Page 1

OPERATING INSTRUCTIONS

CONTROL INPUT UNIT

CONTROL OUTPUT UNIT

SX-2000CI

SX-2000CO

1. SAFETY PRECAUTIONS ........................... 2

2. GENERAL DESCRIPTION ......................... 3

3. NOMENCLATURE AND FUNCTIONS

3.1. SX-2000CI Control Input Unit ............... 4

3.2. SX-2000CO Control Output Unit .......... 6

4. CONNECTIONS

4.1. Removable Terminal Plug

Connection ........................................... 8

4.2. Connection Example ............................ 9

4.3. Power Supply Connections ................ 10

4.4. Control Input Connections

(SX-2000CI Only) ............................... 14

4.5. Control Output Connections

(SX-2000CO Only) ............................. 14

4.6. CI/CO Link Terminal Connections ...... 15

5. SETTINGS

5.1. Stand-Alone Mode Setting ................. 15

5.2. Priority Control Settings of the Control

Inputs (SX-2000CI Only) .................... 16

6. SPECIFICATIONS

6.1. SX-2000CI Control Input Unit ............. 19

6.2. SX-2000CO Control Output Unit ........ 20

Thank you for purchasing TOA's Control Input Unit and Control Output Unit.

Please carefully follow the instructions in this manual to ensure long, trouble-free use of your equipment.

TABLE OF CONTENTS

FOR STAND-ALONE MODE

Note

Two modes of operation are made available for the SX-2000CI and SX-2000CO: Normal mode

where the unit operates within the SX-2000 system and Stand-alone mode where the unit

operates independently of the SX-2000 system.

This book provides instruction when the SX-2000CI and SX-2000CO are used in stand-alone

mode.

When using them in normal operation mode, refer to the instruction manual enclosed with the

SX-2000SM System Manager of the SX-2000 series.

SX-2000CI

192103114125136147158

SX-2000CO

192103114125136147158

172518261927202821292230233124

16

CONTROL INPUT

172518261927202821292230233124

16

CONTROL OUTPUT

32

32

POWER

CPU OFF

FAULT

CONTROL INPUT UNIT SX-2000CI

POWER

CPU OFF

FAULT

CONTROL OUTPUT UNIT SX-2000CO

Page 2

2

When Installing the Unit

• Do not expose the unit to rain or an environment

where it may be splashed by water or other liquids,

as doing so may result in fire or electric shock.

• Use the unit only with the voltage specified on the

unit. Using a voltage higher than that which is

specified may result in fire or electric shock.

• Since the unit is designed for in-door use, do not

install it outdoors. If installed outdoors, the aging of

parts causes the unit to fall off, resulting in personal

injury. Also, when it gets wet with rain, there is a

danger of electric shock.

When the Unit is in Use

• Should the following irregularity be found during

use, immediately switch off the power, disconnect

the power supply plug from the AC outlet and

contact your nearest TOA dealer. Make no further

attempt to operate the unit in this condition as this

may cause fire or electric shock.

· If you detect smoke or a strange smell coming

from the unit.

· If water or any metallic object gets into the unit

· If the unit falls, or the unit case breaks

· If it is malfunctioning (no tone sounds.)

• To prevent a fire or electric shock, never open nor

remove the unit case as there are high voltage

components inside the unit. Refer all servicing to

qualified service personnel.

• Do not place cups, bowls, or other containers of

liquid or metallic objects on top of the unit. If they

accidentally spill into the unit, this may cause a fire

or electric shock.

When Installing the Unit

• Avoid installing the unit in humid or dusty locations,

in locations exposed to the direct sunlight, near the

heaters, or in locations generating sooty smoke or

steam as doing otherwise may result in fire or

electric shock.

• SX-2000CI and SX-2000CO are designed

exclusively to be mounted in an equipment rack.

Be sure to follow the instructions below when rackmounting the unit. Failure to do so may cause a fire

or personal injury.

· Install the equipment rack on a stable, hard floor.

Fix it with anchor bolts or take other arrangements

to prevent it from falling down.

· When connecting the power cord of the DC

power supply panel for the SX-2000CI/CO to an

AC outlet, ensure that the total load current never

exceeds the AC outlet’s allowable current

capacity.

· The supplied rack-mounting screws can be used

for the TOA equipment rack only. Do not use

them for other racks.

When the Unit is in Use

• Use the specified DC power supply unit AD-011 or

AD-031B for the unit. Note that the use of other DC

power supply unit may cause a fire.

1. SAFETY PRECAUTIONS

• Before installation or use, be sure to carefully read all the instructions in this section for correct and safe

operation.

• Be sure to follow all the precautionary instructions in this section, which contain important warnings and/or

cautions regarding safety.

• After reading, keep this manual handy for future reference.

Safety Symbol and Message Conventions

Safety symbols and messages described below are used in this manual to prevent bodily injury and property

damage which could result from mishandling. Before operating your product, read this manual first and

understand the safety symbols and messages so you are thoroughly aware of the potential safety hazards.

WARNING

Indicates a potentially hazardous situation which, if mishandled, could

result in death or serious personal injury.

Indicates a potentially hazardous situation which, if mishandled, could

result in moderate or minor personal injury, and/or property damage.

WARNING

CAUTION

CAUTION

Page 3

3

2. GENERAL DESCRIPTION

The SX-2000CI Control Input Unit is equipped with 32 control input channels, and the SX-2000CO Control

Output Unit with 32 control output channels, allowing various operations to be performed by connecting

external equipment.

One each of the SX-2000CI and SX-2000CO must be used in combination. Connecting the CI/CO link data

terminals of each unit to one another permits the contact data of multiple channels to be transmitted to the

remote locations with simple wiring.

The front-mounted indicators of each unit show the control input status or control output status.

The SX-2000CI and SX-2000CO are 1U-size* units that can be mounted in an EIA equipment rack. It has 2

power supply inputs, one of which can be connected to a backup power source to protect against power

failures. The SX-2000CI has a function to supply a stabilized 24 V DC.

Priority control of the control input can be performed by making settings at the SX-2000CI.

*1U size = 44.5 mm (standard size)

Page 4

4

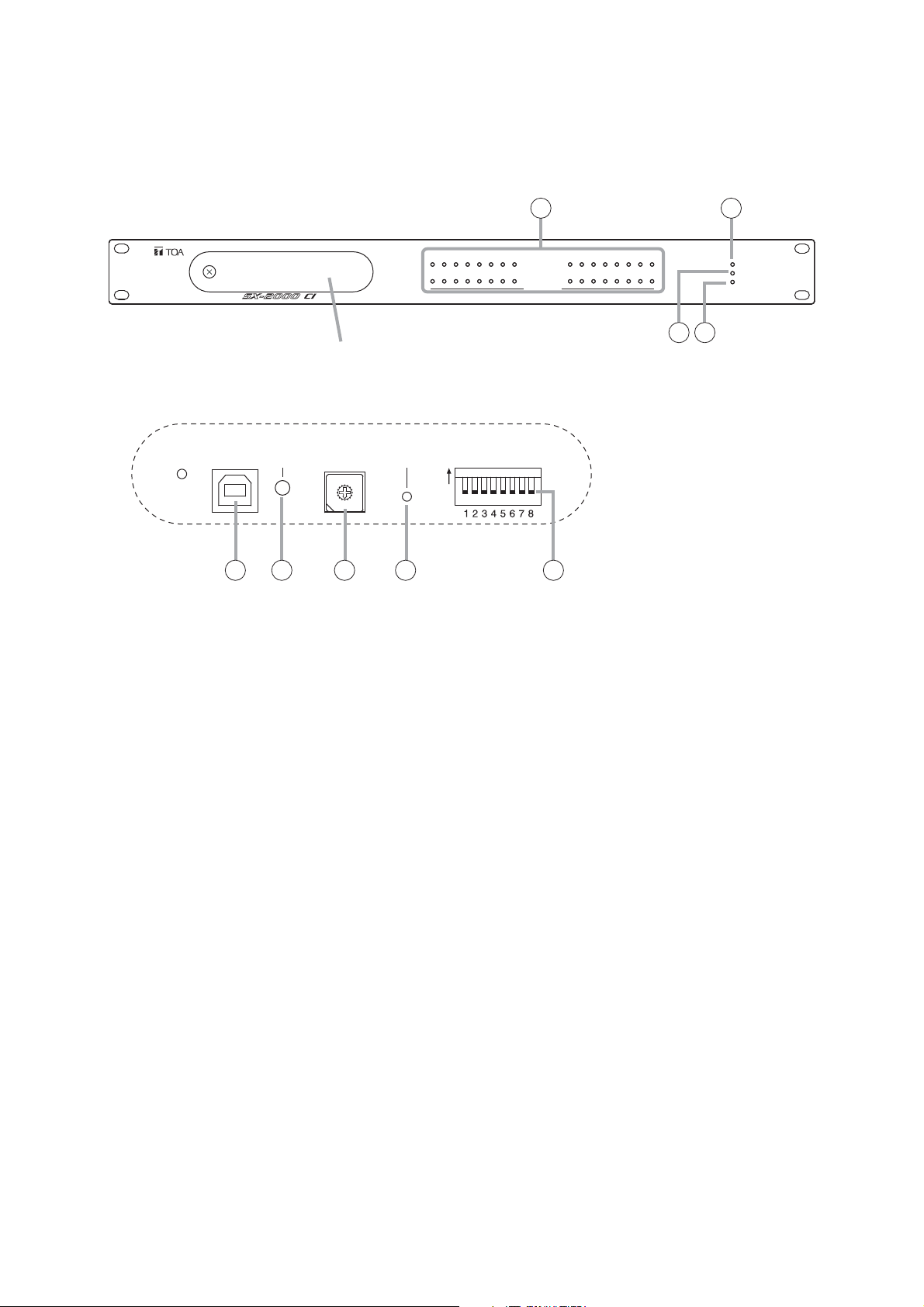

3. NOMENCLATURE AND FUNCTIONS

3.1. SX-2000CI Control Input Unit

[Front]

1. Control Input Indicators

[CONTROL INPUT 1 – 32] (Green)

Light when the corresponding control inputs are

turned ON.

2. Power Indicator [POWER] (Blue)

Lights when the power is switched on.

3. CPU OFF Indicator [CPU OFF] (Red)

This indicator is not used.

4. FAULT Indicator [FAULT] (Yellow)

Lights when communications with the connected

SX-2000CO are interrupted.

5. USB Port [USB]

This port is not used.

6. RUN Indicator [RUN] (Green)

Normally flashes continuously.

7. ID Switch [ID NUMBER]

This switch is not used.

Always set to "0."

Note

This switch is set to "0" by default.

8. Reset Key [RESET]

Pressing this key restarts the SX-2000CI.

9. DIP Switch [SETTING]

• Switch 1

Sets operation mode. (See p. 15.)

ON: Operates in stand-alone mode.

OFF: Operates in normal mode.

• Switch 2

This switch is not used.

• Switches 3, 4

Perform priority control settings of the control

inputs by combined settings of Switches 3 and 4.

(See p. 16.)

• Switches 5 – 8

These switches are not used.

Note

Switches 1 – 8 are set to the OFF position by

default.

Protective cover

Inside of the protective cover

ID NUMBER RESET

9

8

A

7

B

6

C

5

D

4

E

3

F

2

0

1

5 6 7 8 9

1

192103114125136147158

16

CONTROL INPUT

SETTINGUSB RUN

ON

172518261927202821292230233124

32

3 4

2

POWER

CPU OFF

FAULT

CONTROL INPUT UNIT SX-2000CI

Page 5

5

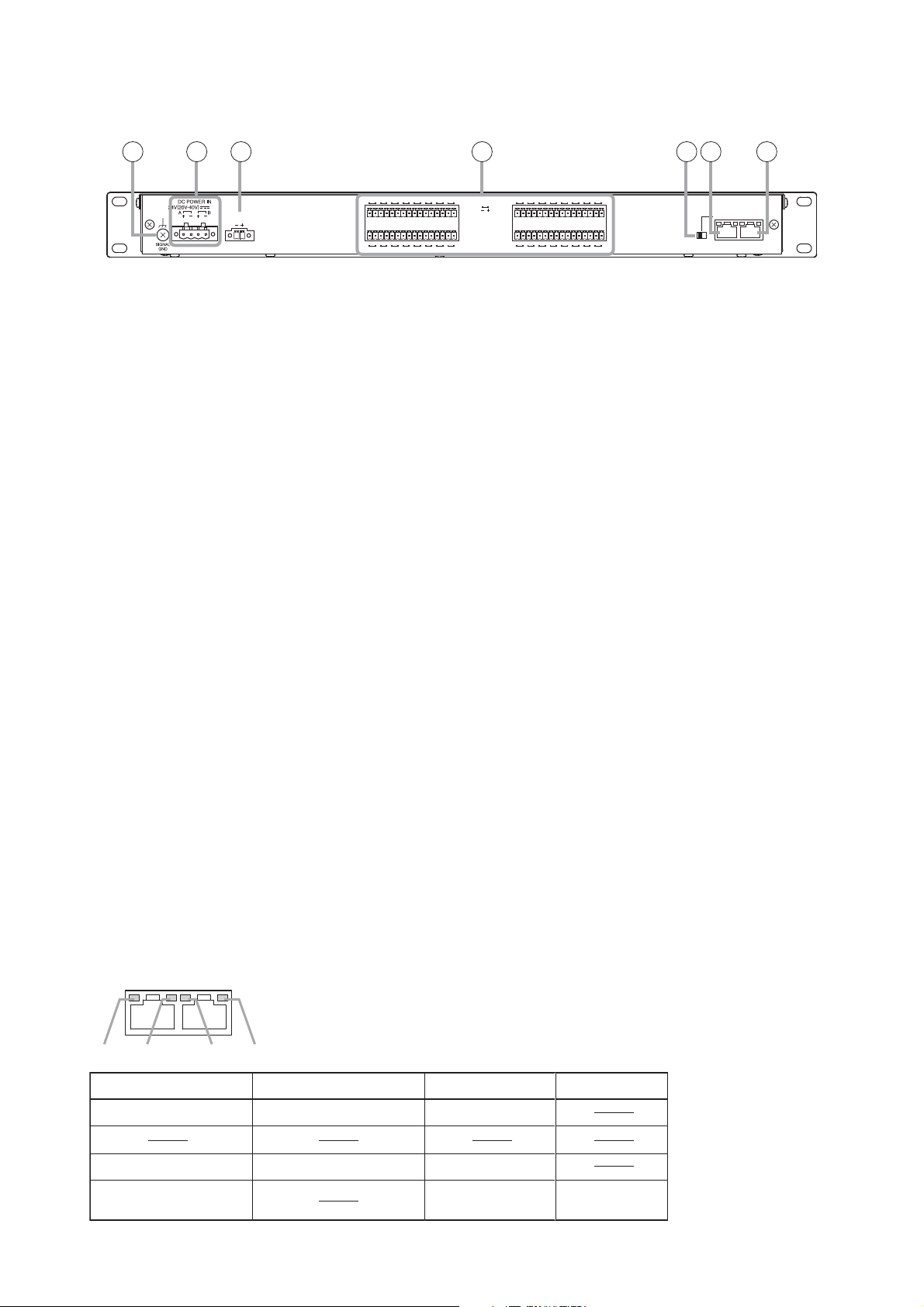

[Rear]

10. Functional Earth Terminal [SIGNAL GND]

Hum noise may be generated when external

equipment is connected to the unit. Connecting

this terminal to the functional earth terminal of

the external equipment may reduce the hum

noise.

Note: This terminal is not for protective earth.

11. DC Power Input Terminal [DC POWER IN]

Connect an optional AD-011 or AD-031B DC

Power Supply Panel to this terminal.

Select the appropriate panel taking into

consideration the total current consumption of all

equipment to be connected to the power supply

unit. (See p. 10.)

When not using a redundant power system*,

connect the [+] terminal of input A to the [+]

terminal of input B, and the [–] terminal of input A

to the [–] terminal of input B.

(See p. 11 and p. 13.)

* A method of connecting separate power

sources to each power input or connecting the

commercial power supply and backup power

supply separately to each power input to

prevent the system from going down when a

cable is broken or power fails.

12. 24 V DC Output Terminal [DC 24 V OUT]

This terminal supplies 24 V DC, max. 100 mA to

connected external equipment.

13. Control Input Terminals

[CONTROL INPUT 1 – 32]

Photo coupler inputs. A current of approximately

2 mA flows when shorted, and the voltage

becomes approximately 24 V DC when opened.

Activating the control input terminal causes the

control output terminal with the same channel

number (SX-2000CO) to close (provides make

contact).

14. CI/CO Link Through Switch [ON/OFF]

Normally, set this switch to the OFF position.

Note

This switch is set to "OFF" by default.

15. CI/CO Link Through Terminal

[CI/CO LINK THROUGH]

This terminal is not used.

Refer to the table below for the indicators'

functions and status.

16. CI/CO Link Data Terminal [CI/CO LINK DATA]

Connect this terminal to the CI/CO Link Terminal

of the SX-2000CO.

Refer to the table below for the indicators'

functions and status.

[Indicators' functions and status of the CI/CO Link Through/Data terminals]

10

12 14 15 1613

11

DC 24V OUT

MAX. 0.1A

1718192021222324

CONTROL

INPUT

2526272829303132

12345678

910111213141516

ONOFF

CI/CO LINK

THROUGH

DATA

CI/CO LINK

THROUGH

1 234

1. CI/CO LINK status Communication start Communication stop

2.

DATA

Functions LED On or Flashing (green) LED Off LED On (orange)

3. CI/CO LINK status Communication start Communication stop

4. CI/CO LINK connection

confirmation

Unconnected Connected

Page 6

6

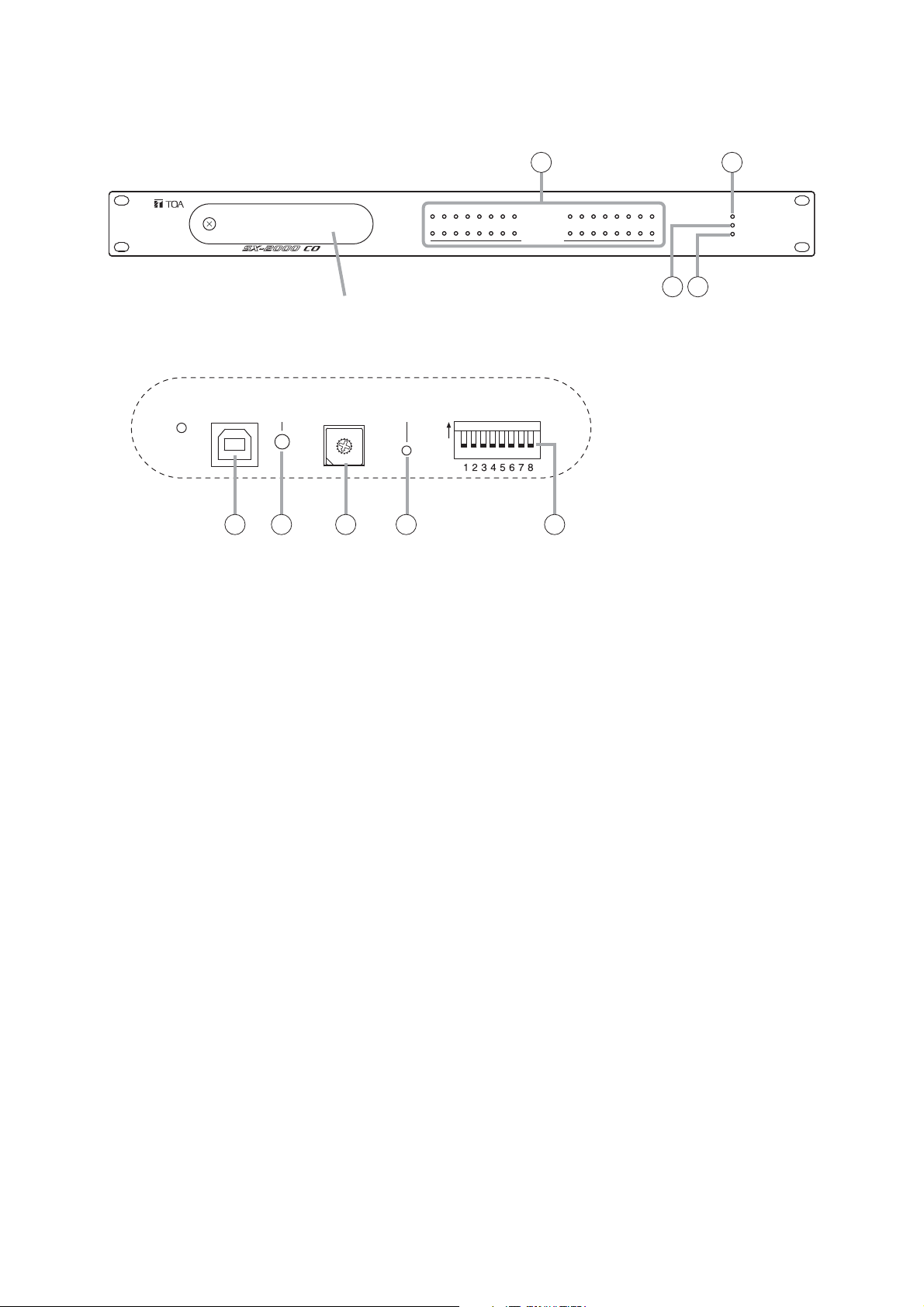

3.2. SX-2000CO Control Output Unit

[Front]

1. Control Output Indicators

[CONTROL OUTPUT 1 – 32] (Green)

Light when the corresponding control outputs are

turned ON.

2. Power Indicator [POWER] (Blue)

Lights when the power is switched on.

3. CPU OFF Indicator [CPU OFF] (Red)

This indicator is not used.

4. FAULT Indicator [FAULT] (Yellow)

Lights when communications with the connected

SX-2000CI are interrupted.

5. USB Port [USB]

This port is not used.

6. RUN Indicator [RUN] (Green)

Normally flashes continuously.

7. ID Switch [ID NUMBER]

This switch is not used.

Always set to "1."

Note

This switch is set to "1" by default.

8. Reset Key [RESET]

Pressing this key restarts the SX-2000CO.

9. DIP Switch [SETTING]

• Switch 1

Sets operation mode. (See p. 15.)

ON: Operates in stand-alone mode.

OFF: Operates in normal mode.

• Switches 2 – 8

These switches are not used.

Note

Switches 1 – 8 are set to the OFF position by

default.

Protective cover

Inside of the protective cover

USB RUN

ID NUMBER

9

8

A

7

B

6

C

5

D

4

E

3

F

2

0

1

RESET

5 6 7 8 9

1

192103114125136147158

16

CONTROL OUTPUT

SETTINGON

172518261927202821292230233124

32

CONTROL OUTPUT UNIT SX-2000CO

3 4

2

POWER

CPU OFF

FAULT

Page 7

7

[Rear]

10. Functional Earth Terminal [SIGNAL GND]

Hum noise may be generated when external

equipment is connected to the unit. Connecting

this terminal to the functional earth terminal of

the external equipment may reduce the hum

noise.

Note: This terminal is not for protective earth.

11. DC Power Input Terminal [DC POWER IN]

Connect an optional AD-011 or AD-031B DC

Power Supply Panel to this terminal.

Select the appropriate panel taking into

consideration the total current consumption of all

equipment to be connected to the power supply

unit. (See p. 10.)

When not using a redundant power system*,

connect the [+] terminal of input A to the [+]

terminal of input B, and the [–] terminal of input A

to the [–] terminal of input B.

(See p. 11 and p. 13.)

When driving the unit with the power supply unit

connected to the SX-2000CI, connect the power

supply to this terminal via an optional RM-200RJ

Terminal Unit.

(See p. 12 and p. 13.)

* A method of connecting separate power

sources to each power input or connecting the

commercial power supply and backup power

supply separately to each power input to

prevent the system from going down when a

cable is broken or power fails.

12. Control Output Terminals

[CONTROL OUTPUT 1 – 32]

Relay make contact outputs.

Activating the control input terminal of the SX2000CI causes the control output terminal with

the same channel number to close.

Each contact capacity is rated at 40 V DC for

withstand voltage, and 2 mA – 300 mA for

control current.

13. CI/CO Link Through Switch [ON/OFF]

Normally, set this switch to the OFF position.

Note

This switch is set to "OFF" by default.

14. CI/CO Link Through Terminal

[CI/CO LINK THROUGH]

This terminal is not used.

Refer to the table below for the indicators'

functions and status.

15. CI/CO Link Data Terminal [CI/CO LINK DATA]

Connect this terminal to the CI/CO Link Terminal

of the SX-2000CI.

Power to operate the unit cannot be supplied

through this terminal.

Refer to the table below for the indicators'

functions and status.

[Indicators' functions and status of the CI/CO Link Through/Data terminals]

10

11

14 151312

1718192021222324

CONTROL

12345678

OUTPUT

CNCNO

CI/CO LINK

THROUGH

DATA

ONOFF

9101112131415162526272829303132

CI/CO LINK

THROUGH

1 234

1. CI/CO LINK status Communication start Communication stop

2.

3. CI/CO LINK status Communication start Communication stop

4. CI/CO LINK connection

confirmation

DATA

Functions LED On or Flashing (green) LED Off LED On (orange)

Unconnected Connected

Page 8

8

4. CONNECTIONS

4.1. Removable Terminal Plug Connection

Notes

• Do not use a micro screwdriver. Sufficient torque is not given to the screws when tightening them, and

connections may not be secured.

• Avoid soldering stranded or shielded cable, as contact resistance may increase when the cable is tightened

and the solder is crushed, possibly resulting in an excessive rise in joint temperatures.

• When connecting 2 cables or a shielded cable to a single terminal,

use a ferrule terminal with an insulation sleeve to crimp the cables

because such cable conductors could become loose.

Recommended ferrule terminals for signal cables

(made by Phoenix Contact)

Recommended ferrule terminals for power supply cables

(made by Phoenix Contact)

Crimping tool: CRIMPFOX UD6-4 (made by Phoenix Contact)

Wiring procedures

Procedures below are for the removable terminal plug with fixing screws.

Step 1. Wiring the supplied removable terminal plug.

1-1. Loosen the terminal screws to insert the wire.

1-2. Tighten the terminal screws.

Ensure that the wire does not break free

when pulled. If the wire does pull free, repeat

the connection procedure from the start.

Step 2. Insert the wired terminal plug into the

corresponding terminal block in the unit's rear

panel.

Step 3. Tighten the fixing screw.

Notes

• Do not reverse Steps 1 and 2 above. Force is applied to the connected receptacle pins while tightening the

terminal screw and they may be damaged, resulting in bad connector contact.

• When detaching the terminal plug, pull it straight out. Pulling it out at an angle may cause the terminal plug

or terminal block to break.

Cable sheath to trim

* Expose 8 mm or more when using the

above ferrule terminal, and cut off an extra

conductor protruding from the sleeve.

Model Number a l

AI 0,34-8 TQ

AI 0,5-8 WH

2 mm

2.5 mm

b

0.8 mm

1.1 mm

12.5 mm

14 mm

1

2

l

8 mm

8 mm

Model Number a

AI 1,5-8 BK

AI-TWIN 2 x 1,5-8 BK 6.6 mm

a

3.4 mm

1

2

a

3.6 mm

b

1.8 mm

1

l

14 mm

16 mm2.3 mm

2

l

8 mm

8 mm

Insulation sleeve

a

Insulation sleeve

1

a

a

Contact section

2

l

1

l

Contact section

2

2

l

1

l

bb

Solid cable and stranded cable

7 mm*

Shielded cable

15 mm

7 mm*

To tighten

Terminal screw

Straight slot screwdriver

To loosen

Removable terminal plug

Fixing screw

Page 9

9

4.2.1. Connection example 1

Connect each 2 power supply units to the SX-2000CI and SX-2000CO separately. (See p. 10 and 15.)

4.2.1. Connection example 2

Connect each one power supply unit to the SX-2000CI and SX-2000CO separately. (See p. 11 and 15.)

4.2.1. Connection example 3

Connect 2 power supply units to the SX-2000CI only via Terminal unit. (See p. 11.)

4.2.1. Connection example 4

Connect a single power supply unit to the SX-2000CI only via Terminal unit. (See p. 13.)

4.2. Connection Example

There are 4 connection configurations depending on the DC power supply and CI/CO link connections.

Note: For the detailed information on the connections of power supply unit and CI/CO links, refer to the page

indicated at the end of each "Connection example."

SX-2000CI

192103114125136147158

16

172518261927202821292230233124

CONTROL INPUT

POWER

CPU OFF

32

FAULT

CONTROL INPUT UNIT SX-2000CI

Redundant power supply system*

Program timer

Power supply unit (1)

Power supply unit (2)

SX-2000CO

192103114125136147158

A method of connecting separate power sources to each power

*

16

CONTROL OUTPUT

172518261927202821292230233124

32

POWER

CPU OFF

FAULT

CONTROL OUTPUT UNIT SX-2000CO

input or connecting the commercial power supply and backup

Digital announce machine

Power supply unit (3)

Power supply unit (4)

power supply separately to each power input to prevent the

system from going down when a cable is broken or power fails.

SX-2000CI

192103114125136147158

SX-2000CO

192103114125136147158

16

16

CONTROL INPUT

CONTROL OUTPUT

172518261927202821292230233124

172518261927202821292230233124

32

32

POWER

CPU OFF

FAULT

CONTROL INPUT UNIT SX-2000CI

POWER

CPU OFF

FAULT

CONTROL OUTPUT UNIT SX-2000CO

Program timer

Power supply unit (1)

Digital announce machine

Power supply unit (2)

SX-2000CI

192103114125136147158

Terminal unit

Supplies power from

the SX-2000CI side

Terminal unit

16

CONTROL INPUT

172518261927202821292230233124

POWER

CPU OFF

32

FAULT

CONTROL INPUT UNIT SX-2000CI

Redundant power

supply system

Program timer

Power supply unit (1)

Power supply unit (2)

SX-2000CO

192103114125136147158

16

CONTROL OUTPUT

172518261927202821292230233124

32

POWER

CPU OFF

FAULT

CONTROL OUTPUT UNIT SX-2000CO

Digital announce machine

SX-2000CI

192103114125136147158

Terminal unit

Supplies power from

the SX-2000CI side

Terminal unit

SX-2000CO

192103114125136147158

16

16

CONTROL INPUT

CONTROL OUTPUT

172518261927202821292230233124

172518261927202821292230233124

32

32

POWER

CPU OFF

FAULT

CONTROL INPUT UNIT SX-2000CI

POWER

CPU OFF

FAULT

CONTROL OUTPUT UNIT SX-2000CO

Program timer

Power supply unit

Digital announce machine

: CI/CO link

: Power cable : CPEV cable : Control line

Page 10

10

4.3. Power Supply Connections

Use an optional AD-011 or AD-031B DC Power Supply Panel to this terminal. Select the appropriate panel

taking into consideration the total current consumption of all equipment to be connected to the power supply

unit.

4.3.1. Connection for Example 1

Connect each 2 power supply units to the SX-2000CI and SX-2000CO separately as follows. Connect one

power supply unit to A channel of the DC power input terminal and the other power supply unit to the B

channel of the DC power input terminal on the SX-2000CI. Connect the power supply units to the SX-2000CO

in the same manner.

Even if one of the 2 units fails or its power supply line is broken, power is still supplied from the other unit,

preventing the system from going down.

Note: When using the AD-031B DC power supply panel (optional), make connections in the same manner.

AD-011 DC power supply panel

24VDC OUT 24VDC IN

Cable: AWG14 – 18

AD-011

24VDC OUT 24VDC IN

Cable: AWG14 – 18

AD-011

24VDC OUT 24VDC IN

SX-2000CI

DC 24V OUT

MAX. 0.1A

SX-2000CO

1718192021222324

CONTROL

INPUT

2526272829303132

DC power input terminal

4P removable terminal plug

(supplied with the SX-2000CI)

STP Category 5 straight cable

(with RJ45 connectors)

1718192021222324

DC power input terminal

12345678

910111213141516

CI/CO LINK

THROUGH

DATA

ONOFF

CONTROL

12345678

OUTPUT

CNCNO

CI/CO LINK

THROUGH

DATA

ONOFF

9101112131415162526272829303132

Cable: AWG14 – 18

AD-011

4P removable terminal plug

(supplied with the SX-2000CO)

24VDC OUT 24VDC IN

Cable: AWG14 – 18

Page 11

11

4.3.2. Connection for Example 2

Supply the power from each one power supply panel to the SX-2000CI and SX-2000CO separately.

Connect the (+) terminal of channel A to the (+) terminal of channel B, and the (–) terminal of channel A to the

(–) terminal of channel B.

Note

Use a ferrule terminal when connecting

2 cables to a single terminal. (See p. 8.)

4.3.3. Connection for Example 3

Both the SX-2000CI and SX-2000CO can be driven by connecting 2 power supply panels to the SX-2000CI

only.

Connect the DC power input terminals of the SX-2000CI to those of the SX-2000CO and the CI/CO link data

terminals of the SX-2000CI to those of the SX-2000CO via the RM-200RJ Terminal Unit (optional).

(See the next page.)

When installing the SX-2000CI and SX-2000CO separately from each other, the power supply panel does not

need to have at each unit by making connection in this manner.

Note

When connecting the power supply panel to one of the equipment, be sure to connect it to the SX-2000CI

side.

If it is connected to the SX-2000CO side, the maximum cable length between the SX-2000CI and SX-2000CO

may be reduced.

[Maximum cable length]

The maximum cable length between the SX-2000CI and SX-2000CO varies depending on the conductor

diameter of the CPEV cable used between the RM-200RJs.

The following table shows the conductor diameter of the CPEV cable vs. maximum cable length when the

power is supplied from the SX-2000CI side.

Note: When using the AD-031B DC power supply panel (optional), make connections in the same manner.

AD-011 DC power supply panel

24VDC OUT 24VDC IN

Cable: AWG14 – 18

AD-011

24VDC OUT 24VDC IN

Cable: AWG14 – 18

SX-2000CI

DC 24V OUT

MAX. 0.1A

SX-2000CO

1718192021222324

CONTROL

INPUT

2526272829303132

12345678

910111213141516

DC power input terminal

STP Category 5 straight cable

(with RJ45 connectors)

4P removable terminal plug

(supplied with the SX-2000CI)

1718192021222324

DC power input terminal

4P removable terminal plug

(supplied with the SX-2000CO)

12345678

9101112131415162526272829303132

CONTROL

OUTPUT

CI/CO LINK

THROUGH

DATA

ONOFF

CNCNO

CI/CO LINK

THROUGH

DATA

ONOFF

Conductor diameter

AWG 22

AWG 19

AWG 16

AWG 19 x 3 pair-CPEV (2 pairs for DC and 1 pair for data)

AWG 16 x 3 pair-CPEV (2 pairs for DC and 1 pair for data)

Maximum cable length

160 m

320 m

570 m

640 m

800 m

Page 12

12

[Connections]

It is recommended to use an optional RM-200RJ Terminal Unit that serves wiring conversion between the

CPEV cable and STP Category 5 straight cable (with RJ45 connectors). Connect the CPEV cable between

the same terminals of both RM-200RJ units pairing cables 3 with 6, 4 with 5, and 7 with 8 as shown below.

Terminals 4 and 5 serve to supply power to B channel.

Note: When using the AD-031B DC power supply panel (optional),

make connections in the same manner.

Note

Terminals 1 and 2

cannot be used for

power supply line.

SX-2000CO

DC power

input terminal

AWG14 – 18

STP Category 5 straight cable

(with RJ45 connectors)

AWG14 – 18

SX-2000CI

DC power

input terminal

CI/CO link

data terminal

5

4

7

8

CI/CO link

data terminal

RM-200RJ

terminal unit

RM-200RJ

4

5

3

6

7

8

Shield

Over 3-pair shielded

CPEV cable (main cable)

AWG14 – 18

AD-011

DC power supply panel

24VDC OUT 24VDC IN

AD-011

24VDC OUT 24VDC IN

5

4

STP Category 5 straight cable

(with RJ45 connectors)

7

8

Note: The RM-200RJ can be installed on a desk or to a wall.

AWG14 – 18

4

5

3

6

7

8

Shield

[RM-200RJ Mounting dimensions]

84

75

44.5

116

44.513.5

Unit: mm

Page 13

13

4.3.4. Connection for Example 4

Drive both the SX-2000CI and SX-2000CO by connecting a single power supply panel to the SX-2000CI only.

Connect the DC power input terminals of the SX-2000CI to those of the SX-2000CO and the CI/CO link data

terminals of the SX-2000CI to those of the SX-2000CO via the RM-200RJ Terminal Unit (optional).

When installing the SX-2000CI and SX-2000CO separately from each other, the power supply panel does not

need to have at each unit by making connection in this manner.

Note

When connecting the power supply unit to one of the equipment, be sure to connect it to the SX-2000CI side.

If it is connected to the SX-2000CO side, the maximum cable length between the SX-2000CI and SX-2000CO

may be reduced.

For the conductor diameter of the CPEV cable vs. maximum cable length when the power is supplied from the

SX-2000CI side, refer to the table on p. 11.

[Connections]

It is recommended to use an optional RM-200RJ Terminal Unit that serves wiring conversion between the

CPEV cable and STP Category 5 straight cable (with RJ45 connectors). Connect the CPEV cable between

the same terminals of both RM-200RJ units pairing cables 3 with 6, and 7 with 8 as shown below.

SX-2000CO

DC power

input terminal

STP Category 5 straight cable

(with RJ45 connectors)

AWG14 – 18

SX-2000CI

DC power

input terminal

CI/CO link

data terminal

7

8

CI/CO link

data terminal

RM-200RJ terminal unit

RM-200RJ

3

6

7

8

Shield

Over 2-pair shielded

CPEV cable

(main cable)

STP Category 5 straight cable

(with RJ45 connectors)

AWG14 – 18

AD-011 DC power supply panel

24VDC OUT 24VDC IN

AWG14 – 18

3

6

7

8

7

8

Shield

Notes

The RM-200RJ can be installed on a desk or to a wall.

•

Refer to the RM-200RJ mounting dimensions on the

previous page.

When using the AD-031B DC power supply panel

•

(optional), make connections in the same manner.

Page 14

14

4.4. Control Input Connections (SX-2000CI Only)

This connection example allows timer-activated automatic broadcasts.

When the TT-104B's preprogrammed time is reached, the SX-2000CI receives a control output signal (make

contact) from the TT-104B and activates preset broadcast patterns.

4.5. Control Output Connections (SX-2000CO Only)

This example shows the connection method to remotely activate the external sound source equipment.

When a broadcast is started, the SX-2000CO provides a make contact to activate the EV-350R.

TT-104B

program timer

Cable: AWG22 – 28

twisted pair cable

SX-2000CI

DC 24V OUT

MAX. 0.1A

16P removable terminal plug

(supplied with the SX-2000CI)

OUTPUT CHANNEL (24 V DC 0.5 A)

OUTPUT CHANNEL (24 V DC 0.5 A)

1718192021222324

CONTROL

INPUT

2526272829303132

Control input terminals

CAUTION

BE SURE TO SET

THIS SWITCH TO “ON”

AFTER INSTALLATION

12345678

910111213141516

ON

OFFONOFF

MEMORY

CHANNEL

BACK UP

ASSIGNMENT

CI/CO LINK

THROUGH

DATA

ONOFF

Open voltage: 24 V DC

Short-circuit current: 2 mA

Control output terminals

SX-2000CO

Cable: AWG22 – 28

twisted pair cable

Activation control input terminal 1

EV-350R

Digital announcer

1718192021222324

COM terminal

CONTROL

12345678

OUTPUT

CNCNO

CI/CO LINK

THROUGH

DATA

ONOFF

9101112131415162526272829303132

Withstand voltage: 40 V DC

Control current: 2 – 300mA

6P removable terminal plug

(supplied with the SX-2000CO)

OUTPUT

UNBAL.

AUX INPUT

UNBAL.

Activation control input terminal 2

Page 15

15

4.6. CI/CO Link Terminal Connections (Applies to the example 1 or 2 on p. 9.)

Connect the same CI/CO link data terminals of both the SX-2000CI and SX-2000CO.

For the connection cable, use a STP Category 5 twisted pair cable (with RJ45 connectors).

The SX-2000CI and SX-2000CO can be connected using the shielded CPEV cable (1-pair for data line) via

the optional RM-200RJ Terminal unit.

Note

Total cable length connecting CI/CO link terminals within the system must be kept shorter than 800 m.

5. SETTINGS

5.1. Stand-Alone Mode Setting

Step 1. Remove the protective cover on the SX-2000CI/CO's front panel by

unscrewing it with a Phillips screwdriver.

Step 2. Set the DIP switch 1 on the SX-2000CI/CO to ON.

Note: Switch 1 is set to OFF by default.

CI/CO link data terminal

SX-2000CI

DC 24V OUT

MAX. 0.1A

1718192021222324

CONTROL

INPUT

2526272829303132

12345678

910111213141516

THROUGH

ONOFF

CI/CO LINK

CI/CO LINK

THROUGH

DATA

ONOFF

DATA

STP Category 5 straight cable

(with RJ45 connectors)

CI/CO link through switch: OFF

(Factory preset: OFF)

SX-2000CO

1718192021222324

CI/CO link data terminal

CI/CO LINK

CONTROL

12345678

THROUGH

9101112131415162526272829303132

ONOFF

DATA

OUTPUT

CNCNO

CI/CO LINK

THROUGH

DATA

ONOFF

CI/CO link through switch: OFF

(Factory preset: OFF)

SX-2000CI

Screw

Protective cover

Note: Fragmentary view of the SX-2000CI. This view is the same for the SX-2000CO.

Inside of the protective cover

USB RUN

ID NUMBER

9

8

A

7

B

6

C

5

D

4

E

3

F

2

0

1

RESET

Reset key

SETTINGON

DIP switches

SETTINGON

Page 16

16

Step 4. Press the Reset key on the SX-2000CI/CO's front panel.

The SX-2000CI/CO is reactivated.

Step 5. Replace the protective cover.

Note

When operating the SX-2000CI/CO in stand-alone mode, do not connect it to the SX-2000AO or SX-2100AO

as doing so may cause system malfunction.

5.2. Priority Control Settings of the Control Inputs (SX-2000CI Only)

Priority control of the control inputs can be performed by combined settings of the DIP switches 3 and 4 inside

the protective cover (see the previous page) on the SX-2000CI's front panel.

Step 3. Set the link through switch on the SX-2000CI/CO's rear panel to the OFF position.

Note: The CI/CO link through switch is set to OFF by default.

Notes

• If you change the DIP switch setting, be sure to press the Reset key inside the protective cover to restart the

SX-2000CI.

• Control inputs act as such that they have been closed in numerical order of terminal numbers after the SX2000CI is switched on or restarted with these inputs closed in any order.

In this case, the highest priority is assigned to the control input of the largest terminal number when the

priority control type is "Last-in-first-out," and to the control input of the smallest terminal number when "Firstin-first-out."

SX-2000CI rear

DC 24V OUT

MAX. 0.1A

1718192021222324

CONTROL

INPUT

2526272829303132

12345678

910111213141516

THROUGH

ONOFF

CI/CO LINK

CI/CO LINK

THROUGH

DATA

ONOFF

DATA

CI/CO link through switch: OFF

Note: Fragmentary view of the SX-2000CI. This view is the same for the SX-2000CO.

RESET

DIP switch 3Type of priority control DIP switch 4 Figure of the DIP switch Reference page

SETTINGON

No priority control

(factory default)

Terminal numberbased priority

Last-in-first-out

First-in-first-out

OFF

ON

OFF

ON

OFF

OFF

ON

ON

P. 1 7

SETTINGON

P. 1 7

SETTINGON

P. 1 8

SETTINGON

P. 1 8

Page 17

17

5.2.1. No priority control (DIP switch 3: OFF, DIP switch 4: OFF)

In this mode, priority control is disabled. (Factory default)

For example, closing the control input 2 while the control input 1 is closed causes

the control output 2 to close simultaneously while the control output 1 remains

closed.

Control inputs 3 – 32 operate in the same manner.

5.2.2. Terminal number-based priority (DIP switch 3: ON, DIP switch 4: OFF)

The smaller the terminal number of the control input, the higher the priority level.

For example, closing the control input 1 while the control input 2 is closed causes

the control output 2 to open.

Opening the control input 1 causes the control output 2 to close.

Control inputs 3 - 32 operate in the same manner. Latency of 100 ms is employed

in order to prevent two or more control outputs from turning ON.

Control input 2 is disabled while the control input 1 is being closed. The control output 2 becomes closed

when the control input 1 is opened.

Closed (make contact)

Control input 1

Closed

Control input 2

Closed

Control output 1

Closed

Control output 2

Open (break contact)

Open

SETTINGON

Open

Open

SETTINGON

Closed

Control input 1

Control input 2

Control output 1

Control output 2

Closed

Closed

Closed Closed

Open

100 ms 100 ms

Open

Open

Closed

Control input 1

Closed

Control input 2

Closed

Control output 1

Open

Open

Control output 2

Closed

100 ms

Page 18

18

5.2.3. Last-in-first-out (DIP switch 3: OFF, DIP switch 4: ON)

The most recent control input takes precedence over the earlier one.

For example, closing the control input 2 while the control input 1 is closed causes

the control output 1 to open. The control output 1 becomes closed when the control

input 2 is opened.

Control inputs 3 - 32 operate in the same manner. Latency of 100 ms is employed

in order to prevent two or more control outputs from turning ON.

5.2.4. First-in-first-out (DIP switch 3: ON, DIP switch 4: ON)

The first control input takes precedence over the later control output.

For example, the control output 2 is not closed while the control input 1 is being

closed.

The control output 2 becomes closed when the control input 1 is opened.

Control inputs 3 - 32 operate in the same manner.

Latency of 100 ms is employed in order to prevent two or more control outputs from

turning ON.

Closed

Control input 1

Control input 2

Control output 1

Control output 2

Closed

Closed

Open

Closed

100 ms 100 ms

Open

Closed

Open

SETTINGON

Closed

Controlinput1

Closed

Controlinput2

Closed

Controloutput

Closed

Controloutpu2

Open

Open

100ms

SETTINGON

Page 19

19

6 SPECIFICATIONS

6.1. SX-2000CI Control Input Unit

Power Source Applicable power supply: AD-011, AD-031B

24 V DC (operational range: 20 – 40 V DC), redundant power supply enabled

using 2 channels of DC inputs

Current Consumption Under 0.7 A (maximum value in the power operating range)

Under 0.55 A (at 24 V DC operation)

Indication Power indicator, Control input indicators (32), CPU-OFF indicator,

FAULT indicator

Control Input 32 inputs, no-voltage make contacts, open voltage: 24 V DC,

short-circuit current: 2 mA, photo coupler inputs,

removable terminal blocks (16P)

Priority Control No priority control, Terminal number-based priority, Last-in-first-out priority,

First-in-first-out priority

CI/CO Link

Connector RJ45 connector

Connection Cable Main cable: Shielded CPEV cable* or STP Category 5 straight cable

* When connecting the power supply to each unit: 1-pair for data line

When connecting the power supply only to the SX-2000CI:

1-pair data line and 2-pair power line for a redundant power supply

system, or 1-pair data line and 1-pair power line for a non-redundant

power supply system

Branch cable: STP Category 5 straight cable

Maximum Cable Distance

800 m

Maximum Delay Time 300 ms

24 V DC Output section

Connector Removable terminal block (2P)

Maximum Feeing Current

100 mA

Output Voltage 24 V DC within ±10%

Operating Temperature 0 – 40 °C

Operating Humidity 35 – 80% RH (no condensation)

Finish Panel: Aluminum, black, anodized aluminum

Case: Surface-treated steel sheet

Dimensions 482 (w) x 44 (h) x 331.5 (d) mm

Weight 3.6 kg

• Accessories

Removable terminal plug (16 pins) ............ 4

Removable terminal plug (4 pins) .............. 1

Removable terminal plug (2 pins) .............. 1

Rack mounting screw

with plain washer (5 x 12) .......................... 4

Note: The design and specifications are subject to change without notice for improvement.

• Optional products

DC power supply panel: AD-011, AD-031B

Terminal unit: RM-200RJ

Page 20

6.2. SX-2000CO Control Output Unit

Power Source Applicable power supply: AD-011, AD-031B

24 V DC (operational range: 20 – 40 V DC), redundant power supply enabled

using 2 channels of DC inputs

Current Consumption Under 0.34 A (maximum value in the power operating range)

Under 0.29 A (at 24 V DC operation)

Indication Power indicator, Control output indicators (32), CPU-OFF indicator,

FAULT indicator

Control Output 32 outputs, no-voltage make contacts, relay contact outputs (withstand

voltage: 40 V DC, control current: 2 – 300 mA),

removable terminal blocks (6P)

CI/CO Link

Connector RJ45 connector

Connection Cable Main cable: Shielded CPEV cable* or STP Category 5 straight cable

* When connecting the power supply to each unit: 1-pair for data line

When connecting the power supply only to the SX-2000CI:

1-pair data line and 2-pair power line for a redundant power supply

system, or 1-pair data line and 1-pair power line for a non-redundant

power supply system

Branch cable: STP Category 5 straight cable

Maximum Cable Distance

800 m

Maximum Delay Time 300 ms

Operating Temperature 0 – 40 °C

Operating Humidity 35 – 80% RH (no condensation)

Finish Panel: Aluminum, black, anodized aluminum

Case: Surface-treated steel sheet

Dimensions 482 (w) x 44 (h) x 331.5 (d) mm

Weight 3.6 kg

• Accessories

Removable terminal plug (6 pins) ............ 16

Removable terminal plug (4 pins) .............. 1

Rack mounting screw

with plain washer (5 x 12) .......................... 4

Note: The design and specifications are subject to change without notice for improvement.

Traceability Information for Europe

Manufacturer:

TOA Corporation

7-2-1, Minatojima-Nakamachi, Chuo-ku, Kobe, Hyogo,

Japan

Authorized representative:

TOA Electronics Europe GmbH

Suederstrasse 282, 20537 Hamburg,

Germany

URL: http://www.toa.jp/

133 - 02-00319-00

Warning

This equipment is compliant with Class A of CISPR 32. In a residential environment this equipment may

cause radio interference.

• Optional products

DC power supply panel: AD-011, AD-031B

Terminal unit: RM-200RJ

Loading...

Loading...