Page 1

IP-EN1-EB Instruction Manual

1

Instruction Manual

Indication Panel for mandatory indications

of EN 54-16 for VX-2000 and SX-2000 IP-EN1-EB

1134

TOA Electronics Europe GmbH

Süderstrasse 282, 20537 Hamburg, Germany

14

1134 - CPR - 102

1134 - CPR - 110

EN 54-16: 2008 Fire detection and fire alarm systems - Part 16:

Voice alarm control and indicating equipment

■ Description

The indication panel IP-EN1-EB is designed to provide the mandatory indications as

required by EN 54-16: 2008 for the VX-2000 and SX-2000 system. Additional 8 indicators

can be used to indicate faults in fire zones (this is an option with requirements in the EN 54-

16) or other faults (EN 54-16 requires yellow indications for faults). A buzzer sounds at

every new fault and can be silenced by depressing the acknowledge button. The lamp test

button allows checking the proper operation of all indicators and the buzzer. All faults can

be reset by using a key.

In addition to above, indication panel IP-EN1-EB provides a general fault output with a

switch-over relay that can be equipped with optional resistors for a surveillance of the

connected fire detection system (FDS) (the surveillance must be performed by the FDS). It

also provides one emergency control input that can either be activated by making/breaking

a contact or by a voltage of 12 or 24 VDC (depending on jumper setting). It supports the

change between emergency and normal mode / silence, controlled by a single contact of

the FDS. The voltage-controlled control input allows a fire detection system to monitor

connection.

The indications and controls require a certain setting in the software that will be described

in this instruction manual.

■ Precautions

Make sure that the power supply of the IP-EN1-EB is switched off or disconnected when

connecting or disconnecting wires to avoid a damage of the IP-EN1-EB.

Make sure that the jumper settings and connection to external equipment is made

correctly, otherwise it may cause malfunctions of the IP-EN1-EB or external equipment

as a fire detection system.

Make sure of right polarity when connecting the power supply and external equipment.

Page 2

IP-EN1-EB Instruction Manual

2

■ Contents

1 Abbreviations .................................................................................................................. 3

2 Software and Firmware Versions supporting the Indication Panel ............................. 3

3 Nomenclature .................................................................................................................. 3

3.1 Appearance Front ........................................................................................................ 3

3.2 Appearance Rear ......................................................................................................... 4

4 Preparation and Connections to Fire Detection Systems ............................................ 5

4.1 Overview ...................................................................................................................... 5

4.2 General Fault Control Output CN9 ............................................................................... 6

4.2.1 Make a contact without surveillance.................................................................................. 6

4.2.2 Make a contact with surveillance ....................................................................................... 6

4.2.3 Break a contact without surveillance ................................................................................. 6

4.2.4 Break a contact with surveillance ...................................................................................... 6

4.3 Emergency Control Input CN13 and System Settings .................................................. 7

4.3.1 Control Voltage Selection .................................................................................................. 7

4.3.2 Total Resistance Setting for Voltage Control .................................................................... 7

4.3.3 Making a Contact: Emergency Activation (VX, SX), breaking a contact: Emergency

Reset (VX, SX) / Silencing (SX) ........................................................................................ 8

4.3.4 Making a Contact: Emergency Activation (VX), breaking a contact: Silencing (VX) ........ 8

4.3.5 Breaking a contact: Emergency Activation (VX, SX), making the contact: Emergency

Reset (VX, SX) / Silencing (SX) ........................................................................................ 9

4.3.6 Breaking a contact: Emergency Activation (VX), making the contact: Silencing (VX) ...... 9

4.3.7 Voltage: Emergency Activation (VX, SX), no voltage: Emergency Reset (VX, SX) /

Silencing (SX) .................................................................................................................. 10

4.3.8 Voltage: Emergency Activation (VX), no voltage: Silencing (VX) ................................... 10

4.3.9 No Voltage: Emergency Activation (VX, SX) Voltage: Emergency Reset (VX, SX) /

Silencing (SX) .................................................................................................................. 11

4.3.10 No Voltage: Emergency Activation (VX) Voltage: Silencing (VX)................................ 11

5 Connections and Settings for the VX-2000 System .....................................................12

5.1 Connections to VX-2000 .............................................................................................12

5.2 Settings in the VX-2000 Setting Software ....................................................................13

5.2.1 Mandatory Indication ....................................................................................................... 13

5.2.1.1 Fault Indications ............................................................................................................ 13

5.2.1.2 Status Indications .......................................................................................................... 14

5.2.2 Control Input Settings for Emergency and Button Controls ............................................ 15

5.2.3 Indication of Failures in Fire Alarm Areas (option of EN 54-16) ..................................... 15

6 Connection and Settings for the SX-2000 System .......................................................16

6.1 Connections to SX-2000 .............................................................................................16

6.2 Connections at SX-2000 Components.........................................................................17

6.3 SX-2000 Settings ........................................................................................................18

6.3.1 Mandatory Indication ....................................................................................................... 18

6.3.1.1 Fault Indications ............................................................................................................ 18

6.3.1.2 Status Indications .......................................................................................................... 19

6.3.2 Indication of Failures in Fire Alarm Areas (option of EN 54-16) ..................................... 19

7 Specifications ................................................................................................................20

8 Accessories ...................................................................................................................20

9 Optional Accessories ....................................................................................................20

Page 3

IP-EN1-EB Instruction Manual

3

1 Abbreviations

FA fire area

FDS fire detection system

2 Software and Firmware Versions supporting the

Indication Panel

VX-2000

Setting software version

3.1.0 and higher

Firmware version of VX-2000 (system manager)

3.10 and higher

Firmware version of VX-2000SF

3.00 and higher

SX-2000

Setting software version

3.10 and higher

Firmware version of SX-2000SM

3.10 and higher

Firmware version of SX-2100AI, SX-2000AO, SX-2100AO

3.10 and higher

3 Nomenclature

3.1 Appearance Front

1 Failure reset key lock

2 power indicator

3 emergency mode indicator

4 general fault indicator

5 CPU fault indicator

6 power fault indicator

7 fireman microphone fault indicator

8 fuse rupture indicator

9 network fault indicator

10 lamp test button

11 fault acknowledge button

12 buzzer

13 8 indicators for faults in fire zones or

other faults

d

IP-EN1-EB INDICATION PANEL

3

2

4

5

6

7

8

9

1

10

11

12

13

13

FAULT FIRE ZONE 5

FAULT FIRE ZONE 1

FAULT FIRE ZONE 6

FAULT FIRE ZONE 2

FAULT FIRE ZONE 7

FAULT FIRE ZONE 3

FAULT FIRE ZONE 8

FAULT FIRE ZONE 4

POWER

EMERGENCY

GENERAL FAULT

CPU FAULT

POWER FAULT

FIREMAN MIC FAULT

FUSE RUPTURE

NETWORK FAULT

EN 54-16

mandatory

indications

optional (FA)

indications

Page 4

IP-EN1-EB Instruction Manual

4

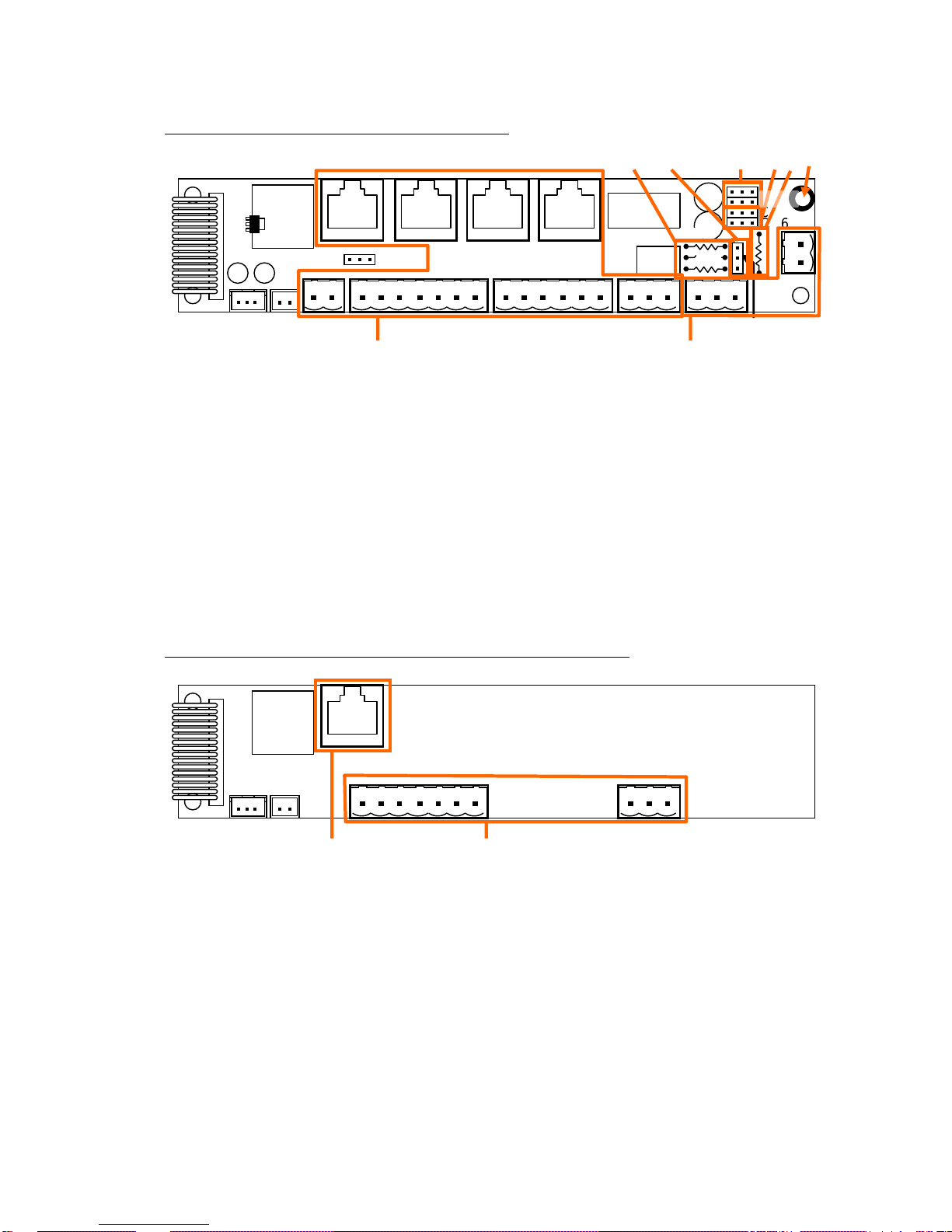

3.2 Appearance Rear

Right side (EN 54-16 mandatory indications)

1 Connectors to VX-2000/SX-2000

2 Connectors to fire detection system (FDS)

3 Insertion place for resistors (R1, R2, R3) for surveillance by FDS

4 Jumper (CN18) for control voltage selection 12/24 VDC from FDS

5 Jumpers (CN19, CN20) for selection pulse/level control from FDS

6 Jumpers (CN6, CN8) for selection of contact or voltage control of FDS

7 Insertion place for resistor (R6) for resistance matching to FDS (chapter 4.3.2)

8 Earth connector: when using the emergency control input, then connect this

point to earth

Left side (fire area fault indications or other fault indications)

9 Connectors to VX-2000 for fault indications in fire areas

10 Connectors to SX-2000 for fault indications in fire areas

CN7

CN15

CN2

CN9

CN12

CN18

CN13

CN10

R6

1

1

1 1 1

1

3 2 1

R2

R3

R1

CN6

CN8

CN19

CN1

CN5

CN11

CN3

1

5 6 4

2

3

7

8

CN20

CN7

CN2

1

1

CN1

10

9

Page 5

IP-EN1-EB Instruction Manual

5

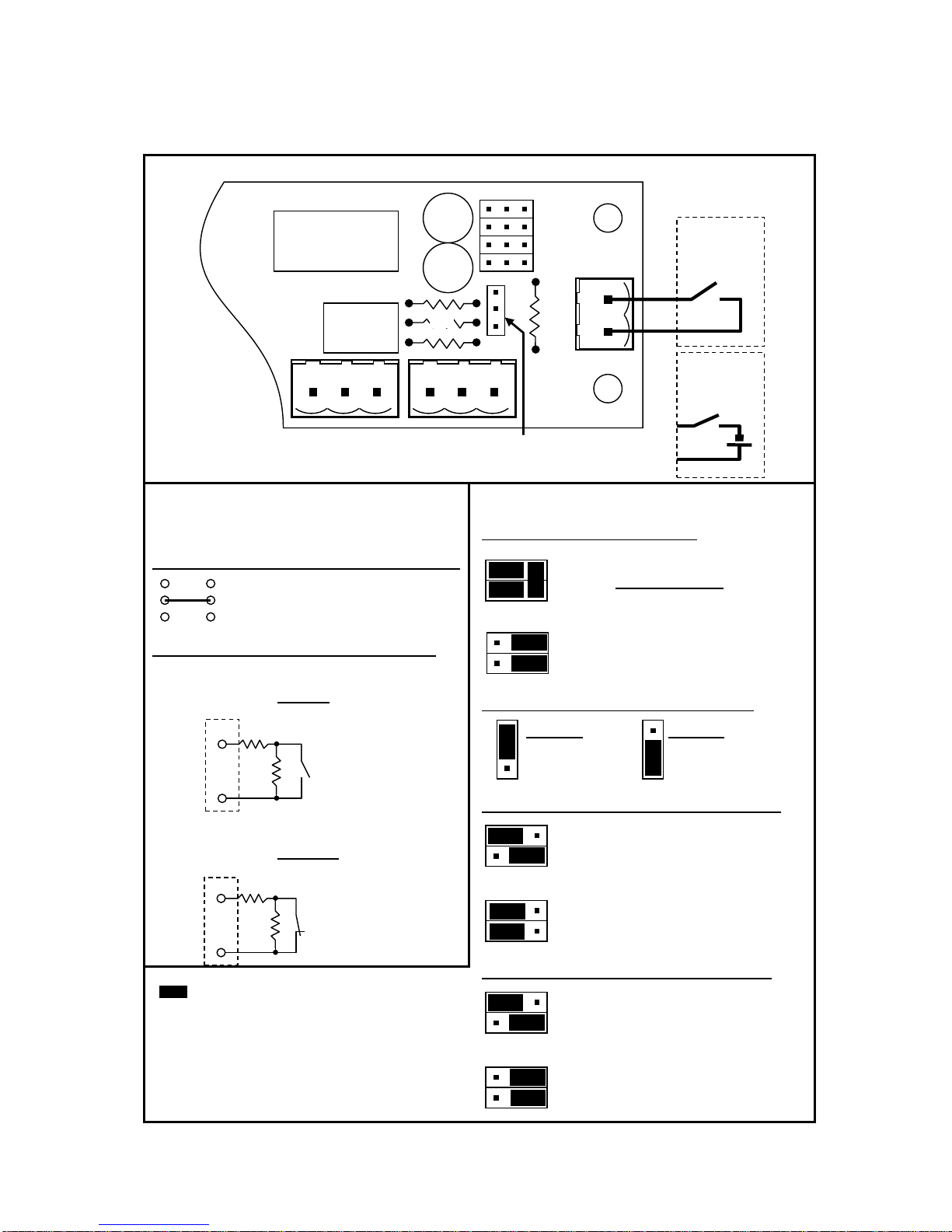

4 Preparation and Connections to Fire Detection Systems

4.1 Overview

CN9

CN18

CN13

R6

1

1

3 2 1

R2

R3

R1

CN20

CN6

CN8

CN19

Emergency control input CN13

FDS

contact

_

+

make: Emergency start

break: emergency reset

(SX: or silence at break)

make: Emergency start

break: silence

(VX-2000 only)

General fault control output CN9

Wire/resistor insertion (R1, R2, R3)

FDS contact output without surveillance

R1

Insert a wire at R1 position

When control output is monitored

and activation by making a contact

Insert R1 and R3

as required by

surveillance

When control output is monitored

and activation by breaking a contact

Insert R1 and R2

as required by

surveillance

R3

R1

1 3 CN9

R2

R1

2

1

CN9

FDS control voltage (CN18 setting)

CN18

24 VDC *

CN18

12 VDC

3 2 1

FDS contact/voltage control

Contact control *

Voltage control

3 2 1

FDS

voltage

+

_

+

Rear of

indication

panel, board

on right side,

right side of the

board

Activation by make contact or voltage on *

make: emergency reset

(SX: or silence at make)

break: Emergency start

make: silence

break: Emergency start

(VX-2000 only)

3 2 1

Activation by break contact or voltage off

* : factory preset

Refer also to the system settings

FDS

FDS

FDS contact output with surveillance

Connection for fire detecting system (FDS)

jumper

CN20

CN19

CN20

CN19

CN6

CN8

CN6

CN8

CN20

CN19

CN20

CN19

1

1

1

Page 6

IP-EN1-EB Instruction Manual

6

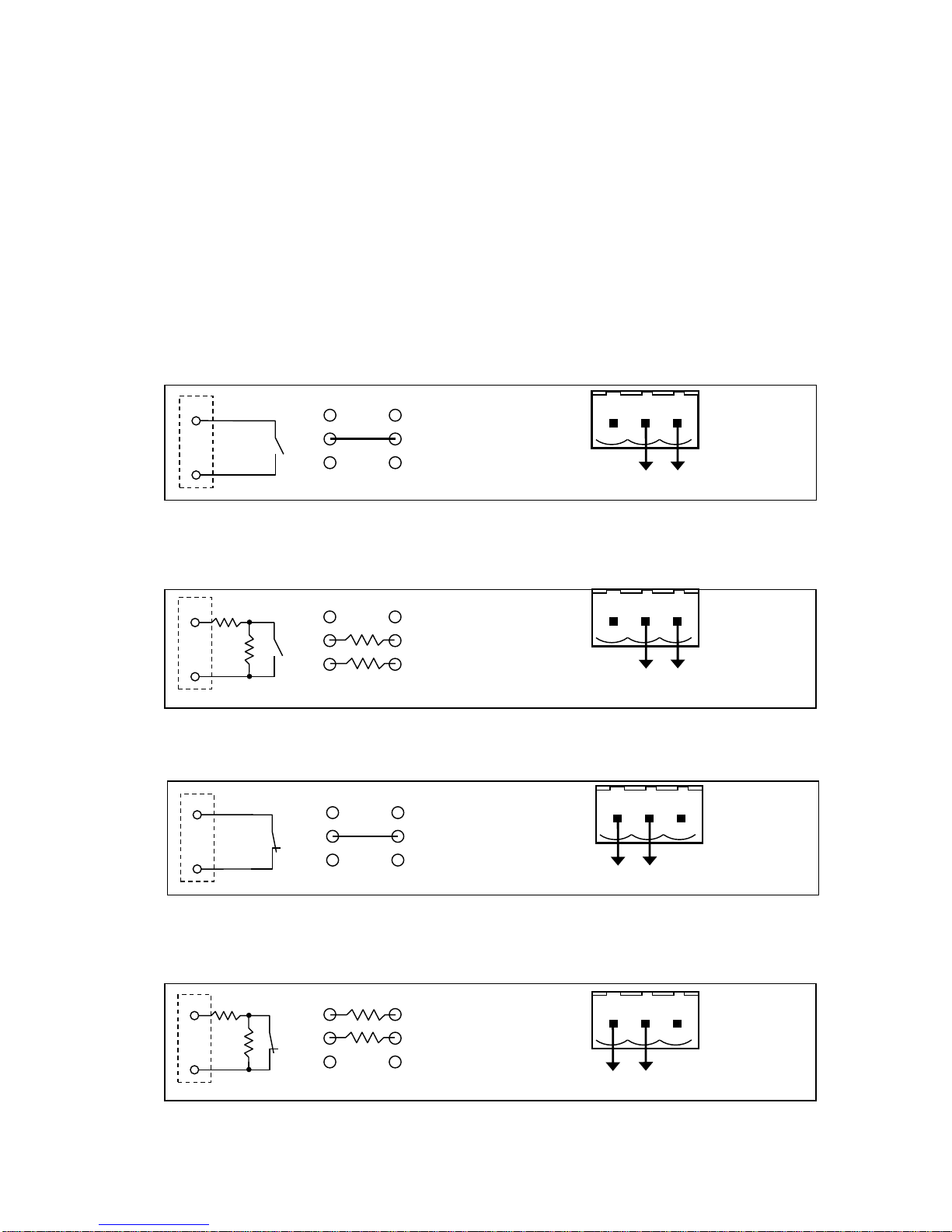

4.2 General Fault Control Output CN9

A general fault information to the fire detection system can be provided in four different

ways:

1. make a contact without surveillance

2. make a contact with surveillance

3. break a contact without surveillance

4. break a contact with surveillance

The corresponding settings in the setting software are described in the chapter 5.2 for the

VX-2000 system and in the chapter 6.3 of the SX-2000 system.

4.2.1 Make a contact without surveillance

Solder in a wire on position “R1” Connect to pins 2 and 3 of CN9 to the FDS

4.2.2 Make a contact with surveillance

Solder in resistors R1 and R3 Connect to pins 2 and 3 of CN9 to the FDS

as required by the FDS

4.2.3 Break a contact without surveillance

Solder in a wire on position “R1” Connect to pins 1 and 2 of CN9 to the FDS

4.2.4 Break a contact with surveillance

Solder in resistors R1 and R2 Connect to pins 1 and 2 of CN9 to the FDS

as required by the FDS

R1

1 2 3

To FDS

CN9

2 3 CN9

R1

1 2 3

To FDS

CN9

R3

R1

2 3 CN9

R3

R1

1

2

3

To FDS

CN9

1 2 CN9

R1

1 2 3

To FDS

CN9

R2

R1

1 2 CN9

R2

Page 7

IP-EN1-EB Instruction Manual

7

4.3 Emergency Control Input CN13 and System Settings

A single control input with two poles is provided that can be used for activating emergency,

and resetting emergency or activating silence. When activating silence, then emergency

reset must be controlled by an emergency or fireman microphone, or a separate contact

connected directly to the VA system. The corresponding settings in the setting software are

described in the chapter 5.2 for the VX-2000 system and in the chapter 6.3 of the

SX-2000 system.

There are various combinations to connect the emergency controls from the FDS, please

find the settings in the indicated chapter:

VX-2000

Emergency activation

Emergency

reset

Silence

chapter

by contact

by voltage

make

break

on

off

4.3.3 *

4.3.4

4.3.5

4.3.6

4.3.7

4.3.8

4.3.9

4.3.10

* : factory preset

SX-2000

Emergency activation

Emergency

reset

Silence

chapter

by contact

by voltage

make

break

on

off

4.3.3 *

4.3.5

4.3.7

4.3.9

* : factory preset

4.3.1 Control Voltage Selection

Set the jumper 18 according to the control voltage as shown below:

4.3.2 Total Resistance Setting for Voltage Control

If a certain resistance is required at voltage control, then solder in a resistor at position

R6.

Resistance FDS

200 Ω

250 Ω

320 Ω

400 Ω

500 Ω

630 Ω

800 Ω

1k Ω

12 VDC [Ω/W]

250 /1

330 /½

470 /½

680 /½

1k /¼

1.8k /¼

3.9k /¼

-

24 VDC [Ω/W]

220 /4

270 /3

390 /2

510 /2

680 /1

910/1

1.33k /1

2k /½

CN18

24 VDC *

CN18

12 VDC

1

1

* : factory preset

Page 8

IP-EN1-EB Instruction Manual

8

4.3.3 Making a Contact: Emergency Activation (VX, SX),

breaking a contact: Emergency Reset (VX, SX) / Silencing (SX)

VX-2000 Settings

Connector

Control input

Setting

CN11

1

Emergency pattern start

CN11

2

Emergency reset

SX-2000 Setting

Connector

Control input

Setting

CN15 pin 4

any

Emergency pattern start

CN15 pin 6

any

Emergency reset /

silence: emergency pattern stop

4.3.4 Making a Contact: Emergency Activation (VX),

breaking a contact: Silencing (VX)

VX-2000 Settings

Connector

Control input

Setting

CN11

1

Emergency pattern start

CN11

2

Silence

CN13

R6

1

1 3 2

1

R2

R3

R1

CN20

CN6

CN8

CN19

FDS

contact

_

+

CN13

R6

1

1

3 2 1

R2

R3

R1

CN20

CN6

CN8

CN19

FDS

contact

_

+

Page 9

IP-EN1-EB Instruction Manual

9

4.3.5 Breaking a contact: Emergency Activation (VX, SX),

making the contact: Emergency Reset (VX, SX) / Silencing (SX)

VX-2000 Settings

Connector

Control input

Setting

CN11

1

Emergency reset

CN11

2

Emergency pattern start

SX-2000 Setting

Connector

Control input

Setting

CN15 pin 4

any

Emergency reset /

silence: emergency pattern stop

CN15 pin 6

any

Emergency pattern start

4.3.6 Breaking a contact: Emergency Activation (VX),

making the contact: Silencing (VX)

VX-2000 Settings

Connector

Control input

Setting

CN11

1

Silence

CN11

2

Emergency pattern start

CN13

R6

1

1

3 2 1

R2

R3

R1

CN20

CN6

CN8

CN19

FDS

contact

_

+

CN13

R6

1

1

3 2 1

R2

R3

R1

CN20

CN6

CN8

CN19

FDS

contact

_

+

Page 10

IP-EN1-EB Instruction Manual

10

4.3.7 Voltage on: Emergency Activation (VX, SX),

voltage off: Emergency Reset (VX, SX) / Silencing (SX)

VX-2000 Settings

Connector

Control input

Setting

CN11

1

Emergency pattern start

CN11

2

Emergency reset

SX-2000 Setting

Connector

Control input

Setting

CN15 pin 4

any

Emergency pattern start

CN15 pin 6

any

Emergency reset /

silence: emergency pattern stop

4.3.8 Voltage on: Emergency Activation (VX),

voltage off: Silencing (VX)

VX-2000 Settings

Connector

Control input

Setting

CN11

1

Emergency pattern start

CN11

2

Silence

CN13

R6

1

1 3 2

1

R2

R3

R1

CN20

CN6

CN8

CN19

_

+

FDS

voltage

_

CN13

R6

1

1

3 2 1

R2

R3

R1

CN20

CN6

CN8

CN19

_

+

FDS

voltage

_

Page 11

IP-EN1-EB Instruction Manual

11

4.3.9 Voltage off: Emergency Activation (VX, SX)

Voltage on: Emergency Reset (VX, SX) / Silencing (SX)

VX-2000 Settings

Connector

Control input

Setting

CN11

1

Emergency reset

CN11

2

Emergency pattern start

SX-2000 Setting

Connector

Control input

Setting

CN15 pin 4

any

Emergency reset /

silence: emergency pattern stop

CN15 pin 6

any

Emergency pattern start

4.3.10 Voltage off: Emergency Activation (VX)

Voltage on: Silencing (VX)

VX-2000 Settings

Connector

Control input

Setting

CN11

1

Silence

CN11

2

Emergency pattern start

CN13

R6

1

1

3 2 1

R2

R3

R1

CN20

CN6

CN8

CN19

_

+

FDS

voltage

_

CN13

R6

1

1 3 2

1

R2

R3

R1

CN20

CN6

CN8

CN19

_

+

FDS

voltage

_

Page 12

IP-EN1-EB Instruction Manual

12

5 Connections and Settings for the VX-2000 System

5.1 Connections to VX-2000

Rear right side (mandatory indications)

1 Connect CN1 to CTRL OUT 1-8 of the VX-2000

(use Cat5/5E/6 FTP or STP or SFTP (with shield)

2 Connect CN11 to CTRL IN 1-8 of the VX-2000

(use Cat5/5E/6 FTP or STP or SFTP (with shield)

3 Connect CN10 with power supply from VX-2000DS or VX-3000DS (don’t connect to

regulated 24 VDC), + on pin 1, - on pin 2

4 Connect CN2 to the CPU OFF output of the VX-2000, connect to pins 2 and 3

5 CN15 provides the access to 4 control inputs of the VX-2000 that are not used by the

indication panel and can be used for other control purposes:

CN15 pin no.

1 2 3 4 5

6

VX-2000 control input no.

5

COM 4 7

COM

8

Rear left side (fault indications of fire areas or other fault indications)

6 Connect CN1 (of rear left side) to CTRL OUT 9-16 of the VX-2000

(use Cat5/5E/6 FTP or STP or SFTP (with shield)

CN7

CN15

CN9

CN12

CN18

CN13

CN10

R6

1 1 1 1 1 1 3 2 1

R2

R3

R1

CN20

CN6

CN8

CN19

CN1

CN5

CN11

CN3

+ -

20-40 VDC

CPU OFF

CTRL OUT 1-8

CTRL IN 1-8

1

CN12

2

3 4 5

CN2

CN7

CN2

1 1 1

CN1

CTRL OUT 9-16

6

Page 13

IP-EN1-EB Instruction Manual

13

5.2 Settings in the VX-2000 Setting Software

5.2.1 Mandatory Indication

5.2.1.1 Fault Indications

No.*

Indication of

VX-2000

connections/

assignment

Settings in Operation setting mode, button

[Failure Output]: use one Fault Output

Pattern per indication (one line in the list),

make a check in

4

General fault

Control output

3

Tab “Equipment” if not noted otherwise:

1. all emergency and fireman microphones

2. external fault CIN connected to the

optional Ethernet Switch **

3. all EV-200M

4. VX-2000

5. all VX-2000SF

6. all amplifiers including the standby

amplifier (tab “Power amplifier”)

7. all faults (short circuit, open circuit,

ground fault) for each loudspeaker line

(tab “Speaker”)

8. each VX-2000DS connection to VX2000SF (tab “Power supply”)

5

CPU fault

CPU OFF

control output

Only connection, no setting

6

Power fault

Control output

5

Tab “Power Supply”:

each existing VX-2000DS connection to

VX-2000SF

7

Fireman/

emergency

microphone fault

Control output

6

Tab “Equipment”:

all emergency and fireman microphones

8

Fuse fault

Control output

4

Tab “Power Amplifier”:

all amplifiers including the standby amplifier

9

Network fault

Control output

7

Tab “Equipment”:

external fault CIN connected to the Ethernet

Switch if used **

12

buzzer

Control output

8

Enable Failure Buzzer (Cout-8) ***

*: number as on “Appearance Front Panel”, page 3

**: refer to next page “Details to number 9”

***: refer to “New function Enable Failure Buzzer”

[ ]: button of the main menu of the VX-2000 setting software

Page 14

IP-EN1-EB Instruction Manual

14

Details to number 9 (network fault):

When using an NX-100S with IES-3000 series Ethernet switch, then the ports used for the

link between decentralised parts of the system on the Ethernet switches must be set for port

surveillance to provide a contact output making a contact when a fault appears. Please refer

to the manual of the IES-3000 Ethernet switch series to do so.

Connect this contact to a control input of the VX-2000. In the activation setting mode of the

VX-2000 setting software, select the function “External Fault CIN” for this control input.

Go to the operation setting mode and select the button [Failure Output]. Select a free line

in the failure pattern list (make a new failure pattern) and select the tab “Equipment”. In the

list “External Fault CIN”, make a check at the control input used for receiving a fault from

the Ethernet switch. Select control output number 7 for this pattern.

New function Enable Failure Buzzer

The new VX-2000 setting software version 3.1.0 provides a setting for the buzzer control of

the indication panel. When selected, then control output 8 cannot be used for other functions.

5.2.1.2 Status Indications

No.*

Indication of

connections

Operation setting mode,

make a check in

2

Power

DC out of

VX-2000DS,

VX-3000DS

- (no setting required)

3

Emergency mode

VX-2000

control output 2

[Emergency], tab “Emergency

Output”: Cout-2

*: number as on “Appearance Front Panel”, page 3

[ ]: button of the main menu of the VX-2000 setting software

Page 15

IP-EN1-EB Instruction Manual

15

5.2.2 Control Input Settings for Emergency and Button Controls

The settings are to be made in the activation setting mode. Select the button “Control Input”

of the main menu.

Control input

Function setting

Refer to

1, 2

Emergency pattern, Emergency reset, silence

Chapter 4.3

3

Failure output reset

-

6

Failure output receipt (no control output required)

-

5.2.3 Indication of Failures in Fire Alarm Areas (option of EN 54-16)

When using this option, then a failure of each fire area must be indicated. Consider that a

fire area may consist of several paging zones, i.e. a fire area can cover a group of zones.

The fire areas should be declared by the responsible party (e.g. fire brigade, fire expert)

who is aware of the emergency concept.

Failures in of up to 8 fire areas can be indicated. The control outputs 9-16 shall be used for

that.

Setting by the VX-2000 Setting Software

a. In operation mode, select the button [Failure Output].

b. Select a free line (make a new failure pattern) and

c. Select the tab “Speaker”.

d. Make a check into each box (short circuit, break, earth leakage) of each speaker zone

that belongs to that fire area.

e. Select the control output for the corresponding indication LED (refer to next table)

f. Proceed again from step 2 on for the other fire zones.

Relation of Control Output to indication LED of fire area (FA)

Indication LED

FA 1

FA 2

FA 3

FA 4

FA 5

FA 6

FA 7

FA 8

Control output no.

9

10

11

16

13

14

12

15

Page 16

IP-EN1-EB Instruction Manual

16

6 Connection and Settings for the SX-2000 System

6.1 Connections to SX-2000

Rear right side (mandatory indications)

1 Connect CN5 to Status output 2 of the SX-2000SM (use Cat5/5E/6 cable)

2 Prepare an RJ45 connector with connections between the pins: 1-8, 2-7, 3-6, 4-5 and

plug into CN11

3 Connect CN3 to Status output 1 of the SX-2000SM (use Cat5/5E/6 cable)

4 Connect CN10 with power supply from VX-2000DS or VX-3000DS (don’t connect to

regulated 24 VDC), + on pin 1, - on pin 2

5 Connect to control outputs for EMG status, fuse rupture, power fault, FM fault, network

fault. For details refer to table “CN7 main connections”

6 Connect to control inputs for fault acknowledge, fault reset, EMG start, EMG reset. For

details refer to table “CN15 connections”

7 Connect to control output for programmed general fault, pins 1 and 3

CN7 main connections CN15 connections

Pin no.

indication

Pin no.

indication

1

Power LED

1 Fault acknowledge

2

Emergency mode

2 COM (ground)

3

Fuse rupture

3 Fault reset

4

COM (ground)

4

Emergency pattern stop /

emergency reset

(refer to chapter 3.3)

5

Power fault

5 COM (ground)

6

Fireman microphone fault

6 Emergency pattern start

7

Network fault

For the connections to the SX-2000 components connections refer to 6.2 Connections at

SX-2000 Components on next page.

CN7

CN15

CN9

CN12

CN18

CN13

CN10

R6

1 1 1 1 1 1 3 2 1

R2

R3

R1

CN20

CN6

CN8

CN19

CN1

CN5

CN11

CN3

STATUS OUTPUT 2

STATUS OUTPUT 1

+ -

20-40 VDC

To control outputs for EMG status, fuse

rupture, power fault, FM fault, network fault

To control inputs for fault acknowledge,

fault reset, EMG start, EMG reset

1 2 3

4 5 6

To control output for general fault

7

CN2

Page 17

IP-EN1-EB Instruction Manual

17

Rear left side (fire area fault indications or other fault indications)

8 Connect to control outputs for faults in the fire areas 1, 2, 5 -8. For details refer to table

“CN7 FA connections”

9 Connect to control outputs for faults in the fire areas 3 and 4. For details refer to table

“CN2 connections”

CN7 FA connections CN2 FA connections

Pin no.

indication

Pin no.

indication

1

Fault in fire area 1

1 Fault in fire area 3

2

Fault in fire area 2

2 Fault in fire area 4

3

Fault in fire area 7

3 COM (ground)

4

COM (ground)

5

Fault in fire area 5

6 Fault in fire area 6

7 Fault in fire area 8

For the connections to the SX-2000 components connections refer to 6.2 Connections at

SX-2000 Components below.

6.2 Connections at SX-2000 Components

Since the control inputs and outputs of the SX-2000 components are isolated from ground

(COM; earth-free), all “C” contacts must be connected together and be connected to the

COM of the indication panel.

Example (using control inputs and outputs of the SX-2000SM):

CN7

CN2

1 1 1

CN1

FA 1

COM

FA 2

FA 7

FA 5

FA 6

FA 8

fire areas (FA)

FA 4

FA 3

COM

7 8

To COM of

indication

panel

To COM of

indication

panel

Connections to control input or output of indication panel

Page 18

IP-EN1-EB Instruction Manual

18

6.3 SX-2000 Settings

6.3.1 Mandatory Indication

Some control outputs are fixed by the SX-2000 system, others require a preparation. Before

preparing the failure settings, prepare 5 control output pattern for activating the indication

panel IP-EN1-EB. Since any control output can be used for the fault output, here we use the

control outputs of the SX-2000SM as an example written in rectangle brackets [#].

6.3.1.1 Fault Indications

In the first step, prepare the “Surveillance Settings”. Set a check for

- “DC Power” of each SX-2000 component

- “DS Link” of each DS link connected to VX-2000DS / VX-3000DS

- “RM” on the SX-2100 where an emergency/fireman microphone is connected

- Each amplifier (used for emergency)

- Each loudspeaker line (used for emergency)

In the second step proceed as described below:

No.*

Indication

of

SX-2000 connector

to IP-EN1-EB

connector

Pattern Settings / Failure Output

4

General

fault

Status control

output 1 to CN3

and any control

output [6] to CN2,

pins 1 and 3

- select DS LINK, DC FUSE, RM LINK; all SX-2000

components, all emergency/fireman microphones,

all amplifiers and all speaker lines

- select the “Failure status output” for the general

fault indication of the indication panel [6]

5

CPU fault

6

Power fault

Any control output

[1]

to CN7 pin 5

- select DS LINK;

- select the “Failure status output” for controlling

the power fault indication of the indication panel [1]

7

Fireman/

emergency

microphone

fault

Any control output

[2]

to CN7 pin 6

- select “RM LINK”;

- select each fireman/emergency microphone of the

SX-2100AI

- select the “Failure status output” for the fireman

microphone fault indication of the indication panel

[2]

8

Fuse fault

Any control output

[3]

to CN7 pin 3

- select “DC FUSE”

- select the “Failure status output” for the amplifier

fault indication of the indication panel [3]

9

Network

fault

Any control output

[4]

to CN7 pin 7

Event Settings: assign “external failure input” to all

control inputs to which the fault control outputs of the

Ethernet switches are connected to.

Pattern settings / failure Output:

make a pattern for each Ethernet switch fault:

- select the “external failure input” prepared (above)

- select the “Failure status output” for controlling the

network fault indication of the indication panel [4]

Make another pattern for each Ethernet switch fault:

- select the “external failure input” prepared (above)

- select the “Failure Status Output” for the general

fault indication of the indication panel [6]

12

buzzer

Status control

output 2 to CN5

No settings required (fixed function)

*: number as on “Appearance Front Panel”, page 3

Page 19

IP-EN1-EB Instruction Manual

19

6.3.1.2 Status Indications

No.*

Indication of

SX-2000 connector

to IP-EN1 connector

Settings

2

Power

-

- (no setting required)

3

Emergency

mode

Any control output

[5]

to CN7 pin 2

Event Setting / System event: in “Control

output pattern of emergency status“,

assign the control output [5] for controlling

the indicating of the emergency status

*: number as on “Appearance Front Panel”, page 3

6.3.2 Indication of Failures in Fire Alarm Areas (option of EN 54-16)

When using this option, then a failure of each fire area must be indicated. Consider that a

fire area may consist of several paging zones, i.e. a fire area can cover a group of zones.

The fire areas should be declared by the responsible party (e.g. fire brigade, fire expert)

who is aware of the emergency concept.

Failures in of up to 8 fire areas can be indicated. Any control output can be used for that.

Setting by the SX-2000 Setting Software

1. In the surveillance settings, make a check for each speaker zone that shall be

monitored.

2. In the pattern settings, control outputs, prepare as many control output pattern as

required for the failure indications of the fire zones.

3. In the pattern settings, failure output, make a failure pattern for each fire area. To do

so, activate the zones in each fire area by a mouse click and select the control output

pattern used for the control of the particular fire zone of the field failure status output

Relation of Control Input connection of the fire area’s Indication LED

The connectors CN2 and CN7 of the right board (view from rear) contain the control

inputs for the failure indications in the fire areas.

Indication LED

FA 1

FA 2

FA 3

FA 4

FA 5

FA 6

FA 7

FA 8

COM

COM

Connector no.

CN7

CN7

CN2

CN2

CN7

CN7

CN7

CN7

CN2

CN7

Pin no.

1 2 1 2 5 6 3 7 3

4

Page 20

IP-EN1-EB Instruction Manual

20 133-05-00022-0A

7 Specifications

Supply voltage

20 – 40 VDC

Current consumption

60 mA max.

Emergency control input

Contact or 12 VDC / 24 VDC (selectable)

Contact control

Open voltage: 24 VDC, current: 12 mA

Voltage control

12 VDC, 12 mA (1 kohm) or

24 VDC, 12 mA (2 kohm); isolated

General fault control output

NC, NO; max. 40 VDC, 100 mA; isolated

Dimensions (W x H x D)

483 x 44 x 47 mm (without plugs) (19”, 1U)

Weight

470 g (incl. plugs)

Finish

Aluminium, brushed, black

8 Accessories

2-pin removable screw terminal .................................. 2

3-pin removable screw terminal .................................. 3

6-pin removable screw terminal .................................. 1

7-pin removable screw terminal .................................. 2

Keys ........................................................................... 2

9 Optional Accessories

Labels in other languages request

24.06.2016

Traceability Information for EU (EMC directive 2004/108/EC); manufacturer:

TOA Electronics Europe GmbH

Süderstraße 282 ♦ 20537 Hamburg ♦ Germany

Tel.: +49-(0)40-25 17 19-0 ♦ Fax: +49-(0)40-25 17 19-98 ♦ URL: www.toa.eu

Loading...

Loading...