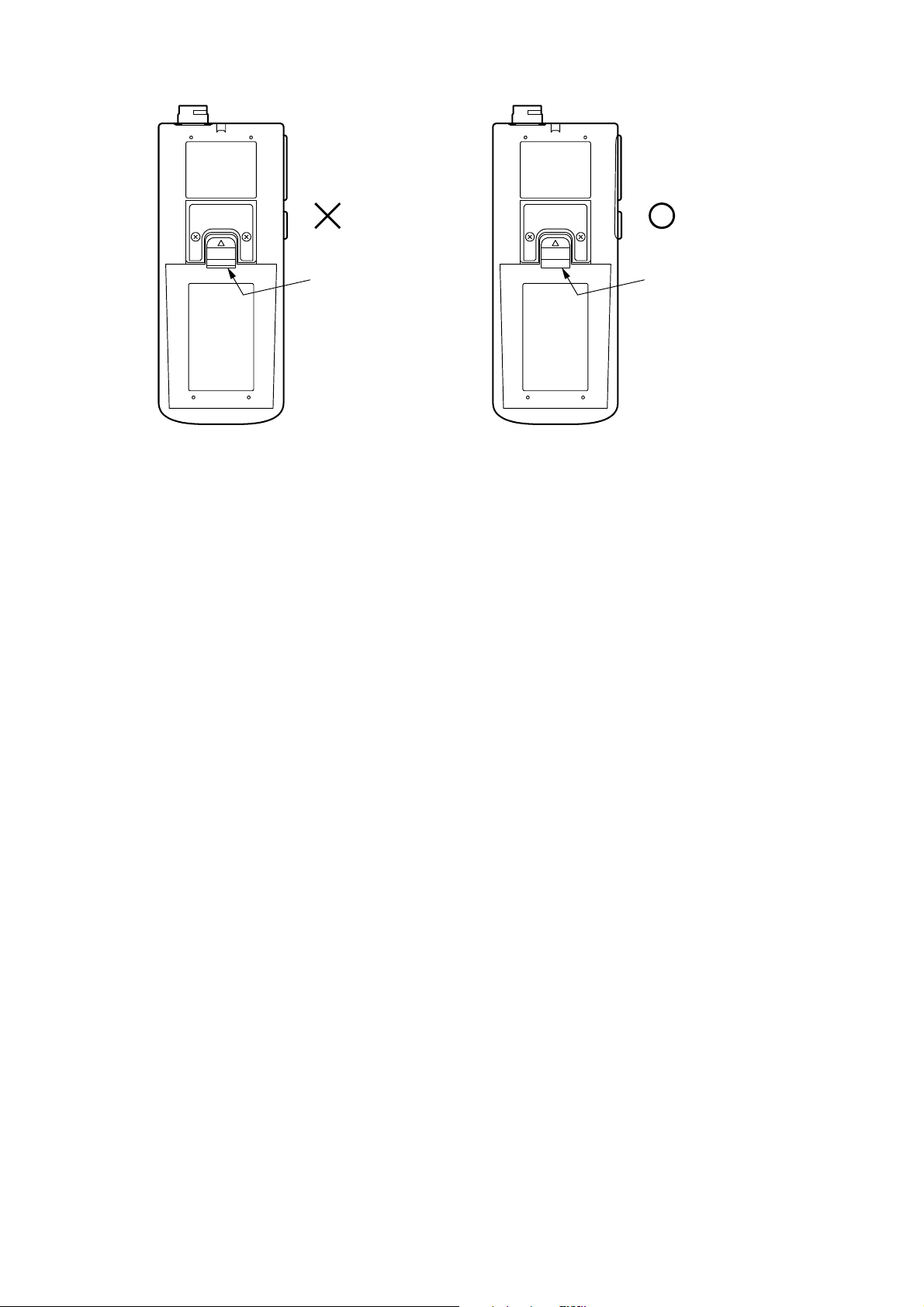

(1) Installing the protective cover

【IMPORTANT】 • Install and remove the protective cover on a desk, etc. At that time, be

careful not to drop the instrument body.

Install the accessory protective cover in accordance with the following figure so that the instrument

body is inserted all the way from the top of the protective cover.

Protective cover

Instrument body

Installing the Protective Cover

(2) Removing the protective cover

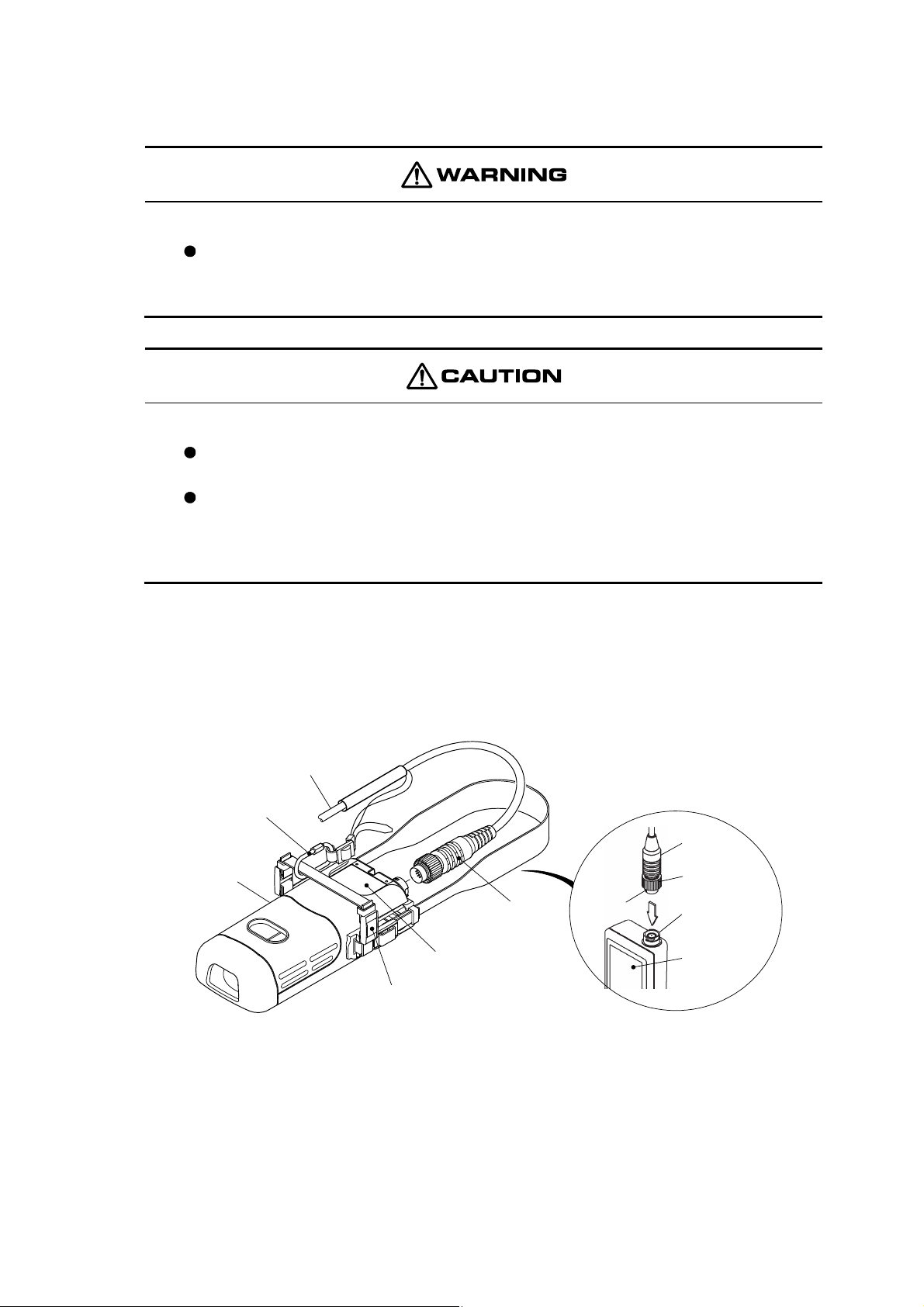

① Flip the top flap. ⋅⋅⋅⋅⋅⋅Flip up the top flap of the protective cover.

Protective cover

Top flap

Flipping Up the Top Flap

-

19 -

Model: TB-31 4.2 Installing and Removing the Protective Cover

② Push out the instrument body. ⋅⋅⋅⋅⋅⋅Insert your middle finger and index finger into the oval

hole in the back of the instrument body and push out the instrument body.

Instrument body

(rear side)

Oval hole for

inserting fingers

Protective cover

Pushing out hole

Pushing Out the Instrument Body

③ Remove the instrument body. ⋅⋅⋅⋅⋅⋅ Remove the instrument body from the protective cover.

Protective cover

Instrument body

Removing the Protective Cover

-

20 -

Model: TB-31 4.3 Turbidity Sensor Connection

4.3 Turbidity Sensor Connection

Fire and electric shock

Always verify that the power is off before connecting or disconnecting the sensor

plug, AC adapter cover, or input/output cover. Water or reagent entering the product

Waterproofing

may short the circuits and cause electric shock or fire.

The construction of the product becomes waterproof (IP67) only when the sensor,

battery cover, AC adapter cover, and input/output cover are installed properly.

Do not touch the instrument with wet hands or wash it with water when the sensor

has been removed or the battery cover, AC adapter cover, or input/output cover is

opened. Besides, do not install or store the product where water or reagent may

enter it.

① Confirm that the power is off. ⋅⋅⋅⋅⋅⋅ Confirm that the instrument power is off.

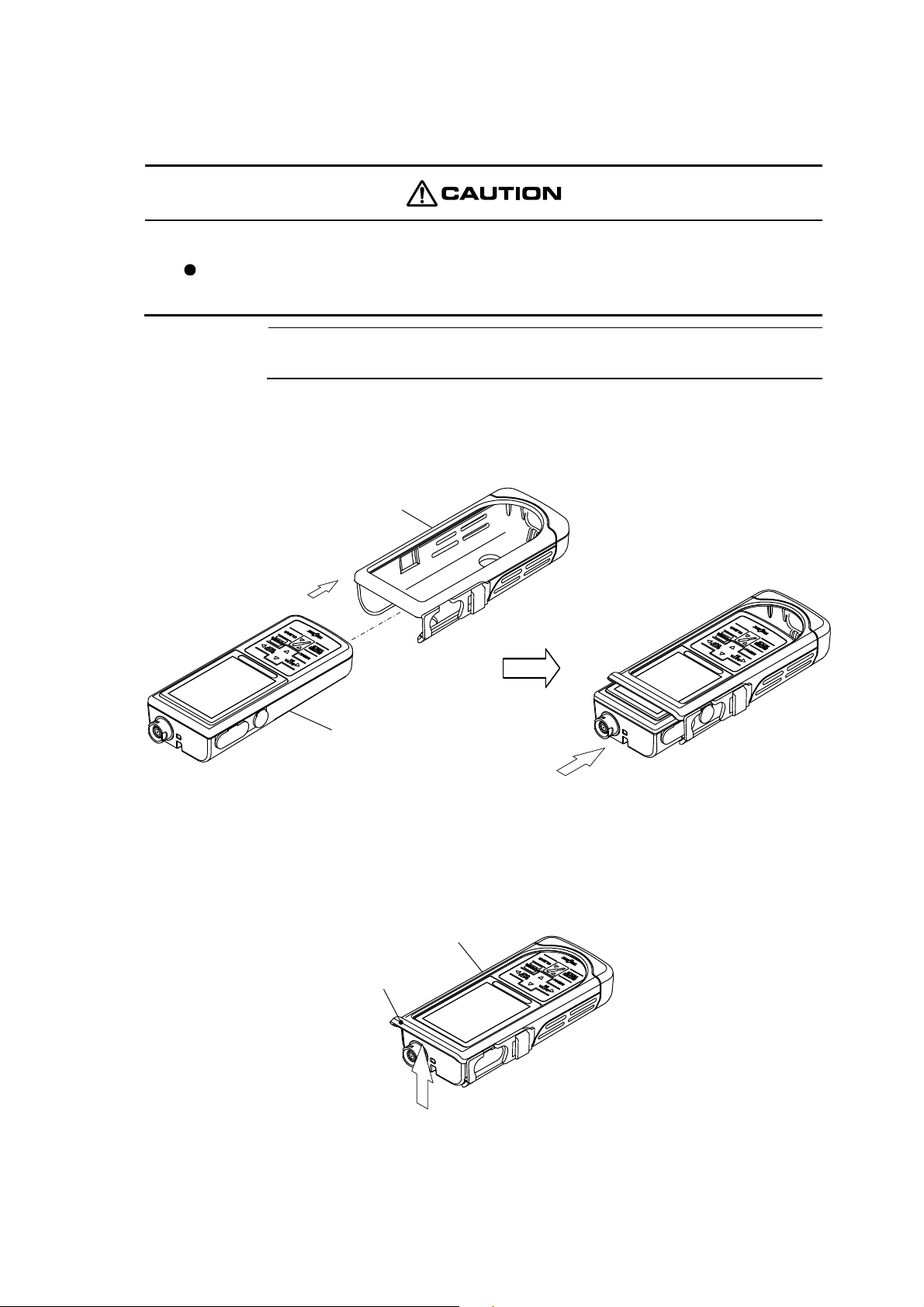

② Insert the plug. ⋅⋅⋅⋅⋅⋅ Hold the plug so that the “O” mark at the end of the plug is facing the front

of the instrument and insert the plug straight into the sensor jack.

Sensor cable

Cable fixing

bracket

Plug

Protective

cover

Instrument body

(rear side)

Shoulder belt

Plug

○(mark)

Fixing ring

Sensor jack

Instrument

body

(front side)

Fastening the Plug and Mount the Cable Fixing Bracket

③ Fasten the plug. ⋅⋅⋅⋅⋅⋅ Fasten the plug by turning the fastener ring only. At this time, do not turn

the plug body.

-

21 -

Model: TB-31 4.3 Turbidity Sensor Connection

【IMPORTANT】 • If the plug body is turned or moved back and forth when removing and

installing the sensor plug, the pins and connector may be damaged. Pull it

straight out or push it straight in.

④ Mount the cable fixing bracket. ⋅⋅⋅⋅⋅⋅ Loose the nut of the cable fixing bracket and mount it to

the shoulder belt of the instrument body (rear side).

-

22 -

Model: TB-31 4.4 Turbidity Sensor Preparation

4.4 Turbidity Sensor Preparation

Before performing the calibration or measurements, inspect the sensor. For details, refer to 8.2

“Turbidity Sensor Maintenance”, or the instruction manual supplied with the sensor.

① Remove the protective tube. ⋅⋅⋅⋅⋅⋅ Remove the protective tube of the sensor by turning it in the

counterclockwise direction.

Sensor end

Protective tube

(counterclockwise)

Remove the Protective Tube

② Wash the light-receiving part and light-emitting part. ⋅⋅⋅⋅⋅⋅ Wash out the light-receiving part

and light-emitting part of the sensor end by pure water and wipe off them gently using tissue paper,

etc.

Light-emitting part

Beaker

Sensor

Pure water

Light-receiving part]

Wash the Light-receiving Part and Light-emitting Part by Pure Water

③ Install the protective tube. ⋅⋅⋅⋅⋅⋅ Install the protective tube of the sensor as its original state.

【IMPORTANT】 • When washing the sensor, never use cleanser or other abrasive or

ethanol or other organic solvent.

• If cleanser or other abrasive is use, the surface of the sensor will be

scratched. If ethanol or other organic solvent is used, the acryl window of

the light-receiving part and light-emitting part will become cloudy and their

performance will drop.

-

23 -

Model: TB-31 5.1 Operation Screens Map

5. Basic Operation

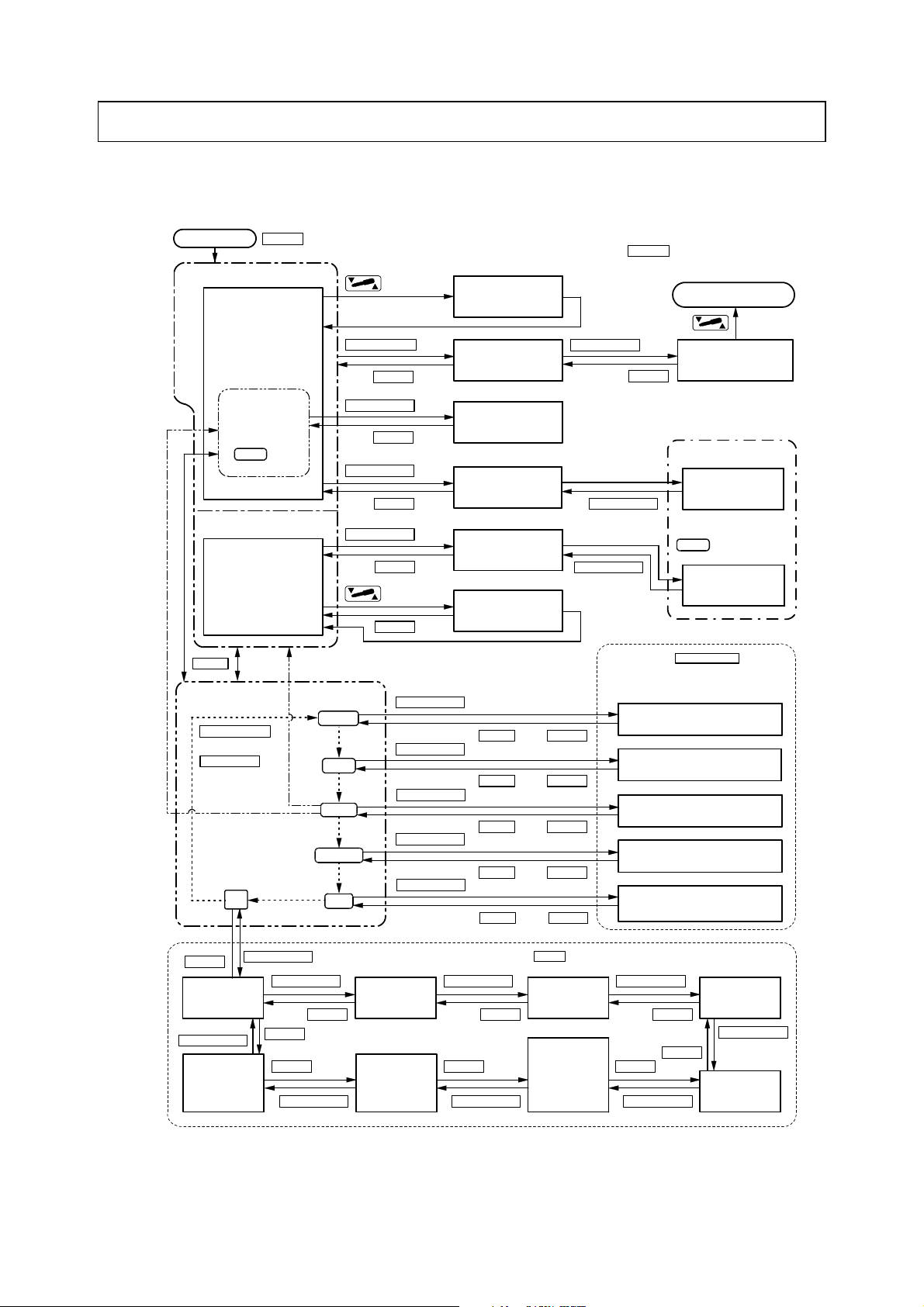

5.1 Operation Screens Map

Power on (ON)

<Measurement state>

[Real-time mode

measurement screen]

POWER

Interval

standby state*

( Blinking)

INT.

<Measurement standby state>

[Batch mode measurement

standby screen]

(Main display: ----)

MENU

[Menu screen]

DATA OUT/→

or

←/DATA IN

(reversed)

(blinking)

etc.

(Press for 2 seconds or more.)

DATA OUT/→

ENTER/HOLD

ENTER/HOLD

ENTER/HOLD

(blinking)

MODE

(blinking)

No.

<disabled>

(blinking)

INT.

<enabled>

(blinking)

CLOCK

(blinking)

C.

When pressing (less than 2 seconds) at any

screen, the display returns directly to the measurement state

(Press for 2

seconds or more.)

(Cancel)

CLEAR

CLEAR

(Cancel)

CLEAR ENTER/HOLD

(Cancel)

(Cancel)

CLEAR

(Press for 2

seconds or more.)

(Cancel)

CLEAR

[One-touch zero

calibration

execution screen]

[Memory data display

screen]

[Interval execution

screen]

[Auto hold execution

screen]

[Batch mode

measurement

execution screen]

[One-touch zero

calibration execution

screen]

(measurement standby state).

(Returns

immediately after.)

ENTER/HOLD

*When Interval setting screen is set to enabled, the display

switches to the interval standby state. When setting to

disabled (oFF), the display returns to measurement state.

(After stability check,

switches automatically.)

(After 1 minute,

switches automatically.)

ENTER/HOLD

(After 1 minute,

returns.)

ENTER/HOLD

or

MENU CLEAR

POWER

CLEAR

◎When pressing at these 5

screens, the display returns directly to the

measurement state (or measurement standby

state).

[Measurement mode setting screen]

ENTER/HOLD

[Date number setting screen]

or

MENU CLEAR

ENTER/HOLD

or

MENU CLEAR

ENTER/HOLD

[Date and time setting screen]

or

ENTER/HOLD

MENU CLEAR

or

MENU CLEAR

[Calibration execution screen]

Data continuous output

processing

[Memory data output /

erase screen]

<Hold standby state>

[Hold standby screen]

(Measurement data is always

saved at the same time as

lights.)

HOLD

[Batch mode

measurement end

screen]

ENTER/HOLD

[Interval setting screen]*

CLEAR

[Calibration

value display

screen]

ENTER/HOLD

[Auto power off

setting screen]

ENTER/HOLD

ENTER/HOLD

CLEAR

CLEAR

ENTER/HOLD

CLEAR

◎When pressing a t these 8 screens, the disp lay returns directly to the

menu screen.

[Display range

setting screen]

[Buzzer on/off

setting screen]

ENTER/HOLD

CLEAR

CLEAR

ENTER/HOLD

Operation Screens Map

-

24 -

MENU

[Measurement

unit setting

screen]

[Memory

overwrite on/off

setting screen]

ENTER/HOLD

CLEAR

CLEAR

CLEAR

ENTER/HOLD

[Response screen]

ENTER/HOLD

[Temperature

calibration screen]

Model: TB-31 5.2 Turning on the Power

S

5.2 Turning on the Power

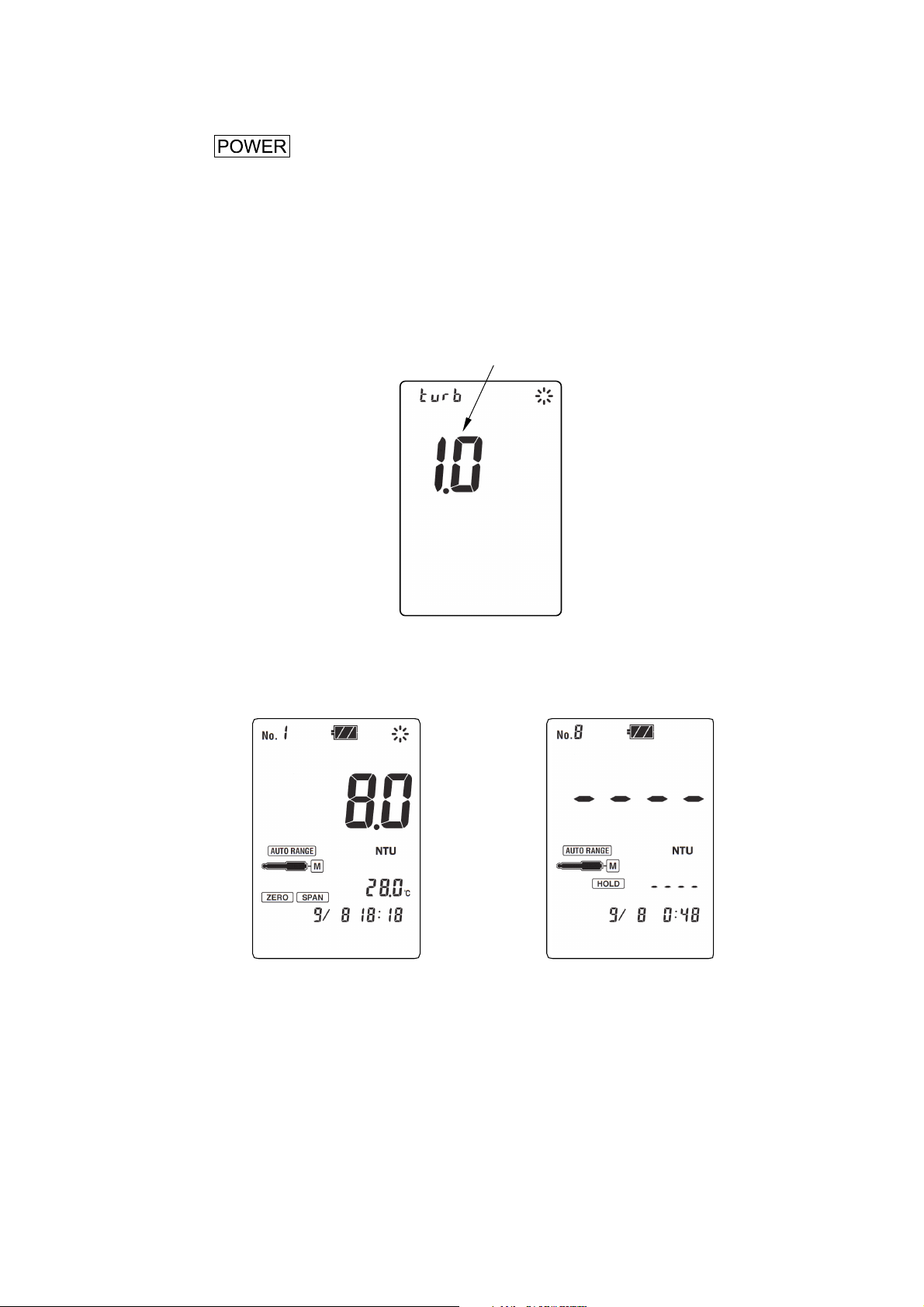

(a) Press for 2 seconds or more (until you hear a beep).

(b) When the instrument power is turned on for the first time after purchase, the real-time mode

measurement screen is displayed subsequently to the version No. display, and the instrument enters

the measurement standby state.

(c) In normal use, once the instrument power is turned off after the measurement mode was set to

batch mode measurement, when the power is turned on again, the batch mode measurement

standby screen is displayed subsequently to the version No. display and the instrument enters the

measurement standby state.

Version No.

Version No. Display Screen (example)

Real-time Mode Measurement

Screen (example)

Batch Mode Measurement

tandby Screen (example)

-

25 -

Model: TB-31 5.3 Time Setting

5.3 Time Setting

Set the current date and time in accordance with the following procedure.

Time Setting Procedure

Operation Screen example

① Display the menu screen. ⋅⋅⋅ Press at the each

screen in the measurement state or in the measurement standby

state

Year

② Cause

CLOCK

to blink by pressing or

several times.

③ Display the date and time setting screen. ⋅⋅⋅ Press

④ Set the date and time. ⋅⋅⋅ Press

• Press

• Setting range: Year…2011 to 2050

⑤ Ente r. ⋅⋅⋅ After checking the set value, press

real-time mode measurement screen or batch mode

measurement standby screen by the setting of measurement

mode.

• To return to the menu screen, press

CLOCK

on the menu screen is blinking, cause

to blink. ⋅⋅⋅ When a mark other than

.

to move the blinking point.

or and change the blinking value.

Month and day…January 1 to December 31

Time…00:00 to 23:59

. After entry, the display returns to the

.

CLOCK

or

Month

and day

Hour and

minute

(24H system)

[Date and time setting

screen]

-

26 -

Loading...

Loading...